Xerox WorkCentre PE16 Service Manual

WorkCentre PE16

SERVICE Manual

WorkCentre PE16 |

CONTENTS |

1. |

Precautions |

2. |

Reference Information |

3. |

Specifications |

4. |

Summary of product |

5. |

Disassembly and Reassembly |

6. |

Alignment and Adjustments |

7. |

Troubleshooting |

8. |

Exploded Views and Parts List |

9. |

Block Diagram |

10. |

Connection Diagram |

XXX-XXXX-XX

1 |

Precautions |

|

1. Precautions

Product Terms

Caution: A personal injury hazard exists that may not be apparent. For example, a panel may cover the hazardous area.

Danger: A personal injury hazard exists in the area where you see the sign.

Symbols Marked on the Product

Hot surface on or in the printer. Use caution to avoid personal injury.

Use caution (or draws attention to a particular component).

Refer to the manual(s) for information.

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Precautions

Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J for Class 1(1) laser products, and elsewhere, it is certified as a Class I laser product conforming to the requirements of IEC 60825. Class I laser products are not considered to be hazardous. The laser system and printer are designed so there is never any human access to laser radiation above a Class I level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The reflected beam, although invisible, can damage your eyes. When using this product, these basic safety precautions should always be followed to reduce risk of fire, electric shock, and injury to persons.

CAUTION - INVISIBLE LASER RADIATION

WHEN THIS COVER OPEN.

DO NOT OPEN THIS COVER.

VORSICHT - UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GE FFNET.

NICHT DEM STRAHL AUSSETZEN.

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS

D OUVERTURE. EXPOSITION DANGEREUSE

AU FAISCEAU.

ATTENZIONE - RADIAZIONE LASER INVISIBILE IN CASO DI

APERTURA. EVITARE L ESPOSIZIONE AL

FASCIO.

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

ADVARSEL. - USYNLIG LASERSTR LNING VED BNING, N R

SIKKERHEDSBRYDERE ER UDE AF FUNKTION.

UNDG UDSAETTELSE FOR STR LNING.

ADVARSEL. - USYNLIG LASERSTR LNING N R DEKSEL

PNES. STIRR IKKE INN I STR LEN.

UNNG EKSPONERING FOR STR LEN.

VARNING - OSYNLIG LASERSTR LNING N R DENNA DEL

R PPNAD OCH SP RREN R URKOPPLAD.

BETRAKTA EJ STR LEN. STR LEN R FARLIG.

VARO! - AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTIINA N KYM TT M LLE LASER-

S TEILYLLE L KATSO S TEESEEN.

Service Manual

July 2003 WorkCentre PE16

Precautions

Power Safety Precautions

Power Source

For 110 VAC units, do not apply more than 140 volts RMS between the supply conductors or between either supply conductor and ground. Use only the specified power cord and connector. For 220 VAC units, do not apply more than 264 volts RMS between the supply conductors or between either supply conductor and ground.

Use only the specified power cord. This manual assumes that the reader is a qualified service technician.

Plug the three-wire power cord (with grounding prong) into a grounded AC outlet only. If necessary, contact a licensed electrician to install a properly grounded outlet. If the product loses its ground connection, contact with conductive parts may cause an electrical shock.

Disconnecting Power

Turning the power off using the On/Off switch does not completely de-engergize the equipment. You must also disconnect the unit power cord from the AC outlet. Position the power cord so that it is easily accessible during servicing

so that you may power down the unit during an emergency.

Disconnect the power plug by pulling the plug, not the cord.

Disconnect the power cord in the following cases:

■if the power cord or plug is frayed or otherwise damaged,

■if any liquid or foreign material is spilled into the case,

■if the equipment is exposed to any excess moisture,

■if the equipment is dropped or damaged,

■if you suspect that the product needs servicing or repair,

■whenever you clean the product.

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Precautions

Electrostatic Discharge (ESD) Precautions

Some semiconductor components, and the respective sub-assemblies that contain them, are vulnerable to damage by Electrostatic discharge (ESD). These components include Integrated Circuits (ICs), Large-Scale Integrated circuits (LSIs), field-effect transistors and other semiconductor chip components. The following techniques will reduce the occurrence of component damage caused by static electricity.

Be sure the power to the chassis or circuit board is off, and observe all other safety precautions.

■Before handling any semiconductor components assemblies, drain the electrostatic charge from your body. This can be accomplished by touching an earth ground source or by wearing a wrist strap device connected to an earth ground source. Wearing a wrist strap will also prevent accumulation of additional bodily static charges. Be sure to remove the wrist strap before applying power to the unit to avoid potential shock.

■After removing a static sensitive assembly from its anti-static bag, place it on a grounded conductive surface. If the anti-static bag is conductive, you may ground the bag and use it as a conductive surface.

■Do not use freon-propelled chemicals, as they can generate electrical charges that may damage some devices.

■Do not remove a static sensitive replacement component or electrical subassembly from its protective package until you are ready to install it.

■Before removing the protective material from the leads of a replacement device, touch the protective material to the chassis or circuit assembly into which the device will be installed.

■Minimize body motions when handling unpackaged replacement devices. Simple motions such as your clothes brushing together or lifting a foot from a carpeted floor can generate enough static electricity to damage a static sensitive device

■Handle IC’s and EPROM’s carefully to avoid bending pins.

■Pay attention to the direction of parts when mounting or inserting them on Printed Circuit Boards (PCB’s).

Service Manual

July 2003 WorkCentre PE16

Precautions

Service Safety Summary

General Guidelines

Note

The material presented here is intended as a safety reminder for qualified service personnel. Refer also to the preceding Power Safety Precautions.

Avoid servicing alone: Do not perform internal service or adjustment of this product unless another person capable of rendering first aid or resuscitation is present.

Use care when servicing with power: Dangerous voltages may exist at several points in this product. To avoid personal injury, do not touch exposed connections and components while power is on. Disconnect power before removing the power supply shield or replacing components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and other metallic objects could come into contact with dangerous voltages and currents.

Power source: This product is intended to operate from a power source that will not apply more then 264 volts rms for a 220 volt AC outlet or 140 volts rms for a 110 volt AC outlet between the supply conductors or between either supply conductor and ground. A protective ground connection by way of the grounding conductor in the power cord is essential for safe operation.

Warning Labels

Read and obey all posted warning labels. Warning labels are displayed on potentially dangerous printer components. As you service the printer, check to make certain that all warning labels remain in place.

Safety Interlocks

Make sure all covers and the products’s front panel are in place and all interlock switches are functioning correctly after you have completed a unit service call. If you bypass an interlock switch during a service call, use extreme caution when working on or around the product.

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Precautions

Servicing Electrical Components

Before starting any service procedure, switch off the product power and unplug the power cord from the wall outlet. If you must service the unit with power applied, be aware of the potential for electrical shock.

Warning

Turning the power off by using the On/Off switch does not completely de-energize the unit. You must also disconnect the unit's power cord from the AC outlet. Position the power cord so that it is easily accessible during servicing.

Warning

Do not touch any electrical component unless you are instructed to do so by a service procedure.

S7300-02

Servicing Mechanical Components

When servicing mechanical components within the unit, manually rotate drive assemblies, rollers, and gears.

Warning

Do not try to manually rotate or manually stop the drive assemblies while any unit drive motor is running.

S7300-03

Servicing Fuser Components

Warning

This product uses heat to fuse the toner image to media. The Fuser Assembly is VERY HOT. Turn the unit power off and wait at least 5 minutes for the Fuser

to cool before you attempt to service the Fuser Assembly or adjacent components.

Service Manual

July 2003 WorkCentre PE16

22. Reference Information

This chapter provides reference information for this service manual consisting of the tool list, a list of acronyms and abbreviations, and examples of test patterns.

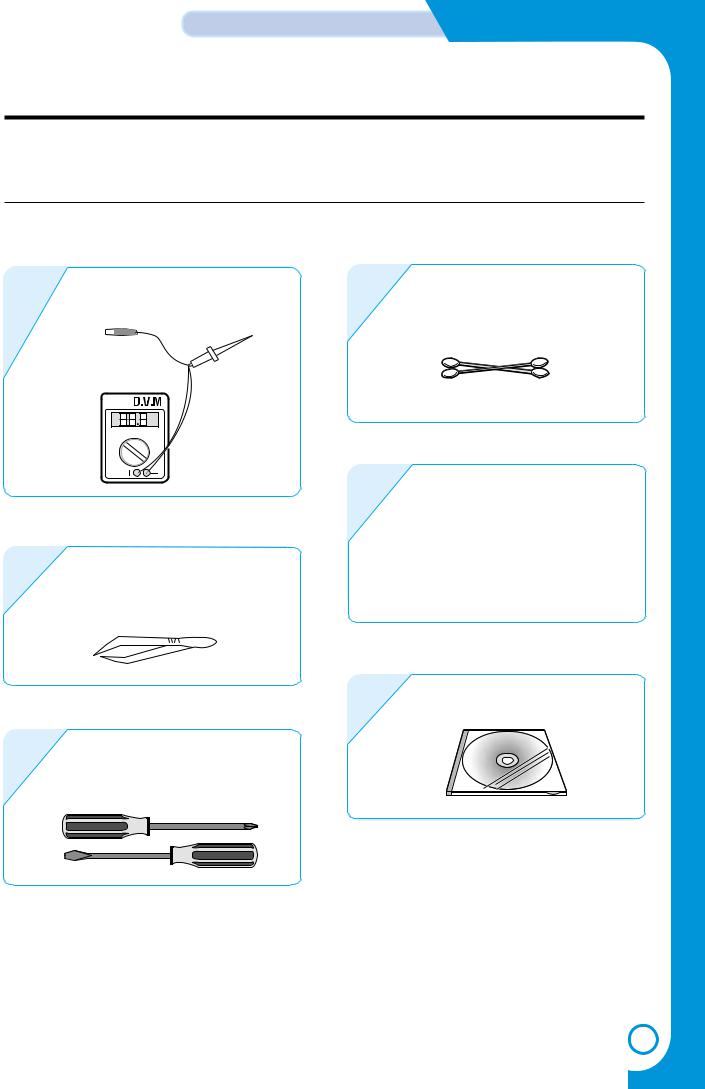

2.1 Tool for Troubleshooting

The following tools are recommended for perfomance of the troubleshooting functions described in this service manual.

1 |

DVM(Digital Volt Meter) |

4 |

Cotton Swab |

Standard: Indicates more than 3 digits. |

Standard : For general home use, for |

||

|

medical service.

5 |

Cleaning Equipment IPA |

(Isopropyl Alcohol) dry cloth or a |

liquid neutral detergent.

2 Tweezers

Standard: For general home use, small type.

6 |

Software(Driver) installation CD |

ROM |

3 Driver

Standard : "-" type, "+" type (M3 long, M3 short, M2 long, M2 short).

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Reference Information

2.2 Acronyms and Abbreviations

The table below explains the acronyms and abbreviations used in this service manual. These are used throughout the text of this service manual. Please refer to the table.

AC |

Alternating Current |

ADF |

Automatic Document Feeder |

ASIC |

Application Specific Integrated Circuit |

ASSY |

assembly |

BIOS |

Basic Input Output System |

CCD |

Charge Coupled Device |

CMOS |

Complementary Metal Oxide Semiconductor |

CN |

connector |

CON |

connector |

CPU |

Central Processing Unit |

dB |

decibel |

dbA |

decibelampere |

dBM |

decibel milliwatt |

DC |

direct current |

DCU |

Diagnostic Control Unit |

DPI |

Dot Per Inch |

DRAM |

Dynamic Random Access Memory |

DVM |

Digital Voltmeter |

ECP |

Enhanced Capability Port |

EEPROM |

Electronically Erasable Programmable Read |

|

Only Memory |

EMI |

Electro Magnetic Interference |

EP |

electrophotographic |

EPP |

Enhanced Parallel Port |

F/W |

firmware |

GDI |

graphics device interface |

GND |

ground |

HBP |

Host Based Printing |

HDD |

Hard Disk Drive |

HV |

high voltage |

HVPS |

High Voltage Power Supply |

I/F |

interface |

I/O |

Input and Output |

IC |

integrated circuit |

IDE |

Intelligent Drive electronics or Imbedded |

|

Drive Electronics |

IEEE |

Institute of Electrical and Electronics |

|

Engineers. Inc |

IPA |

Isopropy Alcohol |

IPM |

Images Per Minute |

Kg |

Kilogram |

LAN |

local area network |

lb |

pound(s) |

LBP |

Laser Beam Printer |

LCD |

Liquid Crystal Display |

LED |

Light Emitting Diode |

LSU |

Laser Scanning Unit |

MB |

Megabyte |

MHz |

Megahertz |

NVRAM |

Nonvolatile random access memory |

OPC |

Organic Photo Conductor |

PBA |

Printed Board Assembly |

PCL |

Printer Command Language , Printer Control |

|

Language |

PDL |

Page Discription Language |

PPM |

Page Per Minute |

PTL |

Pre-Transfer Lamp |

Q’ty |

Quantity |

RAM |

Random Access Memory |

ROM |

Read Only Memory |

SCF |

Second Cassette Feeder |

SMPS |

Switching Mode Power Supply |

SPGP |

Samsung Printer Graphic Processor |

SPL |

Samsung Printer Language |

Spool |

Simultaneous Peripheral Operation Online |

SW |

Switch |

Sync |

Synchronous or synchronization |

USB |

Universal Serial Bus |

Service Manual

July 2003 WorkCentre PE16

Reference Information

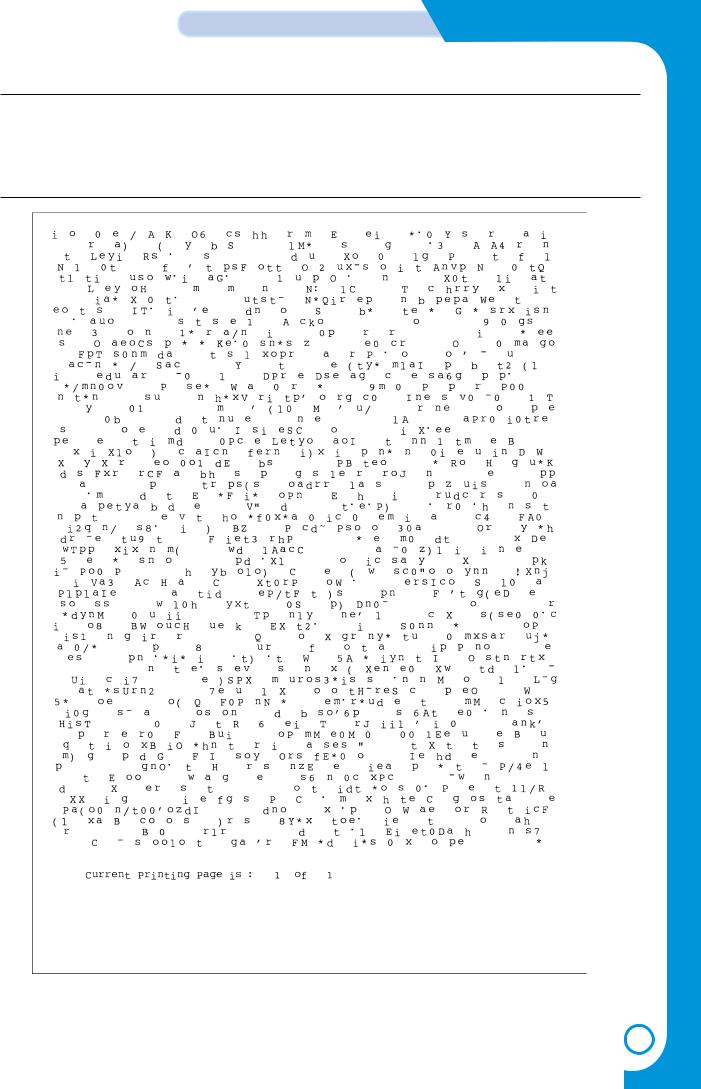

2.3 The Sample Test Patterns

The following test patterns are the standard patterns used to test the product in the factory. Cartridge life span and printing speed are measured with the patterns shown below.

(The picture in the manual is 70% size of the actual A4 size.)

2.3.1 A4 5% Pattern

|

Service Manual |

WorkCentre PE16 |

July 2003 |

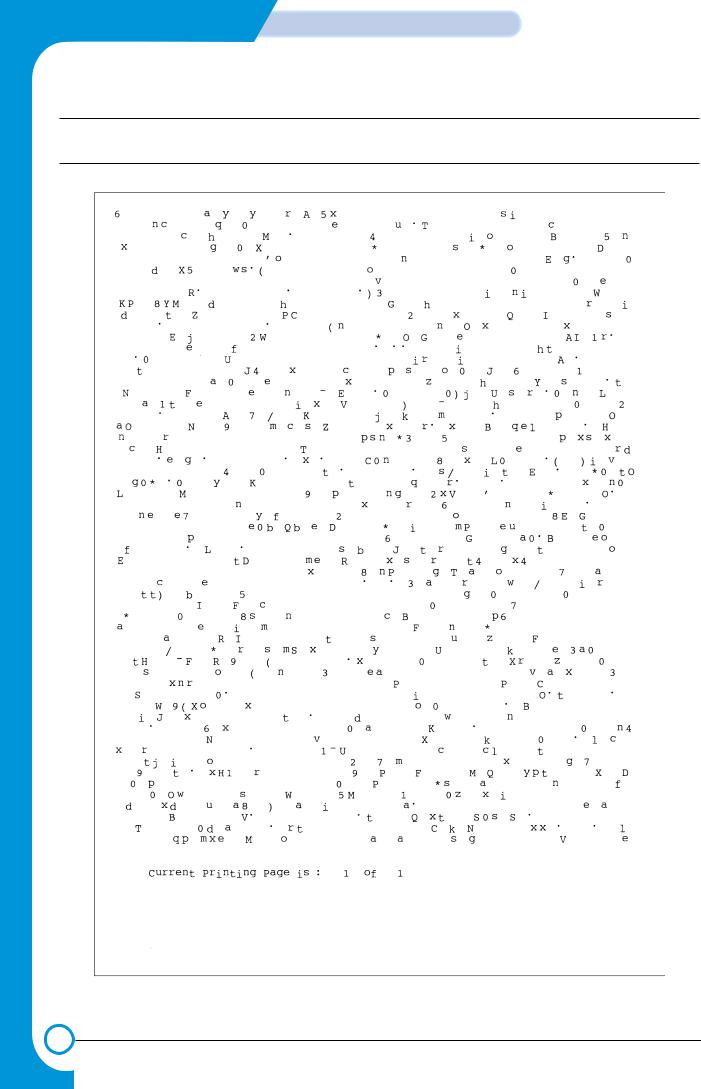

Reference Information

2.3.2 A4 2% Pattern

Service Manual

July 2003 WorkCentre PE16

Reference Information

2.3.3 A4 IDC 5% Pattern

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Reference Information

Service Manual

July 2003 WorkCentre PE16

Specifications

33. Specifications

Specifications are correct at the time of printing. Product specifications are subject to change without notice. See below for product specifications.

3.1 General Specifications

Items |

|

Descriptions |

Remarks |

||

Major Features |

|

Copier, Print, Scan, Fax |

With ADF |

||

Size (W*D*H) |

|

474 X 436 X 417 mm |

w/o Hand Set |

||

Weight |

|

13 Kg (28.8 lbs) |

With Toner Cartridge |

||

LCD |

|

16*2 Char |

|

||

|

|

|

|

|

|

I/O Interface |

|

USB1.1 & IEEE1284 |

|

||

|

|

|

|

|

|

Power Consumption |

|

Printing |

350W |

|

|

|

|

|

|

|

|

|

|

|

Sleep Mode |

20W |

|

|

|

|

|

|

|

Power Switch |

|

Yes |

|

||

|

|

|

|

|

|

Noise |

|

Operating |

55 dBA |

|

|

|

|

|

|

|

|

|

|

|

Standby |

35 dBA |

|

Warm Up |

|

Less than 42 seconds |

|

||

Approval |

|

Class B |

|

||

Device Memory |

|

16 MB (Printer : 8M, Fax : 4M, |

|

||

|

|

|

|

Scan : 2M, System : 2M) |

|

|

|

|

|

||

Internal N/W Connectivity |

N/A |

|

|||

|

|

|

|

|

|

3.2 Print Specification

|

Items |

Descriptions |

Remarks |

|

Print Speed |

|

|

17ppm(Letter) |

5% Character |

|

|

|

16pp,(A4) |

Pattern |

|

|

|

|

|

Print Method |

|

|

Laser Scanning Unit + Electro Photography |

|

|

|

|

|

|

Print Language |

|

|

SPL |

|

|

|

|

|

|

Power Save |

|

|

Yes(5/10/15/30/45min.) |

|

Resolution |

|

Normal |

600 *600dpi |

|

|

|

|

|

|

|

|

RET |

No |

|

Toner Save |

|

|

Yes |

|

|

|

|

|

|

Memory |

|

|

8 MB |

|

FPOT |

|

Stand by |

Approx. 12 seconds |

|

|

|

Power Save |

Less than 54 seconds |

|

Printable Area |

|

|

208 X 271 mm (Letter) |

|

|

|

|

|

|

|

|

|

202 X 289 mm (A4) |

|

|

|

|

|

|

Toner Save |

|

|

Yes |

|

|

|

|

|

|

Service Manual

WorkCentre PE16 |

June 2003 |

Specifications

3.3 Scan Specification

Items |

|

Descriptions |

Remarks |

|||

Halftone(Gray Scale) |

|

256 level |

|

|

|

|

|

|

|

|

|

|

|

Scan Method |

|

Color CCD |

|

|

ITU-T #1 Chart |

|

Scan Speed |

|

ADF |

Letter : 25 sec, |

A4 : |

28 sec |

Text/Mixed Mode : |

(seconds/scan) |

|

Platen |

Letter : 25 sec, |

A4 : |

28 sec |

B/W & 300dpi. (USB) |

|

|

|

|

|

|

|

|

|

ADF |

Letter : 55 sec, |

A4 : |

60 sec |

Photo Mode : Gray |

|

|

Platen |

Letter : 55 sec, |

A4 : |

60 sec |

& 300dpi. (USB) |

|

|

ADF |

Letter : 125 sec, |

A4 |

: 130 sec |

Photo Mode : Color |

|

|

Platen |

Letter : 125 sec, |

A4 |

: 130 sec |

& 300dpi.(USB) |

Resolution |

|

Optical |

600 dpi |

|

|

|

|

|

Enhanced |

4800 dpi |

|

|

|

|

|

|

|

|

|

|

Halftone |

|

256 level |

|

|

|

|

|

|

|

|

|

|

|

Scan Width |

|

Width |

Max.216mm (8.5") |

|

|

|

|

|

Length(Adf) |

Max. 356mm (14.0") |

|

|

|

|

|

Length(Platen) |

Max. 297mm (11.7") |

|

|

|

|

|

|

|

|

||

Scan-to |

|

E-mail, Image, OCR, FAX, WEB |

From SmarThru3 |

|||

|

|

|

|

|

|

|

Service Manual

June 2003 |

WorkCentre PE16 |

Specifications

3.4 Copy Specification

Items |

|

|

Descriptions |

Remarks |

|

Copy Quality Selection |

Text |

600x300dpi |

|

|

|

|

|

|

|

|

|

or Original Image type |

Auto |

600x300dpi |

|

|

|

selection Mode |

Photo |

600x600dpi |

for Platen / 600x300dpi for ADF |

|

|

|

|

|

|

|

|

|

Other |

- |

|

|

|

|

|

|

|

|

|

FCOT |

Platen |

Power Save |

|

Approx. 54 seconds |

|

|

|

|

|

|

|

|

|

Stand by |

|

Approx. 12 seconds |

|

|

|

|

|

|

|

|

ADF |

Power Save |

|

Approx. 54 seconds |

|

|

|

|

|

|

|

|

|

Stand by |

|

Approx. 17 seconds |

|

Copy Speed |

Text Mixed |

SDMC |

|

16 cpm/A4, 17 cpm/LTR |

|

|

|

MDMC |

|

7 cpm/A4, 7 cpm/LTR |

|

|

Photo |

SDMC |

|

16 cpm/A4, 17 cpm/LTR |

|

|

|

MDMC |

|

7 cpm/A4, 7 cpm/LTR |

|

|

|

|

|

|

|

Resolution |

Scan |

600*600dpi |

|

|

|

|

|

|

|

|

|

|

600*600dpi |

|

|

|

|

Zoom Range |

|

25% to 400 % for platen, 25% to 100% for ADF |

|

||

|

|

|

|

|

|

Multi Copy |

|

1~99 |

|

|

|

|

|

|

|

|

|

Preset |

|

Yes |

|

|

|

|

|

|

|

|

|

Contrast Control |

|

3 level(by LED) |

|

||

|

|

|

|

|

|

Copy Mode |

|

TEXT/MIXED/PHOTO |

|

||

|

|

|

|

|

|

Collation Copy |

|

Yes(300dpi only) |

|

||

|

|

|

|

|

|

Auto return to default mode |

Yes(after 1 minute) |

|

|||

|

|

|

|

|

|

N-up copy |

|

2-up, 4-up |

|

|

ADF Only |

|

|

|

|

|

|

AutoFit Copy |

|

Yes |

|

|

Platen Only |

|

|

|

|

|

|

Clone |

|

Yes |

|

|

Platen Only |

|

|

|

|

|

|

Poster |

|

Yes |

|

|

Platen Only |

|

|

|

|

|

|

Service Manual

WorkCentre PE16 |

June 2003 |

Specifications

3.5 Telephone Specification

Items |

|

Descriptions |

Remarks |

|

Handset |

|

No |

|

|

|

|

|

|

|

On hook Dial |

|

Yes |

|

|

|

|

|

|

|

Search |

|

Yes (Phone Book) |

by using Phone Book Button |

|

|

|

|

|

|

1-Touch Dial |

|

10EA (3*4 Numeric Key) |

|

|

|

|

|

|

|

Auto dial |

|

100 locations (Using 3*4 buttons) |

|

|

|

|

|

|

|

TAD I/F |

|

No |

|

|

|

|

|

|

|

Tone/Pulse |

|

Selectable in Tech Mode |

|

|

Pause |

|

Yes |

|

|

|

|

|

|

|

Auto Redial |

|

Yes |

|

|

Last Number Redial |

|

Yes |

|

|

Distinctive Ring |

|

No |

|

|

|

|

|

|

|

Caller ID |

|

No |

|

|

External Phone Interface |

No |

|

||

|

|

|

|

|

Report & List Print out |

|

Tx/Rx Journal |

Yes |

|

|

|

Confirmation |

2 types available |

|

|

|

|

(with Image TCR, w/o image TCR) |

|

|

|

|

|

|

|

|

Help List |

No |

|

|

|

|

|

|

|

|

Auto Dial List |

Yes |

|

|

|

|

|

|

|

|

System Data List |

List all user setting |

|

|

|

|

|

|

Sound Control |

|

Ring Volume |

Yes(Off,Low,MED,HIGH) |

|

|

|

|

|

|

|

|

Key Volume |

Yes(On,Off) |

|

|

|

|

|

|

|

|

Speaker |

Yes(On,Off) |

|

Service Manual

June 2003 |

WorkCentre PE16 |

Specifications

3.6 Fax Specification

Items |

|

Descriptions |

Remarks |

||

Compatibility |

|

ITU-T G3 |

|

||

|

|

|

|

|

|

Communication System |

|

PSTN/PABX |

|

||

|

|

|

|

|

|

Modem Speed |

|

33.6 Kbps |

|

||

|

|

|

|

|

|

TX Speed |

|

Approx. 3 sec |

|

||

|

|

|

|

|

|

Compression |

|

MH/MR/MMR/JPEG |

|

||

|

|

|

|

|

|

ECM |

|

Yes |

|

||

|

|

|

|

|

|

Resolution |

|

Std |

203 x 98 dpi |

|

|

|

|

|

Fine |

203 x 196 dpi |

|

|

|

|

|

|

|

|

|

|

S.Fine |

300 x 300 dpi |

|

Scan Speed(ADF) |

|

Std |

Approx. 5sec/LTR (6 sec/A4) |

|

|

|

|

|

Fine |

Approx.7.5sec/LTR (8 sec/A4) |

|

|

|

|

|

|

|

|

|

|

S.Fine |

Approx.7.5sec/LTR (8 sec/A4) |

|

Rx fax duplex print out |

|

No |

|

||

|

|

|

|

|

|

Multiple page scan speed |

Approx. 7 ppm/LTR (7.5 ppm/A4) |

|

|||

|

|

|

|

|

|

Receive Mode |

|

Fax, TEL |

|

||

|

|

|

|

|

|

Memory |

|

Capacity |

4 MB (320 pages) |

|

|

|

|

|

|

|

|

|

|

|

Optional Memory |

No |

|

|

|

|

|

|

|

|

|

|

Max locations to |

99 locations |

|

|

|

|

store to 1 Group Dial |

|

|

|

|

|

|

|

|

|

|

|

Fax Forward |

Yes (On/Off) |

|

|

|

|

|

|

|

|

|

|

Broadcasting |

Up to 99 locations |

|

|

|

|

|

|

|

|

|

|

Forced Memory TX |

No |

|

|

|

|

|

|

|

|

|

|

Cover page |

No |

|

|

|

|

Delayed fax |

Yes |

|

|

|

|

|

|

|

|

|

|

Memory RX |

Yes |

|

|

|

|

|

|

|

Functions |

|

Voice Request |

No |

|

|

|

|

|

|

|

|

|

|

|

TTI |

Yes |

|

|

|

|

|

|

|

|

|

|

RTI |

Yes |

|

|

|

|

Polling |

No |

|

|

|

|

Earth/Recall |

No |

|

|

|

|

|

|

|

|

|

|

Auto Reduction |

Yes |

|

|

|

|

RDC |

No |

|

|

|

|

Junk Fax barrier |

Yes |

|

|

|

|

|

|

|

|

|

|

Security Mode |

Yes |

|

|

|

|

|

|

|

|

|

|

Battery Backup |

Yes (Min. 15 minutes) |

Not Battery |

|

|

|

|

|

(Using Super Cap.) |

|

|

|

|

|

|

Service Manual

WorkCentre PE16 |

June 2003 |

Specifications

3.7 Paper Handling

|

Items |

Descriptions |

Remarks |

|

Capacity |

|

Main Tray |

250sheets |

|

|

|

|

|

|

(20lbs) |

|

Bypass |

Single Sheet |

|

|

|

|

|

|

Optional Cassette |

|

|

No |

|

|

|

|

|

|

Output Capacity |

|

|

150Sheets/20lb, 1Sheet/Face up |

|

|

|

|

|

|

Output Control |

|

|

Face down/Face up |

|

|

|

|

|

|

Paper Size |

|

Main Tray |

CST : A4,Letter,Legal, Folio,Executive,B5 |

|

|

|

|

|

|

|

|

Bypass |

Bypass : Envelope6 3/4,7 3/4, #9, #10, |

|

|

|

|

DL,C5,B5 |

|

Paper Weight |

|

Main Tray |

60 ~ 90 GSM / 16 ~ 24 lb. |

|

|

|

|

|

|

|

|

Bypass |

60 ~ 150 GSM / 16 ~ 40 lb. |

|

|

|

|

|

|

Paper Path |

|

Standard output |

Bottom to Middle Front (FIFO) |

|

|

|

|

|

|

|

|

Straight Through |

Face up, Single Sheet |

|

|

|

|

|

|

Paper Size |

|

Max |

216 x 356mm(8.5"x14") |

|

|

|

|

|

|

|

|

Min |

76 x 127mm(3"x5") |

|

|

|

|

|

|

Output Stacker |

|

Paper |

Extension |

|

|

|

|

|

|

|

|

Document |

Fixed |

|

|

|

|

|

|

Input Guide |

|

Bypass Tray |

Adjustable |

|

|

|

|

|

|

|

|

Main Tray |

Universal |

|

|

|

|

|

|

|

|

Document |

Adjustable |

|

|

|

|

|

|

ADF |

|

Paper Weight |

60 ~ 105 GSM / 12.5~28lb |

|

|

|

|

|

|

|

|

Capacity |

30 sheets(80 GSM / 20lb) |

|

|

|

|

|

|

|

|

Document Size Width |

148mm - 216mm(5.8" - 8.5") |

|

|

|

|

|

|

|

|

Document Size Length |

127 mm - 356mm(5" - 14.0") |

|

|

|

|

|

|

3.8 Software

|

|

Items |

Descriptions |

Remarks |

||

Compatibility |

|

|

DOS |

No |

|

|

|

|

|

|

Win 3.x |

No |

|

|

|

|

|

|

|

|

|

|

|

|

Win 95 |

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

Win 98&WinME |

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

Win NT 4.0 |

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

Win 2000 |

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

Win XP |

Yes |

WHQL for Printer Only |

|

|

|

|

|

|

|

|

|

|

|

Mac |

Yes |

Mac Printer Only |

|

|

|

|

|

|

|

|

|

|

|

Linux |

No |

|

|

|

|

|

|

|

|

Driver |

|

|

Printer |

SPL(GDI) |

|

|

|

|

|

|

TWAIN |

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

PC-FAX |

No |

PC Fax is only avail- |

|

|

|

|

|

|

able through PC |

|

|

|

|

|

|

Modem |

|

|

|

|

|

|

|

|

Service Manual |

|

|

|

|

|

|

|

|

|

|

|

|

|

June 2003 |

|

|

|

|

WorkCentre PE16 |

Specifications

3.9 Consumables

|

Items |

Descriptions |

Remarks |

|

Type |

|

|

Single Cartridge |

|

How to install |

|

|

Front door open and front loading |

|

|

|

|

|

|

Toner |

|

Life |

Initial 2,000 sheets |

IDC 5% |

|

|

|

running 3,500 sheets |

character printing |

Level Sensor |

|

|

No |

|

|

|

|

|

|

Toner Count |

|

|

Yes |

|

|

|

|

|

|

Service Manual

WorkCentre PE16 |

June 2003 |

Specifications

Service Manual

June 2003 |

WorkCentre PE16 |

4 Summary of product

4. Summary of Product

This chapter describes the functions and operating principals of the main components.

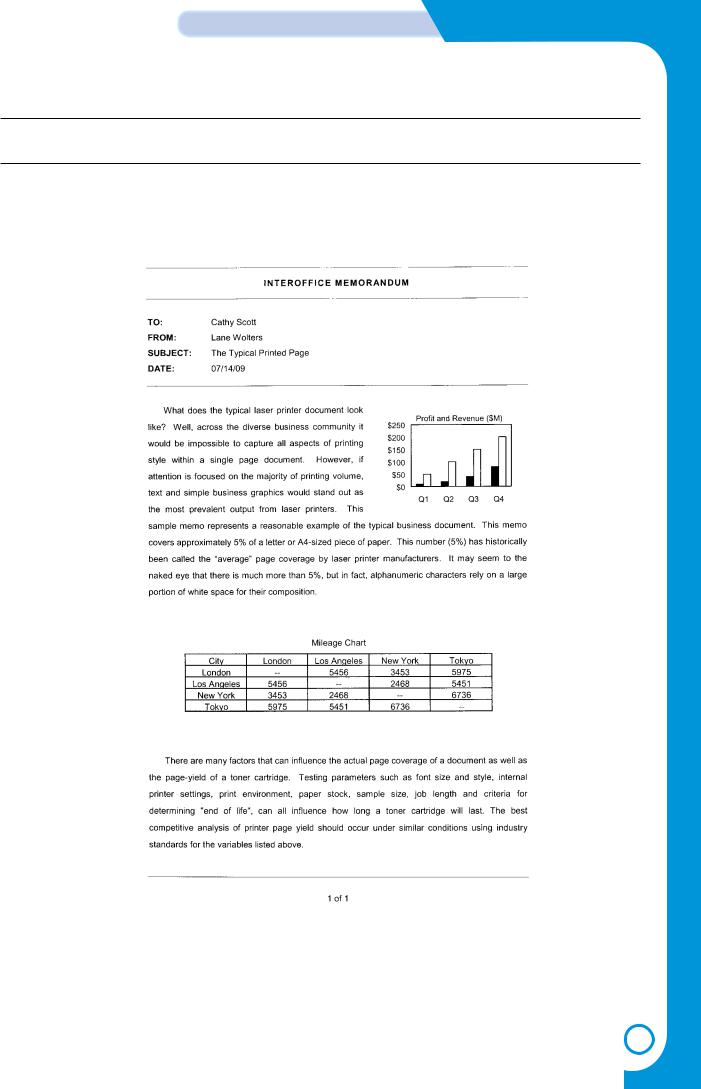

4.1 Printer Components

4.1.1 Front View

|

Document |

Document |

|

Cover |

|

|

Guides |

|

|

|

|

Automatic |

Document |

|

Input Tray |

|

|

Document Feeder |

|

|

|

|

Document Glass

Document

Output Tray

Control Panel

Front Cover

Paper Output |

|

Extension |

|

Paper Tray |

Paper Level |

|

Indicator |

Bypass Tray |

|

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Summary of Product

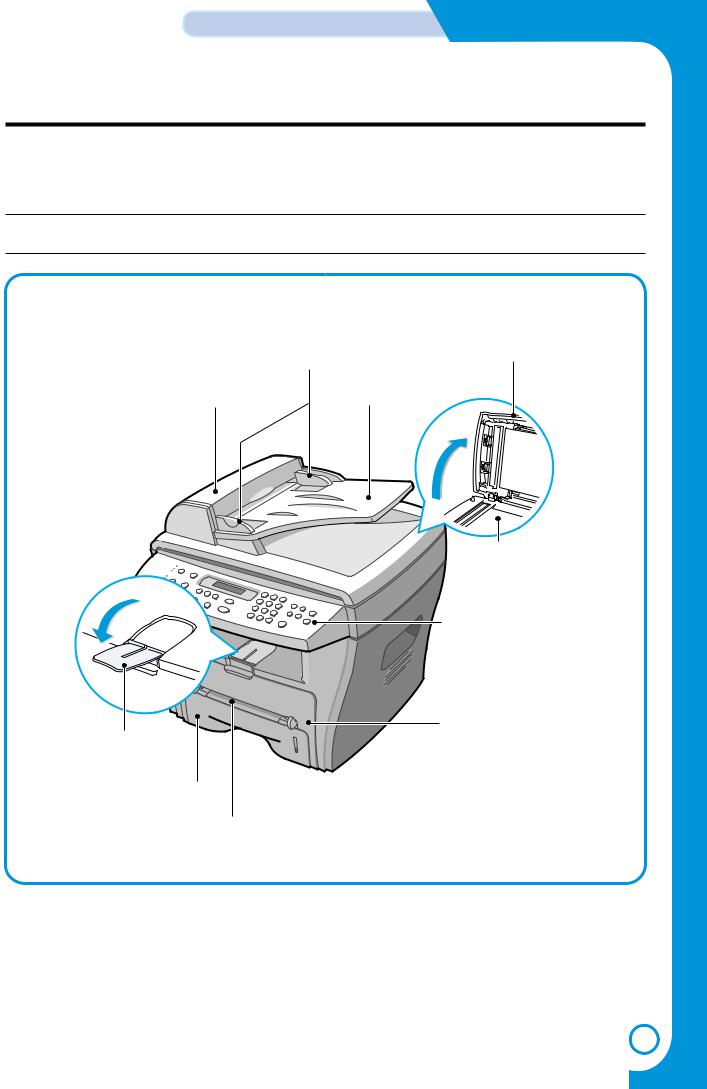

4.1.2 Rear View

Rear Cover |

Rear Output Slot |

(Face up) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power Switch |

Parallel |

|

|

|

||

|

|

|||||

Telephone Line |

||||||

Connector |

|

|||||

|

|

|||||

|

|

Connector |

||||

AC Power Cord |

|

|

|

|||

|

USB |

|||||

|

|

|

||||

Connector |

|

|

|

|||

|

Connector |

|

|

|||

|

|

|

|

|||

Service Manual

July 2003 |

WorkCentre PE16 |

Summary of product

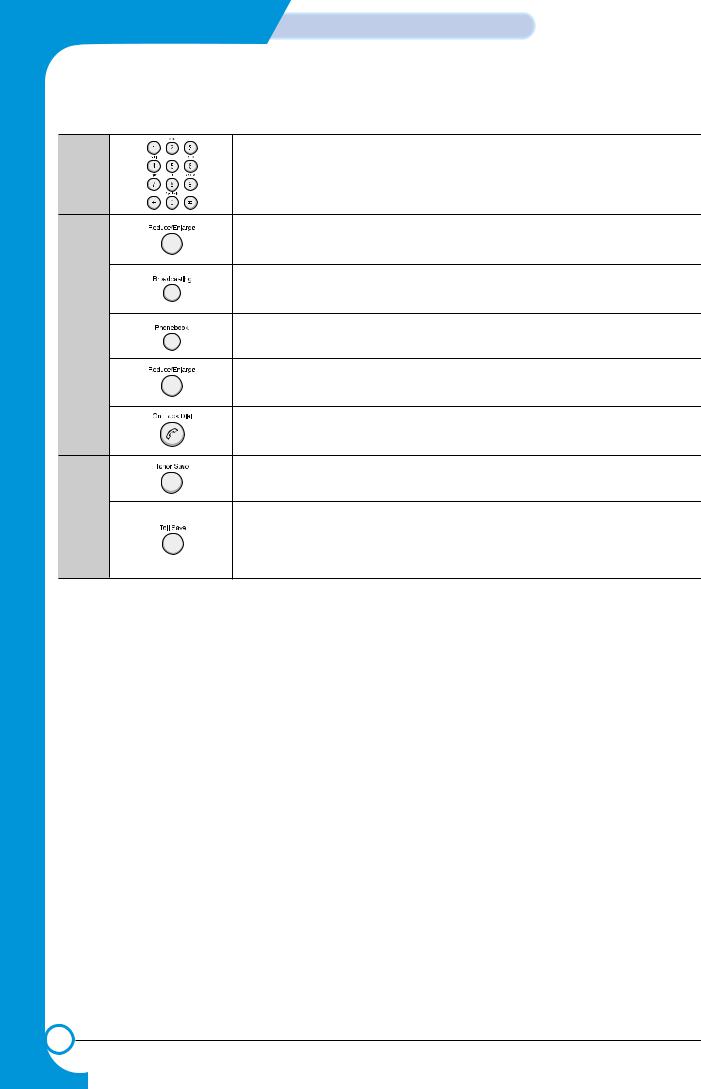

4.1.3 Control Panel

1 |

2 |

3 |

4 |

5 |

6 |

1

C O P Y

2

3

Adjusts the brightness of the documents for the current copy job.

Selects the document type for the current copy job.

Allows you to use special copy features, such as Clone, Collation, Auto fit, 2-side, N-up (multiple pages on a sheet) and Poster copying.

Makes a copy smaller or larger than the original.

Selects the number of copies.

Displays the current status and prompts during an operation.

Turns on when the toner cartridge is empty.

Scrolls through the options available for the selected menu item.

Confirms the selection on the display.

Enters Menu Mode and scrolls through the menus available.

Sends you back to the upper menu level.

Stops an operation at any time.

In Standby Mode, clears/cancels the copy options, such as the contrast, the image setting, the copy size and the number of copies.

Starts a job.

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Summary of Product

4

5

F A X

6

S A V E

Dials a number or enters alphanumeric characters.

Adjusts the resolution of the documents for the current fax job.

Allows you to send a fax to multiple destinations.

Allows you to store frequently-dialed fax numbers using a one or two-digit speed dial or group number for automatic dialing and edits the stored numbers.

Allows you to print a Phonebook list. Redials the last number in Standby Mode or inserts a pause into a fax number in edit mode.

Engages the telephone line.

Allows you to save on toner by using less toner to print a document.

Allows you to save on call costs by sending a fax at a preset toll-saving time. Using this feature, you can take advantage of lower long distance rates at night, for example.

Service Manual

July 2003 WorkCentre PE16

Summary of product

4.2 System Layout

4.2.1 Feeding section

Paper for the machine is supplied from a universal cassette or from the manual feeder, for single sheet feeding. The cassette contains a friction pad, to separate the paper and prevent multi-sheet feeding. There is a sensor to detect the presence of paper in the cassette.

-Feeding Method: Universal Cassette Type

-Feeding Standard: Center Loading

-Feeding Capacity: Cassette-250 sheets (80g/m2, 20lb paper standard)

Manual 1 sheet (Paper, OHP, Envelope, etc.)

-Paper detecting sensor: Photo sensor

-Paper size sensor: None

4.2.2Transfer Ass’y

The Transfer Ass'y consists of the PTL(pre-transfer lamp), OPC Drum, and the Transfer Roller. The PTL lights the surface of the OPC Drum, reducing the charge on the drum surface to improve transfer efficiency. The Transfer Roller transfers toner from the OPC Drum surface to the paper.

-Life span: 60,000 sheets (in 15~30°C)

4.2.3Drive Ass’y

The Drive Ass'y is a motor driven gear unit, that drives the paper feed, the Fuser, and the distributing unit.

4.2.4 Fuser

The Fuser consists of the Heat Lamp, Heat Roller, Pressure Roller, Thermistor, and Thermostat. It melts the toner to the paper using pressure and heat to complete the printing job.

4.2.4.1 Thermostat

The thermostat is a temperature-sensing device, that cuts off the power to prevent overheating or a fire when the heat lamp or the heat coil of the heat roller becomes too hot.

4.2.4.2 Thermistor

The Thermistor detects the surface temperature of the heat roller. The information from the Thermistor provides the on/off control that maintains the selected temperature of the heat roller.

4.2.4.3 Heat Roller

The heat roller transfers the heat from the heat lamp coil to the surface of the paper. The melted toner cannot stick to the Teflon coated heat roller.

4.2.4.4 Pressure roller

The pressure roller mounted right under the heat roller is made of the silicon resin. The toner fuses onto the paper when it passes between the heat roller and the pressure roller.

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Summary of Product

4.2.4.5 Safety Relevant Facts

•Protecting device when overheating

-1st protecting device: H/W cuts off when an overheat condition is detected.

-2nd protecting device: S/W cuts off when an overheat condition is detected.

-3rd protecting device: Thermostat cuts off the power.

•Safety device

-The power to the fuser is cut off when the front cover is open.

-The overheating safety device for customer safety.

-Maintains the surface temperature of the Fuser Cover below 80°C. A customer caution label is attached on the inside of the rear cover.

4.2.5 Scanner

Uses a photosensitive device to read an image. The Scanner consists of a CCD module, Connection board, ADF board, AFE (Analog Front End), Image Processor (located in the CPU), platen glass, and ADF.

•CCD Module Specification

1.Resolution: 600dpi/A4 2.Maximum scan wide: 8.5” 3.Color filter: Red, Green, Blue

4.Output channel: 3 channels (R, G, B) 5.Effective pixel: 5,400 pixel *3 6.Voltage: 24V & 5V

7.Pre-heating time: Maximum 30 seconds (70% of light reach to it) 8.The life span of a lamp: 30,000 hours (25oC)

•Image Processor Specification

1.Operating frequency: 66 MHz

2.Image sensor interface: 200/300/600 dpi CIS or CCD

3.Line time: Copy, FAX, Binary (Lineart, Halftone) PC Scan: 1.5ms/Line Color PC Scan (Grey, 256 Color, True Color): 4.5ms/Line

4.A/D conversion: 10bit conversion

Service Manual

July 2003 WorkCentre PE16

Summary of product

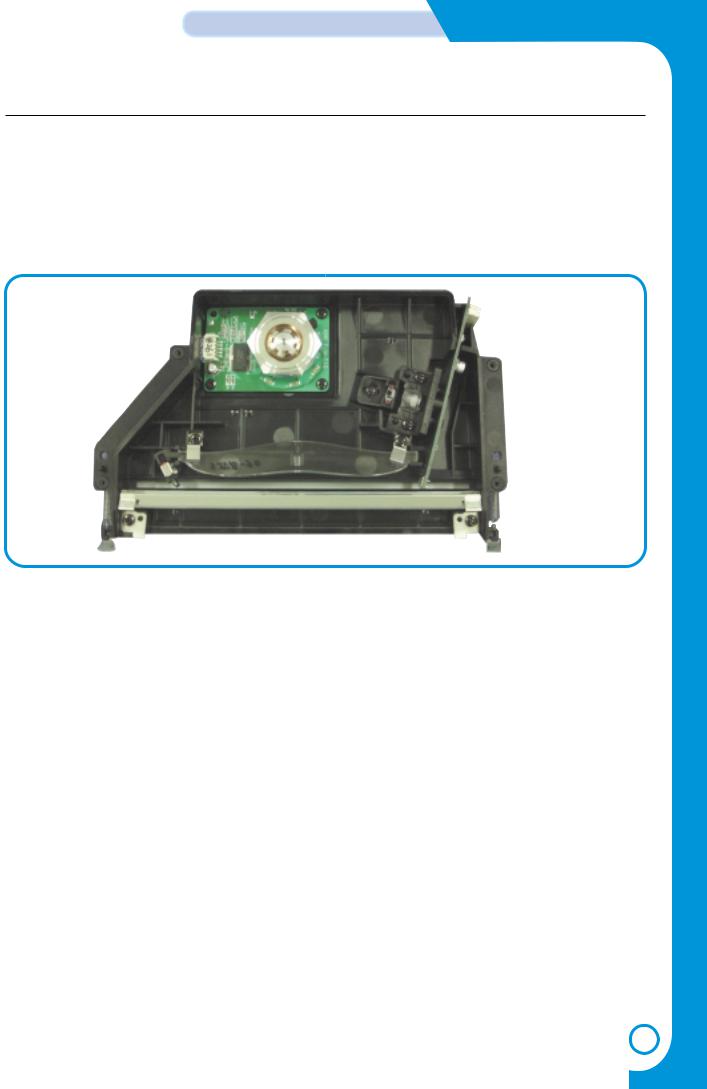

4.2.6 LSU (Laser Scanner Unit)

The LSU is controlled by the video controller. It converts the received video data to pulsed laser light that is scanned onto the surface the OPC drum using a rotating polygon mirror. This creates the latent image on

the drum surface. The OPC drum rotates at the same speed as the paper is fed. When the edge of the polygon mirror is detected, the LSU generates the /HSYNC signal. The CPU syncs the left margin of the image to this signal. After detecting the /HSYNC signal, the image data is sent to the LSU to begin transfer of the image left margin to the paper.

Each surface of the polygon mirror provides one line for scanning.

|

Service Manual |

WorkCentre PE16 |

July 2003 |

Summary of Product

4.2.7 Toner Cartridge

The xerographic process creates a visual image from the latent image. The Toner Cartridge contains the OPC Drum, developer, and toner components in one unit. The OPC unit contains the OPC drum and charging roller. The developer unit contains toner, toner cartridge, supply roller, developing roller, and blade (Doctor blade).

-Developing Method: Non magnetic 1 element contacting method

-Toner: Non magnetic 1 element shatter type toner

-The life span of toner: 3,000 sheets (IDC Pattern/A4 standard)

-Toner remaining amount detecting sensor: None

-OPC Cleaning: Collect the toner by using electric charge + FILM OPC

-Management of excess toner: Collect the toner by using electric charge (Cleanerless TypeNo excess toner)

-OPC Drum protecting Shutter: None

-Classifying device for toner cartridge: ID is classified by interruption of the frame channel.

Service Manual

July 2003 WorkCentre PE16

Loading...

Loading...