Page 1

Service and Maintenance Manual

Model

40H

40H+6

3120240

October 11, 2001

ANSI

Page 2

Page 3

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

A.A GENERAL

This section contains the general safety precautions whi ch

must be o bser ved du ring m ainten anc e of the ae rial pla tform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions

to avoid possible injury to themselves or others , or damage to the equipment. A maintenance program must be

followed to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED, IS A SAFETY VIOLATION.

The sp ecific precau tion s to be o bser ved d uring main tenance are inserted at the appropriate point in the manual.

These precautions are, for the most part, those that apply

when servicing hydraulic and larger machine component

parts.

Your safety, and that of other s, is th e first cons iderati on

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When rai sing

a portion of the equipment , ensure tha t adequa te sup port is

provided.

feed lines to system components c an then be disconnected

with minimal fl uid loss.

A.C MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION MAY RESULT IN MACHINE DAMAGE, PERSONNEL

INJURY OR DEATH AND IS A SAFETY VIOLATION.

• NO SMOKING IS MANDATORY. NEVER REFUEL DURING ELECTRICAL STORMS. ENSURE THAT FUEL

CAP IS CLOSED AND SECURE AT ALL OTHER

TIMES.

• REMOVE ALL RINGS, WATCHES AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE-FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS ON MACHINE AND IN SERVICEMANUAL.

• KEEP OIL, GREASE, WATER, ETC. WIPED FROM

STANDING SURFACES AND HAND HOLDS.

• USE CAUTION WHEN CHECKING A HOT, PRESSURIZED COOLANT SYSTEM.

• NEVER WORK UNDER AN ELEVATED BOOM UNTIL

BOOM HAS BEEN SAFELY RESTRAINED FROM ANY

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE,

SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPERATO R.

A.B HYDRAULIC SYSTEM SAFETY

It shou ld be n ote d that the ma chin es hy drau lic s yst ems

operate at ext rem ely high potentia lly dangerous press ures.

Every effort should be made to relieve any system pr essure prior to disconnecting or removing any portion of the

system.

MOVEMENT BY BLOCKING OR OVERHEAD SLING,

OR BOOM SAFETY PROP HAS BEEN ENGAGED.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

• BATTERY SHOULD ALWAYS BE DISCONNECTEDDURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

Relieve system pressure by cycling the applicable control

several times with the engine stopped and ignition on, to

direct any line pressure back into the reservoir. Pressure

3120240 – JLG Li ft – a

Page 4

EFFECTI VITY CHANGES

REVISON LOG

Aug, 1985 -Original Issue

Nov. 1985 -Revised

Oct. 1998 -Revised

Aug. 1999 -Revised

October 11, 2001 -Revised

b – JLG Li ft – 3120240

Page 5

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A.A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .a

A.B Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .a

A.C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . a

EFFECTIVITY CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .b

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

LIST OF ILLUSTRATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .III

SECTION 1 - SPECIFICATIONS

1.1 Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Component Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Performance Data.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.4 Torque Requirements.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.5 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6 Pressure Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.7 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.8 Boom Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

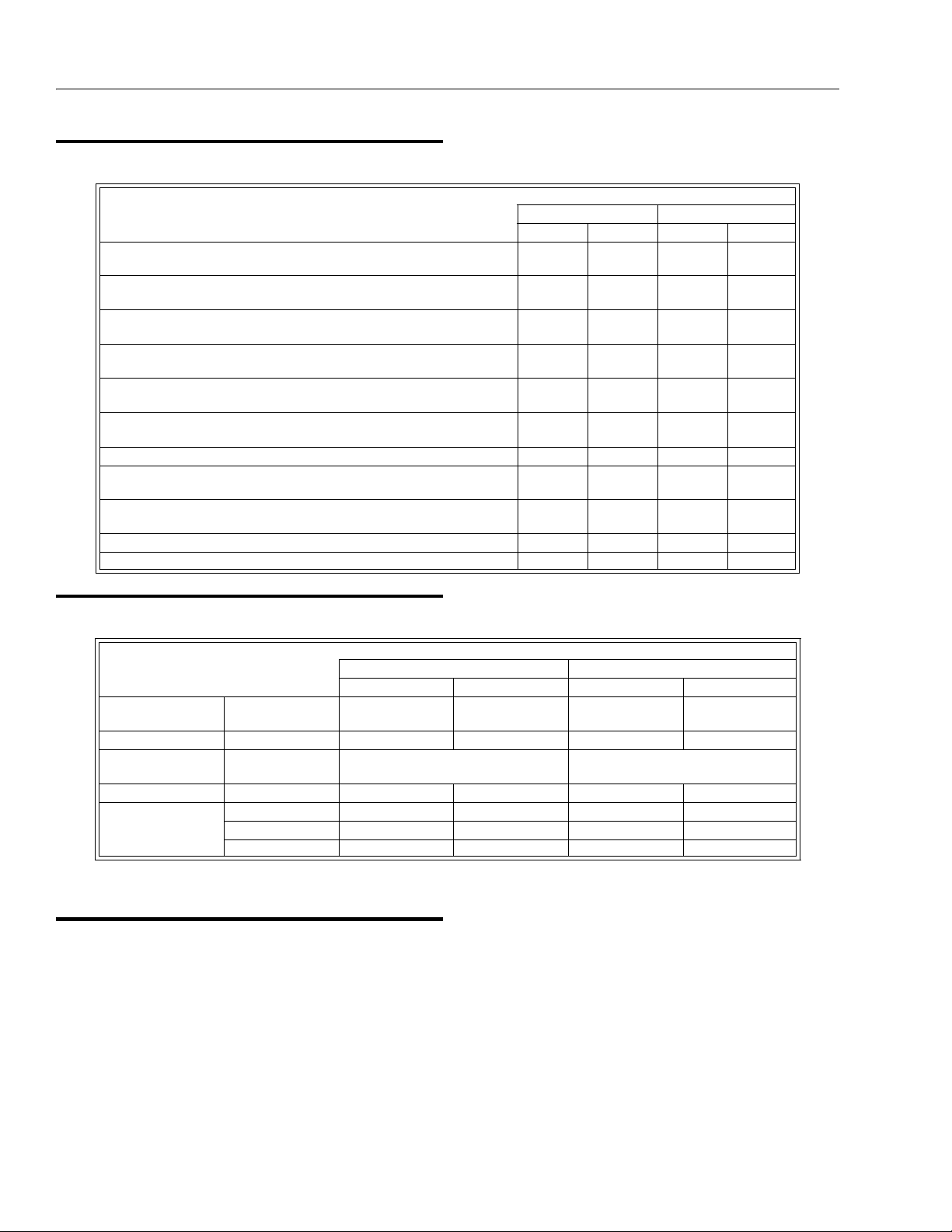

1.9 Major Components Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.10 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.11 Serial Number Location (See Figure 1-4.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

SECTION 2 - PROCEDURES

2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Servicing And Maintenance Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Lubrication Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 Cylinders - Theory Of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5 Valves - Theory Of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.6 Boom Chains. (See Figure 2-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.7 Wear Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.8 Cylinder Checking Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.9 Cylinder Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.10 Cylinder Removal And Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.11 Boom Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.12 Tilt Alarm Switch.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.13 Horizontal High Speed Cutout Switch Adjustment Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.14 Governor Checks And Addco Adjustment, Ford. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2.15 Throttle Checks And Precision Governor Adjustments, Addco (See Figure 2-6.) . . . . . . . . . . . . . 2-21

2.16 Electric Governor And Adjustments - Ford Engines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2.17 Throttle Checks And Adjustments - Deutz F2l511 Engine. (See Figure 2-8.) . . . . . . . . . . . . . . . . 2-29

2.18 Throttle Checks And Adjustments Wisconsin Engine. (See Figure 2-9.) . . . . . . . . . . . . . . . . . . . .2-33

2.19 Throttle Checks And Adjustments - Deutz F3l912 Engine. (See Figure 2-10.) . . . . . . . . . . . . . . . 2-35

2.20 Throttle Checks And Adjustments - Deutz Engine F3l1011. (See Figure 2-11.) . . . . . . . . . . . . . . 2-35

2.21 Pressure Setting Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

2.22 Racine Proportional Air Gap Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

2.23 Swing Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-59

2.24 Torque Hub, 2w/d. (See Figure 2-36.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

2.25 Torque Hub 4wd. (See Figure 2-37.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-66

2.26 Swing Drive Brake, Mico (Machines Built Prior To May 1992). (See Figure 2-39.) . . . . . . . . . . . . 2-71

2.27 Drive Brake, Mico. (Machines Built Prior To May 1992)(See Figure 2-40.) . . . . . . . . . . . . . . . . . . 2-72

2.28 Swing Drive Brake, Ausco (Machines Built Prior To May 1992). (See Figure 2-41.) . . . . . . . . . . . 2-75

2.29 Drive Brake, Ausco. (Machines Built Prior To May 1992) (See Figure 2-43.). . . . . . . . . . . . . . . . . 2-77

2.30 Drive Brake, Mico. (Machines Built From May 1992 To S/n 33476) (See Figure 2-44.) . . . . . . . . 2-79

2.31 Swing Brake, Mico. (Machines Built From May 1992 To S/n 33476) (See Figure 2-45.). . . . . . . .2-81

3120240 – JLG Lift – i

Page 6

TABLE OF CONTENTS (Continued)

2.32 Drive Brake, Mico. (Machines Built From S/n 33476 To Present) (See Figure 2-46.) . . . . . . . . . .2-83

2.33 Swing Brake, Mico.(Machines Built From S/n 33476 To Present) (See Figure 2-46.) . . . . . . . . . .2-85

2.34 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-87

2.35 Oscillating Axle Bleeding Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-87

2.36 Oscillating Axle Lockout Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-88

2.37 Basket Rotator Brake. (See Figure 2-48.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-89

2.38 Free Wheeling Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

2.39 Spark Arrestor Mufflers.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-89

2.40 Footswitch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

2.41 Hydraulic Pump W/hayes Pump Drive Coupling Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-89

2.42 Dual Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

2.43 Preventive Maintenance And Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-90

2.44 Capacity Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-92

SECTION 3 - TROUBLESHOOTING

3.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Troubleshooting Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Hydraulic Circuit Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

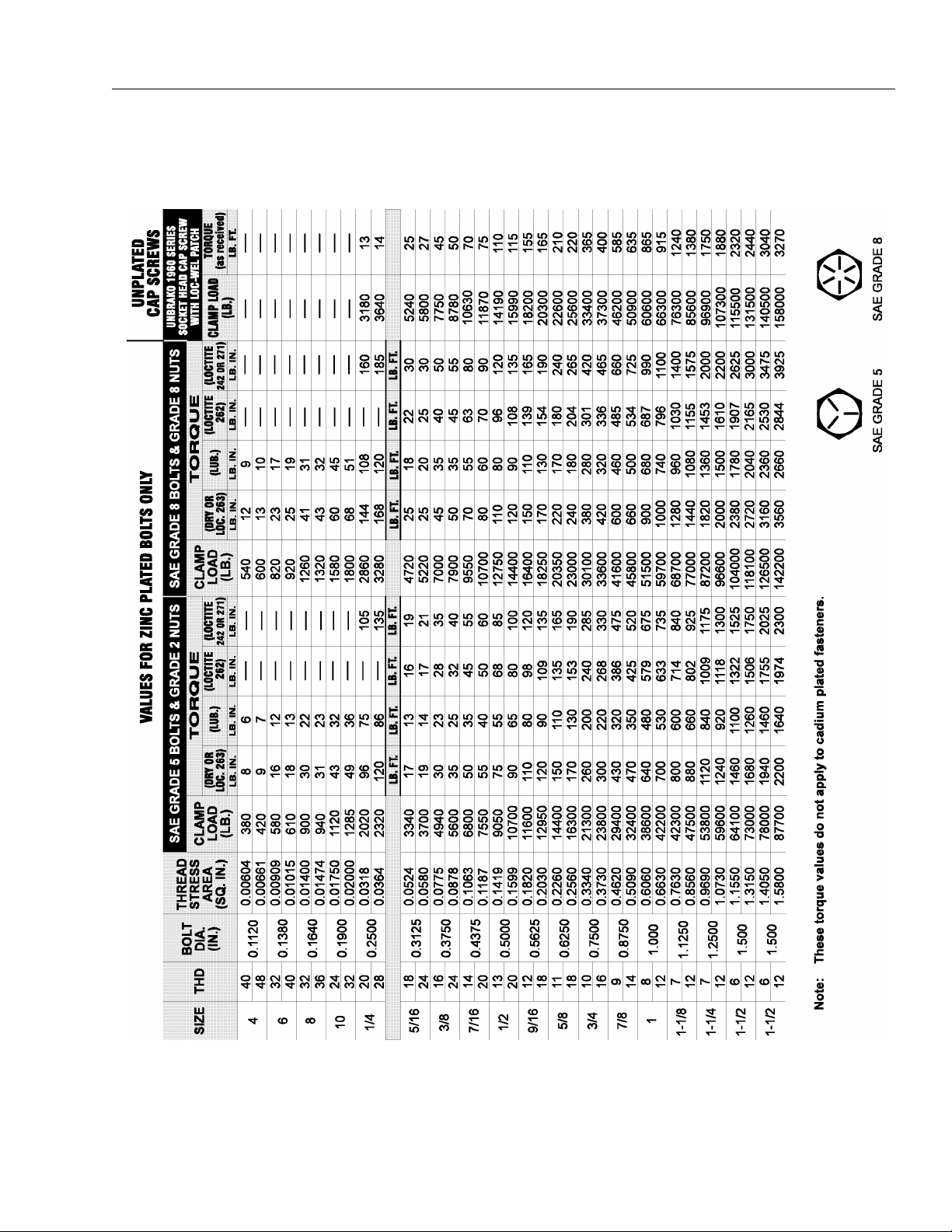

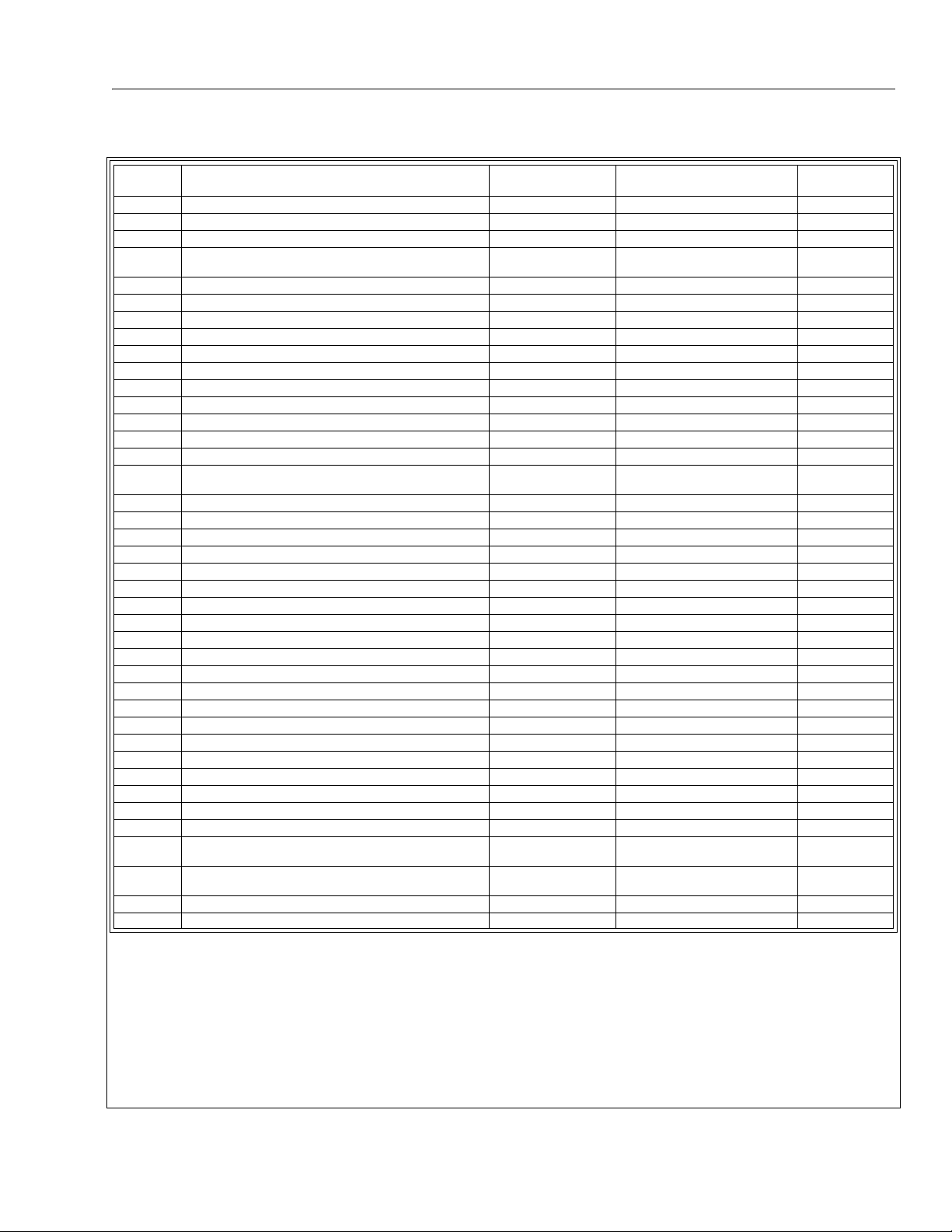

1-1. Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

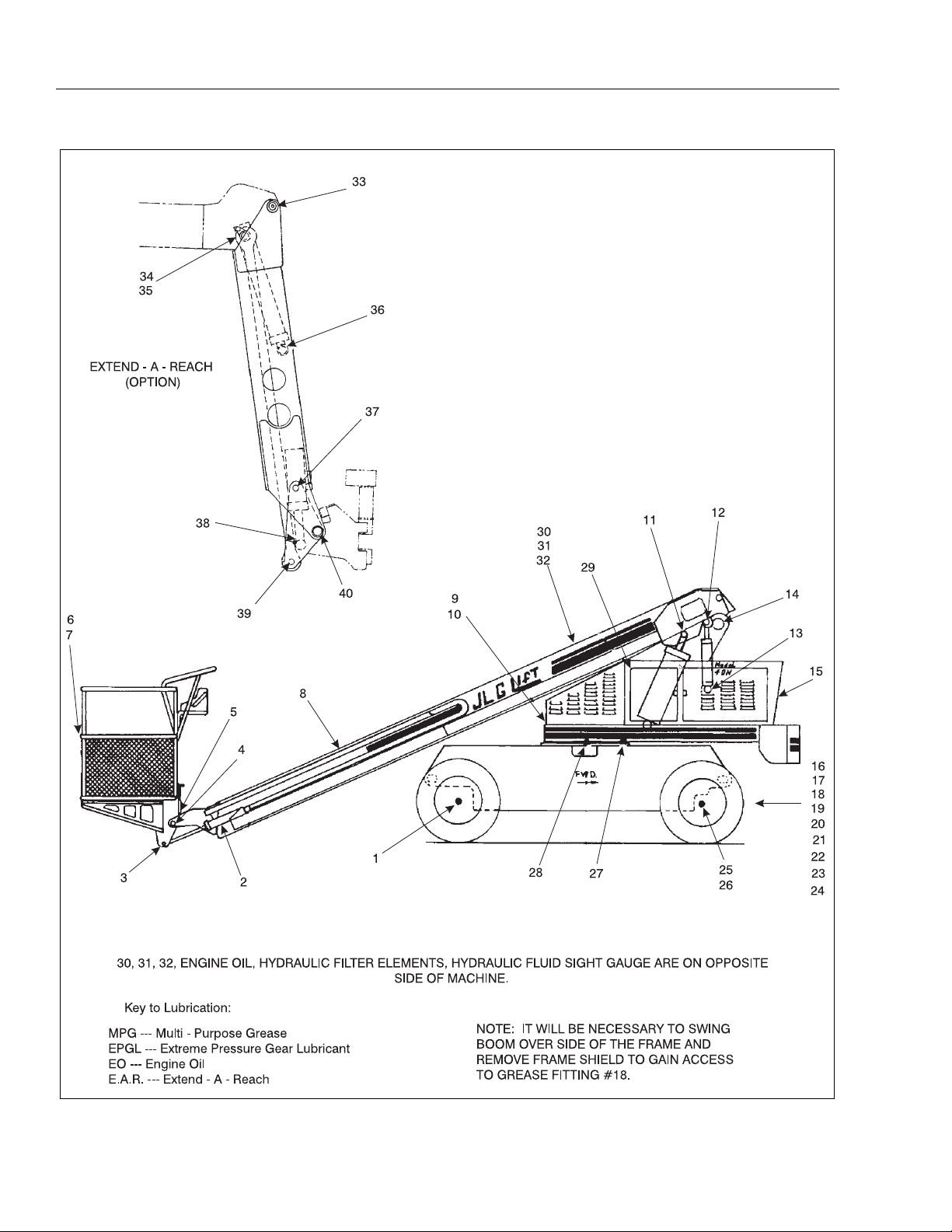

1-2. Lubrication Chart. (Sheet 1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-2. Lubrication Chart. (Sheet 2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1-3. Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

2-1. Typical Three Section Boom Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-2. Boom Positioning and Support, Cylinder Repair.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-3. Poly-Pak Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2-4. Governor Adjustment, Ford with Addco. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2-5. Addco Adjustment, Ford. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

2-6. Precision Governor Adjustment, Ford. (Sheet 1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2-7. Precision governor Adjustment, Ford. (Sheet 2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2-8. Addco Actuator Adjustments, F2L511. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2-9. Addco Actuator Adjustments, VG4D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

2-10. Addco Actuator Adjustments, F3L912. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

2-11. Addco Actuator Adjustments, F3L1011. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

2-12. Racine Proportional Valve Pressure Setting.(Machines Built Prior To Mid 1987) (Sheet 1 of 2). . 2-39

2-13. Racine Proportional Valve Setting.(Machines Built Prior To Mid 1967) (Sheet 2 of 2) . . . . . . . . .2-40

2-14. Vickers Proportional Valve Pressure Setting, Machines Built To Present (Sheet 1 of 4) . . . . . . . .2-41

2-15. Vickers Proportional Valve Pressure Setting, Machines Built To Present. (Sheet2 of 4) . . . . . . . .2-42

2-16. Vickers Proportional Valve Pressure Setting, Machines Built To Present. (Sheet 3 Of 4) . . . . . . . 2-43

2-17. Vickers Proportional Valve Pressure Setting, Machines Built To Present. (Sheet 4 of 4) . . . . . . . 2-44

2-18. Vickers Proportional Valve Pressure Setting,

Machines Built Prior To 1989 With Accessory Valve. (Sheet 1 of 4). . . . . . . . . . . . . . . . . . . . . . . .2-45

2-19. Vickers Proportional Valve Pressure Setting,

Machines Built Prior To 1989 With Accessory Valve. (Sheet 2 of 4) . . . . . . . . . . . . . . . . . . . . . . .2-46

2-20. Vickers Proportional Valve Pressure Setting,

Machines Built Prior To 1989 With Accessory Valve. (Sheet 3 Of 4) . . . . . . . . . . . . . . . . . . . . . . .2-47

2-21. Vickers Proportional Valve Pressure Setting,

Machines Built Prior To 1989 With Accessary Valve. (Sheet 4 Of 4) . . . . . . . . . . . . . . . . . . . . . . . 2-48

2-22. Solenoid Valve Pressure Settings. (Machines Built Prior To 1992 With Steering Wheel) . . . . . . . 2-49

2-23. Pressure And Flow Settings (Machines Built Prior To May 1992 With Steering Wheel). . . . . . . . . 2-50

2-24. Vickers All Hydraulic Machines Pressure Settings (Sheet 1 of 4). . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

ii – JLG Lift – 3120240

Page 7

TABLE OF CONTENTS

2-25. Vickers All Hydraulic Machines Pressure Settings (Sheet 2 of 4). . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

2-26. Vickers All Hydraulic Machines Pressure Settings (Sheet 3 of 4). . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

2-27. Vickers All Hydraulic Machines Pressure Settings (Sheet 4 of 4). . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

2-28. Solenoid Valve Pressure Settings, Machines Built Before 1995. (Sheet 1 of 2) . . . . . . . . . . . . . .2-55

2-29. Solenoid Valve Pressure Settings, Machines Built from 1995 To Present. (Sheet 2 of 2) . . . . . . . 2-56

2-30. Extend-A-Reach Valve Pressure and Speed Settings Model 40+6. . . . . . . . . . . . . . . . . . . . . . . . 2-57

2-31. Racine Proportional Air Gap Adjustment, Machines Built Prior To Mid 1987. . . . . . . . . . . . . . . . . 2-58

2-32. Swing Bearing Tolerance Boom Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

2-33. Swing Bolt Feeler Gauge Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

2-34. Swing Bearing Tolerance Measuring Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

2-35. Swing Bearing Torquing Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

2-36. Torque Hub Assembly, 2/WD.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

2-37. Torque Hub 4/WD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-68

2-38. Torque Hub Carrier Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-70

2-39. Swing Brake Assembly - Mico (Machines Built Prior To May 1992). . . . . . . . . . . . . . . . . . . . . . . . 2-71

2-40. Drive Brake Assembly - Mico (Machines Built Prior To May 1992). . . . . . . . . . . . . . . . . . . . . . . . .2-73

2-41. Swing Brake Assembly - Ausco (Machines Built Prior to May 1992). . . . . . . . . . . . . . . . . . . . . . .2-76

2-42. Drive Brake, (machines Built Prior to May 1992). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-78

2-43. Drive Brake, Mico. (Machines Built From May 1992 To Machine S/N 33476) . . . . . . . . . . . . . . . .2-80

2-44. Swing Brake, Mico. (Machines Built From May 1992 To Machine S/N 33476) . . . . . . . . . . . . . . . 2-82

2-45. Drive Brake, Mico. (Machines Built From S/N 33476 To Present) . . . . . . . . . . . . . . . . . . . . . . . . .2-84

2-46. Swing Brake, Mico. (Machines Built From S/N 33476 to Present) . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

2-47. Basket Rotator Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-88

2-48. Boom Tape Replacement Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-92

2-49. Capacity Indicator Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-92

3-1. Wiring Diagram - Dual Fuel (Ford Or Wisconsin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3-2. Wiring Diagram - 110v Generator (Ford). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3-3. Wiring Diagram - 110v Generator (Deutz). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3-4. Wiring Diagram - Platform Console (W/all Hydraulic Controls).. . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3-5. Wiring Diagram - Platform Console Standard (Sheet 1 Of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3-6. Wiring Diagram - Platform Console Standard (Sheet 2 Of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3-7. Wiring Diagram - Standard (Deutz F2l511/f3l912 & Wisconsin

Engine W/ Standard Controls) (Sheet 1 Of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3-8. Wiring Diagram - Standard (Deutz F2l4511/f3l912 & Wisconsin

Engine W/ Standard Controls) (Sheet 2 Of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

3-9. Wiring Diagram - Standard (Deutz F2l511/f3l912 &

Engine W/ Hydraulic Controls) (Sheet 1 Of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3-10. Wiring Diagram - Standard (Deutz F2l511/f3l912 & Wisconsin

Engine W/ Hydraulic Controls) (Sheet 2 Of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3-11. Wiring Diagram - Standard (Deutz F3l1011 Engine W/ Standard Controls) (Sheet 1 Of 2). . . . . .3-30

3-12. Wiring Diagram - Standard (Deutz F3l1011 Engine W/ Standard Controls) (Sheet 2 Of 2). . . . . .3-31

3-13. Wiring Diagram - Standard (Deutz F3l1011 Engine W/ Hydraulic Controls) (Sheet 1 Of 2). . . . . . 3-32

3-14. Wiring Diagram - Standard (Deutz F3l1011 Engine W/ Hydraulic Controls) (Sheet 2 Of 2). . . . . . 3-33

3-15. Wiring Diagram - Standard (Ford Lrg425 Dis Engine W/ Standard Controls) (Sheet 1 Of 2).. . . .3-34

3-16. Wiring Diagram - Standard (Ford Lrg425 Dis Engine W/ Standard Controls) (Sheet 2 Of 2).. . . .3-35

3-17. Wiring Diagram - Standard (Ford Dis Engine W/ Hydraulic Controls) (Sheet 1 Of 2).. . . . . . . . . . 3-36

3-18. Wiring Diagram - Standard (Ford Dis Engine W/ Hydraulic Controls) (Sheet 2 Of 2).. . . . . . . . . . 3-37

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

2-1 Chain Stretch Tolerance.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-2 Cylinder Piston Nut Torque Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-3 Holding Valve Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-4 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-91

3-1 Platform Assembly Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3120240 – JLG Lift – iii

Page 8

TABLE OF CONTENTS (Continued)

3-2 Boom Assembly Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-3 Turntable Assembly Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-4 Chassis Assembly Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3-5 Hydraulic Assembly Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3-6 Electrical Assembly Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

(INTENTIONAL BLANK PAGE)

iv – JLG Lift – 3120240

Page 9

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

1.1 CAPACITIES.

Fuel Tank - 37 Gallons (140.2 L)

Hydraulic Oil Tank - 37 U.S. Gallons

(104.2 L).

Hydraulic System (Including Tank) - 70 U.S.

Gallons (264.95 L).

Torque Hub Drive - 2.5 Pints (1.18 L).

Torque Hub Swing - 2.0 Pints (1.18 L).

NOTE: Torque Hubs should be one - half full of lubricant.

(EPGL-90)

Engine Crankcase (Ford LSG423) w/Filter

5 quarts (4.73 L).

Engine Crankcase (Ford LRG423) w/Filter

5 quarts (4.73 L).

Engine Crankcase (Deutz F3L912) w/Filter

9.5 quarts (8.99 L).

Engine Crankcase (Deutz F3L1011) w/Filter

6.34 quarts (6 0 L).

Engine Crankcase (Deutz F2L511) w/Filter

3.5 quarts

Engine Crankcase (Wisconsin VG4D) w/Filter

5.0 quarts (4.73 L).

NOTE: Tolerance on all engine rpm settings is plus or minus

10%.

1.2 COMPONENT DATA.

Fuel Consumption High RPM - 2.73 GPH

(10.33 LPH).

Horsepower - 63 @ 2800 RPM, no load.

Engine -Ford LRG-425 D.I.S.

Oil Capacity.

4.50 Quarts (4.25 1) w/Filter.

3.50 Quarts (3.31 1) w/o Filter.

Idle RPM - 1000.

Low RPM - 1800.

High RPM - 2800.

Alternator - 95 Amp, Belt Drive.

Battery - 1000 Cold Cranking Amps, 210 minute reserve

Capacity, 12 VDC.

Fuel Consumption.

Low RPM - 3.45 GPH (13.06 lph).

High RPM - 4.60 GPH (17.41 lph).

Horsepower - 74 @ 3000 RPM, full load.

Cooling System - 16 Quarts (15.14 l.).

Engine - Deutz F3L912.

Oil capacity - 9.5 quarts (8.99L) w/Filter, 8.5

quarts (8.04 L) w/o Filter.

Low RPM 1800.

High RPM 2400.

Alternator - 85 Amp, belt drive.

Engine - Ford LSG423/Lrg423.

Oil capacity - 5 quarts (4.73 L) w/Filter, 4

quarts (3.79 L) w/o Filter.

Cooling System - 16 quarts (15.14 L).

Low RPM - 1000, no load.

Mid RPM - 1800, no load.

High RPM - 3000, no load.

Alternator - 40 Amp, belt drive.

Battery - 1000 cold cranking Amps, 210 minutes reserve capacity,12 VDC.

Fuel Consumption Low RPM - 2.03 GPH

(7.68 LPH).

Battery - 1000 cold cranking Amps, 210 minutes

reserve capacity, 12VDC.

Fuel Consumption Low RPM - 2.03 GPH

(7.68 LPH).

Fuel Consumption High RPM - 2.73 GPH

(10.33 LPH).

Horsepower - 47 @ 2800 RPM, no load.

Engine - Deutz F3L1011.

Oil Capacity - 6.34 quarts (6.0 L) w/Filter, 5.8

quarts (5.5 L) w/0 Filter.

Low RPM 2000.

High RPM 3000.

Alternator - 60 Amp, belt drive.

3120240 – JLG Lift – 1-1

Page 10

SECTION 1 - SPECIFICATIONS

Battery - 1000 cold cranking Amps, 210 minutes reserve capacity, 12VDC.

Fuel Consumption Low RPM - 1.9 GPH (7.19

LPH).

Fuel Consumption High RPM - 2.5 GPH (9.46

LPH).

Horsepower - 42@ 3000 RPM, no load.

Engine - Deutz F2L511.

Oil Capacity - 3.5 quarts (3.31 L) w/Filter, 3.0 quarts (2.84

L) w/o Filter.

Low RPM 1800.

High RPM 2500.

Alternator - 33 Amp, belt drive.

Battery - 1000 cold cranking Amps, 210 minutes

reserve capacity, 12 VDC.

Fuel Consumption Low RPM - 2.03 GPH (7.68 LPH).

Fuel Consumption High RPM - 2.73 GPH (10.34 LPH).

Horsepower - 47 @ 2300 RPM, full load.

Engine - Wisconsin VG4D.

Oil Capacity - 5 quarts (4.73 L) w/Filter, 4.5 quarts (4.26

L) w/o Filter.

Low RPM 1800, no load.

High RPM 2400, no load.

Alternator - 35 Amp, belt drive.

Battery - 1000 cold cranking Amps, 210 minutes

reserve capacity, 12 VDC.

Fuel Consumption Low RPM - 3.21 GPH (12.15 LPH).

Fuel Consumption High RPM - 3.89 GPH (14.72 LPH).

Horsepower - 37 @ 2500 RPM, full load.

Swing System.

Swing Motor - Displacement - 3.0 in3/Rev.

Swing Hub - Ratio - 69:1.

Swing Brake - Automatic spring applied, hydraulically

released disc brakes.

Hydraulic Pump.

Ford LSG423, Deutz F3L912, Wisconsin VG4D with

Racine Valves (Single Speed Drive Motors).

First Section to Proportional Valve-Drive, Lift, Swing -

14.5 GPM (54.88 LPM).

Second Section to High Drive - 9.5 GPM (35.96 LPM).

Third Section to Bang-Bang valve level, Telescope,

Steer, Rotate - 9.5 GPM (35.96 LPM).

Clockwise Rotation.

Ford LSG423, Deutz F3L912, Wisconsin VG4D with

Racine Valves (2 Speed Drive Motors).

First Section to Proportional Valve-Drive, Lift, Swing -

10.8 GPM (40.88 LPM).

Second Section to High Drive - 6.3 GPM (23.85 LPM).

Third Section to Bang-Bang valve level, Telescope,

Steer, Rotate - 6.3 GPM (23.85 LPM).

Clockwise Rotation.

Ford LSG423, Ford LRG423, Deutz F3L912, Deutz

F3L1011, Wisconsin VG4D with Vickers Valves (2 Speed

Drive Motors).

First Section to Proportional Valve-Drive, Lift, Swing 15 GPM (56.78 LPM).

Second Section to High Drive - 9 GPM (34.07 LPM).

Third Section to Bang-Bang Valve Level, Telescope,

Steer, Rotate - 9 GPM (34.07 LPM).

Clockwise Rotation.

Drive System.

Tires - 12.5 x 15, 12 ply rating, 72 PSI. (5 Bar) (4 WD

Same).

Tires - 14 x 17.5, 8 ply rating, 45 PSI. (3 Bar) (4 WD

Same).

Drive Motor Displacement - 2.48 in3/Rev.

Drive Hub Ratio - 49.29:1.

Steer System.

Tires - 12.5 x 15, 12 ply rating, 72 PSI. (5 Bar).

Toe-in, adjust for 1/4 in. (6.35 mm) overall.

Auxiliary Power Pump.

Two section, 3.75 GPM (14.19 lpm) each section, 12

VDC motor, clockwise rotation.

Hydraulic Filter - Tank.

Return - Bypass Type.

10 Microns Nominal.

Hydraulic Filter - On-line (Racine Valve

Only).

Return - Non-Bypass Type.

1-2 – JLG Lift – 3120240

Page 11

SECTION 1 - SPECIFICATIONS

10 Microns Nominal.

1.3 PERFORMANCE DATA.

Travel Speed.

2WD- 4.5 MPH (7.2 KM/HR).

4WD - 4.0 MPH (6.4 KM/HR).

Gradeability.

2WD- 25% or 14°slope, hard surface.

4WD - 40% or 22°slope, hard surface.

Turning Radius .

2WS/2WD- 16 ft. 6 in. (5.1 m).

2WS/4WD - 16 ft. 6 in. (5.1 m).

Boom Speed Lift.

Up 25 - 40 Seconds.

Down 20 - 30 Seconds.

Telescope Speed.

Extend 50 - 80 Seconds.

Retract 40 - 60 Seconds.

Swing Speed 360°.

Left 61 - 92 Seconds.

Machine Stowed Height.

Model 40H (2WD) - 7 ft., 10 in. (2.39 M).

Model 40H (4WD) - 7 ft., 10 in. (2.39 M).

Machine Stowed Length.

Model 40H (2WD) - 25 ft.,2 in. (7.67 M).

Model 40H (4WD) - 25 ft.,2 in. (7.67 M).

Model 40H+6 (4WD) - 26 ft., 10 in. (8.18 M).

Machine Width.

Model 40H/40H+6(2WD/4WD) - 7 ft.,11 in. (2.41 M).

Wheelbase.

Model 40H/40H+6 (2WD/4WD) - 92 in. (2.34 M).

1.4 TORQUE REQUIREMENTS.

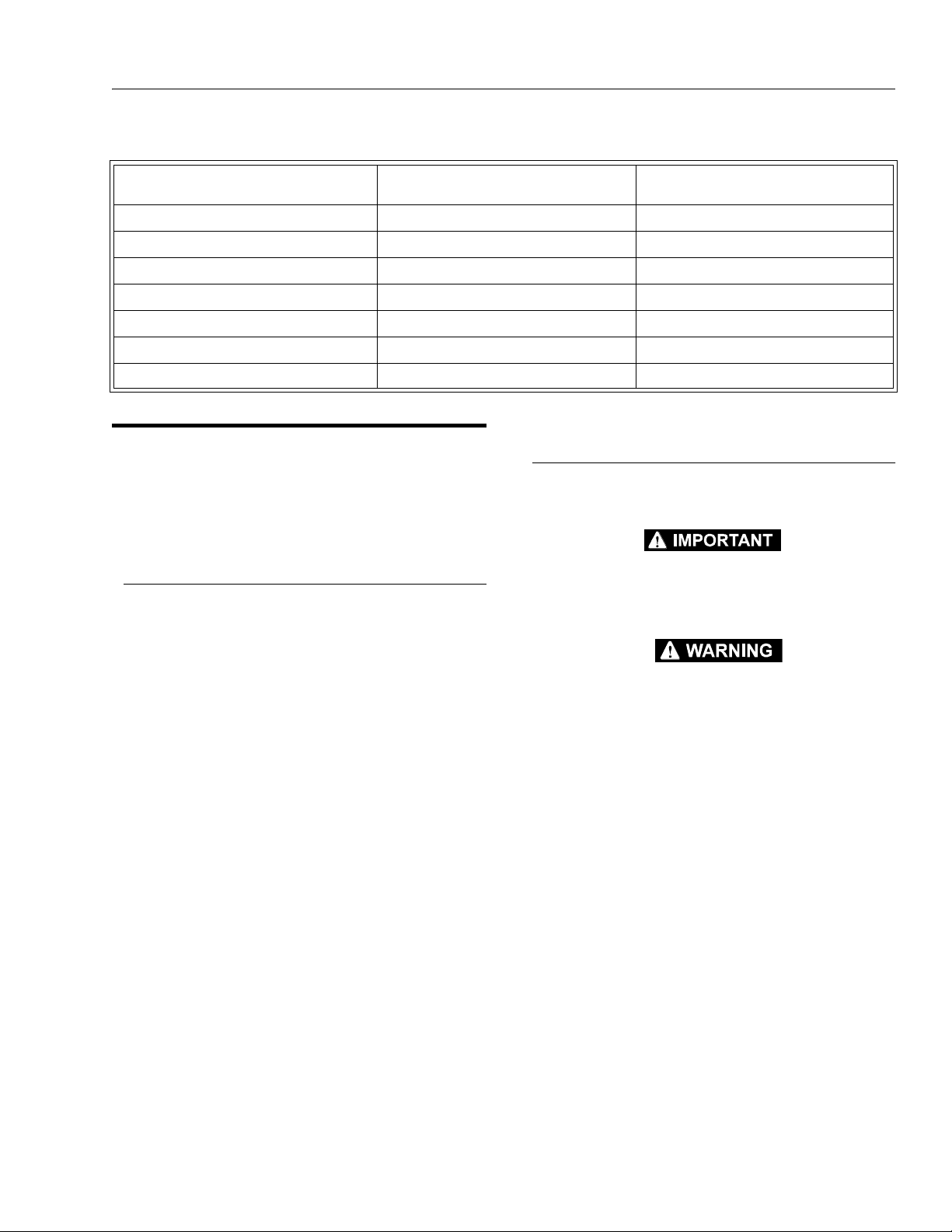

Description Torq ue

A. Bearing To Chassis

B. Bearing To Turntable

C. Wheel Lugs 90 lbs.

D. Drive Hub 150 lbs.

E. Swing Hub 110 lbs.

Value (Dry)

110 lbs.

(149 Nm)

220 lbs.

(298 Nm)

(122 Nm)

(204 Nm)

(149 Nm)

Interval

Hours

*200/500

*200/500

100

*200/500

*200/500

Right 61 - 92 Seconds.

NOTE: *Retorque after first 200 hours of operation and

every 500 hours thereafter.

Boom Elevation.

NOTE: See Procedure Section for tightening sequence of

+74° (above horizontal).

-22° (below horizontal).

Model 40H+6.

74° +15° ART. (above horizontal)

-22° -80° ART. (below horizontal)

NOTE: When maintenance becomes necessary or a fas-

1.5 LUBRICATION.

Machine Weight.

Model 40H (2WD) - 11,600 LBS. (5,266 KG.).

Model 40H (4WD) - 12,000 LBS. (5,448 KG.).

Model 40H+6 - 13,350 LBS. (6,005 KG.).

3120240 – JLG Lift – 1-3

turntable bearing bolts.

tener has loosened, refer to the Torque Chart to

determine proper torque value.

Ford LSG423/LRG423/LRG425 Engine.

Single Viscosity Oils (SF, SF-SE, SF-CC, SF-CD).

When Outside Temp is

Consistently

Use SAE

Viscosity Number

Page 12

SECTION 1 - SPECIFICATIONS

-10° F - +60° F.

(-24°C. to +16°C.)

+10° F - + 90° F.

(+12°C. to +32°C.)

Above +32° F. (+0°C.) 30

Above + 50° F. (+10°C.) 40

Multi-Viscosity Oils (SF, SF-SE, SF-CC, SF-CD).

When Outside Temp

is Consistently

Below +10° F. (+12°C.) *5W-20

Below +60° F. (+16°C.) 5W-30

-10° F - +90° F.

(-23°C. to+32°C>)

Above -10° F. (23°C.) 10W-40 or 10W-50

Above +20° F. (-23°C.) 20W-40 or 20W-50

* Not recommended for severe service - including high

RPM operation.

*10W

20W-20

Use SAE

Viscosity Number

10W-30

Deutz F3L912/F3L1011 Engine.

Single Viscosity Oils (CD-SE, CD-SF).

When Outside Temp

is Consistently

-20° F - +25° F.

(-29°C. to +4°C.)

+5° F - + 50° F.

(+15°C. to +10°C.)

+40° F - +85° F.

(+4°C. to +30°C.)

Above 75° F. (24°C.) 40

Multi-Viscosity Oils (CD-SE, CD-SF).

When Outside Temp

is Consistently

-40° F - +75° F.

(-40°C, to +24°C.)

-15° F - +70° F.

(-26°C. to +21°C.)

-15° F - +85° F.

(-26°C. to +30°C.)

+5° F - +75° F.

(-21°C. to +24°C.)

Above +5° F. (-21°C.) 15W-40

* This viscosity can be used at colder temperatures only

with engine oil preheating.

Use SAE

Viscosity Number

*10W

20W-20

30

Use SAE

Viscosity Number

*5W-20 (Synthetic)

10W-30

10W-40

15W-30

Wisconsin VG4D Engine.

Single Viscosity Oils (MS or SD).

When Outside Temp

is Consistently

+15° F - 0° F. 10W

+40° F - + 15° F. 20-20W

+120° F - + 40° F. 30

Multi-Viscosity Oils (MS, SD, SE).

When Outside Temp

is Consistently

Below Zero.( 5W-20

NOTE: Crankcase oil should meet one of the following API

classification grades: SE/CC, SE/CD, SF/CC, SF/

CD.

Table 1-1. Hydraulic Oil.

Hydraulic System

Operating

Temperature Range

0° F to +180° F (-18°C. to 83°C.) 10W

0° F to +210° F (-18° C to 99° C) 10W-20/10W-30

50° F to 210° F (10° C to 99° C) 20W-20

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system service. JLG Industries recommends Mobilfluid 424

hydraulic oil, which has an SAE viscosity of 10W-30

and viscosity index of 152.

When temperatures remain consistently below +20°

F. (-7° C.), an amount of no. 2 diesel fuel, not to

exceed 20% of system capacity, may be added to

the hydraulic oil reservoir. This diesel fuel will “thin”

the hydraulic oil for easier cold weather operation,

and will almost completely dissipate from the hydraulic system over a several month period of time. When

cold weather is past, it may be necessary to drain

and refill the hydraulic system to rid the system of

any remaining diesel fuel.

Aside from JLG recommendations, it is not advisable

to mix oils of different brands or types, as they may

not contain the same required additives or be of

comparable viscosities. If use of hydraulic oil other

than Kendall Hyken 052 is desired or Mobilfluid 424,

contact JLG Industries for proper recommendations.

Use SAE

Viscosity Number

Use SAE

Viscosity Number

SAE Viscosity

Grade

1-4 – JLG Lift – 3120240

Page 13

SECTION 1 - SPECIFICATIONS

Figure 1-1. Torque Chart.

3120240 – JLG Lift – 1-5

Page 14

SECTION 1 - SPECIFICATIONS

Figure 1-2. Lubrication Chart. (Sheet 1 of 2)

1-6 – JLG Lift – 3120240

Page 15

SECTION 1 - SPECIFICATIONS

INDEX

NO.

1. Wheel Drive Hub Fill Plug/1/2 Full EPGL (SAE - 90) *50/2 years

2. Slave Leveling Cylinder - Barrel End 1 Grease Fitting MPG - Pressure Gun 150

3. Slave Leveling Cylinder - Rod End 1 Grease Fitting MPG - Pressure Gun 150

4. Rotary Platform Control Stand (If Equipped)

5. Rotary Worm Gear (If Equipped) 1 Grease Fitting MPG - Pressure Gun 150

6. Platform Hinges 2 Grease Fittings MPG - Pressure Gun 150

7. Platform Latch & Control Handle Slide Locks N/A SAE 10 - Oil Can A/R

8. Telescope Cylinder Sheave (If Equipped) 1 Grease Fitting MPG - Pressure Gun 150

9. Swing Bearing (Remote Access) 2 Grease Fittings MPG - Pressure Gun 150

10. Lift Cylinder - Barrel End (Remote Access) 1 Grease Fitting MPG - Pressure Gun 150

11. Lift Cylinder - Rod End 2 Grease Fittings MPG - Pressure Gun 150

12. Master Level Cylinder - Rod End 1 Grease Fitting MPG - Pressure Gun 150

13. Master Level Cylinder - Barrel End 1 Grease Fitting MPG - Pressure Gun 150

14. Boom Pivot Bushings 2 Grease Fittings MPG - Pressure Gun 150

15. Engine Crankcase Fill Cap/Drain Plug EO (Refer to end. manual) **10/150

16. Lockout Cylinder - Barrel End

17. Lockout Cylinder - Rod End (If Equipped) 2 Grease Fittings MPG - Pressure Gun 150

18. Oscillating Axle Pivot Pin (If Equipped) 1 Grease Fitting MPG - Pressure Gun *****150

19. Steer Cylinder 2 Grease Fittings MPG - Pressure Gun 150

20. Steer Spindle 2 Grease Fittings MPG - Pressure Gun 150

21. Steer Spindle - 4WD (If Equipped) 4 Grease Fittings MPG - Pressure Gun 150

22. Tie Rod Ends 2 Grease Fittings MPG - Pressure Gun 150

23. Tie Rods - Two Hitch (If Equipped) 4 Grease Fittings MPG - Pressure Gun 150

24. Towing Hitch (If Equipped) 1 Grease Fitting MPG - Pressure Gun 150

25. Wheel Bearings N/A MPG - Repack 500

26. Wheel Drive Hubs - 4WD (If Equipped) Fill Plug/1/2 Full EPGL (SAE - 90) *50/2 yrs.

27. Swing Hub Fill Plug EPGL (SAE - 90) *50/2 yrs.

28. Swing Bearing & Pinion Gear Teeth N/A MPG - Brush 100

29. Door & Access Panel Hinges N/A SAE 10 - Oil Can A/R

30. Hydraulic Filter Element, Return N/A Replacement Element ***40/300

31. Hydraulic Filter Element, Inline N/A Replacement Element ***40/300

32. Hydraulic Fluid (Oil) Fill Plug/1/2 Full HO ****10/2 yrs.

33. E.A.R. Pivot (If Equipped) 2 Grease Fittings MPG - Pressure Gun 150

34. E.A.R. Lift Cylinder Barrel End (If Equipped) 1 Grease Fitting MPG - Pressure Gun 150

35. E.A.R. Link Boom End (If Equipped) 2 Grease Fittings MPG - Pressure Gun 150

36. E.A.R. Lift Cylinder Rod End (If Equipped) 1 Grease Fitting MPG - Pressure Gun 150

37. E.A.R. Slave Cylinder Pivot Points

38. E.A.R. Slave Cylinder Rod End

39. E.A.R. Link Platform End (If Equipped) 1 Grease Fitting MPG - Pressure Gun 150

40. E.A.R. Platform Pivot (If Equipped) 1 Grease Fitting MPG - Pressure Gun 150

COMPONENT NUMBER/TYPE

Platform Pivot

(If Equipped)

(If Equipped)

(If Equipped)

LUBE POINTS

2 Grease Fittings

1 Grease Fitting

1 Grease Fittings MPG - Pressure Gun 100

2 Grease Fittings MPG - Pressure Gun 150

1 Grease Fitting MPG - Pressure Gun 150

LUBE & METHOD INTERVAL

MPG - Pressure Gun

MPG - Pressure Gun

(HOURS)

150

150

*Check oil level after every 50 hours of operation. Change oil after every 2 years (1200 hrs.) of operation.

**Check oil level after every 10 hours of operation. Change oil after every 3 months (150 hrs.) of operation.

***Replace filter element after first 40 hours of operation, then after every 6 months (300 hrs.) of operation thereafter.

****Check oil level after every 10 hours of operation.Change oil after every 2 years(1200 hrs.) of operation.

*****It will be necessary to swing the boom over side of frame and remove the frame shield to gain access to

the grease fitting.

NOTE: Lubrication intervals are based on machine operations under normal conditions. for machines used in multi shift opera-

tions and /or exposed to hostile environments or conditions, lubrication frequencies must be increased accordingly.

Figure 1-2. Lubrication Chart. (Sheet 2 of 2)

3120240 – JLG Lift – 1-7

Page 16

SECTION 1 - SPECIFICATIONS

Lubrication Specifications.

Table 1-2. Lubrication Specifications.

KEY SPECIFICATIONS

MPG Multipurpose Grease having a minimum

dripping point of 350 degrees F. Excellent

water resistance and adhesive qualities;

and being of extreme pressure type

(Timken OK 40 pounds minimum).

EPGL Extreme Pressure Gear Lube (oil) meeting

API Service Classification GL-5 or Mil-Spec

Mil-L-2105.

HO Hydraulic Oil. API Service Classification

GL-3, SAE 10W-20, Viscosity Index 152,

e.g. Kendall Hyken 052 or Mobilfluid 424.

EO Engine (crankcase) Oil. Gas - API SF/SG

class, MIL-L-2104. Diesel - API CC/CD

class, MIL-L-2104B/MIL-L-2104C.

NOTE: Refer to Lubrication Chart, Figure 1-2, for specific

lubrication procedures.

1.6 PRESSURE SETTINGS.

NOTE: All pressure are given in pounds per square inch

(psi), with the metric equivalent, Bar, in parentheses.

Racine Proportional Valve.

Racine.

Main Relief - 2800 psi. (193.06 Bar).

Drive - 2800 psi. (193.06 Bar).

Lift Up - 2800 psi. (193.06 Bar).

Lift Down - 1100 psi. (75.85 Bar).

Swing - 1000 psi. (68.95 Bar).

Solenoid Valve.

Main Relief - 2500 psi. (172.38 Bar).

Tel es c o pe In .

a. 2 Section Boom - 2000 psi

(137.9 Bar).

b. 3 Section Boom - 2500 psi.

(172.38 Bar).

Telescope Out - 1500 psi (103.43 Bar).

Rotate - 2500 psi (172.38 Bar).

Level Up - 2500 psi (172.38 Bar).

Level Down - 1500 psi (103.43 Bar).

Steer.

a. Without Wheel - 1500 psi.(103.43 Bar).

b. Without Wheel - 2500 psi.(172.38 Bar).

Vickers Proportional Valve.

Vickers.

Drive - 3000 psi.(206.85 Bar).

Lift Up - 2500 psi.(172.38 Bar).

Lift Down - 1500 psi. (103.43 Bar).

Telescope In - 2500 psi. (172.38 Bar).

Telescope Out - 1500 psi. (103.43 Bar).

Swing - 1200 psi. (82.74 Bar).

Main Relief - 3200 psi (220.64 Bar).

Sequence Cartridge - 400 psi.

(27.58 Bar).

Pressure Reducing - 600 psi.

(41.37 Bar).

Vickers - Proportional Valve w/o Tele.

Vickers.

Drive - 3000 psi. (206.85 Bar).

Lift Up - 2500 psi. (172.38 Bar).

Lift Down - 1200 psi. (82.74 Bar).

Swing - 1100 psi. (75.85 Bar).

Accessory.

Main Relief - 3200 psi. (220.64 Bar).

Sequence Cartridge - 450 psi. (31.03 Bar).

Pressure Reducing - 600 psi. (41.37 Bar).

1-8 – JLG Lift – 3120240

Page 17

SECTION 1 - SPECIFICATIONS

3 Stack Racine Bang-Bang Valve.

Main Relief - 2500 psi. (172.38 Bar).

Steer - 2000 psi. (137.9 Bar).

4WD Steer Pressure - 2000 psi. (137.9 Bar).

Extend-A-Reach Racine Valve.

Extend Up - 2500 psi. (172.38 Bar).

Extend Down - 800 psi. (55.16 Bar).

NOTE: Refer to Section 2 for pressure setting procedures.

1.7 CYLINDER SPECIFICATIONS

Table 1-3. CYLINDER SPECIFICATIONS.

DESCRIPTION BORE STROKE R OD

DIA.

Master Level 2.50 15.25 1.25

Slave Level 2.50 15.21 1.25

Lift 6.00 23.50 2.50

Lockout

(Oscillating Axle)

Lock-

out

(4WD)

Te le s c op e

(2 Section Boom)

Te le s c op e

(3 Section Boom)

Steer (2WD) 3.00 8.06 1.25

Steer (4WD) 3.00 9.81 1.50

3.00 4.56 1.25

3.00 4.06 1.25

3.00 174.18 2.00

3.00 110.31 2.00

1.8 BOOM TAPE

Two Section Boom (American Standard).

Red - 64 in. (162.56 cm).

Yellow - 41 in. (104.14 cm).

Blue - 71.50 in. (181.61 cm).

Three Section Boom (American Standard).

Red - 24.06 in. (61.11 cm).

Yellow - 20.50 in. (52.07 cm).

Blue - 70.75 in. (179.70 cm).

Two Section Boom (Canadian Standard).

Red - 70.75 in. (179.71 cm).

Yellow - 46.24 in. (117.47 cm).

Blue - 59.49 in. (151.12 cm).

Extend-A-Reach

Lift 3.00 12.687 2.00

Slave 3.50 7.25 1.75

3120240 – JLG Lift – 1-9

Page 18

SECTION 1 - SPECIFICATIONS

1.9 MAJOR COMPONENTS WEIGHTS

TABLE 1-4. COMPONENT WEIGHTS.

Platform - 36" x 48" (91.4 cm x 122 cm)

w/Control Box.

Platform - 36" x 60" (91.4 cm x 152 cm)

w/Control Box.

Platform - 36" x 72" (91.4 cm x 182.88 cm)

w/Control Box.

Platform - 36" x 96" (91.4 cm x 243.84 cm)

w/Control Box.

2 Section Boom (Includes Boom Lift

Cylinder, Rotator and Support).

3 Section Boom (Includes Boom Lift

Cylinder, Rotator and Support).

Turntable Complete. 4687 2126 5925 2688

Frame Complete (Includes Pneumatic Tires and Wheels).

(2WD)

Frame Complete (Includes Pneumatic Tires and Wheels).

(4WD)

Complete Machine - 2WD. 11,600 5,266 13,350 6,055

Complete Machine - 4WD. 12,000 5,448 13,750 6,237

MODEL40H MODEL 40H+6

LBS. KG LBS. KG

170 78 170 78

185 84 185 84

200 90 200 90

240 109 - - - - - -

1795 814 2165 982

2275 1032 2645 1200

5020 2277 5020 2277

5420 2458 5420 2458

1.10 CRITICAL STABILITY WEIGHTS

TABLE 1-5.CRITICAL STABILITY WEIGHTS.

MODEL 40H MODEL 40H+6

LBS. KG LBS. KG

Counterweight

(If Removable)

2:1 1075 487.6 2690 1220.2

Tires

(ballasted Only)

Weight 305 138.4 305 138.4

Engine Ford 525 238.1 525 238.1

Deutz 600 272.2 600 272.2

Wisconsin - - - - - - - - - - - -

1.5:1 910 412.8 2490 1129.5

sIZE 12.5L -15 12.5L -15

1.11 SERIAL NUMBER LOCATION (SEE FIGURE 1-4.)

A serial number plate is affixed to the left rear front of the turntable. If the serial number plate is damaged or missing, the

machine serial number is stamped on the left side of the frame between front and rear wheels, below turntable bearing. In

addition, the last five digits of the serial number are stamped on top of the fly and base end of the boom and on the left side

of the turntable.

1-10 – JLG Lift – 3120240

Page 19

SECTION 1 - SPECIFICATIONS

Figure 1-3. Serial Number Locations.

3120240 – JLG Lift – 1-11

Page 20

SECTION 1 - SPECIFICATIONS

intentional blank page

1-12 – JLG Lift – 3120240

Page 21

SECTION 2. PROCEDURES

SECTION 2 - PROCEDURES

2.1 GENERAL.

This section provides information necessary to perform

maintenance on the aerial platform. Descriptions, techniques and specific procedures are designed to provide

the safest and most efficient maintenance for use by personnel responsible for ensuring the correct installation

and operation of machine components and systems.

WHEN AN ABNORMAL CONDITION IS NOTED AND PROCEDURES

CONTAINED HEREIN DO NOT SPECIFICALLY RELATE TO THE

NOTED IRREGULARITY, WORK SHOULD BE STOPPED AND

TECHNICALLY QUALIFIED GUIDANCE OBTAINED BEFORE WORK

IS RESUMED.

The maintenance procedures included consist of servicing and component removal and installation, disassembly

and assembly, inspection, lubrication and cleaning. Information on any special tools or test equipment is also provided where applicable.

2.2 SERVICING AND MAINTENANCE

GUIDELINES.

General.

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this chapter.

Safety and Workmanship.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

2. At any time when air, fuel, or oil lines are disconnected, clear adjacent areas as well as the openings

and fittings themselves. As soon as a line or component is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their containers until they are ready to be used.

Components Removal and Installation.

4. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpendicular as possible to top of part being

lifted.

5. Should it be necessary to remove a component on

an angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between

the supporting structure and the component

becomes less than 90 degrees.

6. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc., have been

removed and that no adjacent parts are interfering.

Component Disassembly and Reassembly.

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing ha s b ee n

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure-Fit Parts.

When assembling pressure-fit parts, use an “anti-seize” or

molybdenum disulfide base compound to lubricate the

mating surface.

Cleanliness.

Bearings.

1. When a bearing is removed, cover it to keep out dirt

1. The most important single item in preserving the

long service life of a machine is to keep dirt and foreign materials out of the vital components. Precautions have been taken to safeguard against this.

Shields, covers, seals, and filters are provided to

keep air, fuel, and oil supplies clean; however, these

items must be maintained on a scheduled basis in

order to function properly.

3120240 – JLG Lift – 2-1

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bearing.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored, or burned.

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

Page 22

SECTION 2 - PROCEDURES

unwrap reusable or new bearings until they are

ready to install.

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bearing is to be installed on a shaft, apply pressure to the

inner race.

Gaskets.

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand-fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location, as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application.

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat-treated bolts, studs, and steel nuts, in accordance with recommended shop practices.

(See Figure 1-1.)

Hydraulic Lines and Electrical Wiring.

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System.

Battery.

Clean battery, using a non-metallic brush and a solution of

baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry battery and coat terminals with

an anti corrosion compound.

Lubrication and Servicing.

Components and assemblies requiring lubrication and

servicing are shown in Figures 1-2.

2.3 LUBRICATION INFORMATION.

Hydraulic System.

1. The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various

means, e.g., using inadequate hydraulic oil, allowing

moisture, grease, filings, sealing components, sand,

etc., to enter when performing maintenance, or by

permitting the pump to cavitate due to insufficient

system warm-up or leaks in the pump supply (suction) lines.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty operation. Every precaution mst be taken to keep hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced as necessary, at the specified intervals required in Figure 1-2. Always examine

filters for evidence of metal particles.

1. Keep the system clean. If evidence of metal or rubber particles are found in the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

Lubrication.

Service applicable components with the amount, type,

and grade of lubricant recommended in this manual, at

the specified intervals. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

3. Cloudy oils indicate a high moisture content which

permits organic growth, resulting in oxidation or corrosion. If this condition occurs, the system must be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing components.

2-2 – JLG Lift – 3120240

Page 23

SECTION 2 - PROCEDURES

Hydraulic Oil.

5. Refer to Table 1-1 for recommendations for viscosity

ranges.

6. JLG recommends Mobilfluid 424 hydraulic oil, which

has an SAE viscosity of 10W-30 and a viscosity

index of 152.

NOTE: Start-up of hydraulic system with oil temperatures

below -15° F. is not recommended. If it is necessary

to start the system in a sub-zero environment, it will

be necessary to heat the oil with a low density,

100VAC heater to a minimum temperature of -15° F.

7. The only exception to the above is to drain and fill

the system with Mobil DTE 11 oil or its equivalent.

This will allow start up at temperatures down to 20°F. However, use of this oil will give poor performance at temperatures above 120° F. Systems using

DTE 11 oil should not be operated at temperatures

above 200°F. under any condition.

Changing Hydraulic Oil.

8. Use of any of the recommended crankcase or

hydraulic oils eliminates the need for changing the

oil on a regular basis. However, filter elements must

be changed after the first 40 hours of operation and

every 250 hours thereafter. If it is necessary to

change the oil, use only those oils meeting or

exceeding the specifications appearing in this manual. If unable to obtain the same type of oil supplied

with the machine, consult local supplier for assistance in selecting the proper equivalent. Avoid mixing petroleum and synthetic base oils. JLG

Industries recommends changing the hydraulic oil

annually.

9. Use every precaution to keep the hydraulic oil clean.

If the oil must be poured from the original container

into another, be sure to clean all possible contaminants from the service container. Always clean the

mesh element of the filter and replace the cartridge

any time the system oil is changed.

10. While the unit is shut down, a good preventive maintenance measure is to make a thorough inspection

of all hydraulic components, lines, fittings, etc., as

well as a functional check of each system, before

placing the machine back in service.

Lubrication Specifications.

Specified lubricants, as recommended by the component

manufacturers, are always the best choice, however,

multi-purpose greases usually have the qualities which

meet a variety of single purpose grease requirements.

Should any question arise, regarding the use of greases in

maintenance stock, consult your local supplier for evalua-

tion. Refer to Table 1-2 for an explanation of the lubricant

key designations appearing in the Lubrication Chart.

2.4 CYLINDERS - THEORY OF OPERATION.

Systems Incorporating Double Acting

Cylinders:

Cylinders are of the double-acting type. Systems incorporating double-acting cylinders are as follows: Lift, Telescope, Platform Leveling, Steer and Lockout. A double

acting cylinder is one that requires oil flow to operate the

cylinder rod in both directions. Directing oil (by actuating

the corresponding control valve to the piston side of the

cylinder) forces the piston to travel toward the rod end of

the barrel, extending the cylinder rod (piston attached to

rod). When the oil flow is stopped, movement of rod will

stop. By directing oil to the rod side of the cylinder, the

piston will be forced in the opposite direction and the cylinder rod will retract.

Holding valves are used in the Lift, Telescope, Slave Level

and lockout circuits to prevent retraction of the cylinder

rod, should a hydraulic line rupture or a leak develop

between the cylinder and its related control valve.

2.5 VALVES - THEORY OF OPERATION.

Solenoid Control Valves (Bang-Bang).

Control valves used are four-way three-position solenoid

valves of the sliding spool design. When a circuit is activated and the control valve solenoid energizes, the spool

is shifted and the corresponding work port opens to permit oil flow to the component in the selected circuit with

the opposite work port opening to reservoir. Once the circuit is deactivated (control returned to neutral) the valve

spool returns to neutral (center) and oil flow is then

directed through the valve body and returns to reservoir. A

typical control valve consist of the valve body, sliding

spool, and two solenoid assemblies. The spool is

machine fitted in the bore of the valve body. Lands on the

spool divide the bore into various chambers, which when

the spool is shifted, align with corresponding ports in the

valve body open to common flow. At the same time other

ports would be blocked to flow. The spool is spring loaded

to center position, therefore when the control is released,

the spool automatically returns to neutral, prohibiting any

flow through the circuit.

3120240 – JLG Lift – 2-3

Page 24

SECTION 2 - PROCEDURES

Proportional Control Valve - Vickers.

CMX series valves provide a power output matching that

required by the load. A small line connected to a loadsensing port feeds load pressure back to the pump. The

pump senses the difference between the load and pump

outlet pressures, and varies the pump displacement to

keep the difference constant. This differential pressure is

applied across the valves meter-in spool, with the effect

that pump flow is determined by the degree of spool

opening, independent of load pressure. Return lines are

connected together simplifying routing of return flow and

to help reduce cavitation. Load sensing lines connect

through shuttle valves to feed the highest load signal back

to the pump. Integral actuator port relief valves, anti cavitation check valves, and load check valves are standard.

The load drop check prevents any drop of a suspended

load before upward movement.

Relief Valves.

Main relief valves are installed at various points with the

hydraulic system to protect associated systems and components against excessive pressure. Excessive pressure

can be developed when a cylinder reaches its limit of

travel and the flow of pressurized fluid continues from the

system control. The relief valve provides an alternate path

for the continuing flow from the pump, thus preventing

rupture of the cylinder, hydraulic line or fitting. Complete

failure of the system pump is also avoided by relieving circuit pressure. The relief valve is installed in the circuit

between the pump outlet (pressure line) and the cylinder

of the circuit, generally as an integral part of the system

valve bank. Relief pressures are set slightly higher than

the load requirement, with the valve diverting excess

pump delivery back to the reservoir when operating pressure of the component is reached.

2. Torque fly boom retract chains, adjust to

28 ft. lbs. (38 NM).

3. Torque fly boom extend chains, adjust to

28 ft. lbs. (38 NM).

4. Cycle boom (extend at least three feet and

return to the fully retracted position).

5. Recheck fly boom retract chains

(28 ft. lbs. (38 NM) required).

6. Recheck fly boom extend chains

(28 ft. lbs. (38 NM) required).

7. Repeat steps #2, #3 and #4 if necessary.

8. Check for proper operation of boom.

JLG Industries, Inc. requires a complete boom disassembly, per instructions outlined in the 2-11 boom disassembly, every two years. All boom chains and related

components (i.e., sheaves, pins, sprockets, wear pads,

etc.) must also be inspected and replaced (as necessary)

during this disassembly.

A more frequent disassembly of the boom assembly and

inspection of the boom chains and related components is

required if machine is exposed to hostile environments or

conditions (i.e. extreme cold, dust, sand, blasting grit, salt,

chemicals, etc.), which could adversely affect boom operation. Such a disassembly is required if either debris has

accumulated inside the boom assembly or an inspection

of the boom chain and related components, in accordance with the INSPECTION PROCEDURES in this section, reveals any discrepancies to the boom chain or

related components.

An immediate disassembly of the boom assembly and

inspection of the boom chains and related components is

required if any of the following conditions occur:

Relief Valves.

Crossover relief valves are used in circuits where the actuator requires an operating pressure lower than that supplied to the system. When the circuit is activated and the

required pressure at the actuator is developed, the crossover relief diverts excess pump flow to the reservoir, individual, integral reliefs are provided for each side of the

circuits.

2.6 BOOM CHAINS. (SEE FIGURE 2-1)

1. Erratic boom operation or unusual noise exists, due

to discrepancies listed in the INSPECTION PROCEDURES in this section, to the boom chains or related

components. See troubleshooting section in Service

Manual for probable causes.

2. Chain adjustment is required more often than specified in Service Manual or links need to be removed

(chain shortened) to make adjustment.

3. Machine is idle for an extended period (6 months or

longer.)

4. Boom is overloaded or sustained a shock load.

Adjusting Procedures.

FAILURE TO DISASSEMBLE THE BOOM ASSEMBLY AND PROP-

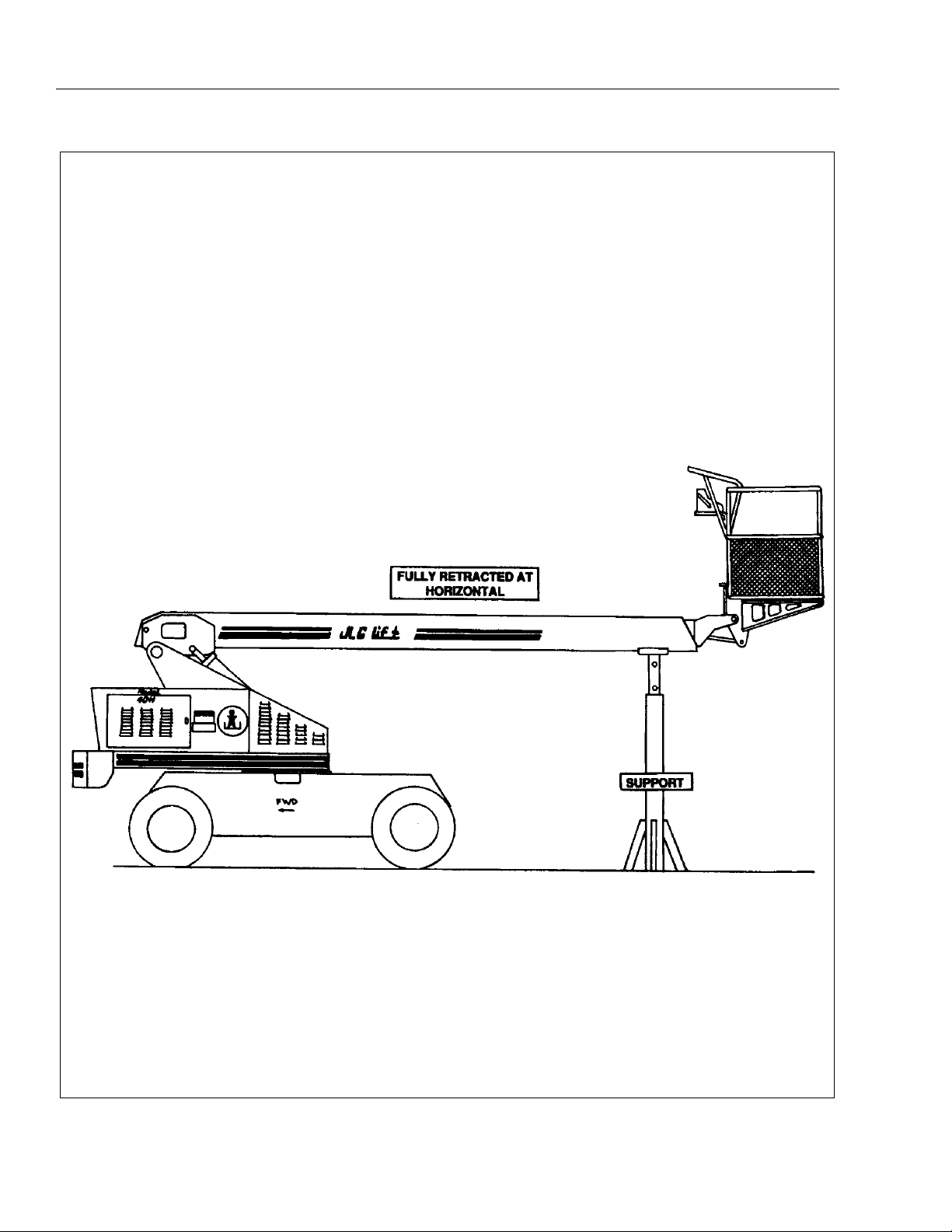

ENSURE MACHINE IS ON A FIRM AND LEVEL SURFACE.

1. Fully retract boom in the horizontal position.

2-4 – JLG Lift – 3120240

ERLY INSPECT AND/OR REPLACE THE BOOM CHAINS AND

RELATED COMPONENTS (I.E., SHEAVES, PINS, SPROCKETS,

WEAR PADS, ETC.) COULD RESULT IN THE DAMAGE AND/OR

BREAKAGE OF THE BOOM CHAINS AND/OR RELATED COMPO-

Page 25

SECTION 2 - PROCEDURES

NENTS. DAMAGE AND/OR BREAKAGE OF THESE ITEMS COULD

RESULT IN UNCONTROLLED EXTENSION OR RETRACTION OF

Figure 2-1. Typical Three Section Boom Assembly.

Inspection Procedures.

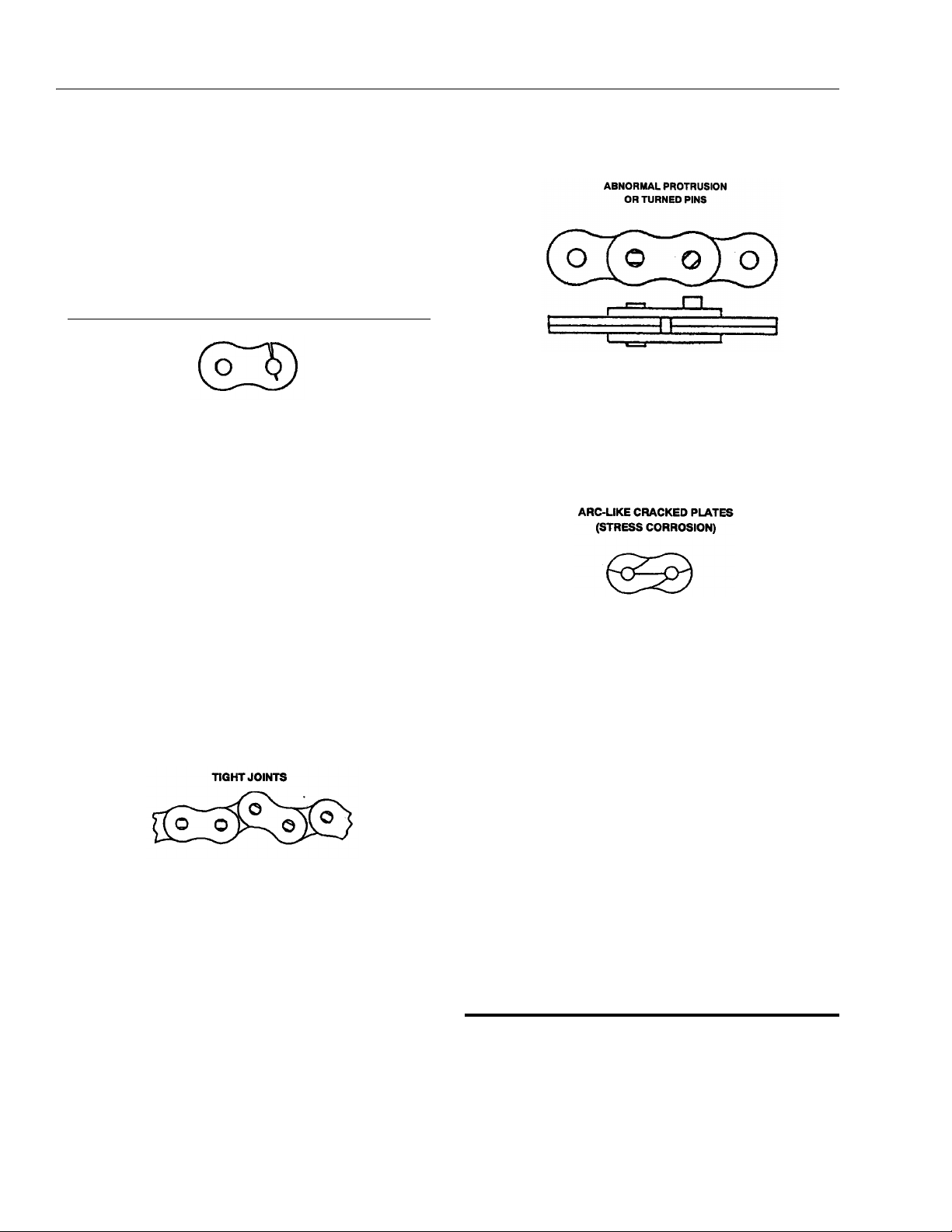

5. Inspect boom chains for the following condition:

Wear: Always inspect that segment of chain that

operates over a sheave. As the chain flexes over

the extend/retract sheaves, joints and plate edges

very gradually wear. Chain “stretch” can be measured using a manufacturers wear scale or steel

tape. When chains have elongated 3% they must

be removed and replaced. Refer to Table 1 for

proper chain specifications and allowable stretch

tolerances. Peening and wear of chain plate

edges are caused by sliding over a chain worn

contact face of a sheave, or unusually heavy

loads. All of the above require replacement of the

chain and correction of the cause. Chain side

wear, noticeable when pin heads and outside

plates show a definite wear pattern, is caused by

misalignment of the sheave/chain anchors and

must be corrected promptly. Do not repair chains;

if a section of chain is damaged, replace the

entire chain set.

THE BOOM ASSEMBLY AND COULD CAUSE SERIOUS INJURY OR

DEATH TO PERSONNEL OPERATING THE JLG BOOM LIFT.

a film of oil on all chain surfaces will inhibit rusting

and corrosion. This is important as corrosion of

highly stressed, hardened steel chain components can cause a major reduction in the load

capacity of leaf chain and result in link plate

cracking.

NOTE: The need for lubrication can be determined by the

presence of rust on the exposed portions of chain.

Rust and Corrosion: Rust and corrosion will

cause a major reduction in the load carrying

capacity of the chain, because these are primary

reasons for side plate cracking. The initial lubrication at the factory is applied in a hot dip tank to

assure full penetration into the joint. Do not steam

clean or degrease this lubricant on chains. A

grade of SAE 30 or 40 weight, non detergent

motor oil should be used as a supplemental lubricant and a film of this oil should be constantly

maintained on the surfaces and internal joints. At

time of chain installation, factory Lube must be

supplemented by a maintenance program to provide a film of oil on the chains at all times. If

chains are corroded, they must be inspected,

especially the outside plates, for cracks in-line

with the pins. If cracks are found, replace the

chain; if no cracks are discovered, lubricate the

chains by dipping in heated oil, and reinstall on

the machine. Keep chains lubricated.

Fatigue Cracks: Fatigue is a phenomenon

that affects most metals, and is the most

Lubrication: One of the most important but often

overlooked factors is adequate lubrication. In

addition to reducing internal friction, maintaining

3120240 – JLG Lift – 2-5

common cause of chain plate failures.

Fatigue cracks are found through the link

holes, perpendicular (90 degrees) from the

Page 26

SECTION 2 - PROCEDURES

pin in-line position. Inspect chains carefully

after long time use and heavy loading for

this type of crack. If any cracks are

discovered, replace all chains, as seemingly

sound plates are on the verge of cracking.

Fatigue and ultimate strength failures on

JLG Lifts are incurred as a result of severe

abuse as design specs are well within the

rated lifting capacity of these chains.

Tight Joints: All joints in the roller chain should

flex freely. On roller chain, tight joints are usually

caused by rust/corrosion, or the inside plates

“walking” off the bushing. Limber up rusty/corroded chains (after inspecting care fully) with a

heavy application of oil (preferably a hot oil dip).

Tap inside “walking” plates inward; if “walking”

persists, replace the chain. This type of problem

is accelerated by poor lubrication maintenance

practice, and most tight joint chains have been

operated with little or no lubrication. Tight joints

on leaf chain are generally caused by:

1. Bent pins or plates.

2. Rusty joints.

3. Peened plate edges.

extend in an arc-like path, often parallel to the rolling grain of the material.

Also, more then one crack can often appear on a

link plate. In addition to rusting, this condition can

be caused by exposure to an acidic or caustic

medium or atmosphere. Stress corrosion is an

environmentally assisted failure. Two conditions

must be present - corrosive agent and static

stress. In the chain, static stress is present at the

aperture due to the press fit pin.

No cycle motion is required and the plates can

crack during idle periods. The reactions of many

chemical agents (such as battery acid fumes) with

hardened metals liberate hydrogen which attacks

and weakens the metal grain structure.

Oil rusty chains, and replace chains with bent or

peened chain components. Keep chains lubricated.

Protruding or Tur ned P i ns: Chains operating

with inadequate lube generate tremendous friction between the pin and plates (pin and bushing

on roller chain). In extreme cases, this frictional

torque can actually turn the pins in the outside

press-fit plates. Inspect for turned pins, which can

be easily spotted as the “V” flats on the pin heads

are no longer in line. Replace all chains showing

evidence of turned or protruding pins. Keep

chains lubricated.

Stress Corrosion Cracking: The outside link

plates, which are heavily press-fitted to the pins,

are particularly susceptible to stress corrosion

cracking. Like fatigue cracks, these initiate at the

point of highest stress (aperture) but tend to

Chain Anchors, Sheaves and Pins: An inspection of the chain must include a close examination

of chain anchors, sheaves and pins. Check chain

anchors for wear breakage and misalignment.

Anchors with worn or broken fingers should be

replaced. They should also be adjusted to eliminate twisting the chain for an even load distribution.

Sheaves should be inspected for worn flanges,

which would indicate misalignment, and wear on

the outside diameter of the sheave. A worn

sheave can mean several problems, as follows:

1. Chains too tight.

2. Sheave bearings/pin bad.

3. Bent/misaligned chains.

2.7 WEAR PADS.

1. Shim up wear pads within 1/16 in. (1.59 mm) tolerance between wear pad and adjacent surface.

2. Replace wear pads when worn within 1/8 in. (3.18

mm) of threaded insert.

2-6 – JLG Lift – 3120240

Page 27

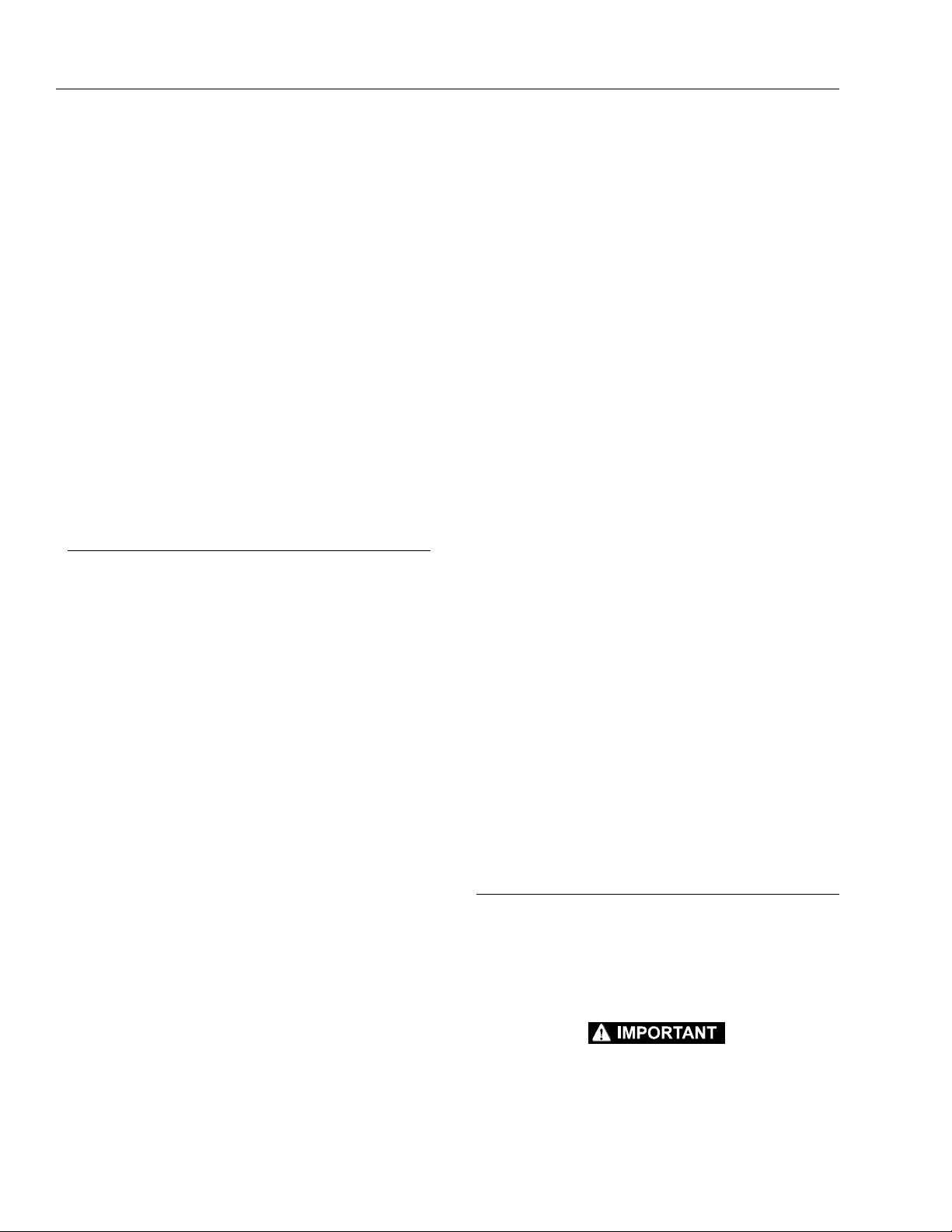

Table 2-1. Chain Stretch Tolerance.

SECTION 2 - PROCEDURES

Chain

Size

0.50 in. (1.27 cm) pitch 14 in. (36 cm) or 28 pitches 0.42 in. (1.07 cm)

0.625 in. (1.59 cm) pitch 15 in. (38 cm) or 24 pitches 0.45 in. (1.14 cm)

0.75 in. (1.91 cm) pitch 15 in. (38 cm) or 20 pitches 0.45 in. (1.14 cm)

1 in. (2.54 cm) pitch 14 in. (36 cm) or 14 pitches 0.42 in. (1.07 cm)

1.25 in. (3.18 cm) pitch 15 in. (38 cm) or 12 pitches 0.45 in. (1.14 cm)

1.75 in. (4.45 cm) pitch 14 in. (36 cm) or 8 pitches 0.42 in. (1.07 cm)

2 in. (5.08 cm) pitch 14 in. (36 cm) or 7 pitches 0.42 in. (1.07 cm)

2.8 CYLINDER CHECKING PROCEDURE.

NOTE: Cylinder checks must be performed any time a cylin-

der component is replaced or when improper system

operation is suspected.

Cylinders Without Counterbalance Valves.

Steer Cylinder and Master Cylinder.

3. Using all applicable safety precautions, activate

engine and fully extend cylinder to be checked. Shut

down engine.

4. Carefully disconnect hydraulic hose from retract port

of cylinder. There will be initial weeping of hydraulic

fluid which can be caught in a suitable container.

After the initial discharge there should be no further

leakage from the retract port.

Pin To Pin

Measurement

Allowable

Stretch

Cylinders With Single Counterbalance

Valve.

Lift Cylinder, Telescope Cylinder and Extend- A-Reach Lift

Cylinder.

OPERATE ALL FUNCTIONS FROM GROUND CONTROLS.

1. Using all applicable safety precautions, activate

hydraulic system.

WHEN WORKING ON THE LIFT CYLINDER, RAISE THE BOOM TO

HORIZONTAL AND PLACE A BOOM PROP APPROXIMATELY 1

INCH (2.50 CM) BELOW THE BOOM. DO NOT WORK ON THE CYLINDER WITHOUT A SUITABLE PROP IN PLACE. REFER TO FIGURE 2-2.

5. Activate engine and extend cylinder.

6. If cylinder retract port leakage is less than 6-8 drops

per minute, carefully reconnect hose to port and

retract cylinder. If leakage continues at a rate of 6-8

drops per minute or more, cylinder repairs must be

made.

7. With cylinder fully retracted, shut down engine and

carefully disconnect hydraulic hose from cylinder

extend port.

8. Activate engine and retract cylinder. Check extend

port for leakage.

9. If extend port leakage is less than 6-8 drops per

minute, carefully reconnect hose to extend port,

then activate cylinder through one complete cycle

and check for leaks. If leakage continues at a rate of

6-8 drops per minute or more, cylinder repairs must

be made.

2. After completing the above, shut down hydraulic

system and allow machine to sit for 10-15 minutes.

Turn IGNITION SWITCH to ON, move control switch

or lever for applicable cylinder in each direction,

then turn IGNITION SWITCH to OFF. This is done to

relieve pressure in the hydraulic lines. Carefully

remove hydraulic hoses from appropriate cylinder

port block.

3. There will be initial weeping of hydraulic fluid, which

can be caught in a suitable container. After the initial

discharge, there should not be any further leakage

from the ports. If leakage continues at a rate of 6-8

drops per minute or more, the following cylinder

repairs must be made. If the retract port is leaking,

the piston seals are defective and must be replaced.

If the extend port is leaking, the counterbalance

valve is defective and must be replaced.

4. If no repairs are necessary or when repairs have

been made, carefully reconnect hydraulic hoses to

the appropriate ports.

3120240 – JLG Lift – 2-7

Page 28

SECTION 2 - PROCEDURES

Figure 2-2. Boom Positioning and Support, Cylinder Repair.

2-8 – JLG Lift – 3120240

Page 29

SECTION 2 - PROCEDURES

5. If used, remove boom prop from beneath boom,

activate hydraulic system and run cylinder through

one complete cycle to check for leaks.

Cylinders With Dual Counterbalance Valves.

Platform Slave Level Cylinder, Lockout Cylinder

and Extend-A-Reach Level Cylinder.

OPERATE ALL FUNCTIONS FROM GROUND CONTROL STATION

ONLY.

1. Using all applicable safety precautions, activate

hydraulic system.

2. When working on the platform slave level cylinder,

stroke platform slave level cylinder forward until platform sits at a 45° angle.

3. Shut down hydraulic system and allow machine to

sit for 10-15 minutes. If machine is equipped with a

bang-bang or proportional control valves, turn IGNITION SWITCH to ON, move control switch or lever

for applicable cylinder in each direction, then turn

IGNITION SWITCH to OFF. If machine is equipped

with hydraulic control valves, move control lever for

applicable cylinder in each direction. This is done to

relieve pressure in the hydraulic lines. Carefully

remove hydraulic hoses from appropriate cylinder

port block.