Xerox WorkCentre 3655 Service Manual

WorkCentre

®

3655

Multifunction Printer

Service Manual

WorkCentre

®

3655

Multifunction Printer

Service Manual

Xerox Internal-Use Only

Sample

Fault Code Structure:

71-101-00

Updated 11/16/15 DAW

WorkCentre 3655 Multifunction Printer

Service Documentation

WorkCentre 3655 Multifunction Printer

705P01355

Initial Issue - Xerox Internal Use Only

5/2014

Xerox Corporation

Content Development and Language Services

26600 Parkway - Bldg. 60

P.O. Box 1000, M/S 7060-776

Wilsonville, OR 97070-1000

NOTICE: All service documentation is supplied to Xerox external cu stomers for informational

purposes only. Xerox service documentation is intended for use by certified, product trained

service personnel only. Xerox does not warrant or represent that such documentation is com-

plete, nor does Xerox represent or warrant that it will notify or provide to such customer any

future changes to this documentation. Customer performed service of equipment, or modules,

components or parts of such equipment may affect the warranty offered by Xerox with respect

to such equipment. You should consult the applicable warranty for its terms regarding cus-

tomer or third party provided service. If the customer services such equipment , modules, com -

ponents or parts thereof, the customer releases Xerox from any and all liability for the customer

actions, and the customer agrees to indemnify, defend and hold Xerox harmless from any third

party claims which arise directly or indirectly from such service.

Unpublished rights reserved under the copyright laws of the United States. Contents of this

publication may not be reproduced in any form without permission of Xerox Corporation.

Copyright protection claimed includes all forms of matters of copyrightable materials and infor-

mation now allowed by statutory or judicial law or hereinafter granted, including without limita-

tion, material generated from the software programs which are displayed on the screen such

as styles, templates, icons, screen displays, looks, etc.

Xerox technical training materials and service manuals are intended for use by authorized

Xerox service technicians and service partners only and are not for resale. These materials

may not be distributed, copied or otherwise reproduced without prior written consent from

Xerox Corporation.

© 2014 Xerox Corporation. All rights reserved. XEROX® and XEROX and design®, P haser®,

PhaserSMART®, DocuCard®, DocuSP®, FreeFlow® CentreWare®, infoSMART®, Made For

Each Other®, PagePack™, ColorCube®, ProfitAccelertor™, and Walk-Up™ are trademarks of

Xerox Corporation in the United States and/or other countries.

Other company trademarks are also acknowledged.

As an ENERGY STAR® partner , Xerox Corporation has determined that this product meets the

ENERGY STAR guidelines for energy efficiency. The ENERGY STAR name and logo are reg-

istered U.S. marks.

5/2014

i

WorkCentre 3655 Multifunction Printer

Introduction

Initial Issue - Xerox Internal Use Only

Introduction

About This Manual .............................................................................. ......... .... .... .... ....... iii

How To Use This Manual................................................................................................ iii

Service Safety Summary..................................................... ............................................ iv

Symbols Used On The Product....................................................................................... v

Voltage Measurement and Specifications....................................................................... vi

Health and Safety Incident Reporting ............................................................................. vii

Regulatory Specifications................................................................................. .... .. .... ..... viii

Translation of Warnings.................................................................................................. ix

WorkCentre 3655 Overview............................................................................................ x

Control Panel Layout...... ................. ................. ............................................................... xii

Options Overview............................................................................................................ xiii

CRU Life Expectancy...................................................................................................... xiii

Product Codes and Serial Number Range...................................................................... xiv

5/2014

iii

WorkCentre 3655 Multifunction Printer

About This Manual, How To Use This Manual

Introduction

Initial Issue - Xerox Internal Use Only

About This Manual

The WorkCentre 3655 Multifunction Printer Service M anual is part of a multinational service

documentation system delivered in the standard Xerox EDOC service manual format. This

manual is the primary document used for diagnosing, repairing, maintaining, and troubleshoot

-

ing these systems. The Service Manual is the controlling publication for a service call. To

ensure product understanding, complete the Xerox Service Training Program for this printer.

Organization

Section titles and the information contained in each is presented in the following paragraphs:

Section 1 Service Call Procedures

This section is used to start and complete a service call. The procedures in this section will

either direct you to a Repair Analysis Procedure (RAP), or identify a faulty component or sub

-

assembly.

Section 2 Status Indicator Repair Analysis Procedures

This section contains the Repair Analysis Procedures (RAPs) and checkouts necessary to

diagnose, isolate and repair faults other than image quality faults.

Section 3 Image Quality

This section contains the Image Quality Repair Analysis Procedures (IQ RAPs), checkouts and

setup procedures necessary to diagnose, isolate and repair image quality faults.

Section 4 Repairs/Adjustments

This section contains the instructions for removal, replacement, and adjustment of parts.

Section 5 Parts List

This section contains the illustrated spare parts list. Any part that is spared or that must be

removed to access a spared part is illustrated.

Section 6 General Procedures / Information

This section contains all other procedures, product specifications and general information.

Section 7 Wiring Data

This section contains the wiring diagrams.

Section 8 Principles of Operation

This section contains details of printer operation and component locations.

Component Names

Names of parts that appear in the disassembly procedures may not be exactly the same as the

names that appear on the part or listed in the Parts List. For example; a part called the Regis

-

tration Chute Assembly may appear on the Parts List as Assembly, Chute REGI.

How To Use This Manual

Always start with the Service Call Procedures, Section 1. Perform Initial Actions and verify the

problem, then follow the directions given.

How to Differentiate Between Machine Variants

The machine will be identified in this manual by the model identifier 3655N/DN or 3655SN/DN.

When a procedure, parts list description or other reference is unique amongst different models

of machine, the appropriate model designator is indicated. Any artwork is also specific.

NOTE: This manual services all configurations of the machine. Ignore references to options

not installed on the machine.

Warnings, Cautions and Notes

WARNING

A warning is used whenever an operating or main tenance procedure, practice, condi-

tion or statement, if not strictly observed, could result in personal injury.

A translated version of all warnings is in Translation of Warnings.

CAUTION

A caution is used whenever an operation or maintenance procedure, practice, condition or

statement, if not strictly observed, could result in damage to the equipment.

NOTE: A note appears to highlight a procedure, practice, condition or statement.

5/2014

iv

WorkCentre 3655 Multifunction Printer

Service Safety Summary

Initial Issue - Xerox Internal Use Only

Introduction

Service Safety Summary

General Guidelines

For qualified service personnel only: Refer also to the preceding Electrical Safety.

Avoid servicing alone: Do not perform internal service or adjustment of this product unless

another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power applied: Dangerous voltages may exist at several points in

this product. To avoid personal injury, do not touch exposed connections and components

while power is on. Disconnect power before removing the power supply shield or replacing

components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and other metallic

objects could come into contact with dangerous voltages and currents.

Electrical Safety

• Use the Power Cord supplied with the printer.

• Plug the Power Cord directly into a properly grounded electrical outlet.

• Do not use a ground adapter plug to connect the printer to an electrical outlet that does

not have a ground connection terminal.

• Do not use an extension cord or power strip.

• Do not place the system in an area where people might step on the power cord.

• Do not place objects on the power cord.

• Do not block ventilation openings. These openings prevent printer overheating.

• Do not drop paper clips or staples into the printer.

Operational Safety

The printer and supplies were designed and tested to meet strict safety requirements. These

include safety agency examination, approval, and compliance with established environmental

standards.

Pay attention to these safety guidelines to ensure the continued, safe operation of the printer.

• Use the supplies specifically designed for your system. The use of unsuitable materials

may cause poor performance and a possible safety hazard.

• Follow all warnings and instructions marked on, or supplied with, the system, options and

supplies.

NOTE: The Total Satisfaction Guarantee is available in the United States and Canada. Cover-

age may vary outside these areas; please contact your local representative for details.

Maintenance Safety

• Do not attempt maintenance not specifically described in the printer documentation.

• Do not use aerosol cleaners. The use of supplies that are not approved may cause poor

performance and could create a hazardous condition.

• Do not burn any consumables or routine maintenance items. For information on Xerox

supplies recycling programs, go to www.xerox.com/gwa.

Warning Labels

Read and obey all posted warning labels. Throughout the printer, warning labels are displayed

on potentially dangerous components. As you service the printer, check to make certain that all

warning labels remain in place.

Safety Interlocks

Make sure all covers are in place an d all interlock switches are functioning correc tly after you

have completed a service call. If you bypass an interlock switch, use extreme caution when

working on or around the printer. Figure 1 shows the interlock circuitry.

5/2014

v

WorkCentre 3655 Multifunction Printer

Service Safety Summary, Symbols Used On The

Introduction

Initial Issue - Xerox Internal Use Only

Figure 1 Interlock circuits

Symbols Used On The Product

The following precautionary symbols may appear on the machine.

This symbol indicates Danger High Voltage.

Figure 1 High voltage symbol

Protective Ground (Earth) symbol.

Figure 2 Protective ground (earth) symbol

This symbol indicates hot surface. Use caution to avoid personal injury.

Figure 3 Hot surface symbol

The surface is hot while the printer is running. After turning off the power, wait 30 minutes.

Figure 4 Wait 30 minutes symbol

Avoid pinching fingers in the printer. Use caution to avoid personal injury.

5/2014

vi

WorkCentre 3655 Multifunction Printer

Symbols Used On The Product, Voltage Measure-

Initial Issue - Xerox Internal Use Only

Introduction

Figure 5 Pinch injury symbol

Use caution (or draws attention to a particular component). Refer to the manual(s) for informa-

tion.

Figure 6 Use caution symbol

Voltage Measurement and Specifications

Measurements of DC voltage must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure. All measurem ents of AC volt

-

age should be made with respect to the adjacent return or ACN wire.

Logic Voltage Levels

Measurements of logic levels must be made with reference to the specified DC Common,

unless some other point is referenced in a diagnostic procedure.

DC Voltage Measurement in RAPs

The RAPs have been designed so that when it is required to use the DMM to measure a DC

voltage, the first test point listed is the location for the red (+) meter lead and the second test

point is the location for the black meter lead. For example, the following statement may be

found in a RAP.

There is +5 VDC from P/J7 to P/J68.

In this example, the red meter lead would be placed on P/J7 and the black lead on P/J68.

If a second test point is not given, it is assumed that the black meter lead may be attached to

chassis ground.

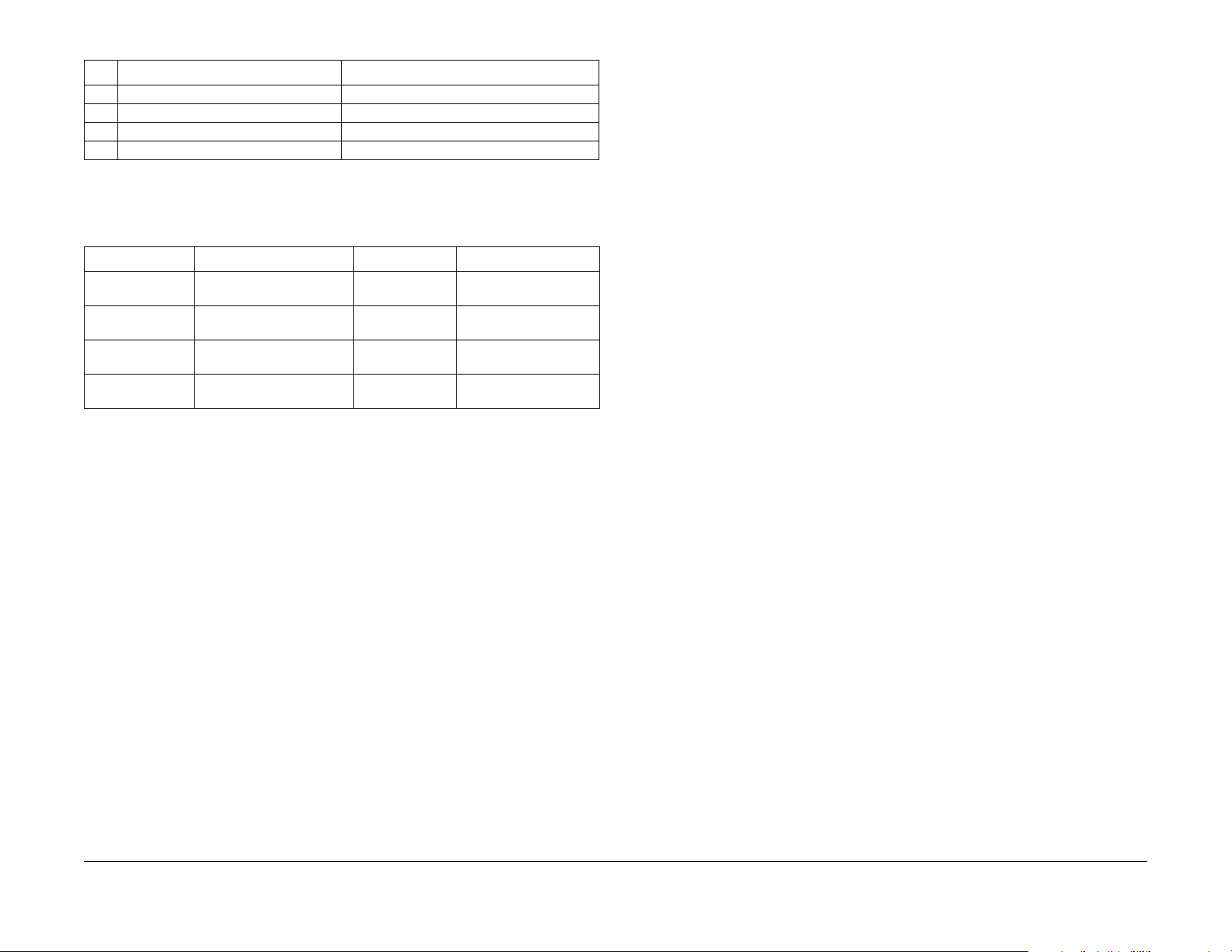

Table 1 Voltage Measurement and Specifications

Voltage Specification

Input Power 220 V 198 VAC TO 254 VAC

Input Power 120 V 90 VAC TO 135 VAC

+3.3 VDC +2.75 VDC TO +3.25 VDC

+5 VDC +4.75 VDC TO +5.25 VDC

+24 VDC +23.37 VDC TO +27.06 VDC

Table 2 Logic Levels

Voltage H/L Specification

+5 VDC H = +3.00 V or greater

L = below 0.8 V

+3.3V H = +2 V or greater

L =below 0.8 V

5/2014

vii

WorkCentre 3655 Multifunction Printer

Health and Safety Incident Reporting

Introduction

Initial Issue - Xerox Internal Use Only

Health and Safety Incident Reporting

I. Summary

This section defines requirements for notification of health and safety incidents involving Xerox

products (equipment and materials) at customer locations.

II. Scope

Xerox Corporation and subsidiaries worldwide.

III. Objective

To enable prompt resolution of health and safety incidents involving Xerox products and to

ensure Xerox regulatory compliance.

IV. Definitions

Incident:

An event or condition occurring in a customer accoun t that has resulted in injury, illness or

property damage. Examples of incidents include machine fires, sm oke generation, physical

injury to an operator or service representative. Alleged events and product conditions are

included in this definition.

V. Requirements

Initial Report:

1. Xerox organizations shall establish a process for individuals to report product incidents to

Xerox Environment Health & Safety within 24 hours of becoming aware of the event.

2. The information to be provided at the time of reporting is contained in Appendix A (Health

and Safety Incident Report involving a Xerox product).

3. The initial notification may be made by any of the following methods:

• For incidents in North America and Developing Markets West (Brazil, Mexico, Latin

American North and Latin American South):

– Phone* Xerox EH&S at: 1-800-828-6571.

– Electronic mail to Xerox EH&S

– Fax Xerox EH&S at: 1-585-422-6449 [intelnet 8*222 6449].

• For incidents in Europe and Developing Markets East (Middle East, Af rica, India,

China and Hong Kong):

– Phone* Xerox EH&S at: +44 (0) 1707 353434.

– Electronic mail Xerox EH&S at: Elaine.Grange@xerox.com.

– Fax Xerox EH&S at: +44 (0) 1707 353914 [intelnet 8*668 3914].

*Initial notification made by phone must be followed within 24 hours by a completed inci-

dent report and sent to the indicated electronic mail address or fax number.

NOTE: If sending a fax, please also send the original via internal mail.

Responsibilities for resolution:

1. Business Groups/Product Design Teams responsible for the product involved in the inci-

dent shall:

a. Manage field bulletins, customer correspondence, product recalls, safety retrofits.

b. Fund all field retrofits.

2. Field Service Operations shall:

a. Preserve the Xerox product involved and the scene of the incident inclusive of any

associated equipment located in the vicinity of the incident.

b. Return any affected equipment/part(s) to the location designated by Xerox EH&S

and/or the Business Division.

c. Implement all safety retrofits.

3. Xerox EH&S shall:

a. Manage and report all incident investigation activities.

b. Review and approve proposed product corrective actions and retrofits, if necessary.

c. Manage all communications and correspondence with government agencies.

d. Define actions to correct confirmed incidents.

5/2014

viii

WorkCentre 3655 Multifunction Printer

Regulatory Specifications

Initial Issue - Xerox Internal Use Only

Introduction

Regulatory Specifications

Xerox has tested this product to electrom agnetic emission and immunity standards. These

standards are designed to mitigate interference caused or received by this product in a typical

office environment.

United States (FCC Regulations)

The Wentre 3655 has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial installation. This equipment generates,

uses, and can radiate radio frequency energy. If it is not installed and used in accordance with

these instructions, it may cause harmful interference to radio communications. Operat ion of

Class A equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his/her own expense. There is no guarantee

that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment Off and On, the user is encouraged to try to c orrect the

interference by one or more of the following measures:

• Reorient or relocate the receiver.

• Increase the separation between the equipment and receiver.

• Connect the equipment to a different electrical circuit.

• Consult the dealer or an experienced radio/television technician for help.

Any modifications not expressly approved by Xerox could v oid the user's authority to operate

the equipment. To ensure compliance with Part 15 of the F CC rules, use shielded interface

cables.

Canada (Regulations)

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

European Union

This product, if used properly in accordance with the user's instructions, is neither dangerous

for the consumer nor for the environment.

To ensure compliance with European Union regulations, use shielded interface cables.

A signed copy of the Declaration of Conformity for this product can be obtained from Xerox.

CE Mark

Figure 1 CE Symbol

The CE mark applied to this product symbolizes Xerox’s

declaration of conformity with the following applicable Direc

-

tives of the European Union as of the dates indicated:

December 12, 2006: Low Voltage Directive 2006/95/EC

December 15, 2004: Electromagnetic Compatibility Directive 2004/108/EC

5/2014

ix

WorkCentre 3655 Multifunction Printer

Translation of Warnings

Introduction

Initial Issue - Xerox Internal Use Only

Translation of Warnings

WARNING

Switch off the electricity to the machine. Di sconnect the power cord fro m th e customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury . Moving parts can cause injury.

DANGER : Mettez la machine hors tension. Déconnectez le cordon d'alimentation de

l'alimentation du client lorsque vous réalisez des tâches qui ne nécessitent pas d'élec

-

tricité. L'électricité peut être à l'origine de blessures, voire d'un accident mortel. Les

pièces amovibles peuvent être à l'origine de blessures.

AVVERTENZA: Spegnere la macchina. Scollegare il cavo di alimentazione dall'alimenta-

tore quando si eseguono attività che non richiedono elettricità. L'elettricità può causare

morte o lesioni personali. Le parti in movimento possono causare lesioni personali.

VORSICHT: Schalten Sie die Stromversorgung der Maschine ab. Zi ehen S ie das S t romk-

abel ab, wenn Sie Aufgaben ausführen, für die keine Stromversorgung benötigt wird.

Stromschläge können Todesfällen oder Verletzungen verursachen. Bewegliche Teile

können zu Verletzungen führen.

AVISO: Apague la electricidad de la máquina. Desconecte el cable de alimentación eléc-

trica de la toma de pared mientras esté realizando tareas que no necesiten corriente. La

electricidad puede causar daños o la muerte. Las partes móviles pueden causar daños.

WARNING

Do not work in a confined space. 1 m (39 inches) space is needed for safe working.

DANGER : Ne pas travailler dans un espace restreint. 1 mètre d'espace est nécessaire

pour un dépannage en tout e s é cu r ité.

AVVERTENZA: Non lavorare in uno spazio limitato; è necessario uno spazio di almeno

un metro attorno alla macchina per la sicurezza dell'operatore.

VORSICHT: Nur mit ausreichendem Bewegungsspielraum (1 m) arbeiten.

AVISO: No trabaje en un espacio reducido. Se necesita 1 metro de espacio para trabajar

con seguridad.

WARNING

Use safe handling procedures when removing the module. Refer to G P 16. The module

is heavy.

DANGER: Conformez-vous aux procédures de manipulation de sécurité pour le retrait

du module. Reportez-vous à GP 16. Le module est lourd.

AVVERTENZA: Utilizzare procedure di gestione sicure durante la rimozione del modulo.

Vedere GP 16. Il modulo è pesante.

VORSICHT: Verwenden Sie sichere Vorgehensweisen zum Entfernen des Moduls. Siehe

auch GP 16. Das Modul ist sehr schwer.

AVISO: Utilice los procedimientos de seguridad cuando elimine el módulo. Consulte el

GP 16. El módulo es pesado.

WARNING

Follow the service procedure exactly as written. Use of controls or adjustments other

than those specified in this manual, may result in an exposure to invisible laser radia

-

tion. During servicing, the invisible laser radiation can cause eye damage if looked at

directly.

DANGER : Les procédures de dépannage doivent être suivies à la lettre. Si les réglages

ou vérifications ne sont pas effectués suivant les instructions de ce manuel, il peu t y

avoir un risque d'exposition dangereuse au faisceau laser. Celui-ci peut provoquer des

lésions oculaires s'il est observé directement.

AVVERTENZA: Eseguire le procedure di servizio esattamente come descritto. L'utilizzo

di dispositivi di controllo o di registrazione diversi da quelli riportati in questo manuale

potrebbe comportare un'esposizione a radiazioni laser invisibili. Tali radiazioni possono

danneggiare gli occhi se si guarda direttamente il fascio laser durante gli interventi di

servizio.

VORSICHT: Die Wartungsarbeiten genau den Anweisungen entsprechend durchführen.

Der Umgang mit Steuer- oder Bedienelementen, deren Verwendung nicht ausdrücklich

in diesem Handbuch angewiesen wurde, kann dazu führen, dass unsichtbare Laser

-

strahlung frei gesetzt wird. Direkter Blickkontakt mit dem Laserstrahl kann b leibende

Augenschäden verursachen.

AVISO: Siga los procedimientos de mantenimiento tal como están descritos. El uso de

controles o ajustes no especificados en este manual puede tener como resultado la

exposición a radiación láser invisible. Durante las operaciones de mantenimiento, la

radiación de láser invisible puede causar daños en los ojos si se mira directamente a

ella.

WARNING

USA and Canada. Do not install this machine in a hallway or exit route that does not

have 1.12 m (44 inches) of space additional to the normal space requirements in front of

the machine. To conform with fire regulations this additional 1.12 m (44 inches) of space

is needed in front of the machine in hallway and exit routes.

DANGER : États-Unis et Canada. Si cette machine est installée dans un couloir ou une

voie de sortie, 1,12 m (44 pouces) d'espace supplémentaire à l'espace normal doit être

disponible devant la machine conformément aux normes de sécurité d'incendie.

AVVERTENZA: N/A

VORSICHT: N/A

AVISO: Estado s Unidos y Canadá. No instale esta máquina en un corredor o ruta de sal-

ida que no tenga 1.12 m (44 pulgadas) de ancho delante de la máquina, sin incluir el

espacio que ocupe la máquina. Este espacio adicional de 1.12 m (44 pulgadas) delante

de la máquina en corredores y rutas de salida es necesario para cumplir los requisitos

de las normas sobre incendios.

5/2014

x

WorkCentre 3655 Multifunction Printer

Translation of Warnings, WorkCentre 3655 Overview

Initial Issue - Xerox Internal Use Only

Introduction

WARNING

Use only Xerox materials and components. This product is safety certified using Xerox

materials and components. The use of non Xerox materials and components may invali

-

date the safety certificate.

DANGER : N'utilisez que des matières premières et des composants Xerox. La sécurité

du produit est assurée dans le cadre de son utilisation avec des matières premières et

des composants Xerox. L'utilisation de matières premières et de composants autres

que ceux de Xerox risque d'invalider le certificat de sécurité.

AVVERTENZA: Utilizzare solo materiali e componenti Xerox per avvalersi della certifi-

cazione di protezione. L'utilizzo di materiali e componenti non Xerox può rendere nulla

la certificazione di protezione.

VORSICHT: Verwenden Sie nur Materialien und Komponenten von Xerox. Dieses

Produkt besitzt die Sicherheitszertifizierung bei Verwendung von Xerox-Materialien und

-Komponenten. Die Verwendung von Materialien und Komponenten anderer Hersteller

setzt möglicherweise das Sicherheitszertifikat außer Kraft.

AVISO: Utilice solo los materiales y componentes Xerox. Este producto dispone d e un

certificado de seguridad si se utilizan los materiales y componentes Xerox. Este certifi

-

cado de seguridad no será válido si se utilizan materiales y compone ntes que no sean

de Xerox.

WARNING

Do not touch the fuser while it is hot.

DANGER : Ne pas toucher au four pendant qu'il est encore chaud.

AVVERTENZA: Non toccare il fonditore quando è caldo.

VORSICHT: Fixierbereich erst berühren, wenn dieser abgekühlt ist.

AVISO: No toque el fusor mientras está calien te.

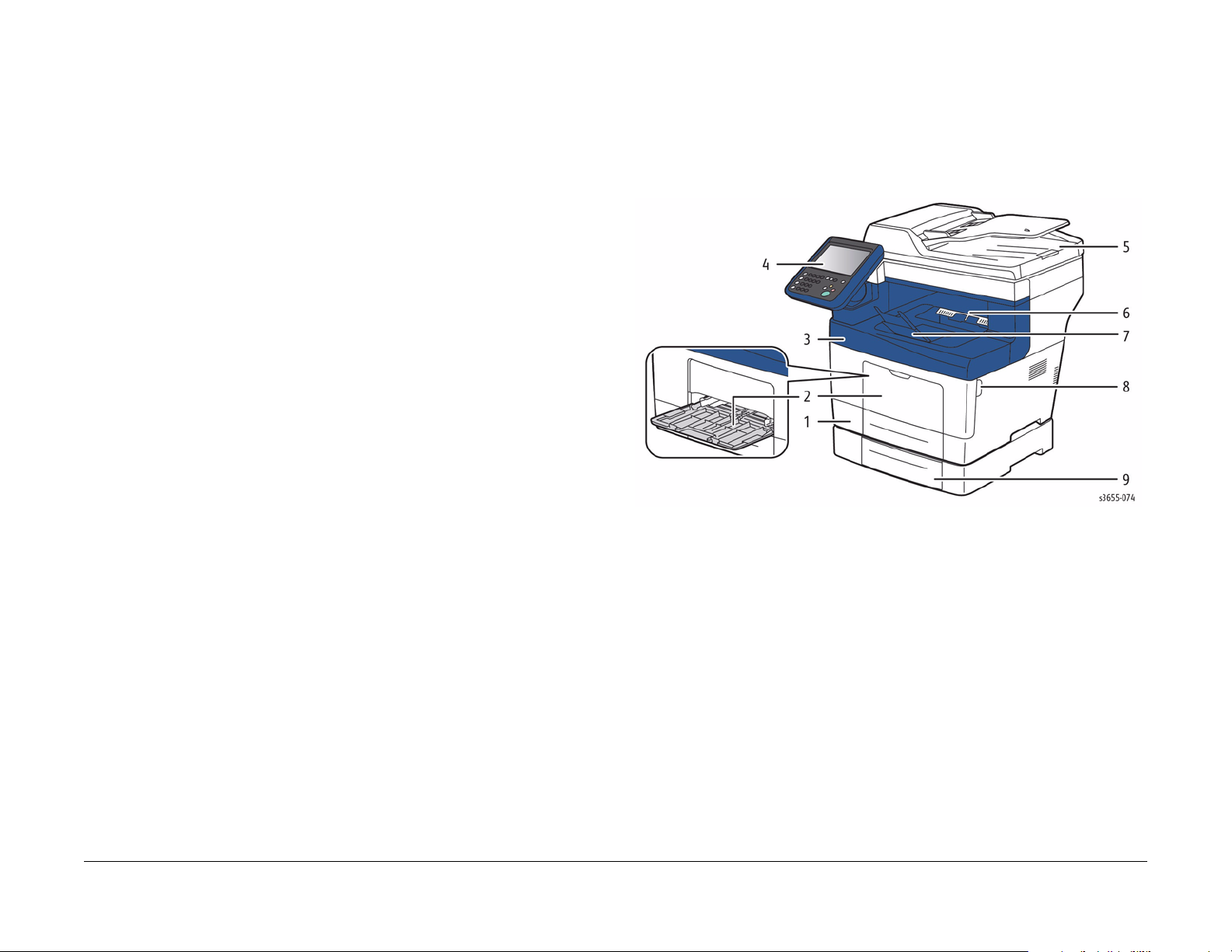

WorkCentre 3655 Ove rvie w

The WorkCentre 3655 in either 4in1 (S) or 3in1 (X) conf igurations combine a monochrome

laser print engine with a scanner and Duplex Automatic Document Feeder (DADF), Tray 1. The

Output Tray holds 250 20lb. sheets facedown. WorkCentre 3655 options add media capacity,

wireless connectivity, and functionality. Configurations of up to three additional 550-Sheet

Feeders are supported. Figure 1 illustrates components accessible from the front.

Front View

Figure 1 Front View

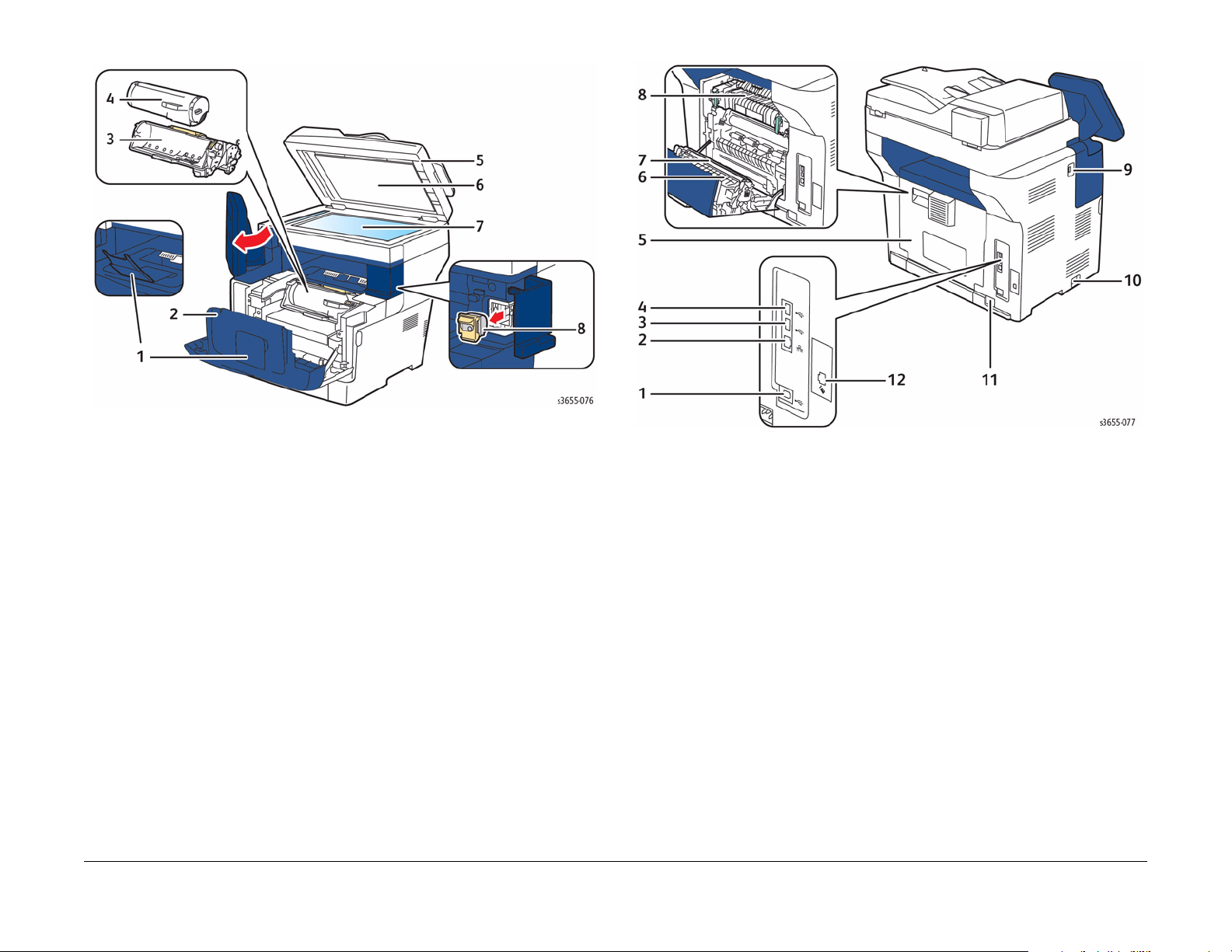

Internal View

Figure 2 shows other system features.

Front View

1. Tray 1 6. Output Tray

2. Bypass Tray 7. Output Tray Extension

3. Top Cover 8. Front Cover Release

4. Control Panel 9. Optional 550-sheet Feeder

5. Automatic Document Feeder (DADF)

5/2014

xi

WorkCentre 3655 Multifunction Printer

WorkCentre 3655 Overview

Introduction

Initial Issue - Xerox Internal Use Only

Figure 2 Internal view

Rear View

Figure 3 shows features located at the rear of the system.

Figure 3 WorkCentre 3655S 4-in1 rear view

Rear View

1. Output Tray Extension 5. Duplex Auto Document Feeder (DADF)

2. Front Cover Assembly 6. DADF Top Cover

3. Drum Cartridge 7. Scanner Platen

4. Toner Cartridge 8. Stapler Cartridge (3655S only)

Rear View

1. USB Port (slave) 7. Transfer Roller

2. Ethernet Port 8. Fuser

3. USB Port (host) 9. USB Port (host)

4. USB Port (host) 10. Power Switch

5. Rear Door 11. AC Input

6. Duplex Chute 12. FAX Connection

5/2014

xii

WorkCentre 3655 Multifunction Printer

Control Panel Layout

Initial Issue - Xerox Internal Use Only

Introduction

Control Panel Layout

The WorkCentre 3655 Control Panel consists of a touchscreen, a keypad, and several buttons.

These buttons are used to navigate the menu system, perfo rm functions, and select opera

-

tional modes.

Figure 1 Control Panel

Control Panel Features

Item Description

1. Display Touchscreen display of printer settings, status, messages and menus

2. Services Home Services Home displays services, such as copy, scan, and fax

3. Services Returns to the active service from the Job Status or Machine Status

screens, or to a preset service

4. Job Status Displays active, held, and completed jobs

5. Machine Status Displays settings and information

6. Keypad Enter alphanumeric characters

7. Clear Deletes numeric values or the last digit entered

8. Pause TBD.

9. Interupt Print Pauses the currently printing job to run a more urgent job.

10. Start Start the selected job

11. Stop Stops the current job. Follow the onscreen instructions to cancel or

resume the job

12. Clear All Clears previous and changed settings for the current service. Press

twice to reset all defaults and clear existing scans

13. Power Restart or shuts down the printer

14. Language Changes the touch screen language and keyboard settings

15. Sleep Enter a reduced power mode

16. Help Displays additional information about the current selection or service

17. Log In / Log Out Access password protected features following login

Control Panel Features

5/2014

xiii

WorkCentre 3655 Multifunction Printer

Options, CRU Life Expectancy

Introduction

Initial Issue - Xerox Internal Use Only

Options Overview

WorkCentre 3655 options include:

• 550-sheet Feeder

• USB wireless network adaptor

• Printer stand

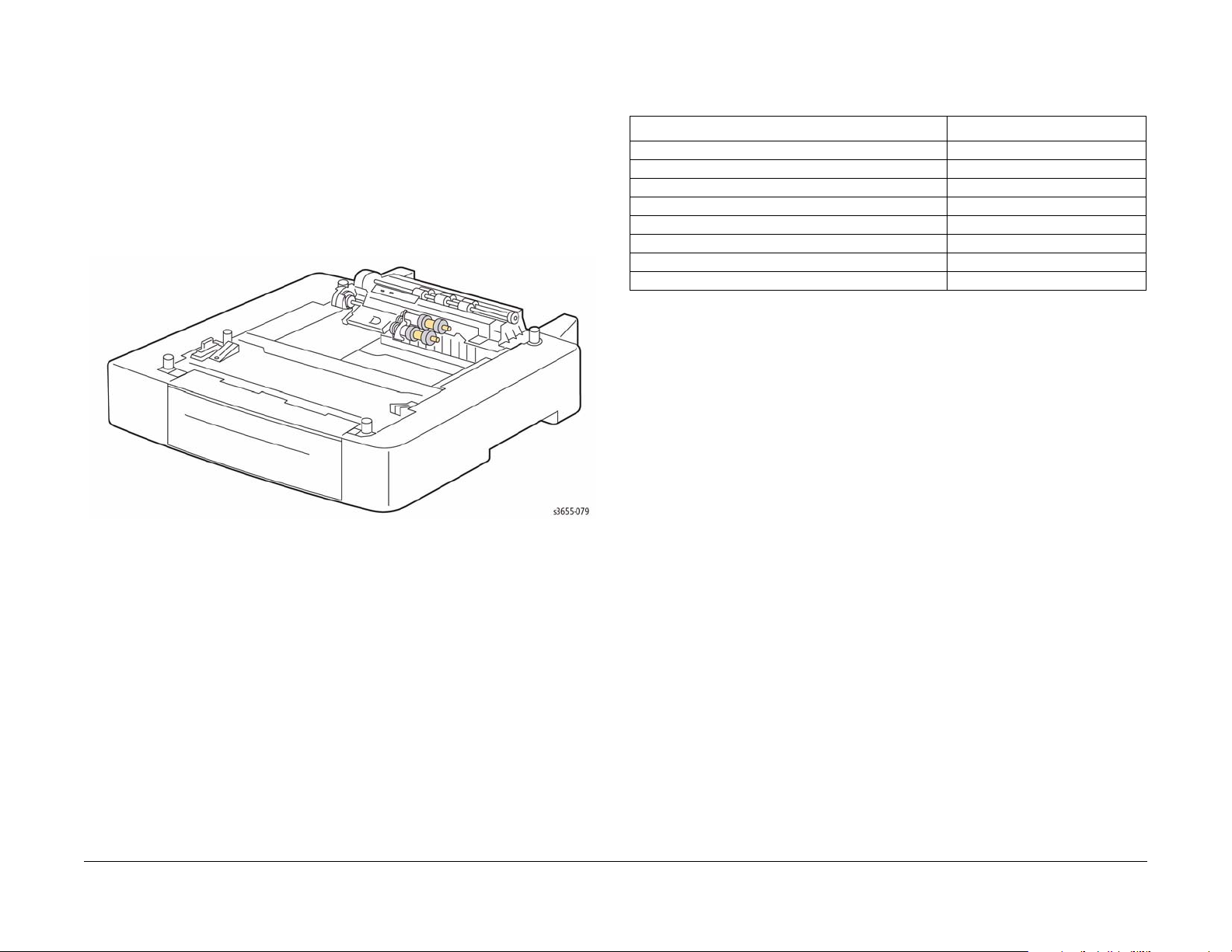

550-Sheet Feeder

The Optional 550-sheet Feeder adds a single, 550-sheet tray. The printer supports up to three

550-sheet feeders. The feeder is secured to the print engine with two screws located under the

front edge of Tray 1.

Figure 1 550-Sheet Feeder

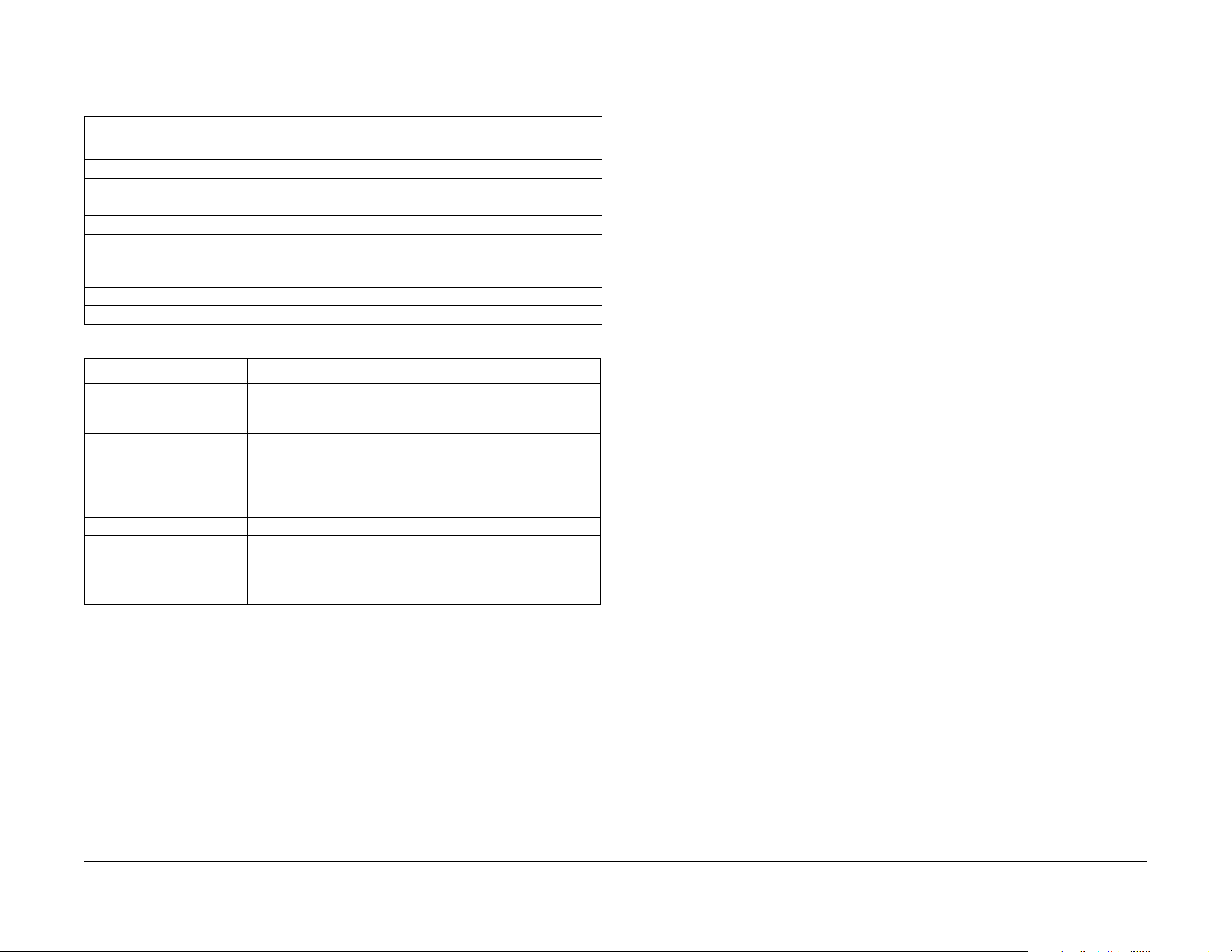

CRU Life Expectancy

The rated life expectancy of WorkCentre 3655 consumables are listed in Table 1.

Table 1 CRU and Consumable Life Expectancy

Description Print Life

Standard Toner Cartridge Capacity 6,100 cycles

High Toner Cartridge Capacity 14,400 cycles

Extra High Toner Cartridge Capacity 25,900 cycles

Metered Toner Cartridge Capacity 25,900 cycles

Drum Cartridge 85,000 cycles

Staple Cartridge 50,000 cycles

Maintenance Kit (Fuser,Transfer Roller) 200,000 cycles

Feed Roller Kit 100,000 cycles

5/2014

xiv

WorkCentre 3655 Multifunction Printer

Initial Issue - Xerox Internal Use Only

Introduction

Product Codes and Serial Number Range

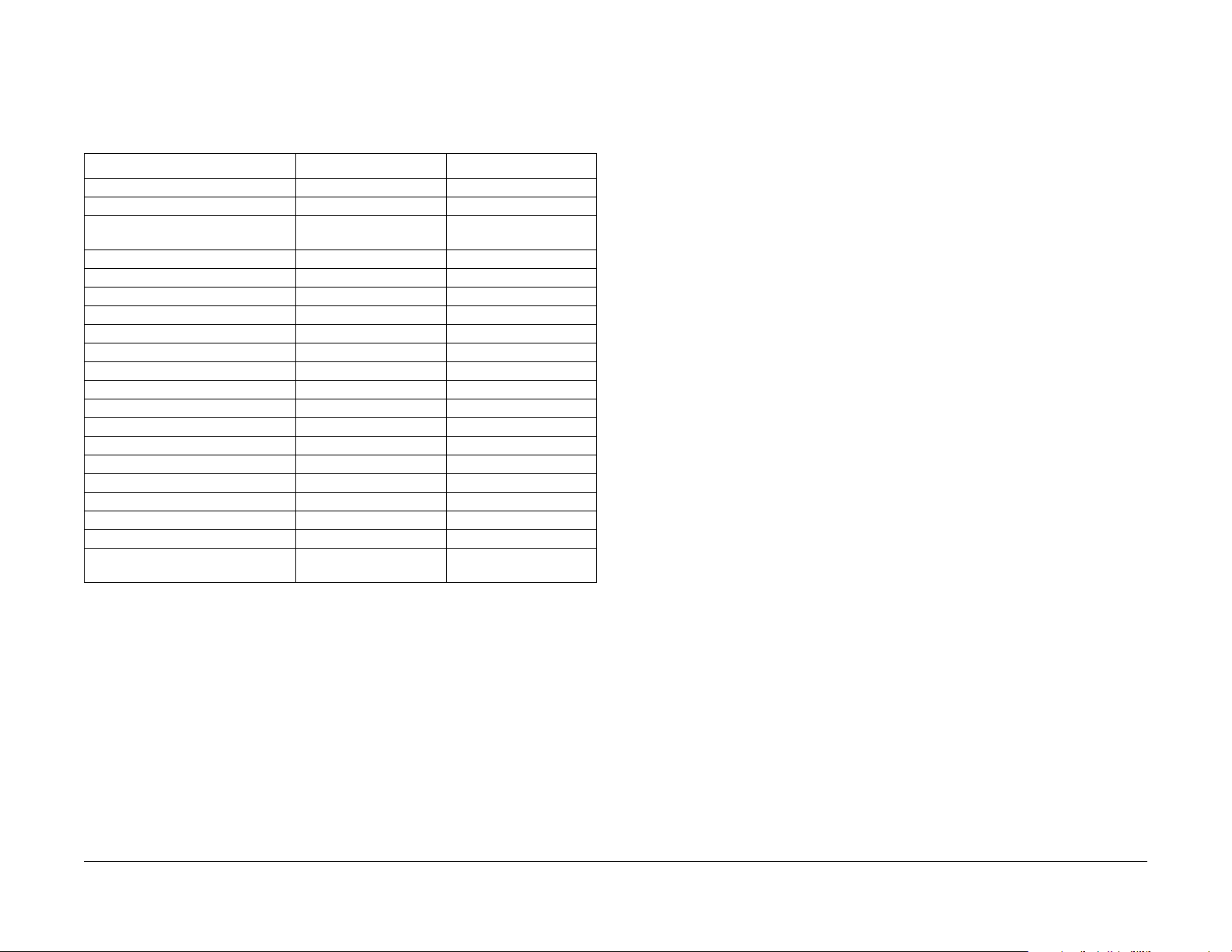

Product codes are listed in Table 1.Serial number ranges for each product appear in Table 2.

Table 1 Product Codes

Product Code

3655_SM 110V (Metered, 3in1 Copy, Pri nt, Scan) C4X

3655_S 110V (Sold, 3in1 Copy, Print, Scan) C4XD

3655V_SM 220V (Metered, 3in1 Copy, Print, Scan) C5X

3655V_S 220V (Sold, 3in1 Copy, Print, Scan) C5XD

3655_XM 110V (Metered, 4in1 Copy, Network Print, Scan, Fax, stapler) C7X

3655_X 110V (Sold, 4in1 Copy, Network Print, Scan, Fax, stapler) C7XE

3655_YXM 110V (Metered, 4in1 Copy, Network Print, Scan, Fax, stapler, TAA-com-

pliant)

C7XR

3655V_XM 220V (Metered, 4in1 Copy, Network Print, Scan, Fax, stapler) C8X

3655V_X 220V (Metered, 4in1 Copy, Network Print, Scan, Fax, stapler) C8XD

Table 2 Serial Number Range

Product Serial Number Range

3655_SM 110V C4X

3655_S 110V C4XD

155,000

000501 -015500

025501 - 165500

3655V_SM 220V C5X

3655V_S 220V C5XD

60,000

015501 -025500

165501-215500

3655_XM 110V C7X 100,000

215501-315500

3655_YXM 110V C7XR TBD

3655_X 110V C7XE 40000

365501-40550

3655V_XM 220V C8X

3655V_X 220V C8XD

50,0000

315501-365500

5/2014

1-1

WorkCentre 3655 Multifunction Printer

Service Call Procedures

Initial Issue - Xerox Internal Use Only

1 Service Call Proced ur es

Service Call Procedures.................................................................................................. 1-3

SCP 1 Initial Actions........................................................................................................ 1-4

SCP 2 First Call Actions.................................................................................................. 1-4

SCP 3 Normal Call Actions............................................................................................. 1-5

SCP 4 Fault Analysis ...................................................................................................... 1-5

SCP 5 Subsystem Maintenance ..................................................................................... 1-6

SCP 6 Final Actions........................................................................................................ 1-7

SCP 7 Configurations and Options................................................................................. 1-8

5/2014

1-3

WorkCentre 3655 Multifunction Printer

Service Call Procedures

Service Call Procedures

Initial Issue - Xerox Internal Use Only

Service Call Procedures

This section provides an overview of the steps a service technician should take to service the

printer and attached options. The printer’s diagnostic routines report problems using error mes

-

sages and fault codes displayed on the Control Panel, logged in the Service Usa ge Profile, or

by flashing LEDs. These error indications serve as the entry point into the troubleshooting pro

-

cess. System problems not directly indicated by or associated with an error message or fault

code are covered in Section 6, General Procedures. Print-quality problems are covered in Sec

-

tion 3, Image Quality.

The steps listed here are a guide for performing any service on this printer. If you choose not to

use these steps, it is recommended that you start at the appropriate troubleshooting procedure

and proceed from there. When servicing the printer, follow the safety measures detailed in the

Service Safety Summary section.

1. Identify the problem.

• Verify the reported problem does exist.

• Check for any error codes and write them down.

• Print normal customer prints and service test prints.

• Make note of any print-quality problems in the test prints.

• Make note of any mechanical or electrical abnormalities present.

• Make note of any unusual noise or smell coming from the printer.

• Print a Usage Profile, if the printer is able to print.

• View the Engine Error and Jam Histories under the Tools menu.

• Verify the AC input from the wall outlet is within specifications.

2. Inspect and clean the printer.

• Follow the cleaning instructions.

• Verify that the power cord is in serviceable condition.

• Restart the printer to check if the error reoccurs.

3. Find the cause of the problem.

• Use the troubleshooting procedures to find the root cause of the problem.

• Use Service Diagnostics to check the printer and optional components.

• Use the Wiring Diagrams and Plug/Jack Locator to locate test points.

• Take voltage readings as instructed in the troubleshooting procedure.

4. Correct the problem.

• Use the Parts List to locate a part number.

• Use the Repair procedures to replace the part.

5. Final Checkout

• Test the printer to verify the problem is corrected and no new problems arose.

Accessing Engine Fault History

Listed below are three ways in which you can access fault history. Additional fault history infor-

mation appears in GP 2.

NOTE: Error and fault code definitions appear in Section 2.

1. Read (if possible) fault history from the Machine Status menu on the Control panel. The

error history is listed on screen.

2. Accessing fault history in Service Diagnostics, GP 1.

a. Enter Service Diagnostics.

b. Touch Service Info.

c. Touch dC122 Fault History.

3. If the printer is connected to a network and has an IP address, view the printer’s web

page using a web browser.

a. Open a web browser.

b. Enter the printer’s IP address as the URL.

c. Selec t Support --> Troubleshooting --> Diagnostics Logs and the fault history

displays.

5/2014

1-4

WorkCentre 3655 Multifunction Printer

SCP 1, SCP 2

Initial Issue - Xerox Internal Use Only

Service Call Procedures

SCP 1 Initial Actions

Initial Actions are used to gather information on printer performance

Start a service call with SCP 1 and end with SCP 6 Final Actions.

Also refer to SCP 7 Configurations and Options.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord fro m th e customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury . Moving parts can cause injury.

WARNING

Do not work in a confined space. 1m (39 inches) space is needed for safe working.

NOTE: Ignore references to options not installed on the printer.

1. Take note of symptoms or error messages.

2. Ask the operator to describe or demonstrate the problem.

3. Make sur e:

a. The power cord is connected to the wall outlet and to the machine.

b. Paper is loaded correctly and all paper trays and covers are closed

c. If installed, the USB cable or network connection is installed correctly.

4. If available, check the service log book for any previous actions that may be relevant to

the call.

5. If this is th e f irst service c a l l to th i s printer, perform SCP 2 First Call Actions, otherwise go

to SCP 3 Normal Call Actions.

SCP 2 First Call Actions

First Call Actions are used for the first service call.

Procedure

1. Check the machine configuration with the customer, refer to SCP 7 Configurations and

Options. Check that all required hardware and software is installed and/or enabled.

2. Check that all the relevant machine settings are correctly entered, refer to GP 3 Customer

Administration Tools.

3. If a fault is present, go to SCP 3 Normal Call Actions. If there is no fault present, go to

SCP 6 Final Actions.

4. Enter the printer and customer details in the service log.

5/2014

1-5

WorkCentre 3655 Multifunction Printer

SCP 3, SCP 4

Service Call Procedures

Initial Issue - Xerox Internal Use Only

SCP 3 Normal Call Actions

Normal Call Actions are used to determine the reason for the service call.

Procedure

NOTE: If a fault message appears at any time. Refer directly to the RAP for the fault message

and perform the procedure.

If possible, perform the following:

1. Review any defective print samples.

2. Determine that the user accessible settings are correct. If necessary refer to the user doc-

umentation.

3. Check all job queues and verify with the customer any requirement to print the documents

in memory, before switching off the power or clearing memory.

4. Print the Customer Assistance Report (Call for Assistance), then record the total print

count.

5. Go to SCP 4 Fault Analysis.

SCP 4 Fault Analysis

Fault Analysis is used to identify a fault.

Procedure

When diagnosing or repairing a fault in a particular subsystem, exercise the machine in all

modes until the fault is determined. In the instance of finding more than one fault or failure, cor

-

rect one fault before going to the next fault. If no fault is found, go to SCP 5 Subsystem Mainte-

nance.

Fault Codes

If a fault code is displayed, go to the relevant RAP.

Control Panel Faults

If the power is on but the Control Panel is blank, test the Control Panel with dC330.

Stapler Faults

If the machine has a stapler fault, test the Stapler with dC330.

Image Quality Defects

If the image quality is defective, go to the IQ1 Image Quality Entry RAP.

For image quality specifications, refer to the following:

• IQS 1 Solid Area Density.

• IQS 2 Skew.

• IQS 3 Registration.

Additional Information

If necessary, refer to the following general procedures and information:

• GP 1 Service Diagnostics Entry and Exit

• GP 2 Fault Codes and History Logs

• GP 3 Customer Administration Tools

• GP 4 How to Switch Off or Switch On the Printe r

• GP 5 Service Copy (Tools) Mode

• GP 6 Electrostatic Discharge Prevention

• GP 7 Machine Specifications

• GP 8 General Disassembly Precautions

• GP 9 Installing System Software

• GP 10 How to Check a Motor

• GP 11 How to Check a Sensor

• GP 12 How to Check a Solenoid or Clutch

• GP 13 How to Check a Switch

• GP 14 Cloning Network Configurations

• GP15 -Removed-

• GP 16 Separate System Modules

• GP 17 External FAX Line Test

5/2014

1-6

WorkCentre 3655 Multifunction Printer

SCP 4, SCP 5

Initial Issue - Xerox Internal Use Only

Service Call Procedures

• GP 18 Printing Reports

• GP 19 Intermittent or Noise Problem

• GP 20 How to Safely Lift or Move Heavy Modules

• GP 21 Machine Lubrication

• GP 22 Installation Space Requirements

• GP 23 First Print Output Time (FPOT)

• GP 24 Restriction of Hazardous Substances (RoHS)

• GP 25 Remote Control Panel

• GP 26 Media Specifications

• GP 27 Environmental Data

• GP 28 Toner CRUM Conversion

SCP 5 Subsystem Maintenance

Subsystem Maintenance contains information regarding the component life of the machine.

Procedure

WARNING

Switch off the electricity to the machine. Di sconnect the power cord from th e customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury . Moving parts can cause injury.

1. Clean the Pick Rollers on every call.

2. Use the Control Panel to check maintenance item counters.

3. Compare the counter values to those listed in Component Life.

4. Advise the customer of any routine maintenance items that are approaching or over the

service limit.

Inspection

Rollers

Replace rollers when you see any of the following defects:

• Flat spots

• Out of roundness

• Cracked rubber

• Loss of traction (tackiness) causing pick or feed failures

Gears

Replace gears that show any signs of wear or damage. Look for these problems:

• Thinned gear teeth

• Bent or missing gear teeth; check especially where a metal gear drives a plastic gear.

• Fractured or cracked gears (oil or incorrect grease on a plastic gear can cause the gear to

crack).

Lubrication

The printer is lubricated during assembly at the factory and does not require periodic lubrica-

tion. Some parts require lubrication following replacement. These parts are identified in the

replacement procedures. When lubricating during replacement, use approved grease.

CAUTION

Plastic parts deteriorate when unspecified lubricants or chemicals are used. To avoid damage,

use only Rheolube 768 grease.

• Rheolube 768 Grease: Part Number 070E00890

Component Life

The design life of the major components are shown in Table 1. Environmental conditions and

actual use will vary these factors. The component life shown in Table 1 is for reference only.

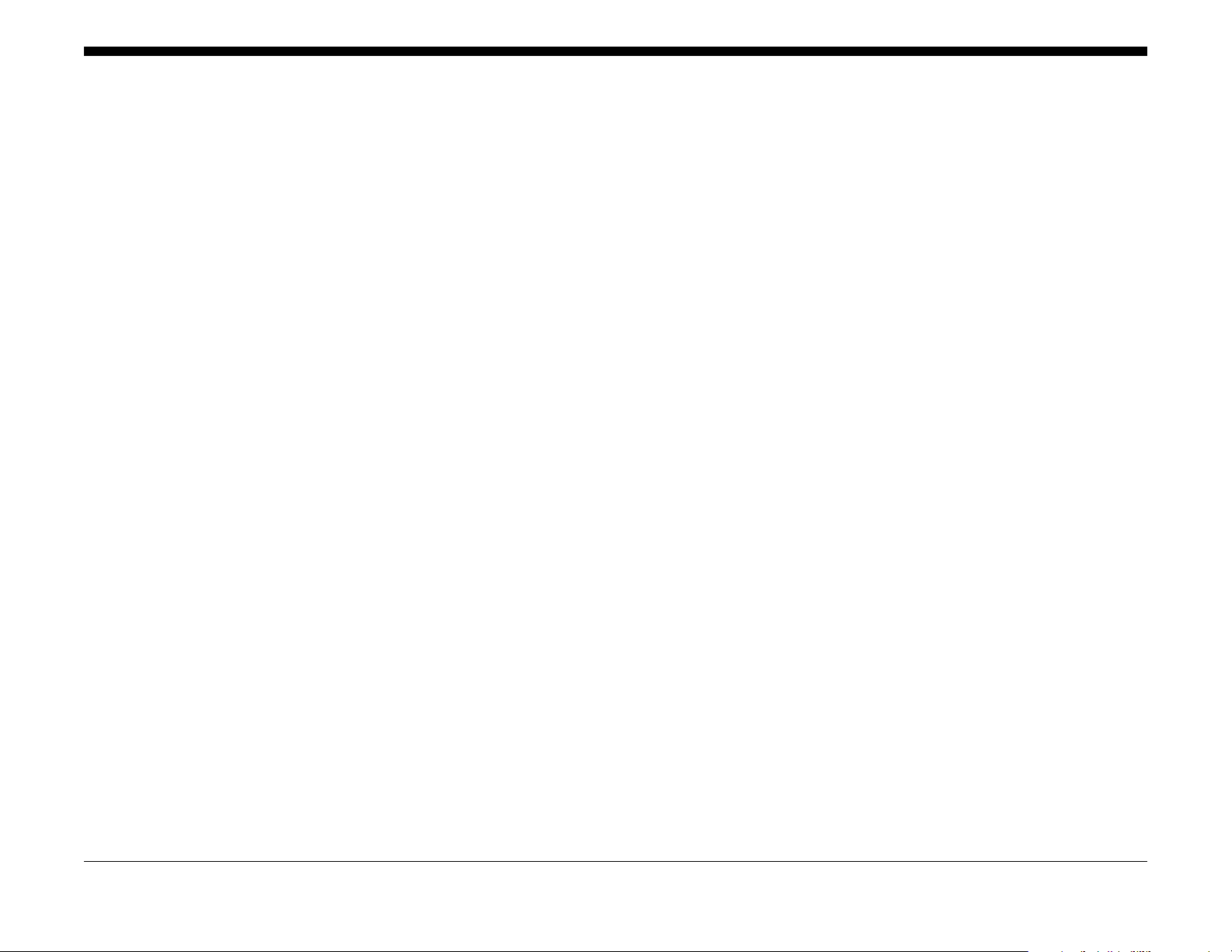

Table 1 Component Life Expectancies

Item Description Print Life

1. Pick and Nudger Rollers 100,000 pages

5/2014

1-7

WorkCentre 3655 Multifunction Printer

SCP 5, SCP 6

Service Call Procedures

Initial Issue - Xerox Internal Use Only

HFSI

The High Frequency Service Items are shown in Table 2.

SCP 6 Final Actions

Final Actions are used to evaluate the total operation of the system and to identify the actions

required to complete the service call.

Procedure

Complete the following, if a fault is identified, return to SCP 4 Fault Analysis:

• Perform the end of call subsystem maintenance actions, SCP 5 Subsystem Maintenance.

• Exercise the machine in all modes, printing from all trays. If a fault message is displayed

or some other problem is evident, go to SCP 4 Fault Analysis.

• Make a print of a customer document.

• If any of the customers selections were changed, return t hem to the cu stomers preferred

settings. Refer to GP 3 Customer Administration Tools.

• At the first service and at any subsequent service where changes are made or options are

added, print the configuration report and store it with machine log book. Discard any pre

-

vious versions of the configuration report.

• Remove and destroy any copies of test patterns.

• Ensure the machine and service area are clean before leaving the customer premises.

• Provide customer training if required.

2. Separator Roller 100,000 pages

3. Transfer Roller 200,000 images

4. Fuser 200,000 images

5. Feed Roller 100,000 pages

Table 2 High Frequency Service Items

Item Description Life Reference

Bypass Tray Pick

Roller

Sheets fed from Tray 1 after

last reset.

100k feeds PL 13.1 Item 15

Tray 1 Pick Roller Sheets fed from Tray 1 af ter

last reset.

100k feeds PL 9.2 Item 98

Optional Tray Pick

Rollers

Sheets fed from Tray 2 after

last reset.

100k feeds PL 11.3 Item 98

Maintenance Kit Total prints after the last

reset.

200k impressions Fuser and Transfer

Roller

Table 1 Component Life Expectancies

Item Descripti on Print Life

5/2014

1-8

WorkCentre 3655 Multifunction Printer

SCP 7

Initial Issue - Xerox Internal Use Only

Service Call Procedures

SCP 7 Configurations and Options

Configurations and Options

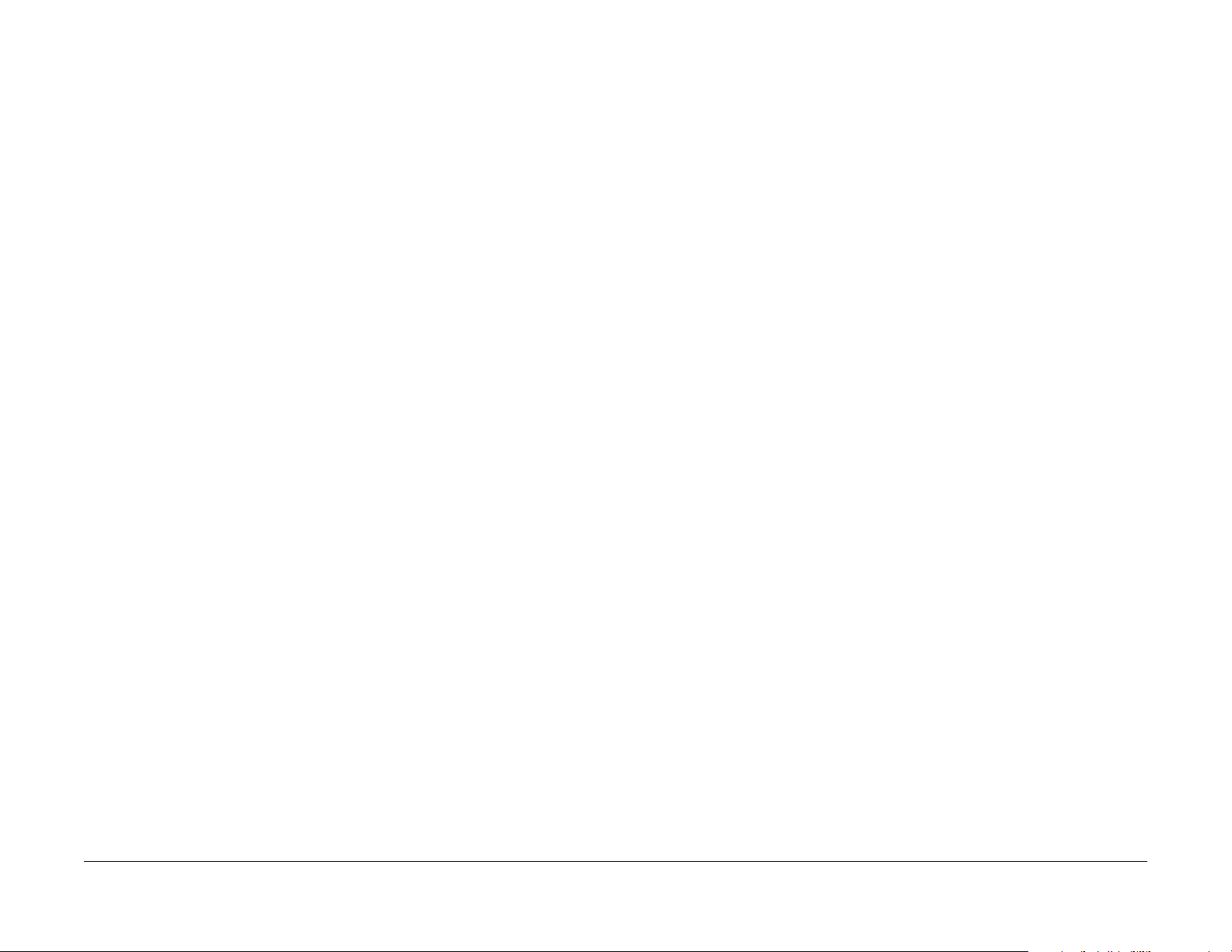

Refer to Table 1 for basic configurations and options. This service manual covers all configura-

tions. Within this manual ignore any references to options that are not installed.

Table 1 WorkCentre 3655 Configurations

Features 3655S 3 in 1 3655X 4 in 1

Processor Speed 1 GHz - Dual Core 1 GHz - Dual Core

Memory 2 GB 2 GB

Print Speed 47 ppm, Letter

45 ppm A4

47 ppm, Letter

45 ppm, A4

PS3 Fonts (136) Standard Standard

PCL6 Fonts (80 Scalable, 9 Bitmap) Standard Standard

USB 2.0 Standard Standard

Ethernet Interface 10/100/1000 Base-TX 10/100/1000 Base-TX

Automatic Document Feeder Standard Standard

Bypass Tray (150 sheet) Standard Standard

Tray 1 (550 sheet) Standard Standard

Tray 2 (550 sheet) Optional Optional

Tray 3 (550 sheet) Optional Optional

Tray 4 (550-sheet) Optional Optional

Duplex Standard Standard

Stapler Not Available Standard

Hard Disk Drive Standard Standard

Printer Stand Optional Optional

FAX Not Available Standard

Wireless LAN Optional Optional

Printer Resolution 600 x 600 dpi

1200 x 1200 dpi

600 x 600 dpi

1200 x 1200 dpi

5/2014

2-1

WorkCentre 3655 Multifunction Printer

Status Indic a tor RAPs

Initial Issue - Xerox Internal Use Only

2 Status Indicator RAPs

Chain 2 - User Interface

02-302-00, 02-306-00, 02-308-00 Flash Failure............................................................. 2-5

02-312-00 Application Checksum Failure ....................................................................... 2-5

02-315-00 Service Registry Bad Data............................................................................. 2-6

02-316-00, 02-317-00 SRS Error.................................................................................... 2-6

02-320-00 Data Time Out Error ...................................................................................... 2-7

02-321-00 XEIP Browser Does Not Respond or is Dead................................................ 2-7

02-380-00, 02-381-00 UI Communication Fault.............................................................. 2-8

02-390-00 Configurable Services Not Stable.................................................................. 2-8

Chain 3 - Machine Run Control

03-306-00 Upgrade Request Failed - Downgrade Not Allowed...................................... 2-9

03-307-00 Sync Failure. Unable to Enter SW Upgrade .................................................. 2-9

03-316-00 Communication Fault..................................................................................... 2-10

03-317-00, 03-318-00, 03-319-00 IOT NVM Error.......................................................... 2-10

03-320-00 Upgrade Failed - Incompatible Product Type ................................................ 2-11

03-324-00 File Transfer Failure During SW Upgrade ..................................................... 2-11

03-325-00 Wall Clock Fault............................................................................................. 2-12

03-326-00 Upgrade Failed - Version Same as Machine................................................. 2-12

03-327-00 SW Upgrade Failed ....................................................................................... 2-13

03-329-00 Upgrade Request Failed due to Active Diagnostics ...................................... 2-13

03-330-00 Upgrade Failed Security Feature Active........................................................ 2-14

03-331-00, 03-332-00 Communication Fault with NC . .................................................... 2-14

03-338-00 CCM Reset.................................................................................................... 2-15

03-346-00, 03-347-00 Communication Fault with UI ...................................................... 2-15

03-355-00 CCM POST Failure........................................................................................ 2-16

03-380-00 POST Boot Failure......................................................................................... 2-16

03-390-00 Upgrade Automation Failed........................................................................... 2-17

03-397-00 System Configuration Error ........................................................................... 2-17

03-398-00 SIM Card Serial Number Mismatch ............................................................... 2-18

03-399-00 SIM Card Data Cannot be Processed ........................................................... 2-18

03-401-00, 03-403-00 FAX Not Detected ....................................................................... 2-19

03-417-00 Incompatible FAX Software Detected....... .... ........... .... .... .... ......... .... .... .... ..... 2-19

03-777-00 Power Loss Detected..................................................................................... 2-20

03-788-00 Failed to Exit Power Save Mode.................................................................... 2-20

03-790-00 Time Zone Overridden to GMT: DST Disabled.............................................. 2-21

Chain 5 - IIT

05-110-00 DADF Pick-up Jam ........................................................................................ 2-23

05-112-00 DADF Jam During Rotation of Document ...................................................... 2-23

05-121-00 CVT-DADF Feed Sensor On Jam ................................................................. 2-24

05-900-00 ADF Sensor Static Jam ................................................................................. 2-24

05-940-00 DADF No Original Fail................................................................................... 2-25

Chain 10 - Fuser / Exit

10-311-00 to 10-376-00 Fuser Thermal Error................................................................. 2-27

10-420-00, 10-421-00 Fuser End of Life......................................................................... 2-27

10-902-00 Fuser Missing ................................................................................................ 2-28

10-903-00 Main Error updating data .............................................................................. 2-28

12-930-00 Exit Tray Full................................................................................................. 2-29

Chain 16 - Network Controller

16A Network Error Entry ................................................................................................. 2-31

16B FTP or SMB Unable to Connect to Remote Server ................................................. 2-31

16C Remote Directory Lock Faile d...................................... ................. ................. ......... 2-33

16-000-00 to 16-000-26 Cannot Create RPC With ENS................................................. 2-33

16-001-09 to 16-001-90 Unable to do Startup Synchronization...................................... 2-34

16-002-09 to 16-002-46 Unable to Register as RPC Server........................................... 2-34

16-003-09 to 16-003-90 Too Many IPC Handles ............................................................ 2-35

16-004-14 to 16-005-92 RPC Failure to Register............................................................ 2-35

16-006-09, 16-006-19 Cannot Register for Events ......................................................... 2-36

16-007-92 to 16-010-99 Invalid IPC / RPC Data.................. .... .. ....... .. .. .... .. .. ....... .. .... .. .. . 2-36

16-013-14, 16-014-14 Copier Synchronization Error ...................................................... 2-37

16-015-14, 16-015-19 SESS Data Store Variable Not Set.............................................. 2-37

16-016-14, 16-016-19 Data Store Initialization Failed..................................................... 2-38

16-017-19 to 16-021-26 Send Event Failure / Could Not Get Host Name RAP.............. 2-38

16-021-46 Unable to Get Host Name.............................................................................. 2-39

16-023-09, 16-023-26 RPC Call Failure.......................................................................... 2-39

16-026-09 to 16-026-92 Memory Allocation Error........................................................... 2-40

16-027-90 Unable to Obtain Well Known Queue ID........................................................ 2-40

16-028-09, 16-028-90 Unable to Complete RPC Call / Invalid Range String.................. 2-41

16-030-19 Unable to Obtain Client RPC Handle............................................................. 2-41

16-031-09 Invalid Event Notification Received................................................................ 2-42

16-032-19, 16-039-00 NVM Connection Failure / Pthread Create Error........................ . 2-42

16-040-92 Semaphore Fault ..................................................................... .. .... ....... .. .... .. . 2-43

16-048-09 Unable to Set Binding.................................................................................... 2-43

16-048-14, 16-048-90 Cannot Set NC Client Binding..................................................... 2-44

16-048-99 Cannot Set NC Client Binding........................................................................ 2-44

16-150-09 Cannot Send Registration Event.................................................................... 2-45

16-150-14 Unable to Obtain RPC Transport................................................................... 2-45

16-150-19 NC Sync Peer Service Fault.......................................................................... 2-46

16-150-26 Fault Service Failed to Write to Log............................................................... 2-46

16-150-90 Invalid IPC Request Destination .................................................. ......... .. .... ... 2-47

16-150-92 Consumer Interface Fault .............................................................................. 2-47

16-151-09 to 16-151-19 Invalid IPC Command / SNMP Reg Failure.............................. 2-48

16-151-26 Fault Service Failed to Get a Log Handle...................................................... 2-48

16-151-90 Put Environment Variable Failure .................................................................. 2-49

16-152-09 Internal IPC Failure........................................................................................ 2-49

16-152-14 Empty Internal Event Received by ENS ..................................................... .. . 2-50

16-152-19 Unable to Send Request to SESS................................................................. 2-50

16-152-26 Fault Service Could Not Open Fault Log....................................................... 2-51

16-153-09 Unable to Obtain IPC Queue......................................................................... 2-51

16-153-14 Cannot Initialize Internal Event List................................................................ 2-52

16-153-19 NVM Save Failure.......................................................................................... 2-52

16-154-09 ESS Registration Configuration Error............................................................ 2-53

16-154-14 Cannot Create Internal Event Queue............................................................. 2-53

5/2014

2-2

WorkCentre 3655 Multifunction Printer

Initial Issue - Xerox Internal Use Only

Status Indicator RAPs

16-154-19 NVM Read Failure ......................................................................................... 2-54

16-155-19 NC Failed to Boot from Alternate Partition..................................................... 2-54

16-156-19 Service Run Loop Failed ............................................................................... 2-55

16-160-09 NC Registration Service Process Death........................................................ 2-55

16-161-09 to 16-164-09 Cannot Send Reg Event / List Access Fa ilure ......................... 2-56

16-429-00, 16-431-00 Unable to Write to Data Store / Get System Time....................... 2-56

16-432-00 Unknown Scheduler Received....................................................................... 2-57

16-433-00 RPC Call Failed .......................................... .. .. ....... .. .. .... .. .. .. ....... .. .... .. .. .. ....... 2-57

16-434-00 Unable to Change Scheduler in DM.............................................................. 2-58

16-600-07 to 16-600-67 Cannot Create RPC Connection .............................................. 2-58

16-601-26 to 16-601-46 Queue Setup / System Control Failed / Invalid UI Info............. 2-59

16-601-47 Diag Service Failed IPC Queue Setup .......................................................... 2-59

16-601-66, 16-601-67 Unable to do Start up Synchronization........................................ 2-60

16-601-68 Unable to Start Up and Sync with SC............................................................ 2-60

16-601-105 Unable Synchronize At Start Up.................................................................. 2-61

16-602-07 to 16-602-105 RPC Service Registration Failure........................................... 2-61

16-603-11, 16-603-28 Replace Handler Call Failed........................................................ 2-62

16-603-46 to 16-603-67 Too Many IPC Handlers........................................................... 2-62

16-603-68 Replace Handler Call Failed.......................................................................... 2-63

16-603-105, 16-604-14 RPC Call Failure to NC Registration Service ............................ 2-63

16-604-38,16-604-99 Could Not Register With Reg Service.......................................... 2-64

16-604-105 SESS Data Store Variable Not Set.............................................................. 2-64

16-605-07 Unable to Register with Registration Service ................................................ 2-65

16-605-14 to 16-605-105 RPC Registration Failure....................................................... 2-65

16-606-07 to 16-606-99 Cannot Register For Events..................................................... 2-66

16-606-105 OS Problem ................................................................................................. 2-66

16-607-19 to 16-608-14 Invalid RPC Data / Unable to Free Resources......................... 2-67

16-608-26 Fault Service Failed to Unbind RAP .............................................................. 2-67

16-608-28 to 16-608-67 Unable to Free IPC Resources ................................................ 2-68

16-608-105 Build UI SVC Obtain Client Failed ............................................................... 2-68

16-609-07 Unknown Message Received ........................................................................ 2-69

16-609-19 to 16-609-105 Invalid IPC Data Failure ........................................................ 2-69

16-610-00, 16-610-07 IPC Send Failure......................................................................... 2-70

16-610-09 Cannot send IPC Message to NC Platform................................................... 2-70

16-610-11 to 16-610-90 Unable to Send IPC Message.................................................. 2-71

16-610-92 Failure to Send Queue Status ....................................................................... 2-71

16-610-99 Unable to Send IPC Message RAP............................................................... 2-72

16-611-07, 16-611-38 Client Removal Failure................................................................ 2-72

16-611-19 to 16-611-99 Unable to Remove RPC Connection........................................ 2-73

16-612-09 to 16-612-68 Unable to Do Shutdown Sync RAP .......................................... 2-73

16-612-47 Upgrade Request Failed - Downgrade Not Allowed...................................... 2-74

16-613-09 to 16-614-19 DC Sync / Comms Error........................................................... 2-74

16-614-47 Invalid Software Upgrade .............................................................................. 2-75

16-615-35 to 16-615-90 SESS Data Store Variable Not Set .......................................... 2-75

16-615-47 Multiple Software Upgrade File...................................................................... 2-76

16-616-35 to 16-616-46 Data Store Initialization Failure ................................................ 2-76

16-616-47 IPC Message Failure ..................................................................................... 2-77

16-616-67 Submission of Email or IFax Job Failed ........................................................ 2-77

16-617-19 Send Event Failure Unable to send event to NC........................................... 2-78

16-617-47 Upgrade Request Failed -TAR Extraction Failure ......................................... 2-78

16-618-47 DLM SPI Extraction Failure RAP ........................................................ .... ....... 2-79

16-619-14 to 16-619-93 Unable to unregister Registration service ................................ 2-79

16-619-47 Upgrade Request Failed - DMPR Failure at Web.......................................... 2-80

16-620-07 to 16-620-99 Registration Service Failed....................................................... 2-80

16-620-47 Upgrade Request Rejected............................................................................ 2-81

16-621-00 to 16-621-99 Unable to Get Host Name ........................................................ 2-81

16-622-07 to 16-622-46 Corrupt O/S RPC Table............................................................ 2-82

16-622-47 FTP "get" Failure............................................................................................ 2-82

16-622-66 to 16-622-68 Failed to Unregister as RPC Service During Shutdown ........... 2-83

16-623-35, 16-623-47, 16-624-46 RPC Call Failure ....................................................... 2-83

16-625-35 to 16-625-90 Invalid IPC Type ................................................. .. .... ....... .. .... .. . 2-84

16-626-00 to 16-626-67 Memory Allocation Error........................................................... 2-84

16-628-07 to 16-628-67 Range String Variable Error .................................................. ... 2-85

16-629-11 to 16-629-93 No Acknowledgment For RPC.................................................. 2-85

16-630-09 to 16-630-99 Unable to Get RPC Client Handle ............................................ 2-86

16-631-19 to 16-636-99 XDR Data Error ........................................................................ 2-86

16-637-11 to 16-637-95 File Error................................................................................... 2-87

16-638-66 to 16-641-46 O/S Failure ............................................................................... 2-87

16-642-46 to 16-645-67 File I/O Errors ........................................................................... 2-88

16-646-26 to 16-650-99 Invalid Service Attribute............................................................ 2-88

16-651-19 to 16-656-38 Registration Failure .................................................................. 2-89

16-658-07 Unable to Get Host Name.............................................................................. 2-89

16-658-07 to 16-667-95 Parser Utility Errors .................................................................. 2-90

16-668-47 Write NVM Failed..................................................................... .... .. ......... .. .... . 2-91

16-668-93, 16-668-95 Unable To Determine Local File Statistics................................... 2-91

16-669-28 to 16-670-00 Unable To Write Job Template................................................. 2-92

16-670-11 to 16-671-47 Unable To Decode Template File............................................. 2-92

16-671-93 to 16-673-95 File Error................................................................................... 2-93

16-674-00 to 16-709-00 XSA Database Error................................... .... .... .... ......... .... .... . 2-93

16-710-00 to 16-750-11 Unable To Create Client Handle............................................... 2-94

16-750-14 to 16-750-90 Invalid Request......................................................................... 2-94

16-750-92 to 16-751-26 Database Error ....................................................... ......... .. .... ... 2-95

16-751-28 to 16-751-93 Unknown Attribute ............................................................... .... . 2-95

16-752-00 to 16-752-47 Invalid File Details .................................................................... 2-96

16-752-66 to 16-753-28 Scan to FAX Registration Error...................... .... .... ......... .... .... . 2-96

16-753-35 to 16-754-09 Data Store Read Failure........................................................... 2-97

16-754-14 to 16-754-68 OS Error ................................................................................... 2-97

16-754-90 to 16-755-28 Fault Service Error.................................................................... 2-98

16-755-35 to 16-756-14 Request Error ........................................................................ ... 2-98

16-756-26 to 16-757-26 NVM Corrupt............................................................................. 2-99

16-757-35 to 16-758-26 Unable to Write NVM................................................................ 2-99

16-758-35 to 16-759-26 Service Run Loop Failed .......................................................... 2-100

16-759-46 to 16-760-46 Fail to Enable Process..................................................... .. .. .... . 2-100

16-760-47 to 16-761-46 File Error................................................................................... 2-101

16-761-47 to 16-769-95 Other Network Faults 1............................................................ . 2-101

16-770-09 to 16-779-95 Other Network Faults 2............................................................ . 2-103

16-780-00 to 16-789-47 Other Network Faults 3............................................................ . 2-104

16-790-09 to 16-799-47 Other Network Faults 4............................................................ . 2-105

16-800-09 to 16-809-47 Other Network Faults 5............................................................ . 2-106

16-810-00 to 16-819-47 Other Network Faults 6............................................................ . 2-107

16-820-47 to 16-829-47 Other Network Faults 7............................................................ . 2-108

16-830-47 to 16-839-47 Other Network Faults 8............................................................ . 2-108

16-840-47 to 16-849-47 Other Network Faults 9............................................................ . 2-109

16-850-47 to 16-859-47 Other Network Faults 10........................................................... 2-109

5/2014

2-3

WorkCentre 3655 Multifunction Printer

Status Indic a tor RAPs

Initial Issue - Xerox Internal Use Only

16-860-47 to 16-869-47 Other Network Faults 11 .......................................................... 2-110

16-870-47 to 16-879-47 Other Network Faults 12 .......................................................... 2-110

16-880-47 to 16-890-47 Other Network Faults 13 .......................................................... 2-111

16-891-00, 16-892-00 Edge Server Error ....................................................................... 2-111

16-900-19 to 16-909-19 Other Network Faults 14 .......................................................... 2-112

16-910-19 to 16-919-19 Other Network Faults 15 .......................................................... 2-112

16-920-19 to 16-929-19 Other Network Faults 16 .......................................................... 2-113

16-930-19 to 16-939-19 Other Network Faults 17 .......................................................... 2-113

16-940-19 to 16-949-19 Other Network Faults 18 .......................................................... 2-114

16-950-19 to 16-959-19 Other Network Faults 19 .......................................................... 2-114

16-960-19 to 16-969-19 Other Network Faults 20 .......................................................... 2-115

16-975-19 to 16-979-35 Other Network Faults 21 .......................................................... 2-115

16-980-00 to 16-989-35 Other Network Faults 22 .......................................................... 2-116

16-990-00 to 16-999-35 Other Network Faults 23 .......................................................... 2-117

Chain 19 - Image Processing

19-300-00 to 19-310-00 Image Disk (HDD) Failure........................................................ 2-119

19-401-00, 19-402-00 Out of Memory............................................................................. 2-119

19-403-00 Out of Memory - Job in EPC .......................................................................... 2-120

19-409-00 Video Integrity Fault ....................................................................................... 2-120

19-410-00 to 19-410-13 Image Structure Failure RAP ................................................... 2-121

19-750-00 EPC Memory Size Fault ................................................................................ 2-121

19-752-00 Image Rotation Config Fault.......................................................................... 2-122

19-754-00 Image Disk Config Fault ................................................................................ 2-122

19-760-00 Test Patterns are Missing from EPC ............................................................. 2-123

Chain 20 - Fax

20A Fax Troubleshooting Entry....................................................................................... 2-125

20B Unable To Send A Fax ............................................................................................ 2-125

20C Unable To Send A Fax To Some Machines ................................................... .... ..... 2-127

20D Unable To Receive A Fax........................................................................................ 2-128

20E Fax Will Not Print..................... ................................................................................ 2-129

20F Fax Board Checkout................................................................................................ 2-129

20G Fax Problems on Digital Networks.......................................................................... 2-130

20H Fax Tab Not Available RAP............... ...................................................................... 2-130

20-302-00 to 20-305-00 Fax Board Hardware or Software Error . ................................... 2-131

20-320-00 Fax Fault Not Cleared by Card Reset............................................................ 2-131

20-322-00 NV Device Not Fitted to Basic Fax Card........................................................ 2-132

20-323-00, 20-324-00 Fax System Memory is Low ........................................................ 2-132

20-327-00 Registers Cannot be Accessed on Extended Card ....................................... 2-133

20-331-00 to 20-341-00 Fax Network Line 1 Fault ......................................................... 2-133

20-342-00 Error Accessing File on a NV Device............................................................. 2-134

20-345-00 FaxPort1 Modem Failure ............................................................................... 2-134

20-701-00 Phonebook Download Failed......................................................................... 2-135

20-710-00, 20-711-00 Fax Card Overwrite Errors .......................................................... 2-135

Chain 22 - System Errors

22-300-05 to 22-309-04 Other Network Faults 24 .......................................................... 2-137

22-310-04 to 22-318-04 Other Network Faults 25 RAP.................................................. 2-137

22-319-04 IOT Integrity Problem While Printing a Job.................................................... 2-138

22-320-00, 22-321-00 Scan to File Fault ........................................................................ 2-138

22-321-04 RS422l ResponseTimeOutError.................................................................... 2-139

22-323-00 to 22-327-00 Service Faults........................................................................... 2-139

22-328-00 Incomplete System Information ..................................................................... 2-140