Lenze 8200 User Manual

EDK82EV303

.6au

Ä.6auä

Information for the operator of the machine

8200 vector 15 ... 30 kW

E82xV153Kxxxxx ... E82xV303Kxxxxx

Frequency inverter

l

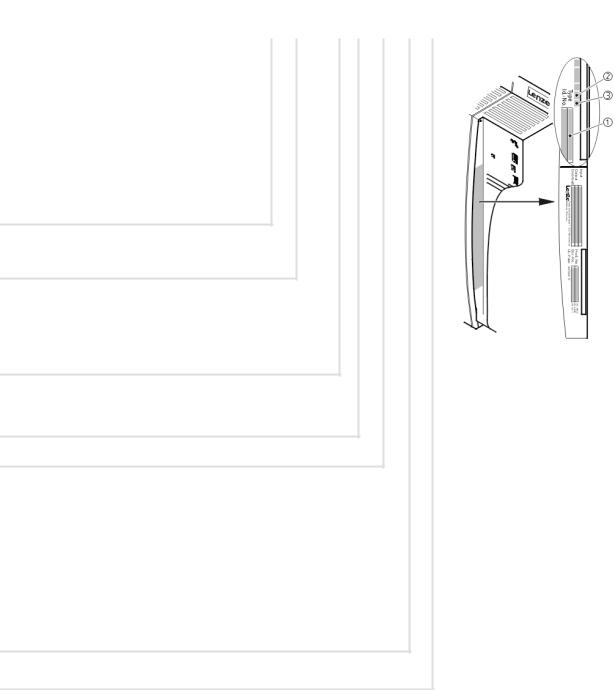

This documentation is valid for ...

... 8200 vector frequency inverters as of nameplate data:

|

|

|

|

• |

‚ |

ƒ |

Nameplate |

|

|

E82 x V |

xxx K |

4 B |

xxx 3x |

3x |

|

||

|

|

|||||||

Product series |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

8200 vector |

|

|

|

|

|||

Type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

E = |

Panel−mounted unit |

|

|

|

||||

C = |

Built−in unit in "cold plate" technique |

|

|

|

||||

D = |

Built−in uni in "push−through" technique |

|

|

|

||||

Design

V = Vector−controlled frequency inverter

Rated power [W]

153 = 15 x 103 W = 15 kW 223 = 22 x 103 W = 22 kW 303 = 30 x 103 W = 30 kW

9300vec112

Voltage class

4 = 400 V / 500 V

Version

Variant

0xx = EMC filter integrated 1xx = For IT systems

2xx = Without EMC filter

x0x = Without "safe standstill" function x4x = With "safe standstill" function xx0 = Not coated

xx1 = Coated

Hardware version

Software version

)Note!

This documentation contains all the information required by the machine operator to run the drive controllers of the 8200 vector series installed in your machine/system.

You may make further use of the information contained in this documentation without asking Lenze for permission if you do not change the contents.

I Tip!

Current documentation and software updates concerning Lenze products can be found on the Internet in the "Services & Downloads" area under

http://www.Lenze.com

© 2007 Lenze Drive Systems GmbH, Hans−Lenze−Straße 1, D−31855 Aerzen

We have compiled all information in this documentation with great care und have checked it with regard to compliance with the hardware and software described. Nevertheless, we cannot entirely exclude deviations. We do not accept legal responsibility or liability for damage possibly resulting therefrom. We will include necessary amendments in the subsequent editions.

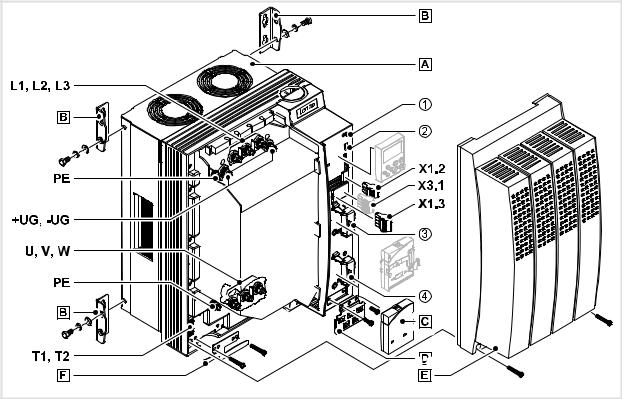

8200vec292 |

Key for overview

Position Description

08200 vector frequency inverter

1 |

Fixing bracket for standard mounting |

|

|

2 |

Blind covers (2 pcs) for the FIF I and FIF II interfaces |

|

|

3 |

EMC shield sheet with fixing screws for shielded control cables |

|

|

4 |

Cover with fixing screws |

|

|

5 |

EMC shield sheet for the motor cable and for the incoming motor temperature monitoring cable |

|

|

T1, T2 |

Connection for PTC or thermal contact (NC contact) of the motor |

|

|

U, V, W, PE |

Motor connection |

|

|

L1, L2, L3, PE |

Mains connection |

|

|

+UG, −UG |

DC supply |

X1.2 |

Terminal strip for connection of relay output K1 |

|

|

X1.3 |

Terminal strip for connection of relay output K2 |

|

|

X3.1 |

Terminal strip for connection of relay output KSR for "safe standstill" (for Bx4x variant only) |

Interfaces and displays

Position |

Description |

Function |

|

• |

2 light−emitting diodes (red, green) |

Status display |

|

|

|

|

|

‚ |

AIF interface |

Slot for communication module |

|

|

(automation interface) |

e. g. E82ZBC keypad |

|

|

|

|

|

ƒ |

FIF I interface |

With cover for operation without function module |

|

|

(function interface) |

or slot for function module |

|

|

|

||

|

|

|

|

|

|

|

|

„ |

FIF II interface |

With cover for operation without function module |

|

|

(function interface) |

or slot for function module |

|

|

|

||

|

|

|

iContents

1 |

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

||

|

1.1 |

General safety and application notes for Lenze controllers . . . . . . . . . . . . . . . . . . |

7 |

|

|

1.2 |

Residual hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

|

|

1.3 |

Definition of notes used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

2 |

Parameter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

||

|

2.1 |

Parameter setting with E82ZBC keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

|

|

2.1.1 |

Installation and commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

|

2.1.2 |

Display elements and function keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

|

|

2.1.3 |

Changing and saving parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

|

2.1.4 |

Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

3 |

Troubleshooting and fault elimination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

||

|

3.1 |

Malfunction of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

|

3.2 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

3.3Fault messages on the keypad or in the parameter setting program

Global Drive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

6 |

l |

EDK82EV303 EN 1.0

Safety instructions |

1 |

General safety and application notes for Lenze controllers

1Safety instructions

1.1General safety and application notes for Lenze controllers

(in accordance with Low−Voltage Directive 2006/95/EC)

For your personal safety

Lenze controllers (frequency inverters, servo inverters, DC speed controllers) and the accessory components can include live and rotating parts − depending on their type of protection − during operation. Surfaces can be hot.

Non−authorised removal of the required cover, inappropriate use, incorrect installation or operation, create the risk of severe injury to persons or damage to material assets.

More information can be obtained from the documentation.

Within the controller there are high energies. Therefore always wear personal protective equipment when working on the live controller (body protection, headgear, eye protection, ear protection, hand guard).

All operations concerning transport, installation, and commissioning as well as maintenance must be carried out by qualified, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report 664 or DIN VDE 0110 and national regulations for the prevention of accidents must be observed).

According to this basic safety information, qualified, skilled personnel are persons who are familiar with the assembly, installation, commissioning, and operation of the product and who have the qualifications necessary for their occupation.

Application as directed

Drive controllers are components which are designed for the installation into electrical systems or machinery. They are not to be used as domestic appliances, but as components only for industrial or professional purposes according to EN 61000−3−2.

When installing the controllers into machines, commissioning (i.e. starting of operation as directed) is prohibited until it is proven that the machine complies with the regulations of the EC Directive 98/37/EC (Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of operation as directed) is only allowed when there is compliance with the EMC Directive (89/336/EEC).

The controllers meet the requirements of the Low−Voltage Directive 73/23/EEC. The harmonised standard EN 61800−5−1 applies to the controllers.

The technical data and information on connection conditions must be obtained from the nameplate and the documentation. They must be observed in any case.

Warning: Drive controllers are products that can be used in drive systems of category 2 according to EN 61800−3. These products can cause radio interferences in residential areas. In this case, special measures are required.

Transport, storage

Please observe the notes on transport, storage and appropriate handling. Observe the climatic conditions according to the technical data.

EDK82EV303 EN 1.0

l 7

Loading...

Loading...