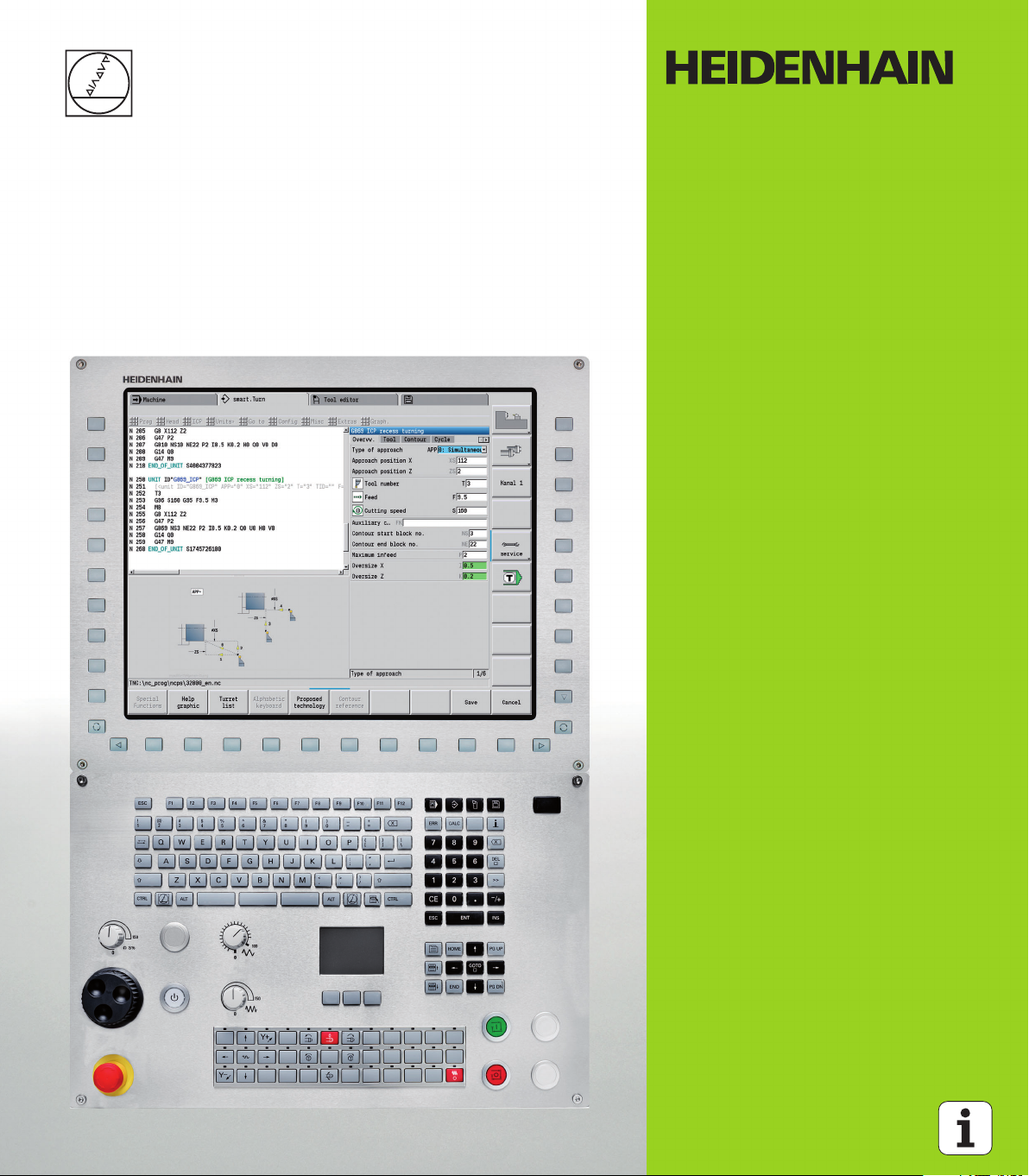

HEIDENHAIN SW 548328-05 User Manual

User’s Manual

MANUALplus 620

CNC PILOT 620/640

smart.Turn and

DIN Programming

NC Software

548328-05

548430-01

548431-01

688945-03

688946-01

688947-01

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 1

English (en)

8/2013

smart.Turn and DIN PLUS programming

This manual describes functions and features provided by lathe

controls as of the following NC software numbers.

Control NC software number

MANUALplus 620E 548328-05

MANUALplus 620 (HEROS 5) 548430-01

MANUALplus 620E (HEROS 5) 548431-01

CNC PILOT 620E 688945-03

CNC PILOT 640 (HEROS 5) 688946-01

CNC PILOT 640E (HEROS 5) 688947-01

The suffix E indicates the export version of the control. The export

version of the control has the following limitations:

Simultaneous linear movement in up to 4 axes

HEROS 5 identifies the new operating system of HSCI-based controls.

Machine operation and cycle programming are described in the

MANUALplus 620 (ID 634864-xx) and CNC PILOT 620/640 (ID

730870-xx) User's Manuals. Please contact HEIDENHAIN if you

require a copy of one of these manuals.

The machine manufacturer adapts the features offered by the control

to the capabilities of the specific machine tool by setting machine

parameters. Therefore, some of the functions described in this manual

may not be among the features provided by the Control on your

machine tool.

Some of the Control functions which are not available on every

machine are:

Positioning of spindle (M19) and driven tool

Operations with the C or Y axis

Please contact your machine manufacturer for detailed information on

the features that are supported by your machine tool.

Many machine manufacturers and HEIDENHAIN offer programming

courses. We recommend these courses as an effective way of

improving your programming skill and sharing information and ideas

with other Control users.

HEIDENHAIN also offers the DataPilot programming station for PCs,

which is designed for use with the respective control. The DataPilot

is excellently suited for both shop-floor programming as well as offlocation program creation and production planning. It is also ideal for

training purposes. The DataPilot can be run on PCs with WINDOWS

operating systems.

Control

Programming

station

NC Software

MANUALplus 620 DataPilot MP620 634132-05

CNC PILOT 620 DataPilot CP620 729665-03

CNC PILOT 640 DataPilot CP640 729666-01

Intended place of operation

The MANUALplus 620, CNC PILOT 620/640 complies with the limits

for a Class A devices in accordance with the specifications in

EN 55022, and is intended for use primarily in industrially-zoned areas.

Legal information

This product uses open source software. Further information is

available on the control under

Organization mode of operation

Second soft-key row

LICENSE INFO soft key

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 3

New functions of software 548328-03

The simulation function now also provides a 3-D view of the

workpiece blank and finished part. Workpieces can be depicted as a

solid-body model or transparent. The graphic can be both rotated

around the main axes and displayed in a three-quarter section view

(see the User’s Manual).

Simplified contour editing with ICP: When graphically supported

interactive contour description with ICP is active, contour-element

editing can now be selected directly by soft key (see the User’s

Manual).

Recessing with cut segmentation: Cut segmentation for recessing

depth is now available for the contour recessing cycle G860. (see

page 71)

The parameters XA and ZA (starting point of blank) were added to

the roughing cycles G810, G820, G830 and G835. This makes it

possible to start the cutting process at any desired diameter of the

contour by entering a starting point. (see page 60)

Workpiece measurement: The Control now supports workpiece

measurement with touch probes. A sample cycle for measurement

of workpieces is available in the control. Additionally, the machine

manufacturers can offer specially developed measuring cycles that

are individually adapted to the machine series (see the User’s

Manual).

A speed limit that is only effective for the respective cycle can now

be defined for the parting cycle in Teach-in mode and smart.Turn

(see page 75)

In the roughing and drilling cycles, an intermittent feed rate can now

be entered for chip breaking. (see page 60)

The approach angle and departure angle have been added to the ICP

cutting cycles. (see page 65)

The graphic window can now be activated automatically when the

cursor is located in the contour description. (see page 44)

4

New functions of software 688945-02 and 548328-04

In the program simulation, the current contour description (of

workpiece blank and finished part) can be mirrored and saved. In

smart.Turn, these contours can be reinserted (see User's Manual)

On machines with counterspindle, the workpiece spindle can now

be selected in the TSF menu (see User’s Manual)

On machines with a counterspindle, it’s datum can be shifted (see

User’s Manual)

The user documentation is now also in the context-sensitive help

system TURNguide (see User’s Manual)

You can make your own project folder in the project management,

so that you can centrally manage associated files (see User’s

Manual)

With a manual tool change system it is possible to insert tools that

are not in the turret during a program run (see User’s Manual)

Engraving cycles are now available in the Teach-In mode of

operation (see User’s Manual)

During tool data backup, you can now select in a dialog window the

data to be saved or restored (see User’s Manual)

The G30 function is now available for converting G functions, M

functions or spindle numbers, as well as for mirroring traverse paths

and tool dimensions (see "Converting and mirroring G30" on page

378)

The "traverse to a fixed stop" function (G916) is now available for

transferring the workpiece to the second traversable spindle or for

pressing the tailstock against the workpiece.(see "Traversing to a

fixed stop G916" on page 382)

The G925 function makes it possible to define and monitor the

maximum contact force for an axis. This function can be applied to

use the opposing spindle as a mechatronic tailstock, for example

(see "Force reduction G925" on page 385)

Controlled parting using servo-lag monitoring (G917) can now be

activated to prevent collisions caused by incomplete parting

processes.(see "Controlled parting using lag error monitoring G917"

on page 384)

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 5

The spindle synchronization option G720 synchronizes the shaft

speeds of two or more spindles so that they rotate synchronously

with a gear ratio or a defined offset.(see "Spindle synchronization

G720" on page 380)

In combination with the synchronization (G720) of main spindle and

tool spindle, the new "Hobbing" cycle (G808) is available for milling

external teeth and profiles.(see "Hobbing G808" on page 520)

With G924, a "fluctuating speed" can now be programmed to

prevent resonance (see "Fluctuating spindle speed G924" on page

374)

6

New functions of software 548328-05, 54843x-01, 688945-03 ad 688946-01

On machines with a B axis it is now also possible to drill, bore, and

mill in oblique planes. In addition to this, the B axis enables you to

use tools even more flexibly during turning (see "Tilted working

plane" on page 558).

The control now provides numerous touch probe cycles for various

applications (see "General information on touch probe cycles

(software option)" on page 430):

Calibrating a touch trigger probe

Measuring circles, circle segments, angle and position of the

C axis

Misalignment compensation

Single- point and double-point measurement

Finding a hole or stud

Zero point setting in the Z or C axis

Automatic tool measurement

The new TURN PLUS function automatically generates NC

programs for turning and milling operations based on a fixed

machining sequence (see "TURN PLUS mode of operation" on page

530).

The G940 function now provides a way to calculate the tool lengths

in the basic (definition) position of the B axis (see "Calculate variables

automatically G940" on page 375)

For machining operations that require rechucking, you can define a

separation point on the contour description with G44 (see

"Separation point G44" on page 215).

The G927 function enables you to convert tool lengths to the

reference position of the tool (B axis = 0) (see "Convert lengths

G927" on page 375).

Recesses that were defined with G22 can now be machined with

the new Cycle 870 ICP Recessing (see ""ICP recessing" unit" on page

77).

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 7

8

About this manual

The symbols used in this manual are described below.

This symbol indicates that important information about the

function described must be considered.

This symbol indicates that there is one or more of the

following risks when using the described function:

Danger to workpiece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operator

This symbol indicates that the described function must be

adapted by the machine tool builder. The function

described may therefore vary depending on the machine.

This symbol indicates that you can find detailed

information about a function in another manual.

About this manual

Do you want any changes, or have you found any errors?

We are continuously striving to improve our documentation for you.

Please help us by sending your requests to the following e-mail

address: tnc-userdoc@heidenhain.de.

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 9

About this manual

10

Contents

„NC programming”

1

„smart.Turn units”

2

„smart.Turn units for the Yaxis”

3

„DIN programming”

4

„Touch probe cycles”

5

„DIN programming for the Y axis”

6

„TURN PLUS”

7

„B axis”

8

„Overview of units”

9

„Overview of G functions”

10

1 NC programming ..... 33

1.1 smart.Turn and DIN (ISO) programming ..... 34

Contour follow-up ..... 34

Structured NC program ..... 35

Linear and rotary axes ..... 36

Units of measure ..... 36

Elements of an NC program ..... 37

1.2 The smart.Turn editor ..... 38

Menu structure ..... 38

Parallel editing ..... 39

Screen layout ..... 39

Selecting the editor functions ..... 39

Shared menu items ..... 40

1.3 Program section code ..... 46

HEADER section ..... 47

CHUCKING EQUIPMENT section ..... 48

TURRET section ..... 48

BLANK section ..... 49

AUXIL_BLANK section ..... 49

FINISHED section ..... 49

AUXIL_CONTOUR section ..... 49

FACE, REAR sections ..... 49

LATERAL section ..... 49

FRONT_Y, REAR_Y sections ..... 49

LATERAL_Y section ..... 50

MACHINING section ..... 51

END code ..... 51

SUBPROGRAM section ..... 51

RETURN code ..... 51

CONST code ..... 52

VAR code ..... 52

1.4 Tool programming ..... 53

Setting up a tool list ..... 53

Editing tool entries ..... 54

Multipoint tools ..... 54

Replacement tools ..... 55

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 13

2 smart.Turn units ..... 57

2.1 smart.Turn units ..... 58

"Units" menu ..... 58

The smart.Turn unit ..... 58

2.2 Units—Roughing ..... 65

"Longitudinal roughing in ICP" unit ..... 65

"Transverse roughing in ICP" unit ..... 66

"Contour-parallel roughing in ICP" unit ..... 67

"Bidirectional roughing in ICP" unit ..... 68

"Longitudinal roughing with direct contour input" unit ..... 69

"Transverse roughing with direct contour input" unit ..... 70

2.3 Units—Recessing ..... 71

"ICP contour recessing" unit ..... 71

"ICP recess turning" unit ..... 72

"Contour recessing with direct contour input" unit ..... 73

"Recess turning with direct contour input" unit ..... 74

"Parting" unit ..... 75

"Undercutting (H, K, U)" unit ..... 76

"ICP recessing" unit ..... 77

2.4 Units—Centric drilling ..... 78

"Centric drilling" unit ..... 78

"Centric tapping" unit ..... 80

"Boring, centric countersinking" unit ..... 81

2.5 Units—Drilling in C axis ..... 82

"Single hole, face" unit ..... 82

"Linear pattern drilling, face" unit ..... 84

"Circular pattern drilling, face" unit ..... 86

"Tapping, face" unit ..... 88

"Linear tapping pattern, face" unit ..... 89

"Circular tapping pattern, face" unit ..... 90

"Single hole, lateral surface" unit ..... 91

"Linear pattern drilling, lateral surface" unit ..... 93

"Circular pattern drilling, lateral surface" unit ..... 95

"Tap hole, lateral surface" unit ..... 97

"Linear tapping pattern, lateral surface" unit ..... 98

"Circular tapping pattern, lateral surface" unit ..... 99

"ICP drilling, C axis" unit ..... 100

"ICP tapping, C axis" unit ..... 101

"ICP boring/countersinking, C axis" unit ..... 102

14

2.6 Units—Predrilling in C axis ..... 103

"Predrill, contour mill, figures on face" unit ..... 103

"Predrill, contour mill, ICP on face" unit ..... 105

"Predrill, pocket mill, figures on face" unit ..... 106

"Predrill, pocket mill, ICP on face" unit ..... 108

"Predrill, contour mill, figures on lateral surface" unit ..... 109

"Predrill, contour mill, ICP on lateral surface" unit ..... 111

"Predrill, pocket mill, figures on lateral surface" unit ..... 112

"Predrill, pocket mill, ICP on lateral surface" unit ..... 114

2.7 Units—Finishing ..... 115

"ICP contour finishing" unit ..... 115

"Longitudinal finishing with direct contour input" unit ..... 117

"Transverse finishing with direct contour input" unit ..... 118

"Relief turns (undercut) type E, F, DIN76" unit ..... 119

"Measuring cut" unit ..... 121

2.8 Units—Threads ..... 122

Overview of thread units ..... 122

Handwheel superimposition ..... 122

"Thread, direct" unit ..... 123

"ICP thread" unit ..... 124

"API thread" unit ..... 126

"Tapered thread" unit ..... 127

2.9 Units—Milling, face ..... 129

"Slot, face" unit ..... 129

"Linear slot pattern, face" unit ..... 130

"Circular slot pattern, face" unit ..... 131

"Face milling" unit ..... 132

"Thread milling" unit ..... 133

"Contour milling, figures, face" unit ..... 134

"ICP contour milling, face" unit ..... 136

"Pocket milling, figures, face" unit ..... 137

"ICP pocket milling, face" unit ..... 139

"Engraving, face" unit ..... 140

"Deburring, face" unit ..... 141

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 15

2.10 Units—Milling, lateral surface ..... 142

"Slot, lateral surface" unit ..... 142

"Linear slot pattern, lateral surface" unit ..... 143

"Circular slot pattern, lateral surface" unit ..... 144

"Helical slot milling" unit ..... 145

"Contour milling, figures, lateral surface" unit ..... 146

"ICP contour milling, lateral surface" unit ..... 148

"Pocket milling, figures, lateral surface" unit ..... 149

"ICP pocket milling, lateral surface" unit ..... 151

"Engraving, lateral surface" unit ..... 152

"Deburring, lateral surface" unit ..... 153

2.11 Units—Special operations ..... 154

"Program beginning (START)" unit ..... 154

"C axis ON" unit ..... 156

"C axis OFF" unit ..... 156

"Subprogram call" unit ..... 157

"Program section repeat" unit ..... 158

"Program end" unit ..... 159

16

3 smart.Turn units for the Y axis ..... 161

3.1 Units—Drilling in the Y axis ..... 162

"ICP drilling, Y axis" unit ..... 162

"ICP tapping, Y axis" unit ..... 163

"ICP boring/countersinking, Y axis" unit ..... 164

3.2 Units—Predrilling in Y axis ..... 165

"Predrill, contour mill, ICP in XY plane" unit ..... 165

"Predrill, pocket mill, ICP in XY plane" unit ..... 166

"Predrill, contour mill, ICP in YZ plane" unit ..... 167

"Predrill, pocket mill, ICP in YZ plane" unit ..... 168

3.3 Units—Milling in Y axis ..... 169

"ICP contour milling in XY plane" unit ..... 169

"ICP pocket milling in XY plane" unit ..... 170

"Single-surface milling, XY plane" unit ..... 171

"Centric polygon milling, XY plane" unit ..... 172

"Engraving in XY plane" unit ..... 173

"Deburring in XY plane" unit ..... 174

"Thread milling in XY plane" unit ..... 175

"ICP contour milling in YZ plane" unit ..... 176

"ICP pocket milling in YZ plane" unit ..... 177

"Single-surface milling, YZ plane" unit ..... 178

"Centric polygon milling, YZ plane" unit ..... 179

"Engraving in YZ plane" unit ..... 180

"Deburring in YZ plane" unit ..... 181

"Thread milling in YZ plane" unit ..... 182

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 17

4 DIN programming ..... 183

4.1 Programming in DIN/ISO mode ..... 184

Geometry and machining commands ..... 184

Contour programming ..... 185

NC blocks of the DIN program ..... 186

Creating, editing and deleting NC blocks ..... 187

Address parameters ..... 188

Fixed cycles ..... 189

Subprograms, expert programs ..... 190

NC program conversion ..... 190

DIN/ISO programs of predecessor controls ..... 191

"Geometry" pull-down menus ..... 193

"Machining" pull-down menus ..... 193

4.2 Definition of workpiece blank ..... 194

Chuck part bar/tube G20-Geo ..... 194

Cast part G21-Geo ..... 194

4.3 Basic contour elements ..... 195

Starting point of turning contour G0-Geo ..... 195

Machining attributes for form elements ..... 195

Line segment in a contour G1-Geo ..... 196

Circular arc of turning contour G2/G3-Geo ..... 198

Circular arc of turning contour G12/G13-Geo ..... 199

4.4 Contour form elements ..... 200

Recess (standard) G22-Geo ..... 200

Recess (general) G23-Geo ..... 202

Thread with undercut G24-Geo ..... 204

Undercut contour G25-Geo ..... 205

Thread (standard) G34-Geo ..... 209

Thread (general) G37-Geo ..... 210

Bore hole (centric) G49-Geo ..... 212

4.5 Attributes for contour description ..... 213

Feed rate reduction factor G38-Geo ..... 213

Attributes for superimposed elements G39-Geo ..... 214

Separation point G44 ..... 215

Oversize G52-Geo ..... 215

Feed per revolution G95-Geo ..... 216

Additive compensation G149-Geo ..... 216

4.6 C-axis contours—Fundamentals ..... 217

Milling contour position ..... 217

Circular pattern with circular slots ..... 220

18

4.7 Front and rear face contours ..... 223

Starting point of front/rear face contour G100-Geo ..... 223

Line segment in front/rear face contour G101-Geo ..... 224

Circular arc in front/rear face contour G102/G103-Geo ..... 225

Bore hole on front/rear face G300-Geo ..... 226

Linear slot on front/rear face G301-Geo ..... 227

Circular slot on front/rear face G302/G303-Geo ..... 227

Full circle on front/rear face G304-Geo ..... 228

Rectangle on front/rear face G305-Geo ..... 228

Eccentric polygon on front/rear face G307-Geo ..... 229

Linear pattern on front/rear face G401-Geo ..... 230

Circular pattern on front/rear face G402-Geo ..... 231

4.8 Lateral surface contours ..... 232

Starting point of lateral surface contour G110-Geo ..... 232

Line segment in a lateral surface contour G111-Geo ..... 233

Circular arc in lateral surface contour G112-/G113-Geo ..... 234

Hole on lateral surface G310-Geo ..... 235

Linear slot on lateral surface G311-Geo ..... 236

Circular slot on lateral surface G312/G313-Geo ..... 236

Full circle on lateral surface G314-Geo ..... 237

Rectangle on lateral surface G315-Geo ..... 237

Eccentric polygon on lateral surface G317-Geo ..... 238

Linear pattern on lateral surface G411-Geo ..... 239

Circular pattern on lateral surface G412-Geo ..... 240

4.9 Tool positioning ..... 241

Rapid traverse G0 ..... 241

Rapid traverse to machine coordinates G701 ..... 241

Setting the tool change position G14 ..... 242

Definition of tool-change point G140 ..... 242

4.10 Linear and circular movements ..... 243

Linear movement G1 ..... 243

Circular path G2/ G3 ..... 244

Circular path G12/G13 ..... 245

4.11 Feed rate, shaft speed ..... 246

Speed limitation G26 ..... 246

Interrupted feed G64 ..... 246

Feed per tooth Gx93 ..... 247

Constant feed rate G94 (feed per minute) ..... 247

Feed per revolution Gx95 ..... 247

Constant surface speed Gx96 ..... 248

Speed Gx97 ..... 248

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 19

4.12 Tool-tip and cutter radius compensation ..... 249

G40: Switch off TRC/MCRC ..... 249

G41/G42: Switch on TRC/MCRC ..... 250

4.13 Zero point shifts ..... 251

Zero point shift G51 ..... 252

Additive zero point shift G56 ..... 253

Absolute zero point shift G59 ..... 254

4.14 Oversizes ..... 255

Switch off oversize G50 ..... 255

Axis-parallel oversize G57 ..... 255

Contour-parallel oversize (equidistant) G58 ..... 256

4.15 Safety clearances ..... 257

Safety clearance G47 ..... 257

Safety clearance G147 ..... 257

4.16 Tools, compensations ..... 258

Tool call T ..... 258

Correction of cut (switching the tool edge compensation) G148 ..... 259

Additive compensation G149 ..... 260

Compensation of right-hand tool tip G150

Compensation of left-hand tool tip G151 ..... 261

4.17 Contour-based turning cycles ..... 262

Working with contour-based cycles ..... 262

Longitudinal roughing G810 ..... 264

Face roughing G820 ..... 267

Contour-parallel roughing G830 ..... 270

Contour cycle, bidirectional (contour-parallel with neutral tool) G835 ..... 273

Recessing G860 ..... 275

Repeat recessing cycle G740/G741 ..... 277

Recess turning cycle G869 ..... 278

Recessing cycle G870 ..... 281

Finish contour G890 ..... 282

Measuring cut G809 ..... 285

4.18 Contour definitions in the machining section ..... 286

Cycle end / Simple contour G80 ..... 286

Linear slot on front/rear face G301 ..... 287

Circular slot on front/rear face G302/G303 ..... 287

Full circle on front/rear face G304 ..... 288

Rectangle on front/rear face G305 ..... 288

Eccentric polygon on front/rear face G307 ..... 289

Linear slot on lateral surface G311 ..... 289

Circular slot on lateral surface G312/G313 ..... 290

Full circle, lateral surface G314 ..... 290

Rectangle, lateral surface G315 ..... 291

Eccentric polygon, lateral surface G317 ..... 291

20

4.19 Thread cycles ..... 292

Overview of threading cycles ..... 292

Handwheel superimposition ..... 292

Thread cycle G31 ..... 293

Simple thread cycle G32 ..... 297

Thread single path G33 ..... 299

Metric ISO thread G35 ..... 301

Tapered API thread G352 ..... 302

Metric ISO thread G38 ..... 304

4.20 Parting cycle ..... 305

Cut-off cycle G859 ..... 305

4.21 Undercut cycles ..... 306

Undercut cycle G85 ..... 306

Undercut according to DIN 509 E with cylinder machining G851 ..... 308

Undercut according to DIN 509 F with cylinder machining G852 ..... 309

Undercut according to DIN 76 with cylinder machining G853 ..... 310

Undercut type U G856 ..... 311

Undercut type H G857 ..... 312

Undercut type K G858 ..... 313

4.22 Drilling cycles ..... 314

Overview of drilling and boring cycles and contour reference ..... 314

Drilling cycle G71 ..... 315

Boring, countersinking G72 ..... 317

Tapping G73 ..... 318

Tapping G36—Single path ..... 320

Deep-hole drilling G74 ..... 321

Linear pattern, face G743 ..... 324

Circular pattern, face G745 ..... 325

Linear pattern, lateral surface G744 ..... 326

Circular pattern, lateral surface G746 ..... 327

Thread milling, axial G799 ..... 328

4.23 C-Axis commands ..... 329

Reference diameter G120 ..... 329

Zero point shift, C axis G152 ..... 329

Standardize C axis G153 ..... 330

4.24 Front/rear-face machining ..... 331

Rapid traverse on front/rear face G100 ..... 331

Linear segment on front/rear face G101 ..... 332

Circular arc on front/rear face G102/G103 ..... 333

4.25 Lateral surface machining ..... 335

Rapid traverse, lateral surface G110 ..... 335

Line segment on lateral surface G111 ..... 336

Circular arc on lateral surface G112/G113 ..... 337

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 21

4.26 Milling cycles ..... 338

Overview of milling cycles ..... 338

Linear slot on face G791 ..... 339

Linear slot on lateral surface G792 ..... 340

Contour and figure milling cycle, face G793 ..... 341

Contour and figure milling cycle, lateral surface G794 ..... 343

Area milling, face G797 ..... 345

Helical-slot milling G798 ..... 347

Contour milling G840 ..... 348

Pocket milling, roughing G845 ..... 358

Pocket milling, finishing G846 ..... 364

4.27 Engraving cycles ..... 366

Character set ..... 366

Engraving on front face G801 ..... 368

Engraving on lateral surface G802 ..... 369

4.28 Contour follow-up ..... 370

Saving/loading contour follow-up G702 ..... 370

Contour follow-up on/off G703 ..... 370

22

4.29 Other G functions ..... 371

Chucking equipment in simulation G65 ..... 371

Workpiece blank contour G67 (for graphics) ..... 371

Period of dwell G4 ..... 371

Precision stop G7 ..... 371

Precision stop off G8 ..... 372

Precision stop G9 ..... 372

Switch off protection zone G60 ..... 372

Actual values in variables G901 ..... 372

Zero-point shift in variables G902 ..... 372

Lag error in variables G903 ..... 372

Read interpolation information G904 ..... 373

Feed rate override 100% G908 ..... 373

Interpreter stop G909 ..... 373

Spindle override 100% G919 ..... 373

Deactivate zero-point shifts G920 ..... 374

Deactivate zero-point shifts, tool lengths G921 ..... 374

End position of tool G922 ..... 374

Fluctuating spindle speed G924 ..... 374

Convert lengths G927 ..... 375

Calculate variables automatically G940 ..... 375

Misalignment compensation G976 ..... 377

Activating zero-point shifts G980 ..... 377

Activate zero-point shifts, tool lengths G981 ..... 377

Activate direct program-run continuation G999 ..... 378

Converting and mirroring G30 ..... 378

Transformations of contours G99 ..... 379

Spindle synchronization G720 ..... 380

C-angle offset G905 ..... 381

Traversing to a fixed stop G916 ..... 382

Controlled parting using lag error monitoring G917 ..... 384

Force reduction G925 ..... 385

Sleeve monitoring G930 ..... 386

4.30 Data input and data output ..... 387

"WINDOW"—Output window for variables ..... 387

"WINDOW"—Output file for variables ..... 387

"INPUT"—Input of variables ..... 387

Output of # variables PRINT ..... 388

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 23

4.31 Programming variables ..... 389

Variable types ..... 390

Reading tool data ..... 392

Reading the current NC information ..... 394

Reading general NC information ..... 395

Reading configuration data—PARA ..... 396

Determining the index of a parameter element—PARA ..... 397

Expanded variable syntax CONST – VAR ..... 398

4.32 Conditional block run ..... 400

Program branching IF..THEN..ELSE..ENDIF ..... 400

Requesting variables and constants ..... 401

WHILE..ENDWHILE program repeat ..... 402

SWITCH..CASE—program branching ..... 403

4.33 Subroutines ..... 404

Subprogram call: L"xx" V1 ..... 404

Dialog texts in subprogram call ..... 405

Help graphics for subprogram calls ..... 406

4.34 M commands ..... 407

M commands for program-run control ..... 407

Machine commands ..... 408

4.35 G functions from previous controls ..... 409

Contour definitions in the machining section ..... 409

Simple turning cycles ..... 411

Thread cycles (4110) ..... 416

4.36 DINplus program example ..... 418

Example of a subprogram with contour repetitions ..... 418

4.37 Connection between geometry and machining commands ..... 421

Turning ..... 421

C-axis machining—front/rear face ..... 422

C-axis machining—lateral surface ..... 422

4.38 Full-surface machining ..... 423

Fundamentals of full-surface machining ..... 423

Programming of full-surface machining ..... 424

Full-surface machining with opposing spindle ..... 425

Full-surface machining with single spindle ..... 427

24

5 Touch probe cycles ..... 429

5.1 General information on touch probe cycles (software option) ..... 430

Principle of function of touch probe cycles ..... 430

Touch probe cycles for automatic operation ..... 431

5.2 Touch probe cycles for single-point measurement ..... 433

Single-point measurement for tool compensation G770 ..... 433

Single-point measurement for zero point G771 ..... 435

Zero point C axis, single-point measurement G772 ..... 437

Zero point C-axis object center G773 ..... 439

5.3 Touch probe cycles for two-point measurement ..... 441

Two-point measurement G18 transverse G775 ..... 441

Two-point measurement G18 longitudinal G776 ..... 443

Two-point measurement G17 longitudinal G777 ..... 445

Two-point measurement G19 longitudinal G778 ..... 447

5.4 Calibrating touch probes ..... 449

Calibrate touch probe standard G747 ..... 449

Calibrate touch probe via two points G748 ..... 451

5.5 Measuring with touch probe cycles ..... 453

Paraxial probing G764 ..... 453

Probing in C axis G765 ..... 454

Probing in two axes G766 ..... 455

Probing in two axes G768 ..... 456

Probing in two axes G769 ..... 457

5.6 Search cycles ..... 458

Find hole in C face G780 ..... 458

Find hole in C lateral surface G781 ..... 460

Find stud in C face G782 ..... 462

Find stud in C lateral surface G783 ..... 464

5.7 Circular measurement ..... 466

Circular measurement G785 ..... 466

Determine pitch circle G786 ..... 468

5.8 Measure angle ..... 470

Angular measurement G787 ..... 470

Misalignment compensation after angle measurement G788 ..... 472

5.9 In-process measurement ..... 473

Measure workpieces (option) ..... 473

Switch on measurement G910 ..... 473

Measuring path monitoring G911 ..... 474

Measured value capture G912 ..... 474

End in-process measuring G913 ..... 474

Switch off measuring-path monitoring G914 ..... 474

In-process measurement example: Measuring and compensating workpieces ..... 475

Example of in-process measurement: Measuring and compensating workpieces

measure_pos_move.ncs ..... 476

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 25

6 DIN programming for the Y axis ..... 477

6.1 Y-axis contours—Fundamentals ..... 478

Position of milling contours ..... 478

Cutting limit ..... 479

6.2 Contours in the XY plane ..... 480

Starting point of contour in XY plane G170 Geo ..... 480

Line segment in XY plane G171 Geo ..... 480

Circular arc in XY plane G172-Geo/G173-Geo ..... 481

Hole in XY plane G370-Geo ..... 482

Linear slot in XY plane, G371-Geo ..... 483

Circular slot in XY plane G372-Geo/G373-Geo ..... 484

Full circle in XY plane G374-Geo ..... 484

Rectangle in XY plane G375-Geo ..... 485

Eccentric polygon in XY plane G377-Geo ..... 485

Linear pattern in XY plane, G471-Geo ..... 486

Circular pattern in XY plane, G472 Geo ..... 487

Single surface in XY plane G376-Geo ..... 488

Centric polygon in XY plane G477-Geo ..... 488

6.3 Contours in the YZ plane ..... 489

Starting point of contour in YZ plane G180-Geo ..... 489

Line segment in YZ plane G181-Geo ..... 489

Circular arc in YZ plane G182-Geo/G183-Geo ..... 490

Hole in YZ plane G380-Geo ..... 491

Linear slot in YZ plane, G381-Geo ..... 491

Circular slot in YZ plane G382-Geo/G383-Geo ..... 492

Full circle in YZ plane G384-Geo ..... 492

Rectangle in YZ plane G385-Geo ..... 493

Eccentric polygon in YZ plane G387-Geo ..... 493

Linear pattern in YZ plane, G481-Geo ..... 494

Circular pattern in YZ plane, G482-Geo ..... 495

Single surface in YZ plane G386-Geo ..... 496

Centric polygon in YZ plane G487-Geo ..... 496

6.4 Working planes ..... 497

Y-axis machining ..... 497

G17 XY plane (front or rear face) ..... 497

G18 XZ plane (turning) ..... 497

G19 YZ plane (lateral view / lateral surface) ..... 497

Tilting the working plane G16 ..... 498

6.5 Tool positioning in the Y axis ..... 499

Rapid traverse G0 ..... 499

Approach tool change point G14 ..... 499

Rapid traverse to machine coordinates G701 ..... 500

26

6.6 Linear and circular movements in the Y axis ..... 501

Milling: Linear movement G1 ..... 501

Milling: Circular movement G2, G3—incremental center coordinates ..... 502

Milling: Circular movement G12, G13—absolute center coordinates ..... 503

6.7 Milling cycles for the Y axis ..... 504

Area milling—roughing G841 ..... 504

Area milling—finishing G842 ..... 505

Centric polygon milling—roughing G843 ..... 506

Centric polygon milling—finishing G844 ..... 507

Pocket milling—roughing G845 (Y axis) ..... 508

Pocket milling—finishing G846 (Y axis) ..... 514

Engraving in XY plane G803 ..... 516

Engraving in the YZ plane G804 ..... 517

Thread milling in XY plane G800 ..... 518

Thread milling in YZ plane G806 ..... 519

Hobbing G808 ..... 520

6.8 Example program ..... 521

Machining with the Y axis ..... 521

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 27

7 TURN PLUS ..... 529

7.1 TURN PLUS mode of operation ..... 530

TURN PLUS concept ..... 530

7.2 Automatic working plan generation (AWG) ..... 531

Generating a working plan ..... 532

Machining sequence – Fundamentals ..... 533

Editing and managing machining sequences ..... 535

Overview of machining sequences ..... 536

7.3 AWG control graphic ..... 545

Setting the AWG control graphic ..... 545

7.4 Machining information ..... 546

Tool selection, turret assignment ..... 546

Contour recessing, recess turning ..... 547

Drilling ..... 547

Cutting data, coolant ..... 548

Inside contours ..... 548

Shaft machining ..... 551

7.5 Example ..... 553

Creating a program ..... 553

Defining the workpiece blank ..... 553

Defining the basic contour ..... 554

Defining form elements ..... 554

Preparing the machining process, chucking ..... 555

Generating and saving a working plan ..... 556

28

8 B axis ..... 557

8.1 Fundamentals ..... 558

Tilted working plane ..... 558

8.2 Compensation with the B axis ..... 561

Compensation during program run ..... 561

8.3 Simulation ..... 562

Simulation of the tilted plane ..... 562

Displaying the coordinate system ..... 562

Position display with the B and Y axes ..... 563

HEIDENHAIN MANUALplus 620, CNC PILOT 620/640 29

9 Overview of units ..... 565

9.1 Units—"Turning" group ..... 566

"Roughing" group ..... 566

"Finishing" group ..... 566

"Recessing" group ..... 567

"Thread" group ..... 567

9.2 Units—"Drilling" group ..... 568

"Centric drilling" group ..... 568

"ICP drilling, C axis" group ..... 568

"C-axis face drilling" group ..... 568

"C-axis lateral surface drilling" group ..... 569

9.3 Units—"Predrilling in C axis" group ..... 570

"Predrilling in C-axis, face" group ..... 570

"Predrilling in C-axis, lateral surface" group ..... 570

9.4 Units—"Milling in C axis" group ..... 571

"Milling in C-axis, face" group ..... 571

"Milling in C axis, face" group ..... 571

"C-axis lateral surface milling" group ..... 572

"C-axis lateral surface milling" group ..... 572

9.5 Units—"Drilling, predrilling in Y axis" group ..... 573

"ICP drilling, Y axis" group ..... 573

"Predrilling in Y axis" group ..... 573

9.6 Units—"Milling in Y axis" group ..... 574

"Milling in front face" group (XY plane) ..... 574

"Milling in lateral surface" group (YZ plane) ..... 575

9.7 Units—"Special units" group ..... 576

30

Loading...

Loading...