bosch CC 220 User Manual

Typ1 osa / CC 220

Signal Description

Version 101

Typ1 osa / CC 220

Signal Description

1070 073 758-101 (96.02) GB

E 1996

by Robert Bosch GmbH,

All rights reserved, including applications for protective rights. Reproduction or handing over to third parties are subject to our written permission.

Discretionary charge 20.– DM

Type1 osa / CC 220

Table of contents

Signal description

Table of contents

Page

Safety instructions / Foreword |

|

|

|

1. |

Digital interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 − 1 |

|

1 .1 |

Interface tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 − 1 |

|

1.1.1 |

Signals from CNC to PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 − 3 |

|

1.1.2 |

Signals from CNC to PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

− 9 |

1.1.3 |

PLC input addresses of the MTB1 I/O inputs (only CC 220) . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

− 15 |

1.1.4 |

PLC output addresses of the MTB1 I/O outputs (only CC 220) . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

− 17 |

1.1.5 |

Signals to the machine for PIC 250 modules with I/O 24/0.2 (only CC 220) . . . . . . . . . . . . . |

1 |

− 18 |

1.1.6 |

Signals from the machine for PIC 250 modules with I/O 24/0.2 (only CC 220) . . . . . . . . . . |

1 − 19 |

|

1.2 |

Signal descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 − 21 |

|

1.2.1 |

Control inputs (PLC outputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 − 23 |

|

1.2.2 |

Control outputs (PLC inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 − 115 |

|

1.3 |

Other signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 − 175 |

|

1.4 |

Signal register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 − 181 |

|

1070 073 |

Contents 1 |

|

758 101 |

||

|

Type1 osa / CC 220

Table of contents

Signal description

1070 073 |

Contents 2 |

|

758 101 |

||

|

Type1 osa / CC 220

Safety Instructions

Signal description

Safety instructions

The following warning labels can be attached to control units to draw attention to certain points:

’ Danger of electrocution!

’ Danger of battery leakage!

’ Electrostatic sensitive devices!

’ Remove plug before opening!

’Bolts only for PE conductor connection!

’ Only for cable screen connection!

Symbols used in the manual:

To draw attention to particular points:

NOTE

NOTE

(Supplementary explanations, recommendations, information and tips are found under these headings)

To draw your attention to particular safety critical points or instructions:

CAUTION!

CAUTION!

Damage to equipment can result if instructions are not observed! For example, files can be erased or modules damaged.

CAUTION!

CAUTION!

Damage to equipment or even personal injury can result if instructions are not

!observed.

!or this warning symbol in the left margin.

1070 073 758 101 |

I |

Type1 osa / CC 220

Safety Instructions

Signal description

Owing to the particular, safety critical significance with regard to drive movements or the evaluation of CNC digital I/Os, we draw your attention to the control signal READY2 (for relay contact; see section "Other signals").

CAUTION!

CAUTION!

The READY2 or Ready contact must be networked to the emergency stop cir

!cuit!

The control is not ready if the Ready 2 contact is open! For this reason all dan gerous functions must be made safe immediately after opening the contact!

1070 073 758 101 |

II |

Type1 osa / CC 220

Foreword

Signal description

Foreword

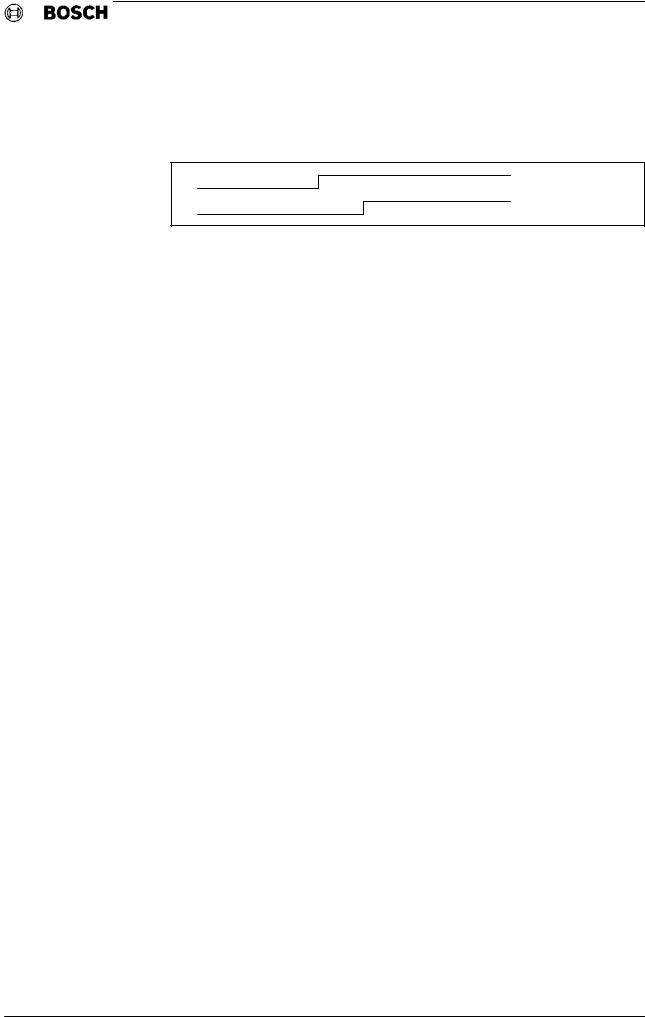

This manual relates to the applications and currently released software versions of the following control units:

Logic controller |

Application |

Software version |

Type1 osa M |

Centre |

T4 ZO |

CC 220 M |

Centre |

Z25 FO |

Type1 osa T |

Rotate |

T... ... |

CC 220 T |

Rotate |

D... ... |

NOTE

NOTE

The group operating mode DIAGNOSIS contains instructions for the current con trol unit software version which may be accessed via the softkey DIAGNOSTIC CONTROL or SOFTWARE VERSION.

As the title suggests, this manual contains information required for normal opera tion of control unit digital I/O signals.

Please refer to the manual •Connection conditions part 1" for the relevant control unit for information on control hardware (I/O connections, etc.).

Since the control unit usually forms part of a larger system, sometimes with com plex, machine specific PLC adaptation programs, this manual cannot deal with PLC adaptation.

Your Bosch service branch or customer advisory service will be pleased to help you if you require more detailed information or if problems with the control unit should arise which are not sufficiently dealt with in this manual.

This manual is intended for technically qualified PLC configuration personnel.

CAUTION!

CAUTION!

Only suitably qualified personnel may carry out configuration and commissioning!

!Such personnel must be able to recognise the dangers which can be caused by mechanical, electrical or electronic equipment.

Please observe our comprehensive training program. An overview of courses may be found on the inside front cover of this manual. Our training centre will be pleased to provide you with further information (tel: 06062 / 78258).

1070 073 758 101 |

III |

Type1 osa / CC 220

Foreword

Signal description

1070 073 758 101 |

IV |

Digital Interface

Type1 osa / CC 220

Signal description

1Digital interface

1.1 Interface tables

The tables list the interface scope between CNC / PLC and (MTB1 I/O for CC220) classified by addresses. The tables contain the interface addresses of the control units Type1 osa and the CC220.

PLC functionality is integrated as software in the Type1 osa softPIC variants under the name •softPIC". PLC functionality is prepared for the relevant hardware (CL400) in the Type1 osa variants.

Note

Type1 osa signals differ from those of the CC220 control unit series in the number of axes which can be used with the NC PLC interface.

For example, only signals which address axes 1 to 5 can be processed in the

Type1 osa NC interface (osa module with 5 axes).

Any signal which has not been allocated a marker cannot be used with the Type1 osa control unit.

Limits on other signals are designated specifically at the signals according to their different NC series.

Addresses

The CNC digital interface has 256 inputs and 256 outputs. The PLC addresses these signals differently depending on the type of coupling between CNC and PLC (Type1 osa: softPIC, CL) or (CC220: PIC250, bit or word coupling).

In the tables all addresses are PLC related, i.e. •I 0.0" corresponds to PLC Input signal 0.0 and •O 0.0" to PLC output signal 0.0. The assignment of addresses for the CNC interface is contained in the •Address bit coupl." column:

e.g. I 0.0 = CNC output 0.0; e.g. O 0.0 = CNC input 0.0

System (name) CC 220

The SYMBOL NAMES for word coupling PLCs (PC 600) must be adopted by the user 1:1 because existing function modules are configured around these symbol names.

For bit coupled PLCs (CL / PIC 250 / PC 600) other symbol names can be used, but the default symbol names should be used to simplify trouble shooting (service).

For multiple bit coupling (CL, PC 600) the symbol is given an index at the first char acter of the symbol name (e.g. •CCDRVON1" ! •1CDRVON1", •2CDRVON1" ! •3CDRVON1").

1070 073 758 101 |

1 − 1 |

Digital Interface

Type1 osa / CC 220

Signal description

Start address CC220

The start address for the CNC interface can be set using the machine parameter of the relevant control unit (in parameter block 6000). This avoids conflicting ad dresses where a number of bit coupled CNCs are connected to a single CL, PC600 (multiple bit coupling).

First CNC: |

P6008=0; |

Start address of CNC digital interface at 0.0 |

|

|

(normal case). |

Second CNC: |

P6008=40; |

Start address of CNC digital interface at 40.0 |

|

|

The CNC input •DRIVE ON 1ST AXIS" is |

|

|

now set by the PLC through the PLC output O40.0 |

e.g. I 0.0 = CNC output 0.0; e.g. O 0.0 = CNC input 0.0

Remarks

The REMARKS for the CNC PLC signals correspond to the standard Bosch Assign ment Lists. The user can change these forms to his/her own remarks provided the meaning of the signal remarks remains unchanged.

1070 073 758 101 |

1 − 2 |

Type1 osa / CC 220

Digital Interface

Signal description

1.1.1Signals from CNC to PLC

–––––––––––––––––Address––––––––––––––––– |

|

|

||||

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

Remarks |

||

|

|

|

|

|||

------------------ |

|

PLC->NC O |

BYTE: 0 (M BYTE: 0) ------------------------------- |

|||

O216.0 |

O0.0 |

0 |

M0.0 |

O0.0 |

CCDRVON1 |

DRIVE ON 1ST AXIS |

O216.1 |

O0.1 |

1 |

M0.1 |

O0.1 |

CCDRVON2 |

DRIVE ON 2ND AXIS |

O216.2 |

O0.2 |

2 |

M0.2 |

O0.2 |

CCDRVON3 |

DRIVE ON 3RD AXIS |

O216.3 |

O0.3 |

3 |

M0.3 |

O0.3 |

CCDRVON4 |

DRIVE ON 4TH AXIS |

O216.4 |

O0.4 |

4 |

M0.4 |

O0.4 |

CCDRVON5 |

DRIVE ON 5TH AXIS |

O216.5 |

O0.5 |

5 |

|

|

CCDRVON6 |

DRIVE ON 6TH AXIS |

O216.6 |

O0.6 |

6 |

|

|

CCDRVON7 |

DRIVE ON 7TH AXIS |

O216.7 |

O0.7 |

7 |

|

|

CCDRVON8 |

DRIVE ON 8TH AXIS |

------------------ |

|

PLC->NC O |

BYTE: 1 (M BYTE: 1) ------------------------------- |

|||

O217.0 |

O1.0 |

8 |

M1.0 |

O1.0 |

CCVFRG1 |

FEED ALLOW 1ST AXIS |

O217.1 |

O1.1 |

9 |

M1.1 |

O1.1 |

CCVFRG2 |

FEED ALLOW 2ND AXIS |

O217.2 |

O1.2 |

10 |

M1.2 |

O1.2 |

CCVFRG3 |

FEED ALLOW 3RD AXIS |

O217.3 |

O1.3 |

11 |

M1.3 |

O1.3 |

CCVFRG4 |

FEED ALLOW 4TH AXIS |

O217.4 |

O1.4 |

12 |

M1.4 |

O1.4 |

CCVFRG5 |

FEED ALLOW 5TH AXIS |

O217.5 |

O1.5 |

13 |

|

|

CCVFRG6 |

FEED ALLOW 6TH AXIS |

O217.6 |

O1.6 |

14 |

|

|

CCVFRG7 |

FEED ALLOW 7TH AXIS |

O217.7 |

O1.7 |

15 |

|

|

CCVFRG8 |

FEED ALLOW 8TH AXIS |

------------------ |

|

PLC->NC O |

BYTE: 2 (M BYTE: 2) ------------------------------- |

|||

O218.0 |

O2.0 |

16 |

M2.0 |

O2.0 |

CCREFP1 |

REFERENCE POINT 1ST AXIS |

O218.1 |

O2.1 |

17 |

M2.1 |

O2.1 |

CCREFP2 |

REFERENCE POINT 2ND AXIS |

O218.2 |

O2.2 |

18 |

M2.2 |

O2.2 |

CCREFP3 |

REFERENCE POINT 3RD AXIS |

O218.3 |

O2.3 |

19 |

M2.3 |

O2.3 |

CCREFP4 |

REFERENCE POINT 4TH AXIS |

O218.4 |

O2.4 |

20 |

M2.4 |

O2.4 |

CCREFP5 |

REFERENCE POINT 5TH AXIS |

O218.5 |

O2.5 |

21 |

|

|

CCREFP6 |

REFERENCE POINT 6TH AXIS |

O218.6 |

O2.6 |

22 |

|

|

CCREFP7 |

REFERENCE POINT 7TH AXIS |

O218.7 |

O2.7 |

23 |

|

|

CCREFP8 |

REFERENCE POINT 8TH AXIS |

------------------ |

|

PLC->NC O |

BYTE: 3 (M BYTE: 3) ------------------------------- |

|||

O219.0 |

O3.0 |

24 |

M3.0 |

O3.0 |

CCREFR1 |

DIR. of REF. 1ST AXIS |

O219.1 |

O3.1 |

25 |

M3.1 |

O3.1 |

CCREFR2 |

DIR. of REF. 2ND AXIS |

O219.2 |

O3.2 |

26 |

M3.2 |

O3.2 |

CCREFR3 |

DIR. of REF. 3RD AXIS |

O219.3 |

O3.3 |

27 |

M3.3 |

O3.3 |

CCREFR4 |

DIR. of REF. 4TH AXIS |

O219.4 |

O3.4 |

28 |

M3.4 |

O3.4 |

CCREFR5 |

DIR. of REF. 5TH AXIS |

O219.5 |

O3.5 |

29 |

|

|

CCREFR6 |

DIR. of REF. 6TH AXIS |

O219.6 |

O3.6 |

30 |

|

|

CCREFR7 |

DIR. of REF. 7TH AXIS |

O219.7 |

O3.7 |

31 |

|

|

CCREFR8 |

DIR. of REF. 8TH AXIS |

------------------ |

|

PLC->NC O |

BYTE: 4 (M BYTE: 4) ------------------------------- |

|||

O220.0 |

O4.0 |

32 |

M4.0 |

O4.0 |

CCRED1 |

(NOT) REDUCTION 1ST AXIS |

O220.1 |

O4.1 |

33 |

M4.1 |

O4.1 |

CCRED2 |

(NOT) REDUCTION 2ND AXIS |

O220.2 |

O4.2 |

34 |

M4.2 |

O4.2 |

CCRED3 |

(NOT) REDUCTION 3RD AXIS |

O220.3 |

O4.3 |

35 |

M4.3 |

O4.3 |

CCRED4 |

(NOT) REDUCTION 4TH AXIS |

O220.4 |

O4.4 |

36 |

M4.4 |

O4.4 |

CCRED5 |

(NOT) REDUCTION 5TH AXIS |

O220.5 |

O4.5 |

37 |

|

|

CCRED6 |

(NOT) REDUCTION 6TH AXIS |

O220.6 |

O4.6 |

38 |

|

|

CCRED7 |

(NOT) REDUCTION 7TH AXIS |

O220.7 |

O4.7 |

39 |

|

|

CCRED8 |

(NOT) REDUCTION 8TH AXIS |

------------------ |

|

PLC->NC O |

BYTE: 5 (M BYTE: 5) ------------------------------- |

|||

O221.0 |

O5.0 |

40 |

M5.0 |

O5.0 |

CCEINFRG |

TRANSFER ALLOW |

O221.1 |

O5.1 |

41 |

M5.1 |

O5.1 |

CCEDITFR |

EDIT INHIBIT |

O221.2 |

O5.2 |

42 |

M5.2 |

O5.2 |

CCSLASHA |

BLOCK SLASH |

O221.3 |

O5.3 |

43 |

M5.3 |

O5.3 |

CCEMSTPQ |

(NOT) EMERGENCY STOP |

O221.4 |

O5.4 |

44 |

M5.4 |

O5.4 |

CC START |

NC START |

O221.5 |

O5.5 |

45 |

M5.5 |

O5.5 |

CCHALTQ |

(NOT) FEED HOLD |

O221.6 |

O5.6 |

46 |

|

|

CCLOCREM |

LOCAL/REMOTE change-over (DNC) |

O221.7 |

O5.7 |

47 |

|

|

CCLOREPO |

LOCAL/REMOTE POTENTIOMETER (DNC) |

1070 073 758 101 |

1 − 3 |

Type1 osa / CC 220

Digital Interface

Signal description

––––––––––––––––––Address–––––––––––––––– |

|

|

||||

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

Remarks |

||

|

|

|

|

|||

------------------ |

|

PLC->NC O |

BYTE: 6 (M BYTE: 6) ------------------------------- |

|||

O222.0 |

O6.0 |

48 |

M6.0 |

O6.0 |

CCEINM01 |

OPTIONAL STOP |

O222.1 |

O6.1 |

49 |

M6.1 |

O6.1 |

CCDIREKT |

DIRECT CALL |

O222.2 |

O6.2 |

50 |

M6.2 |

O6.2 |

|

|

O222.3 |

O6.3 |

51 |

M6.3 |

O6.3 |

CCCPLMAS |

CPL DIALOGUE MACHINE |

O222.4 |

O6.4 |

52 |

M6.4 |

O6.4 |

CCBETRKL |

MODE INHIBIT |

O222.5 |

O6.5 |

53 |

M6.5 |

O6.5 |

CCMULSTR |

MULTISTROBE |

O222.6 |

O6.6 |

54 |

M6.6 |

O6.6 |

CCABSINK |

ABSOLUTE/INCREMENTAL (L/H) |

O222.7 |

O6.7 |

55 |

M6.7 |

O6.7 |

CCSIGN |

SIGN (+/-) (L/H) |

------------------ |

|

PLC->NC O |

BYTE: 7 (M BYTE: 7) ------------------------------- |

|||

O223.0 |

O7.0 |

56 |

M7.0 |

O7.0 |

CCMMOD1 |

MULTIMODE VALUE 1 |

O223.1 |

O7.1 |

57 |

M7.1 |

O7.1 |

CCMMOD2 |

MULTIMODE VALUE 2 |

O223.2 |

O7.2 |

58 |

M7.2 |

O7.2 |

CCMMOD4 |

MULTIMODE VALUE 4 |

O223.3 |

O7.3 |

59 |

M7.3 |

O7.3 |

CCMMOD8 |

MULTIMODE VALUE 8 |

O223.4 |

O7.4 |

60 |

M7.4 |

O7.4 |

CCMMOD16 |

MULTIMODE VALUE 16 |

O223.5 |

O7.5 |

61 |

M7.5 |

O7.5 |

CCMMOD32 |

MULTIMODE VALUE 32 |

O223.6 |

O7.6 |

62 |

M7.6 |

O7.6 |

CCMMOD64 |

MULTIMODE VALUE 64 |

O223.7 |

O7.7 |

63 |

M7.7 |

O7.7 |

CCMMO128 |

MULTIMODE VALUE 128 |

------------------ |

|

PLC->NC O |

BYTE: 8 (M BYTE: 8) ------------------------------- |

|||

O224.0 |

O8.0 |

64 |

M8.0 |

O8.0 |

CCDAT1 |

DATA LINE MULTIMODE 1 * 10**0/2**0 |

O224.1 |

O8.1 |

65 |

M8.1 |

O8.1 |

CCDAT2 |

DATA LINE MULTIMODE 2 * 10**0/2**1 |

O224.2 |

O8.2 |

66 |

M8.2 |

O8.2 |

CCDAT3 |

DATA LINE MULTIMODE 4 * 10**0/2**2 |

O224.3 |

O8.3 |

67 |

M8.3 |

O8.3 |

CCDAT4 |

DATA LINE MULTIMODE 8 * 10**0/2**3 |

O224.4 |

O8.4 |

68 |

M8.4 |

O8.4 |

CCDAT5 |

DATA LINE MULTIMODE 1 * 10**1/2**4 |

O224.5 |

O8.5 |

69 |

M8.5 |

O8.5 |

CCDAT6 |

DATA LINE MULTIMODE 2 * 10**1/2**5 |

O224.6 |

O8.6 |

70 |

M8.6 |

O8.6 |

CCDAT7 |

DATA LINE MULTIMODE 4 * 10**1/2**6 |

O224.7 |

O8.7 |

71 |

M8.7 |

O8.7 |

CCDAT8 |

DATA LINE MULTIMODE 8 * 10**1/2**7 |

------------------ |

|

PLC->NC O |

BYTE: 9 (M BYTE: 9) ------------------------------- |

|||

O225.0 |

O9.0 |

72 |

M9.0 |

O9.0 |

CCDAT9 |

DATA LINE MULTIMODE 1 * 10**2/2**8 |

O225.1 |

O9.1 |

73 |

M9.1 |

O9.1 |

CCDAT10 |

DATA LINE MULTIMODE 2 * 10**2/2**9 |

O225.2 |

O9.2 |

74 |

M9.2 |

O9.2 |

CCDAT11 |

DATA LINE MULTIMODE 4 * 10**2/2**10 |

O225.3 |

O9.3 |

75 |

M9.3 |

O9.3 |

CCDAT12 |

DATA LINE MULTIMODE 8 * 10**2/2**11 |

O225.4 |

O9.4 |

76 |

M9.4 |

O9.4 |

CCDAT13 |

DATA LINE MULTIMODE 1 * 10**3/2**12 |

O225.5 |

O9.5 |

77 |

M9.5 |

O9.5 |

CCDAT14 |

DATA LINE MULTIMODE 2 * 10**3/2**13 |

O225.6 |

O9.6 |

78 |

M9.6 |

O9.6 |

CCDAT15 |

DATA LINE MULTIMODE 4 * 10**3/2**14 |

O225.7 |

O9.7 |

79 |

M9.7 |

O9.7 |

CCDAT16 |

DATA LINE MULTIMODE 8 * 10**3/2**15 |

------------------ |

|

PLC->NC O |

BYTE: 10 (M BYTE: 10) ------------------------------ |

|||

O226.0 |

O10.0 |

80 |

M10.0 |

O10.0 |

CCDAT17 |

DATA LINE MULTIMODE 1 * 10**4/2**16 |

O226.1 |

O10.1 |

81 |

M10.1 |

O10.1 |

CCDAT18 |

DATA LINE MULTIMODE 2 * 10**4/2**17 |

O226.2 |

O10.2 |

82 |

M10.2 |

O10.2 |

CCDAT19 |

DATA LINE MULTIMODE 4 * 10**4/2**18 |

O226.3 |

O10.3 |

83 |

M10.3 |

O10.3 |

CCDAT20 |

DATA LINE MULTIMODE 8 * 10**4/2**19 |

O226.4 |

O10.4 |

84 |

M10.4 |

O10.4 |

CCDAT21 |

DATA LINE MULTIMODE 1 * 10**5/2**20 |

O226.5 |

O10.5 |

85 |

M10.5 |

O10.5 |

CCDAT22 |

DATA LINE MULTIMODE 2 * 10**5/2**21 |

O226.6 |

O10.6 |

86 |

M10.6 |

O10.6 |

CCDAT23 |

DATA LINE MULTIMODE 4 * 10**5/2**22 |

O226.7 |

O10.7 |

87 |

M10.7 |

O10.7 |

CCDAT24 |

DATA LINE MULTIMODE 8 * 10**5/2**23 |

------------------ |

|

PLC->NC O |

BYTE: 11 (M BYTE: 11) ------------------------------ |

|||

O227.0 |

O11.0 |

88 |

M11.0 |

O11.0 |

CCDAT25 |

DATA LINE MULTIMODE 1 * 10**6/2**24 |

O227.1 |

O11.1 |

89 |

M11.1 |

O11.1 |

CCDAT26 |

DATA LINE MULTIMODE 2 * 10**6/2**25 |

O227.2 |

O11.2 |

90 |

M11.2 |

O11.2 |

CCDAT27 |

DATA LINE MULTIMODE 4 * 10**6/2**26 |

O227.3 |

O11.3 |

91 |

M11.3 |

O11.3 |

CCDAT28 |

DATA LINE MULTIMODE 8 * 10**6/2**27 |

O227.4 |

O11.4 |

92 |

M11.4 |

O11.4 |

CCDAT29 |

DATA LINE MULTIMODE 1 * 10**7/2**28 |

O227.5 |

O11.5 |

93 |

M11.5 |

O11.5 |

CCDAT30 |

DATA LINE MULTIMODE 2 * 10**7/2**29 |

O227.6 |

O11.6 |

94 |

M11.6 |

O11.6 |

CCDAT31 |

DATA LINE MULTIMODE 4 * 10**7/2**30 |

O227.7 |

O11.7 |

95 |

M11.7 |

O11.7 |

CCDAT32 |

DATA LINE MULTIMODE 8 * 10**7/(+/-) |

1070 073 758 101 |

1 − 4 |

Type1 osa / CC 220

Digital Interface

Signal description

|

–––––––––––––––––Address–––––––––––––––––– |

|

|

|

|||||

|

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

|

Remarks |

|||

|

|

|

|

|

|

||||

|

------------------ |

|

PLC->NC O |

BYTE: 12 (M BYTE: 12) ------------------------------ |

|||||

|

O228.0 |

O12.0 |

96 |

M12.0 |

O12.0 |

CCHQUIT |

AUX.-FUNCT.-acknowledgement |

||

|

O228.1 |

O12.1 |

97 |

M12.1 |

O12.1 |

CCBSPR |

|

OPTIONAL JUMP ON |

|

|

O228.2 |

O12.2 |

98 |

M12.2 |

O12.2 |

|

|

|

|

|

O228.3 |

O12.3 |

99 |

M12.3 |

O12.3 |

CCSFTAUS |

SUPPRESSION OF SOFTWARE LIMITS |

||

|

O228.4 |

O12.4 |

100 |

M12.4 |

O12.4 |

CC2M3/FS |

2ND SPINDLE C’WISE ROTAT. (M3) / AUTOMATIC |

||

|

O228.5 |

O12.5 |

101 |

M12.5 |

O12.5 |

CC2M4/ES |

2ND SPINDLE COUNTER-CLOCKWISE ROTATION / BLOCK |

||

‘ |

O228.6 |

O12.6 |

102 |

M12.6 |

O12.6 |

CC2SPM5 |

2ND SPINDLE STOP (M5) |

||

‘ |

O228.7 |

O12.7 |

103 |

M12.7 |

O12.7 |

CC2SPM19 |

2nd SPINDLE DIRECT (M19 |

||

|

------------------ |

|

PLC->NC O |

BYTE: 13 (M BYTE: 13) ------------------------------ |

|||||

|

O229.0 |

O13.0 |

104 |

M13.0 |

O13.0 |

CCJOG1P |

JOG 1ST AXIS POSITIVE DIRECTION |

||

|

O229.1 |

O13.1 |

105 |

M13.1 |

O13.1 |

CCJOG1N |

JOG 1ST AXIS NEGATIVE DIRECTION |

||

|

O229.2 |

O13.2 |

106 |

M13.2 |

O13.2 |

CCJOG2P |

JOG 2ND AXIS POSITIVE DIRECTION |

||

|

O229.3 |

O13.3 |

107 |

M13.3 |

O13.3 |

CCJOG2N |

JOG 2ND AXIS NEGATIVE DIRECTION |

||

|

O229.4 |

O13.4 |

108 |

M13.4 |

O13.4 |

CCJOG3P |

JOG 3RD AXIS POSITIVE DIRECTION |

||

|

O229.5 |

O13.5 |

109 |

M13.5 |

O13.5 |

CCJOG3N |

JOG 3RD AXIS NEGATIVE DIRECTION |

||

|

O229.6 |

O13.6 |

110 |

M13.6 |

O13.6 |

CCJOG4P |

JOG 4TH AXIS POSITIVE DIRECTION |

||

|

O229.7 |

O13.7 |

111 |

M13.7 |

O13.7 |

CCJOG4N |

JOG 4TH AXIS NEGATIVE DIRECTION |

||

|

------------------ |

|

PLC->NC O |

BYTE: 14 (M BYTE: 14) ------------------------------ |

|||||

|

O230.0 |

O14.0 |

112 |

M14.0 |

O14.0 |

CCJOG5P |

JOG 5TH AXIS POSITIVE DIRECTION |

||

|

O230.1 |

O14.1 |

113 |

M14.1 |

O14.1 |

CCJOG5N |

JOG 5TH AXIS NEGATIVE DIRECTION |

||

|

O230.2 |

O14.2 |

114 |

|

|

CCJOG6P |

JOG 6TH AXIS POSITIVE DIRECTION |

||

|

O230.3 |

O14.3 |

115 |

|

|

CCJOG6N |

JOG 6TH AXIS NEGATIVE DIRECTION |

||

|

O230.4 |

O14.4 |

116 |

|

|

CCJOG7P |

JOG 7TH AXIS POSITIVE DIRECTION |

||

|

O230.5 |

O14.5 |

117 |

|

|

CCJOG7N |

JOG 7TH AXIS NEGATIVE DIRECTION |

||

|

O230.6 |

O14.6 |

118 |

|

|

CCJOG8P |

JOG 8TH AXIS POSITIVE DIRECTION |

||

|

O230.7 |

O14.7 |

119 |

|

|

CCJOG8N |

JOG 8TH AXIS NEGATIVE DIRECTION |

||

|

------------------ |

|

PLC->NC O |

BYTE: 15 (M BYTE: 15) ----------------------------- |

|||||

|

O231.0 |

O15.0 |

120 |

M15.0 |

O15.0 |

CCJRAPID |

MANUAL FEED RAPID |

||

|

O231.1 |

O15.1 |

121 |

M15.1 |

O15.1 |

CCJHIGH |

MANUAL FEED FAST |

||

|

O231.2 |

O15.2 |

122 |

M15.2 |

O15.2 |

CCJMED |

|

MANUAL FEED MEDIUM |

|

|

O231.3 |

O15.3 |

123 |

M15.3 |

O15.3 |

CCJLOW |

|

MANUAL FEED SLOW |

|

|

O231.4 |

O15.4 |

124 |

M15.4 |

O15.4 |

CCEXVORS |

EXTERNAL FEED |

||

|

O231.5 |

O15.5 |

125 |

M15.5 |

O15.5 |

CCINKX |

|

INCREMENTS X |

|

|

O231.6 |

O15.6 |

126 |

M15.6 |

O15.6 |

CCINK100 |

INCREMENTS 100 |

||

|

O231.7 |

O15.7 |

127 |

M15.7 |

O15.7 |

CCINK10 |

INCREMENTS 10 |

||

|

------------------ |

|

PLC->NC O |

BYTE: 16 (M |

BYTE: 16) ------------------------------ |

||||

|

O232.0 |

O16.0 |

128 |

M16.0 |

O16.0 |

CCINK1 |

|

INCREMENT 1 |

|

|

O232.1 |

O16.1 |

129 |

M16.1 |

O16.1 |

CCREFANF |

REFERENCE |

||

− |

O232.2 |

O16.2 |

130 |

M16.2 |

O16.2 |

CCNULSET |

ZERO RESET |

||

|

O232.3 |

O16.3 |

131 |

M16.3 |

O16.3 |

CCRESETL |

CANCEL DIST. TO GO |

||

|

O232.4 |

O16.4 |

132 |

M16.4 |

O16.4 |

CCRESETA |

CONTROL RESET |

||

|

O232.5 |

O16.5 |

133 |

M16.5 |

O16.5 |

CCE100% |

100% FEED ASYNCHRONOUS AXES |

||

|

O232.6 |

O16.6 |

134 |

M16.6 |

O16.6 |

CCEINTIP |

JOG (MM/MIN) |

||

|

O232.7 |

O16.7 |

135 |

M16.7 |

O16.7 |

CCTIPMMU |

JOG (MM/REV) |

||

|

------------------ |

|

PLC->NC O |

BYTE: 17 (M |

BYTE: 17) ------------------------------ |

||||

|

O233.0 |

O17.0 |

136 |

M17.0 |

O17.0 |

CCVSEXT |

EXTERNAL FEED POT |

||

|

O233.1 |

O17.1 |

137 |

M17.1 |

O17.1 |

CCSPEXT |

EXTERNAL SPINDLE POTI |

||

|

O233.2 |

O17.2 |

138 |

M17.2 |

O17.2 |

CCGETAUT |

AUTOMATIC GEAR RANGE SELECTION (M40) |

||

‘ |

O233.3 |

O17.3 |

139 |

M17.3 |

O17.3 |

CCZAEEIN |

PIECE COUNTER ON |

||

|

O233.4 |

O17.4 |

140 |

M17.4 |

O17.4 |

CCSPUMK |

SPINDLE REVERSE |

||

|

O233.5 |

O17.5 |

141 |

M17.5 |

O17.5 |

CCSPKONS |

CONSTANT SPINDLE SPEED |

||

|

O233.6 |

O17.6 |

142 |

M17.6 |

O17.6 |

CCSP0VQ |

(NOT) SPINDLE SET VALUE 0 VOLT |

||

|

O233.7 |

O17.7 |

143 |

M17.7 |

O17.7 |

CCSP100% |

SPINDLE OVERRIDE 100% |

||

− Only with CC 220 M, Type1 osa M ‘ Only with CC 220 T, Type1 osa T

With CC 220 T, Type1 osa T: 2ND SPINDLE CLOCKWISE ROTATION; with CC 220 M, Type1 osa M:AUTOMATIC

With CC 220 T, Type1 osa T: 2ND SPINDLE COUNTER CLOCKWISE ROTATION; for CC 220 M, Type1 osa M: BLOCK

1070 073 758 101 |

1 − 5 |

Type1 osa / CC 220

Digital Interface

Signal description

|

––––––––––––––––––Address––––––––––––––––– |

|

|

|

|||||

|

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

|

Remarks |

|||

|

|

|

|

|

|

||||

|

------------------ |

|

PLC->NC O |

BYTE: 18 (M BYTE: 18) ------------------------------ |

|||||

|

O234.0 |

O18.0 |

144 |

M18.0 |

O18.0 |

CCGETR1 |

GEAR RANGE 1 ACKNOWLEDGE |

||

|

O234.1 |

O18.1 |

145 |

M18.1 |

O18.1 |

CCGETR2 |

GEAR RANGE 2 ACKNOWLEDGE |

||

|

O234.2 |

O18.2 |

146 |

M18.2 |

O18.2 |

CCGETR3 |

GEAR RANGE 3 ACKNOWLEDGE |

||

|

O234.3 |

O18.3 |

147 |

M18.3 |

O18.3 |

CCGETR4 |

GEAR RANGE 4 ACKNOWLEDGE |

||

~ |

O234.4 |

O18.4 |

148 |

M18.4 |

O18.4 |

CCGETR5 |

GEAR RANGE 5 / 1 ACKNOWLEDGE (2ND SPINDLE) |

||

~ |

O234.5 |

O18.5 |

149 |

M18.5 |

O18.5 |

CCGETR6 |

GEAR RANGE 6 / 2 ACKNOWLEDGE (2ND SPINDLE) |

||

~ |

O234.6 |

O18.6 |

150 |

M18.6 |

O18.6 |

CCGETR7 |

GEAR RANGE 7 / 3 ACKNOWLEDGE (2ND SPINDLE) |

||

~ |

O234.7 |

O18.7 |

151 |

M18.7 |

O18.7 |

CCGETR8 |

GEAR RANGE 8 / 4 ACKNOWLEDGE (2ND SPINDLE) |

||

|

------------------ |

|

PLC->NC O |

BYTE: 19 (M |

BYTE: 19) ------------------------------ |

||||

|

O235.0 |

O19.0 |

152 |

M19.0 |

O19.0 |

CCSPRE |

|

SPINDLE CLOCKWISE ROTATION M03 (MANUAL) |

|

|

O235.1 |

O19.1 |

153 |

M19.1 |

O19.1 |

CCSPLI |

|

SPINDLE COUNTER-CLOCKWISE ROTATION M04 |

|

|

|

|

|

|

|

|

|

(MANUAL) |

|

|

O235.2 |

O19.2 |

154 |

M19.2 |

O19.2 |

CCSPSTOP |

SPINDLE STOP M05 (MANUAL) |

||

|

O235.3 |

O19.3 |

155 |

M19.3 |

O19.3 |

CCSPRICT |

SPINDLE ORIENT M19 (MANUAL) |

||

|

O235.4 |

O19.4 |

156 |

M19.4 |

O19.4 |

CCAWGET1 |

GEAR RANGE SELECTION 1 (MANUAL) |

||

|

O235.5 |

O19.5 |

157 |

M19.5 |

O19.5 |

CCAWGET2 |

GEAR RANGE SELECTION 2 (MANUAL) |

||

|

O235.6 |

O19.6 |

158 |

M19.6 |

O19.6 |

CCAWGET3 |

GEAR RANGE SELECTION 3 (MANUAL) |

||

|

O235.7 |

O19.7 |

159 |

M19.7 |

O19.7 |

CCAWGET4 |

GEAR RANGE SELECTION 4 (MANUAL) |

||

|

------------------ |

|

PLC->NC O |

BYTE: 20 (M |

BYTE: 20) ------------------------------ |

||||

~ |

O236.0 |

O20.0 |

160 |

M20.0 |

O20.0 |

CCAWGET5 |

GEAR RANGE SELECTION 5 (MANUAL) / 1 (2ND |

||

|

|

|

|

|

|

|

|

SP.) |

|

~ |

O236.1 |

O20.1 |

161 |

M20.1 |

O20.1 |

CCAWGET6 |

GEAR RANGE SELECTION 6 (MANUAL) / 2 (2ND |

||

|

|

|

|

|

|

|

|

SP.) |

|

~ |

O236.2 |

O20.2 |

162 |

M20.2 |

O20.2 |

CCAWGET7 |

GEAR RANGE SELECTION 7 (MANUAL) / 3 (2ND |

||

|

|

|

|

|

|

|

|

SP.) |

|

~ |

O236.3 |

O20.3 |

163 |

M20.3 |

O20.3 |

CCAWGET8 |

GEAR RANGE SELECTION 8 (MANUAL) / 4 (2ND |

||

|

|

|

|

|

|

|

|

SP.) |

|

− |

O236.4 |

O20.4 |

164 |

M20.4 |

O20.4 |

CC4KREIS |

QUADRANT PROGRAMMING |

||

|

O236.5 |

O20.5 |

165 |

M20.5 |

O20.5 |

CCRESTRT |

AUTOMATIC RESTART M2/M30 |

||

|

O236.6 |

O20.6 |

166 |

M20.6 |

O20.6 |

CCKONTUR |

RETURN TO CONTOUR |

||

− |

O236.7 |

O20.7 |

167 |

M20.7 |

O20.7 |

CC84TST |

SINGLE BLOCK G84 (TEST) |

||

|

------------------ |

|

PLC->NC O |

BYTE: 21 (M |

BYTE: 21) ------------------------------ |

||||

|

O237.0 |

O21.0 |

168 |

M21.0 |

O21.0 |

CCDNCQTG |

DNC/PLC ACKNOWLEDGEMENT |

||

|

O237.1 |

O21.1 |

169 |

M21.1 |

O21.1 |

CCVS100% |

SET FEED POT 100% |

||

|

O237.2 |

O21.2 |

170 |

M21.2 |

O21.2 |

CCEG100% |

SET RAPID POT 100% |

||

‘− |

O237.3 |

O21.3 |

171 |

M21.3 |

O21.3 |

CCZAEDEK |

COUNTER DECREMENT / ANALOG POT 100% |

||

‘ |

O237.4 |

O21.4 |

172 |

M21.4 |

O21.4 |

CCSTZUEW |

TOOL LIFE MONITOR ON |

||

‘ |

O237.5 |

O21.5 |

173 |

M21.5 |

O21.5 |

CCMESGEW |

THREAD GAUGE / REMACHINE |

||

‘ |

O237.6 |

O21.6 |

174 |

M21.6 |

O21.6 |

CCTEACHV |

TEACH IN FEED |

||

‘ |

O237.7 |

O21.7 |

175 |

M21.7 |

O21.7 |

CCTEACHS |

TEACH IN SPINDLE |

||

|

------------------ |

|

PLC->NC O |

BYTE: 22 (M |

BYTE: 22) ------------------------------ |

||||

|

O238.0 |

O22.0 |

176 |

M22.0 |

O22.0 |

CCHANDR1 |

HANDWHEEL 1ST AXIS |

||

|

O238.1 |

O22.1 |

177 |

M22.1 |

O22.1 |

CCHANDR2 |

HANDWHEEL 2ND AXIS |

||

|

O238.2 |

O22.2 |

178 |

M22.2 |

O22.2 |

CCHANDR3 |

HANDWHEEL 3RD AXIS |

||

|

O238.3 |

O22.3 |

179 |

M22.3 |

O22.3 |

CCHANDR4 |

HANDWHEEL 4TH AXIS |

||

|

O238.4 |

O22.4 |

180 |

M22.4 |

O22.4 |

CCHANDR5 |

HANDWHEEL 5TH AXIS |

||

|

O238.5 |

O22.5 |

181 |

|

|

CCHANDR6 |

HANDWHEEL 6TH AXIS |

||

|

O238.6 |

O22.6 |

182 |

|

|

CCHANDR7 |

HANDWHEEL 7TH AXIS |

||

|

O238.7 |

O22.7 |

183 |

|

|

CCHANDR8 |

HANDWHEEL 8TH AXIS |

||

|

------------------ |

|

PLC->NC O |

BYTE: 23 (M |

BYTE: 23) ------------------------------ |

||||

|

O239.0 |

O23.0 |

184 |

M23.0 |

O23.0 |

CCMSSP1A |

INHIBIT MEAS. SYS. MONITOR 1ST AXIS |

||

|

O239.1 |

O23.1 |

185 |

M23.1 |

O23.1 |

CCMSSP2A |

INHIBIT MEAS. SYS. MONITOR 2ND AXIS |

||

|

O239.2 |

O23.2 |

186 |

M23.2 |

O23.2 |

CCMSSP3A |

INHIBIT MEAS. SYS. MONITOR 3RD AXIS |

||

|

O239.3 |

O23.3 |

187 |

M23.3 |

O23.3 |

CCMSSP4A |

INHIBIT MEAS. SYS. MONITOR 4TH AXIS |

||

|

O239.4 |

O23.4 |

188 |

M23.4 |

O23.4 |

CCMSSP5A |

INHIBIT MEAS. SYS. MONITOR 5TH AXIS |

||

|

O239.5 |

O23.5 |

189 |

|

|

CCMSSP6A |

INHIBIT MEAS. SYS. MONITOR 6TH AXIS |

||

1070 073 758 101 |

1 − 6 |

Type1 osa / CC 220

Digital Interface

Signal description

|

O239.6 |

O23.6 |

190 |

|

|

CCMSSP7A |

INHIBIT MEAS. SYS. MONITOR 7TH AXIS |

|||

|

O239.7 |

O23.7 |

191 |

|

|

CCMSSP8A |

INHIBIT MEAS. SYS. MONITOR 8TH AXIS |

|||

|

|

|

|

|||||||

− Only with CC 220 M, Type1 osa M |

~ Only 4 gear ranges per spindle are possible with CC 220 T, Type1 osa with |

|

||||||||

‘ Only with CC 220 T, Type1 osa T |

|

"2nd spindle" option. |

|

|

|

|||||

|

|

|

|

|

|

|||||

|

–––––––––––––––––Address–––––––––––––––––– |

|

|

|

|

|||||

|

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

|

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

|

Remarks |

||||

|

|

|

|

|

|

|

||||

|

------------------ |

|

PLC->NC O |

BYTE: 24 (M |

BYTE: 24) ------------------------------ |

|||||

‘ |

O240.0 |

O24.0 |

192 |

M24.0 |

O24.0 |

|

|

2ND SPINDLE:AUTOMATIC GEAR RANGE SELECTION |

||

‘ |

O240.1 |

O24.1 |

193 |

M24.1 |

O24.1 |

|

|

2ND SPINDLE:REVERSE SPINDLE DIRECTION |

||

‘ |

O240.2 |

O24.2 |

194 |

M24.2 |

O24.2 |

|

|

2ND SPINDLE:CONSTANT SPINDLE SPEED |

||

‘ |

O240.3 |

O24.3 |

195 |

M24.3 |

O24.3 |

|

|

2ND SPINDLE:(NOT) SPINDLE COMMAND 0 VOLT |

||

‘ |

O240.4 |

O24.4 |

196 |

M24.4 |

O24.4 |

|

|

2ND SPINDLE:SET POT 100% |

||

‘ |

O240.5 |

O24.5 |

197 |

M24.5 |

O24.5 |

|

|

2ND SPINDLE:POT EXTERNAL |

||

|

O240.6 |

O24.6 |

198 |

M24.6 |

O24.6 |

|

|

|

|

|

|

O240.7 |

O24.7 |

199 |

|

|

CCMTBUEB |

MTB/PANEL MONITOR ACTIVE |

|||

|

------------------ |

|

PLC->NC O |

BYTE: 25 (M |

BYTE: 25) ------------------------------ |

|||||

|

O241.0 |

O25.0 |

200 |

M25.0 |

O25.0 |

CCDRKOM1 |

DRIFT COMPENSATION OFF 1ST AXIS |

|||

|

O241.1 |

O25.1 |

201 |

M25.1 |

O25.1 |

CCDRKOM2 |

DRIFT COMPENSATION OFF 2ND AXIS |

|||

|

O241.2 |

O25.2 |

202 |

M25.2 |

O25.2 |

CCDRKOM3 |

DRIFT COMPENSATION OFF 3RD AXIS |

|||

|

O241.3 |

O25.3 |

203 |

M25.3 |

O25.3 |

CCDRKOM4 |

DRIFT COMPENSATION OFF 4TH AXIS |

|||

|

O241.4 |

O25.4 |

204 |

M25.4 |

O25.4 |

CCDRKOM5 |

DRIFT COMPENSATION OFF 5TH AXIS |

|||

|

O241.5 |

O25.5 |

205 |

|

|

CCDRKOM6 |

DRIFT COMPENSATION OFF 6TH AXIS |

|||

|

O241.6 |

O25.6 |

206 |

|

|

CCDRKOM7 |

DRIFT COMPENSATION OFF 7TH AXIS |

|||

|

O241.7 |

O25.7 |

207 |

|

|

CCDRKOM8 |

DRIFT COMPENSATION OFF 8TH AXIS |

|||

|

------------------ |

|

PLC->NC O |

BYTE: 26 (M |

BYTE: 26) ------------------------------ |

|||||

− |

O242.0 |

O26.0 |

208 |

M26.0 |

O26.0 |

\ |

|

|

|

|

− |

O242.1 |

O26.1 |

209 |

M26.1 |

O26.1 |

I |

|

|

|

|

− |

O242.2 |

O26.2 |

210 |

M26.2 |

O26.2 |

I |

|

|

|

|

− |

O242.3 |

O26.3 |

211 |

M26.3 |

O26.3 |

I |

|

The meaning of these signals is set |

||

− |

O242.4 |

O26.4 |

212 |

M26.4 |

O26.4 |

> |

|

according to machine parameter P6516 |

||

− |

O242.5 |

O26.5 |

213 |

M26.5 |

O26.5 |

I |

|

|

|

|

− |

O242.6 |

O26.6 |

214 |

M26.6 |

O26.6 |

I |

|

|

|

|

− |

O242.7 |

O26.7 |

215 |

M26.7 |

O26.7 |

/ |

|

|

|

|

|

------------------ |

|

PLC->NC O |

BYTE: 27 (M |

BYTE: 27) ------------------------------ |

|||||

|

O243.0 |

O27.0 |

216 |

M27.0 |

O27.0 |

CCUMSCHD |

SWITCHOVER ROTARY MODE |

|||

|

O243.1 |

O27.1 |

217 |

M27.1 |

O27.1 |

CCUMSCHF |

SWITCHOVER MILLING MODE |

|||

|

O243.2 |

O27.2 |

218 |

M27.2 |

O27.2 |

CCREFCAC |

REFERENCE C-AXIS |

|||

|

O243.3 |

O27.3 |

219 |

M27.3 |

O27.3 |

CCCAAKSP |

C-AXIS ACTIVE (PLC) |

|||

|

O243.4 |

O27.4 |

220 |

M27.4 |

O27.4 |

|

|

|

|

|

− |

O243.5 |

O27.5 |

221 |

M27.5 |

O27.5 |

CCFRKOST |

START MILLING HEAD COMPENSATION |

|||

|

O243.6 |

O27.6 |

222 |

M27.6 |

O27.6 |

CCREDBV |

FEEDRATE REDUCTION |

|||

‘ |

O243.7 |

O27.7 |

223 |

M27.7 |

O27.7 |

CCGEWMOS |

REMACHINE THREAD WITHOUT ROUGHING |

|||

|

------------------ |

|

PLC->NC O |

BYTE: 28 (M |

BYTE: 28) ------------------------------ |

|||||

|

O244.0 |

O28.0 |

224 |

M28.0 |

O28.0 |

|

|

|

|

|

|

O244.1 |

O28.1 |

225 |

M28.1 |

O28.1 |

|

|

|

|

|

|

O244.2 |

O28.2 |

226 |

M28.2 |

O28.2 |

|

|

|

|

|

|

O244.3 |

O28.3 |

227 |

M28.3 |

O28.3 |

|

|

|

|

|

|

O244.4 |

O28.4 |

228 |

M28.4 |

O28.4 |

|

|

|

|

|

|

O244.5 |

O28.5 |

229 |

M28.5 |

O28.5 |

|

|

|

|

|

|

O244.6 |

O28.6 |

230 |

M28.6 |

O28.6 |

|

|

|

|

|

|

O244.7 |

O28.7 |

231 |

M28.7 |

O28.7 |

|

|

|

|

|

|

------------------ |

|

PLC->NC O |

BYTE: 29 (M |

BYTE: 29) ------------------------------ |

|||||

|

O245.0 |

O29.0 |

232 |

M29.0 |

O29.0 |

\ |

|

|

|

|

|

O245.1 |

O29.1 |

233 |

M29.1 |

O29.1 |

I |

|

|

|

|

|

O245.2 |

O29.2 |

234 |

M29.2 |

O29.2 |

I |

|

|

|

|

|

O245.3 |

O29.3 |

235 |

M29.3 |

O29.3 |

I |

|

|

|

|

|

O245.4 |

O29.4 |

236 |

M29.4 |

O29.4 |

> |

|

Reserved for CPL applications |

||

|

O245.5 |

O29.5 |

237 |

M29.5 |

O29.5 |

I |

|

|

|

|

1070 073 758 101 |

1 − 7 |

Type1 osa / CC 220

Digital Interface

Signal description

O245.6 |

O29.6 |

238 |

M29.6 |

O29.6 |

I |

O245.7 |

O29.7 |

239 |

M29.7 |

O29.7 |

/ |

− Only with CC 220 M, Type1 osa M

‘Only with CC 220 T, Type1 osa T

––––––––––––––––––Address––––––––––––––––– |

|

|||||

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

Remarks |

||

|

|

|

|

|

||

------------------ |

|

PLC->NC O |

BYTE: 30 (M |

BYTE: 30) ------------------------------ |

||

O246.0 |

O30.0 |

240 |

M30.0 |

O30.0 |

\ |

|

O246.1 |

O30.1 |

241 |

M30.1 |

O30.1 |

I |

|

O246.2 |

O30.2 |

242 |

M30.2 |

O30.2 |

I |

|

O246.3 |

O30.3 |

243 |

M30.3 |

O30.3 |

I |

|

O246.4 |

O30.4 |

244 |

M30.4 |

O30.4 |

> |

Reserved for CPL applications |

O246.5 |

O30.5 |

245 |

M30.5 |

O30.5 |

I |

|

O246.6 |

O30.6 |

246 |

M30.6 |

O30.6 |

I |

|

O246.7 |

O30.7 |

247 |

M30.7 |

O30.7 |

/ |

|

------------------ |

|

PLC->NC O |

BYTE: 31 (M |

BYTE: 31) ------------------------------ |

||

O247.0 |

O31.0 |

248 |

M31.0 |

O31.0 |

\ |

|

O247.1 |

O31.1 |

249 |

M31.1 |

O31.1 |

I |

|

O247.2 |

O31.2 |

250 |

M31.2 |

O31.2 |

I |

|

O247.3 |

O31.3 |

251 |

M31.3 |

O31.3 |

I |

|

O247.4 |

O31.4 |

252 |

M31.4 |

O31.4 |

> |

Reserved for CPL applications |

O247.5 |

O31.5 |

253 |

M31.5 |

O31.5 |

I |

|

O247.6 |

O31.6 |

254 |

M31.6 |

O31.6 |

I |

|

O247.7 |

O31.7 |

255 |

M31.7 |

O31.7 |

/ |

|

1070 073 758 101 |

1 − 8 |

Type1 osa / CC 220

Digital Interface

Signal description

1.1.2Signals from CNC to PLC

––––––––––––––––––Address––––––––––––––––– |

|

|

|

|||||

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

|

Remarks |

|||

|

|

|

|

|

|

|||

------------------ |

|

NC->PLC I |

BYTE: 0 |

(M |

BYTE: 32) ------------------------------ |

|||

O176.0 |

I0.0 |

0 |

M32.0 |

I0.0 |

CCDRIV1P |

POS. TRAVEL COMMAND 1ST AXIS |

||

O176.1 |

I0.1 |

1 |

M32.1 |

I0.1 |

CCDRIV1N |

NEG. TRAVEL COMMAND 1ST AXIS |

||

O176.2 |

I0.2 |

2 |

M32.2 |

I0.2 |

CCDRIV2P |

POS. TRAVEL COMMAND 2ND AXIS |

||

O176.3 |

I0.3 |

3 |

M32.3 |

I0.3 |

CCDRIV2N |

NEG. TRAVEL COMMAND 2ND AXIS |

||

O176.4 |

I0.4 |

4 |

M32.4 |

I0.4 |

CCDRIV3P |

POS. TRAVEL COMMAND 3RD AXIS |

||

O176.5 |

I0.5 |

5 |

M32.5 |

I0.5 |

CCDRIV3N |

NEG. TRAVEL COMMAND 3RD AXIS |

||

O176.6 |

I0.6 |

6 |

M32.6 |

I0.6 |

CCDRIV4P |

POS. TRAVEL COMMAND 4TH AXIS |

||

O176.7 |

I0.7 |

7 |

M32.7 |

I0.7 |

CCDRIV4N |

NEG. TRAVEL COMMAND 4TH AXIS |

||

------------------ |

|

NC->PLC I |

BYTE: 1 |

(M |

BYTE: 33) ------------------------------ |

|||

O177.0 |

I1.0 |

8 |

M33.0 |

I1.0 |

CCDRIV5P |

POS. TRAVEL COMMAND 5TH AXIS |

||

O177.1 |

I1.1 |

9 |

M33.1 |

I1.1 |

CCDRIV5N |

NEG. TRAVEL COMMAND 5TH AXIS |

||

O177.2 |

I1.2 |

10 |

|

|

CCDRIV6P |

POS. TRAVEL COMMAND 6TH AXIS |

||

O177.3 |

I1.3 |

11 |

|

|

CCDRIV6N |

NEG. TRAVEL COMMAND 6TH AXIS |

||

O177.4 |

I1.4 |

12 |

|

|

CCDRIV7P |

POS. TRAVEL COMMAND 7TH AXIS |

||

O177.5 |

I1.5 |

13 |

|

|

CCDRIV7N |

NEG. TRAVEL COMMAND 7TH AXIS |

||

O177.6 |

I1.6 |

14 |

|

|

CCDRIV8P |

POS. TRAVEL COMMAND 8TH AXIS |

||

O177.7 |

I1.7 |

15 |

|

|

CCDRIV8N |

NEG. TRAVEL COMMAND 8TH AXIS |

||

------------------ |

|

NC->PLC I |

BYTE: 2 |

(M |

BYTE: 34) ------------------------------ |

|||

O178.0 |

I2.0 |

16 |

M34.0 |

I2.0 |

CCINPOS1 |

1ST AXIS IN POSITION |

||

O178.1 |

I2.1 |

17 |

M34.1 |

I2.1 |

CCINPOS2 |

2ND AXIS IN POSITION |

||

O178.2 |

I2.2 |

18 |

M34.2 |

I2.2 |

CCINPOS3 |

3RD AXIS IN POSITION |

||

O178.3 |

I2.3 |

19 |

M34.3 |

I2.3 |

CCINPOS4 |

4TH AXIS IN POSITION |

||

O178.4 |

I2.4 |

20 |

M34.4 |

I2.4 |

CCINPOS5 |

5TH AXIS IN POSITION |

||

O178.5 |

I2.5 |

21 |

|

|

CCINPOS6 |

6TH AXIS IN POSITION |

||

O178.6 |

I2.6 |

22 |

|

|

CCINPOS7 |

7TH AXIS IN POSITION |

||

O178.7 |

I2.7 |

23 |

|

|

CCINPOS8 |

8TH AXIS IN POSITION |

||

------------------ |

|

NC->PLC I |

BYTE: 3 |

(M |

BYTE: 35) ------------------------------ |

|||

O179.0 |

I3.0 |

24 |

M35.0 |

I3.0 |

CCMST_1E |

MST AUX. FUNCT. 1/1 |

||

O179.1 |

I3.1 |

25 |

M35.1 |

I3.1 |

CCMST_2E |

MST AUX. FUNCT. 2/2 |

||

O179.2 |

I3.2 |

26 |

M35.2 |

I3.2 |

CCMST_4E |

MST AUX. FUNCT. 4/4 |

||

O179.3 |

I3.3 |

27 |

M35.3 |

I3.3 |

CCMST_8E |

MST AUX. FUNCT. 8/8 |

||

O179.4 |

I3.4 |

28 |

M35.4 |

I3.4 |

CCMST_1Z |

MST AUX. FUNCT. 10/16 |

||

O179.5 |

I3.5 |

29 |

M35.5 |

I3.5 |

CCMST_2Z |

MST AUX. FUNCT. 20/32 |

||

O179.6 |

I3.6 |

30 |

M35.6 |

I3.6 |

CCMST_4Z |

MST AUX. FUNCT. 40/64 |

||

O179.7 |

I3.7 |

31 |

M35.7 |

I3.7 |

CCMST_8Z |

MST AUX. FUNCT. 80/128 |

||

------------------ |

|

NC->PLC I |

BYTE: 4 |

(M |

BYTE: 36) ------------------------------ |

|||

O180.0 |

I4.0 |

32 |

M36.0 |

I4.0 |

CCMST_1H |

MST AUX. FUNCT. 100/256 |

||

O180.1 |

I4.1 |

33 |

M36.1 |

I4.1 |

CCMST_2H |

MST AUX. FUNCT. 200/512 |

||

O180.2 |

I4.2 |

34 |

M36.2 |

I4.2 |

CCMST_4H |

MST AUX. FUNCT. 400/1024 |

||

O180.3 |

I4.3 |

35 |

M36.3 |

I4.3 |

CCMST_8H |

MST AUX. FUNCT. 800/2048 |

||

O180.4 |

I4.4 |

36 |

M36.4 |

I4.4 |

CCST_1T |

ST |

AUX. FUNCT. 1000/4096 |

|

O180.5 |

I4.5 |

37 |

M36.5 |

I4.5 |

CCST_2T |

ST |

AUX. FUNCT. 2000/8192 |

|

O180.6 |

I4.6 |

38 |

M36.6 |

I4.6 |

CCST_4T |

ST |

AUX. FUNCT. 4000/16384 |

|

O180.7 |

I4.7 |

39 |

M36.7 |

I4.7 |

CCST_8T |

ST |

AUX. FUNCT. 8000/32768 |

|

------------------ |

|

NC->PLC I |

BYTE: 5 |

(M |

BYTE: 37) ------------------------------ |

|||

O181.0 |

I5.0 |

40 |

M37.0 |

I5.0 |

CCST_1ZT |

ST |

AUX. FUNCT. 1*10**4/2**16 |

|

O181.1 |

I5.1 |

41 |

M37.1 |

I5.1 |

CCST_2ZT |

ST |

AUX. FUNCT. 2*10**4/2**17 |

|

O181.2 |

I5.2 |

42 |

M37.2 |

I5.2 |

CCST_4ZT |

ST |

AUX. FUNCT. 4*10**4/2**18 |

|

O181.3 |

I5.3 |

43 |

M37.3 |

I5.3 |

CCST_8ZT |

ST |

AUX. FUNCT. 8*10**4/2**19 |

|

O181.4 |

I5.4 |

44 |

M37.4 |

I5.4 |

CCST_1HT |

T |

AUX. FUNCT. 1*10**5/2**20 |

|

O181.5 |

I5.5 |

45 |

M37.5 |

I5.5 |

CCST_2HT |

T |

AUX. FUNCT. 2*10**5/2**21 |

|

O181.6 |

I5.6 |

46 |

M37.6 |

I5.6 |

CCST_4HT |

T |

AUX. FUNCT. 4*10**5/2**22 |

|

O181.7 |

I5.7 |

47 |

M37.7 |

I5.7 |

CCST_8HT |

T |

AUX. FUNCT. 8*10**5/2**23 |

|

1070 073 758 101 |

1 − 9 |

Type1 osa / CC 220

Digital Interface

Signal description

|

––––––––––––––––––Address––––––––––––––––– |

|

|

|

|||||

|

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

|

Remarks |

|||

|

|

|

|

|

|

|

|||

|

------------------ |

|

NC->PLC I |

BYTE: 6 |

(M |

BYTE: 38) ------------------------------ |

|||

|

O182.0 |

I6.0 |

48 |

M38.0 |

I6.0 |

CCT_1M |

|

T |

AUX. FUNCT. 2*10**6/2**24 |

|

O182.1 |

I6.1 |

49 |

M38.1 |

I6.1 |

CCT_2M |

|

T |

AUX. FUNCT. 2*10**6/2**25 |

|

O182.2 |

I6.2 |

50 |

M38.2 |

I6.2 |

CCT_4M |

|

T |

AUX. FUNCT. 4*10**6/2**26 |

|

O182.3 |

I6.3 |

51 |

M38.3 |

I6.3 |

CCT_8M |

|

T |

AUX. FUNCT. 8*10**6/2**27 |

|

O182.4 |

I6.4 |

52 |

M38.4 |

I6.4 |

CCT_1ZM |

T |

AUX. FUNCT. 1*10**7/2**28 |

|

|

O182.5 |

I6.5 |

53 |

M38.5 |

I6.5 |

CCT_2ZM |

T |

AUX. FUNCT. 2*10**7/2**29 |

|

|

O182.6 |

I6.6 |

54 |

M38.6 |

I6.6 |

CCT_4ZM |

T |

AUX. FUNCT. 4*10**7/2**30 |

|

|

O182.7 |

I6.7 |

55 |

M38.7 |

I6.7 |

CCT_8ZM |

T |

AUX. FUNCT. 8*10**7/(+/-) |

|

|

------------------ |

|

NC->PLC I |

BYTE: 7 |

(M |

BYTE: 39) ------------------------------ |

|||

|

O183.0 |

I7.0 |

56 |

M39.0 |

I7.0 |

CCMSTR |

|

1ST STROBE (AUX. FUNCT. STROBE) |

|

|

O183.1 |

I7.1 |

57 |

M39.1 |

I7.1 |

CCSSTR |

|

2ND STROBE (AUX. FUNCT. STROBE) |

|

|

O183.2 |

I7.2 |

58 |

M39.2 |

I7.2 |

CCTSTR |

|

3RD STROBE (AUX. FUNCT. STROBE) |

|

|

O183.3 |

I7.3 |

59 |

M39.3 |

I7.3 |

CCHSTR |

|

4TH STROBE (AUX. FUNCT. STROBE) |

|

|

O183.4 |

I7.4 |

60 |

M39.4 |

I7.4 |

CCHIFU5 |

5TH STROBE (AUX. FUNCT. STROBE) |

||

|

O183.5 |

I7.5 |

61 |

M39.5 |

I7.5 |

CCHIFU6 |

6TH STROBE (AUX. FUNCT. STROBE) |

||

|

O183.6 |

I7.6 |

62 |

M39.6 |

I7.6 |

CCHIFU7 |

|

|

|

|

O183.7 |

I7.7 |

63 |

M39.7 |

I7.7 |

CCCPLSTR |

CPL STROBE |

||

|

------------------ |

|

NC->PLC I |

BYTE: 8 |

(M |

BYTE: 40) ------------------------------ |

|||

|

O184.0 |

I8.0 |

64 |

M40.0 |

I8.0 |

CCAUTO |

|

AUTOMATIC MODE |

|

|

O184.1 |

I8.1 |

65 |

M40.1 |

I8.1 |

CCSEMI |

|

SINGLE BLOCK MODE |

|

|

O184.2 |

I8.2 |

66 |

M40.2 |

I8.2 |

CCMDI |

|

MANUAL MODE |

|

|

O184.3 |

I8.3 |

67 |

M40.3 |

I8.3 |

CCMANUEL |

JOG MODE (MANUAL) |

||

|

O184.4 |

I8.4 |

68 |

M40.4 |

I8.4 |

CCBREFAN |

REFERENCE MODE |

||

|

O184.5 |

I8.5 |

69 |

M40.5 |

I8.5 |

CCREFANG |

REFERENCE POINTS REACHED |

||

|

O184.6 |

I8.6 |

70 |

M40.6 |

I8.6 |

CCRAPID |

RAPID |

||

|

O184.7 |

I8.7 |

71 |

M40.7 |

I8.7 |

CCPRGACT |

PROGRAM RUNNING |

||

|

------------------ |

|

NC->PLC I |

BYTE: 9 |

(M |

BYTE: 41) ------------------------------ |

|||

|

O185.0 |

I9.0 |

72 |

M41.0 |

I9.0 |

CCTEST |

|

TEST WITHOUT MOVEMENT |

|

|

O185.1 |

I9.1 |

73 |

M41.1 |

I9.1 |

CCRESETE |

CONTROL RESET |

||

|

O185.2 |

I9.2 |

74 |

M41.2 |

I9.2 |

CCSLASHE |

BLOCK SLASH |

||

|

O185.3 |

I9.3 |

75 |

M41.3 |

I9.3 |

CCMULQUI |

MULTI-ACKNOWLEDGEMENT |

||

|

O185.4 |

I9.4 |

76 |

M41.4 |

I9.4 |

CCPRGANW |

MANUAL PROGRAM SELECTION |

||

|

O185.5 |

I9.5 |

77 |

M41.5 |

I9.5 |

CCSATZVL |

DRY RUN TO BLOCK |

||

|

O185.6 |

I9.6 |

78 |

M41.6 |

I9.6 |

CCF0% |

|

FEED 0% |

|

|

O185.7 |

I9.7 |

79 |

M41.7 |

I9.7 |

CCPRGVHD |

PROGRAM EXISTS |

||

|

------------------ |

|

NC->PLC I |

BYTE: 10 (M |

BYTE: 42) ------------------------------ |

||||

|

O186.0 |

I10.0 |

80 |

M42.0 |

I10.0 |

CCEXPRAN |

EXTERNAL PROGRAM SELECTION |

||

|

O186.1 |

I10.1 |

81 |

M42.1 |

I10.1 |

CCNCBERT |

NC READY (AFTER EXT.PRG.SELECT) |

||

|

O186.2 |

I10.2 |

82 |

M42.2 |

I10.2 |

CCDREZER |

SPINDLE SPEED REACHED |

||

− |

O186.3 |

I10.3 |

83 |

M42.3 |

I10.3 |

CCEILG0% |

RAPID 0% |

||

|

O186.4 |

I10.4 |

84 |

M42.4 |

I10.4 |

CCMZO1 |

|

MSD MODE VALUE 1 |

|

|

O186.5 |

I10.5 |

85 |

M42.5 |

I10.5 |

CCMZO2 |

|

MSD MODE VALUE 2 |

|

|

O186.6 |

I10.6 |

86 |

M42.6 |

I10.6 |

CCMZO4 |

|

MSD MODE VALUE 4 |

|

|

O186.7 |

I10.7 |

87 |

M42.7 |

I10.7 |

CCCPLDST |

CPL DIALOG STROBE |

||

|

------------------ |

|

NC->PLC I |

BYTE: 11 (M |

BYTE: 43) ------------------------------ |

||||

|

O187.0 |

I11.0 |

88 |

M43.0 |

I11.0 |

CCM0_M1 |

PROGRAM STOP AT M0 OR M1 |

||

|

O187.1 |

I11.1 |

89 |

M43.1 |

I11.1 |

CCM2_M30 |

PROGRAM END AT M2 OR M30 |

||

|

O187.2 |

I11.2 |

90 |

M43.2 |

I11.2 |

CCG33 |

|

THREAD CUTTING ACTIVE (G33) |

|

|

O187.3 |

I11.3 |

91 |

M43.3 |

I11.3 |

CCG63 |

|

G63 ACTIVE |

|

|

O187.4 |

I11.4 |

92 |

M43.4 |

I11.4 |

CCHRKORR |

HANDWHEEL COMP. ACTIVE |

||

|

O187.5 |

I11.5 |

93 |

M43.5 |

I11.5 |

CCSCHFKT |

SWITCH FUNCTION MODE |

||

|

O187.6 |

I11.6 |

94 |

M43.6 |

I11.6 |

CCAM01 |

|

OPTIONAL STOP |

|

|

O187.7 |

I11.7 |

95 |

M43.7 |

I11.7 |

CCHIFUSP |

AUX. FUNCT. INHIBIT |

||

− Only with CC 220 M, Type1 osa M

‘Only with CC 220 T, Type1 osa T

1070 073 758 101 |

1 − 10 |

Type1 osa / CC 220

Digital Interface

Signal description

|

–––––––––––––––––Address––––––––––––––––– |

|

|

|

|

|

||||

|

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

|

|

|

|

Word coupl. Bit coupl.dec |

CL |

softPIC |

Symbol |

|

Remarks |

|

|

||

|

|

|

|

|

|

|

|

|||

|

------------------ |

|

NC->PLC I |

BYTE: 12 (M |

BYTE: 44) ------------------------------ |

|

|

|||

|

O188.0 |

I12.0 |

96 |

M44.0 |

I12.0 |

CCEND1 |

|

LIMIT SWITCH RANGE |

1 |

|

|

O188.1 |

I12.1 |

97 |

M44.1 |

I12.1 |

CCEND2 |

|

LIMIT SWITCH RANGE |

2 |

|

|

O188.2 |

I12.2 |

98 |

M44.2 |

I12.2 |

CCEND3 |

|

LIMIT SWITCH RANGE |

3 |

|

|

O188.3 |

I12.3 |

99 |

M44.3 |

I12.3 |

CCEND4 |

|

LIMIT SWITCH RANGE |

4 |

|

|

O188.4 |

I12.4 |

100 |

M44.4 |

I12.4 |

CCEND5 |

|

LIMIT SWITCH RANGE |

5 |

|

|

O188.5 |

I12.5 |

101 |

M44.5 |

I12.5 |

CCEND6 |

|

LIMIT SWITCH RANGE |

6 |

|

|

O188.6 |

I12.6 |

102 |

M44.6 |

I12.6 |

CCEND7 |

|

LIMIT SWITCH RANGE |

7 |

|

|

O188.7 |

I12.7 |

103 |

M44.7 |

I12.7 |

CCEND8 |

|

LIMIT SWITCH RANGE |

8 |

|

|

------------------ |

|

NC->PLC I |

BYTE: 13 (M |

BYTE: 45) ------------------------------ |

|

|

|||

|

O189.0 |

I13.0 |

104 |

M45.0 |

I13.0 |

CCEND9 |

|

LIMIT SWITCH RANGE |

9 |

|

|

O189.1 |

I13.1 |

105 |

M45.1 |

I13.1 |

CCEND10 |

LIMIT SWITCH RANGE |

10 |

|

|

|

O189.2 |

I13.2 |

106 |

M45.2 |

I13.2 |

CCEND11 |

LIMIT SWITCH RANGE |

11 |

|

|

|

O189.3 |

I13.3 |

107 |

M45.3 |

I13.3 |

CCEND12 |

LIMIT SWITCH RANGE |

12 |

|

|

|

O189.4 |

I13.4 |

108 |

M45.4 |

I13.4 |

CCEND13 |

LIMIT SWITCH RANGE |

13 |

|

|

|

O189.5 |

I13.5 |

109 |

M45.5 |

I13.5 |

CCEND14 |

LIMIT SWITCH RANGE |

14 |

|

|

|

O189.6 |

I13.6 |

110 |

M45.6 |

I13.6 |

CCEND15 |

LIMIT SWITCH RANGE |

15 |

|

|

|

O189.7 |

I13.7 |

111 |

M45.7 |

I13.7 |

CCEND16 |

LIMIT SWITCH RANGE |

16 |

|

|

|

------------------ |

|

NC->PLC I |

BYTE: 14 (M |

BYTE: 46) ------------------------------ |

|

|

|||

|

O190.0 |

I14.0 |

112 |

M46.0 |

I14.0 |

CCG95 |

|

FEED IN MM/REV. (G95) |

||

‘ |

O190.1 |

I14.1 |

113 |

M46.1 |

I14.1 |

CCG96 |

|

CUTTING SPEED CONSTANT (G96) |

||

|

O190.2 |

I14.2 |

114 |

M46.2 |

I14.2 |

CCSPPOS |

SPINDLE IN POSITION |

|

|

|

‘ |

O190.3 |

I14.3 |

115 |

M46.3 |

I14.3 |

CCWZSTZ |

TOOL LIFE EXPIRED |

|

|

|

‘ |

O190.4 |

I14.4 |

116 |

M46.4 |

I14.4 |

CCGESSTZ |

LIFE OF BASIC AND ALT. TOOLS EXPIRED |

|||

‘ |

O190.5 |

I14.5 |

117 |

M46.5 |

I14.5 |

CCEIL100 |

RAPID POT 100% SET |

|

|

|

‘ |

O190.6 |

I14.6 |

118 |

M46.6 |

I14.6 |

CCSPI100 |

SPINDLE POT 100% SET |

|||

‘ |

O190.7 |

I14.7 |

119 |

M46.7 |

I14.7 |

CCSTZERR |

TARGET ACHIEVED |

|

|

|

|

------------------ |

|

NC->PLC I |

BYTE: 15 (M |

BYTE: 47) ------------------------------ |

|

|

|||

|

O191.0 |

I15.0 |

120 |

M47.0 |

I15.0 |

CCREFER1 |

REFERENCE POINT REACHED 1ST AXIS |

|||

|

O191.1 |

I15.1 |

121 |

M47.1 |

I15.1 |

CCREFER2 |

REFERENCE POINT REACHED 2ND AXIS |

|||

|

O191.2 |

I15.2 |

122 |

M47.2 |

I15.2 |

CCREFER3 |

REFERENCE POINT REACHED 3RD AXIS |

|||

|

O191.3 |

I15.3 |

123 |

M47.3 |

I15.3 |

CCREFER4 |

REFERENCE POINT REACHED 4TH AXIS |

|||

|

O191.4 |

I15.4 |

124 |

M47.4 |

I15.4 |

CCREFER5 |

REFERENCE POINT REACHED 5TH AXIS |

|||

|

O191.5 |

I15.5 |

125 |

|

|

CCREFER6 |

REFERENCE POINT REACHED 6TH AXIS |

|||

|

O191.6 |

I15.6 |

126 |

|

|

CCREFER7 |

REFERENCE POINT REACHED 7TH AXIS |

|||

|

O191.7 |

I15.7 |

127 |

|

|

CCREFER8 |

REFERENCE POINT REACHED 8TH AXIS |

|||

|

------------------ |

|

NC->PLC I |

BYTE: 16 (M |

BYTE: 48) ------------------------------ |

|

|

|||

|

O192.0 |

I16.0 |

128 |

M48.0 |

I16.0 |

CCSPSTHT |

SPINDLE STOP |

|

|

|

|

O192.1 |

I16.1 |

129 |

M48.1 |

I16.1 |

CCTRUDER |

IDLING SPEED REACHED |

|||

|

O192.2 |

I16.2 |

130 |

M48.2 |

I16.2 |

CCSPIND0 |

SPINDLE OVERRIDE 0 |

PER CENT |

||

|

O192.3 |

I16.3 |

131 |

M48.3 |

I16.3 |

CCSPIRIT |

SPINDLE ON REFERENCE POINT |

|||

|

O192.4 |

I16.4 |

132 |

M48.4 |

I16.4 |

CCCAAKNC |

C-AXIS ACTIVE (CNC) |

|

|

|

|

O192.5 |

I16.5 |

133 |

M48.5 |

I16.5 |

CCG32 |

|

TAPPING ACTIVE |

|

|

|

O192.6 |

I16.6 |

134 |

M48.6 |

I16.6 |

|

|

|

|

|

− |

O192.7 |

I16.7 |

135 |

M48.7 |

I16.7 |

CCUMKRER |

REVERS.RANGE REACHED |

|||

|

------------------ |

|

NC->PLC I |

BYTE: 17 (M |

BYTE: 49) ------------------------------ |

|

|

|||

− |

O193.0 |

I17.0 |

136 |

M49.0 |

I17.0 |

CCFRKOAK |

MILLING HEAD COMPENSATION ACTIVE |

|||

|

O193.1 |

I17.1 |

137 |

M49.1 |

I17.1 |

CCWANAKT |

RE-ENTRY ACTIVE |

|

|

|

‘ |

O193.2 |

I17.2 |

138 |

M49.2 |

I17.2 |

CCPROOPT |

PROGRAM OPTIMISATION ACTIVE |

|||

|

O193.3 |

I17.3 |

139 |

M49.3 |

I17.3 |

CCLINKAK |

LINKING ACTIVE |

|

|

|

− |

O193.4 |

I17.4 |

140 |

M49.4 |

I17.4 |

CCSVLOKR |

DRY RUN TO BLOCK WITHOUT COMPENSATION |

|||

− |

O193.5 |

I17.5 |

141 |

M49.5 |

I17.5 |

CCOWZKR |

TEST WITHOUT COMPENSATION |

|||

|

O193.6 |

I17.6 |

142 |

M49.6 |

I17.6 |

|

|

|

|

|

|

O193.7 |

I17.7 |

143 |

M49.7 |

I17.7 |

CCPRGABW |

CANCEL PROGRAM |

|

|

|

− Only with CC 220 M, Type1 osa M

‘Only with CC 220 T, Type1 osa T

1070 073 758 101 |

1 − 11 |

Type1 osa / CC 220

Digital Interface

Signal description

|

–-----------------Address----------------- |

|

|

|

|

|

||

|

CC220 |

CC220 |

CC220 |

Type1 osa Type1 osa |

|

|

|

|

|

Word coupl. Bit coupl.dec. |

CL |

softPIC |

Symbol |

|

Remarks |

||

|

|

|

|

|

|

|||

|

------------------ |

|

NC->PLC I |

BYTE: 18 (M |

BYTE: 50) ------------------------------ |

|||

|

O194.0 |

I18.0 |

144 |

M50.0 |

I18.0 |

CCRFEND1 |

REFERENCE POINT REACHED 1ST AXIS |

|

|

O194.1 |

I18.1 |

145 |

M50.1 |

I18.1 |

CCRFEND2 |

REFERENCE POINT REACHED 2ND AXIS |

|

|

O194.2 |

I18.2 |

146 |

M50.2 |

I18.2 |

CCRFEND3 |

REFERENCE POINT REACHED 3RD AXIS |

|

|

O194.3 |

I18.3 |

147 |

M50.3 |

I18.3 |

CCRFEND4 |

REFERENCE POINT REACHED 4TH AXIS |

|

|

O194.4 |

I18.4 |

148 |

M50.4 |

I18.4 |

CCRFEND5 |

REFERENCE POINT REACHED 5TH AXIS |

|

|

O194.5 |

I18.5 |

149 |

|

|

CCRFEND6 |

REFERENCE POINT REACHED 6TH AXIS |

|

|

O194.6 |

I18.6 |

150 |

|

|

CCRFEND7 |

REFERENCE POINT REACHED 7TH AXIS |

|

|

O194.7 |

I18.7 |

151 |

|

|

CCRFEND8 |

REFERENCE POINT REACHED 8TH AXIS |

|

|

------------------ |

|

NC->PLC I |

BYTE: 19 (M |

BYTE: 51) ------------------------------ |

|||

|

O195.0 |

I19.0 |

352 |

M51.0 |

I19.0 |

CCEXPOS1 |

EXT.POS.REACHED 1ST AXIS |

|

|

O195.1 |

I19.1 |

153 |

M51.1 |

I19.1 |

CCEXPOS2 |

EXT.POS.REACHED 2ND AXIS |

|

|

O195.2 |

I19.2 |

154 |

M51.2 |

I19.2 |

CCEXPOS3 |

EXT.POS.REACHED 3RD AXIS |

|

|

O195.3 |

I19.3 |

155 |

M51.3 |

I19.3 |

CCEXPOS4 |

EXT.POS.REACHED 4TH AXIS |

|

|

O195.4 |

I19.4 |

156 |

M51.4 |

I19.4 |

CCEXPOS5 |

EXT.POS.REACHED 5TH AXIS |

|

|

O195.5 |

I19.5 |

157 |

|

|

CCEXPOS6 |

EXT.POS.REACHED 6TH AXIS |

|

|

O195.6 |

I19.6 |

158 |

|

|

CCEXPOS7 |

EXT.POS.REACHED 7TH AXIS |

|

|

O195.7 |

I19.7 |

159 |

|

|

CCEXPOS8 |

EXT.POS.REACHED 8TH AXIS |

|

|

------------------ |

|

NC->PLC I |

BYTE: 20 (M |