GE Industrial Solutions E9000 User Manual

imagination at work

GE Energy

Industrial Solutions

Evolution Series E9000

Motor Control Centers

Installation & Maintenance Guide

DEH-40472 Rev. 05

Evolution Series E9000 Installation & Maintenance Guide

Contents

Warnings, Cautions & Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Description – Vertical Section Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Description – Motor Control Center Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Description – Motor Control Center Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Receiving, Handling & Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation of Bottom Entry Conduits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Preparation of Flooring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Positioning and Joining Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Bus Splicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bus Splice Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

NEC Work Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation of Top Entry Conduits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Equipment Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Main Incoming Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Individual Unit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring NEMA Type A Motor Control Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring NEMA Type B Motor Control Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring NEMA Type C Motor Control Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring Between Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation of Motor Control Center Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Removal of Draw-out Motor Control Center Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating Handles, Door Interlocks and Padlocking Provisions . . . . . . . . . . . . . . . . . . . . . . . 14

Operating Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pilot Bracket and Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

NEMA 3R Outdoor Enclosure Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Preparing for Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Initial Operation of the Motor Control Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Door Closing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Equipment Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Control Power Fusing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Suggested Maintenance Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacing or Adding Breaker Accessories to Plug-in E or F Frame Circuit Breaker . . . . . 21

Replacing a Control Power Transformer Mounted Under Disconnect . . . . . . . . . . . . . . . . . 21

Replace a Compact Starter (1/2 X) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Suggested Lifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Publications Available from GE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ordering Additional or Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Other Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6. Overload Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Heaters for Ther-Mag Circuit Breaker Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Heaters for Mag-Break Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Heaters for Fused Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Heaters for Size 6 and 7 Fused Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Electronic Overload for Circuit Breaker and Fused Controllers . . . . . . . . . . . . . . . . . . . . . . . . 33

1

DEH–40472

Warnings, Cautions & Notes

As Used In This Publication

WARNINGS

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or other conditions that could cause personal injury are present in this equipment or may be associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge could

cause either personal injury or damage to equipment.

CAUTIONS

Caution notices are used for situations in

which equipment might be damaged if care

is not taken.

NOTES

Notes call attention to information that is

especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts have been made to ensure accuracy, the information contained herein

does not cover all details or variations in hardware and software, nor does it provide for every possible contingency in connection with installation, operation, and

maintenance. Features may be described herein that are not present in all hardware and software systems. GE Energy assumes no obligation of notice

to holders of this document with respect to changes subsequently made.

GE Energy makes no representation or warranty, expressed, implied, or statutory, with respect to, and assumes no responsibility for the accuracy, completeness,

sufficiency, or usefulness of the information contained herein. No warrantees of merchantability or fitness for purpose shall apply.

© Copyright 2010 General Electric Company

All Rights Reserved

2

Evolution Series E9000 Installation & Maintenance Guide

Chapter 1 – Introduction

This publication provides guidelines for installation and

maintenance of Evolution Motor Control Centers, as

shown in Figure 1. The information provided does not

cover all details or variations in this product offering,

nor does it address all possible contingencies to be

met in connection with installation, operation, or maintenance. Should further information be desired, contact

GE Field Service Administration:

Call GE–RESOLve

1-888-437-3765

Refer to the GE requisition number found on the front

of the equipment when calling for assistance.

Disconnect equipment from all electrical

services before performing any installation

or maintenance work.

For additional information, including safety considerations for personnel working on this product, see NEMA

Standard Publication No. ICS 2.3, Instructions on the

Handling, Installation, Operation, and Maintenance of

Motor Control Centers.

General Description –

Vertical Section Enclosures

Each Evolution MCC vertical section is assembled with

two full-side sheets having openings near the top and

bottom for lateral busing and wiring between sections.

Multiple sections are joined together at the factory in

three-section (maximum) shipping splits. Each shipping

split is provided with continuous floor sills and a lifting

angle. Floor sills and lifting angles are field removable.

Each shipping split includes a continuous non-removable

main horizontal bus. Main bus splice bars are provided

within each shipping split for field connecting main

busses. Refer to motor control center outline drawings

furnished by the General Electric Company for location of

shipping splits within each motor control center lineup.

Vertical sections are normally provided with a top (12"

high) horizontal wireway and a bottom (6" high) horizontal

wireway. Each vertical section is also provided with a

vertical (4" wide) wireway. Hinged doors are provided

over horizontal and vertical wireways. (These doors can

be removed by extracting the hinge pins inside the doors.)

To open the external doors, rotate the

latches 90° counter-clockwise until the

screwdriver slots are vertical.

Secure Open

Because of the great variety of motor controller

assemblies and components provided within industrial

motor control centers and to satisfy floor-space limitations

at installation sites, a large variety of vertical section

dimensions are provided, as follows:

• Section Height: 90”, 78”, 66” etc.

• Section Width: 20”, 24”, 30” etc.

• Section Depth: 13”, 20”, 22” or deeper

for large assemblies.

Refer to motor control center drawings

furnished by GE before performing any

field-installation work.

Figure 1. Evolution Series three-section lineup.

3

Evolution Series E9000 Installation & Maintenance Guide

General Description –

Motor Control Center Buses

The main horizontal power bus is located at the top of

the vertical section. The bus bolted joints are accessible

from the front by loosening the barrier mounting screws

and sliding the Lexan

the main bus. Figure 2 shows a horizontal power bus

with its Lexan barrier. Figure 3 shows the bus barrier

mounting slots and screw.

The vertical bus, either 300A or 600/850 A, is connected

with two bolts per phase to the main bus. The phase

relationship is A–B–C from top to bottom and left to

right, as viewed from the front.

A continuous horizontal ground bus, sized in accordance

with the National Electrical Code, is provided near the

bottom of all motor control centers.

A optional vertical ground bus can be provided in each

section providing additional grounding. A neutral bus is

provided, when specified, in the bottom of the incoming

section or in the bottom of all enclosure(s) as specified.

®

bus barrier up and forward from

General Description –

Control Center Units

Consult Publication DET-291 for detailed listings of

Evolution MCC units.

Plug-in units are supplied with stabs rated at either

250 A or 600 A. Units above 600 A may be fixed (bolted) in place and are either bus or cable connected.

Installation and operation of units are described elsewhere in this guide.

Figure 2. Horizontal bus with Lexan barrier

Loosen screw,

lift and pull

barrier forward

Figure 3. Horizontal bus barrier mounting slot and screw

4

Evolution Series E9000 Installation & Maintenance Guide

Chapter 2 – Receiving, Handling & Storage

Receiving

Before leaving the factory, the motor control center is

given a final mechanical and electrical inspection and

is packed in accordance with the best practices for

electrical equipment.

On receipt of any apparatus, make an immediate

inspection for any damage or loss of equipment in

transit. Should damage or missing material be noted,

file a claim immediately with the carrier and notify the

nearest office of the General Electric Company.

Information such as a description of the damage, the

shipping crate numbers, the requisition numbers and

the panel catalog number should accompany the claim.

Handling

Control center sections are always shipped in an upright

position, in single or group sections. Sections must be

maintained in an upright position during all handling.

Never attempt to jack, lift, or move the equipment at

points other than the lifting angle or floor sills. Use two

or more chains or cables to distribute the weight evenly.

Pinch bars, pipe rollers or slings are useful implements

for handling equipment; but be careful to maintain

distributed loading and to always apply leverage at the

floor sills and/or lifting angle. Figures 4 and 5 illustrate

typical handling techniques.

Figure 5. Positioning the MCC with rollers

Storage

If it is necessary to store the equipment for any length

of time, be sure to observe the following precautions:

• Uncrate the equipment.

• Store the equipment in a clean, dry, humidity-controlled

area at moderate temperature. Cover with a suitable

canvas or heavy-duty plastic cover to prevent

entrance of foreign material.

• If equipment must be stored in cool or high humidity

areas, in addition to completely covering the equipment,

provide a heat source to prevent condensation of

moisture in the equipment . Energize space heaters (if

furnished in the equipment) or place a standard 120volt lamp rated at 75 watts inside the bottom of each

vertical section.

Figure 4. Using standard lifting angles to hoist the MCC

5

Evolution Series E9000 Installation & Maintenance Guide

Chapter 3 – Installation

Before any installation work is begun, consult all

drawings furnished by the General Electric Company

as well as all applicable contract drawings for the

particular installation. Pay particular attention to the

location of units in the motor control center and their

relations to existing or planned conduits and busways.

Installation of Bottom Entry Conduits

Conduits can be stubbed in after the location of the

motor control center lineup has been established. Conduit

should be stubbed approximately 2 inches (51mm)

above the finished floor line. Figure 6 and Figure 7 show

the conduit entrance space available at the bottom of

standard sections. Exceptions to this available space rule

are indicated on drawings furnished by GE for specific

installations. Center the conduit beneath the section

vertical wireway to facilitate direct cable entry. Note:

Bottom rear entrance should only be used with full

rear accessibility.

Figure 6C. Bottom conduit entrance for standard 20-inch deep

section, low bus position, 6-inch bottom cover.

Figure 6A. Bottom conduit entrance details for standard 13-inch

deep section, low bus position.

Figure 6B. Bottom conduit entrance details for standard 13-inch

deep section, bus upper position.

Figure 6D. Bottom conduit entrance details for standard 20-inch

deep section, bus upper position.

Figure 7A. Low bus position of ground and neutral bus (minimum

available space for conduit entry) in 13-inch deep section, 6-inch cover.

Figure 7B. Standard position of ground and neutral bus with 12-inch

cover compartment at the bottom of MCC.

6

Evolution Series E9000 Installation & Maintenance Guide

The overall height of the equipment should be considered

with respect to headroom, top conduit entry space and

alignment with other equipment.

Surface under motor control center base must

be of non-combustible material unless bottom

covers are installed in each vertical section.

Figure 7C. Low bus position of ground and neutral bus (minimum

available space for conduit entry) in 13-inch deep section, 6-inch cover.

Figure 7D. Upper position of ground and neutral bus (maximum

space available for conduit entry), 6-inch bottom cover.

Preparation of Flooring

For most installations, the MCC floor sills can rest on the

finished floor. The foundation for the equipment should

be level and even. Although not normally required, the

purchaser may elect to install, level and grout the steel

members or MCC floor sills in the floor, as illustrated in

Figure 8 and Figure 9. If the floor sills are removed, lifting

and moving the shipping sections must be done carefully.

If anchor bolts are to be imbedded in the foundation,

they must be located according to the drawings furnished

by GE for the specific equipment. For 13-inch (330.2

mm) deep vertical sections, anchor bolts or some form

of external bracing is required. Anchor bolts should be

1/2-inch diameter of Grade 2 steel (minimum).

If there are vertical sections of varying depths

(such as 13, 20, or 22 inches) in a single lineup,

the fronts of the sections must be lined up for

proper alignment of the main bus bars.

Figure 9 illustrates this point.

Figure 8. Control center floor sills grouted to the floor before

installation to provide a level foundation

Note: Cannot be rolled (as in Figure 5) without floor sills

7

Figure 9. Installing steel floor members

Note the front alignment of the 13-inch-deep section

Positioning and Joining Sections

If groups of sections are to be joined together in a final

lineup, remove the end cover plates and the plug buttons,

from the sides of the sections to be joined. Figure 10

shows the side views, with the end cover plates

removed, for 20-inch-deep sections with 2-inch (50.8

mm) and 4-inch (101.6 mm) bus bars.

Carefully check and remove dirt, dust or bits of packing

material from the interior of all sections. Use a brush,

soft cloth or vacuum cleaner.

Evolution Series E9000 Installation & Maintenance Guide

Do not use compressed air to clean the equipment

if it contains moisture. Remove all hardware packages, drawings and other items shipped with the

equipment. Check all nuts, bolts, and electrical joints

for tightness.

All cables entering the bottoms of sections should be

pulled through conduits to a point where they will be

accessible after the equipment is in place. Sections can

be moved to their final position and properly leveled.

Figure 11. Horizontal bus with Lexan barrier

Figure 10. Side view of a 20-inch-deep section showing the cover

plates, plug bottoms and joining points

Bus Splicing

Main, neutral and ground bus splice bars (with all associated hardware) are furnished, as necessary, to join

sections together. They are located in the first section to

the right of the joint. See Figures 13, 14 and 15 for approximate dimensions for main, neutral, and ground bus.

Remove the top Lexan barrier, as shown in Figure 11 and

Figure 12, to access the main bus. Refer to instruction

drawings in splice kit. See Table 2.

Loosen screw,

lift and pull

barrier forward

Figure 12. Horizontal bus barrier mounting slot and screw

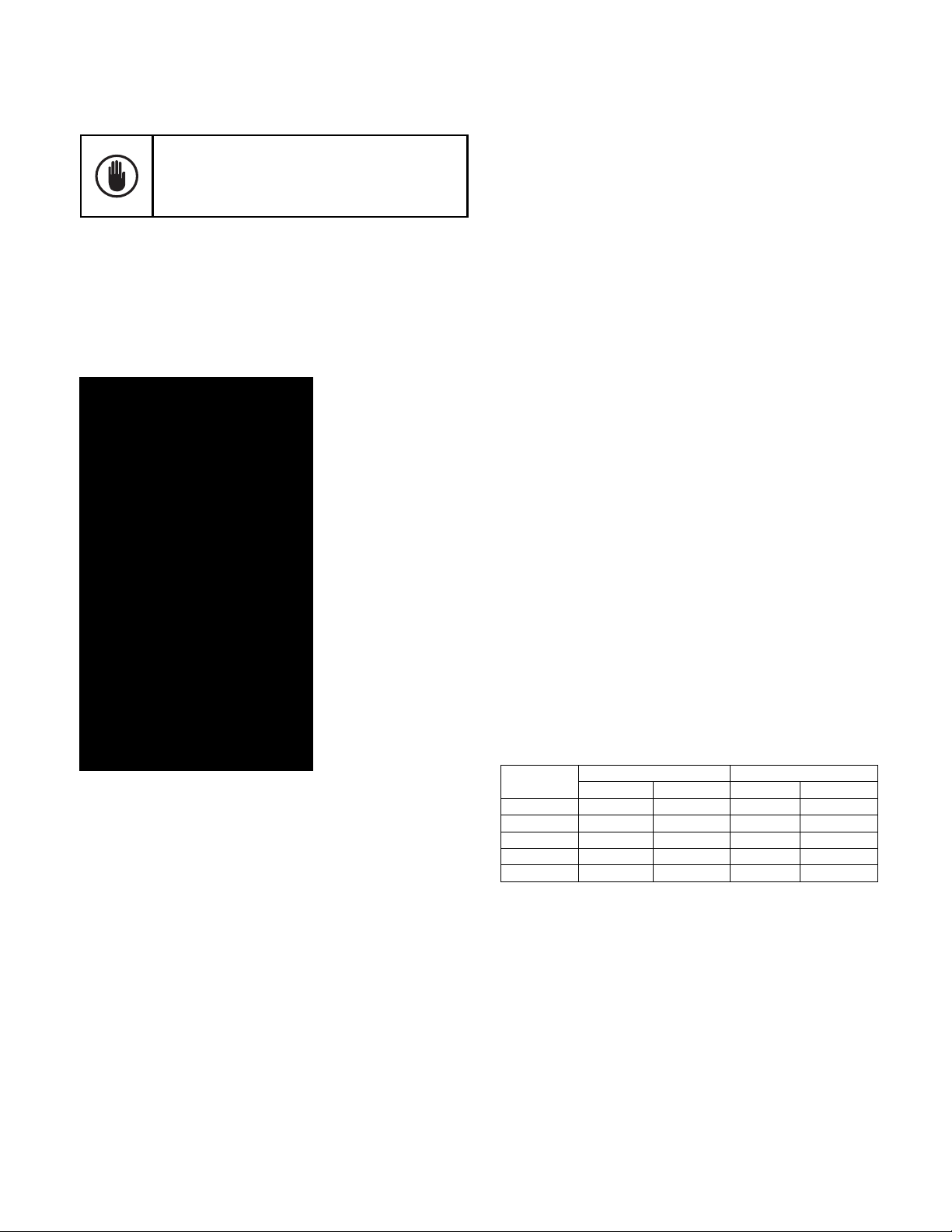

Table 1. Torque values for various bolt sizes and joint types.

Bolt Size

5/16-18 5–9 7–12 6.5–9 9–12

3/8-16 12–16 16–22 10–15 14–20

1/2-13 30–39 41–53 25–35 34–47

5/8-11 65–80 88–108 35–45 47–61

3/4-10 125–150 169–203 50–75 68–102

Note: When assembling or connecting to aluminum bus, apply a suitable joint

compound between the contacting surfaces.

Copper Joints Aluminum Joints

lb-ft N-m lb-ft N-m

8

Evolution Series E9000 Installation & Maintenance Guide

Bus Splice Kits

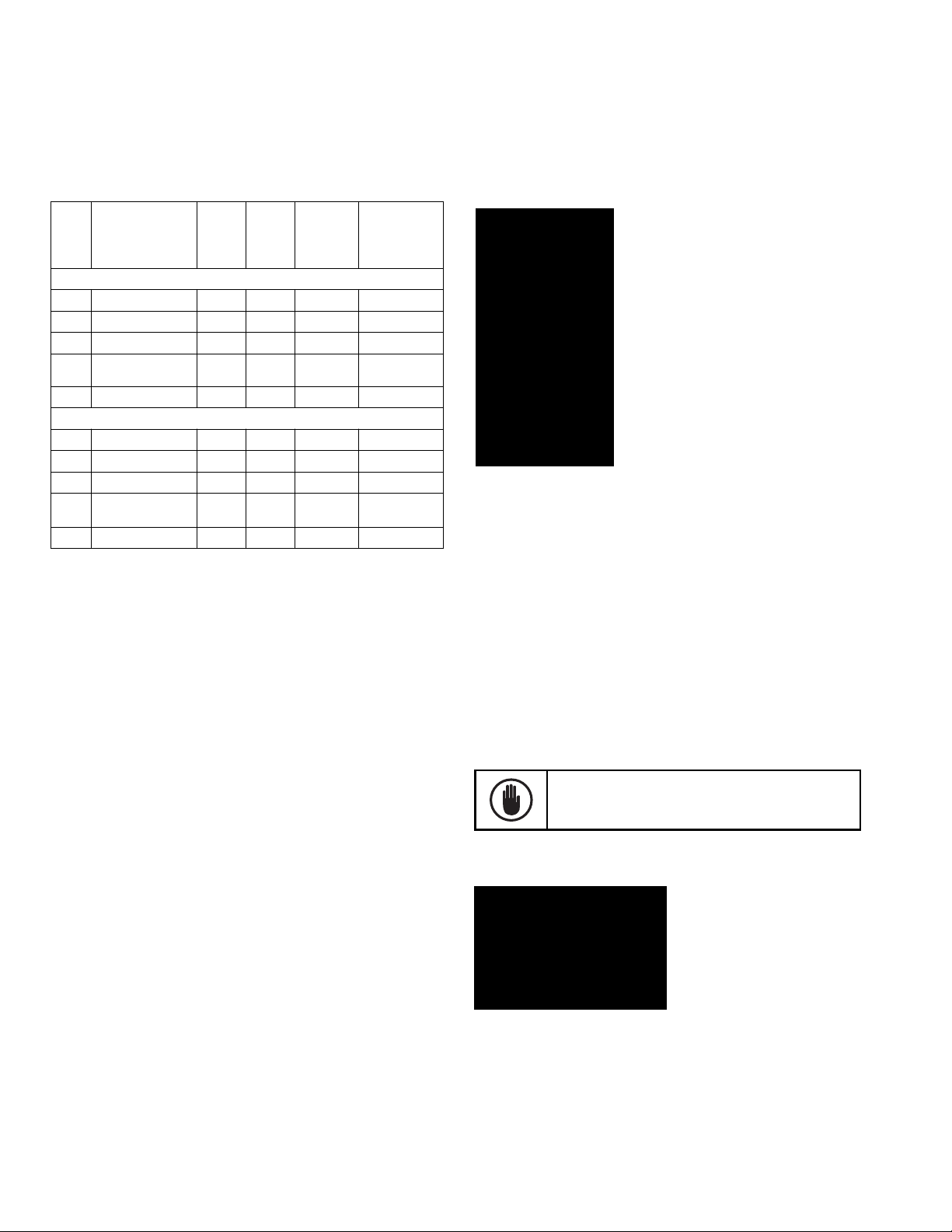

Table 2. Bus Splice Kits

Splicing From / To E9000/E9000

Main Bus Splice

Amps

Assembly Kit

Standard Splicing

600 110C1735G1SM 1 1/4 x 2 65K 110C1258TG1

800 110C1735G4SM 1 3/8 x 2 65K 110C1256TG1

1200 110C1735G7SM 1 1/2 x 2 100K 110C1253TG1

1600/

110C1735G12SM 2 1/2 x 2 100K 110C1263TG1

2000

2500 110C1735G13SM 2 1/2 x 2 100K 110C1785TG1

N3R and Spacer Shells

600 110C1735G14SM 1 1/4 x 2 65K 110C1258TG1

800 110C1735G15SM 1 3/8 x 2 65K 110C1256TG1

1200 110C1735G16SM 1 1/2 x 2 100K 110C1253TG1

1600/

110C1735G17SM 2 1/2 x 2 100K 110C1263TG1

2000

2500 110C1735G13SM 2 1/2 x 2 100K 110C1263TG1

*Included in kits.

Note: Standard plating is tin. Refer to factory for alternate plating.

Bars/

Phase

Copper

Size

(in.)

(thick x

width)

SC Rating

600V Max.

(sym.

amps)

Splice

Instruction

Drawing*

as illustrated. Note that for Condition 3, where there is

an enclosure on opposite sides of the working space,

the clearance for only one working space is required.

Figure 14. General Working Clearance Requirements

Installation of Top Entry Conduits

NEC Work Space

NEC Work Space is defined in Table 110.26(a) Working

Spaces. Included in these clearance requirements is the

step-back distance from the face of the equipment.

Table 110.26(a) provides requirements for clearances

away from the equipment, based on the circuit voltage

to ground, and whether there are grounded or ungrounded objects in the step-back space, or if there are exposed

live parts across from each other. The voltages to ground

consist of two groups: 0 to 150 and 151 to 600, inclusive.

Remember, where an ungrounded system is utilized, the

voltage to ground will be the greatest voltage between

the given conductor and any other conductor of the

circuit. For example, the voltage to ground for a 480volt ungrounded delta system is 480 volts.

See Figure 14 for general working clearance requirements.

Distances are measured from the live parts if the live

parts are exposed, or from the enclosure front if live

parts are enclosed. If any assemblies, such as switchboards or motor control centers, are accessible from the

back and expose live parts, the working clearance

dimensions would be required at the rear of the equipment,

After the motor control center is in place and leveled, and

the sections are joined together, conduits can be brought

into the tops of sections as required. Figure 15 and

Figure 16 show the conduit entry space available at the

tops of standard sections. Refer to drawings furnished by

GE for deviations on specific installations. Note: Top rear

entrance should only be used with full rear accessibility.

Always remove top cover plates when drilling

holes. This prevents small metal chips from falling

into the panel and cause serious damage.

Figure 15. Top conduit entry space for 13-inch sections

9

Evolution Series E9000 Installation & Maintenance Guide

Figure 17. Typical top entry of main cables to the incoming-line lug

Figure 16. Top conduit entry space for 20-inch and 22-inch sections

Table 3. Dimensions for Figures 15 and 16

Width Dimension A Dimension B

20" 20" 17.56"

24" 24" 21.56"

30" 30" 27.56"

compartment (600A shown)

Equipment Wiring

When pulling, bending, and terminating field wiring,

avoid scraping, cutting or otherwise damaging

cable insulation or strands.

Main Incoming Power Cables

Refer to the motor control center drawings provided by

GE for the location of the main disconnect or incoming

line terminals and the direction (top or bottom) of cable

entry. Cable-bending room provided within the vertical

section will meet or exceed National Electrical Code

requirements.

Incoming line sections are provided with cable supports.

Incoming cables must be firmly secured to withstand

the significant forces that may be generated during a

short circuit .

Cables secured at each support, as illustrated in Figure

17 and Figure 18 (600A example), will adequately

brace cables for faults of 100K RMS symmetrical

amperes, based on horizontal bus bracing. However,

cables should always be secured at the first support

inside the enclosure and at the support nearest to the

incoming terminals. Insulated bushings are also recommended at conduit terminations.

Figure 18. Typical bottom entry or main cables to the incomingline lug compartment (600A shown)

Align the conduit linearly directly over or as close as

possible to the supports. Run the cable in a convenient

orientation, making sure the cable is located against

the supports before it connects to the cable terminals.

Lash the cable using the following procedure:

Wrap the line cables together and, if provided, tie cables

together with nominal 3/8-inch (9.5 mm) nylon rope or

rope having a minimum tensile strength of 2000 pounds

(8896 N), at 6 inches (152 mm) and 12 inches (305 mm)

from the line terminals. Use five wraps and complete

every additional 6 inches with five wraps or every 1 inch

(25 mm) with one wrap. Use supplied cable supports as

desired. Refer to UL 891.

Individual Unit Wiring

Open the vertical wireway door(s) and the top and/or

bottom horizontal wireway hinged covers. All doors

can be removed, if desired, by extracting hinge pins or

removing the hinge.

10

Loading...

Loading...