Graco Inc Hydra-Clean 800-907, Hydra-Clean 1040, Hydra-Clean 800-906, Hydra-Clean 800-908, Hydra-Clean 308-534 User Manual

...

INSTRUCTIONS-PARTS LIST

308–534

Rev A

This manual contains IMPORTANT

WARNINGS and INSTRUCTIONS READ

AND RETAIN FOR REFERENCE

HYDRA-CLEAN 735, 740, 1035, 1040

Pressure Washers

Model 800–906, Series A 230/460 Volt, 3 Phase, 35 GPM Model 800–908, Series A 230/460 Volt, 3 Phase, 40 GPM

700 psi (48 bar) OPERATING PRESSURE

1100 psi (75 bar) MAXIMUM WORKING PRESSURE

Model 800–907, Series A 230/460 Volt, 3 Phase, 35 GPM Model 800–909, Series A 230/460 Volt, 3 Phase, 40 GPM

1000 psi (69 bar) OPERATING PRESSURE

1300 psi (91 bar) MAXIMUM WORKING PRESSURE

Water supply tank, gun & wand assembly, hose assembly and motor starter are not included.

GRACO INC. P.O. Box 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT 1991, GRACO INC.

WARNING

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY. FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS.

Read and understand all instruction manuals before operating equipment.

FLUID INJECTION HAZARD

General Safety

This pressure washer generates very high fluid pressure. Spray from the gun, leaks or ruptured components can inject fluid through your skin and into your body and cause extremely serious bodily injury including the need for amputation. Also, fluid injected or splashed into the eyes or on the skin can cause serious damage.

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including fluid injection and splashing in the eyes or on the skin, always follow this procedure whenever you stop spraying for more than 10 minutes, when shutting down, and before checking or repairing any part of the system.

1. Engage the trigger safety latch.

NEVER point the spray gun or wand at anyone or at any part of the body .NEVER put hand or fingers over the spray tip.

ALWAYS follow the Pressure Relief Procedure, before cleaning or servicing any part of the sprayer.

NEVER try to stop or deflect leaks with your hand or body.

Be sure equipment safety devices are operating properly before each use.

Medical Treatment

If any fluid appears to penetrate your skin, get

EMERGENCY MEDICAL TREATMENT AT ONCE. DO NOT TREAT AS A SIMPLE CUT. Tell the doctor exactly what fluid was injected.

NOTE TO PHYSICIAN: Injection in the skin is a traumatic injury. It is important to treat the injury surgically as soon as possible. Do not delay treatment to research toxicity. Toxicity is a concern with some exotic coatings injected directly into the bloodstream. Consultation with a plastic surgeon or reconstructive hand surgeon may be advisable.

2.Turn the sprayer off.

3.Disconnect the electrical supply.

4.Shut off the water supply.

5.Disengage the trigger safety latch and trigger the gun to relieve pressure, and then engage the trigger safety latch again.

6.Before long–term (overnight) storage, disconnect the water supply and disconnect the electricity.

Spray Gun Safety Devices

Be sure all gun safety devices are operating properly before each use. Do not remove or modify any part of the gun; this can cause a malfunction and result in serious bodily injury.

SAFETY LA TCH: Whenever you stop spraying for a moment, always set the gun safety latch in the engaged or “safe” position, making the gun inoperative. Failure to properly set the safety latch can result in accidental triggering of the gun.

SPRAY |

TIP SAFETY: Use extreme |

caution when |

cleaning or changing spray tips. If a spray tip clogs while |

||

spraying, |

engage the gun safety latch |

immediately. |

ALWAYS follow the Pressure Relief Procedure and then remove the spray tip to clean it.

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or break down, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This equipment is equipped with a cord having an equipment–grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

|

DANGER |

|

|

|

|

|

|

|

Improper connection of the |

equipment– |

|

|

grounding conductor can result in the risk of |

||

|

electrocution. Check with a qualified electrician or |

||

|

service person if you are in doubt as to |

whether |

|

|

the outlet is properly grounded. |

|

|

|

|

|

|

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

To comply with the National Electrical Code (NFP A 70) and to provide additional protection from the risk of electric shock, connect this pressure washer to a circuit that is protected by a ground–fault circuit–interrupter (GFCI).

EQUIPMENT MISUSE HAZARD

General Safety

Any misuse of the pressure washer or accessories, such as overpressurizing, modifying parts, using incompatible chemicals and fluids, or using worn or damaged parts, can cause them to rupture and result in fluid injection, splashing in the eyes or on the skin, or other serious bodily injury, fire, explosion or property damage.

NEVER alter or modify any part of this equipment; doing so could cause it to malfunction.

CHECK all spray equipment regularly and repair or replace worn or damaged parts immediately.

ALWAYS wear protective eyewear and appropriate clothing. If using a chemical injector, read and follow the chemical manufacturer’s literature for recommendations on additional protective equipment, such as a respirator.

System Pressure

This sprayer can develop high operating pressure. Be sure that all spray equipment and accessories are rated

to withstand the maximum working pressure of this sprayer. DO NOT exceed the maximum working pressure of any component or accessory used in the system.

Chemical Compatibility

BE SURE that all chemicals used in the chemical injector are compatible with the wetted parts of the hose, gun, wand and tip, as given in the Technical Data (inside back

cover). Always read the chemical manufacturer ’s literature before using any chemical in this pressure washer.

3 8 534 3

HOSE SAFETY

High pressure fluid in the hoses can be very dangerous. If the hose develops a leak, split or rupture due to any kind of wear, damage or misuse, the high pressure spray emitted from it can cause a fluid injection injury or other serious bodily injury or property damage.

ALL FLUID HOSES MUST HA VE STRAIN RELIEFS ON BOTH ENDS. The strain reliefs help protect the hose from kinks or bends at or close to the coupling, which can result in hose rupture.

TIGHTEN all fluid connections securely before each use. High pressure fluid can dislodge a loose coupling or allow high pressure spray to be emitted from the coupling.

NEVER use a damaged hose. Before each use, check entire hose for cuts, leaks, abrasion, bulging cover , or damage or movement of the hose couplings. If any of these conditions exist, replace the hose immediately. DO NOT try to recouple high pressure hose or mend it with tape or any other device. A repaired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULL Y.Do not pull on hoses to move the pressure washer. Do not use chemicals which are not compatible with the inner tube and cover of the hose. DO NOT expose Graco hose to temperatures above 200_ F (93_ C) or below –40_ F (–40_ C).

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers or other body parts. KEEP CLEAR of moving parts when starting or operating the pressure washer.

NEVER operate the pressure washer without all guards and interlocks installed and functioning. Follow the

Pressure Relief Procedure before checking or servicing the pressure washer to prevent discharging high pressure fluid from the gun.

TERMS

WARNING or DANGER: Alerts user to avoid or correct |

NOTE: Identifies helpful procedures and information. |

conditions that could cause bodily injury. |

|

CAUTION: Alerts user to avoid or correct conditions that |

|

could cause damage to the equipment. |

|

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards—particularly the General Standards, Part 1910, and the Construction Standards, Part 1926—should be consulted.

4 3 8 534

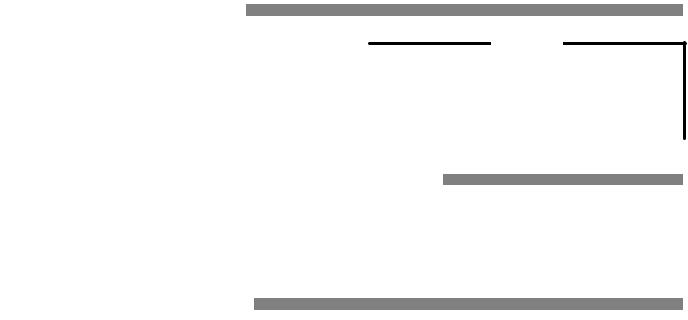

INSTALLATION

PUMP OIL

LEVEL

INDICATOR

WINDOW

HIGH |

|

PRESSURE |

|

HOSE |

PUMP DIP- |

CONNECTION |

|

2 x 1/2” NPT(f) |

STICK |

WATER |

|

CONNECTION |

|

2 x 1” NPT(f) |

|

Water supply tank, gun & wand assembly, hose assembly and motor starter are

not included.

Figure 1

Check for Shipping Damage

Check the unit for any damage that may have occurred in shipping. Notify the carrier immediately if there is any damage.

Set Up

Before connecting the unit, be sure the electrical service matches the specification in Technical Data (inside back cover) and the voltage label on the unit. With the unit off, connect the power supply cord to a grounded, GFCI–protected circuit.

If you are using a downstream chemical injector, install it between the pump unloader and the high pressure hose.

Connect the high pressure hose between the pump outlet and the gun inlet.

CAUTION

Up to 100 ft (30 m) of high pressure hose may

be used. Longer hoses may af fect sprayer performance, and chemical injector performance,

if used.

Install the appropriate spray tip on the wand. See Installing and Changing Spray T ips. If you are using a sandblaster kit, see its separate manual for installation instructions.

Connect to Water Supply CAUTION

Before attaching to the water supply, check your local plumbing code regarding cross–connection to the water supply.

A backflow preventer P/N 801–133 is available to prevent backflow of contaminated water into the fresh water supply . Install it upstream from the pump.

Install a regulating water valve, P/N 800–258, if inlet water pressure is over 60 psi (4.1 bar).

Do not exceed 160_ F (70_ C) inlet water temperature.

NOTE: The water source for the unit must have a minimum 100 gallon float valve controlled water holding tank.

3 8 534 5

STARTUP

Use this procedure whenever starting the pressure washer to help insure that the unit is ready to operate and starting is done safely.

1.Check the oil level.

Pump: Add SAE 20 or 30 weight non–detergent oil as necessary.

2.Turn on the water supply.

CAUTION

Never run the unit dry . Costly damage to the pump will result. Always be sure the water supply is completely turned on before operating.

3.Trigger the gun until water sprays from the tip indicating that the air is purged from the system.

4.Start the unit.

5.ALWAYS engage the gun’ s trigger safety whenever you stop spraying, even for a moment to reduce the risk of fluid injection or splashing in the eyes or on the skin if the gun is bumped or triggered accidentally.

6.ALWAYS observe the following CAUTIONS to avoid costly damage to the pressure washer.

CAUTION

DO NOT allow the pressure washer to idle for more than 10 minutes. Doing so may cause the recirculating water to overheat and seriously damage the pump. T urn of f the pressure washer if it will not be spraying or cleaning at least every 10 minutes. If heated inlet water is used, reduce this time further.

DO NOT run the pump dry , which will quickly damage the pump. Be sure the water supply is fully turned on before starting the pump.

DO NOT pump caustic materials; such materials may corrode the pump components.

latch

7.See the chemical injector or sandblaster kit manual for detailed cleaning information if these accessories are used.

6 3 534

Loading...

Loading...