Bosch Compress 3000, HP 200-1 E Al-F, HP200-1E, HP 200-1 E AI-F Instruction Manual

HP 200-1 E AI-F

Compress 3000

Electric Heat Pump Water Heater

6720646804-00.1V

6 720 646 804 (2011/06) US

6 720 646 804

2

Index

Index

1Warnings 3

2 Appliance details 5

2.1 Overview 5

2.2 Features and safety devices 5

2.3 Specification tables 7

2.4 Principle of Operation

(brief overview of modes) 8

2.5 Dimensions 9

3 Installation instructions 10

3.1 Tools required 10

3.2 Location requirements 10

3.3 Venting (specifications and vent runs) 11

3.4 Water piping 11

3.5 Electric requirements 13

3.6 Installation configurations 14

3.7 Insulation blanket 16

3.8 Filling the water heater 16

3.9 Installation checklist 16

3.10 What to expect for “normal startup” 17

4 Operating Instructions 18

4.1 Control Pad 18

4.2 Safety warnings 20

4.3 Water temperature setting 20

4.4 Operating modes 21

4.5 Feature buttons on the user interface 21

4.6 Using the combination buttons 21

4.7 Reset the temperature limiting control 22

5 Maintenance and repair 23

5.1 Periodic Inspection 23

5.2 Temperature and pressure relief valve 23

5.3 Flushing tank 23

5.4 Draining the Water Heater 23

5.5 Vacation and Extended Shutdown 24

5.6 Cleaning the Filter 24

5.7 Clearing the Condensation Drain Tubes 24

5.8 Anode Rod servicing 25

6 Troubleshooting/Problem Solving 26

7 Electrical diagram 33

8 Interior components and parts list 34

9 Protecting the environment 36

10 Limited Warranty 37

6 720 646 804

Warnings

3

1 Warnings

For your safety

Do not store or use gasoline or other flammable,

combustible or corrosive vapors and liquids in the

vicinity of this or any other appliance.

FCC:

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2)

this device must accept any interference received,

including interference that may cause undesired operation.

Fig. 1

To prevent serious injury, unit damage or damage to

other property, please use the electric heat pump

properly, please read this manual carefully and

understand the following information correctly.

Warning: Field wiring connections and

electrical grounding must comply with

local codes, or in the absence of local

codes, with the latest edition of the

National Electric Code, ANSI/NFPA 70,

or in Canada, all electrical wiring must

comply with the local codes and the

Canadian Electrical Code, CSA C22.1

Part 1.

Danger: Shock hazard: line voltage is

present. Before servicing the water

heater, disconnect power supply.

Failure to do so could result in severe

personal injury or death.

Warning: The appliance should be

located in an area where leakage of the

heater or connections will not result in

damage to the area adjacent to the

appliance or to lower floors of the

structure. When such locations cannot

be avoided, a suitable drain pan,

adequately drained, must be installed

under the appliance.

Warning: If a water heater is installed in

a closed water supply system, such as

one having a backflow preventer in the

cold water supply line, means shall be

provided to control thermal expansion

and to avoid the potential that the water

heater may burst. Contact a plumbing

professional on how to control this

situation.

Warning: To avoid the potential for ignition and fire, keep appliance area clear

and free from combustible materials,

gasoline and other flammable vapors

and liquids.

Warning: This water heater is not

suitable for pool heating.

Warning: Precautions must be taken

prior to manually operating the relief

valve to avoid contact with hot water

which may cause a scalding injury and

to prevent water damage.

Caution: Label all wires prior to

disconnection when servicing controls.

Improper wiring may lead to shock

hazards and fires, which may cause

serious injury or death.

Verify proper operation after servicing.

Warning: Improper or incorrect

operation of the water heater can

create a hazardous condition that may

lead to serious injury or death. Read

this manual before installing or

operating the water heater.

BURN

DANGER

Water temperature over 120°F can

cause severe burns instantly or

death from scalds.

Children, disabled and elderly are

at highest risk of being scalded.

See instruction manual before

setting temperature at water

heater.

Feel water before bathing or

showering.

HOT

6 720 646 804

4

Warnings

For installation in the state of California

California Law requires that residential water heaters

must be braced, anchored or strapped to resist falling

or horizontal displacement due to earthquake motions.

For residential water heaters up to 52 gallon capacity, a

brochure with generic earthquake bracing instructions

can be obtained from:

Office of the State Architect, 400 P Street,

Sacramento, CA 95814

or you may call 916.324.5315 or ask a water heater

dealer.

However, applicable local codes shall govern installation. For residential water heaters of a capacity greater

than 52 gallons, consult the local building jurisdiction

for acceptable bracing procedures.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish

a list of substances known to the State of California to

cause cancer, birth defects, or other reproductive harm,

and requires businesses to warn of potential exposure

to such substances.

Proposition 65 Warning: this product contains a chemical known to the

State of California to cause cancer,

birth defects, or other reproductive

harm. This appliance can cause low-level exposure to some of the substances

included in the Act.

6 720 646 804

Appliance details

5

2 Appliance details

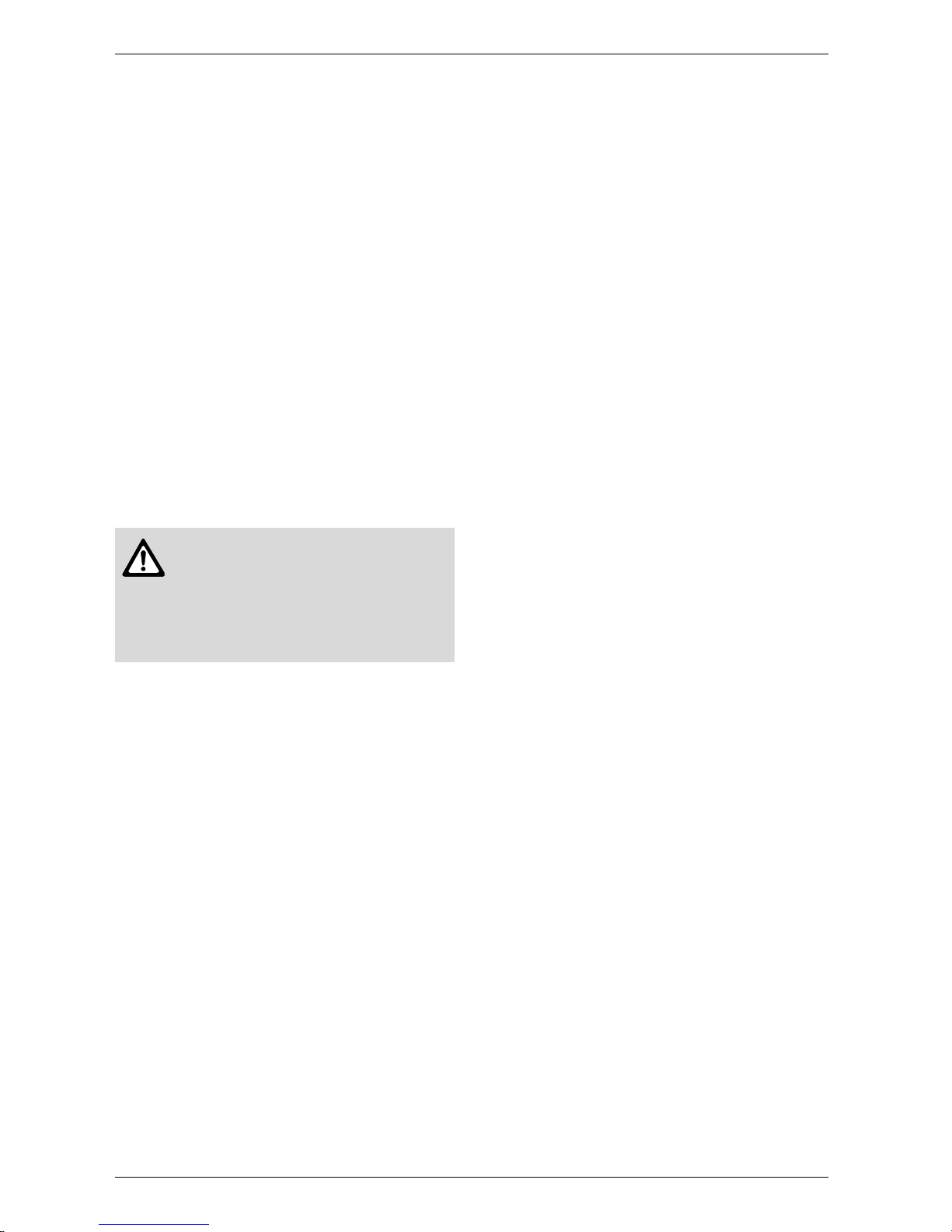

2.1 Overview

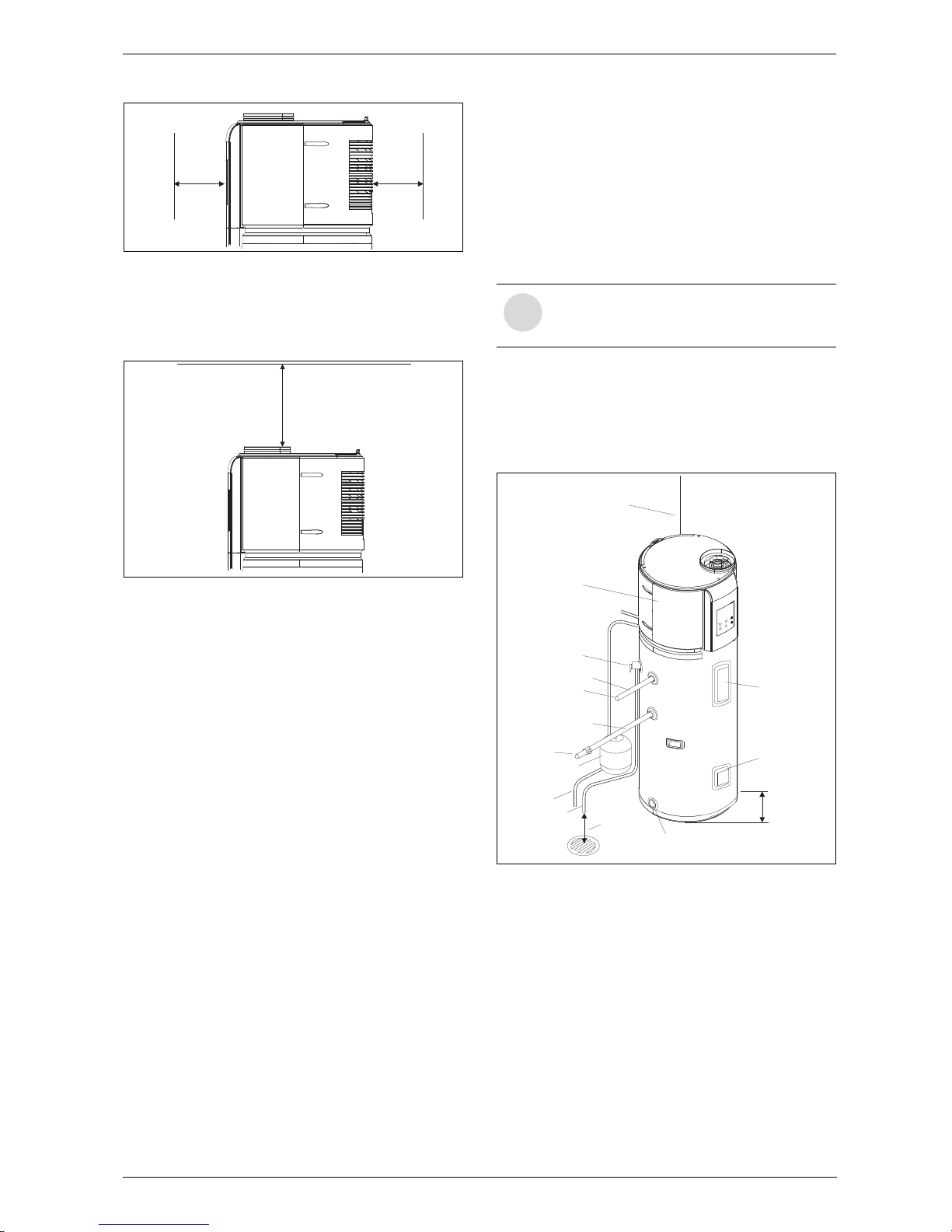

Fig. 2 Appliance overview

1 Temperature & pressure relief valve

2 Hot outlet

3 Cold intlet

4 Drain

5 Vent opening

6 Display

7 8" vent collar

2.2 Features and safety devices

Environmentally friendly and safe

Produces no harmful gas locally from the combustion of

oil, coal, or gas and is free of potential hazards from carbon monoxide.

Easy to operate and multiple heat sources

Easy to use adjustment keys for easy setting of the

water temperature. Depending upon the location of the

air exchanger, heat may be taken from a mechanical

room or a sun porch or attic space, or from hot areas in

any other domestic environments.

Heating capacity

The unit absorbs ambient energy and releases the heat

into the water stored in the tank. If the ambient temperature is low, the heating capacity of the heat pump will

be reduced, but you can still rely on the electrical elements for backup.

6

5

4

1

6720646804-04.1V

7

3

2

i

Vent collar does not come installed on the

water heater.

6 720 646 804

6

Appliance details

Temperature limiting controls (TCOs)

The water heater is equipped with two temperature-limiting controls (TCOs) that are located above the upper

heating heating element in contact with the tank surface. If for any reason the water temperature becomes

excessively high, the temperature-limiting control (TCO)

breaks the power circuit to the heating element. Once

the control opens, it must be reset manually. Resetting

of the temperature limiting controls should be done by

a qualified service technician.

Defrosting

Under the heating mode, the unit will shut down the

heat pump automatically if an unusually low temperature

is detected at the evaporator. This cycle can last

between 2 and 10 minutes and ensures maximum heating efficiency.

The fan motor will stop running when the unit is defrosting.

Working conditions

In order to use the unit correctly, please run the unit at

ambient temperature 45°F - 115°F.

The unit includes sophisticated electronic devices, care

should be taken to feed the unit only with potable water.

Do not use untreated water from lakes, rivers or

untreated groundwater!

Overheating protection

When the water temperature reaches 165°F power to

the unit will be cut off (see section 4.7 for instructions

on resetting the temperature limiter).

Water temperature or pressure protection

The unit is equipped with a T&P valve for your safety. If

the tank pressure reaches 150PSI or the temperature

reaches 210°F, the T&P valve will open automatically to

relieve the pressure and or reduce the temperature to

safe limits.

Caution: The cause of high

temperature conditions must be

investigated by a qualified service

technician and corrective action must

be taken before placing the water heater

in service again.

6 720 646 804

Appliance details

7

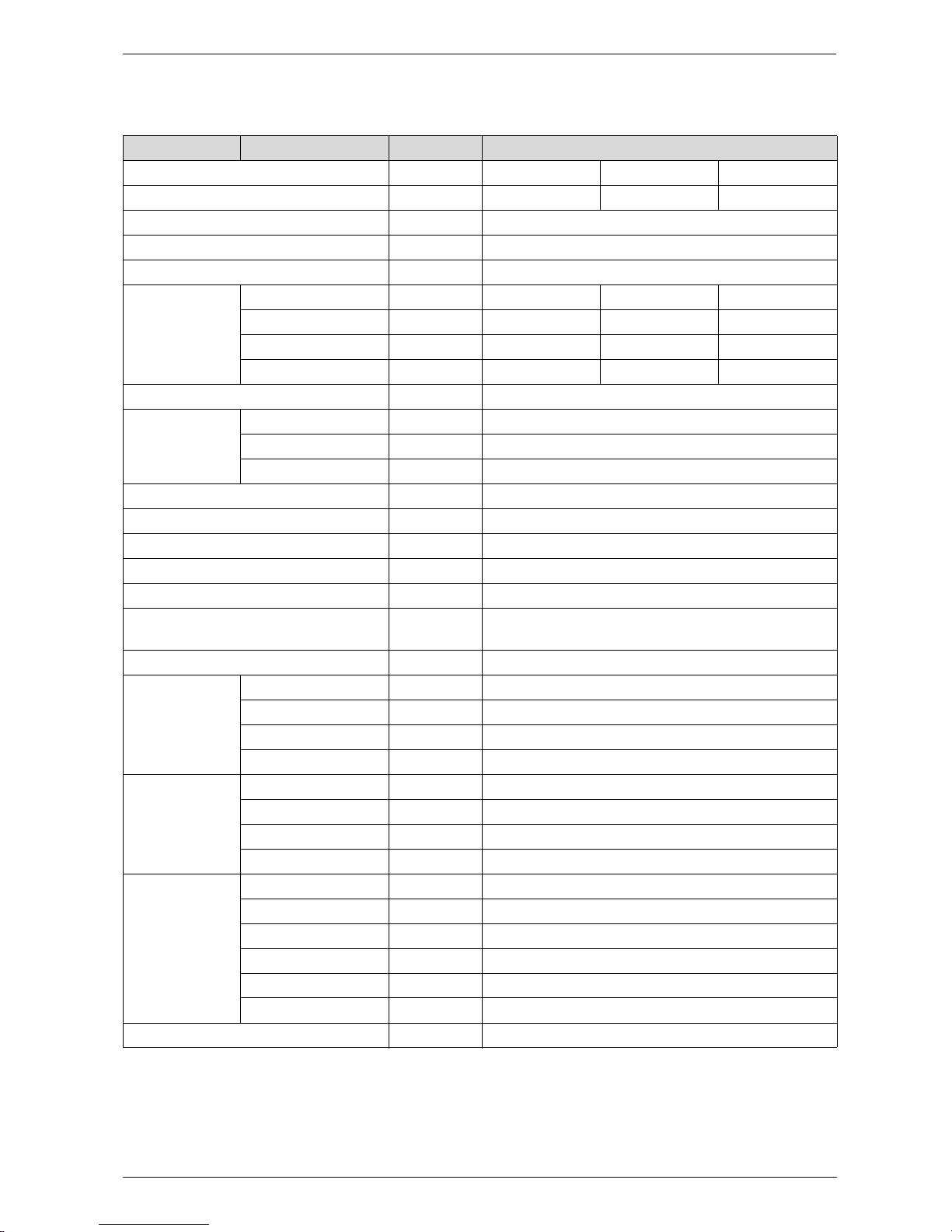

2.3 Specification tables

Model HP200-1E...

Running models Economy Auto E-heater

Running ambient temp. °F 45 - 115 45 - 115 -5 - 130

Outwater Temp. °F Default 120°,100°F - 140°F

Power supply Ph/V/Hz 1-240-60

Storage size US Gal 50

Water heating

Capacity kW / BTU/h 1.50 / 5123 1.50 / 5123 4.00 / 13661

Max. input kW / BTU/h 0.80 / 2732 4.50 / 15368 4.00 / 13661

First Hour Rating US Gal - 56.00 52.00

Max. current A 6.5 21.6 18.7

Ambient temp. °F - 5 - 130

Unit

Dimension (D×H) inch Ø22.4 × 64.5

Packing (W×H×D) inch 25 × 68.5 × 27

Weight lbs 209.4 / 242.5

Noise level dB(A) 48

Refrigerant type/quantity lbs R134a/1.7

Refrigerant design pressure PSIA 331/86 at ambient 70°F

Tank design pressure PSI 150

Throttling type Thermal expansion valve

System protection TCO, TDO, P&T valve, over-load protector temp.

ground fault protector etc.

Air flow Ft

3

/h 13066 / 9888 / 7063

Compressor

Model FFC110HBX

Type Piston

Brand Embraco

Input kW 0.7

Fan motor

Model YDK12-6B

Brand welling

Input W 40

Speed RPM 970/750/550

Water pipeline

Water inlet pipe Male NPT ¾

Water outlet pipe Male NPT ¾

Drainage pipe Hose fitting NPT ¾

PT valve joint Female NPT ¾

Max. pressure psi 145

Heat exchanger Dividing wall type heat exchanger

E-heater kW 4.0 × 2

Table 1

6 720 646 804

8

Appliance details

2.4 Principle of Operation (brief overview of modes)

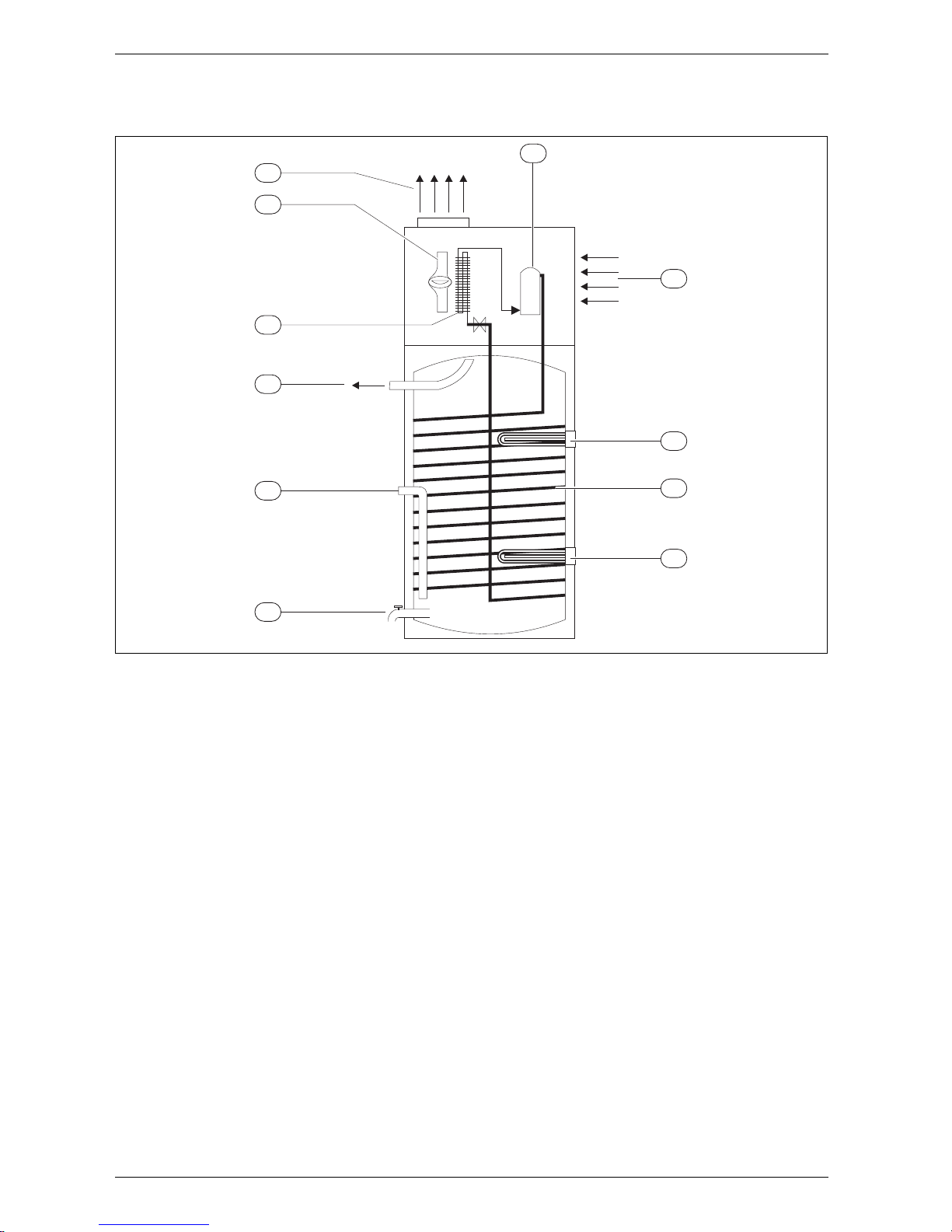

Fig. 3

1 Air Heat Exchanger

2 Compressor

3 Cooled / Dehumidified Air

4 Upper/Lower Electric element

5 Condensor Coil (heat exchanger)

6 Drain valve

7 Domestic Hot Water outlet

8 Ambient Room Air

9 Fan

10 Cold water supply

System theory

An Electric Heat Pump Water Heater draws heat from

the ambient air and transfers that heat to the water in

the tank. Ambient air inside the room where the water

heater is installed is blown across an evaporator by a

fan. Cold refrigerant inside an expansion valve is heated

from this ambient air. This warmed refrigerant is then

sent through a compressor where it becomes extremely

hot. The hot refrigerant then passes through a

condenser coil that is wrapped around the outside of

the tank. The heat from the hot refrigerant is transferred

to the stored water inside the tank. After transferring it's

heat, the now warm refrigerant is pushed through an

expansion valve where it is cooled and depressurized so

the process can begin again. In addition, the ambient air

is cooled and dehumidified as it passes through the

evaporator and can be used to adjust the climate of the

room.

Built in controls offer a variety of operational modes to

suit every user’s needs. When operating with the heat

pump only (Economic Mode), the water is heated using

only the ambient air. Economic mode does not activate

the electric element inside. This mode may take longer

to heat the water to set temperature but uses less than

1/2 the electricity of a similar size electric tank.

The Auto mode use the electric element to supplement

the heat pump in the event that the water is not reaching

set temperature.

Electric mode allows for the water heater to function as

a standard electric tank without the use of the heat

pump.

Brief overview of modes

• Economic Mode;

• Electric Mode;

• Auto Mode (default mode);

• Vacation Mode.

9

3

7

6

5

2

8

6720646804-01.1V

4

4

1

10

6 720 646 804

Appliance details

9

2.5 Dimensions

Fig. 4 Dimensions (inches)

64.5

37.6

27.9

3.07

8

22.4

6720646804-03.1V

6 720 646 804

10

Installation instructions

3 Installation instructions

The manufacturer’s warranty does not cover any

damage or defect caused by improper installation,

attachment or use of any type of energy-saving or other

unapproved devices (other than those authorized by the

manufacturer) into, onto or in conjunction with the water

heater.

The manufacturer disclaims any responsibility for such

loss or injury resulting from the use of such

unauthorized devices.

3.1 Tools required

• Wrench ¾"

• Phillips screwdriver

• Flat screwdriver

• Wire strippers

• Level

• Measuring tape

• Standard plumbing tools.

3.2 Location requirements

Locate the water heater in a clean, dry area as near as

practical to the area of greatest hot water demand.

Long uninsulated hot water lines can waste energy and

water.

Note: Because this unit draws in air from the room to

heat the water, the room must be at least 10' x 10' x 7'

(700 cubic feet) or larger. If the room is smaller, there

must be louvers installed to allow for adequate airflow.

Place the water heater in such a manner that the air filter, cover and front panels can be removed to permit

inspection and servicing, such as removal of elements,

draining the tank, or cleaning of the filter.

The water heater and water lines should be protected

from freezing temperatures and highly corrosive atmospheres. Do not install the water heater in outdoor or

unheated, unprotected areas.

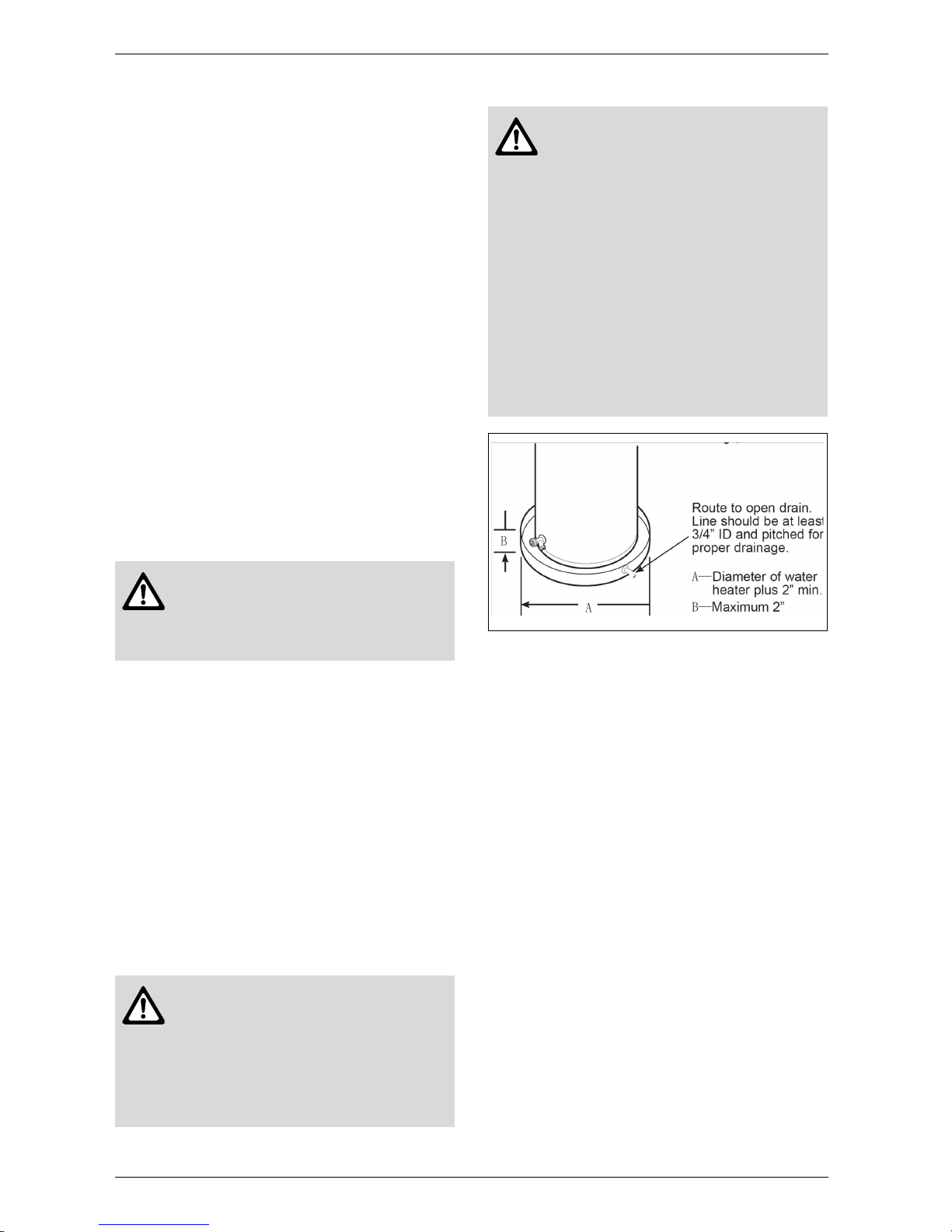

Fig. 5

NOTE: Auxiliary catch pan MUST conform to local

codes. Catch Pan Kits are available from the store

where the water heater was purchased, a building supply store or any water heater distributor.

Local installation regulations

This water heater must be installed in accordance with

these instructions, local codes, plumbing codes (UPC

or IPC), utility codes, utility company requirements or, in

the absence of local codes, the latest edition of the

National Electrical Code. It is available from some local

libraries or can be purchased from the National Fire Prevention Association, Batterymarch park, Quincy, MA

02169 as booklet ANSI/NFPA 70.

Required clearances

It is recommended that there is 5-½” of clearance (air

space) between any object and the front and rear

shrouds.

Warning: To avoid the potential for

ignition and fire, the water heater should

not be installed in a space where liquids

which give off flammable vapors are to

be used or stored.

Caution: The water heater should not

be located in an area where leakage of

the tank or connection will result in

damage. In installations where risk of

water damage cannot be avoided, a

suitable catch pan, adequately drained,

must be installed under the water

heater.

Warning: This water heater SHOULD

NOT be installed in a space where

liquids which give off flammable vapors

are to be used or stored. Such liquids

include gasoline, LP gas (butane and

propane), paint or adhesives and their

thinners, solvents or removers.

Because of natural air movement in a

room or other enclosed space,

flammable vapors can be carried from

where their liquids are being used or

stored. Any arc within the water

heater's electronic controls can ignite

these vapors causing an explosion or

fire which may result in severe burns or

death to those in range, as well as

property damage.

6 720 646 804

Installation instructions

11

Fig. 6

A 27” minimum vertical clearance is required to remove

the filter for cleaning and to replace the anode rod. The

hot and cold water plumbing and electrical connections

must not interfere with the removal of the filter.

Fig. 7

Condensation drain

The unit has a condensate drain, therefore a drain must

be available in close proximity to the unit. The drain must

be no higher than 36” above the floor (laundry drain is

acceptable).

If no drain is available, then a common condensate

pump with a capacity no less than 1 gallon/day must be

purchased from a local builder and supply store and

installed.

3.3 Venting (specifications and vent

runs)

Venting the outlet air of the water heater to another

room may be an option for specific applications. See

Section 3.6.

• Duct diameter: 8”

• Maximum outlet duct length: 16.5 feet

• Maximum Air flow: 219 CFM

• Maximum no. of elbows: 1.

The vent collar accessory (see Fig. 2) must be installed

in order to accommodate the required 8" diameter vent

pipe. Line up tabs on vent collar with slots in vent

opening. Rotate to lock into place.

If terminating venting to the outdoors, pitch horizontal

pipe downward towards termination 1/4" per foot to

avoid damage from rain.

3.4 Water piping

3.4.1 Inlet - Outlet connections

Refer to the illustration below for suggested typical

installation. The installation of unions or flexible copper

connectors is recommended on the hot and cold water

connections so that the water heater may be easily disconnected for servicing if necessary. The HOT and

COLD water connections are clearly marked and are

¾”NPT on all models.

IMPORTANT: Do not apply heat to the HOT or COLD

water connections. If sweat connections are used,

sweat tubing to adapter before fitting the adapter to the

water connections on heater. Any heat applied to the

hot or cold water connection will permanently damage

the dip tube.

Fig. 8 Typical installation

3.4.2 Dielectric union (recommended accessory)

Different metals between plumbing and tank materials

and additionally the effect of hot water can cause

corrosion of one of the metals (generally the one in the

tank is the metal attacked)

The Dielectric union will avoid any physical contact

between the two metals, acting as an effective insulator

and preventing this attack. How quick this corrosion

progresses, if at all, depends on the content of your

water, its pH, the dissolved minerals and the metals

involved.

5”½5”½

6720646804-06.1V

27”

6720646804-05.1V

i

Install a shut-off valve in the cold water line

near the water heater. This will enable easier service or maintenance of the unit later.

6720646804-09.1V

6” air gap

Relief discharge

line to suitable

open drain

6’ drain hose

Thermal expansion

tank (if required)

To cold water

supply

Hot water outlet

to fixtures

Union

Union

Temperature and

pressure relief valve

(shown in different

location for clarity)

Drain valve

Jacket

access panel

Jacket

access panel

Auxiliary catch

pan 2” maximum

Electrical junction box

(use only copper

conductors)

To electrical

distribution panel

6 720 646 804

12

Installation instructions

Failing to install this accessory will void the tank

warranty.

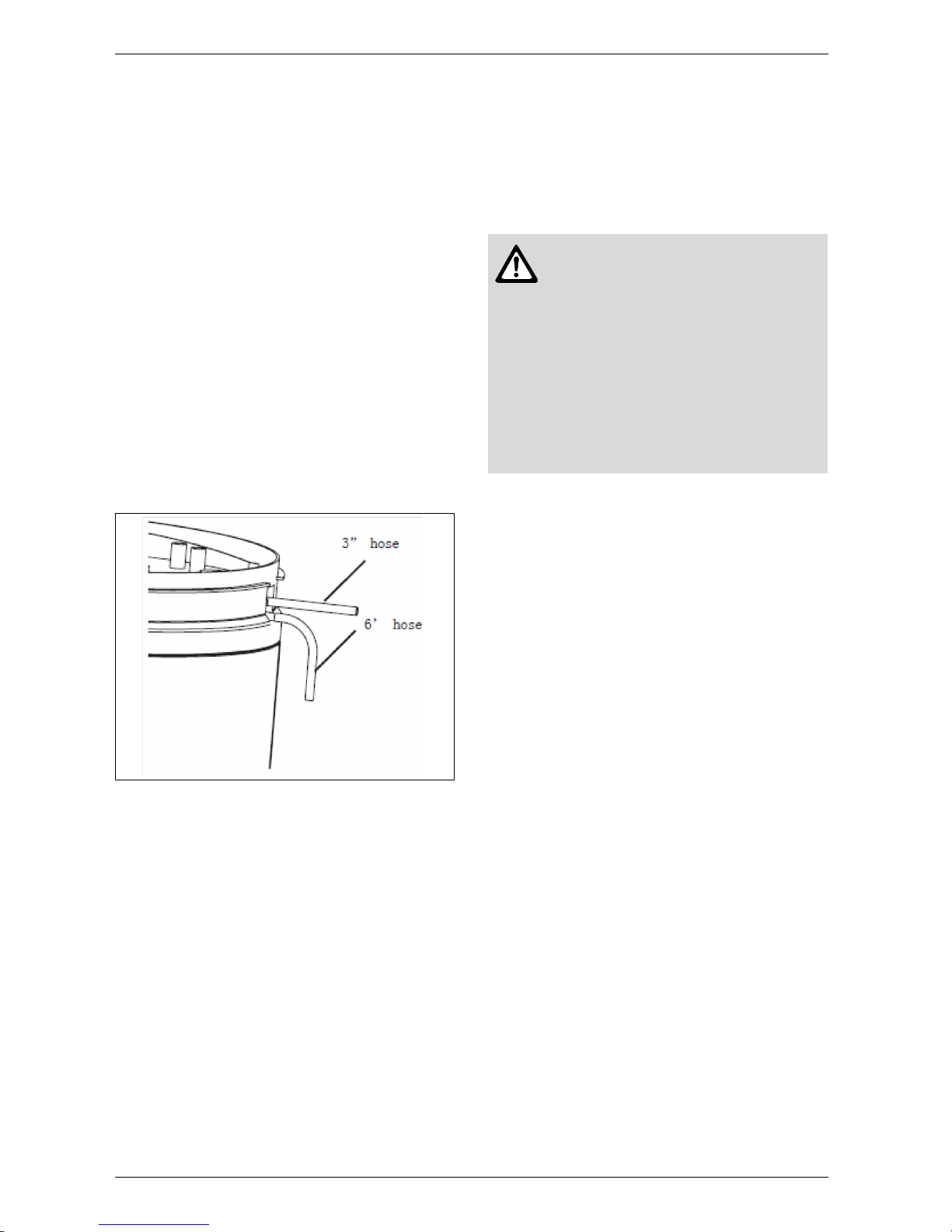

3.4.3 Condensate Drain Tubes

This unit has a condensation tray. The water collected

in the tray drains out of the drain ports coming off the

back of the unit. Two flexible hoses are included with

this unit. It is important that both of these hoses are

attached to the two drain ports coming off the back of

the unit. The upper drain serves as an overflow drain

that will operate only if the bottom drain is blocked.

Water leaking from the upper drain is an indicator that

the lower drain, and possibly the condensate pan itself,

require cleaning.

B Attach one end of the longer 6’ hose to the lower

drain port on the back of the unit, underneath the rear

cover.

B Direct the other end to a drain in the floor or no higher

than 3’ above the floor.

If such drain is unavailable, a condensate drain pump

(not provided) must be purchased and installed.

B Attach the shorter 3” hose to the top drain port.

Fig. 9

3.4.4 T&P Valve

A combination temperature and pressure-relief valve,

complying with the Standard for Relief Valves for Hot

Water Supply Systems, ANSI Z21.22, is supplied and

must remain installed in the opening provided and

marked for the purpose on the water heater. No valve of

any type should be installed between the relief valve and

the tank. Local codes shall govern the installation of

relief valves.

Connect the outlet of the relief valve to a suitable open

drain so that the discharge water cannot contact live

electrical parts or persons and to eliminate potential

water damage. Under no circumstances should the

relief valve vent be connected to the condensate drain

line.

Piping used should be of a type approved for hot water

distribution. The discharge line must be no smaller than

the outlet of the valve and must pitch downward from

the valve to allow complete drainage (by gravity) of the

relief valve and discharge line. The end of the discharge

line should not be threaded or concealed and should be

protected from freezing. No valve of any type, restriction, reducing coupling or tee should be installed in the

discharge line.

This valve must be marked with a maximum set pressure

not to exceed the marked maximum working pressure of

the water heater. It should be installed into an opening

provided and marked for this purpose in the water

heater, and vented so that any discharge from the valve

exits only within 6 inches above, or at any distance

below, the structural floor, and does not contact any live

electrical part. The discharge opening must not be

blocked or reduced in size under any circumstances.

3.4.5 Thermal expansion tank

Determine if a check valve exists in the inlet water

supply line. It may have been installed in the cold water

line as a separate backflow preventer, or it may be part

of a pressure-reducing valve, water meter or water

softener. A check valve located in the cold water inlet

line can cause what is referred to as a "closed water

system". A cold water inlet line with no check valve or

backflow prevention device is referred to as an "open"

water system.

As water is heated, it expands in volume and creates an

increase in the pressure within the water system. This

action is referred to as "thermal expansion". In an

"open" water system, expanding water which exceeds

the capacity of the water heater flows back into the city

main where the pressure is easily dissipated.

A "closed water system", however, prevents the

expanding water from flowing back into the main supply

line, and the result of "thermal expansion" can create a

rapid and dangerous pressure increase in the water

heater and system piping. This rapid pressure increase

can quickly reach the safety setting of the relief valve,

causing it to operate during each heating cycle. Thermal

expansion, and the resulting rapid and repeated

expansion and contraction of components in the water

heater and piping system, can cause premature failure

Warning: To reduce the risk of

excessive pressures and temperatures

in this water heater, install temperature

and pressure protective equipment

required by local codes and no less

than a combination temperature and

pressure relief valve certified by a

nationally recognized testing laboratory

that maintains periodic inspection of

production of listed equipment or

materials, as meeting the requirements

for Relief Valves for Hot Water Supply

Systems, ANSI Z21.22.

Loading...

Loading...