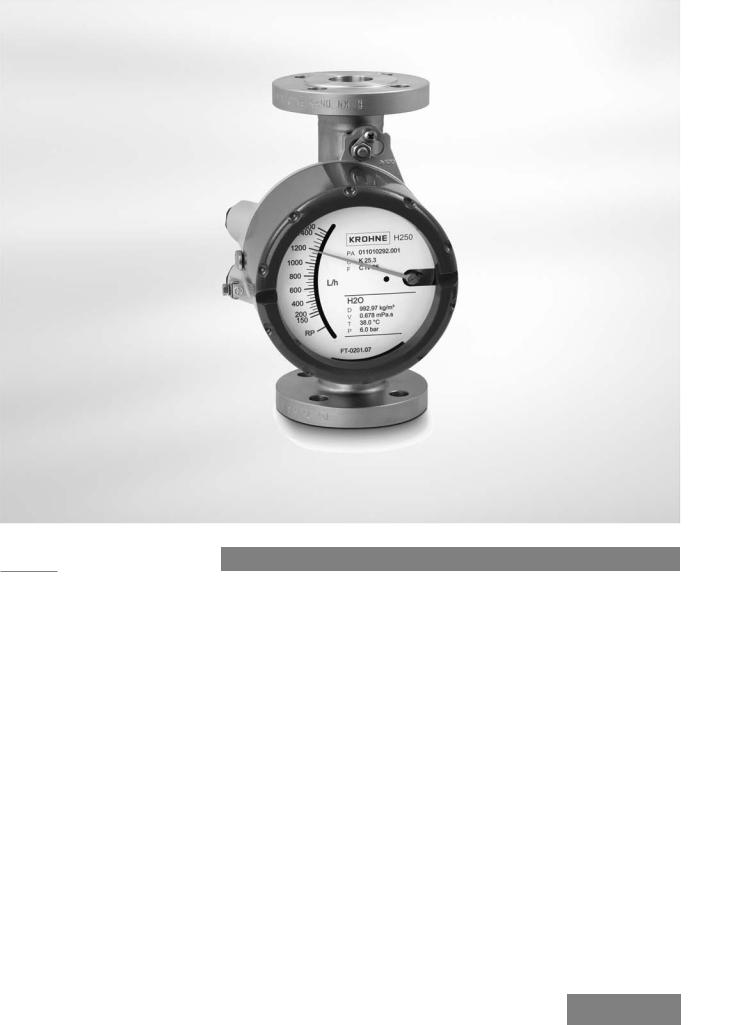

Krohne H250 M40 User Manual

H250 M40 Handbook

H250 M40 Handbook

Variable area flowmeter

© KROHNE 08/2015 - 4000640703 - MA H250 M40 R03 en

:IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2015 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

|

|

CONTENTS |

|

|

|

|

H250 M40 |

|

|

||||

|

|

|

|

|

|

||

1 |

Safety instructions |

5 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

1.1 |

Intended use ..................................................................................................................... |

5 |

|

|

|

|

|

1.2 |

Certifications .................................................................................................................... |

6 |

|

|

|

|

|

1.3 |

Pressure equipment directive.......................................................................................... |

6 |

|

|

|

|

|

1.4 |

Safety instructions from the manufacturer ..................................................................... |

7 |

|

|

|

|

|

1.4.1 Copyright and data protection ................................................................................................ |

7 |

|

||

|

|

|

1.4.2 Disclaimer ............................................................................................................................... |

7 |

|

||

|

|

|

1.4.3 Product liability and warranty ................................................................................................ |

8 |

|

||

|

|

|

1.4.4 Information concerning the documentation........................................................................... |

8 |

|

||

|

|

|

1.4.5 Warnings and symbols used................................................................................................... |

9 |

|

||

|

|

|

1.5 |

Safety instructions for the operator................................................................................. |

9 |

|

|

|

|

2 Device description |

10 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

2.1 |

Scope of delivery............................................................................................................. |

10 |

|

|

|

|

|

2.2 |

Device version................................................................................................................. |

11 |

||

|

|

|

2.2.1 Indicator versions ................................................................................................................. |

12 |

|

||

|

|

|

2.2.2 Float damping ....................................................................................................................... |

14 |

|

||

|

|

|

2.2.3 Pointer damping.................................................................................................................... |

14 |

|

||

|

|

|

2.3 |

Nameplate ...................................................................................................................... |

15 |

||

|

|

|

2.4 |

Description code............................................................................................................. |

16 |

|

|

|

|

|

2.5 |

Electronics revision ........................................................................................................ |

17 |

|

|

3 |

Installation |

18 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

3.1 |

Notes on installation ...................................................................................................... |

18 |

|

|

|

|

|

3.2 |

Storage ........................................................................................................................... |

18 |

||

|

|

|

3.3 |

Installation conditions .................................................................................................... |

19 |

|

|

|

|

|

3.3.1 Tightening torques................................................................................................................ |

21 |

|

||

|

|

|

3.3.2 Magnetic filters ..................................................................................................................... |

21 |

|

||

|

|

|

3.3.3 Heat insulation ...................................................................................................................... |

22 |

|

||

|

|

4 Electrical connections |

23 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

4.1 |

Security information....................................................................................................... |

23 |

|

|

|

|

|

4.2 |

Electrical connection indicator M40............................................................................... |

24 |

|

|

|

|

|

4.2.1 Limit switches K1/K2 ............................................................................................................ |

24 |

|

||

|

|

|

4.2.2 Current output ESK4 / ESK4A............................................................................................... |

27 |

|

||

|

|

|

4.2.3 ESK4-T limit outputs............................................................................................................. |

30 |

|

||

|

|

|

4.2.4 Connection Harting HAN® 7D............................................................................................... |

32 |

|

||

|

|

|

4.3 |

Grounding connections................................................................................................... |

33 |

|

|

|

|

|

4.4 |

Protection category ........................................................................................................ |

33 |

|

|

|

|

5 Start-up |

34 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

5.1 |

Standard device .............................................................................................................. |

34 |

|

|

|

|

|

5.2 |

Indicator ESK4-T ............................................................................................................ |

34 |

|

|

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

3 |

|

CONTENTS |

H250 M40 |

|

|

|

||

|

|

|

|

6 Operation |

|

35 |

|

|

|

|

|

6.1 |

ESK4 / ESK4A - Loop Check Mode ................................................................................. |

35 |

|

6.2 |

Operating elements ESK4-T........................................................................................... |

36 |

|

6.3 |

Basic principles of operation ESK4-T ............................................................................ |

37 |

|

6.3.1 Functional description of the keys........................................................................................ |

37 |

||

6.3.2 Navigation within the menu structure.................................................................................. |

37 |

||

6.3.3 Change the settings in the menu.......................................................................................... |

38 |

||

6.4 |

Overview of the units ESK4-T......................................................................................... |

39 |

|

6.5 |

Error messages ESK4-T................................................................................................. |

40 |

|

6.6 |

Menu indicator ESK4-T................................................................................................... |

43 |

|

6.6.1 Factory settings .................................................................................................................... |

43 |

||

6.6.2 Menu structure ..................................................................................................................... |

44 |

||

6.6.3 Menu explanations................................................................................................................ |

46 |

||

7 Service |

|

54 |

|

|

|

|

|

7.1 |

Maintenance ................................................................................................................... |

54 |

|

7.2 |

Replacement and retrofitting......................................................................................... |

54 |

|

7.2.1 Replacing floats .................................................................................................................... |

54 |

||

7.2.2 |

Retrofitting float damping..................................................................................................... |

55 |

|

7.2.3 |

Retrofitting limit switch ........................................................................................................ |

55 |

|

7.2.4 Replacement - Retrofitting ESK4 / ESK4A ........................................................................... |

56 |

||

7.2.5 Replacement - Retrofitting add-on module ESK4-T / PA / FF............................................. |

57 |

||

7.3 |

Spare parts availability................................................................................................... |

57 |

|

7.3.1 List of spare parts................................................................................................................. |

57 |

||

7.4 |

Availability of services .................................................................................................... |

61 |

|

7.5 |

Returning the device to the manufacturer..................................................................... |

61 |

|

7.5.1 General information.............................................................................................................. |

61 |

||

7.5.2 Form (for copying) to accompany a returned device............................................................ |

62 |

||

7.6 |

Disposal .......................................................................................................................... |

62 |

|

8 Technical data |

63 |

||

|

|

|

|

8.1 |

Functional principle........................................................................................................ |

63 |

|

8.2 |

Technical data................................................................................................................. |

64 |

|

8.3 |

Dimensions and weights ................................................................................................ |

71 |

|

8.4 |

Measuring ranges........................................................................................................... |

74 |

|

9 Notes |

|

|

82 |

|

|

|

|

4 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

SAFETY INSTRUCTIONS 1 |

|

H250 M40 |

|

|

|

|

1.1 Intended use

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and corrosion resistance of the used materials against the measured fluid lies solely with the operator.

INFORMATION!

This device is a Group 1, Class A device as specified within CISPR11:2009. It is intended for use in industrial environment. There may be potential difficulties in ensuring electromagnetic compatibility in other environments, due to conducted as well as radiated disturbances.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than the intended purpose.

The variable area flowmeters are suitable for measuring clean gases, vapours and liquids.

Intended use:

•The product may not contain any ferromagnetic particles or solids. It may be necessary to install magnetic filters or mechanical filters.

•The product must be sufficiently liquid and free of deposits.

•Avoid pressure surges and pulsing flows.

•Open valves slowly. Do not use solenoid valves.

Use suitable measures to eliminate compression vibrations during gas measurements:

•Short pipeline lengths to next restriction

•Nominal pipe size not greater than nominal device size

•Use of floats with damping

•Increase in operating pressure (while taking into account the resulting change in density and thus change in scale)

Observe installation conditions according to VDI/VDE 3513-3.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex documentation.

CAUTION!

Do not use any abrasive media containing solid particles or highly viscous media.

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

5 |

1 SAFETY INSTRUCTIONS |

|

|

H250 M40 |

|

|

|

|

|

1.2 Certifications

CE marking

The device fulfils all applicable statutory requirements of the following EC directives:

•Pressure equipment directive

•For devices with electrical installations: EMC directive

•Devices for use in hazardous areas: ATEX directive

as well as

• NAMUR recommendations NE 21, NE 43 and NE 107

The manufacturer certifies successful testing of the product by applying the CE marking. A CE declaration of conformity regarding the directives in question and the associated harmonised standards can be downloaded from our internet site.

1.3 Pressure equipment directive

A conformity assessment in accordance with pressure equipment directive has been carried out for the devices described. Conformity is certified by applying the CE mark. The number of the notified body is also stated.

The PED key describes rating of devices:

Example: PED/G1/III/H

G |

Gases and vapours |

1 |

Fluid group 1 |

III |

Category III |

H |

Conformity assessment method according to Module H |

The PED key identification can be found on the nameplate of the device (for details refer to

Nameplate on page 15).

INFORMATION!

The stated pressures (PS) and temperatures (TS) only apply as refers to the pressure resistance of the sensor body. As regards the functionality of the entire device, further restrictions of the maximum temperature may need to be observed (e.g. ATEX approval). Devices rated below Category I due to their size, do not receive the CE mark in the scope of the PED. These devices are subject to applicable Sound Engineering Practice SEP.

6 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

SAFETY INSTRUCTIONS 1 |

|

H250 M40 |

|

|

|

|

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third parties are identified as such. Reproduction, processing, dissemination and any type of use beyond what is permitted under copyright requires written authorisation from the respective author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the manufacturer's documents is always on a voluntary basis whenever possible. Whenever feasible, it is always possible to make use of the offerings and services without providing any personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when communicating by e-mail) may involve gaps in security. It is not possible to protect such data completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish an imprint for the purpose of sending us any advertising or informational materials that we have not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including, but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross negligence. In the event any applicable law does not allow such limitations on implied warranties or the exclusion of limitation of certain damages, you may, if such law applies to you, not be subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable in any way for possible consequences of such changes.

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

7 |

1 SAFETY INSTRUCTIONS |

|

|

H250 M40 |

|

|

|

|

|

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose. The manufacturer accepts no liability for the consequences of misuse by the operator. Improper installation or operation of the devices (systems) will cause the warranty to be void. The respective "Standard Terms and Conditions" which form the basis for the sales contract shall also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the information in this document and observe applicable national standards, safety requirements and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the text, we advise you to contact your local office for assistance. The manufacturer can not accept responsibility for any damage or injury caused by misunderstanding of the information in this document.

This document is provided to help you establish operating conditions, which will permit safe and efficient use of this device. Special considerations and precautions are also described in the document, which appear in the form of icons as shown below.

8 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

SAFETY INSTRUCTIONS 1 |

|

H250 M40 |

|

|

|

|

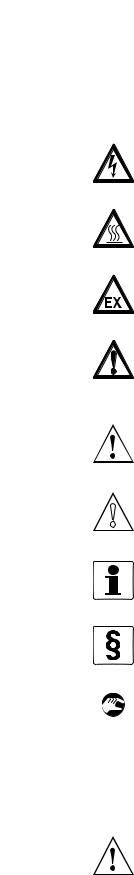

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to serious health problems and even death. There is also the risk of seriously damaging the device or parts of the operator's plant.

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems. There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

This symbol designates all instructions for actions to be carried out by the operator in the specified sequence.

iRESULT

This symbol refers to all important consequences of the previous actions.

1.5Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and efficient use of this device.

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

9 |

2 DEVICE DESCRIPTION |

H250 M40 |

|

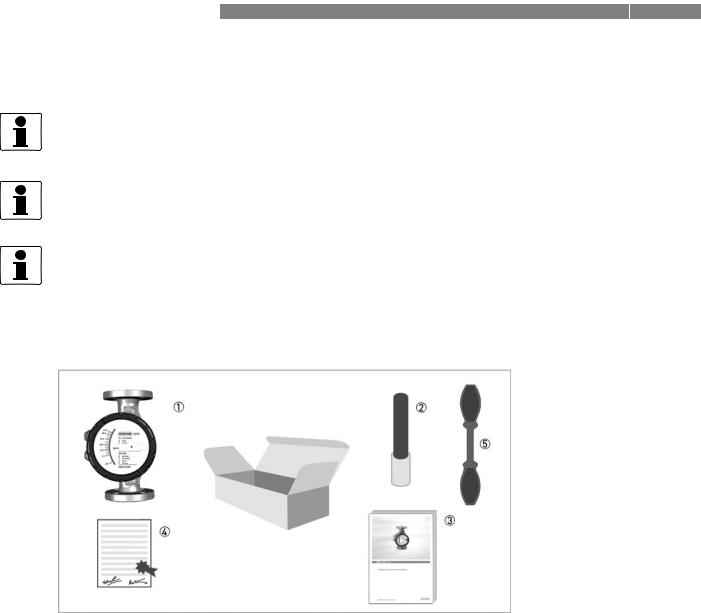

2.1 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate.

Figure 2-1: Scope of delivery

1Measuring device in ordered version

2For the ESK4-T version - bar magnet

3Documentation

4Certificates, calibration report (supplied to order only)

5Wrench

10 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

DEVICE DESCRIPTION 2 |

|

H250 M40 |

|

|

|

|

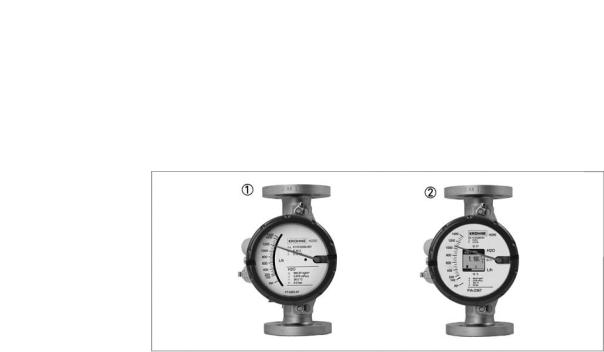

2.2Device version

•H250 with indicator M40

•H250 with M40 indicator with display cut-out for ESK4-T

1. H250/RR/M40

•Local indicator without auxiliary power

•max. 2 limit switches, type NAMUR, NAMUR safety-oriented or transistor (3-wire)

•Electrical signal output 4...20 mA, HART® or Fieldbus communication

•Intrinsically safe [Ex i] or in explosion-proof enclosure [Ex d]

2. H250/RR/M40

•additional LCD, measured value and/or flow counter

•2 configurable binary outputs, limit value or pulse output

•1 binary input, Start / Stop / Reset flow counter

•2-wire current output 4…20 mA, HART® communication

•Intrinsically safe [Ex i] or in explosion-proof enclosure [Ex d]

The following designs are available as options:

•H250 with indicator M40 as high-temperature version HT

•H250 with indicator M40 with increased corrosion protection (special paint finish)

•H250H for use in horizontal pipelines

•H250U for use in vertical fall pipes

•H250F with hygienic measuring tube design for Food & Pharma

•H250C with PTFE / TFM liner for aggressive media

Display options

•M40 - Aluminium, single-layer powder coating (polyester)

•M40S - Aluminium, two-layer powder coating (epoxy / polyester)

•M40R - Stainless steel without coating

Offshore wet coating for aluminium or stainless steel on request

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

11 |

2 DEVICE DESCRIPTION |

H250 M40 |

|

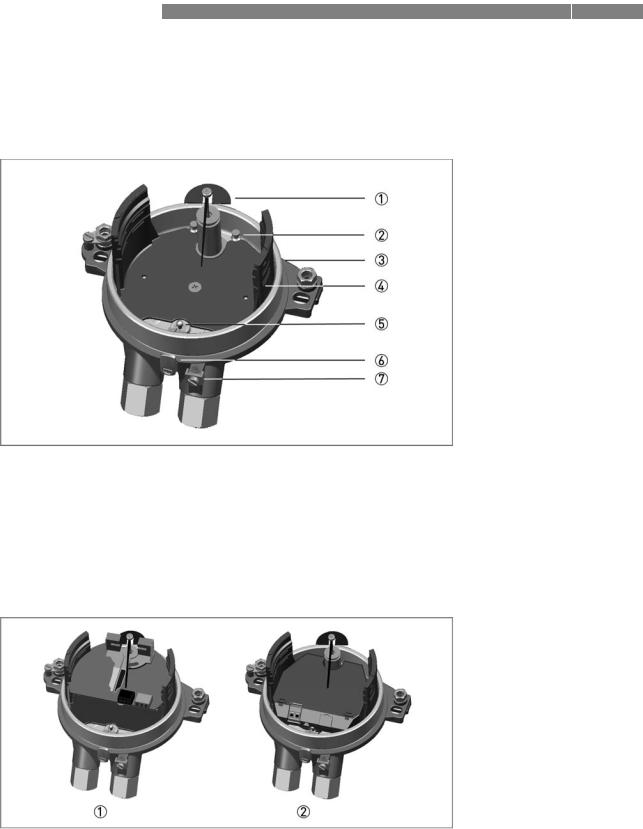

2.2.1 Indicator versions

The M40 indicator can be fitted with various modules.

Basic version

1Pointer module

2Bolts for ESK4 / ESK4A attachment

3Baseplate

4Module profile

5Pressure piece for ESK4 / ESK4A attachment

6Housing cover locking device

7Earth terminal external

Versions K1 / K2 and ESK4 / ESK4A

1Indicator with K2 contact module

2Indicator with ESK4 / ESK4A current output 4...20 mA

Both versions can be combined with one another.

12 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

DEVICE DESCRIPTION 2 |

|

H250 M40 |

|

|

|

|

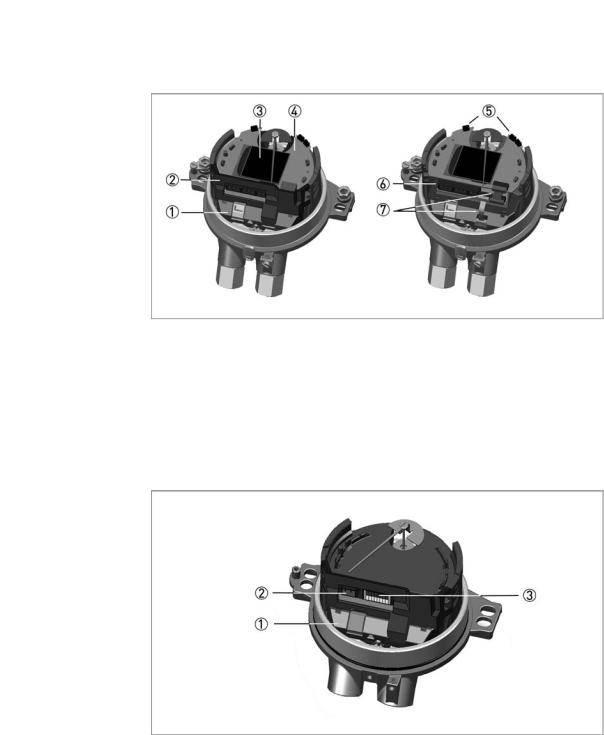

Version ESK4-T

1ESK4 / ESK4A connection

2Module cover

3Display

4Display module ESK4-IO

5Operating keys ^ ↑

6Connection binary outputs and reset input

7Module connection cable

Version Fieldbus ESK4-FF / ESK4-PA

1Basic module with electronic magnet sensors ESK4 / ESK4A

2Connection bus module

3DIP switch for bus settings

For more details see the supplementary instructions "H250 M40 Foundation Fieldbus" and "H250 M40 Profibus PA"

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

13 |

2 DEVICE DESCRIPTION |

H250 M40 |

|

2.2.2 Float damping

Float damping is characterised by high standstill times and self-centering. The damping sleeve is made of high performance ceramic or PEEK, depending on the medium and the application. Float damping can also be retrofitted for the user (refer to "Service").

Use of damping

•Generally when CIV and DIV floats are used for gas measurement.

•For TIV floats (H250/RR and H250/HC only) with an operating primary pressure:

Nominal size acc. to |

Operating primary pressure |

||

|

|

|

|

EN 1092-1 |

ASME B16.5 |

[bar] |

[psig] |

|

|

|

|

DN 50 |

½" |

≤0.3 |

≤4.4 |

|

|

|

|

DN25 |

1" |

≤0.3 |

≤4.4 |

|

|

|

|

DN50 |

2" |

≤0.2 |

≤2.9 |

|

|

|

|

DN80 |

3" |

≤0.2 |

≤2.9 |

|

|

|

|

DN 100 |

4" |

≤0.2 |

≤2.9 |

|

|

|

|

2.2.3 Pointer damping

In principle, the indicating element with its magnetic system contains indicator damping. An additional eddy current brake is advantageous in the event of fluctuating or pulsing flows. The magnets on the eddy current brake surround the pointer vane without touching it, damping its movement. The result is a much steadier pointer position, without distorting the measured value. A turnbuckle ensures a proper fit. The eddy current brake can be retrofitted during operation without recalibrating (refer to "Service").

1Eddy current brake

2Pointer vane

3Bracket

4Pointer cylinder

14 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

DEVICE DESCRIPTION 2 |

|

H250 M40 |

|

|

|

|

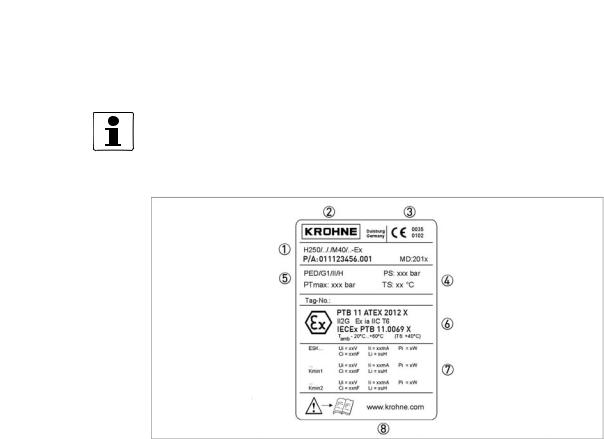

2.3 Nameplate

INFORMATION!

Check on the device nameplates, that the device is supplied according to your order.

Figure 2-2: Nameplate on the indicator

1Device type

2Manufacturer

3Notified ATEX & PED body

4Rating data: temperature & pressure rating

5PED data

6Ex data

7Electrical connection data

8Internet site

Additional markings on the indicator

•SN - serial number

•SO - sales order / item

•PA - Production order

•Vx - product configurator code

•AC - article code

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

15 |

2 DEVICE DESCRIPTION |

H250 M40 |

|

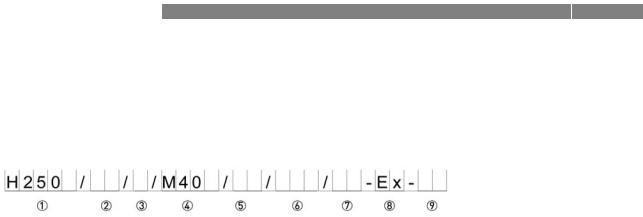

2.4 Description code

The description code* consists of the following elements:

1 Device type

H250 - standard version

H250H - horizontal flow direction

H250U - flow direction from top to bottom

2Materials / versions RR - stainless steel

C - PTFE or PTFE/ceramics HC - Hastelloy

Ti - Titanium Mo - Monel

F - aseptic version (food)

3Heating jacket version B - with heating jacket

4Series of indicators M40 - Indicator M40

M40S - Indicator with increased corrosion protection M40R - Indicator in stainless steel housing

5High temperature version

HT - Version with HT extension

6 Electrical signal output

ESK - Electrical signal output 4...20mA (ESK4 / ESK4A)

-optionally available with counter, I/O module and display (ESK4-T) or

-Foundation Fieldbus (ESK4-FF) or

-Profibus PA (ESK4-PA)

7Limit switches K1 - One limit switch

K2 - Two limit switches

8Explosion protection

Ex - Explosion-protected equipment

9 SIL Version

SE - SIL compliant electronic signal output SK - SIL compliant limit switch

* positions which are not needed are omitted (no blank positions)

16 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

DEVICE DESCRIPTION 2 |

|

H250 M40 |

|

|

|

|

2.5 Electronics revision

The Electronic Revision (sticker on the base module ESK4 / ESK4A) indicates the respective hardware/software status of the electronics. All add-on modules (ESK4-T, ESK4-FF and ESK4PA) have an additional sticker indicating their respective firmware version.

Electronics |

Explanations |

revision |

|

|

|

ER 1.1.x |

Basic version (cannot be combined with other indicator versions): |

|

ESK4 / Current output 4…20mA with HART® communication; |

|

(ESK4 HART DD 01.01. AMS10x AMS11x |

|

ESK4 HART DD 01.01. PDM6.0 |

|

ESK4 HART DTM 1.0.3 FDT1.2) |

ER 2.0.x |

Functional add-on to ER 1.1.x: |

|

can be combined with indicator version ESK4 FF / Foundation Fieldbus; |

|

(Firmware Version FF module from 1.0.2) |

|

|

ER 2.1.x |

Functional add-on to ER 2.0.x |

|

can be combined with indicator version ESK4-PA / Profibus PA; |

|

(Firmware Version PA module from 1.0.0) |

|

can be combined with indicator version ESK4-T / LCD, binary inputs/outputs; |

|

(Firmware Version T module from 1.1.0) |

|

|

ER 2.2.x |

Functional add-on to ER 2.1.x: |

|

Support of failure signal (low) according to NE43 |

|

for the ESK 4 current output module |

|

|

ER 3.0.x |

Functional add-on: |

|

Update for HART® communication from 5.9 to 7.4 including new DD/DTM |

|

can be combined with ESK4-FF (Firmware Version FF module from 1.0.2) |

|

Firmware Version ESK4-PA (... PA module from 1.0.0) |

|

Firmware Version ESK4-T (... T module from 1.2.0) |

|

|

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

17 |

3 INSTALLATION |

H250 M40 |

|

3.1 Notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate.

3.2Storage

•Store the device in a dry and dust-free location.

•Avoid lasting direct exposure to the sun.

•Store the device in its original packing.

•The permissible storage temperature for standard devices is -40...+80°C / -40...+176°F.

18 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

INSTALLATION 3 |

|

H250 M40 |

|

|

|

|

3.3 Installation conditions

CAUTION!

When installing the device in the piping, the following points must be observed:

•The variable area flowmeter must be installed vertically (measuring principle). Flow direction from bottom to top. For installation recommendations please refer also to directive VDI/VDE 3513, sheet 3.

H250Hs are installed horizontally and H250U devices are installed vertically with the flow direction from top to bottom.

•A straight unimpeded inlet run of ≥ 5x DN upstream of the device and a straight outlet run of ≥ 3x DN downstream of the device are recommended.

•Screws, bolts and gaskets are to be provided by the customer and must be selected in accordance with the pressure rating of the connection or the operating pressure.

•The inside diameter of the flange deviates from the standard dimensions. Flange seal standard DIN 2690 can be applied without any limitation.

•Align the gaskets. Tighten the nuts with the tightening torques of the appropriate pressure rating.

For devices with PTFE liner or ceramic liner and PTFE raised faces, refer to chapter "Tightening torques".

•Control devices are to be positioned downstream of the measuring device.

•Shut-off devices are preferably to be positioned upstream of the measuring device.

•Before connecting, blow or flush out the pipes leading to the device.

•Pipes for gas flow need to be dried before the device is installed.

•Use connectors suitable for the particular device version.

•Align the pipes centrically with the connection bores on the measuring device so they are free of stresses.

•If necessary, the piping has to be supported to reduce the vibrations transmitted to the measuring device.

•Do not lay signal cables directly next to cables for the power supply.

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

19 |

3 INSTALLATION |

H250 M40 |

|

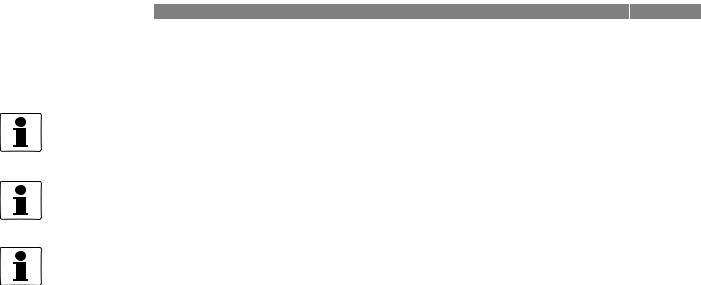

Minimum distance between devices

When several devices are installed next to one another, a minimum distance of a > 300 mm / 11.8" between the devices is necessary.

Take special note of the installation position for the H250H with horizontal flow direction:

In order to comply with thermal parameters and measuring accuracy, H250H flowmeters for horizontal installation are to be installed in the pipeline so that the display is located on the side of the measuring tube. The maximum product and ambient temperatures indicated as well as the measuring accuracy are based on lateral installation of the display.

20 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

INSTALLATION 3 |

|

H250 M40 |

|

|

|

|

3.3.1 Tightening torques

For measuring devices with PTFE liner or ceramic liner and PTFE raised face, tighten the flange threads with the following torques:

Nominal size according to |

|

Stud bolts |

|

|

Max. torque |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||

EN 1092-1 |

ASME B 16.5 |

EN |

|

ASME |

EN 1092-1 |

ASME 150 lb |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

DN |

PN |

Inch |

lb |

|

|

150 lb |

|

300 lb |

Nm |

ft*lbf |

Nm |

ft*lbf |

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

40 |

½“ |

150/300 |

4x M12 |

|

4x ½“ |

|

4x ½“ |

9.8 |

7.1 |

5.2 |

3.8 |

25 |

40 |

1“ |

150/300 |

4x M12 |

|

4x ½“ |

|

4x 5/8“ |

21 |

15 |

10 |

7.2 |

50 |

40 |

2“ |

150/300 |

4x M16 |

|

4x 5/8“ |

|

8x 5/8“ |

57 |

41 |

41 |

30 |

80 |

16 |

3“ |

150/300 |

8x M16 |

|

4x 5/8“ |

|

8x ¾“ |

47 |

34 |

70 |

51 |

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

16 |

4“ |

150/300 |

8x M16 |

|

8x 5/8“ |

|

8x ¾“ |

67 |

48 |

50 |

36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

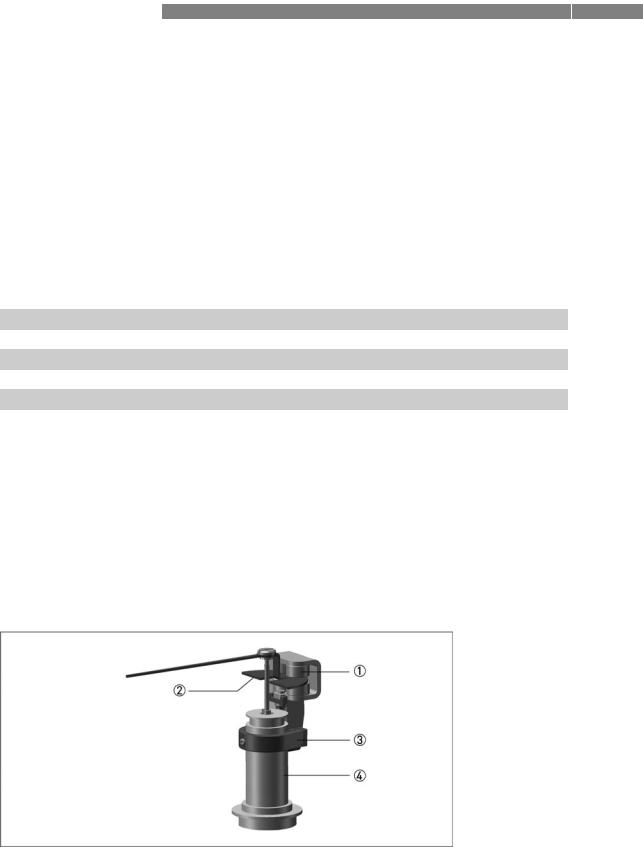

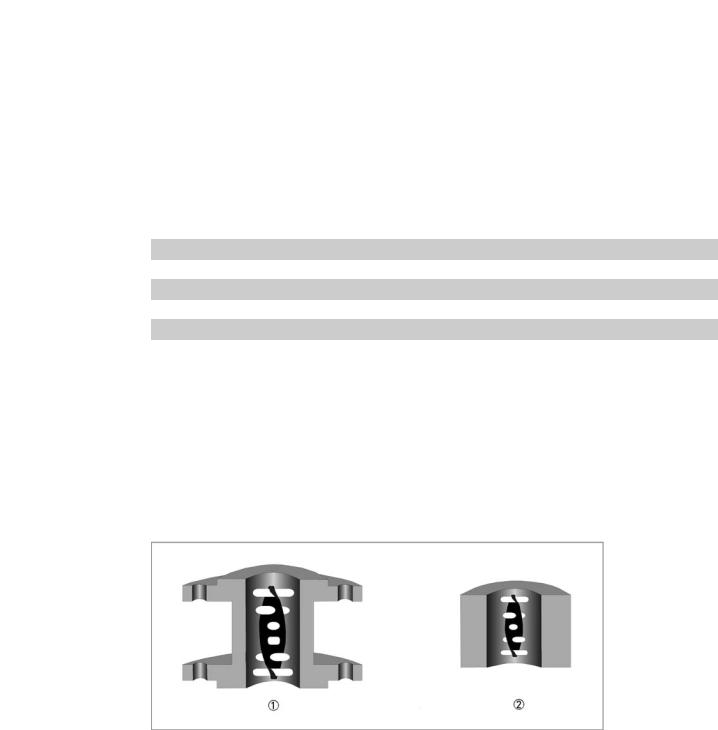

3.3.2 Magnetic filters

The use of magnetic filters is recommended when the medium contains particles which can be influenced magnetically. The magnetic filter is to be installed in the flow direction upstream of the flowmeter. Bar magnets are positioned helically in the filter to provide optimal efficiency at low pressure loss. All of the magnets are coated individually with PTFE to protect against corrosion. Material: 1.4404/316L

Magnetic filters

1Type F - fitting part with flange - overall length 100 mm / 4"

2Type FS - fitting part without flange - overall length 50 mm / 2"

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

21 |

3 INSTALLATION |

H250 M40 |

|

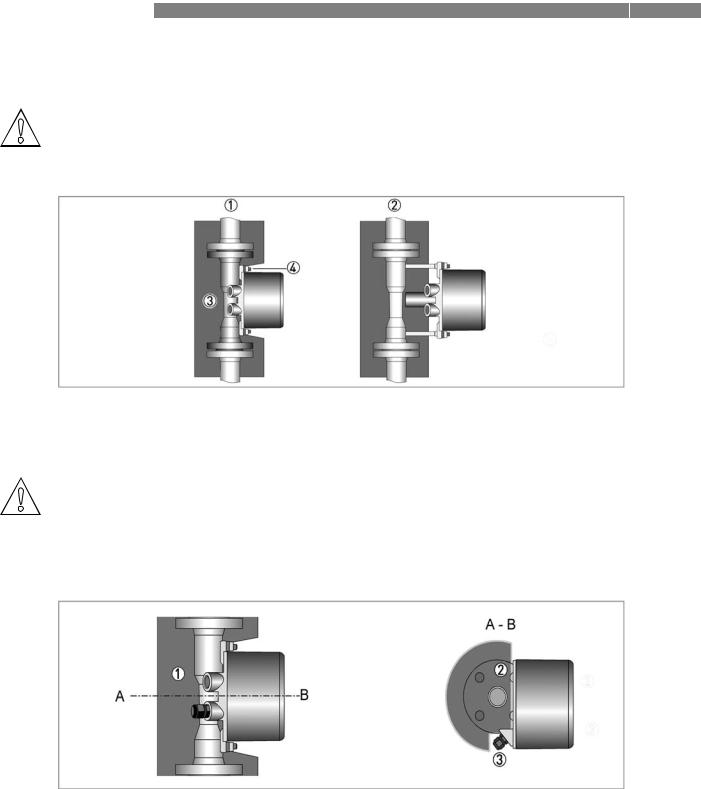

3.3.3 Heat insulation

CAUTION!

The indicator housing may not be heat-insulated.

The heat insulation 3 may only reach as far as the housing fastening 4.

1Standard indicator M40

2Indicator with HT extension

CAUTION!

The heat insulation 1 may only reach to the rear of the housing 2. The area around the cable entries 3 must be freely accessible.

Figure 3-1: Insulation - cross section

22 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

H250 M40 |

|

|

|

|

4.1 Security information

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the electrical components of the measuring device may only be carried out by properly trained specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate.

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

23 |

4 ELECTRICAL CONNECTIONS |

|

|

H250 M40 |

|

|

|

|

|

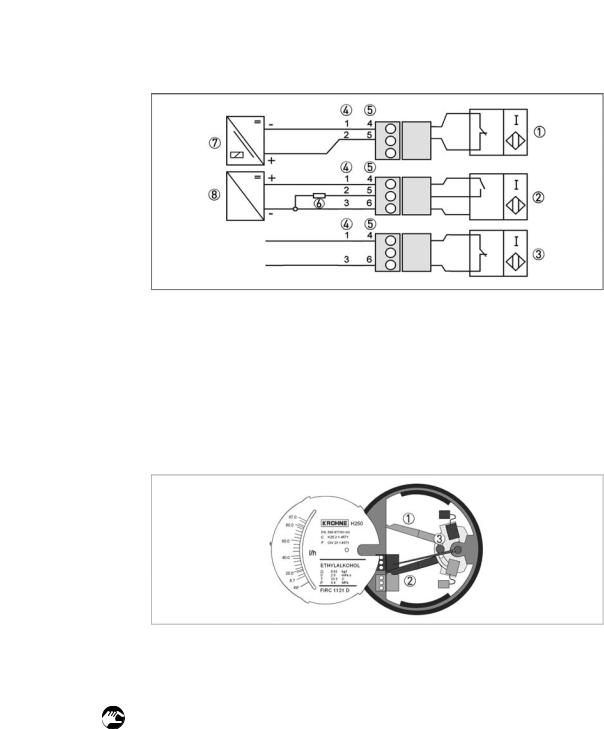

4.2 Electrical connection indicator M40

4.2.1 Limit switches K1/K2

The M40 indicator can be fitted with a maximum of two limit switches. The limit switch works as a slot sensor which is inductively activated via the semi-circular metal vane of the pointer. The switching points are set using the contact pointer. The position of the contact pointer is indicated on the scale.

Limit switch module

1Min. contact

2Max. contact

3Locking screw

4Maximum pointer

5Connection terminal

The connection terminals feature a pluggable design and can be removed to connect the cables. The built-in limit switch types are shown on the indicator.

Electrical connection of the limit switches

Contact |

|

MIN |

|

|

MAX |

|

|

|

|

|

|

|

|

Terminal no. |

1 |

2 |

3 |

4 |

5 |

6 |

|

|

|

|

|

|

|

Connection 2-wire NAMUR |

- |

+ |

|

- |

+ |

|

|

|

|

|

|

|

|

Connection 3-wire |

+ |

|

- |

+ |

|

- |

|

|

|

|

|

|

|

Connection Reed SPST |

+ |

|

- |

+ |

|

- |

|

|

|

|

|

|

|

24 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

|

|

ELECTRICAL CONNECTIONS 4 |

|

H250 M40 |

|

|

|

|

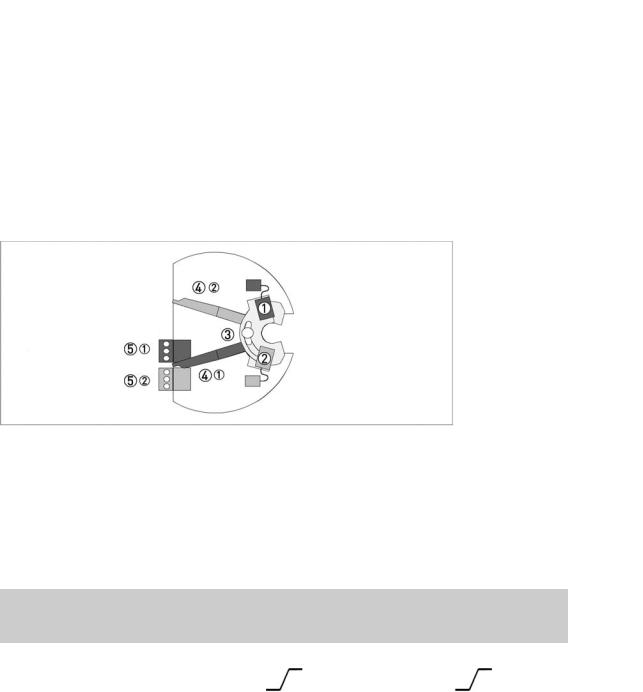

Limit switch connection terminals

12-wire limit switch NAMUR

23-wire limit switch

3Reed SPST Limit switch

4Terminal connection min contact

5Terminal connection max contact

63-wire load

7NAMUR isolated switching amplifier

83-wire power supply

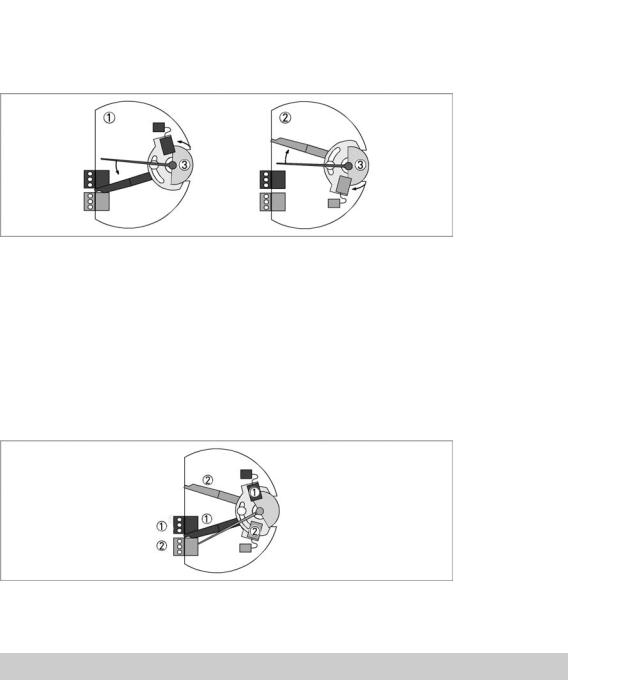

Limit setting

Figure 4-1: Limit switch settings

1Contact pointer MAX

2Contact pointer MIN

3Locking screw

Setting is carried out directly via contact pointers 1 and 2:

•Slide the scale away.

•Loosen the locking screw 3 slightly.

•Slide the scale back to the latching point.

•Set contact pointers 1 and 2 to the desired switching point.

After setting has been carried out, fix the contact pointers with the locking screw 3.

08/2015 - 4000640703 - MA H250 M40 R03 en |

www.krohne.com |

25 |

4 ELECTRICAL CONNECTIONS |

|

|

H250 M40 |

|

|

|

|

|

Switch contact definition

1MIN contact

2MAX contact

3Pointer vane with switching vane

If the measuring pointer vane goes into the slot an alarm is triggered. If the pointer vane is outside the slot sensor, a wire break in a NAMUR contact also triggers the alarm.

The 3-wire limit switch does not have any wire break detection.

Definition MinMin - MaxMax

1MIN 2 contact or MAX 1 contact

2MIN 1 contact or MAX 2 contact

Current consumption in the position shown:

Contact |

Type |

current |

|

|

|

MIN 1 |

NAMUR |

≤ 1 mA |

|

|

|

MIN 2 |

NAMUR |

≤ 1 mA |

|

|

|

MAX 1 |

NAMUR |

≥ 3 mA |

|

|

|

MAX 2 |

NAMUR |

≥ 3 mA |

|

|

|

26 |

www.krohne.com |

08/2015 - 4000640703 - MA H250 M40 R03 en |

Loading...

Loading...