Page 1

Operation & Safety

An Oshkosh Corporation Company

Manual

Original Instructions

Keep this manual with machine at all times.

Models

3614RS

4017RS

31200938

Revised

October 1, 2014

Page 2

Page 3

Revision Log

Revision Log

REVISION LOG

March 17, 2014 - A - Original Issue of Manual

September 2, 2014 - B - Revised pages d, 2-5, 2-6, 2-7, 3-4, 3-5, 3-23, 4-1, 4-10, 4-13, 4-14,

4-15, 5-2, 5-20, 5-21, 7-7, 9-1, 9-2, 9-3 & 9-4.

October 1, 2014 - C - Revised pages 5-2, 5-16, 5-26, 9-4 & 9-7.

a31200938

Page 4

Read This First

Read This First

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees

with the precautions and operating procedures essential for the safe and proper machine

operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make

specification changes without prior notification. Contact JLG Industries, Inc. for updated

information.

Operator Qualifications

The operator of the machine must not operate the machine until this manual has been

read, training is accomplished and operation of the machine has been completed under

the supervision of an experienced and qualified operator. Operation within the U.S.A.

requires training per OSHA 1910.178.

Operators of this equipment must possess a valid, applicable driver’s license, be in good

physical and mental condition, have normal reflexes and reaction time, good vision and

depth perception and normal hearing. Operator must not be using medication which

could impair abilities nor be under the influence of alcohol or any other intoxicant during

the work shift.

In addition, the operator must read, understand and comply with instructions contained

in the following material furnished with the material handler:

• This Operation & Maintenance Manual

• Telehandler Safety Manual (ANSI only)

• All instructional decals and plates

• Any optional equipment instructions furnished

The operator must also read, understand and comply with all applicable Employer,

Industry and Governmental rules, standards and regulations.

Modifications

Modifications to this machine may affect compliance with Industry Standards and/

or Governmental Regulations. Any modification must be approved by JLG.

b 31200938

Page 5

Read This First

This product must comply with all safety related bulletins. Contact JLG Industries, Inc. or

the local authorized JLG representative for information regarding safety-related bulletins

which may have been issued for this product.

JLG Industries, Inc. sends safety related bulletins to the owner of record of this machine.

Contact JLG Industries, Inc. to ensure that the current owner records are updated and

accurate.

JLG Industries, Inc. must be notified immediately in all instances where JLG products have

been involved in an accident involving bodily injury or death of personnel or when

damage has occurred to personal property or the JLG product.

FOR:

• Accident Reporting and Product Safety Publications

• Current Owner Updates

• Questions Regarding Product Applications and Safety

• Standards and Regulations Compliance Information

• Questions Regarding Product Modifications

CONTACT:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

In USA:

Toll Free: 1-877-JLG-SAFE (1-877-554-7233)

Outside USA:

Phone: +1-717-485-6591

E-mail:

ProductSafety@JLG.com

c31200938

Page 6

Read This First

OZ4390

D

1001139654 A

S

15 mg/kg

1

Other Publications Available

Service Manual.............................................................................................................................31200940

Parts Manual .................................................................................................................................31200939

Engine Parts Manual ..................................................................................................................31211006

Note: The following standards may be referenced in this manual:

ANSI is compliant to ANSI/ITSDF B56.6

AUS is compliant to AS 1418.19

CE is compliant to EN1459

Refer to the machine Serial Number Plate to identify the applicable compliance standard.

Machine Configuration

Two configurations of each machine are included in this manual. Determine if

machine is equipped with Ultra Low Sulfur Fuel Decal (1) as indicated below.

• If equipped with the Ultra Low Sulfur decal, all specific references to this machine

configuration will be referred to as Ultra Low Sulfur (ULS) from this point forward.

•If not equipped with the Ultra Low Sulfur decal, all specific references to this

machine configuration will be referred to as Low Sulfur (LS) from this point

forward.

d 31200938

Page 7

Table of Contents

TABLE OF CONTENTS

Revision Log

Read This First

Operator Qualifications ........................................................................... b

Modifications............................................................................................... b

Other Publications Available ................................................................. d

Machine Configuration............................................................................ d

Table of Contents

Section 1 - General Safety Practices

1.1 Hazard Classification System ....................................................................1-1

Safety Alert System and Safety Signal Words...............................1-1

1.2 General Precautions .....................................................................................1-1

1.3 Operation Safety............................................................................................1-2

Electrical Hazards ....................................................................................1-2

Tip Over Hazard .......................................................................................1-3

Travel Hazard............................................................................................1-6

Load Falling Hazard ...............................................................................1-7

Lifting Personnel .....................................................................................1-8

Driving Hazards on Slopes...................................................................1-9

Pinch Points and Crush Hazards.....................................................1-10

Fall Hazard.............................................................................................. 1-12

Chemical Hazards ................................................................................ 1-13

Table of Contents

Section 2 - Pre-Operation and Inspection

2.1 Pre-Operation Check and Inspection.....................................................2-1

2.2 Safety Decals ...................................................................................................2-3

2.3 Walk-Around Inspection .............................................................................2-6

2.4 Warm-Up and Operational Checks .........................................................2-8

Warm-Up Check ......................................................................................2-8

Operational Check..................................................................................2-8

2.5 Operator Cab...................................................................................................2-9

2.6 Windows........................................................................................................2-10

Cab Door Window ............................................................................... 2-10

Rear Window ......................................................................................... 2-11

Section 3 - Controls and Indicators

3.1 General..............................................................................................................3-1

3.2 Controls.............................................................................................................3-2

Instrument Cluster..................................................................................3-4

Ignition .......................................................................................................3-6

Park Brake ..................................................................................................3-7

Parking Procedure ..................................................................................3-7

Transmission Control Lever (if equipped)......................................3-8

i31200938

Page 8

Table of Contents

Load Stability Indicator - LSI ............................................................ 3-10

Steering Column Adjuster................................................................ 3-12

Joystick .................................................................................................... 3-14

Console Switches................................................................................. 3-20

Accessory Control Lever.................................................................... 3-22

3.3 Anti Theft ...................................................................................................... 3-23

3.4 Steer Modes ................................................................................................. 3-24

Manual Steering Alignment Mode Change ............................... 3-24

3.5 Operator Seat .............................................................................................. 3-25

Operator Presence .............................................................................. 3-25

Adjustments .......................................................................................... 3-26

Seat Belt .................................................................................................. 3-27

3.6 Boom Indicators ......................................................................................... 3-28

Boom Extension ................................................................................... 3-28

Section 4 - Operation

4.1 Engine ............................................................................................................... 4-1

Starting the Engine ................................................................................4-1

Battery Boosted Starting......................................................................4-2

Normal Engine Operation ...................................................................4-3

Shut-Down Procedure ..........................................................................4-3

4.2 Operating with a Non-Suspended Load...............................................4-4

Lift Load Safely ........................................................................................4-4

Picking Up a Load ...................................................................................4-4

Transporting a Load ..............................................................................4-5

Leveling Procedure ................................................................................4-5

Placing a Load..........................................................................................4-6

Disengaging a Load............................................................................... 4-6

4.3 Operating with a Suspended Load.........................................................4-7

Lift Load Safely ........................................................................................4-7

Picking Up a Suspended Load ...........................................................4-7

Transporting a Suspended Load.......................................................4-8

Leveling Procedure ................................................................................4-8

Placing a Suspended Load ..................................................................4-9

Disengaging a Suspended Load .......................................................4-9

4.4 Road Operation (CE).................................................................................. 4-10

4.5 Loading and Securing for Transport ................................................... 4-11

Tiedown .................................................................................................. 4-11

Lifting....................................................................................................... 4-12

4.6 ClearSky (if equipped) .............................................................................. 4-13

General .................................................................................................... 4-13

Quick Start Instructions ..................................................................... 4-13

Power ....................................................................................................... 4-14

Communication ................................................................................... 4-15

ii 31200938

Page 9

Section 5 - Attachments

5.1 Approved Attachments...............................................................................5-1

5.2 Unapproved Attachments .........................................................................5-1

5.3 JLG Supplied Attachments.........................................................................5-2

Standard Quick Attach..........................................................................5-2

5.4 Telehandler/Attachment/Fork Capacity...............................................5-4

5.5 Use of the Capacity Chart ...........................................................................5-5

Capacity Indicator Locations ..............................................................5-5

Sample Capacity Chart..........................................................................5-6

Example......................................................................................................5-8

5.6 Attachment Installation ........................................................................... 5-10

Standard Quick Attach....................................................................... 5-10

Manitou Quick Attach ........................................................................ 5-12

JCB Quick Attach ..................................................................................5-14

Hydraulic Operated Attachment....................................................5-16

5.7 Adjusting/Moving Forks .......................................................................... 5-17

5.8 Attachment Operation ............................................................................. 5-18

Carriage w/Forks .................................................................................. 5-19

Fork Positioning Carriage.................................................................. 5-20

Bucket ...................................................................................................... 5-22

Multi-Purpose Bucket ......................................................................... 5-24

Fork Mounted Hook............................................................................5-26

Quick Attach Mounted Hook........................................................... 5-27

Truss Boom............................................................................................. 5-28

Table of Contents

Section 6 - Emergency Procedures

6.1 Towing a Disabled Product........................................................................6-1

Moving Short Distances .......................................................................6-1

Moving Longer Distance ......................................................................6-1

6.2 Emergency Lowering of Boom.................................................................6-2

6.3 Cab Emergency Exit......................................................................................6-2

Section 7 - Lubrication and Maintenance

7.1 Introduction ....................................................................................................7-1

Clothing and Safety Gear .....................................................................7-1

7.2 General Maintenance Instructions..........................................................7-2

7.3 Service and Maintenance Schedules......................................................7-3

10 & 1st 50 Hour Maintenance Schedule .......................................7-3

50 & 1st 250 Hour Maintenance Schedule.....................................7-4

250 & 500 Hour Maintenance Schedule .........................................7-5

1000 & 3000 Hour Maintenance Schedule ....................................7-6

6000 & 12000 Hour Maintenance Schedule..................................7-7

7.4 Lubrication Schedules .................................................................................7-8

3614RS ........................................................................................................7-8

4017RS ........................................................................................................7-9

iii31200938

Page 10

Table of Contents

7.5 Operator Maintenance Instructions.................................................... 7-10

Fuel System............................................................................................ 7-10

Tires .......................................................................................................... 7-12

Engine Oil ............................................................................................... 7-14

Engine Cooling System ..................................................................... 7-15

Hydraulic Oil .......................................................................................... 7-16

Transmission Oil................................................................................... 7-17

Air Intake System ................................................................................. 7-18

Cab Air Filters (if equipped) ............................................................. 7-20

Battery ..................................................................................................... 7-22

Windshield Washer System (if equipped)................................... 7-23

Section 8 - Additional Checks

8.1 General..............................................................................................................8-1

8.2 Load Stability Indicator System ...............................................................8-1

8.3 Boom Interlock...............................................................................................8-2

Section 9 - Specifications

9.1 Product Specifications.................................................................................9-1

Fluids........................................................................................................... 9-1

Capacities ..................................................................................................9-3

Tires .............................................................................................................9-4

Performance .............................................................................................9-5

Dimensions ...............................................................................................9-6

Declaration of Vibration .......................................................................9-8

Noise Emission Level (CE) .................................................................... 9-8

Machine Towing Capacity ...................................................................9-8

Index

Inspection, Maintenance and Repair Log

Transfer Of Ownership

iv 31200938

Page 11

Section 1 - General Safety Practices

DANGER

OW0010

WARNING

OW0021

CAUTION

OW0031

SECTION 1 - GENERAL SAFETY PRACTICES

1.1 HAZARD CLASSIFICATION SYSTEM

Safety Alert System and Safety Signal Words

DANGER indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WAR NIN G indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a potentiality hazardous situation which, if not avoided, may result in

minor or moderate injury.

1.2 GENERAL PRECAUTIONS

WARNING

Before operation, read & understand this manual. Failure to comply with the safety

precautions listed in this manual could result in machine damage, property damage,

personal injury or death.

1-131200938

Page 12

Section 1 - General Safety Practices

OW0040

10 FT

(3 M)

1.3 OPERATION SAFETY

Note: The manufacturer has no direct control over machine application and operation.

Therefore, safety issues listed in this manual are non-exhaustive. The user and operator are

responsible for conforming with good safety practices.

Electrical Hazards

• This machine is not insulated and does not provide protection from contact or being

near electrical current.

• NEVER operate the telehandler in an area where overhead power lines, overhead or

underground cables, or other power sources may exist without ensuring the

appropriate power or utility company de-energizes the lines.

• Always check for power lines before raising the boom.

• Follow employer, local and governmental regulations for clearance from powerlines.

1-2 31200938

Page 13

Section 1 - General Safety Practices

OW0050

OW0080

OW0100

4 FT

(1,2 M)

Tip Over Hazard

General

• For additional load requirements, refer to the appropriate capacity chart.

• Never use an attachment without the appropriate JLG approved capacity chart

installed on the telehandler.

• Understand how to properly use the capacity charts located in cab.

• DO NOT exceed rated lift capacity.

• Be sure that the ground conditions are able to support the machine.

• DO NOT raise boom unless frame is level (0 degrees), unless otherwise noted on

capacity chart.

• DO NOT level machine with boom/attachment above 1,2 m (4 ft).

(AUS - DO NOT level machine with load more than 300 mm (11.8 in) above ground

surface.)

1-331200938

Page 14

Section 1 - General Safety Practices

OH2291

OH20911

OH2221

• MAINTAIN proper tire pressure at all times. If proper tire pressures are not

maintained, this machine could tip over.

• Refer to manufacturer’s specifications for proper fill ratio and pressure requirements

for tires equipped with ballast.

• Always wear the seat belt.

• Keep head, arms, hands, legs and all other body parts inside operator’s cab at all times.

If the telehandler starts to tip over:

• DO NOT JUMP

• BRACE YOURSELF and STAY WITH THE MACHINE

• KEEP YOUR SEAT BELT FASTENED

• HOLD ON FIRMLY

• LEAN AWAY FROM THE POINT OF IMPACT

1-4 31200938

Page 15

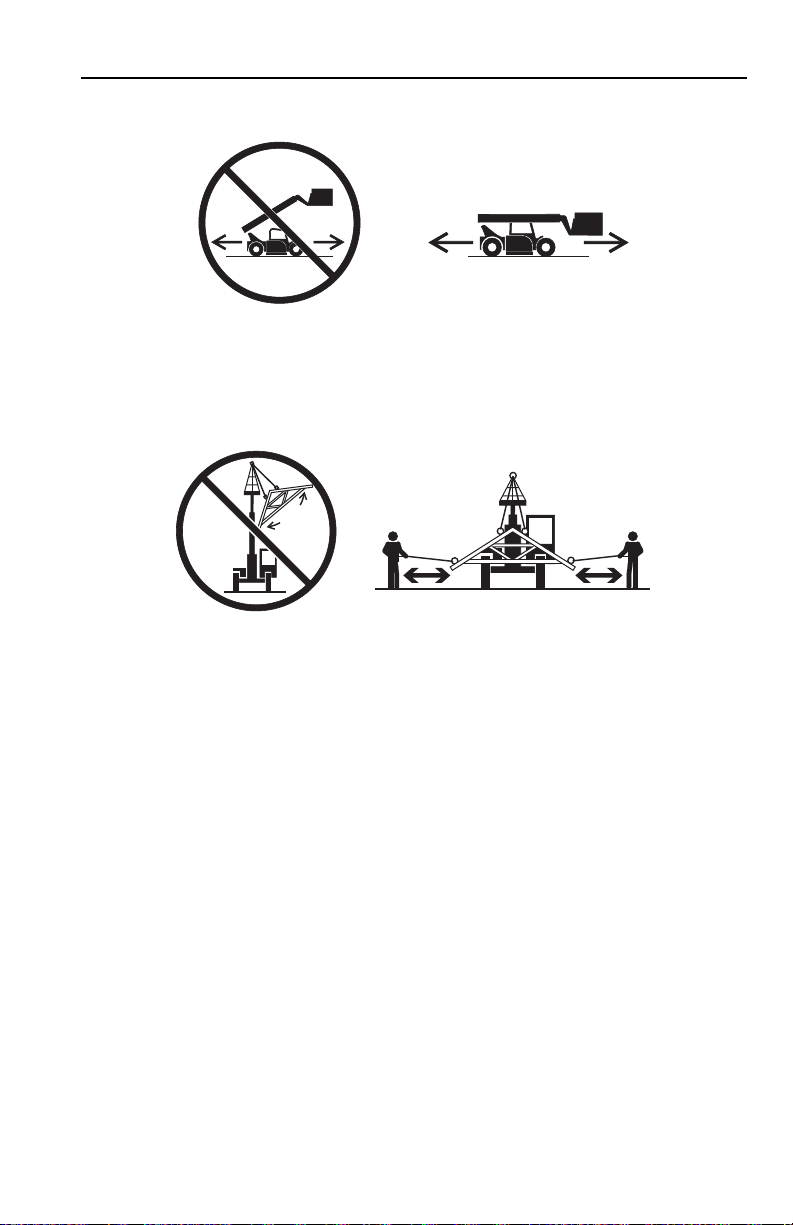

Non-Suspended Load

OW0060

O

W0150

• DO NOT drive with boom raised.

Suspended Load

Section 1 - General Safety Practices

• Tether suspended loads to restrict movement.

• Weight of all rigging (slings, etc.) must be included as part of load.

• Beware of wind. Wind can cause a suspended load to swing and cause dangerous side

loads - even with tag lines.

• DO NOT attempt to use telehandler frame-leveling to compensate for load swing.

• Keep heavy part of load closest to attachment.

• Never drag the load; lift vertically.

When driving with a suspended load:

• Start, travel, turn and stop slowly to prevent load from swinging.

• DO NOT extend boom.

• DO NOT raise the load more than 300 mm (11.8 in) above ground surface or the

boom more than 45°.

• DO NOT exceed walking speed.

1-531200938

Page 16

Section 1 - General Safety Practices

OAL2030

2-Wheel Front Steer 4-Wheel Circle Steer 4-Wheel Crab Steer

Travel Hazard

• Steering characteristics differ between steer modes. Identify the steer mode settings

of the telehandler being operated.

• DO NOT change steer modes while traveling. Steer modes must be changed while

telehandler is stationary.

• Visually verify proper wheel alignment after each steer mode change.

• Ensure that adequate clearance is provided for both rear tail swing and front fork

swing.

• Look out for and avoid other personnel, machinery and vehicles in the area. Use a

spotter if you DO NOT have a clear view.

• Before moving be sure of a clear path and sound horn.

• When driving, retract boom and keep boom/attachment as low as possible while

maintaining visibility of mirrors and maximum visibility of path of travel.

• Always look in the direction of travel.

• Always check boom clearances carefully before driving underneath overhead

obstructions. Position attachment/load to clear obstacles.

• When driving in high speed, use only front wheel steer (if steering modes are

selectable).

• Telehandlers equipped with solid tires should not be used in applications requiring

excessive roading or driving extended distances. In the event an application requires

excessive roading or driving expanded distances, it is recommended to use

telehandlers not equipped with solid tires.

1-6 31200938

Page 17

Section 1 - General Safety Practices

OW0130

Load Falling Hazard

• Never suspend load from forks or other parts of carriage weldment. Use only JLG

approved lift points.

• DO NOT burn or drill holes in fork(s).

• Forks must be centered under load and spaced apart as far as possible.

1-731200938

Page 18

Section 1 - General Safety Practices

OW0170

O

W0190

Lifting Personnel

• When lifting personnel, USE ONLY an approved personnel work platform, with proper

capacity chart displayed in the cab.

• DO NOT drive machine from cab when personnel are in platform.

1-8 31200938

Page 19

Section 1 - General Safety Practices

OW0200

Driving Hazards on Slopes

To maintain sufficient traction and braking capabilities, travel on slopes as follows:

• When unloaded, drive with forks pointed downhill.

• When loaded, drive with the forks pointed uphill.

• For additional travel requirements, refer to the appropriate capacity chart.

• To avoid overspeeding the engine and drivetrain when driving down slopes,

downshift to a lower gear and use the service brake as necessary to maintain a slow

speed. DO NOT shift into neutral and coast downhill.

• Avoid excessively steep slopes or unstable surfaces. To avoid tip over DO NOT drive

across excessively steep slopes under any circumstances.

• Avoid turning on a slope. Never engage “inching” or shift to “Neutral” when going

downhill.

• DO NOT park on a slope.

1-931200938

Page 20

Section 1 - General Safety Practices

OW0210

OW0220

O

W0230

Pinch Points and Crush Hazards

Stay clear of pinch points and rotating parts on the telehandler.

• Stay clear of moving parts while engine is running.

• Keep clear of steering tires and frame or other objects.

• Keep clear from under boom.

1-10 31200938

Page 21

Section 1 - General Safety Practices

OW0240

OW0250

OW0260

OW0960

• Keep clear of boom holes.

• Keep arms and hands clear of attachment tilt cylinder.

• Keep hands and fingers clear of carriage and forks.

• Keep others away while operating.

1-1131200938

Page 22

Section 1 - General Safety Practices

OW0280

OW0290

Fall Hazard

• Enter using the proper hand holds and steps provided. Always maintain 3-point

contact when mounting or dismounting. Never grab control levers or steering wheel

when mounting or dismounting the machine.

• DO NOT get off the machine until the shutdown procedure on page 4-3 has been

performed.

• DO NOT carry riders. Riders could fall off machine causing death or serious injury.

1-12 31200938

Page 23

Section 1 - General Safety Practices

OW0300

OW0950

Chemical Hazards

Exhaust Fumes

• DO NOT operate machine in an enclosed area without proper ventilation.

• DO NOT operate the machine in hazardous environments unless approved for that

purpose by JLG and site owner. Sparks from the electrical system and the engine

exhaust can cause an explosion.

Flammable Fuel

• DO NOT fill the fuel tank or service the fuel system near an open flame, sparks or

smoking materials. Engine fuel is flammable and can cause a fire and/or explosion.

Hydraulic Fluid

• DO NOT attempt to repair or tighten any hydraulic hoses or fittings while the engine is

running or when the hydraulic system is under pressure.

• Stop engine and relieve trapped pressure. Fluid in the hydraulic system is under

enough pressure that it can penetrate the skin.

• DO NOT use your hand to check for leaks. Use a piece of cardboard or paper to search

for leaks. Wear gloves to protect hands from spraying fluid.

1-1331200938

Page 24

Section 1 - General Safety Practices

This Page Intentionally Left Blank

1-14 31200938

Page 25

Section 2 - Pre-Operation and Inspection

OAH1000

PARENT METAL CRACK WELD CRACK

SECTION 2 - PRE-OPERATION AND INSPECTION

2.1 PRE-OPERATION CHECK AND INSPECTION

Note: Complete all required maintenance before operating unit.

WARNING

FAL L HA ZARD. Use extreme caution when checking items beyond your normal reach.

Use an approved ladder.

The pre-operation check and inspection, performed at beginning of each work shift or at

each change of operator, should include the following:

1. Cleanliness - Check all surfaces for leakage (oil, fuel or battery fluid) or foreign

objects. Report any leakage to the proper maintenance personnel.

2. Structure - Inspect the machine structure for dents, damage, weld or parent metal

cracks or other discrepancies.

3. Safety Decals - Ensure all safety decals are legible and in place. Clean or replace as

required. See page 2-3 for details.

4. Operation and Safety Manuals - Operation & Maintenance Manual and AEM Safety

Manual (ANSI only) located in cab manual holder.

5. Walk-Around Inspection - See page 2-6 for details.

6. Fluid Levels - Check fluids, including fuel, hydraulic oil, engine oil and coolant. When

adding fluids, refer to Section 7 - Lubrication and Maintenance and Section

9 - Specifications to determine proper type and intervals. Before removing filler caps

or fill plugs, wipe all dirt and grease away from the ports. If dirt enters these ports, it

can severely reduce component life.

7. Attachments/Accessories - Ensure correct capacity charts are installed on the

telehandler. If provided, reference the Operation & Maintenance Manual of each

attachment or accessory installed for specific inspection, operation and maintenance

instructions.

2-131200938

Page 26

Section 2 - Pre-Operation and Inspection

8. Operational Check - Once the walk-around inspection is complete, perform a warmup and operational check (see page 2-8) of all systems in an area free of overhead

and ground level obstructions. See Section 3 - Controls and Indicators for more

specific operating instructions.

WARNING

If telehandler does not operate properly, immediately bring machine to a stop, lower

boom and attachment to ground and stop the engine. Determine cause and correct

before continued use.

2-2 31200938

Page 27

Section 2 - Pre-Operation and Inspection

OZ4360

1001100957

1001100957

8006038

8006038

1706285

1706098

1706098B

8005670

1001139164A

1001139164

AU2105

AU2105

1001138051

(IF EQUIPPED -

GERMANY)

JLG MANUFACTURING EUROPE BVBA

1001138051

HOMOLOGATION NUMBER:

NUMERO DI OMOLOGAZIONE:

GENEHMIGUNGS NUMMER:

NUMERO IDENTIFICAZIONE:

VEHICLE IDENTIFICATION NUMBER:

FAHRZEUG-IDENTIFIZIERUNGS-NUMMER:

ALLOWED TOTAL WEIGHT:

MASSA TOTALEAMMISSIBILE:

ZUL. GESAMTGEWICHT:

ALLOWED FRONTAXLE WEIGHT:

CARICOAMMISSIBILE SULLASSEANTERIORE:

ZUL.ACHSLAST VORN:

ALLOWED REARAXLE WEIGHT:

CARICOAMMISSIBILE SULLASSE POSTERIORE:

ZUL.ACHSLAST HINTEN:

Kg

Kg

Kg

PERMISSIBLE TOWABLE MASS:

MASSA RIMORCHIABILEAMMISSIBILE:

TECHNISCH ZULAESSIGEANHAENGELAST:

-:UNBRAKED TOWABLE MASS

MASSA RIMORCHIABILE NON FRENATA:

UNGEBREMSTEANHAENGELAST:

-:INDEPENDENTLY-BRAKED TOWABLE MASS

MASSA RIMORCHIABILE CON FRENATURA INDIPENDENTE:

ANHAENGELAST FUER UNABHAENGIGE BREMSUNG:

-:INERTIA-BRAKED TOWABLE MASS

MASSA RIMORCHIABILE CON FRENATURAAD INERZIA:

AUFLAUFGEBREMSTEANHAENGELAST:

-TOWABLE MASS FITTED WITHANASSISTED BRAKING

SYSTEM:

(HYDRAULIC OR PNEUMATIC)

MASSA RIMORCHIABILE CON FRENATURAASSISTITA:

(IDRAULICA O PNEUMATICA)

Kg

Kg

Kg

Kg

TYPE/MODEL:

TIPO/MODELLO:

TYP/MODELL:

TIPO/MODELO:

NÚMERO DE HOMOLOGACIÓN:

NÚMERO DE IDENTIFICACIÓN:

MASA TOTALAUTORIZADA:

CARGAAUTORIZADA SOBRE EL EJE DELANTERO:

CARGAAUTORIZADA SOBRE EL EJE TRASERO:

MASA REMOLCABLEADMISIBLE:

MASA REMOLCABLE NO FRENADA:

MASA REMOLCABLE CON FRENADO INDEPENDIENTE:

MASA REMOLCABLE FRENADA POR INERCIA:

HYDRAULSCH ODER PNEUMATISCH GEBREMSTE

ANHAENGELAST:

MASA REMOLCABLE CON FRENADOASISTID:

(HIDRÁULICO-NEUMÁTICO)

YEAR OF MANUFACTURE:

ANNO DI FABRICAZIONE:

BAUJAHR:

AÑO DE FABRICACIÓN:

8008657

8008657B

8005617

20 - 2603207

(GERMANY)

25 - 1001153442

(FRANCE)

20

3700016

8008657

8008657B

8005671

8005671

8005675

8005616

3700016

3700016

8006612

1001121555

(RUSSIA)

MP13

1001121555 A

1001168718A

1001168718

1001139647

ModelYear:

100100YYYA

Model:

Year of Manufacture:

Product Identification Number

Serial Number

Nominal engine power, kW:

Unladen mass:

Maximum capacity:

Maximum capacity at max. Height:

kg

kg

kg

JLG Manufacturing Europe BVBA

Industrieterrein Oude Bunders 1034

Breitwaterstraat 12

3630 Maasmechelen - Belgium

1001139647A

1001173703

(RUSSIA)

VIEW OF ENGINE

COMPART MENT

2.2 SAFETY DECALS

Ensure all DANGER, WAR NI NG, CAUTION and instructional decals and proper capacity

charts are legible and in place. Clean and replace as required.

2-331200938

Page 28

Section 2 - Pre-Operation and Inspection

OZ4370

20 - 2603207

(GERMANY)

25 - 1001153442

(FRANCE)

20

8006612

8006612

8005870

8005870

1001104319

1001158844

1001158844A

8005675

3700016

8008657

8008657B

8005617

8005616

37000163700016

8005671

8005671

8006612

8008657

8008657B

A

1001168718A

1001168718

20 - 2603207

(GERMANY)

25 - 1001153442

(FRANCE)

20

D

1001139654 A

S

15 mg/kg

1001139654

(IF EQUIPPED FOR ULS)

1001102782

L

WA

06

dB

1

1705980

A - 1706753

B - 1706754

C - 1706755

D - 1706756

ABCD

2-4 31200938

Page 29

OZ4381

1706209

ON OFF

P P

A

A

B

B

B

A

B

B

B

A

A

A

A

A

C

C

A

A

A

EVERY

C

5

00

5

0

A

5

0

B

3614RS - 1001161264

4017RS - 1001165433

XXX kg MAX

-

XXX mm

XXX mm

XXXX

EN 1459:1998-ANNEX B

8m

9m

10m

11m

12m

13m

14m

o

10

o

20

o

30

o

40

o

50

o

60

o

75

o

0

0m

-1m

1m

2m

3m

4m

5m

6m

7m

0m

1m

2m

3m4m5m

9m 8m

7m

6m

XXX mm

350kg

500kg

750kg

100

0kg

1500kg

2000kg

2500kg

3700kg

A

B

C

D

10

D

50

150

LB

F

T

(m

N

)

50

1001161263

XXXX

XXX

XX

XXXXXX

1001094708B

1001094708

1001158300

3m

1001101895

1001101895

8005670

8005670

Korrekter Bodenabstand von 290-300mm

(ab Unterkante Schaufel)

wird durch rote Linie angezeigt

1001119218

(GERMANY)

1001172172

(LIFT PATTERN)

1001158303

(LOADER PATTERN)

1001158309

1001092878

1001120989A

1001120989

(IF EQUIPPED

WITH CLEARSKY)

VIEW A-A

AA

CAPACITY

CHARTS

B

EN 15830

CHARTS

B

VIEW B-B

Section 2 - Pre-Operation and Inspection

2-531200938

Page 30

Section 2 - Pre-Operation and Inspection

OZ3892

16

2

3

1

4

5

6

8

9

11

10

12

13

14

15

17

18

7

19

19

20

20

2.3 WALK-AROUND INSPECTION

-

Begin your walk-around inspection at item 1, as noted below. Continue to your right

(counterclockwise when viewed from top) checking each item in sequence.

INSPECTION NOTE: On all components, make sure there are no loose or missing parts, that

they are securely fastened and no visible leaks or excessive wear exists in addition to any

other criteria mentioned. Inspect all structural members including attachment for cracks,

excessive corrosion and other damage.

1. Boom Sections and Lift, Tilt, Extend/Retract, Compensating (Slave) Cylinders

• Check front, top, side and rear wear pads for presence of grease.

• Pivot pins secure; hydraulic hoses undamaged, not leaking.

2-6 31200938

Page 31

Section 2 - Pre-Operation and Inspection

2. Front Axle - Steer cylinders undamaged, not leaking; pivot pins secure (if equipped);

hydraulic hoses undamaged, not leaking.

3. Left Outrigger

4. Wheel/Tire Assembly

Inspect for worn tread, cuts, tears or other discrepancies.

5. Mirror

6. Cab and Electrical

• General appearance; no visible damage.

• Frame level indicator(s) and window glass undamaged and clean.

• Gauges, switches, joystick, foot controls and horn operational.

• Check seat belt for damage, replace belt if frayed or cut webbing, damaged

buckles or loose mounting hardware.

7. Wheel Chock

8. Wheel/Tire Assembly

Inspect for worn tread, cuts, tears or other discrepancies.

9. LSI Sensor

10. Main Control Valve

11. Rear Axle

hoses undamaged, not leaking.

12. Wheel/Tire Assembly

Inspect for worn tread, cuts, tears or other discrepancies.

13. Engine Compartment

• Drive belts, check condition and replace as required.

• Engine mounts - See inspection note.

• Battery cables tight, no visible damage or corrosion.

• Engine cover properly secured.

14. Mirrors

- Pins secure; hydraulic hoses and cylinder undamaged, not leaking.

- Properly inflated and secured; no loose or missing lug nuts.

- Clean and undamaged.

-

(if equipped) - See inspection note.

- Properly inflated and secured; no loose or missing lug nuts.

- See inspection note.

- See inspection note.

- Steer cylinders undamaged, not leaking; pivot pins secure; hydraulic

- Properly inflated and secured; no loose or missing lug nuts.

-

- Clean and undamaged.

15. Wheel/Tire Assembly

Inspect for worn tread, cuts, tears or other discrepancies.

16. Frame Level Cylinder

17. Right Outrigger

18. Attachment

19. Front Lights

20. Rear Lights

horizontal position. For off-road use, orientate in the horizontal or down position.

See “Road Operation (CE)” on page 4-10.

- Properly installed, see “Attachment Installation” on page 5-10.

(if equipped) - Clean and undamaged.

(if equipped) - Clean and undamaged. For road use, orientate in the

- Properly inflated and secured; no loose or missing lug nuts.

- Pins secure; hydraulic hoses undamaged, not leaking.

- Pins secure; hydraulic hoses and cylinder undamaged, not leaking.

2-731200938

Page 32

Section 2 - Pre-Operation and Inspection

2.4 WARM-UP AND OPERATIONAL CHECKS

Warm-Up Check

During warm-up period, check:

1. Heater, air conditioning and wipers (if equipped).

2. Check all lighting systems (if equipped) for proper operation.

3. Adjust mirrors for maximum visibility.

WARNING

CUT/CRUSH/BURN HAZARD. Keep engine cover closed while engine is running.

Operational Check

When engine warms, perform an operational check:

1. Service brake and parking brake operation.

2. Forward and reverse travel.

3. Each gear.

4. Steering in both directions with engine at low idle (steering lock to lock will not be

reached). Check in each steering mode

5. Horn and back-up alarm. Must be audible from inside operators cab with engine

running.

6. All joystick functions - operate smoothly and correctly.

7. Perform any additional checks described in Section 8.

2-8 31200938

Page 33

Section 2 - Pre-Operation and Inspection

2.5 OPERATOR CAB

The telehandler is equipped with an open or enclosed ROPS/FOPS cab.

WARNING

Never operate telehandler unless the overhead guard, cab structure and right side

glass or screen are in good condition. Any modification to this machine must be

approved by JLG to assure compliance with ROPS/FOPS certification for this cab/

machine configuration. If the overhead guard or cab structure is damaged, the CAB

CANNOT BE REPAIRED. It must be REPLACED.

2-931200938

Page 34

Section 2 - Pre-Operation and Inspection

OAM3880

1

2

3

4

2.6 WINDOWS

Keep all windows clean and unobstructed.

Cab Door Window

• Cab door (1) must be closed during operation.

• During operation the cab door window (2) must either be latched open or closed.

• Open the cab door window using lever (3) and secure it in the latch (4).

• Press the release inside the cab to unlatch the window.

2-10 31200938

Page 35

Section 2 - Pre-Operation and Inspection

5

6

OAM2110

Rear Window

•Lift lever (5) and push to open the rear window (6).

• Lift lever and pull to close.

2-1131200938

Page 36

Section 2 - Pre-Operation and Inspection

This Page Intentionally Left Blank

2-12 31200938

Page 37

Section 3 - Controls and Indicators

SECTION 3 - CONTROLS AND INDICATORS

3.1 GENERAL

This section provides the necessary information needed to understand control functions.

3-131200938

Page 38

Section 3 - Controls and Indicators

OZ4010

9

3

1

4

2

6

7

8

5

11

10

12

13

14

5

3.2 CONTROLS

1. Park Brake: See page 3-7.

2. Accelerator Pedal

3. Ignition Switch

4. Service Brake Pedal

5. Console Switches

6. Climate Controls

7. Transmission Control Lever

8. Steering Wheel

the corresponding direction. Three steering modes are available. See “Steer Modes”

on page 3-24.

9. Steering Column Adjuster

10. Instrument Cluster

3-2 31200938

: Pressing down the pedal increases engine and hydraulic speed.

: Key activated. See page 3-6.

: The further the pedal is depressed, the slower the travel speed.

: See page 3-20.

: See page 3-21.

: See page 3-8.

: Turning the steering wheel to the left or right steers the machine in

: See page 3-12.

: See page 3-4.

Page 39

11. Accessory Control Lever: See page 3-22.

12. Joystick

: See page 3-14.

Section 3 - Controls and Indicators

13. LSI Indicator

14. Frame Level Indicator

of the telehandler.

: See page 3-10.

: Enables operator to determine the left to right level condition

3-331200938

Page 40

Section 3 - Controls and Indicators

OZ4081

1

2

3

4

5

6

7

8

11

1

1 KPH

1127 RPM

127°C

10

9

12

0000

DISPLAY SHOWN WITH ANTI THEFT

ACTIVE AT SYSTEM START

DISPLAY SCREEN

Instrument Cluster

NOTICE

EQUIPMENT DAMAGE. When a red indicator illuminates (except park brake),

immediately bring machine to a stop, lower boom and attachment to ground and stop

the engine. Determine cause and correct before continued use.

1. Low Fuel Indicator: Illuminates when fuel level is low.

2. Fuel Gauge:

3. Engine Warning Light

bring machine to a stop, retract and lower boom and stop the engine. Determine

cause and correct before continued use.

4. Engine Preheat Indicator

out when start temperature is reached.

5. Steer Mode Indicators

6. System Distress Indicator

system is present. Flashes when an issue with the machine charge system is present.

7. Park Brake Indicator

3-4 31200938

Indicates amount of fuel in fuel tank.

: Illuminates when the engine is in a critical state. Immediately

: Illuminates with ignition key in position 1. Indicator goes

: Illuminates active steering mode.

: Illuminates when an issue with the fuel level or machine

: Illuminates when park brake is applied.

Page 41

Section 3 - Controls and Indicators

8. Check Engine Indicator: Illuminates when maintenance is required. See Service

Manual for details.

Note: All indicators perform a bulb check at system start up.

Display Screen

9. Speed, Boom Angle and Operating Hours

a. Speed - Telehandler travel speed displayed in kilometers per hour (km/h) or miles

per hour (m/h).

b. Boom Angle - Displays boom angle in degrees.

c. Operating Hours - Displays total hours of telehandler operation. Displays when

ignition is in ON position and engine is not started.

10. Engine Coolant Temperature and Fault Codes

a. Engine Coolant Temperature - Displays engine coolant temperature.

b. Fault Codes - Replaces the engine coolant temperature. Displays fault codes of

engine and machine systems. See Service Manual for details.

11. Driving Direction and Gear, Engine Speed and Operating Hours

a. Driving Direction and Gear - Displays current driving condition.

Direction - Forward (F), Neutral (N) or Reverse (R).

Gear - First (1), Second (2) or Third (3).

b. Engine Speed - Displays engine speed in revolutions per minute (rpm).

c. Battery Voltage - Displays voltage supplied by battery. Displays when vehicle is

not in motion.

12. Anti Theft Code Entry

the engine. See “An ti Th eft” on page 3-23.

: If active, the four digit code must be entered prior to starting

:

:

:

3-531200938

Page 42

Section 3 - Controls and Indicators

OZ2300

0

I

II

III

P

Ignition

• Position 0 - Engine off.

• Position I - Voltage available for all electrical functions.

• Position II - Wait to start engine until preheat indicator on instrument panel goes out.

• Position III - Engine start. In the event the engine does not start, rotate key to position

0 then back to position III to re-engage the starter.

• Position P - Not active, reserved for future use.

Note: Key is removable in the 0 and P positions.

3-6 31200938

Page 43

Section 3 - Controls and Indicators

OZ4090

1

2

3

1

4017RS3614RS

Park Brake

The park brake lever (1) controls the application and release of the park brake.

• Pull lever back to apply park brake.

• 3614RS - Squeeze release (2) and push lever forward to release park brake.

4017RS - Lift detent ring (3) and push lever forward to release park brake.

WARNING

MACHINE ROLL-AWAY HAZARD. Always move park brake lever to "ON" position,

lower boom to ground and stop engine before leaving cab.

WARNING

CRUSH HAZARD. Applying park brake while traveling will cause unit to stop abruptly

and could cause load loss. To stop the machine in an emergency, apply the park brake.

Parking Procedure

1. Using service brake, stop telehandler in an appropriate parking area.

2. Follow “Shut-Down Procedure” on page 4-3.

3-731200938

Page 44

Section 3 - Controls and Indicators

OZ4131

F

N

R

1

Transmission Control Lever (if equipped)

Direction of Travel Selection

Transmission control lever (1) engages forward or reverse travel.

• Push lever forward for forward travel; pull lever rearward for reverse travel. Move lever

to centered position for neutral.

• Forward or reverse travel can be selected while in any gear.

• When traveling in reverse, the back-up alarm will automatically sound.

• Drive in reverse and turn only at slow rates of speed.

• If clutch lock is activated do not increase engine speed with the transmission in

forward or reverse and the service brake depressed in an attempt to get quicker

hydraulic performances. This could cause unexpected machine movement.

WARNING

TIP OVER/CRUSH HAZARD. Bring telehandler to a complete stop before shifting

transmission control lever. A sudden change in direction of travel could reduce

stability and/or cause load to shift or fall.

3-8 31200938

Page 45

Section 3 - Controls and Indicators

OZ4142

2

2

nd

3

rd

1

st

Gear Selection

Gear selection is located on the twist grip handle (2) of transmission control lever.

• Twist hand grip to select gear.

• The Transmission is equipped with three forward and three reverse gears.

• Select the appropriate gear for the task being performed. Use a lower gear when

transporting a load. Use a higher gear only when driving unloaded for longer

distances.

• Slow down prior to downshifting. Do not downshift more than one gear at a time.

Downshifting is not permitted if current gear is flashing on display. Intended

downshifting speeds are 9 kph (5.5 mph) for third to second gear and 4 kph (2.5 mph)

for second to first gear.

3-931200938

Page 46

Section 3 - Controls and Indicators

OZ4100

1

2

3

4

5

6

Load Stability Indicator - LSI

WARNING

TIP OVER HAZARD. The LSI considers only longitudinal stability limitations, observe

all operating parameters. Failure to follow operating parameters of the telehandler

could damage the equipment and/or cause tip over.

The LSI (1) provides visual and audible indication of forward stability limitations when

machine is static on firm, level surface.

• Green LED (2) will illuminate when LSI power is on.

• When approaching forward stability limitations LEDs progressively illuminate, green

(3), then orange (4) and finally red (5).

• If the red LED illuminates the warning buzzer also sounds.

• As the telehandler reaches forward stability limitations and the red LED (5) illuminates,

the automatic function cut-out is activated. All boom, frame level and outrigger

functions are disabled except for boom retract (CE & AUS) and boom lift (CE). Retract

boom to re-enable functions.

• In some instances the LSI system may slow down or stop boom functions if operated

close to forward stability limitations. When LEDs begin to flash, certain functions can

not be operated. Retract boom and/or return the joystick to neutral position for a

short period to allow system to reset and LEDs to stop flashing before proceeding

with operation.

3-10 31200938

Page 47

Section 3 - Controls and Indicators

• Travel in accordance with the requirements set forth in Section 1 - General Safety

Practices.

•Test LSI (6) at the beginning of each work shift. See Section 8 - Additional Checks.

• When placing a load, ensure axles are not fully steered in either direction.

WARNING

TIP OVER HAZARD. If the green, orange and red LEDs flash and warning buzzer

sounds, retract and lower boom immediately. Determine cause and correct before

continued use.

3-1131200938

Page 48

Section 3 - Controls and Indicators

OZ4120

1

Steering Column Adjuster

• Follow “Shut-Down Procedure” on page 4-3.

•Turn lever (1) counterclockwise to unlock.

• Place steering column in desired position.

• Turn lever clockwise to lock.

WARNING

TIP OVER/CRUSH HAZARD. Bring telehandler to a complete stop and shutdown

engine before adjusting steering column. A sudden change in direction of travel could

reduce stability and/or cause load to shift or fall.

3-12 31200938

Page 49

Section 3 - Controls and Indicators

This Page Intentionally Left Blank

3-1331200938

Page 50

Section 3 - Controls and Indicators

OZ3940

5

F

N

R

7

2

3

8

5

4

9

6

1

Joystick

Verify the joystick decal located inside the cab matches the machine controls.

Lift Joystick Pattern

The joystick (1) controls the boom, attachment, auxiliary hydraulics, outrigger and

transmission functions.

Boom Functions

• Move the joystick back to lift boom; move joystick forward to lower boom; move

joystick right to extend boom; move joystick left to retract boom.

• The speed of boom functions depends upon the amount of joystick travel in

corresponding direction. Increasing engine speed will also increase function speed.

• For two simultaneous boom functions, move the joystick between quadrants. For

example; moving the joystick forward and to the left will lower and retract boom

simultaneously.

3-14 31200938

Page 51

Section 3 - Controls and Indicators

WARNING

TIP OVER/CRUSH HAZARD. Rapid, jerky operation of controls will cause rapid, jerky

movement of the load. Such movements could cause the load to shift or fall or could

cause the machine to tip over.

Attachment Functions

Attachment tilt is controlled by the roller switch (2).

• Push the roller switch up to tilt attachment down; push the roller switch down to tilt

attachment up.

Auxiliary Hydraulic Functions (if equipped)

Auxiliary Hydraulics roller switch (3) controls function of attachments that require

hydraulic supply for operation. See Section 5 - Attachments for approved attachments

and control instructions.

Continuous Auxiliary Hydraulic Functions (if equipped)

• Depress and release joystick button (4) for continuous operation of hydraulic powered

attachments.

• Set continuous auxiliary hydraulic level (-100% to 100%) using the auxiliary hydraulic

roller switch (3). Push the roller switch up to increase or down to decrease hydraulic

flow.

• Depress and release joystick button (4) again to stop continuous operation.

Outrigger Functions

Joystick button (5) controls both outriggers.

• Press and hold the button; move the joystick forward to lower both outriggers; move

the joystick back to raise both outriggers.

• Press and hold the button; move the joystick left then forward to lower the left

outrigger; move the joystick left then back to raise the left outrigger.

• Press and hold the button; move the joystick right then forward to lower the right

outrigger; move the joystick right then back to raise the right outrigger.

• Outriggers operable with boom at any extension and below 20 degrees or with boom

fully retracted and below 55 degrees.

WARNING

TIP OVER HAZARD. Outriggers increase stability and load capacity only if they are

used properly. Using outriggers on soft surfaces could cause telehandler to tip over.

Always ensure surface can support telehandler and load.

3-1531200938

Page 52

Section 3 - Controls and Indicators

Transmission Control (if equipped)

Transmission roller switch (6) engages forward or reverse travel.

• Press switch up for forward travel; Press switch down for reverse travel. Move switch to

centered position for neutral.

• Forward or reverse travel can be selected while in any gear.

• When traveling in reverse, the back-up alarm will automatically sound.

• Travel at slow rates of speed when making turns and driving in reverse.

WARNING

TIP OVER/CRUSH HAZARD. Bring telehandler to a complete stop before shifting

transmission. A sudden change in direction of travel could reduce stability and/or

cause load to shift or fall.

Gear selection is controlled by buttons (7 & 8).

• Depress upshift button (7) to select a higher gear; Depress downshift button (8) to

select a lower gear.

• The Transmission is equipped with three forward and three reverse gears.

• Select the appropriate gear for the task being performed. Use a lower gear when

transporting a load. Use a higher gear only when driving unloaded for longer

distances.

• Slow down prior to downshifting. Do not downshift more than one gear at a time.

Downshifting is not permitted if current gear is flashing on display. Intended

downshifting speeds are 9 kph (5.5 mph) for third to second gear and 4 kph (2.5 mph)

for second to first gear.

Clutch Lock is controlled by button (9).

• Squeeze and hold trigger to deactivate system and have transmission disengage

while depressing service brake. Release trigger to activate system and keep

transmission engaged while depressing service brake.

3-16 31200938

Page 53

Loader Joystick Pattern

OZ4110

5

F

N

R

7

2

3

8

5

4

9

6

1

Section 3 - Controls and Indicators

The joystick (1) controls the boom, attachment, auxiliary hydraulics, outrigger and

transmission functions.

Boom Functions

• Move the joystick back to lift boom; move joystick forward to lower boom.

• Extend/retract is controlled by the roller switch (2). Push roller switch up to extend

boom; push roller switch down to retract boom.

• The speed of boom functions depends upon the amount of joystick travel in

corresponding direction. Increasing engine speed will also increase function speed.

• For two simultaneous boom functions, move the joystick between quadrants. For

example; moving the joystick forward and to the left will lower boom and tilt

attachment up simultaneously.

3-1731200938

Page 54

Section 3 - Controls and Indicators

WARNING

TIP OVER/CRUSH HAZARD. Rapid, jerky operation of controls will cause rapid, jerky

movement of the load. Such movements could cause the load to shift or fall or could

cause the machine to tip over.

Attachment Functions

Attachment tilt is controlled by the joystick.

• Move joystick right to tilt down; move joystick left to tilt up.

Auxiliary Hydraulic Functions (if equipped)

Auxiliary Hydraulics roller switch (3) controls function of attachments that require

hydraulic supply for operation. See Section 5 - Attachments for approved attachments

and control instructions.

Continuous Auxiliary Hydraulic Functions (if equipped)

• Depress and release joystick button (4) for continuous operation of hydraulic powered

attachments.

• Set continuous auxiliary hydraulic level (-100% to 100%) using the auxiliary hydraulic

roller switch (3). Push the roller switch up to increase or down to decrease hydraulic

flow.

• Depress and release joystick button (4) again to stop continuous operation.

Outrigger Functions

Joystick button (5) controls both outriggers.

• Press and hold the button; move the joystick forward to lower both outriggers; move

the joystick back to raise both outriggers.

• Press and hold the button; move the joystick left then forward to lower the left

outrigger; move the joystick left then back to raise the left outrigger.

• Press and hold the button; move the joystick right then forward to lower the right

outrigger; move the joystick right then back to raise the right outrigger.

• Outriggers operable with boom at any extension and below 20 degrees or with boom

fully retracted and below 55 degrees.

WARNING

TIP OVER HAZARD. Outriggers increase stability and load capacity only if they are

used properly. Using outriggers on soft surfaces could cause telehandler to tip over.

Always ensure surface can support telehandler and load.

3-18 31200938

Page 55

Section 3 - Controls and Indicators

Transmission Control (if equipped)

Transmission roller switch (6) engages forward or reverse travel.

• Press switch up for forward travel; Press switch down for reverse travel. Move switch to

centered position for neutral.

• Forward or reverse travel can be selected while in any gear.

• When traveling in reverse, the back-up alarm will automatically sound.

• Travel at slow rates of speed when making turns and driving in reverse.

WARNING

TIP OVER/CRUSH HAZARD. Bring telehandler to a complete stop before shifting

transmission. A sudden change in direction of travel could reduce stability and/or

cause load to shift or fall.

Gear selection is controlled by buttons (7 & 8).

• Depress upshift button (7) to select a higher gear; Depress downshift button (8) to

select a lower gear.

• The Transmission is equipped with three forward and three reverse gears.

• Select the appropriate gear for the task being performed. Use a lower gear when

transporting a load. Use a higher gear only when driving unloaded for longer

distances.

• Slow down prior to downshifting. Do not downshift more than one gear at a time.

Downshifting is not permitted if current gear is flashing on display. Intended

downshifting speeds are 9 kph (5.5 mph) for third to second gear and 4 kph (2.5 mph)

for second to first gear.

Clutch Lock is controlled by button (9).

• Squeeze and hold trigger to deactivate system and have transmission disengage

while depressing service brake. Release trigger to activate system and keep

transmission engaged while depressing service brake.

3-1931200938

Page 56

Section 3 - Controls and Indicators

OZ4150

1

2

3

4

5

6

7

8 9

10

11

12

13

15

16

14

Console Switches

1. Joystick Function Switch: On/Off switch. All joystick functions are enabled when on.

2. LSI Override Switch

and hold up to 30 seconds while operating joystick to momentarily disable the

automatic function cut-out.

3. Rear Wiper Switch

4. Roof Wiper Switch

: Momentarily disables the automatic function cut-out. Depress

: On/Off switch.

(if equipped): On/Off switch.

5. Hazards Lights Switch

6. Driving Lights Switch

7. Fog Lights Switch

8. Beacon Light Switch

cab roof. Power supplied by 12V receptacle at rear left of cab roof.

9. Front and Rear Cab Work Lights Switch

10. Steer Select Switch

wheel steer. See page 3-24.

11. High Beam and Turn Signal Indicators

are active.

12. Power Outlet

: 12V receptacle.

3-20 31200938

: On/Off switch.

(if equipped): On/Off switch.

(if equipped): On/Off switch.

(if equipped): On/Off switch. Place magnetic base of beacon on

: Three positions: 4-wheel circle steer, 4-wheel crab steer and 2-

(if equipped): On/Off switch.

: Illuminates when high beams or turn signals

Page 57

Section 3 - Controls and Indicators

13. Frame Level Switch: Controls the left to right frame level. Depress right side of switch

to rotate frame right; depress left side of switch to rotate frame left. Frame level

operable with boom below 20 degrees or with boom fully retracted and between 20

and 55 degrees.

Climate Controls

14. Air Conditioning Switch

15. Fan Speed Switch

: On/Off switch.

: Adjustable rotary switch.

16. Temperature Control

: Adjustable lever.

3-2131200938

Page 58

Section 3 - Controls and Indicators

OZ4340

1

2

3

4

OZ4350

1

O

I

II

5

6

Accessory Control Lever

Turn Signals and Low/High Beam Headlights

• Push accessory control lever (1) forward (2) to activate left turn signal.

• Pull lever backward (3) to activate right turn signal.

• The lever must be manually returned to the center position to deactivate either turn

signal. The lever will not cancel automatically after a turn.

• Pull lever up (4) to switch between low and high beam headlights.

Front Windshield Wiper

• Rotate hand grip (5) to activate front windshield wiper.

O - Off, I - Continuous or II - Fast

• Push hand grip (5) towards column to activate windshield wiper fluid.

Horn

• Depress button (6) at end of lever to sound horn.

3-22 31200938

Page 59

Section 3 - Controls and Indicators

OZ4460

1

0000

O 4470Z

2

3

3.3 ANTI THEFT

Machines with the anti theft feature active require entering a numeric code before

operation to prevent unauthorized use. Code entry is accomplished using the display and

joystick.

1. Turn ignition switch to position I. If anti theft is active, the display (1) will prompt the

operator for a numeric code.

2. Use the joystick roller switch (2) to select the first digit. Push roller switch up to

increase the number; push roller switch down to decrease the number.

3. Depress and release joystick button (3) to enter the current number.

4. Continue until the code is complete.

5. If an incorrect code is entered, the buzzer will sound briefly and the display will

prompt the operator again for the numeric code.

6. If the correct code is entered, normal start up can continue.

Note: If the anti theft feature is active and the current access code is not known, it may be

viewed in Diagnostics > Datalog Menu or changed in Operator Tools Menu (level 2 password

required for both). See Service Manual for information.

3-2331200938

Page 60

Section 3 - Controls and Indicators

OAL2030

2-Wheel Front Steer 4-Wheel Circle Steer 4-Wheel Crab Steer

OZ4160

3

2

1

OAM2400

4 5

3.4 STEER MODES

Three steer modes are available for operator use.

Note: 2-Wheel Front Steer mode is required for travel on public roads.

Manual Steering Alignment Mode Change

Note: Steer mode will change immediately after selection.

1. Bring machine to a stop using service brake. If front steer mode (2) is active and rear

wheels are aligned, go directly to step 4.

2. With circle steer (1) or crab steer (3) mode active, turn the steering wheel until the

left rear wheel (4) is aligned with the side of the machine.

3. Select front steer mode (2).

4. Turn the steering wheel until the left front wheel (5) is aligned with the side of the

machine.

5. Wheels are now aligned. Select desired steer mode.

3-24 31200938

Page 61

Section 3 - Controls and Indicators

OZ4181

3

1

3

2

(IF EQUIPPED)

(IF EQUIPPED)

3.5 OPERATOR SEAT

Operator Presence

The operator seat (1) is equipped with an operator presence system. Engine start and

hydraulic functions are prohibited if operator is not present. If the system detects a loss of

pressure during operation, after a two second delay one of the following will occur:

1. With the park brake (2) engaged and transmission in neutral (3):

• Hydraulic controls are disabled. (Continuous Auxiliary function permitted)

• Upon returning to seated position, hydraulic controls are enabled.

2. With the park brake (2) disengaged and transmission in neutral (3):

• Hydraulic controls are disabled and horn sounds continuously. (Continuous

Auxiliary function permitted)

• Upon returning to seated position, hydraulic controls are enabled and horn will

cease.

3. With the park brake (2) disengaged and transmission in forward or reverse (3):

• Hydraulic controls are disabled, horn sounds continuously and transmission shifts

to neutral.

• Upon returning to seated position, hydraulic controls are enabled and horn will

cease. Return transmission to neutral to allow system to reset prior to reengaging

forward or reverse travel.

3-2531200938

Page 62

Section 3 - Controls and Indicators

OZ4170

1

2

3

4

5

5

Adjustments

Prior to starting the engine adjust seat for position and comfort.

1. Fore/Aft: Use handle to move seat fore and aft.

2. Suspension

setting.

3. Weight

4. Backrest

5. Seat Belt

3-26 31200938

: Use the handle to adjust the suspension to the appropriate weight

: Displays current weight setting.

: Use lever to adjust backrest angle.

: Always fasten seat belt during operation.

Page 63

Section 3 - Controls and Indicators

OH20912

Seat Belt

Fasten seat belt as follows:

1. Grasp both free ends of the belt making certain that belt webbing is not twisted or

entangled.

2. With back straight in the seat, couple the retractable end (male end) of the belt into

the receptacle (buckle) end of the belt.

3. With belt buckle positioned as low on the body as possible, pull the retractable end

of the belt away from the buckle until it is tight across the lap.

4. To release belt latch, depress red button on the buckle and pull free end from buckle.

3-2731200938

Page 64

Section 3 - Controls and Indicators

OAM3750

1

A

B

3.6 BOOM INDICATORS

Boom Extension

• The boom extension indicators (1) are located on the left side of the boom. Use these

indicators to determine boom extension when using the capacity chart (see “Use of

the Capacity Chart” on page 5-5).

3-28 31200938

Page 65

Section 4 - Operation

SECTION 4 - OPERATION

4.1 ENGINE

Note: Refer to Engine Operation & Maintenance Manual for additional information.

Starting the Engine

This machine can be operated under normal conditions in temperatures of -20°C to 48°C

(0°F to 118°F). Consult JLG for operation outside this range or under abnormal conditions.

1. Make sure all controls are in “Neutral” and all electrical components (lights, heater,

etc.) are turned off. Apply park brake.

2. Turn ignition switch to position II and wait for engine preheat indicator on

instrument panel to go out. If active, enter anti theft code.

3. Turn ignition switch to position III to engage starting motor. Release key immediately

when engine starts. If engine fails to start within 20 seconds, release key and allow

starting motor to cool for a few minutes before trying again.

4. After engine starts, observe indicators. If indicators remain on for more than five

seconds, stop engine and determine cause before restarting engine.

5. Warm up engine at approximately 1/2 throttle.

Note: Engine will not start unless transmission is in neutral and park brake is applied.

WARNING

UNEXPECTED MOVEMENT HAZARD. Always ensure that transmission is in neutral

and the service brake is applied before releasing park brake. Releasing park brake in

either forward or reverse could cause the machine to move abruptly.

WARNING

ENGINE EXPLOSION. Do not spray ether into air intake for cold weather starting.

4-131200938

Page 66

Section 4 - Operation

OW0530

Battery Boosted Starting

If battery-boost starting (jump-start) is necessary, proceed as follows:

• Never allow vehicles to touch.

• Ensure boosting vehicle engine is running.

• Connect the positive (+) jumper cable to positive (+) post of discharged battery.

• Connect the opposite end of positive (+) jumper cable to positive (+) post of booster

battery.

• Connect the negative (-) jumper cable to negative (-) post on booster battery.

• Connect opposite end of negative (-) jumper cable to ground point on machine away

from discharged battery.

• Follow standard starting procedures.

• Remove cables in reverse order after machine has started.

WARNING

BATTERY EXPLOSION HAZARD. Never jump start or charge a frozen battery as it

could explode. Keep sparks, flames and lighted smoking materials away from the

battery. Lead acid batteries generate explosive gases when charging. Wear safety

glasses.

4-2 31200938

Page 67

Section 4 - Operation

Normal Engine Operation

• Observe instrument panel and display frequently to be sure all systems are

functioning properly.

• Be alert for unusual noises or vibration. When an unusual condition is noticed, park

machine in safe position and perform shut-down procedure. Report condition to your

supervisor or maintenance personnel.

• Avoid prolonged idling. If the engine is not being used, turn it off.

Shut-Down Procedure

When parking the telehandler, park in a safe location on flat level ground and away from

other equipment and/or traffic lanes.

1. Apply the park brake.

2. Shift the transmission to “Neutral.”

3. Lower forks or attachment to the ground.

4. Operate engine at low idle for 3 to 5 minutes. DO NOT over rev engine.

5. Shut off engine and remove ignition key.

6. Exit telehandler properly.

7. Turn off electrical master switch (if equipped).

8. Block wheels (if necessary).

4-331200938

Page 68

Section 4 - Operation

4.2 OPERATING WITH A NON-SUSPENDED LOAD

Lift Load Safely

• You must know the weight and load center of every load you lift. If you are not sure of

the weight and load center, check with your supervisor or with the supplier of the

material.

WARNING

TIP OVER HAZARD. Exceeding lift capacity of the telehandler could damage the

equipment and/or cause tip over.

• Know the rated load capacities (refer to Section 5) of the telehandler to determine the

operating range in which you can safely lift, transport and place a load.

Picking Up a Load