KROHNE IFC-100 User Manual

Signal converter for electromagnetic flowmeters

Electronic Revision:

ER 2.1.xx

(SW.REV. 3.0x)

IFC 100

IFC 100IFC 100

IFC 100

Quick Start

Quick Start Quick Start

Quick Start

© KROHNE 07/2010 - 4000124104 - QS IFC 100 R04 en

The documentation is only complete when used in combination with the relevant

documentation for the sensor.

CONTENTS

2

www.krohne.com 07/2010 - 4000124104 - QS IFC 100 R04 en

IFC 100

1 Safety instructions 3

2 Installation 4

2.1 Intended use ..................................................................................................................... 4

2.2 Scope of delivery............................................................................................................... 4

2.3 Storage ............................................................................................................................. 5

2.4 Transport .......................................................................................................................... 5

2.5 Installation specifications ................................................................................................5

2.6 Mounting of the compact version..................................................................................... 6

2.7 Mounting the wall-mounted housing, remote version .................................................... 6

2.7.1 Wall mounting......................................................................................................................... 6

2.7.2 Mounting plate, wall-mounted version .................................................................................. 8

3 Electrical connections 9

3.1 Safety instructions............................................................................................................ 9

3.2 Important notes on electrical connection........................................................................ 9

3.3 Electrical cables for remote device versions, notes...................................................... 10

3.3.1 Notes on signal cable A ........................................................................................................ 10

3.3.2 Notes on field current cable C.............................................................................................. 10

3.3.3 Requirements for signal cables provided by the customer ................................................. 11

3.4 Preparing the signal and field current cables ............................................................... 12

3.4.1 Signal cable A (type DS 300), construction........................................................................... 12

3.4.2 Length of signal cable A........................................................................................................ 13

3.4.3 Preparing signal cable A, connection to signal converter ................................................... 14

3.4.4 Preparing field current cable C, connection to signal converter......................................... 15

3.4.5 Prepare signal cable A, connect to measuring sensor ........................................................ 17

3.4.6 Preparing field current cable C, connection to measuring sensor ..................................... 18

3.5 Connecting the signal and field current cables............................................................. 19

3.5.1 Connecting the signal and field current cables to the signal converter, remote version... 20

3.5.2 Connection diagram for signal and field current cable ....................................................... 22

3.6 Grounding the measuring sensor .................................................................................. 23

3.6.1 Classical method................................................................................................................... 23

3.7 Connecting the power..................................................................................................... 24

3.8 Overview of outputs ........................................................................................................26

3.8.1 Description of the CG number .............................................................................................. 26

3.8.2 Fixed, non-alterable output versions ................................................................................... 26

3.9 Electrical connection of the outputs .............................................................................. 27

3.9.1 Electrical connection of the outputs.....................................................................................27

3.9.2 Laying electrical cables correctly......................................................................................... 28

4 Start-up 29

4.1 Switching on the power .................................................................................................. 29

4.2 Starting the signal converter ......................................................................................... 29

5 Notes 30

SAFETY INSTRUCTIONS 1

3

IFC 100

www.krohne.com07/2010 - 4000124104 - QS IFC 100 R04 en

Warnings and symbols used

HANDLING

• This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULTRESULT

RESULT

This symbol refers to all important consequences of the previous actions.

Safety instructions for the operator

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

LEGAL NOTICE!

The responsibility as to the suitability and intended use of this device rests solely with the user.

The supplier assumes no responsibility in the event of improper use by the customer. Improper

installation and operation may lead to loss of warranty. In addition, the "Terms and Conditions of

Sale" apply. They appear on the back of the invoice and form the basis of the purchase contract.

INFORMATION!

•

Further information can be found on the supplied CD-ROM in the manual, on the data sheet,

in special manuals, certificates and on the manufacturer's website.

•

If you need to return the device to the manufacturer or supplier, please fill out the form

contained on the CD-ROM and send it with the device. Unfortunately, the manufacturer

cannot repair or inspect the device without the completed form.

2 INSTALLATION

4

IFC 100

www.krohne.com 07/2010 - 4000124104 - QS IFC 100 R04 en

2.1 Intended use

The electromagnetic flowmeters are designed exclusively to measure the flow and conductivity

of electrically conductive, liquid media.

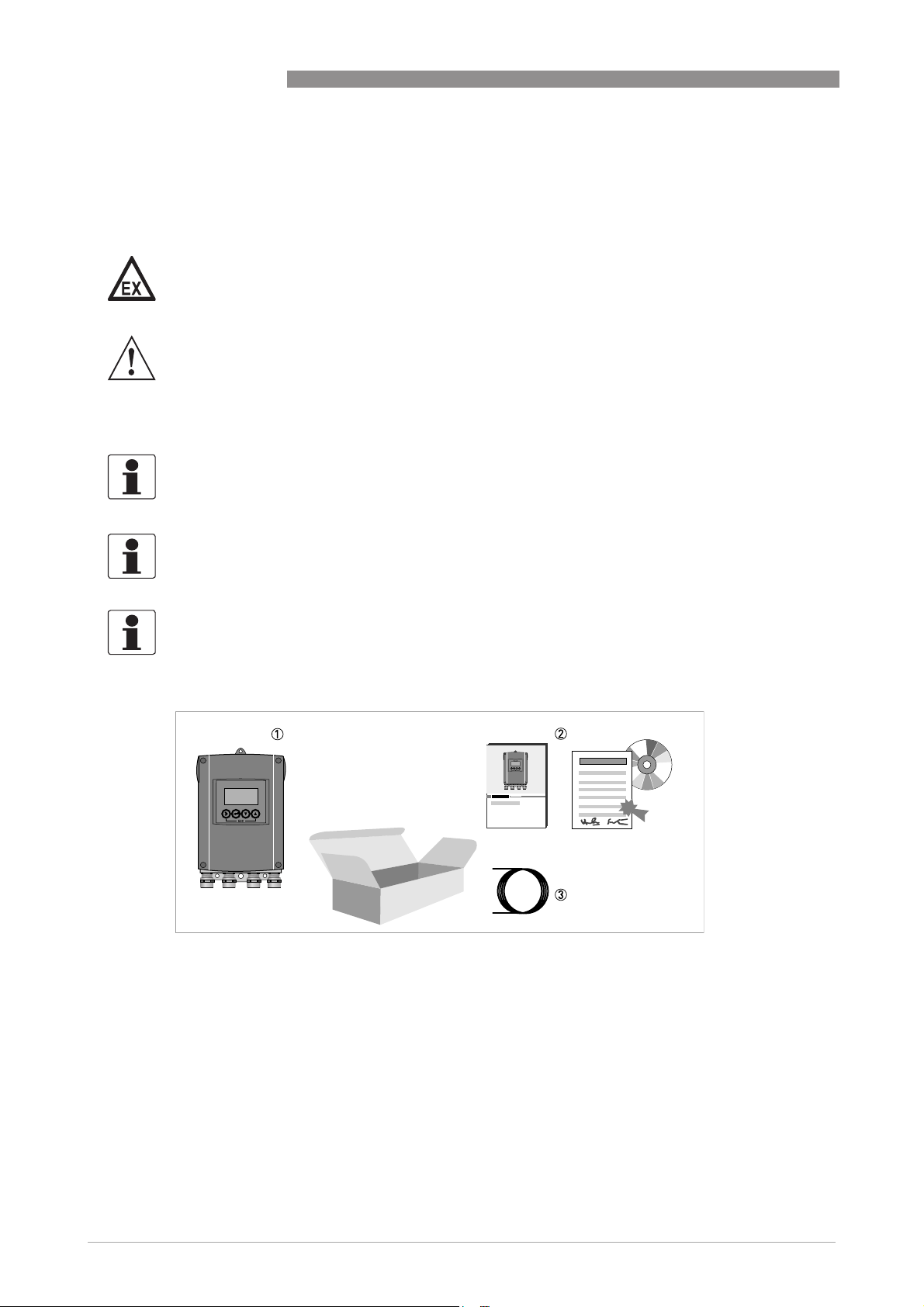

2.2 Scope of delivery

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

If the device is not used according to the operating conditions (refer to chapter "Technical data),

the intended protection could be affected.

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

Figure 2-1: Scope of delivery

1 Device in the version as ordered

2 Documentation (calibration report, Quick Start, CD-ROM with product documentation for measuring sensor and signal

converter)

3 Signal cable (only for remote version)

INSTALLATION 2

5

IFC 100

www.krohne.com07/2010 - 4000124104 - QS IFC 100 R04 en

2.3 Storage

• Store the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• Store the device in its original packing.

• Storage temperature: -40...+70°C / -40...+158°F

2.4 Transport

Signal converter

• No special requirements.

Compact version

• Do not lift the device by the signal converter housing.

• Do not use lifting chains.

• To transport flange devices, use lifting straps. Wrap these around both process connections.

2.5 Installation specifications

INFORMATION!

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

Protect the signal converter from direct sunlight and install a sun shade if necessary.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibration. The flowmeters are tested for a

vibration level in accordance with IEC 68-2-3.

2 INSTALLATION

6

IFC 100

www.krohne.com 07/2010 - 4000124104 - QS IFC 100 R04 en

2.6 Mounting of the compact version

2.7 Mounting the wall-mounted housing, remote version

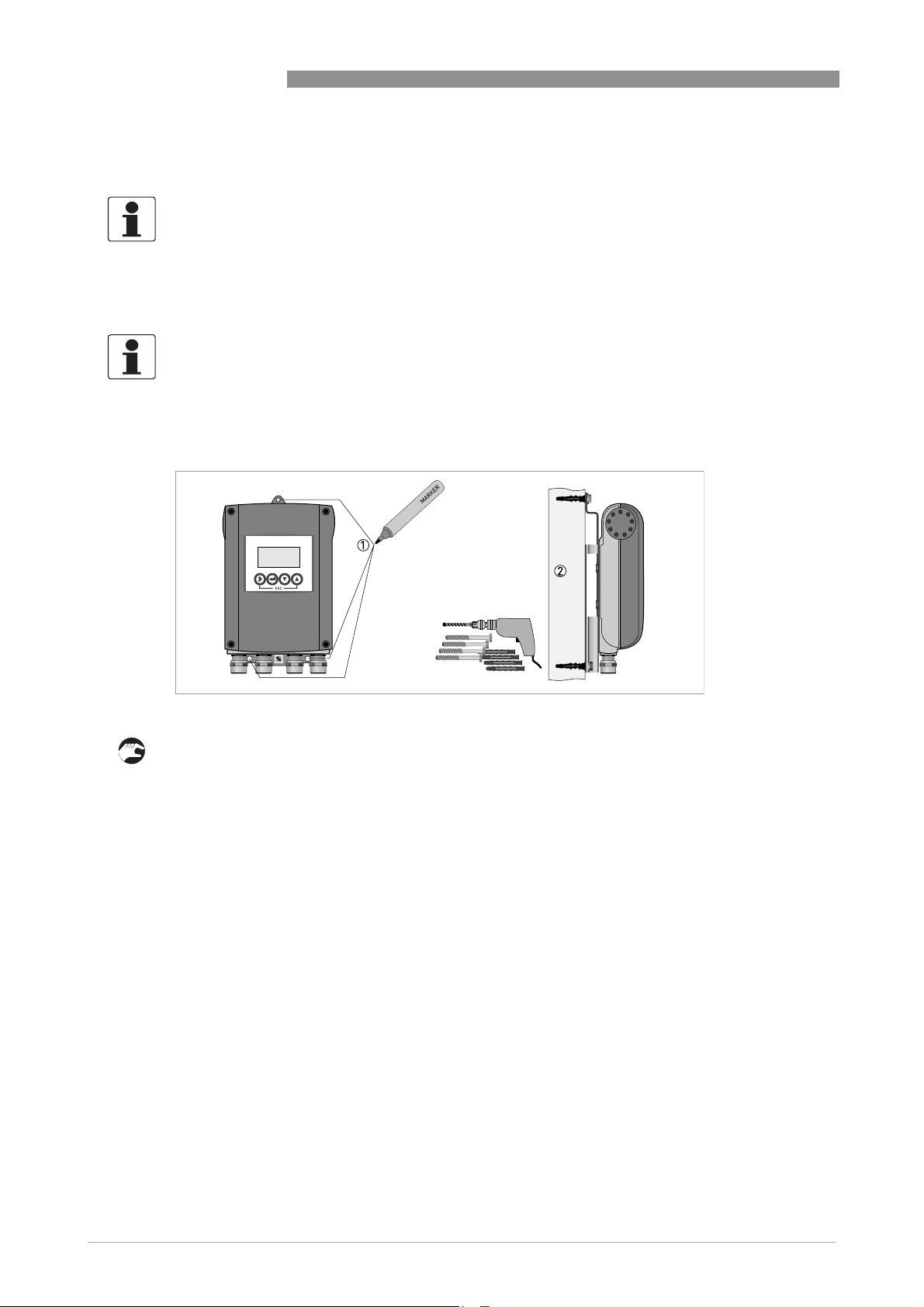

2.7.1 Wall mounting

1 Prepare the holes with the aid of the mounting plate. For further information refer to

Mounting

plate, wall-mounted version

on page 8.

2 Fasten the device securely to the wall with the mounting plate.

INFORMATION!

The signal converter is mounted directly on the measuring sensor. For installation of the

flowmeter, please observe the instructions in the supplied product documentation for the

measuring sensor.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

Figure 2-2: Mounting the wall-mounted housing

INSTALLATION 2

7

IFC 100

www.krohne.com07/2010 - 4000124104 - QS IFC 100 R04 en

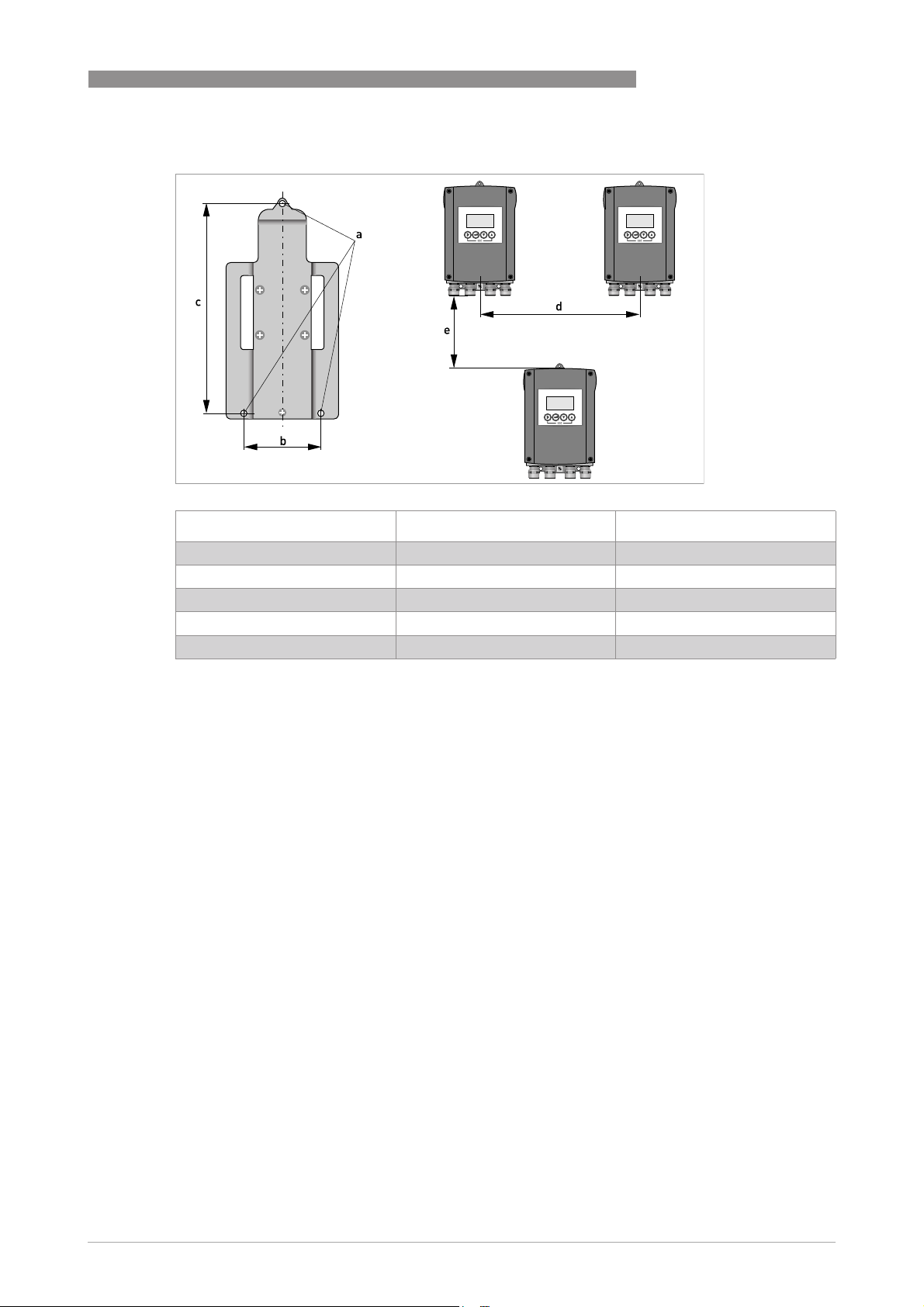

Mounting multiple devices next to each other

[mm] [inches]

a Ø6.5 Ø0.26

b 87.2 3.4

c 241 9.5

d 310 12.2

e 257 10.1

2 INSTALLATION

8

IFC 100

www.krohne.com 07/2010 - 4000124104 - QS IFC 100 R04 en

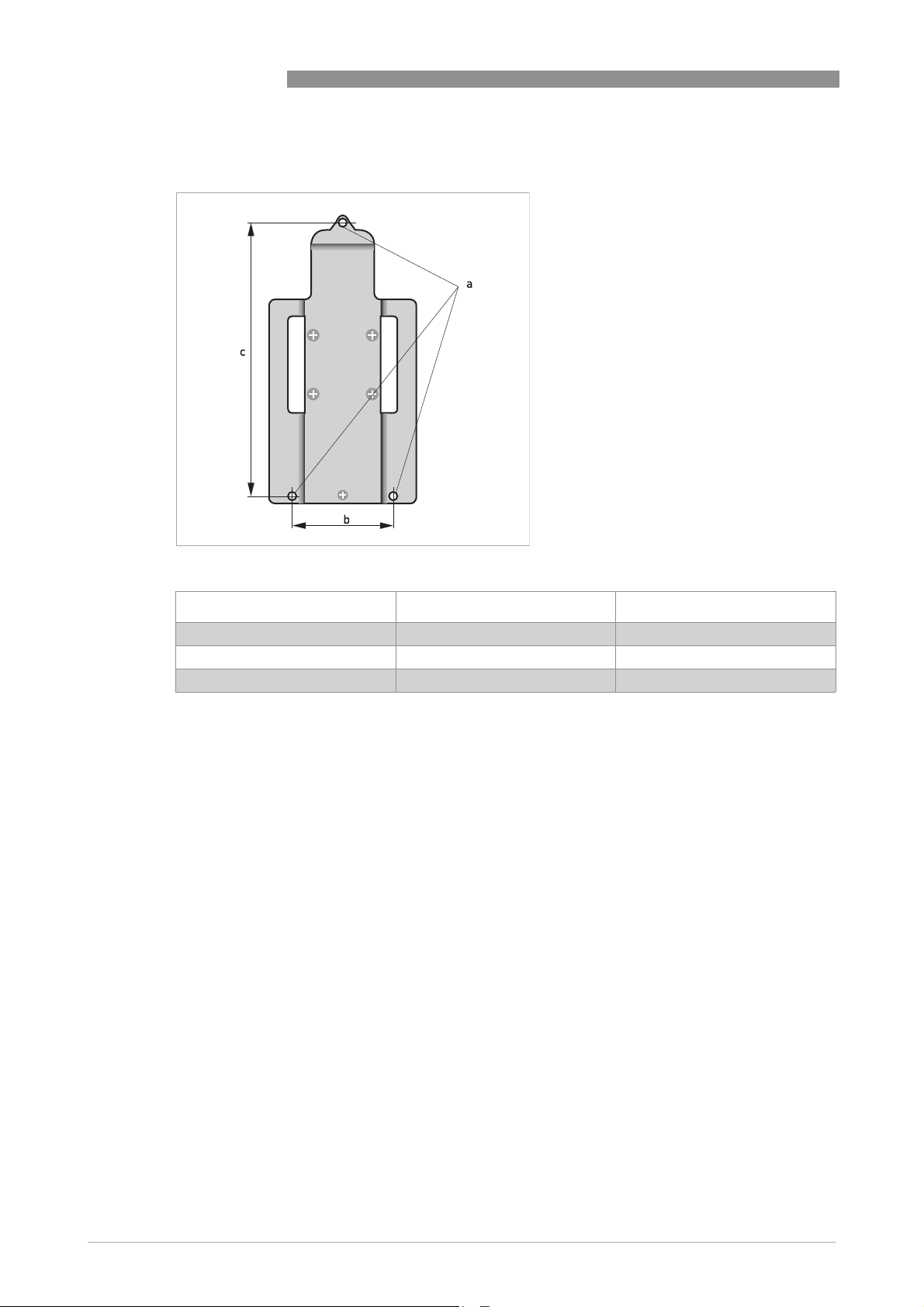

2.7.2 Mounting plate, wall-mounted version

Dimensions in mm and inches

[mm] [inches]

a Ø6.5 Ø0.26

b 87.2 3.4

c 241 9.5

ELECTRICAL CONNECTIONS 3

9

IFC 100

www.krohne.com07/2010 - 4000124104 - QS IFC 100 R04 en

3.1 Safety instructions

3.2 Important notes on electrical connection

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DANGER!

Electrical connection is carried out in conformity with the VDE 0100 directive "Regulations for

electrical power installations with line voltages up to 1000 V" or equivalent national regulations.

CAUTION!

•

Use suitable cable entries for the various electrical cables.

•

The sensor and converter are configured together in the factory. For this reason, please

connect the devices in pairs. Ensure that the sensor constant GK/GKL (see type plates) are

identically set.

•

If delivered separately or when installing devices that were not configured together, set the

converter to the DN size and GK/GKL of the sensor.

3 ELECTRICAL CONNECTIONS

10

IFC 100

www.krohne.com 07/2010 - 4000124104 - QS IFC 100 R04 en

3.3 Electrical cables for remote device versions, notes

3.3.1 Notes on signal cable A

Observe the following notes:

• Lay the signal cable with fastening elements.

• It is permissible to lay the signal cable in water or in the ground.

• The insulating material is flame-retardant to EN 50625-2-1, IEC 60322-1.

• The signal cable does not contain any halogens and is unplasticized, and remains flexible at

low temperatures.

• The connection of the inner shield is carried out via the stranded drain wire (1).

• The connection of the outer shield (60) is carried out via the stranded drain wire (6).

3.3.2 Notes on field current cable C

INFORMATION!

Signal cable A (type DS 300) with double shielding ensures proper transmission of measured

values.

DANGER!

A shielded two-wire copper cable is used as the field current cable. The shielding MUST

MUSTMUST

MUST be

connected in the housing of the measuring sensor and signal converter.

INFORMATION!

The field current cable is not part of the scope of supply.

Loading...

Loading...