KROHNE IFM5080K User Manual

|

© KROHNE 03/2002 |

7.02422.22.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GR

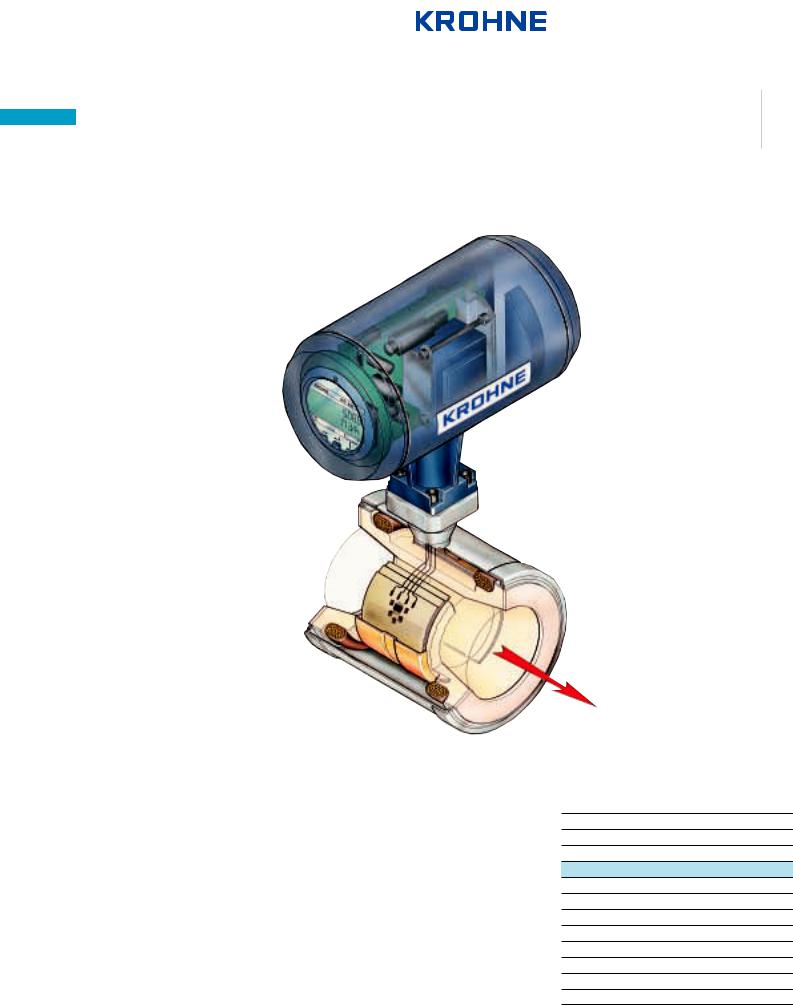

Capaflux IFM 5080 K-CAP

Electromagnetic Flowmeter

... non-contact process flow measurment from 0.05 µS/cm electrical conductivity

● Ceramic measuring tube, dimensionally stable, vacuum resistant

● Optimum flow shaping and unimpeded tube cross-section

● Outstanding accuracy

● Non-wetted electrodes

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

No restrictions ...

... through insulating products with a film-forming tendency:

asphalt, latex suspensions

... through low electrical conductivity: ultrahigh-purity water, alcohols, glycerins, glycols

... through high solids contens: fruit pieces, pulps, concrete

... for sterile processes: chemical and food industries

... when used in hazardous areas:

ATEX approval

FM certification pending

... through electrode materials:

the capacitive electrodes are located behind the ceramic tube, i.e. noncontact measurement, no contact with the process product.

Calibrated on EN 17 025 accredited calibration rigs, accuracy of calibration better

than 99.97% of the measured value.

Capaflux IFM 5080 K-CAP

Electromagnetic Flowmeter

... non-contact process flow measurment from 0.05 µS/cm electrical conductivity

non-contact flow measurement no electrodes

easy to specify

unimpeded flow cross-sectional area optimum flow shaping

resistant to abrasion ceramic measuring tube

dimensionally stable vacuum-resistant outstanding accuracy

Special advantages

●capacitive electrodes for non-contact measurement.

●the measuring section is resistant to abrasion from even high solids contents.

●the ceramic measuring tube is dimensionally stable and vacuumresistant.

●the special shape of the measuring tube helps to optimize the flow profile, even with minimum pressure drop, refer to diagram on page 3.

●the measuring error is less than 0.5% of the measured value.

●the integral design ensures easy installation, safe and reliable operation.

●the crevice-free measuring tube has no blind spots and conforms to food requirements, the ceramic surface is ultrasmooth,

Ra < 0,8 µm surface finish.

ATEX approval

Ex II 2 GD KEMA 01 ATEX 2232X

●CAPAFLUX IFM 5080 K/CAP-EEx: EEx d IIC T6 … T4

EEx de IIC T6 … T4

●CAPAFLUX IFM 5080 K/CAP/i-EEx: with outputs intrinsic safety

EEx d [ia] IIC T6 … T4 EEx de [ia] IIC T6 … T4

2

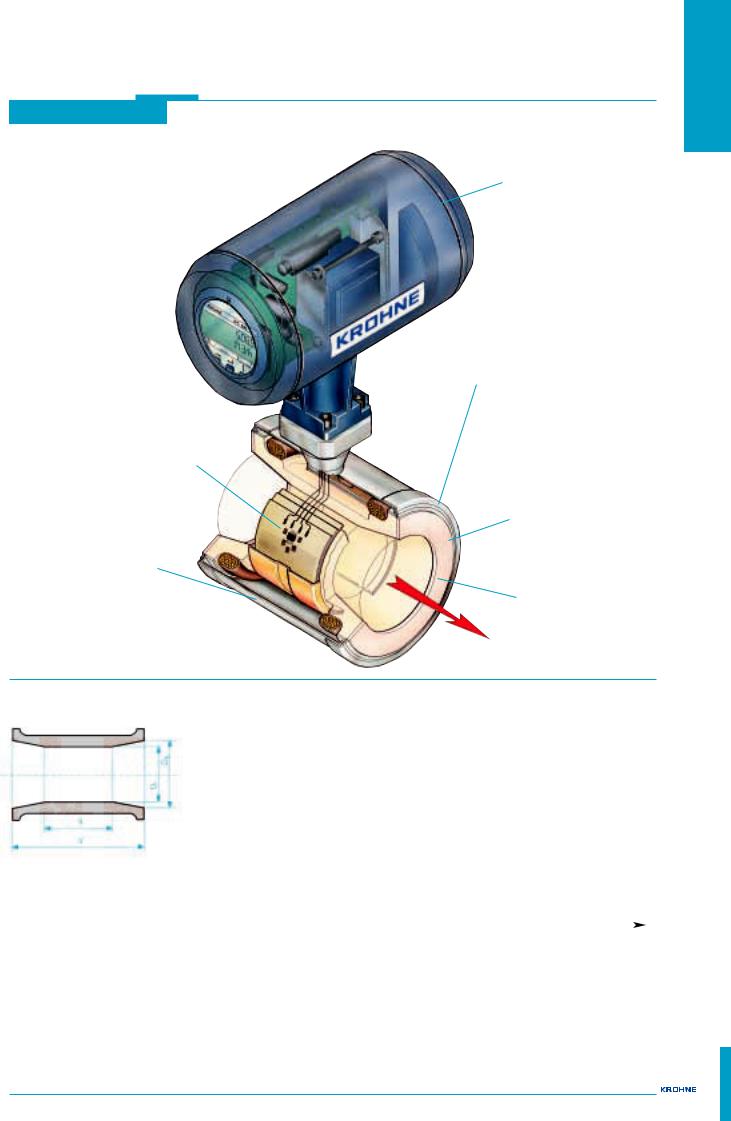

CAPAFLUX

Highlights

Measuring error ≤ 0.5% of the measured value, ‘sandwich’ design, easy installation,

reliable and safe operation

Electrical conductivity ≥ 0.05µS/cm, e.g. ultrahigh-purity water, alcohols, glycerols, glycols, etc.

Capacitive electrodes for non-contact measurement

No crevices, no blind spots in the measuring tube, conforms to food standards, extremely smooth, surface roughness < 0.8 µm

Hazardous-duty version, flameproof enclosure

Dimensionally stable measuring tube, very good thermal and long-time stability, no flow, creep and no abrasion,

as is usually the case with plastic liners

Meter sizes DN 25 -100 or 1”- 4”

Self-supporting ceramics measuring tube, press-fitted into stainless steel housing

Design

Meter size |

|

Dimensions in mm (inches) |

|

|

|

|||

|

|

|

|

|

|

|

|

|

DN mm |

|

inches |

Da |

Di |

X |

|

Y |

|

25 |

|

1 |

24 (0.95) |

20 (0.79) |

26 (1.02) |

55 (2.17) |

||

|

|

|

|

|

|

|

|

|

40 |

|

11/2 |

37 (1.46) |

30 (1.18) |

36 |

(1.42) |

80 |

(3.15) |

50 |

|

2 |

49 (1.92) |

40 (1.57) |

51 (2.01) |

100 |

(3.94) |

|

|

|

|

|

|

|

|

|

|

80 |

|

3 |

78 (3.06) |

60 (2.36) |

70 |

(2.76) |

150 (5.91) |

|

100 |

|

4 |

98 (3.84) |

80 (3.15) |

103 |

(4.06) |

200 |

(7.87) |

Flow profile influence

(± SE) as % of measured value

Example for DN80 (3’’) with quarter bend, straight inlet run

5 × DN (= 400mm = 16’’) from quarter bend to electrode plane

1.0

± SE CAPAFLUX IFM 5080 K-CAP [%]

Conventional flangeless flowmeter

0.5

0

0 |

0.5 |

|

1.0 |

1.5 |

2.0 |

2.5 |

3.0 [m/s] 3.5 |

|

||||||

0 |

1.5 |

|

3.0 |

4.5 |

6.0 |

7.5 |

|

|

v |

|

||||

|

|

|

|

|||||||||||

|

9.0 [ft/s]10.5 |

|

||||||||||||

|

Pressure drop: |

|

|

|

|

|

|

|

|

|

|

|

||

|

∆P = ρ × v2 (in mbar) |

|

∆P = ρ × v2 |

(in psig) |

|

|

|

|

|

|

||||

|

|

800 |

|

|

|

|

550 |

|

|

|

|

|

|

|

|

ρ = product density in (kg/m3) |

ρ = specific gravity (e.g. water = 1) |

|

|||||||||||

|

v = flow velocity in m/s |

|

v = flow velocity in ft/s |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAPAFLUX 3

Loading...

Loading...