GE Industrial Solutions EPM4500 User Manual

GE Energy

Industrial Solutions

EPM 4500

SUB METER

Instruction Manual

Manual P/N: 1601-0157-A9

Manual Order Code: GEK-106555I

Copyright © 2010 GE Energy

GE Energy

Industrial Solutions

41 Woodford Avenue

Plainville, CT 06062

Internet: http://www.geindustrial.com

Table of Contents

1: OVERVIEW |

GETTING STARTED ........................................................................................................................... |

1-1 |

|

DESCRIPTION ........................................................................................................................ |

1-1 |

|

APPLICATIONS ................................................................................................................................... |

1-2 |

|

STAND-ALONE METER ........................................................................................................ |

1-2 |

|

METERING SYSTEM .............................................................................................................. |

1-2 |

|

INTERIOR VIEW .................................................................................................................... |

1-3 |

|

CAUTIONS AND WARNINGS ............................................................................................... |

1-3 |

|

PROTECTIVE CONDUCTOR TERMINAL ............................................................................... |

1-4 |

|

PREVENTIVE MAINTENANCE ............................................................................................... |

1-4 |

|

SPECIFICATIONS ............................................................................................................................... |

1-5 |

|

MONITORING ........................................................................................................................ |

1-5 |

|

POWER SUPPLY ................................................................................................................... |

1-5 |

|

METERING ............................................................................................................................. |

1-5 |

|

INPUTS .................................................................................................................................. |

1-6 |

|

COMMUNICATIONS .............................................................................................................. |

1-6 |

|

PHYSICAL .............................................................................................................................. |

1-6 |

|

TYPE TESTS AND APPROVALS ............................................................................................ |

1-6 |

|

ORDERING ........................................................................................................................................... |

1-8 |

|

EPM4500 RESIDENTIAL .................................................................................................... |

1-8 |

|

EPM4500 COMMERCIAL ................................................................................................... |

1-8 |

|

OPTIONS ............................................................................................................................... |

1-8 |

|

CURRENT TRANSFORMERS (0.1 A SECONDARY) ............................................................. |

1-9 |

|

TRANSPONDER MODELS ..................................................................................................... |

1-9 |

|

PULSE INPUTS ...................................................................................................................... |

1-9 |

|

|

|

2: INSTALLATION |

GETTING READY ................................................................................................................................ |

2-1 |

|

DETERMINATION OF METERING SYSTEM REQUIREMENTS .............................................. |

2-1 |

|

PHASE ASSOCIATION ........................................................................................................... |

2-1 |

|

WIRING ................................................................................................................................................. |

2-2 |

|

OVERVIEW OF METER WIRING .......................................................................................... |

2-2 |

|

WIRING OVERVIEW ............................................................................................................. |

2-2 |

|

THREE-PHASE FOUR-WIRE WYE WIRING ....................................................................... |

2-3 |

|

SINGLE-PHASE, THREE-WIRE 120 V WIRING ............................................................... |

2-6 |

|

THREE-PHASE, THREE-WIRE DELTA WIRING ................................................................. |

2-9 |

|

SINGLE-PHASE, THREE-WIRE WIRING ............................................................................. |

2-12 |

|

INSTALLATION OF METER, MCI BOARD, AND CTS ............................................................. |

2-15 |

|

PROCEDURE .......................................................................................................................... |

2-15 |

|

INSTALLING THE SCAN TRANSPONDER ................................................................................. |

2-18 |

|

PROCEDURE .......................................................................................................................... |

2-18 |

|

|

|

3: USING THE METER |

MENU NAVIGATION ........................................................................................................................ |

3-1 |

|

USER INTERFACE .................................................................................................................. |

3-1 |

|

CT MULTIPLIER TABLE .................................................................................................................... |

3-4 |

|

CT MULTIPLIERS .................................................................................................................. |

3-4 |

|

VERIFYING METER FUNCTIONALITY ......................................................................................... |

3-5 |

|

OVERVIEW ............................................................................................................................ |

3-5 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

TOCTOC–I |

|

VERIFYING VOLTAGE ........................................................................................................... |

3-5 |

|

VERIFYING KWH READING ................................................................................................. |

3-5 |

|

VERIFYING CURRENT AND ENERGY ................................................................................... |

3-6 |

|

RESETTING THE DEMAND VALUES ........................................................................................... |

3-7 |

|

PROCEDURE .......................................................................................................................... |

3-7 |

|

|

|

4: COMMUNICATIONS |

MODBUS COMMUNICATIONS ..................................................................................................... |

4-1 |

|

RS485 WIRING FOR MODBUS ......................................................................................... |

4-1 |

|

RS232 WIRING FOR MODBUS ......................................................................................... |

4-2 |

|

MODBUS COMMANDS ......................................................................................................... |

4-2 |

|

FIXED MODBUS VALUES ..................................................................................................... |

4-2 |

|

MODBUS DATA REGISTER (R4 TYPE) GROUPS ................................................................ |

4-3 |

|

INSTANTANEOUS DATA ITEMS ............................................................................................ |

4-3 |

|

32-BIT LONG AND FLOAT DATA FORMATS ..................................................................... |

4-4 |

|

MODBUS ACTIVATION .................................................................................................................... |

4-5 |

|

OVERVIEW ............................................................................................................................ |

4-5 |

|

CONFIGURING A NEW HYPERTERMINAL SESSION .......................................................... |

4-5 |

|

CONFIRMING CONNECTION TO THE EPM4500 ............................................................. |

4-6 |

|

LOGGING INTO THE METER ................................................................................................ |

4-6 |

|

ACTIVATING MODBUS COMMUNICATIONS ....................................................................... |

4-7 |

|

CHANGING MODBUS SETTINGS ......................................................................................... |

4-8 |

|

LOGGING OUT ...................................................................................................................... |

4-8 |

|

DISABLING MODBUS COMMUNICATIONS ......................................................................... |

4-8 |

|

MODBUS MEMORY MAP ................................................................................................................ |

4-9 |

|

MEMORY MAP ...................................................................................................................... |

4-9 |

|

|

|

5: MISCELLANEOUS |

REVISION HISTORY .......................................................................................................................... |

5-1 |

|

RELEASE DATES ................................................................................................................... |

5-1 |

|

CHANGES TO THE MANUAL ................................................................................................ |

5-2 |

|

WARRANTY ......................................................................................................................................... |

5-4 |

|

GE ENERGY WARRANTY ..................................................................................................... |

5-4 |

TOCTOC–II |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

GE Energy

Industrial Solutions

EPM4500 Sub Meter

Chapter 1: Overview

709710A1.CDR

1.1Getting Started

1.1.1 Description

Thank you for purchasing the GE Energy EPM4500 24-point sub-meter to monitor energy for your residential, commercial, or industrial applications. At GE Energy, we pride ourselves by providing our customers with best-in-class products, which have been carefully selected by GE to best serve your solution needs.

The EPM4500 is sold in KWh or Demand meter versions and is available for 120/208V and 277/480V applications. An integrated liquid crystal display (LCD) is standard on all versions, providing local access to real-time and historical data. The meter provides two standard communication modes: power line communications (PLC), which utilizes existing AC power lines as the communication medium, eliminating dedicated wiring, and Modbus (RS232, RS485, and modem).

The EPM4500 is packaged with either solid or split-core CTs in various amperages to suit both new construction and retrofit applications.

The EPM4500 is primarily used for commercial and industrial applications and is available in voltages ranging from 120 to 600 V in both wye and delta forms. The following installation instructions are applicable to the EPM4500 meter only.

EPM 4500 SUB METER – INSTRUCTION MANUAL |

1–1 |

APPLICATIONS |

CHAPTER 1: OVERVIEW |

1.2Applications

1.2.1 Stand-Alone Meter

The GE Energy EPM4500 can be installed as a stand-alone device that is locally accessed via the LCD or remotely accessed via modem. A modem can be installed in each meter allowing the meter(s) to be read remotely.

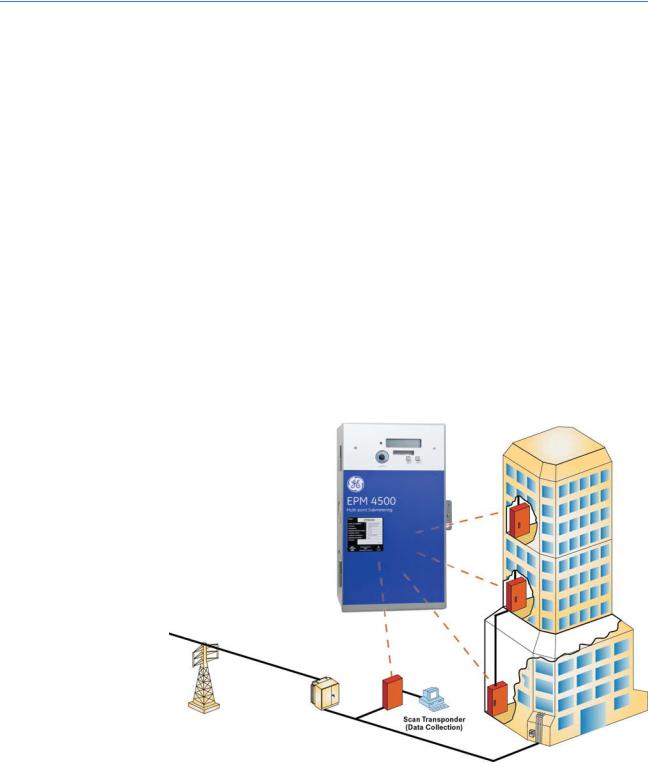

1.2.2Metering System

The GE Energy EPM4500 family of meters are ideally designed to comprise a metering system within a residential/commercial building or industrial site. This metering system can measure electrical usage for each tenant, cost center, or common area space and communicate this information over the building's power wires or dedicated communication wiring (RS485). A metering system is comprised of two or more EPM4500 meters and at least one communication transponder (see figure below). The transponder collects metering data from multiple meters via AC power lines. For larger sites, additional transponders may be required. Multiple transponders can communicate via a data link network using RS485 or via a wireless network.

The metering data can be accessed from the transponder or network of transponders using a telephone modem or local RS232 connection to a PC for data transfers.

709712A1.CDR

FIGURE 1–1: Overview of Scan Transponder Functionality

1–2 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

CHAPTER 1: OVERVIEW |

APPLICATIONS |

1.2.3Interior View

The interior of the EPM4500 is shown below.

709711A1.CDR

FIGURE 1–2: Interior View of the EPM4500

Where the  and

and  symbols are seen on the EPM4500 meter, the manual must be consulted to determine the nature of any potential hazard and/or actions to be taken.

symbols are seen on the EPM4500 meter, the manual must be consulted to determine the nature of any potential hazard and/or actions to be taken.

1.2.4Cautions and Warnings

• Do not install if the device is damaged. Inspect the housing for obvious defects such as cracks in the housing.

CAUTION |

WARNING |

• If the device is installed or used in a manner not specified by accompanying |

|

|

|

|

|

documents, the protection of the device may be impaired. |

|

|

• If the device functions abnormally, proceed with caution. The protection of the |

|

|

device may be impaired. |

|

|

• Do not install the meter around combustible gas or gas vapor. |

|

|

• Do not install the meter in an electrical service with current or voltage outside of |

|

|

the specified limit of the device. |

|

|

• Do not operate the meter with the cover removed. |

|

|

• To avoid electric shock, disconnect mains before replacing fuses! |

|

|

• See instructions for connection diagram. |

|

|

• Risk of electric shock. Beware of working around this meter when the voltage is |

|

|

live. |

|

|

• For continued protection against fire, replace only with fuses of specified voltage |

|

|

and current rating. |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

1–3 |

APPLICATIONS |

CHAPTER 1: OVERVIEW |

1.2.5Protective Conductor Terminal

Securely fasten one end of the earthing wire so that the screw cuts the paint on the back box. Securely fasten other end of the wire to a true earth ground connection. When earthing to the electrical conduit, use continuous pipes, bending when necessary instead of using couplers.

1.2.6Preventive Maintenance

There are no necessary preventative maintenance or inspection.

A Toshiba CR2032 coin battery is used in each device and is intended to be good for decades before replacement. Return to manufacturer for replacement.

1–4 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

CHAPTER 1: OVERVIEW |

SPECIFICATIONS |

1.3Specifications

1.3.1 Monitoring

DEMAND

|

Consumption and demand: ..................... |

kW and kWh |

|

Demand reset: ................................................. |

allows local reset of peak demand register |

|

INTERVAL DATA AND PEAK DEMAND |

|

|

Commercial:...................................................... |

15 minute block demand interval and peak demand with |

|

|

date and time stamp |

|

Residential: ........................................................ |

1 hour block demand interval |

|

DATA LOGGER |

|

|

Duration:............................................................. |

120 days with kW and kWh |

|

Battery:................................................................ |

internal battery maintains time and current interval |

|

|

metering data during power outage only |

1.3.2 |

Power Supply |

|

|

CONTROL POWER |

|

|

Input: .................................................................... |

120 V phase A to neutral |

|

|

277 V phase A to neutral |

|

|

480 V phase to phase |

|

|

(internally powered through metered voltage; no external |

|

|

source is required) |

|

Frequency:......................................................... |

50 to 60 Hz |

|

Operating power: ........................................... |

2 watts for 120 V |

|

|

5 watts for 277 V and 480 V |

|

Fuses:................................................................... |

1 - Buss fuse 250 V / 500 V 0.25 A / 0.125 A slow-acting |

|

|

3 - Buss fuse 250 V /600 V 4.0 A fast-acting |

1.3.3 |

Metering |

|

|

MEASURED VALUES |

|

|

Real time per phase:..................................... |

voltage, current, kW, kvar, kVA, power factor, frequency, |

|

|

phase angle |

|

Data logging:.................................................... |

kWh, kW demand |

|

METER ACCURACY |

|

|

Accuracy: ........................................................... |

0.5 class accuracy |

|

|

±0.5% unity and 50% power factor, 1 to 100% of full- |

|

|

scale |

|

Standards: ......................................................... |

meets revenue certifiable ANSI C12.1 and C12.16 |

|

|

accuracy standards |

|

LIQUID CRYSTAL DISPLAY (LCD) |

|

|

Display size:....................................................... |

32-digit LCD, 16 digits in two rows |

|

Data digit height:............................................ |

0.31" |

|

Consumption register: ................................. |

6 digits |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

1–5 |

SPECIFICATIONS |

CHAPTER 1: OVERVIEW |

1.3.4Inputs

AC CURRENT INPUTS

|

CT input:.............................................................. |

50 to 800 A primary available |

|

Secondary inputs: .......................................... |

0.1 A or 5 A |

|

AC VOLTAGE INPUTS |

|

|

Metered voltage:............................................. |

120/208 V wye, 277/480 V wye, or 600 V delta |

|

|

at 50 to 60 Hz |

|

Rated voltage:.................................................. |

90 to 110% |

|

PULSE INPUTS |

|

|

Inputs: .................................................................. |

up to 48 form-A pulse inputs logged in programmable |

|

|

intervals also count during power outage |

|

Minimum wire gauge:................................... |

20 AWG |

|

Maximum wire length: ................................. |

300 ft. |

|

Maximum rate: ................................................ |

5 transitions/second |

|

Minimum pulse width:.................................. |

100 ms |

1.3.5 |

Communications |

|

|

EPM4500 COMMUNICATIONS |

|

|

Protocols:............................................................ |

Power line communications (PLC) |

|

|

RS485 Modbus (2-wire, half-duplex, isolated) |

|

Ports: .................................................................... |

IEC front optical point-of-access (POA) port |

1.3.6 |

Physical |

|

|

ENVIRONMENT |

|

|

Usage:.................................................................. |

For indoor use only |

|

Enclosure:........................................................... |

NEMA 1 rated |

|

Temperature:.................................................... |

–20°C to +60°C |

|

Humidity: ............................................................ |

0 to 95% relative humidity (non-condensing) |

|

Pollution degree:............................................. |

1 |

|

Maximum altitude:......................................... |

2000 m |

|

DIMENSIONS |

13.5"H × 8.5"W × 4.5"D |

|

Meter enclosure: ............................................. |

|

|

CT terminal board enclosure: 13.5"H × 8.5"W × 4.5"D |

|

|

SHIPPING |

|

|

Shipping weight: ............................................. |

1 meter assembly 34 lbs. (total weight) |

|

Shipping dimensions: ................................... |

2 enclosures, each 13.5"H × 8.5"W × 4.5"D |

1.3.7 Type Tests and Approvals |

|

|

|

TYPE TESTS |

|

|

Transient/surge suppression: ANSI C37.90.1-1989 |

|

|

Installation category:.................................... |

III. This product falls under Installation Category III |

|

|

because of its distribution level, fixed installation and has |

|

|

smaller transient overvoltages than an Installation |

|

|

Category IV. |

1–6 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

CHAPTER 1: OVERVIEW |

SPECIFICATIONS |

APPROVALS

ANSI: ..................................................................... |

C12.1 and C12.16 accuracy |

UL and CUL: ...................................................... |

recognized under E204142 |

Industry Canada:............................................ |

MC#AE-1148 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

1–7 |

ORDERING |

CHAPTER 1: OVERVIEW |

1.4Ordering

1.4.1 Enclosure

Step 1: Select Enclosure

Family |

Back Box |

Voltage |

Options |

Description |

|

|

|

|

|

PL4500 |

BBA |

* |

* |

Back Box Assembly |

|

|

120V |

|

120/208V 3 phase, 4 wire |

|

|

|

|

|

|

|

208V |

|

208V 3 phase 3 wire |

|

|

240V |

|

120/240V, 1 phase, 3 wire |

|

|

|

|

|

|

|

277V |

|

277/480V 3 phase, 4 wire |

|

|

347V |

|

347/600V 3 phase, 4 wire |

|

|

|

|

|

|

|

480V |

|

480V 3 phase 3 wire |

|

|

|

E |

Future Communications Provision |

|

|

|

|

|

1.4.2EPM 4500 Residential

The EPM 4500 residential package is available in single-phase 120/208 V or 120/240 V connections. Residential use measures kWh only (no demand measurement).

Step 2: Select required meter head

Residential

Family |

Voltage |

Phase |

Wires |

Application |

Metering Points |

CTs |

Options |

Description |

|

|

|

|

|

|

|

|

|

PL4500 |

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

|

|

|

|

|

|

|

120 |

3 |

4 |

R |

|

|

|

120/208V 3 phase, 4 wire |

|

|

|

|

|

03 |

|

|

3 Points |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

06 |

|

|

6 Points |

|

|

|

|

|

09 |

|

|

9 Points |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

12 Points |

|

|

|

|

|

24 |

|

|

24 Points |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

0.1 Amps Secondary Input |

|

|

|

|

|

|

H |

|

5 Amps Secondary Input |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

Pulse Data Input Module |

|

240 |

1 |

3 |

R |

|

|

|

120/240V, 1 phase, 3 wire |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

12 Points |

|

|

|

|

|

24 |

|

|

24 Points |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

0.1 Amps Secondary Input |

|

|

|

|

|

|

H |

|

5 Amps Secondary Input |

|

|

|

|

|

|

|

P |

Pulse Data Input Module |

|

277 |

|

|

|

|

|

|

277/480V 3 phase, 4 wire |

|

347 |

|

|

|

|

|

|

347/600V 3 phase, 4 wire |

|

|

3 |

4 |

R |

24 |

L |

|

24 points, 0.1 secondary CTs |

1.4.3EPM 4500 Commercial 4-Wire

The EPM 4500 commercial package is available in three-phase 120/208 V, 277/480 V, or 347/600 V connections (delta optional). Commercial use measures kWh and kW demand.

Commercial 4-Wire

Family |

Voltage |

Phase |

Wires |

Application |

Metering Points |

CTs |

Options |

Description |

|

|

|

|

|

|

|

|

|

PL4500 |

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

|

|

|

|

|

|

|

120 |

|

|

|

|

|

|

120/208V 3 Phase |

|

277 |

|

|

|

|

|

|

277/480V 3 Phase |

|

|

|

|

|

|

|

|

|

|

347 |

|

|

|

|

|

|

347/600V 3 Phase |

|

|

3 |

4 |

C |

|

|

|

3 Phase 4 wire Commercial |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

06 |

|

|

6 Points |

|

|

|

|

|

08 |

|

|

8 Points |

|

|

|

|

|

|

L |

|

0.1 Amps Secondary Input |

|

|

|

|

|

|

H |

|

5 Amps Secondary Input |

|

|

|

|

|

|

|

P |

Pulse Data Input Module |

|

|

|

|

|

|

|

M |

Modem |

|

|

|

|

|

|

|

RS |

RS485 Connection |

|

|

|

|

|

|

|

MOD |

Modbus Communication |

1–8 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

CHAPTER 1: OVERVIEW |

ORDERING |

1.4.4EPM 4500 Commercial 3-Wire

Commercial 3-Wire

Family |

Voltage |

Phase |

Wires |

Application |

Metering Points |

CTs |

Options |

Description |

|

|

|

|

|

|

|

|

|

PL4500 |

* |

* |

* |

* |

* |

* |

* |

|

|

208 |

|

|

|

|

|

|

208V 3 phase 3 wire |

|

|

|

|

|

|

|

|

|

|

480 |

|

|

|

|

|

|

480V 3 phase 3 wire |

|

|

3 |

3 |

C |

12 |

|

|

12 points |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

0.1 Amps Secondary Input |

|

|

|

|

|

|

|

P |

Pulse Data Module |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M |

Modem |

|

|

|

|

|

|

|

RS |

RS485 Connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOD |

Modbus Communication |

1.4.5Current Transformers (0.1 A Secondary)

CTs

Type |

Description |

Cat. No. |

|

|

|

|

|

|

CT-50 (50/0.1A) |

PLSUBCTSL050 |

|

Solid Core - 0.1 A Secondary |

CT-1 (100/0.1A) |

PLSUBCTSL101 |

|

CT-2 (200/0.1A) |

PLSUBCTSL201 |

||

|

|||

|

CT-4 (400/0.1A) |

PLSUBCTSL401 |

|

Solid Core - Canadian |

CT-2/5DARL (200A/5A) |

PLSUBCTSL201CDN |

|

|

CTSP-50 (50/0.1A) |

PLSUBCTSP050 |

|

|

|

|

|

|

CTSP-1 (100/0.1A) |

PLSUBCTSP101 |

|

|

CTSP-2 (200/0.1A) |

PLSUBCTSP201 |

|

|

|

|

|

|

CTSP-4 (400/0.1A) |

PLSUBCTSP401 |

|

Split Core - 0.1 A Secondary |

CTSP-8 (800/0.1A) |

PLSUBCTSP801 |

|

|

CTSP-12 (1200/0.1A) |

PLSUBCTSP1201 |

|

|

CTSP-20 (2000/0.1A) |

PLSUBCTSP2001 |

|

|

|

|

|

|

CTSP-30 (3000/0.1A) |

PLSUBCTSP3001 |

|

|

CTSP-40 (4000/0.1A) |

PLSUBCTSP4001 |

|

|

|

|

1.4.6Transponder Models

To order: Select Back Box, then select transponder model with options.

1. Order Back Box

Description |

Cat. No. |

120V service back box |

TRANS BBA 120V |

|

|

277V service back box |

TRANS BBA 277V |

347V service back box |

TRANS BBA 347V |

2. Order Transponder Model with options

Description |

Cat. No. |

|

|

120/208V with modem |

TRANS120M |

120/208V with RS485 and RS2332 connections |

TRANS120RS |

|

|

277/480V with modem |

TRANS277M |

277/480V with RS485 and RS232 connections |

TRANS277RS |

|

|

347/600V with modem |

TRANS347M |

347/600V with RS485 and RS 232 connections |

TRANS347RS |

|

|

1.4.7Pulse Inputs

The order codes for the pulse inputs are indicated below.

Cat. No.

PL4500PULSINA

PL4500PULSINB

PL4500PULSINC

PL4500PULSIND

For additional information on pulse inputs, please contact GE Energy.

EPM 4500 SUB METER – INSTRUCTION MANUAL |

1–9 |

ORDERING |

CHAPTER 1: OVERVIEW |

1–10 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

GE Energy

Industrial Solutions

EPM4500 Sub Meter

Chapter 2: Installation

709710A1.CDR

2.1Getting Ready

2.1.1 Determination of Metering System Requirements

Determine if the application is for a metering system or for a stand-alone meter. If the application is for a stand-alone meter, please read Overview of Meter Wiring on page 2–2. If the application is for a metering system, then also read Installing the Scan Transponder on page 2–18.

2.1.2Phase Association

As shown in Table 2–1: Wiring Diagram / Model Reference on page 2–3, there are four wiring types for the EPM4500 meter. Each wiring type has a specific phase association table to ensure that current transformers are in-phase with the reference voltage. These phase association tables must be followed for the meter to function properly with the chosen wiring type.

The phase association of the current transformers must be followed or meter will not be installed correctly.

EPM 4500 SUB METER – INSTRUCTION MANUAL |

2–1 |

WIRING |

CHAPTER 2: INSTALLATION |

2.2Wiring

2.2.1 Overview of Meter Wiring

Although this document treats the installation and certification stages separately, this does not imply that the recommended procedure is to install the entire system at once and then proceed to certification.

The recommended procedure is to install and certify the system in stages. By doing this, systematic error can be corrected before it propagates through the entire installation. To follow the recommended procedure, divide the job up into manageable stages and install and certify at each stage before proceeding to the installation of the next stage.

For the purposes of this discussion, the colors black, red and blue have been chosen to distinguish among the three phases of a three-phase network. White is the designated color of neutral and green is the color of earth ground. Please substitute the correct color according to local electrical code. For a two-phase installation, ignore the third phase (the blue phase in the following description).

Failure to follow the proper procedures and reference the correct wiring diagram can result in damage to the equipment and/or physical harm.

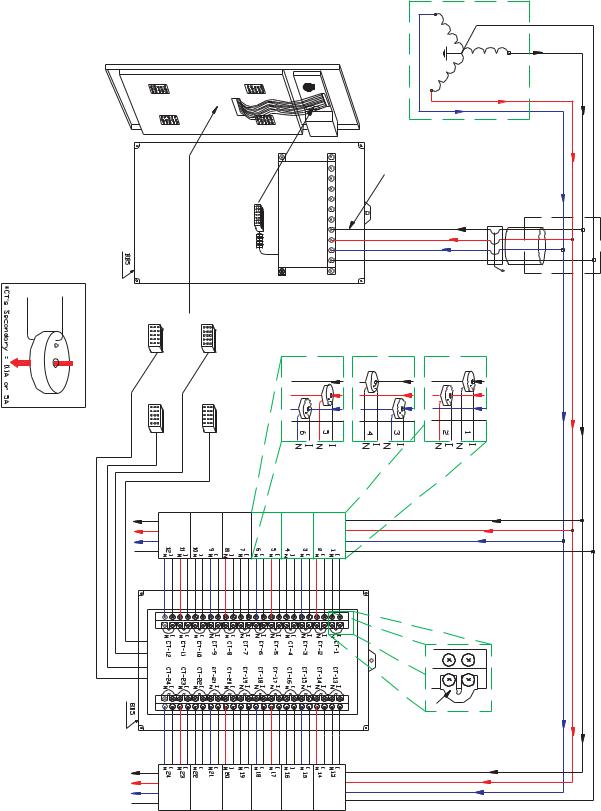

709714A1.CDR

FIGURE 2–1: Vertical Mounting Option

2.2.2Wiring Overview

Review the following wiring types and select the one that matches your installation requirements and part number using the following table.

2–2 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

CHAPTER 2: INSTALLATION |

WIRING |

Table 2–1: Wiring Diagram / Model Reference

Section

Three-Phase Four-Wire Wye Wiring on page 2–3

Single-Phase, Three-Wire 120 V Wiring on page 2–6

Three-Phase, Three-Wire Delta Wiring on page 2–9

Single-Phase, Three-Wire Wiring on page 2–12

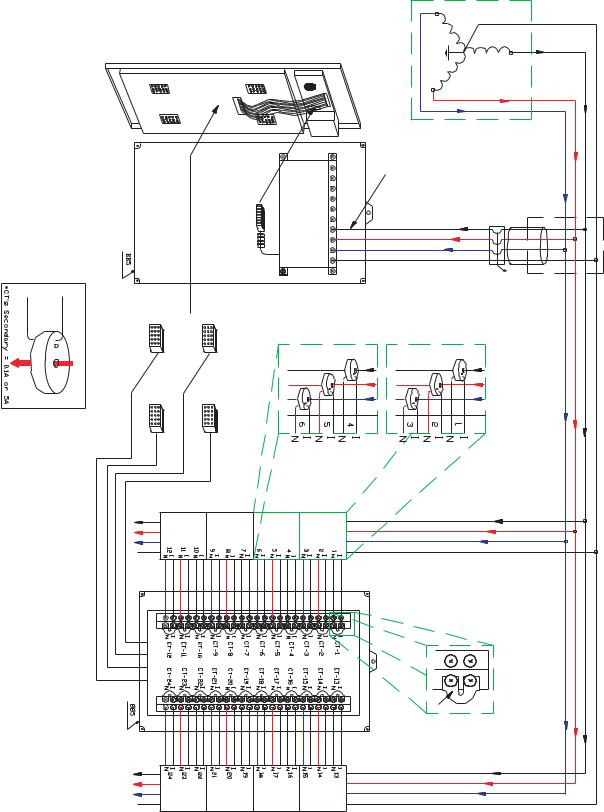

2.2.3Three-Phase Four-Wire Wye Wiring

The phase association and polarity of the current transformers must be followed or the meter will not be correctly installed.

1.Current transformers must be in-phase with the reference voltage. The MCI board runs in an A-B-C phase rotation (see table below) and each of the three CT connections repeat an A-B-C order.

For example, a current transformer installed in-phase with reference voltage A must be installed on CT1, CT4, CT7, etc. Current transformers installed in-phase with reference voltage B must be installed on CT2, CT5, CT8, etc. Likewise, current transformers installed in-phase with reference voltage C must be installed on CT3, CT6, CT9, etc.

2.For the “C” or commercial 3-phase/4-wire model, each A-B-C combination is a single meter point (see the following table for full listing). That is,

3.– Meter 1 (M#1) is CT1, CT2, and CT3

–Meter 2 (M#2) is CT4, CT5, and CT6

–Repeated for M#3 to M#8

4.After completing all current transformer terminations, connect four (4) current connectors and then remove the twenty-four (24) shorting links.

5.Follow all local codes for installation requirements; e.g. conduit, fused disconnect, distance, and wiring.

6.Installation of “L” (0.1 A inputs) and “H” (CL10 or 5A inputs) are the same. For 6 point models, use meter points M#1 to M#6; M#7 and M#8 are not functional.

If breakers are energized, shorting links must be installed before:

1.disconnecting the CT headers

2.replacing or installing meter heads on the panel.

Bodily injury may result if shorting links are not installed!

EPM 4500 SUB METER – INSTRUCTION MANUAL |

2-3 |

WIRING |

CHAPTER 2: INSTALLATION |

Table 2–2: Phase Association Table for 3-Phase 4-Wire Wye Wiring

Mete |

MCI Board CT |

Voltage |

r |

|

Phase |

|

|

|

|

|

|

|

1 |

A |

|

|

|

1 |

2 |

B |

|

|

|

|

3 |

C |

|

|

|

|

4 |

A |

|

|

|

2 |

5 |

B |

|

|

|

|

6 |

C |

|

|

|

|

7 |

A |

|

|

|

3 |

8 |

B |

|

|

|

|

9 |

C |

|

|

|

|

10 |

A |

|

|

|

4 |

11 |

B |

|

|

|

|

12 |

C |

|

|

|

Mete |

MCI Board CT |

Voltage |

r |

|

Phase |

|

|

|

|

|

|

|

13 |

A |

|

|

|

5 |

14 |

B |

|

|

|

|

15 |

C |

|

|

|

|

16 |

A |

|

|

|

6 |

17 |

B |

|

|

|

|

18 |

C |

|

|

|

|

19 |

A |

|

|

|

7 |

20 |

B |

|

|

|

|

21 |

C |

|

|

|

|

22 |

A |

|

|

|

8 |

23 |

B |

|

|

|

|

24 |

C |

|

|

|

2–4 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

CHAPTER 2: INSTALLATION |

WIRING |

BK/RD/BL |

WHITE |

|

|

Dot |

LINE |

H1 |

|

SOURCE |

orlinethetowards .source |

pointshouldH1orDot |

PhasingCT.3Diagram |

|

|

. |

CDR.709701A3

Header CT Header CT

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

N |

A |

Load |

|

Neutral |

|

|

|

|

|

Power Source |

|

|

|

Phase |

|

|

CT3 |

|

|

|

|

|

|

A |

CT4 |

|

|

MC |

B |

Load |

|

(ØA) |

||

|

|

|

|

|

|||||

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

5 |

Load |

|

|

|

Phase |

|

|

|

|

|

|

|

|

||

CT2 |

|

CT1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

toHeaderCTConnect meterhead |

HeaderPower |

120/208V 277/480V 347/600V |

ØBØANCIC NB IB NA IA |

|

VoltageReference |

RECOMMENDED: SwitchDisconnectService OnlyActing Fast15A |

Conduit |

(ØC)CPhase |

(ØB) |

|

|

|

|

|

BK |

|

|

|

|

|

|

|

|

|

RD |

|

|

|

|

|

Ferrite Beads |

|

NØC |

|

BL |

|

|

|

|

|

|

|

WH |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

CT4To CT2To |

HeaderCT |

CT3To CT1To |

installedTransformersCurrent.1Diagram .panelbreakertenantinside |

WHBLRD BK |

BL |

WH |

RD |

WH |

ØABK |

WH |

HeaderCT |

||||||||||

|

|

|

|

|

|

|

Meter |

#2 |

|

|

|

|

|

|

|

|

|

ØB |

|

|

|

|

|

|

|

|

ØC |

|

|

|

|

|

Meter #4 |

|

Meter #3 |

Meter #2 |

Meter #1 |

||||||

TENANT BREAKER PANEL |

|

|||||||||

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH WH |

WH |

BL |

BK RD |

|

BL |

RD |

BK |

BL |

BK RD |

BL |

RD |

BK |

WH BL RD BK

|

|

Meter #1 |

|

||

|

|

|

|

ØA |

|

|

|

ØB |

|

|

|

ØC |

|

|

|

|

|

BL |

WH |

RD |

WH |

BK |

WH |

BK

RD

BL

WH

be must (CT) Transformers Current - CRITICAL installation CT for 1 Diagram See .correctly installed polarity CT for 3 Diagram See .point meter each for .relationships Association Phase for 1 Table and

BL |

BK |

RD |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

INTERFACEMCI |

forNotesInstallation |

Shorting.2Diagram |

WH BK RD BL |

WH |

.details |

See.Links |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Shorting Links |

|

|

BL |

RD |

BK |

BL |

RD |

BK |

BL |

RD |

BK |

BL |

RD |

BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BK |

|

|

TENANT BREAKER PANEL |

|

RD |

|

|

||||||||||

|

BL |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Meter #8 |

Meter #7 |

Meter #6 |

Meter #5 |

WH |

|

|

||||||||

|

|

|

||||||||||||

FIGURE 2–2: 3-Phase 4-Wire Wye Wiring

Panel Breaker Tenant

EPM 4500 SUB METER – INSTRUCTION MANUAL |

2–5 |

WIRING |

CHAPTER 2: INSTALLATION |

2.2.4Single-Phase, Three-Wire 120 V Wiring

The phase association and polarity of the current transformers must be followed or the meter will not be correctly installed.

1.Current transformers must be in-phase with the reference voltage. The MCI board runs in an A-B-C phase rotation (see table below) and each of the three CT connections repeat an A-B-C order.

For example, a current transformer installed in-phase with reference voltage A must be installed on CT1, CT4, CT7, etc. Current transformers installed in-phase with reference voltage B must be installed on CT2, CT5, CT8, etc. Likewise, current transformers installed in-phase with reference voltage C must be installed on CT3, CT6, CT9, etc.

2.For the “R” or residential 3-phase/3-wire model, each A-B, C-A, and B-C combination is a single meter point (see the table below for full listing). That is,

3.– Meter 1 (M#1) is CT1 and CT2

–Meter 2 (M#2) is CT3 and CT4

–Repeated for M#3 to M#12

4.After completing all current transformer terminations, connect four (4) current connectors and then remove the twenty-four (24) shorting links.

5.Follow all local codes for installation requirements; e.g. conduit, fused disconnect, distance, and wiring.

6.Installation of “L” (0.1 A inputs) and “H” (CL10 or 5 A inputs) are the same. For the 3, 6 and 9 point models, use meter points M#1 to M#3, M#1 to M#6, and M#1 to M#9, respectively. M#4 to M#12, M#7 to M#12, and M#10 to M#12 are not functional for the 3, 6 and 9 point models, respectively.

If breakers are energized, shorting links must be installed before:

1.disconnecting the CT headers

2.replacing or installing meter heads on the panel.

Bodily injury may result if shorting links are not installed!

2-6 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

CHAPTER 2: INSTALLATION |

WIRING |

Table 2–3: Phase Association Table for 1-Phase 3-Wire 120 V Wiring

Meter |

MCI Board CT |

Voltage |

|

|

|

Phase |

|

|

|

|

|

|

|

|

|

1 |

1 |

A |

|

|

|

||

2 |

B |

||

|

|||

|

|

|

|

2 |

3 |

C |

|

|

|

||

4 |

A |

||

|

|||

|

|

|

|

3 |

5 |

B |

|

|

|

||

6 |

C |

||

|

|||

|

|

|

|

4 |

7 |

A |

|

|

|

||

8 |

B |

||

|

|||

|

|

|

|

5 |

9 |

C |

|

|

|

||

10 |

A |

||

|

|||

|

|

|

|

6 |

11 |

B |

|

|

|

||

12 |

C |

||

|

|||

|

|

|

Meter |

MCI Board CT |

Voltage |

|

|

|

Phase |

|

|

|

|

|

|

|

|

|

7 |

13 |

A |

|

|

|

||

14 |

B |

||

|

|||

|

|

|

|

8 |

15 |

C |

|

|

|

||

16 |

A |

||

|

|||

|

|

|

|

9 |

17 |

B |

|

|

|

||

18 |

C |

||

|

|||

|

|

|

|

10 |

19 |

A |

|

|

|

||

20 |

B |

||

|

|||

|

|

|

|

11 |

21 |

C |

|

|

|

||

22 |

A |

||

|

|||

|

|

|

|

12 |

23 |

B |

|

|

|

||

24 |

C |

||

|

|||

|

|

|

EPM 4500 SUB METER – INSTRUCTION MANUAL |

2–7 |

WIRING |

CHAPTER 2: INSTALLATION |

BK/RD/BL |

WHITE |

|

|

Dot |

LINE |

H1 |

|

SOURCE |

orlinethetowards .source |

pointshouldH1orDot |

PhasingCT.3Diagram |

|

|

. |

CDR.709722A1

Header CT Header CT

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

A |

|

|

Load |

|

Neutral |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Source |

Power |

|

|

|

|

|

|

|

Phase |

|

CT4 |

|

|

|

CT3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

(ØA) |

|

|||

|

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

Load |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

MC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

Load |

|

|

|

|

|

|

|

Phase |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

CT2 |

|

|

|

CT1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

ØAØBNØCNCIC NB IB NA IA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

meterhead |

toHeaderCTConnect |

|

Beads |

Ferrite |

|

347/600V |

277/480V |

120/208V |

|

|

|

|

VoltageReference |

|

|

|

|

|

|

|

OnlyActingFast15A |

SwitchDisconnectService |

RECOMMENDED: |

|

|

|

(ØC)CPhase |

(ØB) |

PanelBreakerTenant |

|

|

|

|

Power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Header |

|

|

|

|

|

|

|

|

|

|

|

BK |

|

|

|

|

|

|

|

|

|

|

Conduit |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CT4To CT2To |

|

CT3To CT1To |

|

.panelbreakertenantinside |

installedTransformersCurrent.1Diagram |

|

|

|

|

|

|

|

|

|

|

WH |

|

|

|

|

|

|

|

.relationshipsAssociationPhasefor1Tableand |

polarityCTfor3DiagramSee.pointmetereachfor |

installationCTfor1DiagramSee.correctlyinstalled |

bemust(CT)TransformersCurrent- CRITICAL |

|

|

|

HeaderCT |

|

WH |

ØCBL |

WH |

RD |

WH |

WHBLRD |

ØABK |

WH |

BL |

WH |

WHBKBLRD |

RD |

WH |

BK |

WH |

|

|

|

WH BK RD BL |

|

|||||||||

|

Header CT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Meter #3 |

|

Meter #2 |

Meter #1 |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

BL RD BK |

|

|

ØB |

|

BK |

|

|

ØC |

|

|

ØB |

|

ØA |

|

|

|

|

|

|

|

|

|

|

|

Meter #6 |

Meter #5 |

Meter #4 |

Meter #3 |

Meter #2 |

Meter #1 |

BK |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

TENANT BREAKER PANEL |

|

RD |

||||||||||

|

BL |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

WH |

|

BL |

RD |

BK |

BL |

RD |

BK |

BL |

RD |

BK |

BL |

RD |

BK |

|

WH |

WH |

WH |

WH |

WH WH |

WH |

WH |

WH |

WH |

WH |

INTERFACEMCI |

forNotesInstallation |

Shorting.2Diagram |

WH BK RD BL |

WH |

.details |

See.Links |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

Shorting Links |

|

|

BL |

RD |

BL BK |

RD |

BK |

BL |

RD |

BK |

BL |

RD |

BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BK |

|

|

TENANT BREAKER PANEL |

|

RD |

|

|

|||||||||

|

BL |

|

|

||||||||||

Meter #12 |

Meter #11 Meter #10 |

Meter #9 |

Meter #8 |

Meter #7 |

WH |

|

|

||||||

|

|

|

|||||||||||

FIGURE 2–3: 1-Phase 3-Wire 120 V Wiring (Network)

2–8 |

EPM 4500 SUB METER – INSTRUCTION MANUAL |

CHAPTER 2: INSTALLATION |

WIRING |

2.2.5Three-Phase, Three-Wire Delta Wiring

The phase association and polarity of the current transformers must be followed or the meter will not be correctly installed.

1.Current transformers must be in-phase with the reference voltage. The MCI board runs in an A-C phase rotation (see table below) and every two CT connections repeat an A-C order.

For example, a current transformer installed in-phase with reference voltage A must be installed on CT1, CT3, CT5, etc. Current transformers installed in-phase with reference voltage C must be installed on CT2, CT4, CT6, etc.

2.For the “C” or commercial 3-phase/3-wire model, each A-C combination is a single meter point (see the table below for full listing). That is,

–Meter 1 (M#1) is CT1 and CT2

–Meter 2 (M#2) is CT3 and CT4

–Repeated for M#3 to M#12

3.After completing all current transformer terminations, connect four (4) current connectors and then remove the twenty-four (24) shorting links.

4.Follow all local codes for installation requirements; e.g. conduit, fused disconnect, distance, and wiring.

5.Installation of “L” (0.1 A inputs) and “H” (CL10 or 5 A inputs) are the same.

If breakers are energized, shorting links must be installed before:

1.disconnecting the CT headers

2.replacing or installing meter heads on the panel.

Bodily injury may result if shorting links are not installed!

EPM 4500 SUB METER – INSTRUCTION MANUAL |

2–9 |

Loading...

Loading...