GE Industrial Solutions ASTAT XT User Manual

GE Consumer & Industrial

ASTAT XT

User Manual

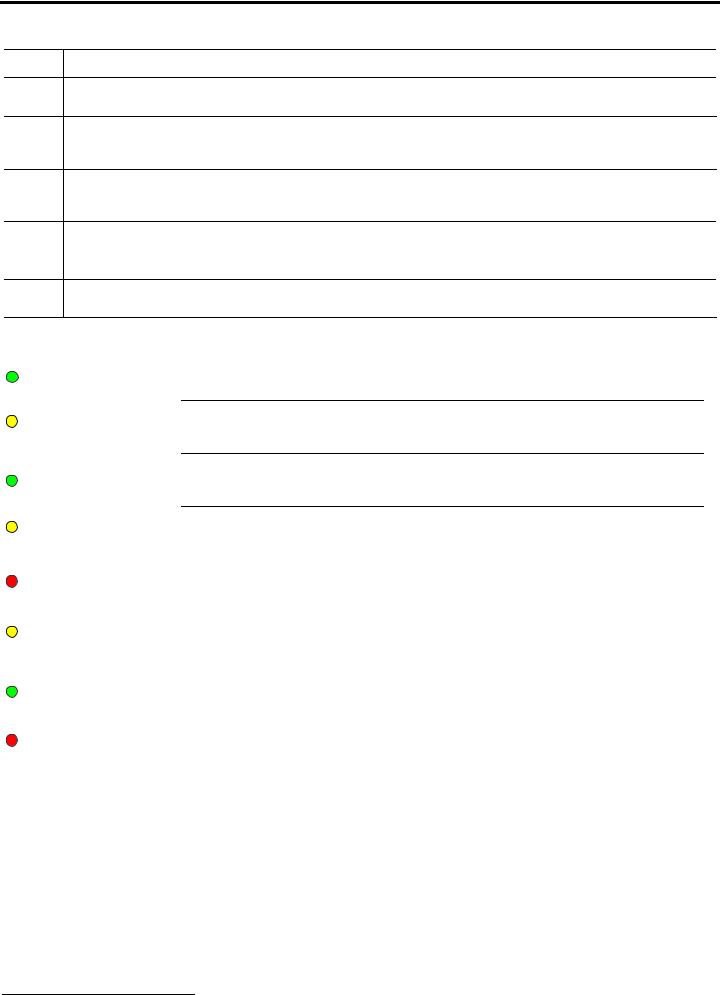

2 •Warnings

WARNINGS

1.DISCONNECT POWER BEFORE INSTALLING OR SERVICING.

2.HAZARDOUS VOLTAGES ARE PRESENT IN THE MOTOR CIRCUIT EVEN WHEN THE STARTER IS OFF. AN ISOLATION CONTACTOR IS RECOMMENDED, CONFIGURED TO PROVIDE AUTOMATIC ISOLATION WHEN THE MOTOR IS TURNED OFF.

3.UNIT MAY CONTAIN MORE THAN ONE LIVE CIRCUIT. DISCONNECT BOTH CONTROL AND MAIN CIRCUITS BEFORE INSTALLING OR SERVICING.

4.SOFT STOP SHOULD NOT BE USED AS AN EMERGENCY STOP.

5.STOPPING MODE MUST BE SET TO MEET APPLICABLE STANDARDS FOR OPERATOR SAFETY.

6.SEPARATE MOTOR OVERCURRENT PROTECTION IS REQUIRED TO BE PROVIDED IN ACCORDANCE WITH THE CANADIAN ELECTRICAL CODE, PART 1. ASTAT-XT PROVIDES SEPARATE MOTOR PROTECTION.

CAUTIONS

CAUTIONS

1.SEMI-CONDUCTOR FUSES SPECIFIED MAY NOT PROVIDE BRANCH CIRCUIT PROTECTION. REFER TO LOCAL APPLICABLE ELECTRICAL CODES.

2.OVERLOAD RELAY SETTING SHOULD BE PROPERLY COORDINATED WITH MOTOR.

3.SLOW SPEED RUNNING WILL AFFECT THE MOTOR THERMAL CHARACTERISTIC DUE TO REDUCED COOLING.

CARE MUST BE TAKEN WHEN OPERATING MOTOR UNDER THESE CONDITIONS.

4.ABNORMAL STARTING TIMES IN EXCESS OF 30 SECONDS, OR CLOSELY REPEATED OPERATIONS OF ACCELERATION RAMP/DECELERATION RAMP, SLOW SPEED, MAY CAUSE MOTOR DAMAGE. CONTACT MOTOR MANUFACTURER FOR PROPER MOTOR SELECTION.

5.IF CONTROL POWER IS LOST BETWEEN STARTS, THE OVERLOAD RELAY PROTECTION IS RESET TO COLD START CONDITIONS.

REMARKS:

1.Read this manual thoroughly before using the ASTAT-XT and store in a safe place for reference.

2.Make sure that this manual is delivered to the end user.

3.The policy of GE Industrial Systems is one of continuous improvement.

The right is reserved to alter the design on any structural details of the products at any time without giving notice.

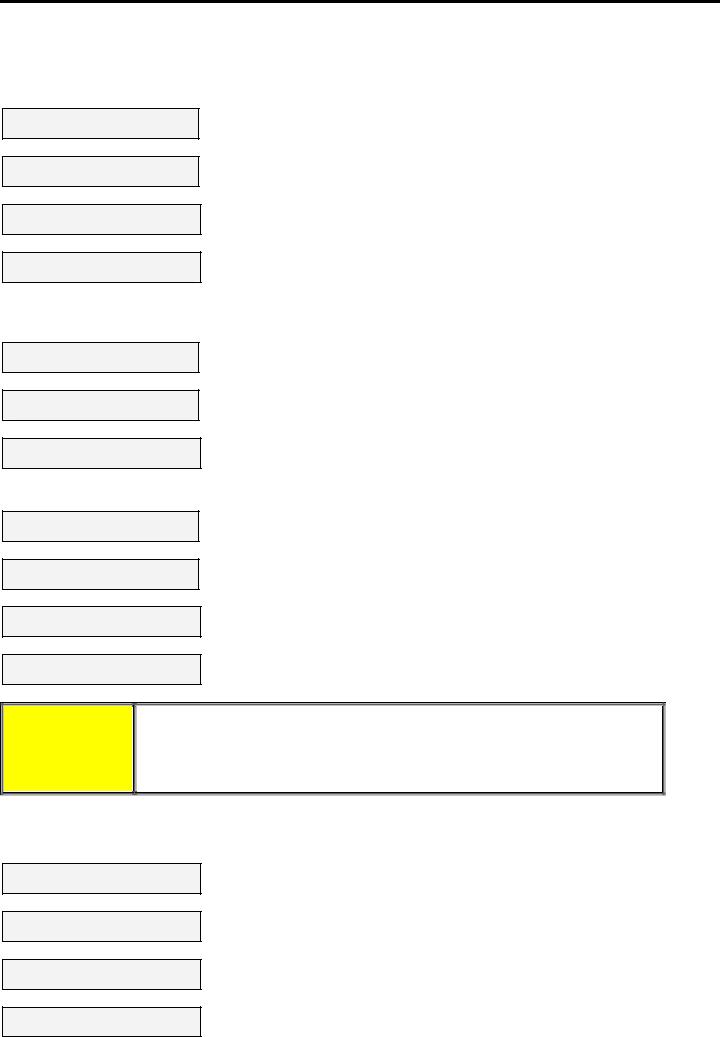

3 • Table of Contents

ASTAT-XT User Manual |

|

|||

1. |

Generalities..................................................................................................................................................... |

7 |

||

1.1 |

Squirrel-Cage Motor Starting.................................................................................................................................................... |

7 |

||

1.2 |

Advantages of the ASTAT-XT Solid State Soft Starters................................................................................................. |

7 |

||

2. |

Types and Ratings ......................................................................................................................................... |

8 |

||

2.1 |

IEC Ratings. Recommended Motor and Type Unit Ratings........................................................................................ |

8 |

||

2.2 |

NEMA Ratings . Recommended Motor and Type Unit Ratings................................................................................. |

9 |

||

2.3 |

Thermal Characteristics ............................................................................................................................................................ |

10 |

||

3. |

Technical Specifications ............................................................................................................................. |

11 |

||

3.1 |

General Specifications ............................................................................................................................................................... |

11 |

||

3.2 |

Weight |

................................................................................................................................................................................................ |

|

13 |

3.3 |

I/O Terminal Board Specifications........................................................................................................................................ |

13 |

||

3.4 |

I/O Wiring.......................................................................................................................................................................................... |

|

17 |

|

3.5 |

Ordering ..................................................................................................................................................................Information |

18 |

||

3.6 |

3.5.1 ................................................................................................................................................. |

Ordering Accessories |

18 |

|

Operating ..........................................................................................................................................................................Modes |

19 |

|||

4. |

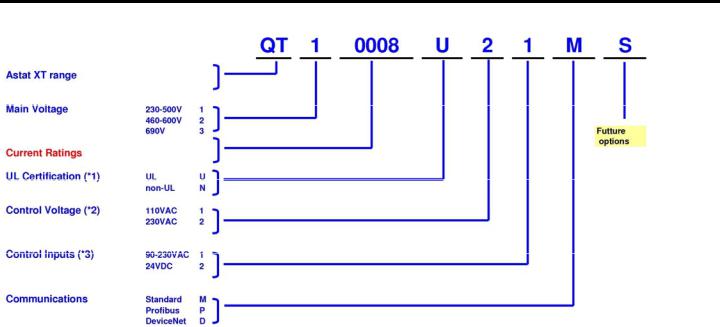

Control .............................................................................................................................................Keypad |

20 |

||

4.1 |

LCD Arrangement......................................................................................................................................................................... |

20 |

||

4.2 |

Push-Buttons .................................................................................................................................................................................. |

21 |

||

4.3 |

Status LEDs...................................................................................................................................................................................... |

|

21 |

|

4.4 |

Reviewing ...............................................................................................................................and Modifying Parameters |

21 |

||

4.5 |

Special .............................................................................................Actions Performed in Test/Maintenance Mode |

22 |

||

|

4.5.1 ................................................................................................................................................................... |

Run Self Test |

22 |

|

|

4.5.2 ............................................................................................................................................... |

View Software Version |

22 |

|

|

4.5.3 ..................................................................................................................................... |

Obtain Default Parameters |

22 |

|

|

4.5.4 ................................................................................................................................................. |

Reset Statistical Data |

22 |

|

4.6 |

4.5.5 ..................................................................................... |

Calibrate Voltage and Current (Factory Use Only!) |

23 |

|

Mode Pages..................................................................................................................................................................................... |

|

23 |

||

4.7 |

Overview ......................................................................................................of All Mode Pages and Factory Defaults |

24 |

||

|

4.7.1 .............................................................................................................................................. |

Display Mode – Page 0 |

26 |

|

|

4.7.2 .............................................................................................................................................. |

Main Settings – Page 1 |

27 |

|

|

4.7.3 .............................................................................................................................................. |

Start Settings – Page 2 |

29 |

|

|

4.7.3.1 ....................................................................................................................................... |

Soft Start Parameters |

32 |

|

|

4.7.4 ............................................................................................................................................... |

Stop Settings – Page 3 |

34 |

|

|

4.7.4.1 ....................................................................................................................................... |

Soft Stop Parameters |

35 |

|

|

4.7.5 ................................................................................................................... |

DUAL Settings Parameters – Page 4 |

36 |

|

|

4.7.6 ........................................................................................ |

Slow Speed & Energy Save Parameters – page 5 |

37 |

|

|

4.7.7 .............................................................................................................................................. |

Fault Settings – Page 6 |

38 |

|

|

4.7.8 ........................................................................................................................ |

I/O Settings Parameters – Page 7 |

40 |

|

|

4.7.8.1 ..................................................................................................................Terminal 7 and 8 Programming |

41 |

||

|

4.7.9 .......................................................... |

COMM. Parameters – Page 8 – With the Modbus standard PCB |

42 |

|

|

4.7.10 ............................................................ |

Comm. Parameters – Page 8 – With the Profibus optional PCB |

42 |

|

|

4.7.11 ...................................................... |

Comm. Parameters – Page 8 – With the DeviceNet Optional PCB |

43 |

|

4.8 |

4.7.12 ...........................................................................................................................................Statistical Data – page 9 |

44 |

||

Non Adjustable .....................................................................................................................Protection and Fault Reset |

45 |

|||

|

4.8.1 ............................................................................................................................................. |

Under/Over Frequency |

45 |

|

|

4.8.2 ....................................................................................................................................................................... |

Phase Loss |

45 |

|

|

4.8.3 ........................................................................................................................................................... |

Phase Sequence |

45 |

|

|

4.8.4 ...................................................................................................................................................... |

Wrong Connection |

45 |

|

|

4.8.5 .................................................................................................................................................................... |

Shorted SCR |

45 |

|

|

4.8.6 ................................................................................................................................. |

Heat - Sink Over Temperature |

45 |

|

|

4.8.7 ................................................................................................................................................................. |

External Fault |

45 |

|

|

4.8.8 ............................................................................................................................................................. |

Fault and Reset |

45 |

|

4.9 |

4.8.9 ........................................................................................................................................................................ |

Auto Reset |

46 |

|

Timing ..........................................................................................................................................................Occurrence Table |

46 |

|||

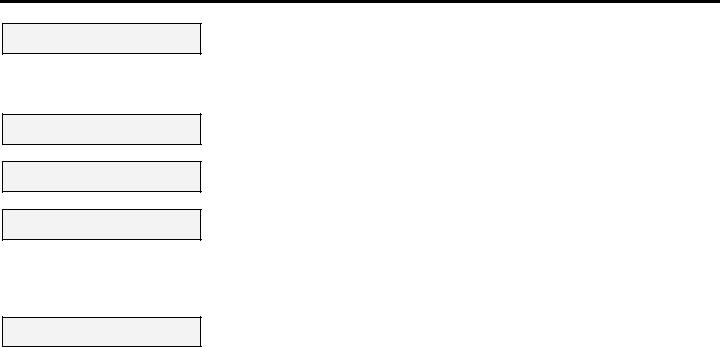

4 • Table of Contents

5. |

|

Installation |

.................................................................................................................................................... |

47 |

|

5.1 |

Prior to Installation....................................................................................................................................................................... |

47 |

|||

5.2 |

Mounting........................................................................................................................................................................................... |

|

47 |

||

5.3 |

Temperature Range & Heat Dissipation............................................................................................................................ |

47 |

|||

5.4 |

|

5.3.1 |

Forced Ventilation........................................................................................................................................................ |

48 |

|

Main PCB and Optional PCBs.................................................................................................................................................. |

48 |

||||

5.5 |

Dip Switch Settings on the Main PCB.................................................................................................................................. |

49 |

|||

|

|

5.5.1 Switch # 1 – Display Modes .................................................................................................................................... |

49 |

||

|

|

5.5.2 Switch # 2 – Not used ................................................................................................................................................ |

50 |

||

|

|

5.5.3 Switch # 3 – Main/ D.Set: Generator Parameters......................................................................................... |

50 |

||

|

|

5.5.4 Switches # 5, 6 – Language Selection................................................................................................................ |

50 |

||

|

|

5.5.5 Switch # 7 – Expanded Settings............................................................................................................................ |

50 |

||

5.6 |

|

5.5.6 Switch # 8 – Software Lock ..................................................................................................................................... |

50 |

||

Internal Fan Control .................................................................................................................................................................... |

51 |

||||

5.7 |

Analog I/O (Terminals T1, T2, Gnd, Out (-), Out (+)) ........................................................................................................ |

51 |

|||

5.8 |

Remote Key-Pad Installation.................................................................................................................................................. |

52 |

|||

6. |

|

Starting Procedure ...................................................................................................................................... |

53 |

||

6.1 |

Standard Starting Procedure.................................................................................................................................................. |

54 |

|||

6.2 Examples of Starting Curves................................................................................................................................................... |

55 |

||||

|

|

6.2.1 |

Light Loads - Pumps, Etc. ......................................................................................................................................... |

55 |

|

|

|

6.2.2 High Inertia Loads: Crushers, Centrifuges, Mixers, Etc............................................................................... |

55 |

||

|

|

6.2.3 Special Starting Using DUAL Settings ................................................................................................................ |

56 |

||

|

|

6.2.3.1 Special Starting – Using DUAL Settings – Wiring Diagram ............................................................ |

57 |

||

|

|

6.2.4 Choosing a Suitable Pump Curve (Centrifugal Pumps).............................................................................. |

57 |

||

|

|

6.2.4.1 |

Starting Curve ...................................................................................................................................................... |

57 |

|

|

|

6.2.4.2 |

Stopping Curve.................................................................................................................................................... |

58 |

|

|

|

6.2.4.3 End Torque During Soft-Stopping a Pump Motor............................................................................... |

58 |

||

7. |

|

Trouble Shooting.......................................................................................................................................... |

59 |

||

8. |

|

Application diagrams.................................................................................................................................. |

62 |

||

8.1 |

Terminal 21 Connections With Various Mains................................................................................................................ |

62 |

|||

8.2 |

Control Supply, Control Input and Mains are From the Same Source, Neutral Connected to Terminal 21 |

||||

8.3 |

63 |

|

|

|

|

Control Supply and Control Input From the Same Source, Neutral not Connected to Terminal 21.... |

63 |

||||

8.4 |

Control Supply and Control Input from Separate Sources ...................................................................................... |

64 |

|||

8.5 |

Soft Start, Soft Stop and Stop, Control Supply and Control Input from the Same Source........................ |

64 |

|||

8.6 |

Soft Start, Soft Stop and Stop, Control Supply and Control Input from Separate Sources ...................... |

64 |

|||

8.7 |

Soft Start and Immediate Stop (no Soft Stop)................................................................................................................. |

65 |

|||

8.8 |

Soft Start and Soft Stop ............................................................................................................................................................. |

65 |

|||

8.9 |

Soft Start, Soft Stop and Immediate Stop......................................................................................................................... |

65 |

|||

8.10 Energy Save, Slow Speed or Reset................................................................................................................................. |

66 |

||||

8.11 Slow Speed and Slow Speed Reverse ........................................................................................................................... |

66 |

||||

8.12 |

External Fault............................................................................................................................................................................ |

67 |

|||

8.13 |

Line Contactor.......................................................................................................................................................................... |

67 |

|||

8.14 |

Bypass Contactor................................................................................................................................................................... |

68 |

|||

8.15 Reversing with Two Line Contactors............................................................................................................................. |

69 |

||||

8.16 Operating via Communication Links............................................................................................................................. |

70 |

||||

8.17 D.Set: Generator Parameters Wiring............................................................................................................................. |

71 |

||||

8.18 |

Short Circuit Protection........................................................................................................................................................ |

72 |

|||

|

|

8.18.1 Type 1 Coordination ................................................................................................................................................... |

72 |

||

|

|

8.18.1.1 Type 1 Coordination with GE Circuit Breakers: .................................................................................... |

72 |

||

|

|

8.18.1.2 Type 1 Coordination with Type aM Siba Fuses:................................................................................... |

72 |

||

8.19 |

8.18.2 Type 2 Coordination ................................................................................................................................................... |

72 |

|||

Transient Protection .............................................................................................................................................................. |

73 |

||||

8.20 |

Inside Delta Configuration.................................................................................................................................................. |

74 |

|||

|

|

8.20.1 General Information ................................................................................................................................................... |

74 |

||

|

|

8.20.2 Notes on Inside Delta Connection ....................................................................................................................... |

74 |

||

|

|

8.20.3 Motor Connection and Terminals......................................................................................................................... |

75 |

||

|

|

5 • Table of Contents |

|

|

8.20.4 ASTAT-XT Connected Inside Delta w/Bypass Contactor and Inside Delta Contactor |

................76 |

|

|

8.20.5 ASTAT-XT Connected Inside Delta - Reverse Speed.................................................................................... |

77 |

|

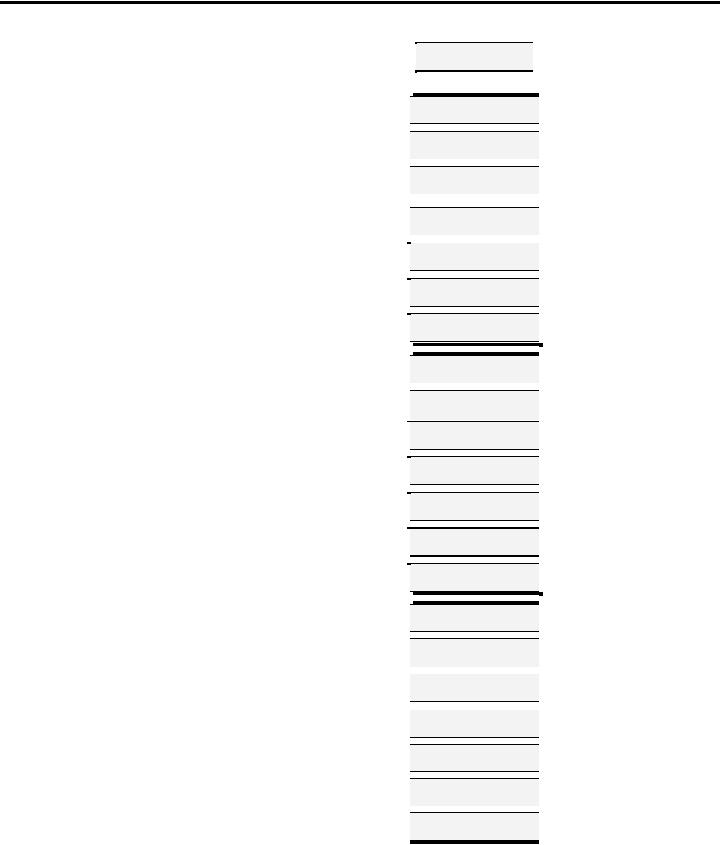

9. |

Dimensions.................................................................................................................................................... |

78 |

|

9.1 |

UL cUL Approved Models.......................................................................................................................................................... |

78 |

|

9.2 |

Non UL cUL Approved Models................................................................................................................................................ |

82 |

|

Appendix A - MODBUS RTU Protocol...................................................................................................................... |

86 |

||

A.1. Introduction..................................................................................................................................................................................... |

86 |

||

A.2. Basic Structure of the Serial Link Frame ........................................................................................................................... |

87 |

||

A.3. SYNC (Silent Interval) ................................................................................................................................................................... |

87 |

||

A.4. Serial Link No. (Slave Address)............................................................................................................................................... |

87 |

||

A.5. Function ............................................................................................................................................................................................ |

87 |

||

A.6. List of Functions Supported By The ASTAT-XT ............................................................................................................... |

87 |

||

A.7. Actual Data (3X References & 4X References)................................................................................................................ |

89 |

||

A.8. Parameter Settings (4X References).................................................................................................................................... |

91 |

||

A.9. Control Register Write (4X Reference) ................................................................................................................................ |

94 |

||

A.10. |

Discrete Commands (Coils, 0x References)............................................................................................................... |

95 |

|

A.11. |

Discrete Hardwired Inputs (1x References)............................................................................................................... |

97 |

|

A.12. |

Diagnostics ................................................................................................................................................................................ |

98 |

|

A.13. |

Exception Responses ............................................................................................................................................................ |

99 |

|

Appendix B - Profibus.............................................................................................................................................. |

101 |

||

B.1. Operation Mode in PROFIBUS:............................................................................................................................................. |

101 |

||

|

B.1.1. Structure of the ASTAT-XT Receiving Frame................................................................................................ |

101 |

|

|

B.1.2. Structure of the ASTAT-XT Transmitting Frame ......................................................................................... |

101 |

|

|

|

B.1.2.1. Selection of the DPV0 Registers through Data Request (DPV1)................................................ |

101 |

|

B.1.3. Read and Write from Random Registers via Data Request ................................................................. |

102 |

|

B.2. Configure the PROFIBUS in the ASTAT-XT...................................................................................................................... |

103 |

||

B.3. Watch Dog Definition .............................................................................................................................................................. |

103 |

||

B.4. Actual Data Register Numbers (decimal)....................................................................................................................... |

104 |

||

B.5. Setting Parameters Registers for Data Request......................................................................................................... |

106 |

||

Appendix C - DeviceNet™ to Modbus™ Gateway.............................................................................................. |

108 |

||

C.1. Introduction.................................................................................................................................................................................. |

108 |

||

|

C.1.1. Overview........................................................................................................................................................................ |

108 |

|

|

C.1.2. Definitions..................................................................................................................................................................... |

108 |

|

|

C.1.3. Reference Documents ............................................................................................................................................ |

108 |

|

|

C.1.4. Open DeviceNet Vendor Association, Inc. (ODVA) ..................................................................................... |

108 |

|

|

C.1.5. Rotary Switch Configuration ............................................................................................................................... |

109 |

|

|

C.1.6. LED Indicators............................................................................................................................................................. |

109 |

|

C.2. Identity Object (01HEX - 1 Instance) ..................................................................................................................................... |

111 |

||

|

C.2.1. Class Attributes (Instance 0)................................................................................................................................. |

111 |

|

|

C.2.2. Instance Attributes (Instance 1) ......................................................................................................................... |

111 |

|

|

C.2.3. Common Services ..................................................................................................................................................... |

111 |

|

C.3. Message Router Object (02HEX - 1 Instance) ................................................................................................................... |

111 |

||

C.4. DeviceNet Object (03HEX - 1 Instance)................................................................................................................................ |

111 |

||

|

C.4.1. Class Attributes (Instance 0)................................................................................................................................. |

111 |

|

|

C.4.2. Instance Attributes (Instance 1) ......................................................................................................................... |

111 |

|

|

C.4.3. Common Services ..................................................................................................................................................... |

111 |

|

C.5. Assembly Object (04HEX – 4 Instances) ............................................................................................................................ |

112 |

||

|

C.5.1. Class Attributes (Instance 0)................................................................................................................................. |

112 |

|

|

C.5.2. Output (O2T) Instance Attributes – Register 40752 .................................................................................. |

112 |

|

|

|

C.5.2.1. Output Instance 112 (0x70) – Control Output.................................................................................... |

112 |

|

C.5.3. Input (T20) Instance Attributes – Register 40257....................................................................................... |

112 |

|

|

|

C.5.3.1. Input Instance 60 (0x3C) – Basic Softstart Input .............................................................................. |

112 |

|

|

C.5.3.2. Input Instance 61 (0x3D) – Extended Softstart Input ..................................................................... |

112 |

|

|

C.5.3.3. Input Instance 100 (0x64) – Status ......................................................................................................... |

112 |

|

C.5.4. Common Services ..................................................................................................................................................... |

113 |

|

C.6. Connection Object (05HEX – 2 Instances) .......................................................................................................................... |

113 |

||

|

|

6 • Table of Contents |

|

C.6.1. Class Attributes (Instance 0)................................................................................................................................. |

113 |

||

C.6.2. Instance Attributes (Instances 1-2) Explicit, Polled I/O............................................................................ |

113 |

||

C.6.3. Common Services ..................................................................................................................................................... |

115 |

||

C.7. Softstart Object (2DHEX - 1 Instance)................................................................................................................................... |

115 |

||

C.7.1. Class Attributes (Instance 0)................................................................................................................................. |

115 |

||

C.7.2. Instance Attributes (Instance 1) ......................................................................................................................... |

115 |

||

|

C.7.2.1. Extended AtReference Values................................................................................................................... |

115 |

|

|

C.7.2.2. Extended StartMode Values....................................................................................................................... |

115 |

|

C.7.3. Common Services ..................................................................................................................................................... |

115 |

||

C.8. Control Supervisor Object (29HEX - 1 Instances) ............................................................................................................ |

115 |

||

C.8.1. Class Attributes (Instance 0)................................................................................................................................. |

115 |

||

C.8.2. Instance Attributes (Instance 1) ......................................................................................................................... |

115 |

||

C.8.3. Common Services ..................................................................................................................................................... |

116 |

||

C.9. Modbus / Serial Object (65HEX – 1 Instance).................................................................................................................... |

116 |

||

C.9.1. Class Attributes (Instance 0)................................................................................................................................. |

116 |

||

C.9.2. Instance Attributes (Instance 1) ......................................................................................................................... |

116 |

||

C.9.3. Common Services ..................................................................................................................................................... |

117 |

||

C.10. |

Input Object (70HEX – 1 Instance) .................................................................................................................................... |

117 |

|

C.10.1. |

Class Attributes (Instance 0) ............................................................................................................. |

117 |

|

C.10.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

117 |

|

C.10.3. |

Common Services.................................................................................................................................. |

118 |

|

C.11. |

Main Parameter Object (71HEX – 1 Instance)............................................................................................................. |

118 |

|

C.11.1. |

Class Attributes (Instance 0) ............................................................................................................. |

118 |

|

C.11.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

118 |

|

C.11.3. |

Common Services.................................................................................................................................. |

119 |

|

C.12. |

Start Settings Object (72HEX – 1 Instance)................................................................................................................... |

119 |

|

C.12.1. |

Class Attributes (Instance 0) ............................................................................................................. |

119 |

|

C.12.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

119 |

|

C.12.3. |

Common Services.................................................................................................................................. |

119 |

|

C.13. |

Stop Settings Object (73HEX – 1 Instance) ................................................................................................................... |

119 |

|

C.13.1. |

Class Attributes (Instance 0) ............................................................................................................. |

119 |

|

C.13.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

119 |

|

C.13.3. |

Common Services.................................................................................................................................. |

119 |

|

C.14. |

Dual Settings Object (74HEX – 1 Instance) ................................................................................................................... |

119 |

|

C.14.1. |

Class Attributes (Instance 0) ............................................................................................................. |

119 |

|

C.14.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

120 |

|

C.14.3. |

Common Services.................................................................................................................................. |

120 |

|

C.15. Slow SP & Saving Parameters Object (75HEX – 1 Instance)................................................................................. |

120 |

||

C.15.1. |

Class Attributes (Instance 0) ............................................................................................................. |

120 |

|

C.15.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

120 |

|

C.15.3. |

Common Services.................................................................................................................................. |

120 |

|

C.16. |

Fault Settings Object (76HEX – 1 Instance) .................................................................................................................. |

120 |

|

C.16.1. |

Class Attributes (Instance 0) ............................................................................................................. |

120 |

|

C.16.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

120 |

|

C.16.3. |

Common Services.................................................................................................................................. |

121 |

|

C.17. |

I/O Settings Object (77HEX – 1 Instance) ...................................................................................................................... |

121 |

|

C.17.1. |

Class Attributes (Instance 0) ............................................................................................................. |

121 |

|

C.17.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

121 |

|

C.17.3. |

Common Services.................................................................................................................................. |

121 |

|

C.18. |

Communication Parameter Object (78HEX – 1 Instance) ..................................................................................... |

121 |

|

C.18.1. |

Class Attributes (Instance 0) ............................................................................................................. |

121 |

|

C.18.2. |

Instance Attributes (Instance 1) ...................................................................................................... |

121 |

|

C.18.3. |

Common Services.................................................................................................................................. |

122 |

|

7 • Generalities

1.GENERALITIES

1.1Squirrel-Cage Motor Starting

There are numerous applications where soft starting and limited current peak are needed, thereby making direct starting of squirrel-cage motors impossible. Traditionally in such cases other types of starting with reduced stator voltage have been resorted to. The best-known are star-delta starters, autotransformer starters, stator resistance starters or using part winding motors.

Any reduced starting voltage imposes a current limitation, thus reducing the starting torque, but there will always be peaks during the change from one point or state to another which can damage the machine being driven. Note that in general, all reduced voltage starts reduce torque in squared proportion to the current in the phases of the motor (not on the line) and the latter in turn is reduced in linear proportion to the voltage. From this it can be deduced that any start with reduced voltage reduces the torque in squared proportion to the voltage per motor

phase. From this point of view soft starting produces just like any other reduced voltage start, a reduction in starting torque, according to the adjusted parameters. The advantage is the ease with which this ramp can be controlled to produce a soft start in accordance with the actual requirement of the machine.

1.2Advantages of the ASTAT-XT Solid State Soft Starters

Increase in productivity and reliability with the use of static soft starters

Starting and stopping the motor without steps or transitions lengthens the life of power-driven machine mechanical elements, greatly reducing stress on transmission and coupling parts.

Consequently, overhauling times are reduced and machine and facility lifespans are lengthened.

Improvement in acceleration / deceleration characteristics

Being able to start by using the voltage ramp or alternatively by limiting current lets acceleration fit the load characteristics. Application of a pulse start may also be selected in cases of high static friction load.

Stopping may be made by cutting-off power or by soft stop ramp.

Protected motor

The soft starter protects the motor from overloads as well as from incorrect operating conditions such as loss of an input or output phase, blocked rotor, thyristor short circuit, etc.

Digital technology

The control system is based on the use of a highly specialized microcontroller by which signals are treated digitally, thereby avoiding deratings and adjustments common to analogue circuits and obtaining excellent precision and speed of execution.

The control board is made with the technology of surface mounting devices (SMD), which increases equipment reliability.

Easy to run and adjust

This unit can be used for a wide range of applications.

Adjustments are very easy to make and diverse options maybe selected for have equipment capabilities suited to application needs every time.

Easy maintenance due to full monitoring

The alphanumeric display and the LEDs on its front overlay makes the equipment working conditions known at any time.

Pump control

The ASTAT-XT includes several soft stop curves which is more effective than the standard soft stop, reducing fluid surges or hammering in a pipe line system. This method reduces the motor speed, by controlling internal parameters in the motor as well as the output voltage in a close-loop system.

Advanced functions

The ASTAT-XT includes advanced functions, like linear acceleration ramp, forward and reverse jog, programmable I/O or connection to a control system via Modbus protocol included as standard and other optional protocols. These functions allow the incorporation of the soft starter to a distributed control net, in automated plant processes, together with other soft starters, programmable controllers, variable speed drives, etc.

High level of immunity

Design of the unit was closely tied to the conditions of supply lines, which handle more disturbances every day. The control signals are opto-electronically isolated and various levels of protection have been set up in the circuits to immunize the equipment against external disturbance and its effects.

8 • Types and Ratings

2.TYPES AND RATINGS

2.1IEC Ratings1. Recommended Motor and Type Unit Ratings.

Light |

Normal Duty (IEC Class 10) |

|

|

|

Heavy Duty (IEC Class 20) |

|

|

|

Type Unit |

||||

Duty |

Recommended Motor Ratings |

|

|

|

Recommended Motor Ratings |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max |

Current |

230V |

400V |

480V |

575V |

690V |

Current |

230V |

400V |

480V |

575V |

690V |

|

Current |

rating2 |

|

415V |

500V |

|

|

rating3 |

|

415V |

500V |

|

|

|

Rating |

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

A |

kW |

kW |

kW |

HP |

kW |

A |

kW |

kW |

kW |

HP |

kW |

|

8 |

8 |

2 |

3.0 |

4 |

5 |

5.5 |

8 |

1.5 |

3.0 |

4 |

5 |

5.5 |

QTx0008Uxxxx |

17 |

17 |

4 |

7.5 |

7.5 |

15 |

15 |

12 |

3 |

5.5 |

5.5 |

10 |

8 |

QTx0017Uxxxx |

34 |

31 |

8 |

15 |

18.5 |

15 |

22 |

31 |

8 |

15 |

18.5 |

25 |

22 |

QTx0031Uxxxx |

54 |

44 |

11 |

22 |

30 |

40 |

37 |

44 |

11 |

22 |

30 |

40 |

37 |

QTx0044Uxxxx |

65 |

58 |

15 |

30 |

37 |

50 |

55 |

55 |

15 |

30 |

37 |

50 |

45 |

QTx0058Uxxxx |

72 |

72 |

22 |

37 |

45 |

60 |

55 |

66 |

18.5 |

37 |

45 |

60 |

55 |

QTx0072Uxxxx |

104 |

85 |

22 |

45 |

55 |

75 |

75 |

80 |

22 |

45 |

55 |

75 |

75 |

QTx0085Uxxxx |

130 |

105 |

30 |

55 |

55 |

100 |

90 |

99 |

30 |

55 |

55 |

100 |

90 |

QTx0105Uxxxx |

156 |

145 |

45 |

75 |

90 |

150 |

132 |

130 |

37 |

55 |

90 |

125 |

90 |

QTx0145Uxxxx |

170 |

170 |

55 |

90 |

110 |

150 |

160 |

134 |

37 |

75 |

90 |

125 |

132 |

QTx0170Uxxxx |

248 |

210 |

55 |

110 |

132 |

200 |

200 |

203 |

55 |

110 |

132 |

200 |

200 |

QTx0210Nxxxx |

361 |

310 |

90 |

160 |

200 |

300 |

250 |

310 |

75 |

160 |

200 |

300 |

250 |

QTx0310Nxxxx |

390 |

390 |

110 |

200 |

250 |

300 |

355 |

344 |

110 |

160 |

250 |

350 |

315 |

QTx0390Nxxxx |

480 |

460 |

132 |

250 |

315 |

450 |

400 |

432 |

132 |

250 |

315 |

450 |

400 |

QTx0460Nxxxx |

480 |

460 |

132 |

250 |

315 |

450 |

400 |

432 |

132 |

250 |

315 |

450 |

400 |

QTx0460Uxxxx |

610 |

580 |

160 |

315 |

400 |

500 |

560 |

488 |

160 |

250 |

355 |

500 |

400 |

QTx0580Nxxxx |

610 |

580 |

160 |

315 |

400 |

500 |

560 |

552 |

160 |

315 |

400 |

|

560 |

QTx0580Uxxxx |

820 |

650 |

200 |

355 |

400 |

|

630 |

552 |

160 |

315 |

400 |

|

560 |

QTx0650Nxxxx |

820 |

820 |

250 |

400 |

560 |

|

800 |

690 |

200 |

400 |

500 |

|

710 |

QTx0820Uxxxx |

1180 |

950 |

315 |

560 |

630 |

|

900 |

950 |

315 |

560 |

630 |

|

900 |

QTx0950Nxxxx |

1375 |

1100 |

355 |

630 |

800 |

|

1000 |

1076 |

355 |

630 |

800 |

|

1000 |

QTx1100Nxxxx |

1750 |

1400 |

400 |

800 |

1000 |

|

|

1400 |

400 |

800 |

1000 |

|

|

QTx1400Nxxxx |

Note:

Select the appropriate ASTAT-XT, according to the main power supply and motor voltage rating. Use QT1xxxx units for power supply and motors rated at 230V-500V

Use QT2xxxx units for power supply and motors rated at 460V-600V Use QT3xxxx units for power supply and motors rated at 690V

1 Ratings in Amps. given for ambient temperature up to 40°C and 1000m altitude.

For higher ambient temperature between 40°C and 50°C, derate the current by 2.5% for each °C that is above 40°C.

2Normal duty ratings, only IEC Class 10 protection is allowed.

3Heavy duty ratings, IEC Class 10 and 20 protections are allowed.

9 • Types and Ratings

2.2NEMA Ratings4 . Recommended Motor and Type Unit Ratings.

Light Duty |

|

|

|

Normal Duty |

|

|

Heavy Duty |

|

|

|

Type Unit |

||

Nema 10 |

|

|

|

Nema 20 |

|

|

|

Nema 30 |

|

|

|

|

|

Current |

230V |

460V |

575V |

Current |

230V |

460V |

575V |

Current |

230V |

460V |

575V |

|

|

rating5 |

|

|

|

rating6 |

|

|

|

rating7 |

|

|

|

|

|

A |

HP |

HP |

HP |

A |

HP |

HP |

HP |

A |

HP |

HP |

HP |

|

|

8 |

2 |

5 |

5 |

8 |

2 |

5 |

5 |

8 |

|

2 |

5 |

5 |

QTx0008Uxxxx |

17 |

5 |

10 |

15 |

17 |

5 |

10 |

15 |

12 |

|

3 |

7.5 |

10 |

QTx0017Uxxxx |

34 |

10 |

25 |

30 |

31 |

10 |

20 |

25 |

31 |

|

10 |

20 |

25 |

QTx0031Uxxxx |

54 |

20 |

40 |

50 |

44 |

15 |

30 |

40 |

44 |

|

15 |

30 |

40 |

QTx0044Uxxxx |

65 |

20 |

50 |

60 |

58 |

20 |

40 |

50 |

55 |

|

20 |

40 |

50 |

QTx0058Uxxxx |

72 |

25 |

50 |

60 |

72 |

25 |

50 |

60 |

66 |

|

20 |

50 |

60 |

QTx0072Uxxxx |

104 |

40 |

75 |

100 |

85 |

30 |

60 |

75 |

80 |

|

30 |

60 |

75 |

QTx0085Uxxxx |

130 |

50 |

100 |

125 |

105 |

40 |

75 |

100 |

99 |

|

40 |

75 |

100 |

QTx0105Uxxxx |

156 |

60 |

125 |

150 |

145 |

50 |

100 |

150 |

130 |

|

50 |

100 |

125 |

QTx0145Uxxxx |

170 |

60 |

125 |

150 |

170 |

60 |

125 |

150 |

134 |

|

50 |

100 |

125 |

QTx0170Uxxxx |

262 |

100 |

200 |

250 |

210 |

75 |

150 |

200 |

203 |

|

75 |

150 |

200 |

QTx0210Uxxxx |

387 |

150 |

300 |

400 |

310 |

100 |

250 |

300 |

310 |

|

100 |

250 |

300 |

QTx0310Uxxxx |

414 |

150 |

350 |

400 |

390 |

150 |

300 |

400 |

361 |

|

150 |

300 |

300 |

QTx0390Uxxxx |

480 |

200 |

400 |

500 |

460 |

150 |

350 |

400 |

432 |

|

150 |

350 |

400 |

QTx0460Uxxxx |

610 |

250 |

500 |

|

580 |

200 |

400 |

400 |

552 |

|

200 |

400 |

500 |

QTx0580Uxxxx |

820 |

|

|

|

820 |

250 |

500 |

500 |

690 |

|

250 |

500 |

|

QTx0820Uxxxx |

Note:

Select the appropriate ASTAT-XT, according to the main power supply and motor voltage rating. Use QT1xxxxUxxxx units for power supply and motors rated at 230V-500V

Use QT2xxxxUxxxx units for power supply and motors rated at 460V-600V

4 Ratings in Amps. given for ambient temperature up to 40°C and 1000m altitude.

For higher ambient temperature between 40°C and 50°C, derate the current by 2.5% for each °C that is above 40°C.

5Light duty ratings, only NEMA Class 10 protection is allowed.

6Normal duty ratings, NEMA Class 10 and 20 protections are allowed.

7Heavy duty ratings, NEMA Class 10, 20 and 30 protections are allowed

10 • Types and Ratings

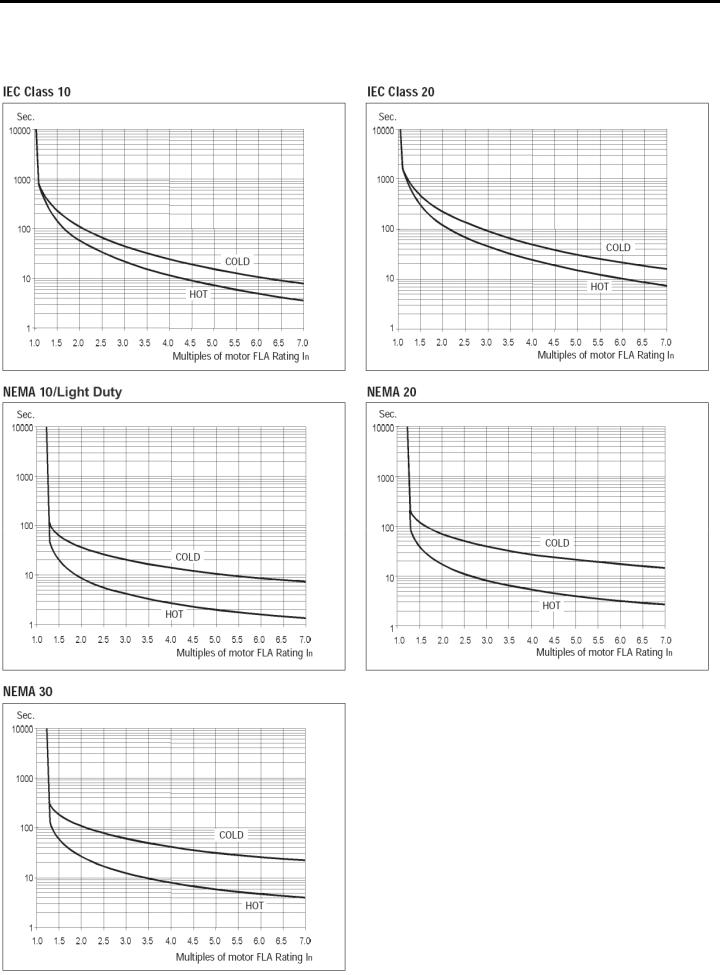

2.3Thermal Characteristics

The ASTAT-XT allows the user to select motor protection according IEC Class 10, 20 and NEMA 10, 20 or 30, selectable by Overload Class parameter (refer to section 4.7.2 page 27)

11 • Technical Specifications

3.TECHNICAL SPECIFICATIONS

3.1General Specifications

|

General Information: |

Line to line 230-690V (to be specified) + 10%-15% |

|

|

Supply Voltage: |

||

|

Frequency: |

45 – 65 Hz (fixed or variable frequency source) |

|

|

Control Supply: |

Either 110VAC or 230VAC (to be specified) +10% - 15% |

|

|

Control Inputs: |

Either 90-230VAC or 24VDC (to be specified) |

|

|

|

Three phases, three/six wires, squirrel cage induction motor |

|

|

Load: |

||

|

Connection type: |

Standard 3 wire U, V, W connection, or 6 wire Inside Delta (programmable) |

|

|

Rated Insulation Voltage: |

1,000V |

|

|

Rated Impulse Voltage: |

4kV |

|

|

Form designation: |

Form 1 |

|

|

This product was tested for |

compliance with IEC 60947-4-2 for class A equipment. |

|

|

Start-Stop Parameters: |

ASTAT-XT’s rated current according to its nameplate. |

|

|

Starter Current: |

||

|

Motor Current: |

Motor Full Load Ampere (Im) 50-125%8 of Starter Current. |

|

|

Start/Stop Curve 0 |

2 standard starting and stopping curves |

|

|

(Standard) |

6 field selectable curves preventing over-pressure during start and water hammer |

|

|

Pump Control Curves (1!, |

||

2!, 3!) |

during stop |

||

|

Torque Control Curve (4) |

2 selectable curves preventing over-pressure during start and water hammer during |

|

|

|

stop. In addition, these curves may be used for torque control starting of constant |

|

|

|

torque applications. |

|

|

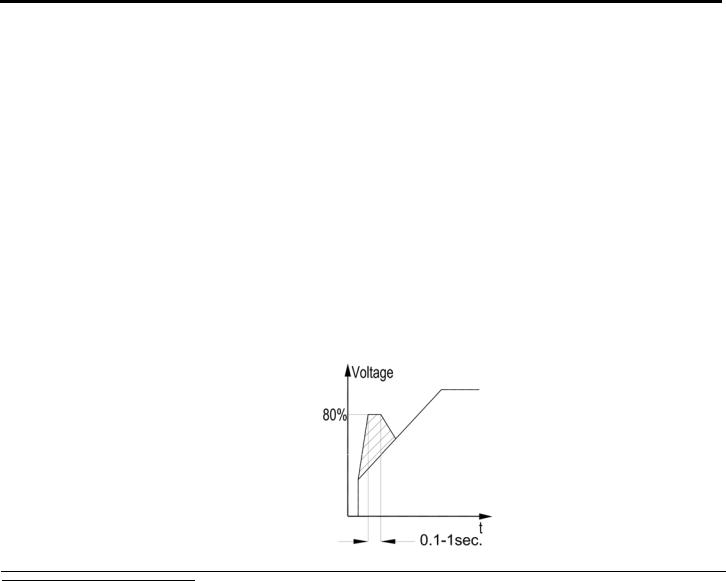

Kick Start Duration: |

A pulse of 80% Un, for an adj. time 0.1-1 Sec, for starting high friction loads |

|

|

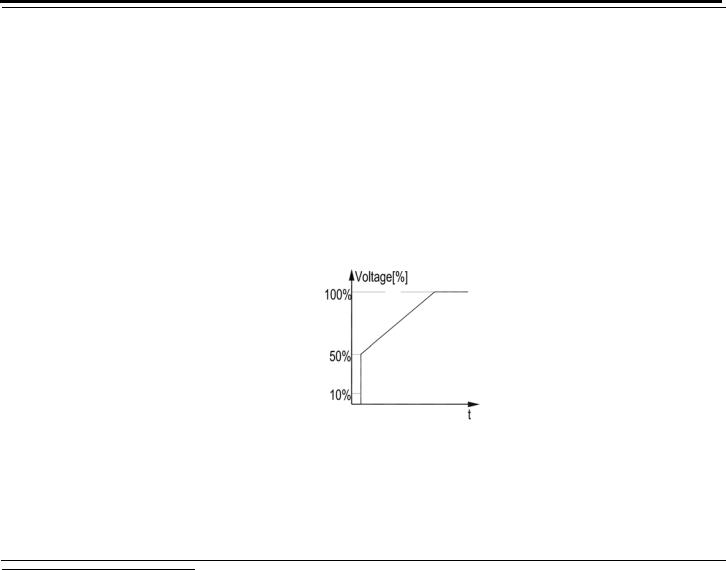

Starting Voltage: |

10-50% Un (5-80%9) |

|

|

Initial Current: |

100-400% In. A single current control starting curve. It appears when Starting |

|

|

|

Voltage is displayed, the up arrow is pressed and Starting Voltage has |

|

|

|

reached its max. |

|

|

Current Limit: |

100-700% of Motor Current |

|

|

Ramp UP Time: |

1-30 Sec (1-90 sec9) |

|

|

Ramp DOWN Time: |

1-30 Sec (1-90 sec9) |

|

|

DUAL Settings Parameters: |

Secondary start stop characteristic for: Starting Voltage, Starting Current, Current |

|

|

|

Limit, Ramp UP, Ramp DOWN and Motor Current. |

|

|

Energy Saving: |

Energy save for lightly loaded motors |

|

|

Slow Speed Torque: |

Torque while motor is at 1/6 nominal speed |

|

|

Motor Protection: |

Maximum number of starts, range: Off or 1-10, during a time period 1-60 min. |

|

|

Too Many Starts: |

||

|

Starts Inhibit: |

Time period 1-60 min, when starting is prevented, after too many starts fault |

|

|

Long Start Time (stall |

Maximum allowable starting time 1-30 sec. (1-250 Sec9) |

|

|

protection): |

Three trip functions: |

|

|

Over Current (JAM Fault): |

||

|

|

At all time - If I > 850% of Starter Current it trips the ASTAT-XT within 1 cycle |

|

|

|

(overrides the value of the O/C – JAM Delay setting). |

|

|

|

At starting process - If I > 850% of Motor Current it trips the ASTAT-XT after O/C |

|

|

|

JAM Delay (see here after) |

|

|

|

At run time - If I > O/C – JAM Fault setting of Im it trips the ASTAT-XT after O/C |

|

|

|

JAM Delay |

|

|

Electronic Overload: |

Can be set as IEC Class 10, 20 or NEMA Class 10, 20 or 30. |

|

|

|

Can be set to operate at all times, disabled or operate during Run only. |

|

|

Under Current: |

Trips when current drops below 20-90% of Motor Current, time delay 1-40 sec. |

|

|

|

Optional auto reset after time delay. |

|

|

Under Voltage: |

Trips when main voltage drops below 120-600V, time delay 1-10 Sec. Optional Auto |

|

|

|

Reset. |

|

|

Over Voltage: |

Trips when main voltage increase above 250-750V, time delay 1-10 sec. |

|

|

|

|

|

8Refer to sections 2.1 page 8 and 2.2 page 9 for detailed information.

9Refer to section 5.5.5 page 50 for expanded setting.

|

|

|

12 • Technical Specifications |

|

|

|

Trips when one or two phases are missing, or frequency is < 40Hz or > 65Hz. |

|

Phase Loss, Under/over |

||

|

Frequency: |

|

Optional auto reset. |

|

Phase Sequence: |

|

Trips when phase sequence is wrong |

|

Long Slow Speed Time: |

|

Trips if operating at slow speed TRQ for more than 1-30 sec (1-250 sec9) |

|

Wrong Connection: |

|

Prevents starting, trips if motor is not connected / incorrectly connected to the |

|

|

|

ASTAT-XT (not active in D.Set: Generator Parameters) |

|

Shorted SCR: |

|

Trips if one or more SCRs have been shorted |

|

|

|

(not active in D.Set: Generator Parameters) |

|

Heat Sink Over |

|

Trips when heat-sink temperature rises above 85°C |

|

Temperature: |

|

Trips when an external contact closes for 2 sec. |

|

External Fault: |

|

|

|

Motor Thermistor: |

|

Trip level setting 1-10KΩ, trips when resistance decreases below the level set |

|

Control: |

|

LCD in 4 – Field selectable languages and 8 LEDs |

|

Displays: |

|

|

|

Keypad: |

|

6 keys for easy setting |

|

Aux Contact – Immediate: |

|

1 C/O, 8A, 250VAC, 2000VA |

|

Aux Contact – End Of |

|

1 C/O, 8A, 250VAC, 2000VA |

|

Ramp: |

|

1 C/O, 8A, 250VAC, 2000VA |

|

Fault Contact: |

|

|

|

Communication: |

|

RS 485 with Modbus protocol for full control and supervision |

|

Communication (optional): |

|

Profibus DPV1 for full control and supervision |

|

Communication (optional): |

|

DeviceNettm for full control and supervision |

|

Temperatures Operating: |

|

-10° to 50°C |

|

|

|

-20° to 70°C |

|

Storage: |

||

|

Standards: |

|

2500VAC |

|

Dielectric Test: |

|

|

|

Degree of Protection: |

|

IP 20 for QTx0008 - QTx0072 ; IP 00 for QTx0085 – QTx1400 |

|

Pollution Degree: |

3 |

|

|

EMC Emissions: |

|

EN 61000-6-4 CISPR 11 Class A |

|

Immunity: |

|

EN 61000-6-2 ESD 8KV air, IEC 801-2; |

|

|

|

Electric RF field 10 V/m, 20-1000Mhz, IEC 801-3 |

|

|

|

Fast transients 2KV, IEC 801-4 |

|

Safety: |

|

EN IEC 600947-4-2 and EN IEC 60947-1 Related to safety requirements. |

|

|

|

UL508C |

|

Rated Operational Current |

|

AC:53a:4-30: 50-4 |

|

Normal Service Conditions: |

|

|

|

Altitude: |

|

Up to 1000m. |

|

Humidity: |

|

95% at 50°C or 98% at 45˚C |

Fan and Control Consumption Ratings:

QTx0008 to QTx0031:No fan |

Total approximate consumption: |

150VA |

QTx0044 to QTx0072:Fan 35 VA |

Total approximate consumption |

185VA |

QTx0085 to QTx0170 :Fan 60 VA |

Total approximate consumption |

210VA |

QTx0210 to QTx0390 : Fans 105 VA (35VA x 3) |

Total approximate consumption |

255VA |

QTx0460 to QTx1400A : Fans 150 VA (50VA x 3) |

Total approximate consumption |

300VA |

|

|

|

13 • Technical Specifications |

||

|

3.2 Weight |

|

|

|

|

|

|

|

|

|

|

|

Model |

|

Weight |

||

|

|

|

|

|

|

|

|

Kg |

Lbs |

||

|

QTx0008Uxxxx |

4.2 |

9.3 |

|

|

|

QTx0017Uxxxx |

4.2 |

9.3 |

|

|

|

QTx0031Uxxxx |

5.3 |

11.7 |

|

|

|

QTx0044Uxxxx |

6.7 |

14.8 |

|

|

|

QTx0058Uxxxx |

6.7 |

14.8 |

|

|

|

QTx0072Uxxxx |

6.7 |

14.8 |

|

|

|

QTx0085Uxxxx |

15.2 |

33.5 |

|

|

|

QTx0105Uxxxx |

15.2 |

33.5 |

|

|

|

QTx0145Uxxxx |

15.2 |

33.5 |

|

|

|

QTx0170Uxxxx |

15.2 |

33.5 |

|

|

|

QTx0210Nxxxx |

32.7 |

72.1 |

|

|

|

QTx0210Uxxxx |

46.5 |

102.5 |

|

|

|

QTx0310Nxxxx |

32.7 |

72.1 |

|

|

|

QTx0310Uxxxx |

46.5 |

102.5 |

|

|

|

QTx0390Nxxxx |

32.7 |

72.1 |

|

|

|

QTx0390Uxxxx |

46.5 |

102.5 |

|

|

|

QTx0460Nxxxx |

58.4 |

128.7 |

|

|

|

QTx0460Uxxxx |

61.8 |

136.2 |

|

|

|

QTx0580Nxxxx |

63.2 |

139.3 |

|

|

|

QTx0580Uxxxx |

69.5 |

153.2 |

|

|

|

QTx0650Nxxxx |

64.8 |

142.9 |

|

|

|

QTx0820Uxxxx |

69.5 |

153.2 |

|

|

|

QTx0950Nxxxx |

86.7 |

191.1 |

|

|

|

QTx1100Nxxxx |

169.8 |

374.3 |

|

|

|

QTx1400Nxxxx |

175.5 |

386.9 |

|

|

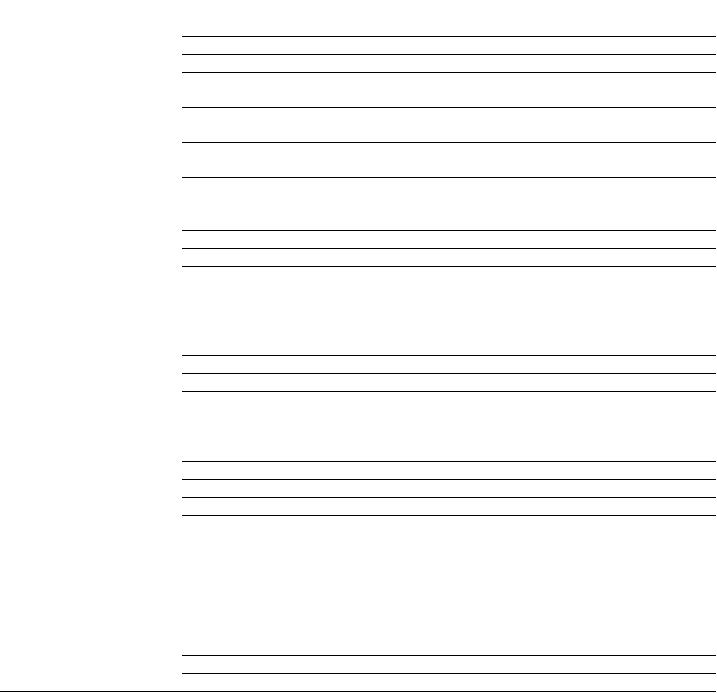

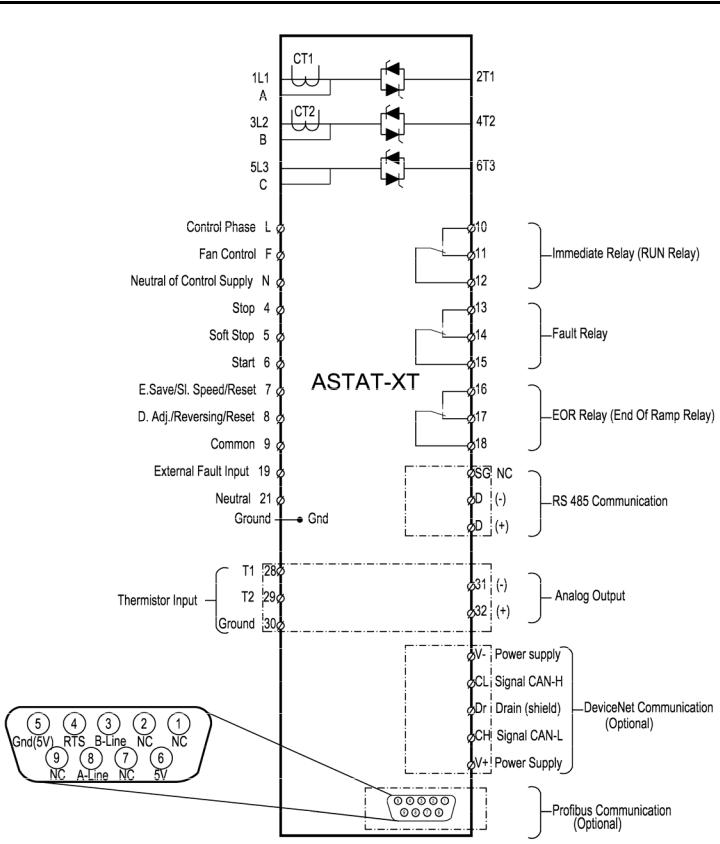

3.3 I/O Terminal Board Specifications

Refer to drawing on page 17.

Terminal |

Function |

Description |

|

|

|

1L1, 3L2, 5L3 |

Connection to mains voltage up |

Thyristor’s PIV rating, internal circuitry and insulation defines |

|

to 690V |

three voltage levels: |

|

|

QT 1 x : for 230-500V +10%/ -15% 50/60Hz |

|

|

QT 2 x: for 460-600V +10% /-15% 50/60Hz |

|

|

QT 3 x: for 690V +10% /-15% 50/60Hz |

|

|

Each ASTAT-XT is suitable for one of the above levels & for |

|

|

50/60 Hz. |

A, B, C |

Preparation for bypass |

Bypass preparation is standard in all models. |

|

connection |

All models from ASTAT-XT 950A and up must be operated |

|

|

with a bypass contactor. |

|

|

Refer to section 5.3 page 47 for more details. |

2T1, 4T2, 6T3 |

Connection to motor |

Connect motor’s terminals to these terminals/busbars. |

|

|

|

G |

Connection to ground |

For proper operation and for safety reasons soft ASTAT-XT |

|

|

must be properly grounded. |

Terminal L |

Control phase |

The control voltage operates the electronic circuitry and the |

|

|

fans (when they exist). |

Terminal N |

Control neutral (return) |

Two control voltages are available: |

|

|

QT x xxxx x 1 x x S for 110V +10%/-15% 50/60Hz |

|

|

QT x xxxx x 2 x x S for 230V +10%/-15% 50/60Hz |

|

|

|

|

14 • Technical Specifications |

||

|

|

|

|

|

|

|

|

|

Terminal |

Function |

Description |

||

|

|

|

|

|

|

|

|

|

Terminal F |

Fan control |

An internal jumper, connected between the fan and |

||

|

|

|

|

|

terminal 2 enables three modes of operation (refer to section |

|

|

|

|

|

|

5.6 page 51). |

|

|

|

|

|

|

For fan power consumption, see technical specification in |

|

|

|

|

|

|

section 3 page 11. |

|

|

|

Terminal 4 |

Input – STOP command. |

•Control Input voltage (STOP, SOFT STOP, START, terminal |

|

|

|

|

|

•Input from a N.C. contact |

inputs 7 and 8) can be the same as Control Supply |

||

|

|

|

•To stop the motor, disconnect |

(terminals 1, 3) or voltage from a different source. |

||

|

|

|

Control Input voltage from |

•The Control Inputs are opto-coupled and isolated from the |

||

|

|

|

terminal 4 for at least |

microprocessor circuitry. |

||

|

|

|

250mSec. (no SOFT STOP) |

Control Input voltages available: |

||

|

|

Terminal 5 |

Input – SOFT STOP command10. |

|||

|

|

|

•Input from a N.C. contact |

QT x xxxx x x 1 x S for 90-230V +10%/-15% 50/60Hz. |

||

|

|

|

•To SOFT STOP the motor |

QT x xxxx x x 2 x S for 24VDC +10%/-15%. |

||

|

|

|

disconnect Control Input |

|

|

|

|

|

|

voltage from terminal 5 for at |

|

|

|

|

|

|

least 250mS |

|

|

|

|

|

Terminal 6 |

Input – START command11. |

|

|

|

|

|

|

•Input from a N.O. contact. |

|

|

|

|

|

|

•To SOFT START the motor, |

|

|

|

|

|

|

connect Control Input voltage |

|

|

|

|

|

|

to terminal 4 for at least |

|

|

|

|

|

|

250mSec. |

|

|

|

|

|

Terminal 7 |

Programmable input – Energy |

Refer to section 4.7.8.1 page 41. |

|

|

|

|

|

Save / Slow Speed / Reset |

|

|

|

|

|

Terminal 8 |

Programmable input – Dual Set |

|

|

|

|

|

|

/ Reverse / Reset |

|

|

|

|

|

Terminal 9 12 |

Common to terminals 4-8. |

This terminal is a reference for terminals 4, 5, 6, 7 & |

|

|

|

|

|

|

|

8. |

|

|

|

Terminal 10 |

Immediate Relay (N.O.) |

Immediate Relay (RUN relay) is the immediate output relay. |

|

|

|

|

|

|

|

•Voltage free 8A, 250VAC, 2000VA max. |

|

|

|

Terminal 11 |

Immediate Relay (N.C.) |

•The relay is energized upon the START signal. |

||

|

|

Terminal 12 |

Immediate Relay (Common) |

•The relay is de-energized when one of the following occurs: |

||

|

|

|

|

|

Fault, Control Supply outage or STOP signal. |

|

|

|

|

|

|

•When SOFT STOP is operated - the relay is de-energized at |

|

|

|

|

|

|

the end of the SOFT STOP process. |

|

|

|

|

|

|

•The Immediate Relay (RUN relay) can be used for the |

|

|

|

|

|

|

following purposes: Release a brake of a motor, Interlock |

|

|

|

|

|

|

with other systems, Signalling, Delay the opening of a line |

|

|

|

|

|

|

contactor at the end of SOFT STOP, thus allowing current to |

|

|

|

|

|

|

decrease to zero before opening the contactor or to switch |

|

|

|

|

|

|

to / from DUAL settings with a time delay from the START |

|

|

|

|

|

|

signal (see Special Starting section 6.2.3.1 page 57). |

|

|

|

|

|

|

•The relay incorporates ON and OFF delays of 0-3600 sec. |

|

|

|

|

|

|

each. Refer to section 4.7.8 page 40 for Relay ON Delay |

|

|

|

|

|

|

programming. |

|

|

|

Terminal 13 |

Programmable Fault Output |

Voltage free 8A, 250VAC, 2000VA max. changes its position |

|

|

|

|

|

relay (N.O.) |

upon fault. |

||

|

|

Terminal 14 |

Programmable Fault Output |

The contact is programmable to function as At Fault |

||

|

|

|

relay (N.C.) |

Close or At Fault Open. |

||

|

|

|

|

|

|

|

10If SOFT STOP is not required, connect a jumper between terminals 4 and 5.

11Motor will start only if STOP (terminal 4) and SOFT STOP (terminal 5) terminals are connected to Control Input voltage. To reset a fault the START command must be removed.

12When Control Supply and Control Input voltage are from the same source, connect a jumper between terminals 3 and 9.

15 • Technical Specifications