Honeywell VR8200 Installation Manual

V8200, VR8200, VR8201 Continuous

Pilot Combination Gas Controls

|

INSTALLATION INSTRUCTIONS |

APPLICATION |

3/4 in. pipe. See Table 3 for adapter part numbers. |

|

Angle and straight adapters are available for 3/8, 1/2 and |

These continuous pilot combination gas controls are |

Flange kits include one flange with attached O-ring, four |

mounting screws, a 9/64 in. hex wrench and instruction |

|

used in gas-fired appliances that have up to 200 cfh |

sheet. |

capacity of natural gas. They include safety shutoff, a |

|

manual valve, a pressure regulator and pilot adjustment. |

IMPORTANT |

The V8200 has a single automatic operator, except for |

Controls are factory-set for natural (and |

the V8200F, which, like the VR8200, has two automatic |

manufactured) or LP gas. Do not attempt to use |

operators. The VR8201 has two independently controlled |

a control set for natural (manufactured) gas on |

automatic operators. Body pattern is straight-through |

LP gas, or a control set for LP on natural |

with 1/2 in. inlet and 1/2 in. outlet. Some models include |

(manufactured) gas. |

two optional 1/4 in. quick-connect convenience terminals. |

|

See Table 1 for differences between models, and Table 2 |

Controls with standard or slow opening regulators can be |

converted from one gas to the other with a conversion kit |

|

for temperature ranges and regulator types. If a 7 follows |

(ordered separately). Order conversion kit part no. |

the suffix letter in the model number (e.g., V8200A7001), |

393691 to convert from natural (manufactured) to LP |

the unit includes an electrical cut-off (ECO) connector |

gas; order conversion kit part no. 394588 to convert from |

with two 1/4 in. quick-connect terminals. |

LP to natural (manufactured) gas. Controls with step |

opening regulators cannot be converted. Controls with unregulated step openings (V8200F) are convertible.

Table 1. Continuous Pilot Combination Gas Control Models.

|

|

Number of |

|

|

Model |

Voltage/Frequency |

Automatic |

Gas Control Knob |

Current Draw |

Operators |

Positions |

(Amps) |

||

V8200 |

24 Vac/60 Hz |

One |

OFF-PILOT-ON |

0.335 |

VR8200/V8200Fa |

24 Vac/60 Hz |

Two |

OFF-PILOT-ON |

0.5 |

VR8201 |

24 Vac/50/60 Hz |

Two, Independently |

OFF-PILOT-ON |

0.5 |

|

|

Controlled |

|

|

a V8200F is a non-redundant valve due to a step bypass orifice.

Table 2. Model Number Suffix Letter Designation.

Model No. |

Ambient |

|

Temperature |

Regulator |

|

Suffix Letter |

Range |

Type |

A |

0°F to 175°F |

Standard |

|

(-18°C to +79°C) |

|

C |

Step-opening |

|

|

|

|

F |

|

Unregulated |

|

|

step-opening |

H |

|

Slow-opening |

|

|

|

K |

-40°F to +175°F |

|

|

(-40°C to +79°C) |

|

M |

Standard |

|

|

|

|

P |

|

Step-opening |

|

|

|

Table 3. Flange Part Numbers.

Inlet/Outlet |

|

Part Number |

||

Pipe Size |

Flange |

With Hex Without Hex |

||

(NPT) |

Type |

Wrench |

Wrench |

|

3/8 in. |

Straight |

393690-1 393690-11 |

||

|

Elbowa |

393690-2 393690-12 |

||

1/2 in. |

Straight |

393690-6 |

399390-16 |

|

|

|

|

|

|

|

Elbowa |

393690-3 |

|

393690-13 |

3/4 in. |

Straight |

393690-4 |

|

393690-14 |

|

|

|

|

|

|

Elbowa |

393690-5 |

|

393690-15 |

aElbow (angle) flanges cannot provide right hand inlet when the ECO connector is used.

69-0234—6

V8200, VR8200, VR8201 CONTINUOUS PILOT COMBINATION GAS CONTROLS

CAUTION

CAUTION

Equipment Damage Hazard.

Improper installation can cause equipment damage.

The V8200F is not functionally equivalent to other V8200 models and they should not be used interchangeably. The V8200F is a non-redundant valve and is not suitable for applications that require dual shutoff valves. If the application requires a redundant shutoff function, a VR8200 Valve should be used. The V8200F includes a step-opening feature. Use of a valve with non-step opening characteristics could produce a rough light-off, resulting in nuisance shutdowns or possible damage to the appliance.

NOTE: Flange kits include one flange with attached O-ring and four mounting screws. TRADELINE® kits include a 9/64 in. hex wrench, as noted.

Approvals:

American Gas Association Design Certificate: UP-70-57A.

Canadian Gas Association Design Certificate: 1029-CC-8375.

Australian Gas Association Design Certificate: 4214. Approved for Delta C applications.

PLANNING THE INSTALLATION

WARNING

WARNING

Fire or Explosion Hazard.

Can cause property damage, serious injury or death.

Follow these warnings exactly:

1.Review the installation as outlined in this section.

2.Plan for frequent maintenance as described in the Maintenance section.

When gas controls are used on heating appliances such as commercial cookers, agricultural equipment, industrial heating equipment and pool heaters, heavy demands are made on the controls. Special steps may be required to prevent nuisance shutdowns and control failure due to frequent cycling and severe environmental conditions related to moisture, corrosive chemicals, dust or excessive heat. These applications require Honeywell Environmental and Combustion Controls Engineering review; contact your Honeywell Sales Representative for assistance.

Review the following conditions that may apply to your specific installation and take the precautionary steps suggested.

Frequent Cycling

These controls are designed for use on appliances that typically cycle only three to four times an hour during the heating season. In year-round applications with greater cycling rates, the control can wear out more quickly. Perform a monthly checkout.

Water or Steam Cleaning

If a gas control gets wet, replace it. If the appliance is likely to be cleaned with water or steam, protect (cover) the controls and wiring from water or steam flow. Mount the controls high enough above the bottom of the cabinet to avoid getting wet during normal cleaning procedures. NEMA 4 enclosure is recommended for the ignition module; see the Electronic Ignition Service Handbook, form no. 71-97927.

High Humidity or Dripping Water

Dripping water can cause the module to fail. Never install an appliance where water can drip on the controls.

In addition, high ambient humidity can cause the gas control to corrode and fail.

If the appliance is in a humid atmosphere, make sure air circulation around the controls is adequate to prevent condensation. Also, regularly check out the system. NEMA 4 enclosure is recommended for the ignition module; see the Electronic Ignition Service Handbook, form no. 71-97927.

Corrosive Chemicals

Corrosive chemicals can attack the module and gas control, eventually causing a failure. If chemicals are used for routine cleaning, avoid contact with the controls. Where chemicals are suspended in air, as in some industrial or agricultural applications, NEMA 4 enclosure is recommended for the ignition module; see the Electronic Ignition Service Handbook, form no. 71-97927.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause controls to malfunction. Where dust or grease can be a problem, provide covers for the module and the gas control to limit contamination. NEMA 4 enclosure is recommended for the ignition module; see the Electronic Ignition Service Handbook, form no. 71-97927.

Heat

Excessively high temperatures can damage controls. Make sure the maximum ambient temperature at the control does not exceed the rating of the control. If the appliance operates at very high temperatures, use insulation, shielding, and air circulation, as necessary, to protect the controls. Proper insulation or shielding should be provided by the appliance manufacturer; verify proper air circulation is maintained when the appliance is installed.

69-0234—6 |

2 |

V8200, VR8200, VR8201 CONTINUOUS PILOT COMBINATION GAS CONTROLS

INSTALLATION

When Installing This Product...

1.Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

2.Check the ratings given in the instructions and on the product to make sure the product is suitable for your application.

3.Installer must be a trained, experienced service technician.

4.After installation is complete, check out the product operation as provided in these instructions.

WARNING

WARNING

Fire or Explosion Hazard.

Can cause property damage, serious injury or death.

Follow these warnings exactly:

1.Disconnect power supply before wiring to prevent electrical shock or equipment damage.

2.To avoid dangerous accumulation of fuel gas, turn off gas supply at the appliance service valve before starting installation, and perform Gas Leak Test after completion of installation.

3.Do not bend pilot tubing at gas control or pilot burner after compression fitting is tightened. Gas leakage at the connection may result.

4.Always install sediment trap in gas supply line to prevent contamination of gas control.

5.Do not force the gas control knob. Use only your hand to push down the reset button or turn the gas control knob. Never use any tools. If the gas control knob or reset button will not operate by hand, have a qualified service technician replace the control. Force or attempted repair may result in fire or explosion.

CAUTION

CAUTION

Equipment Damage Hazard. Can cause property damage.

Never apply a jumper across or short the valve coil terminals. This can burn out the heat anticipator in the thermostat.

IMPORTANT

These gas controls are shipped with protective seals over inlet and outlet tappings. Do not remove seals until ready to connect piping.

Follow the appliance manufacturer instructions if available; otherwise, use the instructions provided.

Converting Between Natural and LP Gas

WARNING

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury or death.

1.Use a gas control set for natural (manufactured) gas only on a natural (manufactured) gas system. Use a gas control set for LP gas only on an LP gas system.

2.When making conversions, be sure main and pilot burner orifices are changed to meet appliance manufacturer specifications.

Gas controls with standard or delayed opening regulators can be converted between LP and natural gas. Gas controls with step opening regulators cannot be converted. Refer to appliance manufacturer instructions for orifice specifications and conversion procedures. Gas controls are factory-set for natural (manufactured) or LP gas. Do not attempt to use a control set for natural (manufactured) gas on a LP gas control, or a control set for LP gas on a natural (manufactured) gas control. Gas controls with step opening regulators cannot be converted.

Models Requiring Conversion Kit

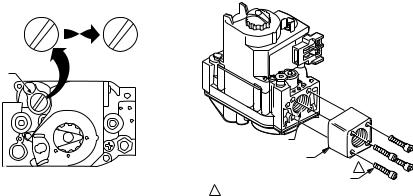

Models with slotted pressure regulator cap, (see Fig. 5), require a conversion kit. Gas controls with standard or slow opening regulators can be converted from one gas to the other with a conversion kit (ordered separately). Order part no. 393691 to convert from natural (manufactured) to LP gas; order part no. 394588 to convert from LP to natural (manufactured) gas. Follow instructions provided with kit. Gas controls with step opening regulators cannot be converted.

Models with Convertible Pressure Regulators

Models with NAT or LP stamped on the pressure regulator cap (see Fig.1), are convertible pressure regulator models.

To convert between natural and LP gas:

1.Check valve label and appliance manufacturer’s rating plate to determine if the factory pressure regulator setting meets the appliance manifold requirement.

2.Check for letters NAT (natural manufactured gas) or LP (liquid petroleum gas) on the pressure regulator cap.

3.If the appropriate letters are not visible, remove the cap.

4.Invert cap until letters appear that represent the gas type selected.

5.Replace and tighten 1/4 turn past finger tight.

NOTE: Convertible pressure regulator models do not have field-adjustable regulators.

3 |

69-0234—6 |

V8200, VR8200, VR8201 CONTINUOUS PILOT COMBINATION GAS CONTROLS

.

A |

T |

OR |

L |

P |

|

|

N |

|

|

||

N |

|

|

L |

||

|

T |

A |

|

P |

|

|

|

|

|||

|

|

|

|

|

PRESSURE

OTHER SIDE

REGULATOR

CAP

OF CAP

A |

T |

N |

N |

|

|

|

T |

A |

M11678A

Fig. 1. Top view of convertible pressure regulator cap.

Install Adapters to Control

If adapters are to be installed on the gas control, mount them as follows:

Flanges:

1.Choose the appropriate flange for your application.

NOTE: A right angle inlet flange cannot be used with the ECO connected.

2.Remove seal over gas control inlet or outlet.

3.ensure that the O-ring is fitted in the groove of the flange. If the O-ring is not attached or is missing, do not use the flange.

4.With O-ring facing the valve, align the screw holes on the control with the holes in the flange. Insert and tighten the screws provided with the flange. (See Fig. 2). Tighten the screws to 25 in. pounds (2.82 n·m) of torque to provide a gas-tight seal.

Bushings:

1.Remove seal over gas control inlet or outlet.

2.Apply moderate amount of good quality pipe compound to bushing, leaving two end threads bare. On LP installation, use compound resistant to LP gas. Do not use Teflon tape.

3.Insert bushing into control and thread pipe carefully until tight.

Complete instructions below for installing piping, installing gas control, connecting pilot gas tubing, connecting thermocouple and wiring. Make certain the leak test you perform on the control after completing the installation includes leak testing the adapters and screws. If you use a wrench on the gas control after flanges are installed, use the wrench only on the flange, not on the control.

GAS CONTROL OUTLET |

|

FLANGE |

|

|

1 |

9/64 INCH HEX SCREWS (4) |

|

1 DO NOT OVERTIGHTEN SCREWS. |

|

TIGHTEN TO 25 INCH-POUNDS. |

M2913A |

Fig. 2. Fasten flange to valve firmly, but do not overtighten screws.

Location

The combination gas control is mounted in the appliance vestibule on the gas manifold. If this is a replacement application, mount the gas control in the same location as the old control.

Do not locate the gas control where it may be affected by steam cleaning, high humidity, dripping water, corrosive chemicals, dust or grease accumulation, or excessive heat. To ensure proper operation, follow these guidelines:

•Locate gas control in a well-ventilated area.

•Mount gas control high enough above the cabinet bottom to avoid exposure to flooding or splashing water.

•Ensure the ambient temperature does not exceed the ambient temperature ratings for each component.

•Cover gas control if appliance is cleaned with water, steam, or chemicals to avoid dust and grease accumulation.

•Avoid locating gas control where exposure to corrosive chemical fumes or dripping water is likely.

Install Piping to Gas Control

All piping must comply with local codes and ordinances or with the National Fuel Gas Code (ANSI Z223.1 NFPA No. 54), whichever applies. Tubing installation must comply with approved standards and practices.

1.Use new, properly reamed pipe, free from chips. If tubing is used, ensure the ends are square, deburred and clean. All tubing bends must be smooth and without deformation.

2.Run pipe or tubing to the control. If tubing is used, obtain a tube-to-pipe coupling to connect the tubing to the control.

3.Install sediment trap in the supply line to the gas control. (See Fig. 3).

69-0234—6 |

4 |

Loading...

Loading...