Sony MKS-7471X, BZS-7200X, BZS-7510X, BZS-7540X, BZS-8560X Installation Manual

...

SWITCHER PROCESSOR PACK

MVS-8000X-C

MVS-7000X-C

MULTI FORMAT SWITCHER PROCESSOR

MVS-8000X

MVS-7000X

HK-PSU05

MKS-7171X

MKS-7471X

MKS-8170X

MKS-8440X

BZS-7200X

BZS-7510X

BZS-7540X

BZS-7561X

BZS-8560X

MKS-7210X

MKS-8110X

MKS-8180X

MKS-8450X

BZS-7420X

BZS-7520X

BZS-7541X

BZS-8200X

MKS-7470X

MKS-8160X

MKS-8210X

BZS-7500X

BZS-7530X

BZS-7560X

BZS-8420X

INSTALLATION MANUAL

1st Edition (Revised 2)

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

MVS-8000X (SY) Serial No. 10001 and Higher

MVS-7000X (SY) Serial No. 10001 and Higher

HK-PSU05 (SY) Serial No. 10001 and Higher

MKS-8110X (SY) Serial No. 10001 and Higher

MKS-8160X (SY) Serial No. 10001 and Higher

MKS-8170X (SY) Serial No. 10001 and Higher

MKS-8180X (SY) Serial No. 10001 and Higher

MKS-8210X (SY) Serial No. 10001 and Higher

MKS-8440X (SY) Serial No. 10001 and Higher

MKS-8450X (SY) Serial No. 10001 and Higher

MKS-7171X (SY) Serial No. 10001 and Higher

MKS-7210X (SY) Serial No. 10001 and Higher

MKS-7470X (SY) Serial No. 10001 and Higher

MKS-7471X (SY) Serial No. 10001 and Higher

BZS-8200X

BZS-8420X

BZS-8560X

BZS-7200X

BZS-7420X

BZS-7500X

BZS-7510X

BZS-7520X

BZS-7530X

BZS-7540X

BZS-7541X

BZS-7560X

BZS-7561X

MVS-8000X/7000X

Attention-when the product is installed in Rack:

For kundene I Norge

1. Prevention against overloading of branch circuit

When this product is installed in a rack and is supplied

power from an outlet on the rack, please make sure

that the rack does not overload the supply circuit.

2. Providing protective earth

When this product is installed in a rack and is supplied

power from an outlet on the rack, please confi rm that

the outlet is provided with a suitable protective earth

connection.

3. Internal air ambient temperature of the rack

When this product is installed in a rack, please make

sure that the internal air ambient temperature of the

rack is within the specifi ed limit of this product.

4. Prevention against achieving hazardous condition

due to uneven mechanical loading

When this product is installed in a rack, please make

sure that the rack does not achieve hazardous condition due to uneven mechanical loading.

5. Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer

to the specifi cations of the Operation Manual.

Dette utstyret kan kobles til et IT-strømfordelingssystem.

FORSIKTIG

For å redusere risikoen for støt, plugg inn strømtilførselsledningene i hver sin kurs, med separat jording.

6. When performing the installation, keep the following space away from walls in order to obtain

proper exhaust and radiation of heat.

Front, Right and Left: 10 cm (4 inches) or more.

c

. For safety, do not connect the connector for peripheral

device wiring that might have excessive voltage to the

following port(s).

: NETWORK A (CTRL) connector

: NETWORK B (DATA) connector

: NETWORK C

*

connector (MVS-8000X only)

: FM DATA connector

Follow the instructions for the above port(s).

. When you connect the NETWORK A (CTRL), NET-

WORK B (DATA), NETWORK C (MVS-8000X only),

and FM DATA connectors of the unit to peripheral

device, use a shielded-type cable to prevent malfunction due to radiation noise.

* Not supported.

MVS-8000X/7000X

1 (P)

Table of Contents

Manual Structure

Purpose of this manual .................................................................. 2

Related manuals ............................................................................ 2

Contents ........................................................................................ 2

1. Installation

1-1. Operating Environment ................................................... 1-1

1-2. Power Supply ..................................................................1-1

1-2-1. Power Specifi cations .............................................. 1-1

1-2-2. Recommended Power Cord ................................... 1-2

1-3. Installation Space (External dimensions) ........................ 1-3

1-3-1. MVS-8000X ..........................................................1-3

1-3-2. MVS-7000X ..........................................................1-4

1-4. Installing the Options ...................................................... 1-5

1-4-1. Installing the Plug-in Boards .................................1-6

1-4-2. Installing the Connector Board .............................. 1-8

1-4-3. Installing the HK-PSU05 ..................................... 1-10

1-4-4. Installing the Software Options ...........................1-10

1-5. Rack Mounting .............................................................. 1-11

1-5-1. MVS-8000X ........................................................ 1-11

1-5-2. MVS-7000X ........................................................1-13

1-6. Matching Connectors ....................................................1-15

1-6-1. MVS-8000X ........................................................1-15

1-6-2. MVS-7000X ........................................................1-16

1-7. Input/Output Signals of Connectors ..............................1-17

1-8. Checks on Completion of Installation ...........................1-19

1-8-1. Description of On-board Switches and LEDs...... 1-19

1-9. System Connection ....................................................... 1-46

2. Service Overview

2-1. Troubleshooting...............................................................2-1

2-2. Periodic Inspection and Maintenance .............................2-1

2-2-1. Periodic Inspection ................................................2-1

2-2-2. Cleaning ................................................................. 2-2

2-3. About the Data Backup Capacitor ................................... 2-2

MVS-8000X/7000X

1

Purpose of this manual

Related manuals

Manual Structure

This manual is the installation manual of Switcher Processor Pack MVS-8000X-C/

MVS-7000X-C and their optional boards and units.

This manual is intended for use by trained system and service engineers, and describes the information on installing the MVS-8000X-C/MVS-7000X-C system.

The following manuals are prepared for MVS-8000X-C/MVS-7000X-C and their

optional boards and units.

. Operation Manual (Supplied with MVS-8000X-C/MVS-7000X-C)

This manual describes the application and operation of MVS-8000X-C/MVS7000X-C.

. System Setup Manual (Available on request)

This manual describes the information that is required to connect the MVS-8000X/

MVS-7000X/MVE-9000/MKS-8700/CCP-8000 to the MVS-8000 system, and to

start up the system.

If this manual is required, please contact your local Sony Sales Offi ce/Service Cen-

ter.

Contents

. Maintenance Manual (Available on request)

This manual describes the detailed service information.

If this manual is required, please contact your local Sony Sales Offi ce/Service Cen-

ter.

This manual is organized by following sections.

Section 1 Installation

This section describes the operating environment, power supply, installation space,

installation of optional boards and units, rack mounting, connectors, input and

output signals of connectors, checking upon completion of installation, and system

confi guration.

Section 2 Service Overview

This section describes the troubleshooting and periodic inspection and maintenance.

2

MVS-8000X/7000X

Section 1

Installation

1-1. Operating Environment

Operating guaranteed temperature : +5 dC to +40 dC

Performance guaranteed temperature : +10 dC to +35 dC

Operating humidity : 10 % to 90 %

(relative humidity)

Storage temperature : _20 dC to +60 dC

Mass (when all options are installed) :

MVS-8000X : Approx. 58 kg

MVS-7000X : Approx. 49 kg

Prohibited locations for installation

. Areas where the unit will be exposed do direct sunlight

or any other strong lights.

. Dusty areas

. Areas subject to vibration.

. Areas with strong electric or magnetic fi elds.

. Areas near heat sources.

. Areas subject to electrical noise.

. Areas subject where is subjected to static electricity.

Ventilation

The inside of the MVS-8000X/MVS-7000X is cooled by a

fan (right side).

The power supply can be damaged if the exhaust vent (right

side) and air intake (front panel) are blocked or the fan is

stopped.

Therefore, leave a blank space of more than 10 cm in the

front and both sides of the MVS-8000X.

1-2. Power Supply

1-2-1. Power Specifi cations

A switching regulator is used for the power supply of this

unit. The voltage within the range of 100 V to 240 V can be

used without changing the supply voltage.

Power requirements : AC 100 to 240 V ? 10 %

Power frequency : 50/60 Hz

Current consumption (when all options are installed) :

MVS-8000X : 15 to 6.5 A

MVS-7000X : 15 to 6.5 A

m

. As the inrush current at turn-on is a maximum 100 A (at

100 V)/175 A (at 230 V), the capacity of the AC power

source must be commensurate with this load.

If the capacity of the AC power is not adequately large,

the AC power source braker will operate or the unit will

abnormally operate.

. The MVS-8000X contains the three power supply units

as the standard confi guration. A maximum of four power

supply units may be installed. When starting up the

MVS-8000X, be sure to turn on the power of three or

more power supply units.

. The MVS-7000X contains the two power supply units as

the standard confi guration. A maximum of four power

supply units may be installed. When starting up the

MVS-7000X, be sure to turn on the power of two or

more power supply units.

MVS-8000X/7000X

1-1

1-2-2. Recommended Power Cord

w

. Use the approved Power Cord (3-core mains lead)/Appli-

ance Connector/Plug with earthing-contacts that conforms

to the safety regulations of each country if applicable.

. Use the Power Cord (3-core mains lead)/Appliance

Connector/Plug conforming to the proper ratings (Voltage, Ampere).

If you have questions on the use of the above Power Cord/

Appliance Connector/Plug, please contact your local Sony

Sales Offi ce/Service Center.

c

. Never use an injured power cord.

. Plugging the power cord in the AC inlet, push as far as it

will go.

For customers in the U.S.A and Canada

1 Power cord, 125 V 10 A (2.4 m) : ! 1-551-812-31

1

AC inlet

For customers in the all European countries

1 Power cord, 250 V 10 A (2.4 m) : ! 1-782-929-12

1

AC inlet

1-2

MVS-8000X/7000X

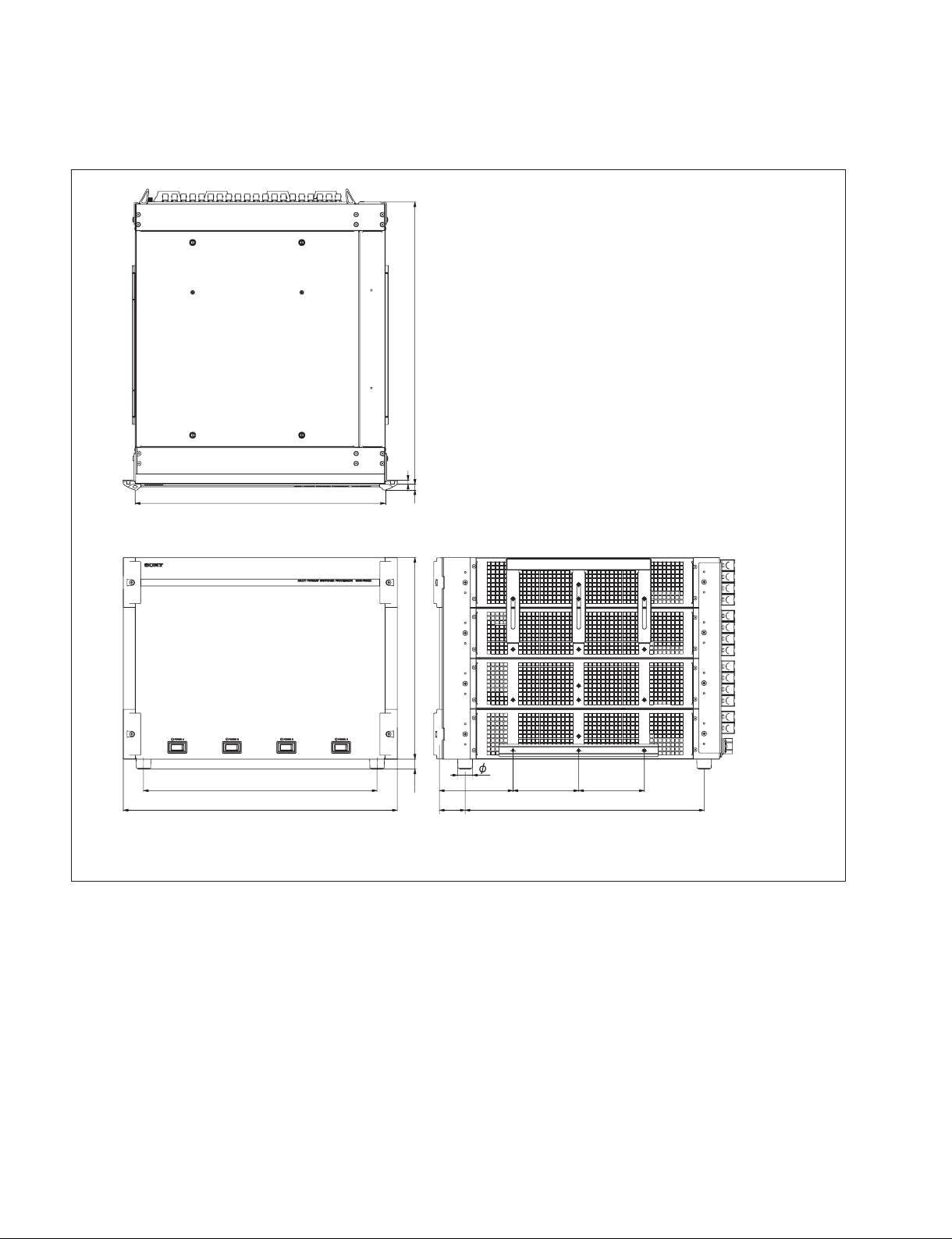

1-3. Installation Space (External dimensions)

1-3-1. MVS-8000X

497

7

440

410.8

482

10

443.6 (10U)17.5

26

129.5 115.5115.5

45.2 420.4

Unit : mm

MVS-8000X/7000X

1-3

1-3-2. MVS-7000X

497

7

440

410.8 129.5 115.5 115.5

482

10

26

17.5 354.7 (8U)

45.2 420.4

Unit: mm

1-4

MVS-8000X/7000X

1-4. Installing the Options

MVS-7000X Option List

The MVS-8000X-C/MVS-7000X-C is shipped from the

factory with the necessary option boards (refer to the

following table) already installed in accordance with the

specifi ed system confi guration.

The following options are available for the MVS-8000X/

MVS-7000X.

MVS-8000X Option List

Name of option Board confi guration

Plug-in board

(Front)

MKS-8110X

20 Input Board

MKS-8160X

Output Board Set

MKS-8170X

DME Interface Board Set

MKS-8180X

Cross Point Board Set

MKS-8210X

Mix/Effect Board

MKS-8440X

Frame Memory Board Set

MKS-8450X

Format Converter Board

HK-PSU05

Power Supply Unit

BZS-8200X

Multi Program 2 Software

BZS-8420X

Color Correction Software

BZS-8560X

Switcher Upgrade Software

*1: Currently M/E4 is not supported.

*1

_

OUT-35A board CNO-38 board

XPT-32 board CNI-37 board

XPT-31A board CNI-37 board

MIX-53 board

MY-118 board CN-3235 board

FC-112 board

__

__

__

__

Connector

board (Rear)

CNI-37 board

CNO-37 board

_

_

Name of option Board confi guration

MKS-7171X

DME Output Connector Board

MKS-7210X

Mix/Effect Board

MKS-7470X

DME Board Set

MKS-7471X

Additional DME Board

MKS-8110X

20 Input Board

MKS-8160X

Output Board Set

MKS-8440X

Frame Memory Board Set

MKS-8450X

Format Converter Board

HK-PSU05

Power Supply Unit

BZS-7200X

Multi Program 2 Software

BZS-7420X

Color Correction Software

BZS-7500X

Switcher Upgrade Software

BZS-7510X

Switcher Upgrade Software

BZS-7520X

Switcher Upgrade Software

BZS-7530X

Switcher Upgrade Software

BZS-7540X

DME Upgrade Software

BZS-7541X

DME Upgrade Software

BZS-7560X

Switcher Upgrade Software

BZS-7561X

DME Upgrade Software

Plug-in board

(Front)

_

MIX-53 board

DVP-53 board

XPT-32 board

DVP-53 board

_

OUT-35A board CNO-38 board

MY-118 board CN-3235 board

FC-112 board

__

__

__

__

__

__

__

__

__

__

__

Connector

board (Rear)

CNO-37 board

_

_

_

CNI-37 board

_

MVS-8000X/7000X

1-5

1-4-1. Installing the Plug-in Boards

c

Be sure to turn off the POWER switch before starting

installation work.

If installation work is started with the POWER switch left

on, it may cause electrical shock or damage to printed

circuit boards.

Each plug-in board of the Production Switcher Processor

MVS-8000X/MVS-7000X is allocated to a specifi c slot

into which they must be installed. Check to see that the

respective plug-in boards are installed in their respective

slots.

The name of the board is shown near the eject lever at the

right-most end of each plug-in board.

Names of the plug-in boards and the slot numbers, to which

the plug-in boards are allocated, are shown on the

Extract PWB stopper assembly inside the front panel of the

MVS-8000X Install the respective plug-in boards according to this instruction.

c

. Check to see that connectors of the plug-in boards are

securely inserted into the mother board (MVS-8000X:

MB-1150 board, MVS-7000X: MB-1151 board) without

loose contact.

If any plug-in board is inserted into the incorrect slot, it

causes a system error and the system will not work

correctly.

. After installing the plug-in board, the software must be

installed. Install the software same version as the MVS8000X/MVS-7000X.

For installing the software, refer to the user’s guide of

the MVS-8000X/MVS-7000X system.

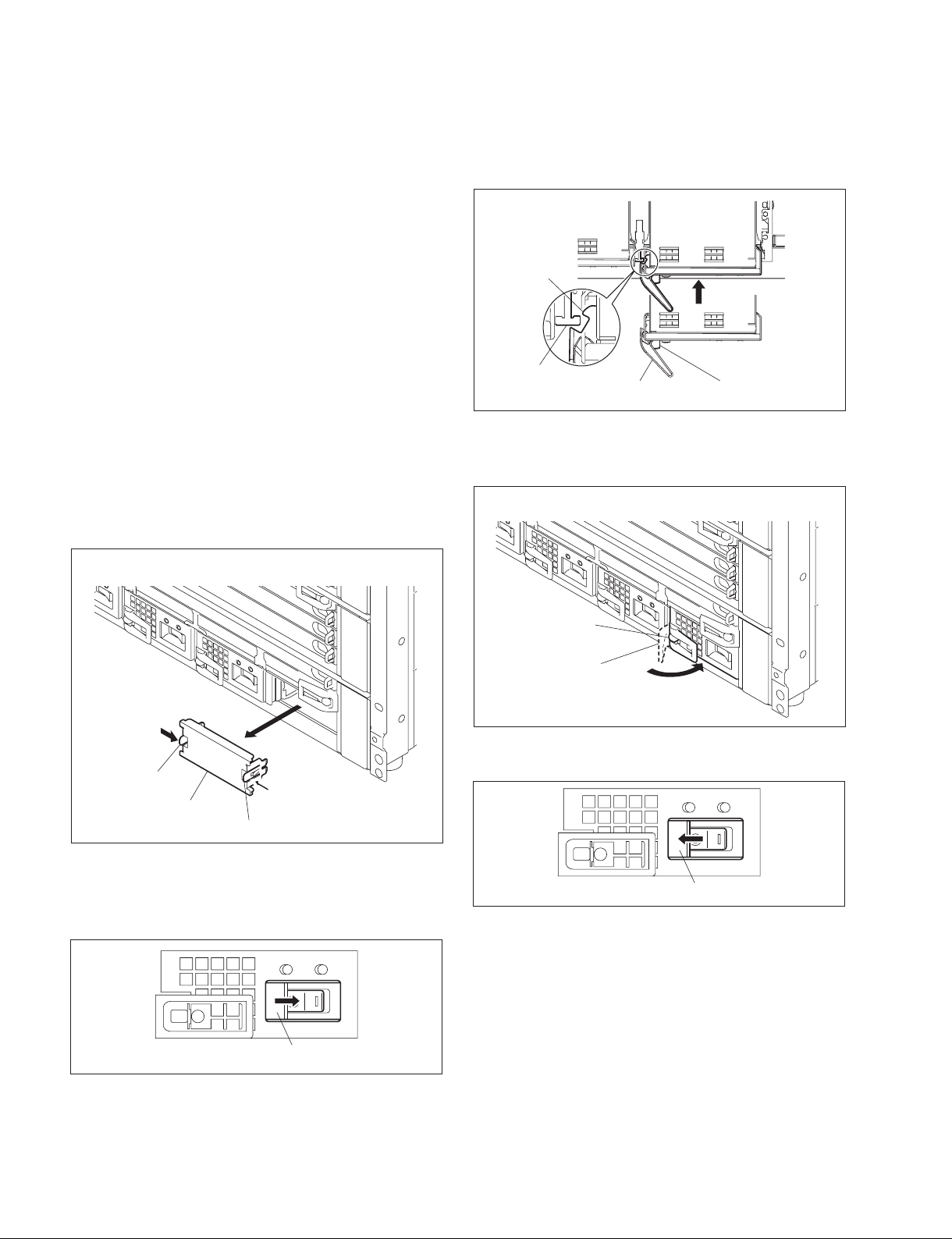

Installation Procedure

1. Turn off the main power of this unit (MVS-8000X)

and disconnect the AC power cord from the wall outlet.

2. Loosen the four screws (with drop-safe) and remove

the front panel to the arrow.

This figure shows MVS-8000X

Screw (with

drop-safe)

Screw (with

Front panel

drop-safe)

3. Push the black panel lock toward the (1) direction to

unlock, pull the knob toward the (2) direction an

remove the blank panel.

n

Store the removed blank panel in a safe place.

This figure shows MVS-8000X

1-6

Blank panel

Lock

1

2

Knob

MVS-8000X/7000X

4. While the eject levers are opened as shown in the illustration, insert the plug-in board into the board guide rail.

n

While the eject levers are opened as shown in the illus-

tration, insert the plug-in board into the board guide rail.

This figure shows MVS-8000X

Board guide rail

Board guard

Short Rib

Long Rib

MVS-8000X Option List

Name of option Name of board Slot on the front side

MKS-8160X OUT-35A board 14

MKS-8170X XPT-32 board 3

MKS-8180X XPT-31A board 6

*1

MKS-8210X

MIX-53 board 1, 2, 4

MKS-8440X MY-118 board 16

MKS-8450X FC-112 board 11, 12

*1: Installation order of MIX-53 board

First board: Slot no. 8 (standard)

Second board: Slot no. 7 (standard)

Third board: Slot no. 4 (option)

Fifth board: Slot no. 2 (option)

Sixth board: Slot no. 1 (option)

MVS-7000X Option List

Name of option Name of board Slot on the front side

MKS-7210X *1 MIX-53 board 5, 6, 9

MKS-7470X DVP-53 board 3

XPT-32 board 4

MKS-7471X DVP-53 board 2

MKS-8160X OUT-35A board 12

MKS-8440X MY-118 board 13

MKS-8450X FC-112 board 10

Eject lever

*1: Installation order of MIX-53 board

First board: Slot no. 9 (option)

Second board: Slot no. 6 (option)

Third board: Slot no. 5 (option)

MVS-8000X/7000X

1-7

5. Close the both eject levers at a time, when the eject

lever claws reach the A position (1).

And push the eject levers (2) until the unlock buttons

pop out.

1-4-2. Installing the Connector Board

Service Tool

Lever unlock jig : Part No. 4-193-124-01

This figure shows MVS-8000X

1. Insert the protrusion of the lever unlock jigs into the

red groove of the blank panel's rear levers (1) and

while pushing the lever unlock jigs, open the rear

levers outward to unlock.

This figure shows MVS-8000X

Lever unlock jig

Lever unlock jig

Blank panel

A

Eject lever Eject lever

2

3

Eject lever

Unlock button Unlock button

11

2

A

3

Unlock button

1 1

Lever unlock jig

Rear leverRear lever

1-8

MVS-8000X/7000X

2. While the rear levers are opened, remove the blank

panel.

m

. Store the removed blank panel in a safe place.

. In case there is a blank panel consecutive in steps

above (in a unit), remove these blank panel too.

This figure shows MVS-8000X

In case there is a blank panel consecutive in steps

above (in a unit), remove these blank panel too.

Rear lever

Rear lever

Blank panel

4. Push the rear levers inward until a click sound is made

and they are locked.

This figure shows MVS-8000X

Rear lever

Rear lever

Unit

3. While the rear levers are opened as shown in the

illustration, insert the plug-in board into the board

guide rail.

n

Insert making sure the board's upper and lower spring

plates do not catch on the board.

This figure shows MVS-8000X

Spring plate

Plug-in board

MVS-8000X Option List

Name of option Name of board Slot on the rear side

MKS-8110X CNI-37 board 6, 7, 8, 9, 10, 11

MKS-8160X CNO-38 board 14

MKS-8170X CNI-37 board 1

CNO-37 board 2

MKS-8180X CNI-37 board 3

MKS-8440X CN-3235 board 16

MVS-7000X Option List

Name of option Name of board Slot on the rear side

MKS-7171X CNO-37 board 3

MKS-8110X CNI-37 board 2, 6, 7, 8

MKS-8160X CNO-38 board 10

MKS-8440X CN-3235 board 12

5. Install the blank panel removed once in the slot on one

step.

MVS-8000X/7000X

1-9

1-4-3. Installing the HK-PSU05

The HK-PSU05 is used after it is installed in the MVS8000X or the MVS-7000X.

n

Before installing the HK-PSU05, be sure to turn off the

main power. If the HK-PSU05 is installed while the main

power is turned on, it can result in electrical shock or

damage to printed circuit boards.

4. Push the unlock button, and open the eject lever.

5. Insert the HU-PSU05 into the slot, and push until the

eject lever claws catch the chassis.

Claw

Installation procedure

1. Remove the front panel of the MVS-8000X/MVS7000X.

(Refer to Section 1-4-1.)

2. While pushing either of blank panel's knobs toward the

(1) position, remove by pulling toward the (2)

position.

This figure shows MVS-8000X

Left

1

Knob

Blank panel

2

Right

1

Knob

Chassis

Eject lever

Unlock button

6. Push the unlock button, as shown in the illustration it

is in the locked position.

This figure shows MVS-8000X

Unlock button

Eject lever

7. Slide the switch cover left to open.

3. Turn OFF the power switch and close the switch cover

by sliding it right. If the switch is ON, the switch cover

will not slide and the unlock button cannot be pressed.

Switch cover

1-10

Switch cover

1-4-4. Installing the Software Options

For the installation procedure of the software options

BZS-8200X/8420X/8560X/7200X/7420X/7500X/7510X/

7520X/7530X/7540X/7541X/7560X/7561X, refer to the

MVS-8000X/MVS-7000X System User’s Guide.

MVS-8000X/7000X

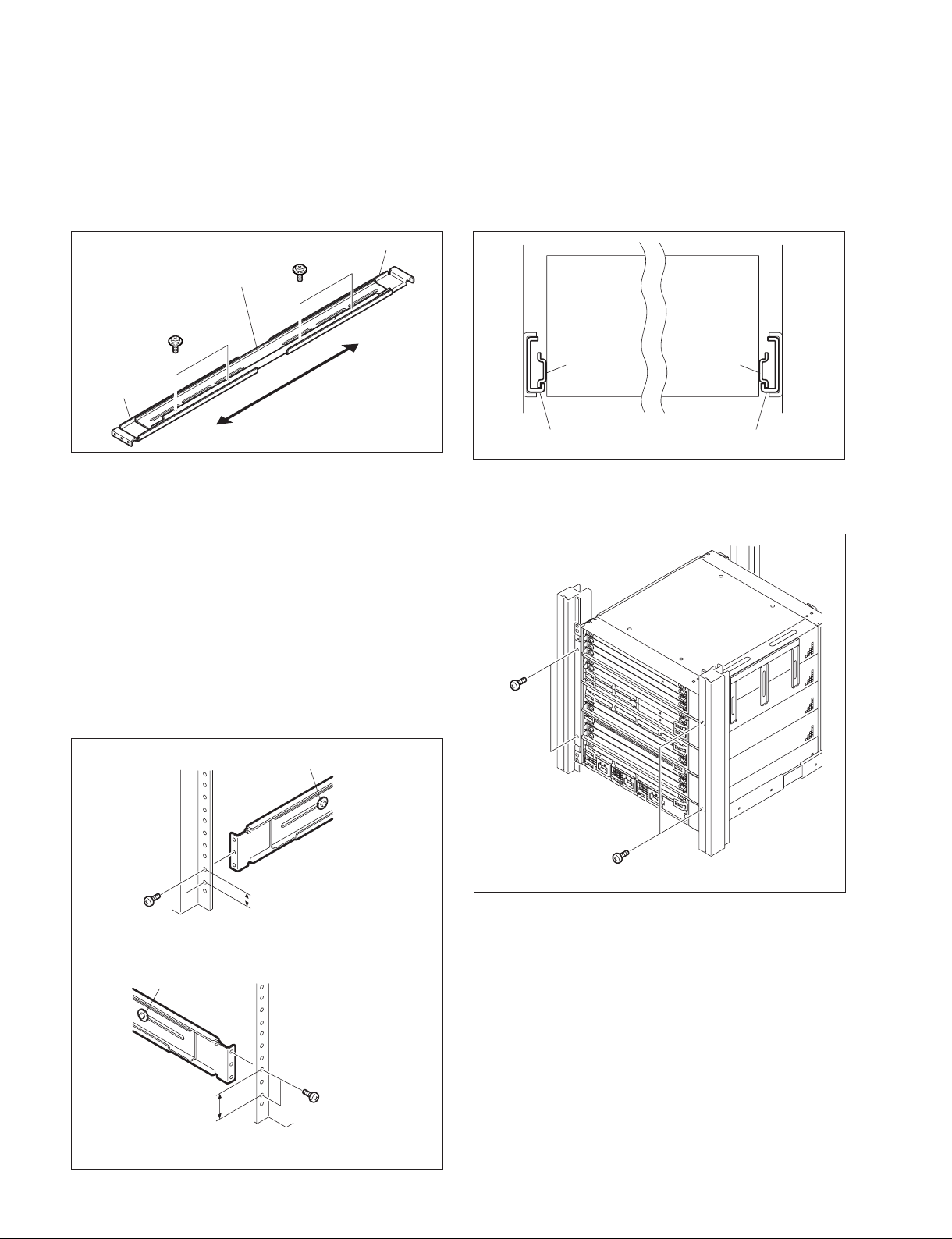

1-5. Rack Mounting

Rack Mounting Procedure

The MVS-8000X/MVS-7000X is mounted in the 19-inch

standard rack.

Precautions for Rack Mounting

w

. To prevent the rack from falling or moving, fi x the rack

on a fl at and steady fl oor and the like using bolts or

others. If the rack falls due to the weight of the equipment, it may cause death or serious injury.

. Be sure to use the rack mount parts (supplied with MVS-

8000X). If not, injury may result and the equipment may

fall due to insuffi cient strength.

. After rack mounting, be sure to tighten the screws on the

rack angle and fi x the unit in the rack. If the screws on

the rack angle are not tightened, the unit may slip from

the rack and fall, causing injury.

w

When mounting the unit in the rack, note the following:

. Be sure to mount in the rack with two persons or more.

. Be careful not to catch your fi ngers or hands in the rack

mount rail or others.

. Hold the bottom of unit and mount in the rack in a stable

position.

w

If several units are mounted in a rack, it is recommended to

install a ventilation fan to prevent temperature rise inside

the rack.

1. Loosen the four screws (+B4 x 8) and remove the four

feet.

Feet

+B4 s8

Feet

+B4 s8

2. Remove the front panel of the equipment.

(Refer to Section 1-4-1.)

3. Attach the rack tool to the side of the equipment using

the specifi ed six screws.

n

Use +B4 x 6 screws. Tighten the screws to the follow-

ing torque.

Tightening torque : 120 x 10_2 N.m {12.2 kgf . cm}

+B4 s6

Rack tool

1-5-1. MVS-8000X

To mount the MVS-8000X in the rack, use the rack mount

parts (supplied with MVS-8000X) and follow the procedure described below.

n

If other than the rack mount parts (supplied with MVS8000X) is used, the unit may not be mounted in the 19-inch

standard rack.

Using parts list (Accessory of the MVS-8000X)

. Rack tool 2pcs

. Support angle 2pcs

. Bracket 4pcs

. Rack tool attaching screw

(+B4 x 6 : 7-682-560-04) 6pcs

. Support angle attaching screw

(+PSW4 x 10 : 7-682-962-01) 8pcs

. Bracket attaching screw

(+B4 x 10 : 7-682-562-04) 8pcs

Other required parts

. Screw for rack mounting

(+B5 x 12 : 7-682-576-09) 4pcs

MVS-8000X/7000X

Rack tool

+B4 s6

1-11

4 Attach the bracket to the support angle by inserting the

specifi ed four screws and loosely tightening.

5. Loosen the screws on the rear of the right and left

adapters and adjust the length of the adapter accordin

to the depth of the rack.

8. Align the groove of the rack tool at the side of the

equipment with the rail, and slide the equipment to the

rear.

n

The rack tools are hooked on the rails as shown below.

+PSW4 s10

Bracket

Support angle

+PSW4 s10

Bracket

n

Maximum depth of bracket : 750 mm

Minimum depth of bracket : 545 mm

6. Attach the right and left adapters to the rack completely using the specifi ed eight screws.

(The illustration below shows the left adapter.)

7. Tighten the screws (+PSW4 x 10 : four screws each

on the right and left) for adjusting the length of the

adapter completely (the screws that were loosened in

step 5).

Rack tool Rack tool

Support angle Support angle

9. Fix the rack angle in the rack using the specifi ed

screws.

+B5 s12

1-12

Front side

+B4 s10

Rear side

+PSW4 s10

31.75

+PSW4 s10

+B5 s12

15.9

10. Attach the front panel to the equipment.

(Refer to Section 1-4-1.)

+B4 s10

Unit:mm

MVS-8000X/7000X

Loading...

Loading...