KROHNE BM90 User Manual

Level-Sonic

Non contact level gauging

using ultrasonic waves

Inst allation and

operating

instructions

BM90/BM90L

BM90E/BM90LE

05/99

KROHNE S.A.

CERTIFIED

ISO 9001

C E

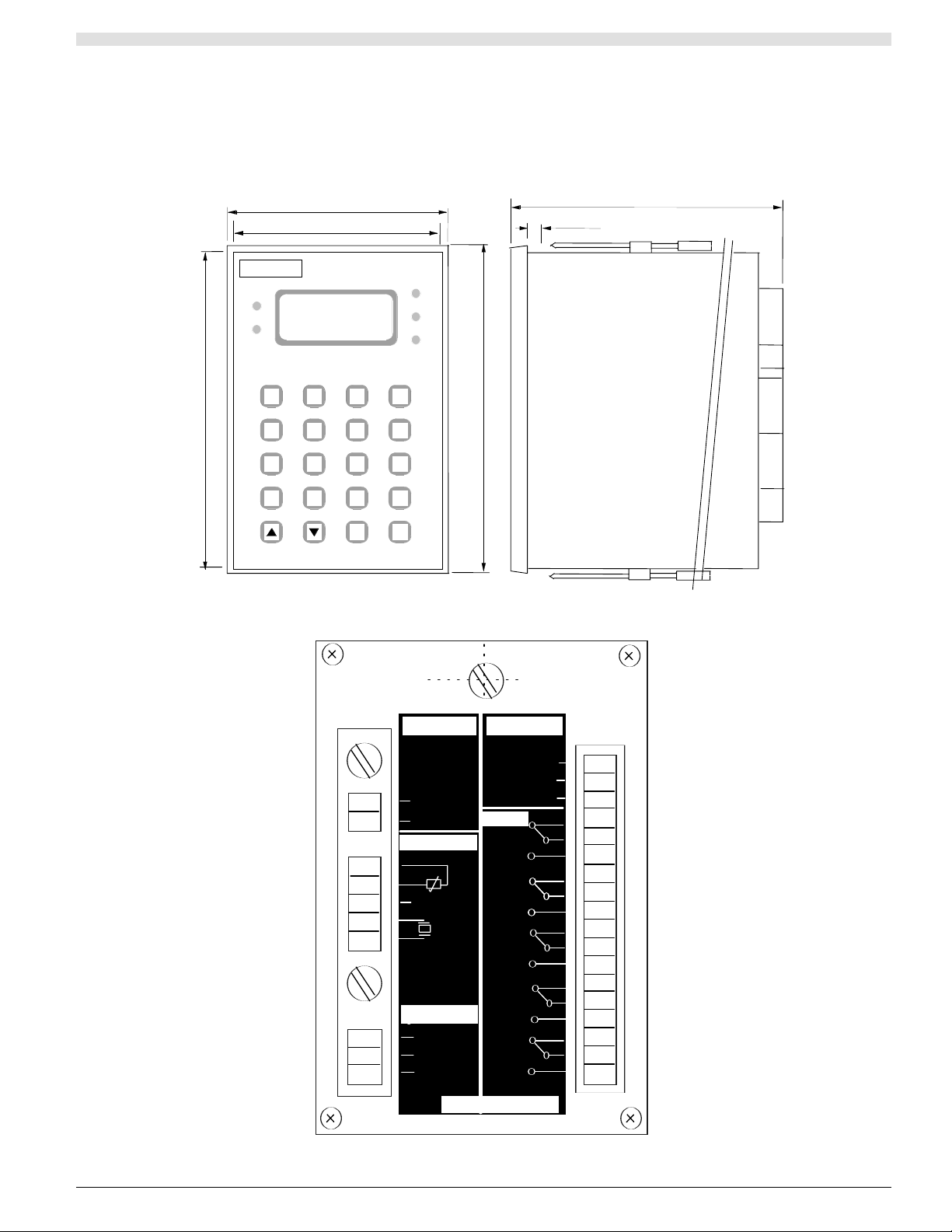

BM90 / L

BM 90 E / LE Panel mounted

2

LEVEL-SONIC BM90 SERIES

Contents Page

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1. Level-Sonic BM90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2. Initial start up Level-Sonic BM90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2.1. How to view parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2.2. How to change parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2.3. Programming example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3. Program checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.1. Program correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2. Inst allation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1. Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1.1. BM90 / L Wall mounted converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1.2. Transducer wiring for BM90 / L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.3 Transducer Cable Extensions for BM90 / L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.4. BM90 E/ LE Panel mounted converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.1.5. Transducer wiring for BM90 E / LE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.1.6 Tranducer Electrical Connections for BM90 E / LE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.1.7 Transducer Cable Extensions for BM90 E / LE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2. Transducer mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.2.1. Alternativ mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3. Temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1. Keypad definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2. Display descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3. Security code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.4. Application programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.5. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.5.1. Parameter index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.5.2. Parameter definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4. Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.1. Level measurement mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.2. Measurement with volumetric conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4.3. Pump control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.4. Differential level mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.6. Open channel flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.7. Open channel flowmeter with penstock control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5. Fault finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.1. Trouble shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.2. Programming sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6. Technical data Level-Sonic . . . . . . . . . . . . . . . . . . . . . .37

6.1. Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.2. Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Appendix 1 : Vessel - Flume linearisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Appendix 2 : Serial Communications BM90 L only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Appendix 3 : Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

1. Introduction

1.1. Level-Sonic BM90

The KROHNE S.A. Level-Sonic BM90/BM90E is a multipurpose liquid level measurement and flow control instrument.

The KROHNE S.A. Level-Sonic BM90L/BM90LE is also available for powder and granulate level.

It consists of two main elements, a microprocessor based transceiver and a high-efficiency transducer.

Ultrasonic pulses are transmitted by the transducer to the surface of the material to be monitored and, within millisec-

onds, are reflected back to the transducer. The time period between transmission and reception of the pulses is

directly proportional to the distance between the transducer and the material.

The Level-Sonic BM90 microprocessor computes this time period continuously for all echoes received and analyses

which is the correct reflection from the surface being monitored. It uses this data as the basis for giving control outputs

and displays, in useable engineering units.

Level-Sonic BM90 is capable of the following functions :

a) Level Measurement

b) Volume Measurement

c) Distance Measurement

d) Pump Control

e) Differential Level Measurement

f) Open Channel Flow Measurement

WARNING

DO NOT OPEN THE ELECTRICAL COVER WHEN THE POWER IS ON TO

THE SUPPLY OR RELAY TERMINALS.

NOTE : There is no need to remove the upper cover. If you need to access to the RS232 or RS485 terminal for the

BM90L then you have to open it.

IN THIS EVENTUALLITY, PLEASE REMOVE IT GENTLY, A FLAT CABLE IS ATTACHED TO THE COVER. TAKE

CARE NOT TO DESTROY IT.

3

4

1.2. Initial st art up Level-Sonic

The Level-Sonic BM90 system requires programming by

the operator to obtain the required measurements and

control. To become familiar with the use of the system, it

is suggested that the following Q UICK START G UIDE is

used before the instrument is installed.

Quick Start Guide :

1. Connect power and transducer cables as defined on

the instrument.

ac Power Supply Transducer dc Power Supply

[ 1 ] [ 2 ] [ 3 ] Terminal Nos: [ 19 ] [ 20 ] [21 ] [27 ] [28]

E N L Black Blue Screen +ve -ve

2. The instrument is supplied factory set on initial power

up to work in distance measurement up to 10 metres

from the transducer on the Level-Sonic BM90/E and 15

metres on the Level-Sonic BM90L/LE.

3. Hold the transducer approximately 1.5 metres from a

flat surface and switch on.

After a short period, the display will show the distance

(e.g. 1.50) between the transducer and the surface.

If the transducer is now moved slowly towards the sur-

face, the reading should decrease. This shows that the

unit is correctly wired and is operating as expected in

response to the reduction in distance.

If the reading increases as the transducer is moved

towards the surface, it indicates that the unit has been

previously programmed to read level not distance.

1.2.1. How to view parameters

The operational program for Level-Sonic BM90 is con-

tained within the parameters listed on Page 17 . Each

parameter instructs the unit to carry out a specific func -

tion. To look at the complete list of parameters, please

refer to chapter 3 but as an intitial guide proceed as fol -

lows :

Press ’MODE’, the display will show ’PROG’. (there

may be a delay of up to 6 seconds if the instrument is

busy). Press ’1’ immediately to obtain a display of

Pr.01 or the previous parameter number used.

It is now possible to key in any parameter number, via

the keypad. To display its value press ’DSP’. To

return to the parameter number press ’DSP’ again.

To view a sequence of parameter numbers, enter the

first one that is of interest and then press ’ s’ to

increase the parameter number or ’t’ to decrease the

parameter number.

Similarly, if a parameter value is displayed then press-

ing ’s’ or ’t ’ key will momentarily flash the next para-

meter number and then display that parameter value.

If a key is not pressed for a period of 30 seconds

the unit will automatically return to the run mode.

Press ’MODE’ to return Level-Sonic BM90 to the

’RUN’ mode.

1.2.2. How to change parameters

l Press ‘MODE‘ t o display ‘prog‘.

Whilst ’prog’ is displayed press ‘1‘

and the display will show either Pr.01

or previous Pr. number. If not Pr. 01

then press ‘1‘ to obtain display of

Pr.01.

l Press ‘DSP‘ t o display the value of Pr.01.

l Press ‘ENT‘ and the display will show ‘COdE‘

requesting that a security code is

entered.

l Press ‘9753‘ to enter the factory set security code.

(see page 16 to change code)

l Press ‘ENT‘ and the display will blink and show

either the default value of Pr.01 which is 2, or any other

value previously programmed into it.

The unit is now ready to be programmed.

Note : Whenever ‘COdE‘ is displayed, re-enter the secu-

rity code.

The display should now beshowing the value entered in

‘Pr.01‘ which is 2.

To change the value of this or any other parameter press

the new number required and ‘ENT‘. For our example

press 1 and ‘ENT‘ and the value of Pr.01 will change to 1

which means it is in level mode i.e. measuring liquid

height above datum.

Then using the ‘

s‘ key move to the other parameters that

require changing.

To change the value of any other parameter either use

the ’ s’ key to move to higher Pr numbers, or press ’DSP’

and then enter the Pr number required and press ’DSP’

again to display its value.

5

1.2.3. Programming example

The following example shows how Level-Sonic BM90

should be programmed for a simple level application

including setting a high alarm.

Having changed the value in Pr.01 to = 1 (level

Press

‘s‘ Display Pr.02 = 2 (units in meters)

‘s‘ Change Pr.03 = 1.5 (empty distance)

‘s‘ Change Pr.04 = 1.0 (operational span)

‘s‘ Change Pr. 05 = 0.5 (blanking distance)

‘s‘ Display Pr.06 = 1 (rate of change of

level in metres)

Press Pr.08 Change Pr.08 = 1 (relay 1 designated

normally energised)

‘s‘ Change Pr.09 = 0.7 (relay 1 set)

‘s‘ Change Pr.10 = 0.5 (relay 1 re-set)

MODE to return to normal running

For a full description of parameter options, please refer to

chapter 3.

Note : The display does not show the decimal point until

the first decimal figure is keyed in.

1.3. Program checking

To check that the previous program functions properly,

hold the transducer approximately 1.5 m above a surface

and press ‘MODE‘ to return to the run condition.

The display will read approximately zero.

If it displays LOST it is because the transducer is more

than the 1.5 metre (distance to furthest point) from your

target. Go closer and wait for LOST to change to 0.000

and then a level.

By slowly moving the transducer towards the surface, the

display will increase simulating a rising level. When the

display exceeds 0.7 the relay will switch, as indicated by

the light on relay 1, and if the transducer is then raised,

the display will decrease and the relay will reset below

0.5.

1.3.1. Program correction or

resetting factory defaults

If at any time you feel that a mistake has been made, the

following routine clears the program back to the known

starting position of the factory set values shown on

page 26. It is also advisable to return to the factory

default values before building a program for a new appli-

cation. This is achieved as follows :

Press

‘MODE‘ to display PROG .

1 immediately to display a Pr number

‘99 ‘ to display Pr.99.

D S P to show ====

‘C E ‘ to clear the display.

‘E N T‘ to display COdE requesting the security

code.

‘9753‘

‘E N T‘ the display will now show ‘t.rES‘

followed by ’P.rES’ and finally ‘====‘.

‘DSP‘ to display ‘Pr.99‘ and now the new

program can be entered.

The above is a brief introduction.

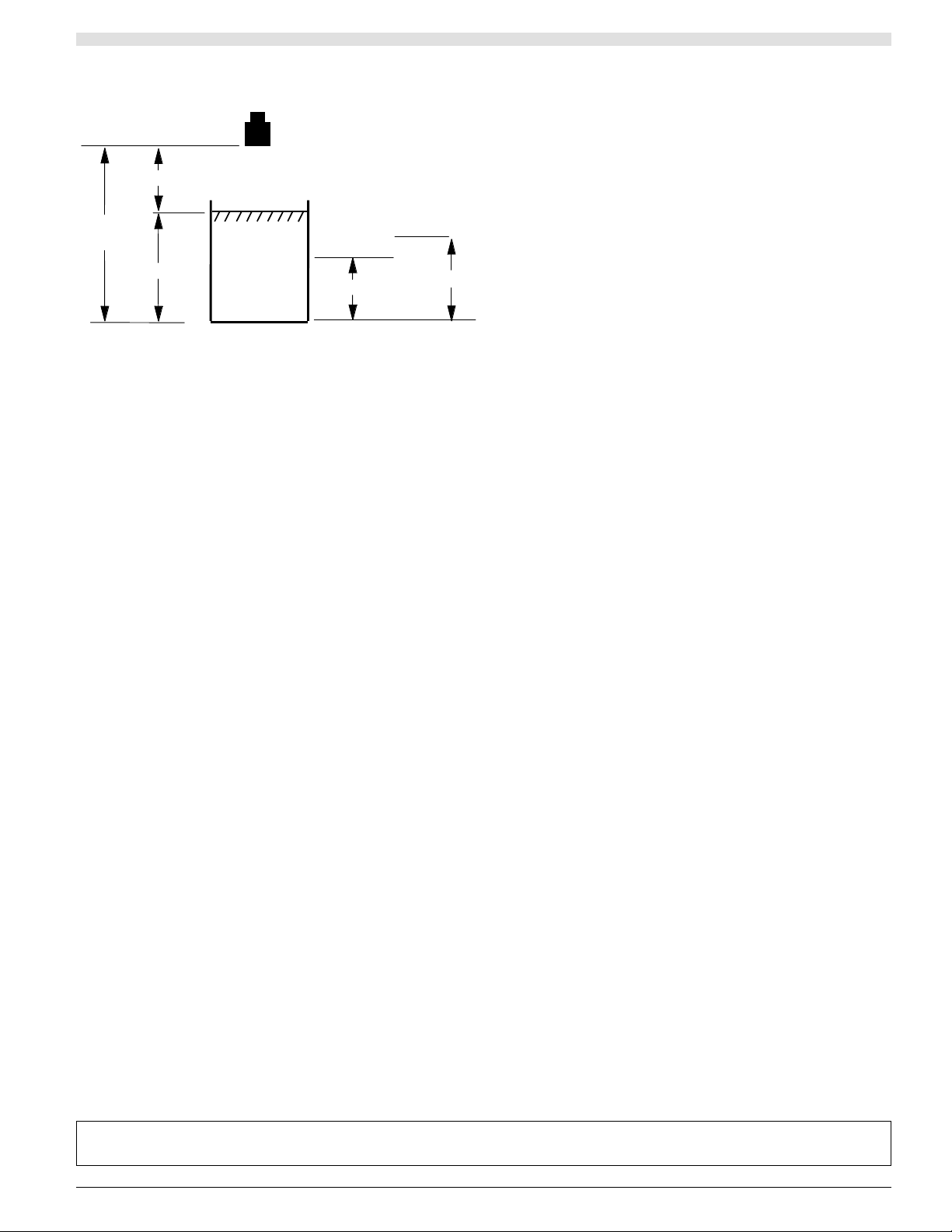

1.0 (Pr.4)

1.5

(Pr.3)

0.5 (Pr.5)

Relay 1 Reset

0.5 (Pr.10)

0.7 (Pr.9)

Nota : To understand programming completely it is necessary to read the detailed section describing Programming,

Section 3, along with the parameter descriptions, Section 4, and the examples, Section 5, before continuing.

6

2. Inst allation

The installation of the Level-Sonic BM90 unit is straight

forward, providing the guidelines in this chapter are fol -

lowed.

2.1. Converter

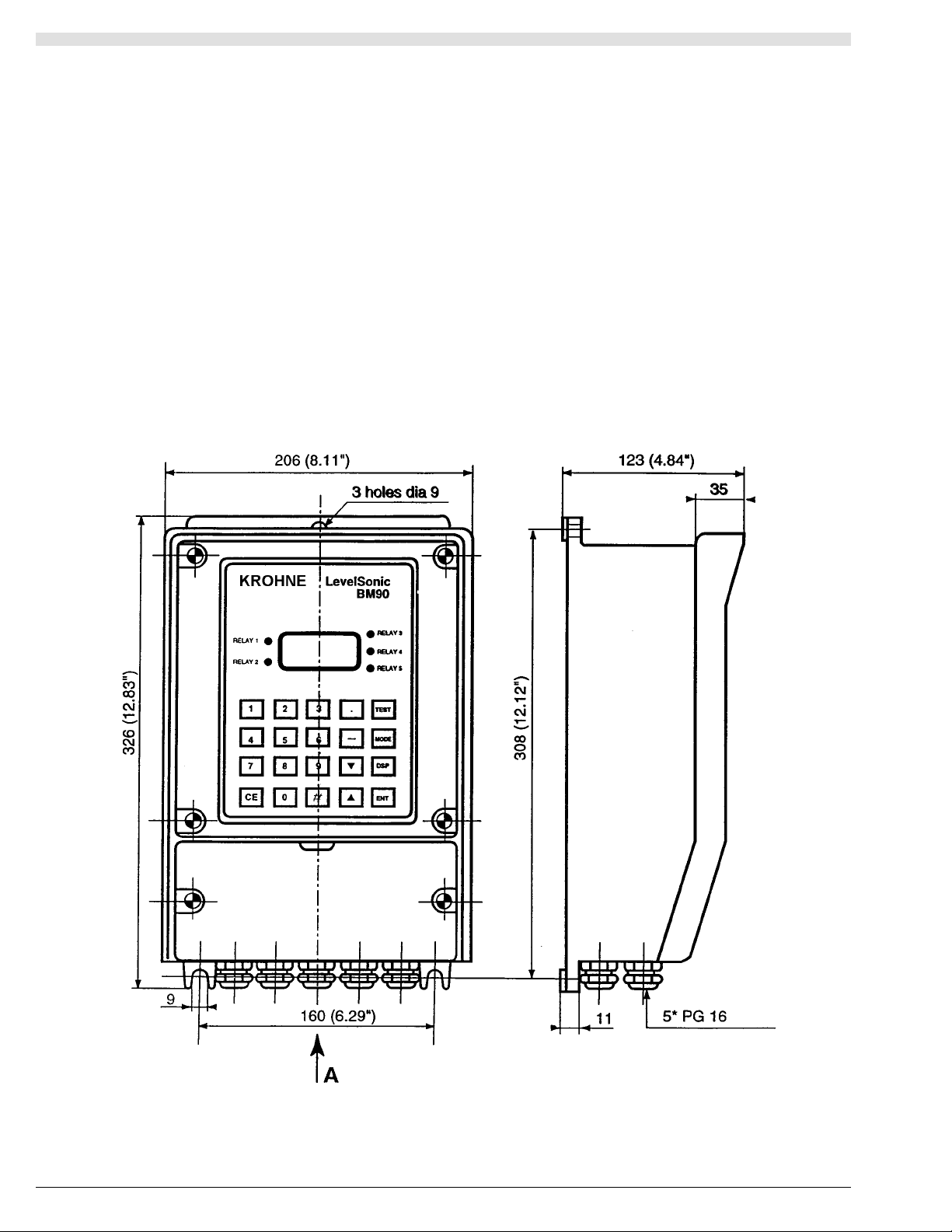

The BM90 / L unit (Fig 1) must be mounted on a flat sur-

face secured by the 3 mounting holes.

For the BM90 E/LE, see panel cut out figure 5.

When mounting the unit avoid vibration or close proximity

to high voltage cables, contactors and drive controls. The

unit should not be mounted in direct sunlight or in a con-

fined space where temperatures may exceed the normal

working temperature. If the unit is mounted outside it

must be protected from severe weather conditions.

Note : Electrical Connection

Converter instrument has 2 covers, the bottom one with 2

screws is protecting terminals. See Fig. 6 for the wiring

diagram. Replace cover after completion of wiring.

Note : Select the correct working voltages for AC

On converter instrument the voltage selector switch is on

the left hand side of the bottom PCB.

Note : If DC power supply is required, instruments will be

marked accordingly.

NOTE : There is no need to remove the upper cover. If

you need to access to the RS232 or RS485 terminal for

the BM90E then you have to open it.

IN THIS EVENTUALLITY, PLEASE REMOVE IT GEN-

TLY, A FLAT CABLE IS ATTACHED TO THE COVER.

TAKE CARE NOT TO DESTROY IT.

2.1.1 BM90 / L Wall mounted converter

Fig 1:

7

Figure 2:

AC power supply - connected:

Earth to terminal 1

Neutral to terminal 2

Live to terminal 3

The instrument will automatically accept either 110V or

230V AC –10%, 50Hz or 60Hz, 12VA. A time lag fuse

T160mA is fitted.

DC power supply - connected :

Positive +ve to terminal 27

Negative -ve t o terminal 28

The instrument will accept 24V DC + 25%, - 10%. 9W.

A time lag fuse T315mA is fitted.

5 SPDT Relays - rated 8A/250V AC/30V DC resistive,

with gold contacts for lower power switching, are connect-

ed to terminals 4 to 18, for activating external alarms,

contactors, pumps etc..

Transducer RZV15 - i s connected:

Black to terminal 19

Blue to terminal 20

Screen t o terminal 21

Temperature compensated transducer RZT15 -

is connected:

(Screen t o terminal 19

Must enable Pr.37 (Blue to terminal 20

(Black to terminal 22

Isolated Analogue - i s connected :

Screen t o terminal 24

Positive +ve to terminal 25

Negative -ve t o terminal 26.

Separate Temperature Compensation - when compen-

sation is provided by a separate temperature sensor, the

sensor should be connected with a shielded twisted pair

and connected:-

(Screen to terminal 21

Must enable Pr.37 (Core* t o terminal 22

(Core* to terminal 23

* The polarity of the cores is unimportant, but it is impor -

tant that the screen is connected only at the instrument

end and not at the temperature sensor end.

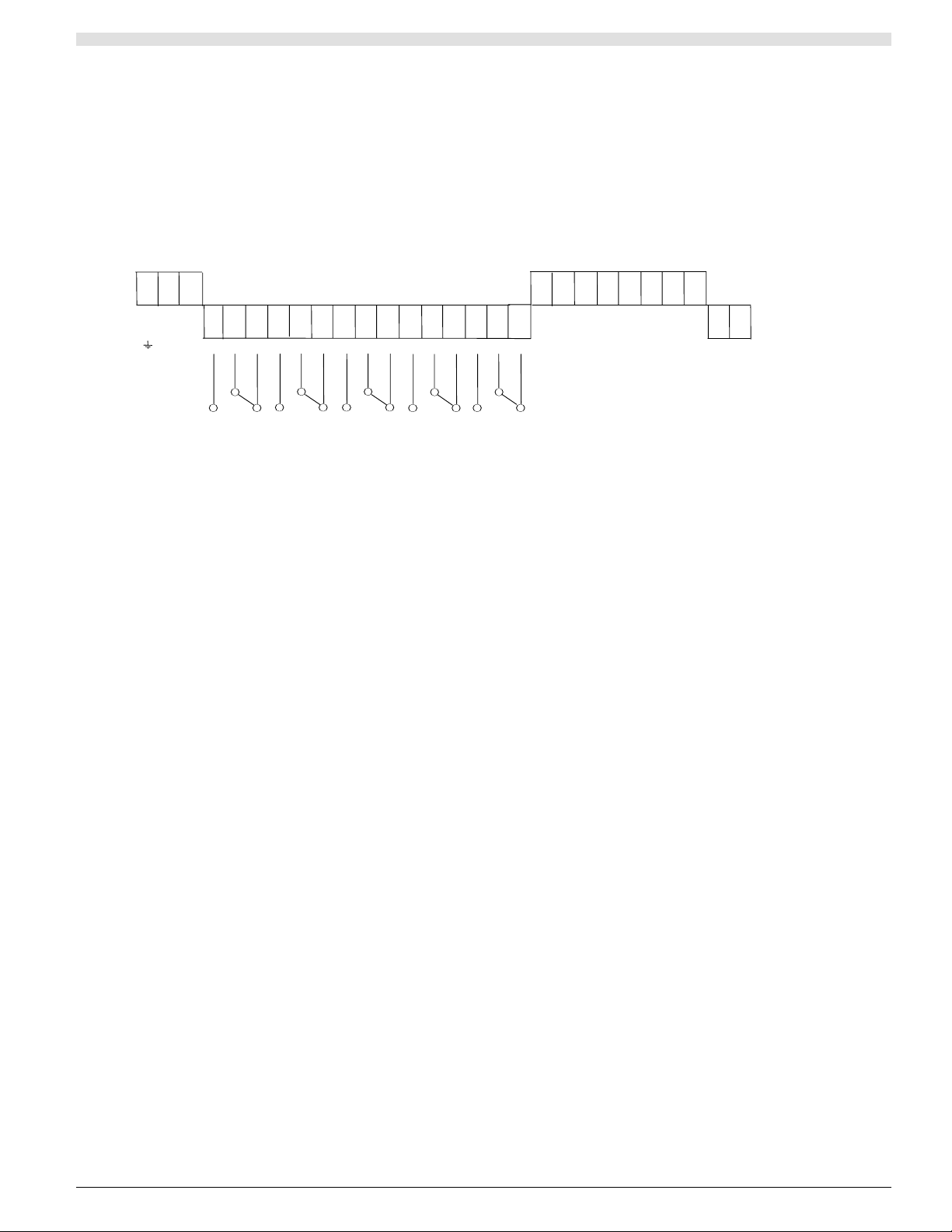

1 2 3

E N L

L2 L1

AC POWER

110/230 VAC

+10%/-10%

50/60 HZ

12VA

19 20 21 22 23 24 25 26

27 28

+ -

DC Power

21.6-30VDC

9W

Isolated

Analog

Output

+

-

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

RELAY 1

RELAY

RELAY

RELAY 5

RELAY 2

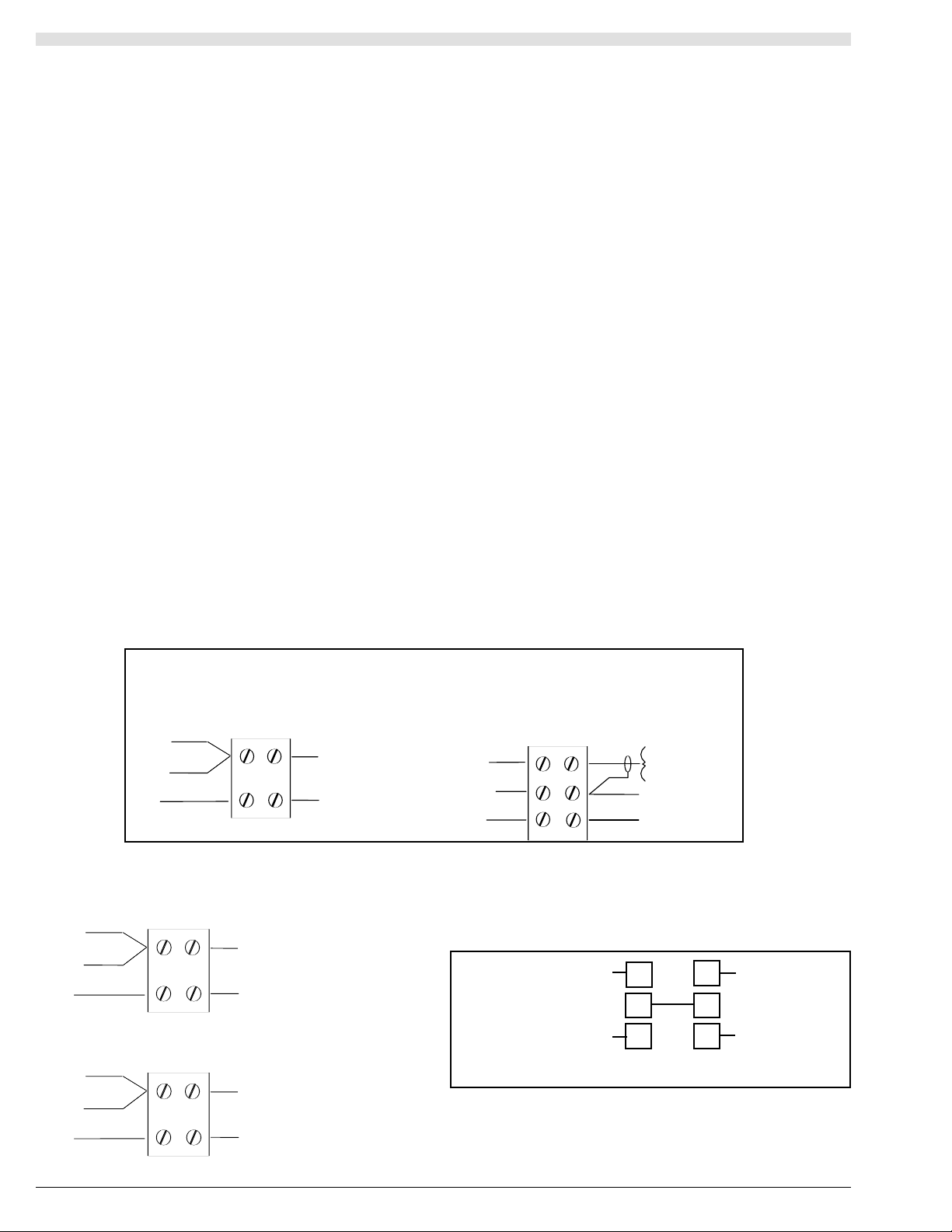

2.1.2. Transducer Wiring for BM90 / L

The wall mount instrument has two-part screw terminals. It can be powered from either an AC or DC supply.

Simultaneous AC & DC powering can be done through an external relay which switch on the other power when the

main one is off. The relay contact will be released when main power is off. Ask for scheme if necessary.

8

2.1.3. Transducer Cable Extensions for BM90 / L

Transducer cables may be extended using junction boxes as shown below in Figure 3:

Junction

Screen - Term 19

Standard Transducer

Transceiver

Core - Term 20

Transducer

Black

Screen

Blue

RG62AU

Temperature Compensation Transducer

RG62AU

Blue

Junction

Core - Term.22

Screen - Term.19

Core - Term. 20

Screen - Term.19

Transceiver

Transducer

Black

Screen

Figure 4:Transducer Wiring for Differential Mode

UP & DOWNSTREAM SHIELD

Junction

Screen - Term 19

Transceiver

Core - Term 18

Upstream Transducer

Black

Screen

RG62AU

Junction

Screen - Term 21

Transceiver

Core - Term 16

Downstream Transducer

Black

Screen

Blue

RG62AU

Extend transducer cable if necessary

with RG62AU as shown.

1 2 3

E N L

L 2 L1

AC POWER

110/230 VAC

+10%/-10%

50/60 HZ 12VA

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

RELAY 1

RELAY 3

RELAY 2

27 28

+ -

DC POWER

21.6-30VDC

9W

19 20 21 22 23 24 25 26

ISOLATED

ANALOG

OUTPUT

-

SHIELD

HOT.BLUE

BLACK

+

TEMP

SENSOR

TRANS-

DUCER

SHIELD

RELAY 4

RELAY 5

LINK

UPSTREAM - BLUE

DOWNSTREAM - BLUE

UP & DOWNSTREAM BLACK

9

KROHNE

1

3

4

5

2

Level-Sonic

1

HI.TO

5

R1.HR

9

R1.ST

CE

R5.HR

R5.ST

2

LO.TO

TEMP

6

R2.HR

0

R2.ST

#

3

HEAD

7

R3.HR

.

R3.ST

MODE

DSP

DIST

4

FLOW

8

R4.HR

_

R4.ST

TEST

GAIN

ENT

m

96

144

90-91 PANEL CUTOUT

150 BEHIND PANEL

2-20 PANEL WIDTH

10

8

FUSE

160mA

ANTISURGE

ANALOGUE

6

5

9

4

3

7

TRANSDUCER

TCOMP

TRANSDUCER

HOT

1

2

N

E

L

MAINS

SUPPLY

SER.NO.

FUSE

315mA

ANTISURGE

RELAYS

18

17

19

RELAY 4

21

20

22

12

11

13

15

14

16

24

23

28

SHIELD

27

25

26

+

_

ANALOGUE

OUTPUT

RELAY 4

RELAY 3

RELAY 2

RELAY 1

RELAY 5

0V

24V

DC SUPPLY

AC SUPPLY

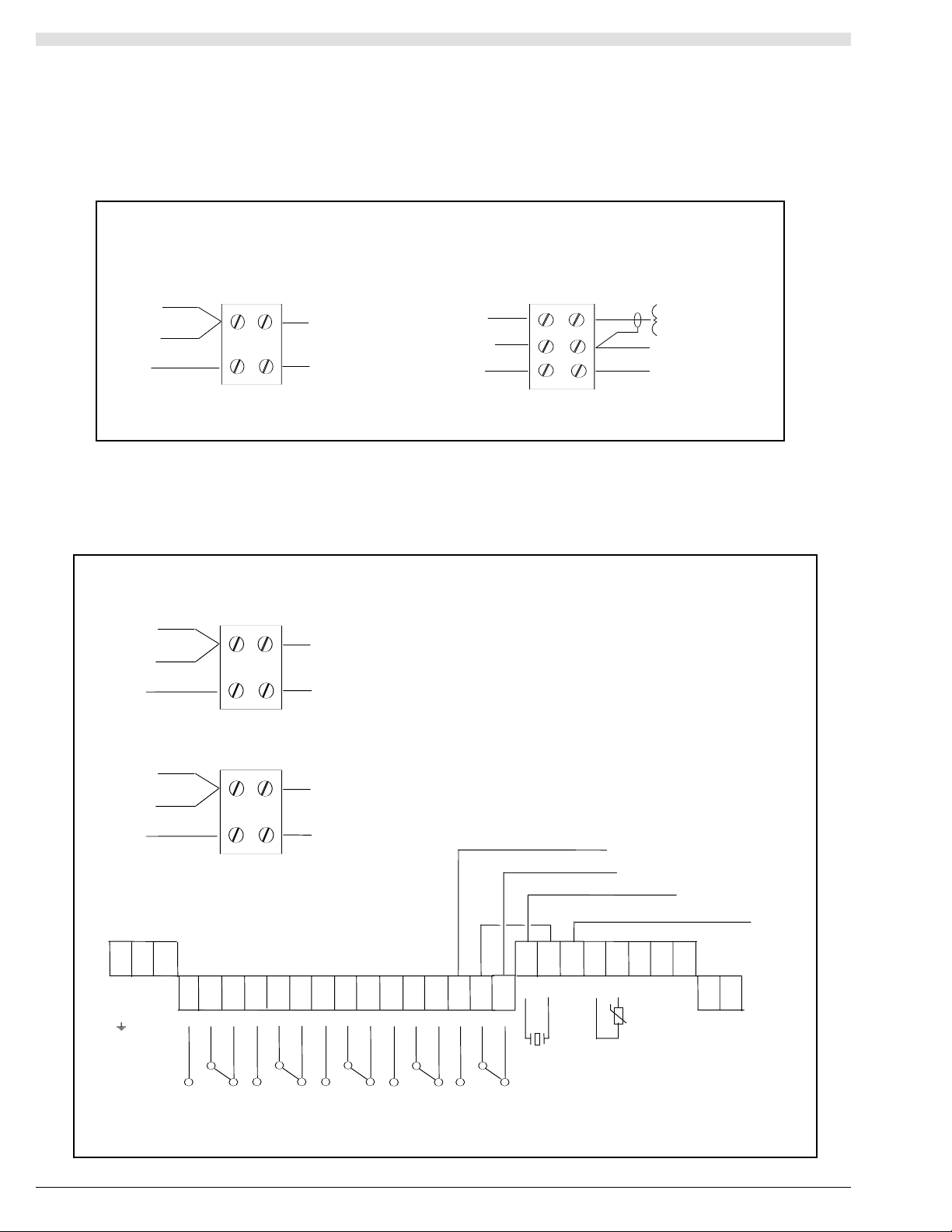

2.1.4. BM90 E/LE Panel mounted converter

The panel mount instrument has two rear screw termi-

nals. There is no serial commnucation connector even on

the BM90 LE

2.1.5. Transducer wiring for BM90E / LE

fig 6

fig 5

10

2.1.6 Transducer Electrical Connections

For BM90 E /LE - Figure 7 below

The panel mount instrument has two-part screw termi-

nals. It can be powered from either an AC or DC supply.

AC power supply - connected: Earth to terminal 1

Neutral to terminal 2

Live to terminal 3

The instrument will automatically accept either 110V or

230V AC –10%, 50Hz or 60Hz, 12VA. A time lag fuse

T160mA is fitted.

DC power supply - connected :

Positive +ve to terminal 10

Negative -ve t o terminal 0v

The instrument will accept 24V DC + 25%, - 10%. 9W.

A time lag fuse T315mA is fitted.

5 SPDT Relays - rated 8A/250V AC/30V DC resistive,

with gold contacts for lower power switching, are connect-

ed to terminals 11 to 25, for activating external alarms,

contactors, pumps etc..

Transducers:

The Level-Sonic BM90 uses RZV15 series transducer.

The Level-Sonic BM90L uses RXV15 series transducer.

Transducer RZV15 and RXV15 - are connected:

Black to terminal 4

Blue to terminal 5

Screen t o terminal 6

Temperature compensated transducer RZT15 and

RXT15 - are connected:

(Screen t o terminal 4

Must enable Pr.37 (Blue to terminal 5

(Black to terminal 8

Isolated Analogue - i s connected :-

Screen t o terminal 26

Positive +ve to terminal 27

Negative -ve t o terminal 28

Separate Temperature Compensation - when compen-

sation is provided by a separate temperature sensor, the

sensor should be connected with a shielded twisted pair

and connected:

(Screen to terminal 6

Must enable Pr.37 (Core* to terminal 7

(Core* to terminal 8

* The polarity of the cores is unimportant, but it is impor -

tant that the screen is connected only at the instrument

end and not at the temperature sensor end.

2.1.7 Transducer Cable Extensions for BM90 E / LE

Junction

Screen - Term 4

Standard Transducer

Transceiver

Core - Term 5

Transducer

Black

Screen

Blue

RG62AU

Temperature Compensation Transducer

RG62AU

Blue

Junction

Core -Term.7

Screen - Term.4

Core - Term.5

Screen - Term.4

Transceiver

Transducer

Black

Junction

Screen - Term 4

Transceiver

Core - Term 25

Upstream Transducer

Black

Screen

Blue

RG62AU

Junction

Screen - Term 4

Transceiver

Core - Term 23

Downstream Transducer

Black

Screen

Blue

RG62AU

Transducer cables may be extended using junction boxes as shown in Figure 7 below

fig 7

Transducer wiring for Differential Mode - fig 8

Extend transducer

cable if necessary

with RG62AU as

shown

Link terminals 5

and 24 together

4

23

6

5

24

25

Link

(Without extension cable)

Up & Downstream Sreens

Up & Downstream Blacks

Upstream Blue

Downstream Blue

8

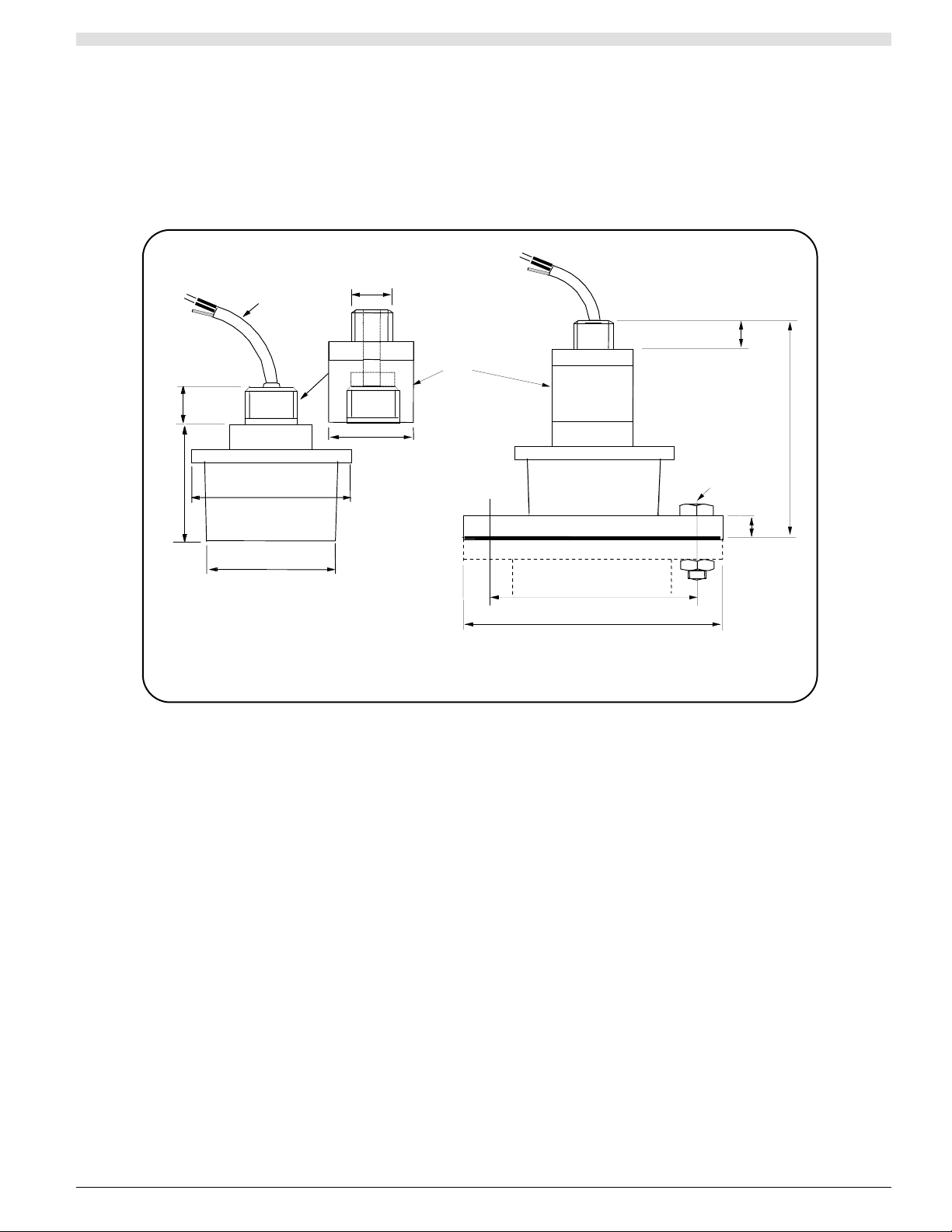

11

2.2. Transducer Mounting

The transducer can be supplied as ’standard’ or mounted in a Teflon faced flange for applications requiring chemical

compatibility. The figure below shows the dimensions:

20

170

Isolation Kit

Fit as shown

20

21

72

100

10m cable

6.9 dia

50

M20 x 1.5

95

Dia to suit flange selected

No. & size of bolts

to suit flange selected

Bolt hole PCD to suit

flange selected

DIA

DIA

DIA

Standard

Flanged

An isolation kit is provided with each transducer to min-

imise any ringing transmitted through the mounting struc

ture.

The transducer must be mounted perpendicular to the

monitored surface and, ideally, at least 0.5 metres above

it.

The transducer has a 10 inclusive conical beam angle

at 3dB and must be mounted with a clear unobstructed

sight of the liquid to be measured over the complete

measurement range.

The transducer is provided with integral cable which can

be extended up to 300 metres using a suitable junction

box and RG62AU cable. The temperature compensated

transducer requires an additional single core screen

extension.

The extended cable should then be terminated directly

into the instrument.

Transducer cables and temperature compensation

cables can be run together but should be separated from

power cables by at least 150mm and preferably installed

in their own earthed steel conduit.

12

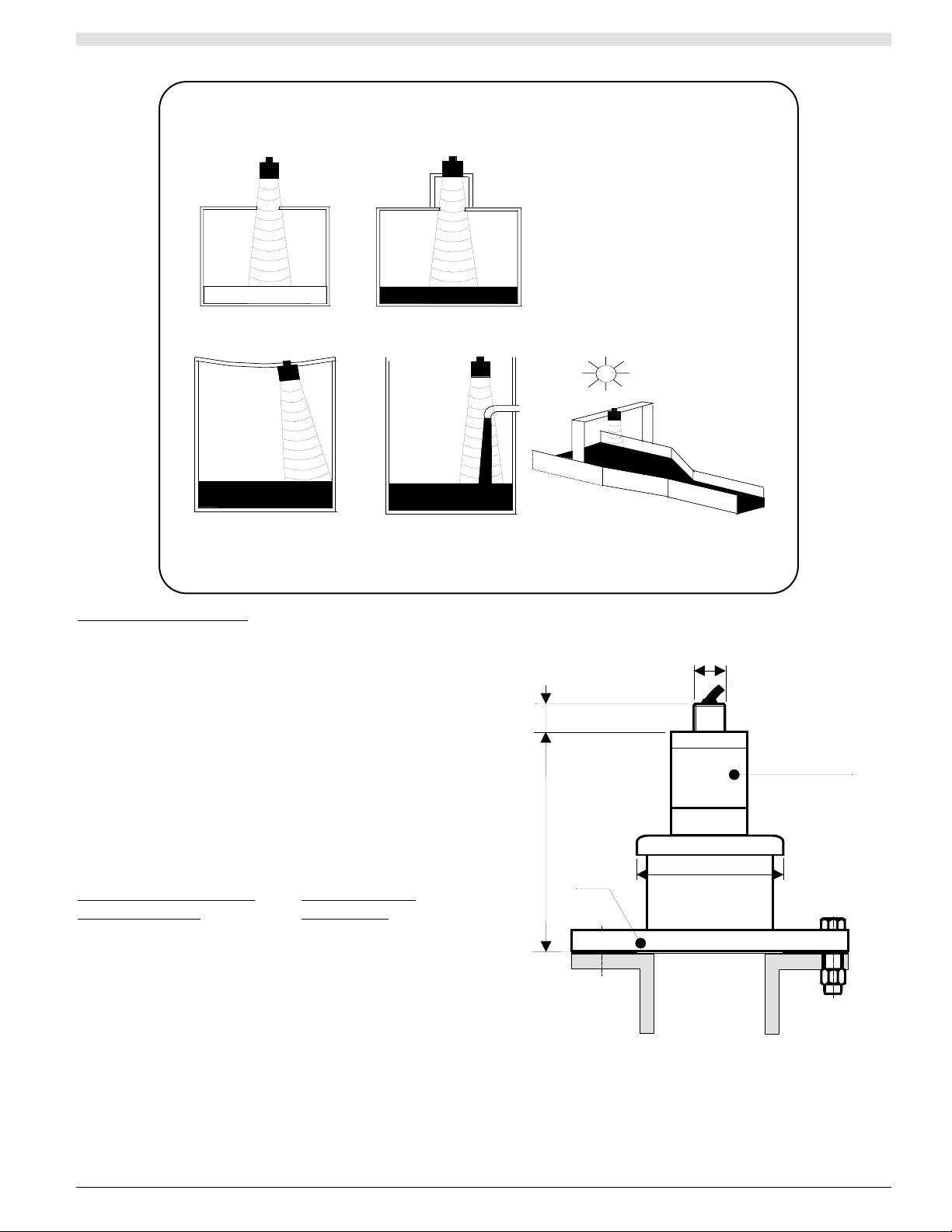

2.2.1. Alternative mounting arrangements for transducer

FLEXIBLE OR RIGID

CONDUIT.

BRACKET.

UNDER FLANGE.

INTEGRAL FLANGE WITH PTFE FACE.

SLIP-ON FLANGE.

ISOLATION KIT.

ISOLATION KIT.

OPTIONAL

ISOLATION KIT

Do not mount transducers incorporating temperature

compensation in direct sunlight.

Do not over-tighten the bolts on flange construction trans-

ducers.

Flange transducers are not pressure rated and are suit-

able only for atmospheric pressure.

CENELEC approved transducers must be mounted and

wired in accordance with the appropriate National

Standards concerning installation in hazardous environ-

ments.

For differential applications mount both transducers at the

same height above the zero datum point.

For open channel flow applications the transducer must

be mounted upstream of the flume or weir as detailed in

BS3680 (usually 3 or 4 times maximum head).

13

KEEP TRANSDUCER

PERPENDICULAR

TO LIQUID.

KEEP TRANSDUCERS AND

TEMPERATURE COMPENSATION

PROBES OUT OF DIRECT

SUNLIGHT

DO NOT AIM THROUGH

HOLES IN THE TANK

.

AVOID ROUGH EDGES

IN STANDPIPES

.

AVOID INFLOWS OR

OTHER OBSTRUCTIONS

.

CAUTION: AVOID THE FOLLOWING TRANSDUCER INSTALLATION FAULTS

Standpipe Installations

In many applications access to a vessel must be made

via a standpipe. However, it is necessary to observe

some basic rules when fitting transducers into stand-

pipes.

BLANKING: Parameter 5 should always be set at

least 150 mm longer than the length of

the standpipe.

STANDPIPE should be in accordance with the follo-

wing table

DIMENSIONS:

Flange size and minimum Maximum length

bore of Standpipe of Standpipe

3" ( 75mm) 300mm

4" (100mm) 300mm

6" (150mm) 400mm

8" (200mm) 600mm

12" (300mm) 600mm

e.g. : Using a 4" flanged transducer would require the

standpipe length to be no more than 300mm and Pr.5 set

at 450 mm minimum.

The inside of the pipe and joint with vessel top must

be clean and free of any obstructions, seams or

welds.

Isolation kit

dia 95 (3.74")

M20 X 1.5

22 (0.86")

155 (6.10")

PVC

flange

Loading...

Loading...