KROHNE IFS5000 User Manual

05/98

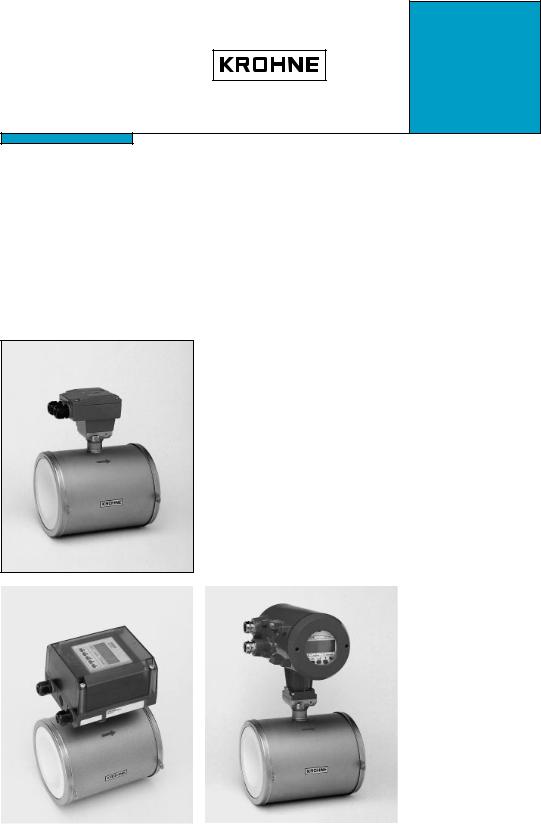

Electromagnetic flowmeters

•Primary heads

•Compact flowmeters

CONTENTS

Installation in the pipeline

Grounding

IFS 5000 F

Installation instructions

PROFIFLUX IFS 5000 F

IFM 5010 K IFM 5020 K IFM 5080 K 1010 K IFM 1080 K

Pages 4-5 and 7-8

Pages 8-9

IFM 5010 K |

|

|

IFM 5080 K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.1M46EA1 059821 Order No. DIN size 7.02142.31.00 US size 7.02142.71.00 0.73.00

Contents

System description |

2 |

|

Product liability and warranty |

2 |

|

Standards and approvals |

2 |

|

Items included with supply |

3 |

|

1 |

Important information for installation: PLEASE NOTE |

4-5 |

2 |

Suggestions for installation |

5 |

3 |

Instrument nameplate |

6 |

4 |

Flowmeter versions |

6 |

5 |

Installation in the pipeline |

7 |

6 |

Torques |

8 |

7 |

Grounding |

8-9 |

8 |

Replacement of separate primary head IFS 1000 F |

10 |

9 |

Spares and order numbers |

10 |

10 |

Technical data |

11 |

11 |

Dimensions and weights |

12-13 |

Notes |

14 |

|

Printed form to accompany flowmeters returned to Krohne |

15 |

|

System description

PROFIFLUX electromagnetic flowmeters are precision measuring instruments designed for the linear flow measurement of process liquids.

The process liquids must be electrically conductive: ³ 05 mS/cm (³ 10 mS/cm for DN 2.5/1/10”) ³ 20 mS/cm for demineralized cold water

The full-scale range Q100% can be set as a function of the meter size:

DN 2.5 - 100 / 1/10” - 4” Q100% = 0.01 - 340 m3/hr = 0.03 - 1500 US Gal/min This is equivalent to a flow velocity of 0.3 - 12 m/s, or 1 - 40 ft/s.

Product liability and warranty

PROFIFLUX electromagnetic flowmeters are designed solely for measuring the volumetric flowrate of electrically conductive, liquid process products.

Special codes and regulations apply to their use in hazardous locations, and these are referred to in the special “Ex” installation and operating instructions (supplied only with hazardous-duty equipment).

Responsibility as to suitability and intended use of these electromagnetic flowmeters rests solely with the operator.

Improper installation and operation of the flowmeters (systems) may lead to loss of warranty.

In addition, the “General conditions of sale” forming the basis of the purchase contract are applicable.

If PROFIFLUX flowmeters need to be returned to Krohne, please note the information given on the last-but-one page of this manual. Krohne regret that they cannot repair or check your flowmeter(s) unless accompanied by the completed form sheet.

Standards and approvals

Please refer to the installation and operating instructions for the signal converter.

2

Items included with supply

IFS 5000 F |

IFM 5010 K, IFM 5020 K and IFM 5080 K |

||

primary head |

compact flowmeters |

||

• |

primary head |

• |

compact flowmeter |

|

in the size as ordered |

|

in the size as ordered |

• certificate of calibration data |

• certificate of calibration data |

||

• installation material as specified |

• installation material as specified |

||

• |

in the following table |

• |

in the following table |

installation instructions |

installation instructions |

||

•installation and operating instructions for the signal converter

Flowmeter |

|

|

|

|

Scope of supply ... |

X = Standard |

O = Option |

|

||

|

|

|

|

|

|

|

|

|

|

|

Size of |

Pipe flanges |

max. allowable |

... with |

... with |

... with |

2) |

... without |

2) |

||

measuring |

|

|

operating |

centering |

stud bolts |

grounding |

grounding |

|

||

tube |

|

|

pressure 1) |

material |

|

rings E and |

rings but with |

|

||

to ... |

|

|

|

|

|

|

gaskets ... |

gaskets D3 |

|

|

Meter sizes |

Pressure rating |

|

|

|

|

|

|

and wires V |

|

|

|

|

flange class |

bar |

psig |

|

|

D1 |

D1+D2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

... DIN 2501 (BS 4504) |

|

|

|

|

|

|

|

||

DN 002.5 – 10 |

DN |

010,15 |

PN 40 |

≤ 40 ≤ 580 |

2 x ring |

4 x M12 |

X |

|

|

DN 015 |

DN |

015 |

PN 40 |

≤ 40 ≤ 580 |

2 x ring |

4 x M12 |

X |

|

|

DN 025 |

DN |

025 |

PN 40 |

≤ 40 ≤ 580 |

2 x ring |

4 x M12 |

O |

X |

|

DN 040 |

DN |

040 |

PN 40 |

≤ 40 ≤ 580 |

4 x sleeve |

4 x M16 |

O |

X |

|

DN 050 |

DN |

050 |

PN 40 |

≤ 40 ≤ 580 |

4 x sleeve |

4 x M16 |

O |

X |

|

DN 080 |

DN |

080 |

PN 40 |

≤ 40 ≤ 580 |

6 x sleeve |

8 x M16 |

O |

X |

|

DN 100 |

DN |

100 |

PN 16 |

≤ 16 ≤ 230 |

6 x sleeve |

8 x M16 |

O |

X |

|

000 |

|

|

PN 25 |

≤ 25 ≤ 360 |

6 x sleeve |

8 x M20 |

O |

X |

|

... ANSI B 16.5 |

|

|

|

|

|

|

|

|

|

1/10”–3/8” |

1/2” |

|

150 lb |

≤ 20 |

≤ 290 |

2 x ring |

4 x 1/2” |

X |

|

|

|

|

300 lb |

≤ 40 |

≤ 580 |

2 x ring |

4 x 1/2” |

X |

|

1/2” |

1/2” |

|

150 lb |

≤ 20 |

≤ 290 |

4 x sleeve |

4 x 1/2” |

O |

X |

|

|

|

300 lb |

≤ 40 |

≤ 580 |

2 x ring |

4 x 1/2” |

O |

X |

1” |

1” |

|

150 lb |

≤ 20 |

≤ 290 |

4 x sleeve |

4 x 1/2” |

O |

X |

|

|

|

300 lb |

≤ 40 |

≤ 580 |

4 x sleeve |

4 x 5/8” |

O |

X |

11/2” |

11/2” |

150 lb |

≤ 20 |

≤ 290 |

4 x sleeve |

4 x 1/2” |

O |

X |

|

|

|

|

300 lb |

≤ 40 |

≤ 580 |

4 x sleeve |

4 x 3/4” |

O |

X |

2” |

2” |

|

150 lb |

≤ 20 |

≤ 290 |

4 x sleeve |

4 x 5/8” |

O |

X |

|

|

|

300 lb |

≤ 40 |

≤ 580 |

6 x sleeve |

8 x 5/8” |

O |

X |

3” |

3” |

|

150 lb |

≤ 20 |

≤ 290 |

4 x sleeve |

4 x 5/8” |

O |

X |

|

|

|

300 lb |

≤ 40 |

≤ 580 |

6 x sleeve |

8 x 3/4” |

O |

X |

4” |

4” |

|

150 lb |

≤ 20 |

≤ 290 |

6 x sleeve |

8 x 5/8” |

O |

X |

|

|

|

300 lb |

≤ 25 |

≤ 360 |

6 x sleeve |

8 x 3/4” |

O |

X |

1)For ANSI pipe flanges the max. allowable operating pressure is dependent on the process temperature, see Sect. 10 “Technical data”.

2)For arrangement of gaskets and connection of wires V, see Section 7 “Grounding”.

3

1 Important information for installation: PLEASE NOTE

•Handling

Do not lift flowmeter by the signal converter housing or the terminal box.

Do not set flowmeter down on signal converter housing or terminal box.

•Use only solventless detergents to clean the signal converter housing (polycarbonate).

•Temperatures

For operating pressure and vacuum load based on flange standards, see Section 10 “Technical data“.

|

|

|

Ambient temperature |

Process temperature |

|

|

|

|

|

|

|

||

Compact systems |

Standard |

-25 to +60 °C (-13 to + 140 °F) |

-60 to + 060 °C (-76 to + 140 °F) |

|||

|

|

|

-25 to +40 °C (-13 to + 104 °F) |

-60 to + 140 °C (-76 to + 284 °F) |

||

|

|

EEx-version |

-25 to +60 °C (-13 to + 140 °F) |

-20 to + 160 °C (- |

4 to + 140 °F) |

|

|

|

|

-25 to +40 °C (-13 to + 104 °F) |

-20 to + 140 °C (- |

4 to + 284 °F) |

|

|

IFS 5000 F (separate): |

Standard |

-25 to +60 °C (-13 to + 140 °F) |

-60 to + 180 °C (-76 to + 356 |

°F) |

|

|

|

EEx version |

-25 to +60 °C (-13 to + 140 °F) |

-20 to + 160 °C (- |

4 to + 140 |

°F) |

|

|

|

-25 to +40 °C (-13 to + 104 °F) |

-20 to + 150 °C (- |

4 to + 302 |

°F) |

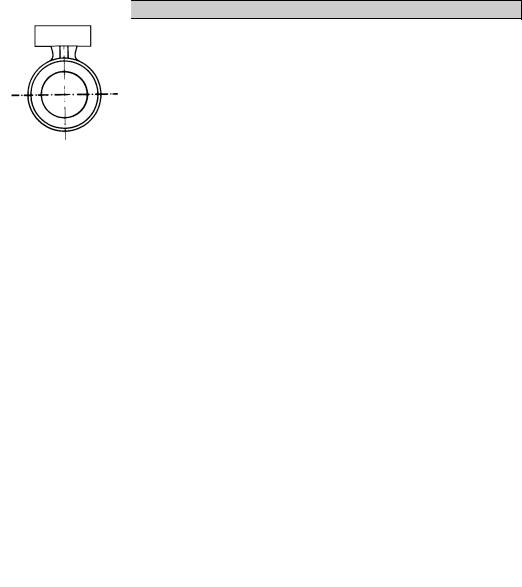

•Location and position as required, but electrode axis X – • – • – • – X

must be approximately horizontal in a horizontal pipe run.

Y terminal box or converter housing

Y

X X

•Measuring tube must be completetly filled at all times.

•Direction of flow is arbitrary. Arrow on flowmeter can normally be ignored.

For exceptions, refer to Section ”Factory settings” in the installation and operating instructions for the signal converter.

•Stud bolts and nuts: to fit, make sure there is sufficient room next to the pipe flanges.

•Vibration: support the pipeline on both sides of the compact flowmeter. Level of vibration in conformity with IEC 068-2-34:

20-500 Hz, ran dom / 2 g rms / 30 minutes / x, y, z directions.

•Do not expose to direct sunlight,

fit a sunshade if necessary, not included with flowmeter, to be provided by customer.

4

•Strong electromagnetic fields, avoid in vicinity of flowmeter.

•Straight inlet run minimum of 5 × DN and outlet run minimum of 2 × DN,

(DN = meter size), measured from the electrode axis.

•Vortex and corkscrew flow: increase length of inlet and outlet runs or install flow conditioners.

•Mixing different process liquids: install flowmeter upstream of mixing point or at an adequate distance downstream (minimum of 30 x DN), otherwise display may be unsteady.

•Plastic pipes and internally coated metal pipelines: grounding rings required, see Section 7 ”Grounding”.

•Insulated pipeline: do not insulate flowmeter.

•Zero setting not necessary. To check, it should be possible to set ”zero” flow velocity

in the completely filled measuring tube. Shutoff valves should therefore be provided either downsteam of the flowmeter or upsteam and downstream of the flowmeter.

2 Suggestions for installation

To avoid measuring errors due to gas/air inclusion or to pipe runing empty please observe the following:

Highest point of pipe run

(Air bubbles collect in measuring tube - faulty measurements!)

Preferred locations

Downpipe

”Zero” flow velocity. Line drained. Faulty

measurements!

Horizontal pipe run

Install in slightly ascending pipe section. If not possible, assure adequate velocity to prevent air, gas or vapor from collecting in

upper part of flow tube.

Open feed or discharge

Install meter in low section of pipe.

Downpipe over 5 m (16 ft) length

Install air valve X downstream of flowmeter.

5m |

ft16 |

> |

> |

Long pipeline

Always install control and shutoff valves downstream of flowmeter.

Pumps

Never install flowmeter on pump suction side.

open discharge

5

Loading...

Loading...