KROHNE UFM3030EEx User Manual

© KROHNE 06/2005 |

DIN A4: 7.10028.31.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

7.30942.32.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

GR

GR

Addition to the installation and operating instructions

Universal 3-Beam ultrasonic flowmeter

UFM 3030 K/…EEx compact ultrasonic flowmeter

UFC 030 F/…EEx ultrasonic flow converter

UFS 3000 F/…EEx ultrasonic flow sensor

Electromagnetic flowmeters

Variable area flowmeters

Mass flowmeters

Ultrasonic flowmeters

Vortex flowmeters

Flow controllers

Level measuring instruments

Pressure and temperature

Heat metering

Communications technology

Switches, counters, displays and recorders

Engineering systems & solutions

Subject to change without notice.

General advice on safety

•Do not install, operate or maintain this flow meter without reading, understanding and following the factory-supplied instructions, otherwise injury or damage may result.

•Read these instructions carefully before starting installation and save them for future reference.

•Observe all warnings and instructions marked on the product.

•Use only mains supply with protective earthing connected.

•Do not use the product with removed covers under wet conditions.

•Consider handling and lifting instructions to avoid damage.

•Install the product securely and stable.

•Install and connect cabling proper to exclude damage or harmful situations.

•If the product does not operate normally, refer to the service instructions or refer to qualified KROHNE service engineers.

•There are no operator-serviceable parts inside the product.

The following symbols may appear in this manual or on the product

ATTENTION: Refer to operating and installation instructions!

DANGER: Risk of electric shock!

PROTECTIVE EARTH (PE) conductor terminal!

These terms may appear in this manual or on the instrument:

WARNING statement: Identify conditions or practice that could result in injury or loss of life.

CAUTION statement: Identify conditions or practice that could result in damage to the instrument or other property.

2 |

UFM 3030 |

Disclaimer

•This document contains important information on the instrument. KROHNE attempts to be as accurate and up-to-date as possible but assumes no responsibility for errors or omissions. Nor does KROHNE make any commitment to update the information contained herein. This manual and all other documents are subject to change without prior notice.

•KROHNE will not be liable for any damage of any kind by using its instrument, including, but not limited to direct, indirect, incidental, punitive and consequential damages.

•This disclaimer does not apply in case KROHNE has acted on purpose or with gross negligence. In the event any applicable law does not allow such limitations on implied warranties or the exclusion of limitation of certain damages, you may, if such law applies to you, not be subject to some or all of the above disclaimer, exclusions or limitations.

•Any instrument purchased from KROHNE is warranted in accordance with the relevant product documentation and our Terms and Conditions of Sale.

•KROHNE reserves the right to alter the content of its documents, including this disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable in any way for possible consequences of such changes.

Product liability and warranty

•Responsibility for suitability and intended use of this ultrasonic flow meter rests solely with the user. Improper installation and operation of the flow meter (system) may lead to loss of warranty.

•In addition, the Terms and Conditions of Sale are applicable and are the basis for the purchase contract.

•If flow meters need to be returned to KROHNE, please note the information given on the last pages of the installation and operating instructions. KROHNE regrets that they cannot repair or check flow meter(s) unless accompanied by the completed form (see last pages of the installation and operating instructions).

Items included with order

•UFM 3030 ultrasonic flow meter, comprising of a flow sensor, UFS 3000 and a flow converter, UFC 030 either built together as a compact system or supplied as two separate pieces, in the size as indicated on the packaging box

•Signal cable (only in case of a separate system)

•Special tool for opening the converter housing

Documentation supplied

•Condensed installation and operating manual

•For Ex-units: installation and operating instructions for use in hazardous areas

•Instruction card: overview of the configuration menu and display markers

•Service Handbook

•Approval documents, unless reproduced in the installation and operating instructions

•Report of factory settings of the flow converter

•Certificate of system calibration data

This instrument is developed and manufactured by:

KROHNE Altometer

Kerkeplaat 12

3313 LC Dordrecht

The Netherlands

For information, maintenance or service please contact your nearest local KROHNE representative.

UFM 3030 |

3 |

WARNING! No changes may be made to the devices. Unauthorized changes might affect the explosion safety of the devices.

Be sure to follow these instructions!

IMPORTANT! • The prescriptions and regulations as well as the electrical data described in the EC type examination certificate must be obeyed.

•Beside the instructions for electrical installations in non-hazardous locations according to the applicable national standard (equivalent of HD 384 or IEC 364, e.g. VDE 0100), especially the regulations in EN 60079-14 "Electrical installations in hazardous locations" or equivalent national standard (e.g. DIN VDE 0165 Part 1) must be strictly followed.

•Installation, establishment, utilization and maintenance are only allowed to be executed by personnel with an education in explosion safety!

These additional instructions are an extension to the installation and operating instructions and only apply to the EEx versions of the UFM 3030 K, UFS 3000 F and UFC 030 F ultrasonic flowmeters. All technical information as described in the installation and operating instructions is applicable, when not specifically excluded, completed or replaced by the instructions in these additional instructions.

4 |

UFM 3030 |

Table of contents

1 |

System Components |

6 |

1.1 |

General information |

6 |

1.2 |

Compact flowmeter |

6 |

1.3 |

Flow sensor |

7 |

1.4 |

Flow converter |

8 |

1.5 |

Electrical data |

11 |

2 |

Technical data |

13 |

2.1 |

Mains supply |

13 |

2.2 |

Signal in-/outputs |

13 |

2.3 |

Ultrasonic sensor circuits |

13 |

2.4 |

Environment temperatures |

13 |

2.5 |

Power dissipation |

13 |

3 |

Electrical connections |

14 |

3.1 |

Safety instructions |

14 |

3.2 |

Power supply connection |

14 |

3.3 |

Equipotential bonding |

14 |

3.4 |

Standard versions |

15 |

3.5 |

Namur versions |

16 |

3.6 |

MODIS versions |

17 |

4 |

Operation of the flow converter |

20 |

4.1 |

Operation of the flow converter |

20 |

4.2 |

Connecting cables |

20 |

4.3 |

Connection diagrams |

21 |

4.4 |

Namur NE 43 settings |

25 |

5 |

Service and maintenance |

26 |

5.1 |

Introduction |

26 |

5.2 |

Replacement of electronics unit or power fuse(s) |

26 |

5.3 |

Replacement of electronics unit |

27 |

5.4 |

Replacement of mains fuse and analogue input fuses |

27 |

UFM 3030 |

5 |

1System Components

1.1General information

The UFM 3030 ultrasonic flowmeters in compact and separate design are in accordance with the European Directive 94/9 EC (ATEX 100a) and approved for hazardous classified locations of Zone 1 and 2 by the PTB conform to the European Standards of the EN 500xx series, approval number: PTB 03 ATEX 2021 X.

1.2Compact flowmeter

The standard UFM 3030 K-EEx compact flowmeter is designed for ambient temperatures (i.e. Ta) in the range of -40°C up to +65°C. The MODIS version of type UFM 3030 K/i-EEx with intrinsically safe signal in-/outputs is suitable for ambient temperatures in the range from -20°C up to +65°C.

The maximum allowed process liquid (medium) temperature is restricted by the combustible atmosphere that (possibly) surrounds the apparatus, determined by the temperature class of the atmosphere, see table below.

Temperature class |

Maximum process liquid temperature at |

|

|

||

|

Ta ≤ 40°C |

Ta ≤ 50°C |

|

Ta ≤ 60°C |

Ta ≤ 65°C |

T6 |

80°C |

80°C |

|

80°C |

80°C |

T5 |

95°C |

95°C |

|

95°C |

95°C |

T4 |

130°C |

130°C |

|

125°C |

100°C |

T3 |

180°C |

165°C |

|

125°C |

100°C |

The UFM 3030 K/…-EEx compact flowmeter consists of the UFC 030…-EEx flow converter that is screwed on top of the UFS 3000-EEx flow sensor by four hexagonal socket head cap screws of size M6. The standard (i.e. non-MODIS) compact flowmeter is marked with one of the codes below:

Default:

•II 2G EEx de [ib] IIC T6…T3 for the terminal compartment of the flow converter housing in type of protection increased safety "e" according to EN 50019.

Optional (only if explicitly ordered!):

•II 2G EEx d [ib] IIC T6…T3 for the terminal compartment of the flow converter housing designed as flameproof enclosure "d" according to EN 50018.

The MODIS version of the compact flowmeter, i.e. UFM 3030 K/i-EEx, is marked with one of the following codes:

Default MODIS:

•II 2G EEx de [ia/ib] IIC T6…T3 for the terminal compartment of the flow converter housing in type of protection increased safety "e" according to EN 50019.

Optional MODIS (only if explicitly ordered!):

•II 2G EEx d [ia/ib] IIC T6…T3 for the terminal compartment of the flow converter housing designed as flameproof enclosure "d" according to EN 50018.

For service purposes the electronics unit of the two beam ultrasonic converter UFC 500…-EEx unit can be replaced by the new UFC 030…-EEx electronics unit.

6 |

UFM 3030 |

1.3Flow sensor

1.3.1 Standard instruments

The UFS 3000…-EEx flow sensor is the default measuring unit of the UFM 3030 (3-beam) ultrasonic flowmeters. It contains the ultrasonic sensor (three pairs of opposite transducers) in type of protection intrinsic safety category "ib" according to EN 50020. All sensor circuits are wired by separate coaxial cables and connected through SMB connectors, which are marked by the respective numbers 1.1, 1.2, 2.1, 2.2, 3.1 and 3.2. The flow sensors are available in size DN25 (1”) up to DN3000 (120”) in diameter.

The UFS 3000…-EEx flow sensor is used in combination with the flow converter unit type UFC 030…-EEx, which is either directly mounted on top of the flow sensor (compact meter) or installed on a distance and connected via a cable (separate version). In the last case the flow sensor as well as the flow converter unit are both provided with a junction box, in which the SMB connectors are mounted.

The UFS 3000 F/…-EEx flow sensor in separate design is the measuring unit of the separate flowmeter system. There is a standard version, suitable for process liquid temperatures from -25°C up to 180°C and an extended temperature (XT) version UFS 3000 F/XT-EEx, which allows a maximum process temperature of 220°C. Both versions are designed for an ambient temperature in the range of -40°C up to +65°C.

The UFS 3000 F/…-EEx flow sensors in separate design are classified according to the temperature classification table below.

Temperature class |

Maximum process liquid temperature at Ta = 65°C |

|

|

Standard design |

XT-design |

T6 |

80°C |

80°C |

T5 |

95°C |

95°C |

T4 |

130°C |

130°C |

T3 |

180°C |

195°C |

T2 |

N.A. |

220°C |

The UFS 3000 F/…-EEx flow sensors are marked with the explosion safety codes:

•Standard UFS 3000 F-EEx: II 2G EEx ib IIC T6…T3

•XT-version UFS 3000 F/XT-EEx: II 2G EEx ib IIC T6…T2

The intrinsically safe "ib" ultrasonic sensor circuits inside the UFS 3000…-EEx flow sensor have the following maximum values (i.e. entity parameters):

•Maximum input voltage : Vmax = 13.1 V

•Maximum input current : Imax = 600 mA

•Maximum internal capacitance : Ci = 13.1 nF (maximum, 3 sensor circuits)

•Maximum internal inductance : Li = 134 µH (maximum, 3 sensor circuits)

The intrinsical safe sensor circuits of the UFM 3030 K/…-EEx compact flowmeter are only internal circuits and not accessible for the user.

UFM 3030 |

7 |

1.3.2 Optional instruments

The following options are available to support customers that have one or more ultrasonic flowmeter systems (in compact and/or separate design) based on the UFM 500…-EEx series and need to replace the UFC 500…-EEx electronics unit.

Because the intrinsically safe “ib” sensor circuits of UFS 500…-EEx flow sensor have almost the same maximum values (i.e. entity parameters) as the UFS 3000…-EEx, it can also be driven by the UFC 030…-EEx electronics unit. Therefore only four of the six SMB connectors on the front-end printed circuit board of the UFC 030…-EEx electronics unit must be connected to the four SMB connectors of the UFS 500…-EEx flow sensor. For proper functioning must connector number 1.1, 1.2, 2.1 and 2.2 of the UFC 030…-EEx be connected to respective number 4, 3, 1 and 2 of the UFS 500…-EEx flow sensor.

An exception applies to the ALTOSONIC V-version UFS 500 F/5STR-EEx, which can only be driven by five UFC 500…-EEx electronics units.

The intrinsically safe "ib" ultrasonic sensor circuits inside the UFS 500…-EEx flow sensor have the same maximum values (i.e. entity parameters) as the UFS 3000…-EEx, except for the internal capacitance, which is a little smaller, namely: Ci = 7.7 nF (maximum, 2 sensor circuits)

The UFS 500-EEx as part of the UFM 500 K…-EEx compact flowmeter is approved under number PTB 01 ATEX 2015 X and the UFS 500 F/…-EEx flow sensor with a separate design has approval number PTB 01 ATEX 2012 X. See Appendix 1.

1.4Flow converter

The UFC 030…-EEx flow converter consists of an approved cylindrical housing, made of a diecasted aluminium alloy (type AX/P/…-EEx with KEMA No. Ex-99.E.8128 U) or of stainless steel (type VX-EEx with PTB No. Ex-96.D.1068 U). It contains two separate compartments, divided from each other by wall with an integrated encapsulated flameproof terminal feed-through. The housing of the compact version is screwed on top of the flow sensor, the housing of the separate version is screwed on an aluminium or stainless steel wall-mounting bracket. A junction box made of diecasted aluminium alloy or stainless steel is screwed to the side of the bracket by four M6 recessed head screws with internal hexagonal socket set (only applicable for the flow converter in separate design).

The flow converter housing is on both ends closed by a threaded cylindrical cover with O-ring sealing. Coaxial cables of type RG179 or RG316 with SMB plugs at their ends connect the intrinsically safe sensor output circuits of the flow converter to the corresponding SMB male-to-male bulkheads in the junction box.

The equipotential bonding conductor is screwed under the external M5 U-clamp terminal, which is located on the mounting flange at the bottom of the neck of the flow converter housing. The flow converter housing has an ingress protection degree of at least IP67 in accordance with EN 60529.

1.4.1 Electronics compartment

The electronics compartment accommodates the UFC 030…-EEx electronics unit. The compartment is designed with type of protection flameproof enclosure "d" in accordance with EN 50018. It is closed by a flameproof display cover with glass window, which is glued and additionally mechanical supported by a screwed in back-up ring made of aluminum or stainless steel (depends on the material of the housing). The interconnecting part (i.e. neck) at the bottom of the housing contains a flameproof cable feed-through, through which the coaxial cables run. The feed-through provides a flameproof sealing at the bottom of the electronics compartment.

8 |

UFM 3030 |

The UFC 030…-EEx electronics unit is inserted into the electronics compartment with the help of two sliding rubbers that position and fixate the unit at the front of the inside of the housing. Two M4

screws mount the unit and a third M4 screw fixates the brass earth strip at the back-end of the frontend printed circuit board, which contains the integrated voltage/current limiting circuit. The three screws are screwed to the integrated wall inside the electronics compartment. The on the front-end PCB integrated voltage/current limiting circuit provides the ultrasonic sensors inside the flow sensor with type of protection intrinsic safety category "ib" according to EN 50020.

The voltage/current limiting circuit has the following maximum output values:

•Maximum output voltage : VO = 8.15 V

•Maximum output current : IO = 220 mA

•Maximum allowed external capacitance : CO = 1.3 µF

•Maximum allowed external inductance : LO = 0.5 mH

1.4.2 MODIS electronics units

The MODIS electronics units have type designation UFC 030i-EEx and are provided with two MODIS modules. The modules provide intrinsically safe signal input/output circuits, which are accessible by the user for connection in the terminal compartment of the flow converter housing. Three types of modules can be used on the UFC 030i-EEx electronics unit, namely: P-SA (current output), FA-ST (pulse or status output) and F-PA (fieldbus type Profibus).

A combination of two of the above listed modules is installed on the power supply printed circuit board of the MODIS versions of the UFC 030…-EEx electronics.

1.4.3 Terminal compartment

The terminal compartment accommodates seven M4 clamp terminals for connection of the power supply and the signal in-/output circuits. The terminals are separated from each other by insulation plates (eight in total, from which one at each end of the row).

The terminal compartment (default in type of protection increased safety “e”) is standard equipped with two metal cable glands of size M20x1.5 or Pg13.5. The terminal compartment can optionally be provided as a flameproof enclosure “EEx d”, in which case the customer must use pre-certified “EEx d” cable glands or conduits.

For flameproof conduit systems, the terminal compartment must have type of protection flameproof enclosure “d” according to EN 50018. The conduits must be sealed by “EEx d” approved (in accordance with ATEX 100a directive) sealing devices (i.e. stopping boxes) directly at the conduit entrances of the as flameproof enclosure “EEx d” performed terminal compartment.

1.4.4 MODIS terminal design

The connections for the intrinsically safe MODIS input/output circuits consist of four M4 U-clamp terminals, separated from the two power supply terminals by an earthed metal plate, which is screwed to a non-used M4 U-clamp terminal. Eight dividing plates of insulating material in-between the seven terminals and at each end of the row separate the terminals from each other and from the earthed metal housing.

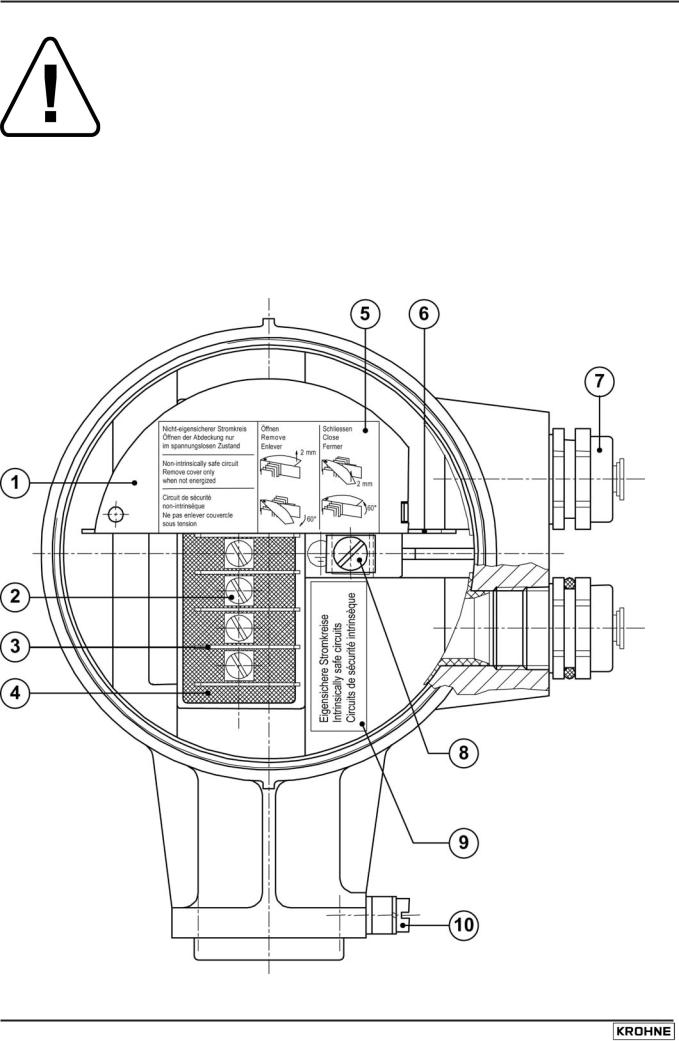

After the power supply cable is connected to the appropriate two terminals, these two terminals are covered by a semi-circular insulating plate to prevent any possible contact with the intrinsically safe MODIS conductors. See figure below.

UFM 3030 |

9 |

“EEx d” approved cable glands are no part of the standard delivery package, but must be provided by the customer himself or ordered explicitly at KROHNE.

1)Semi-circular insulating cover plate

2)U-clamp terminal size M4 (7 in total)

3)Dividing plate of insulating material (8 in total)

4)Flameproof terminal feed-through

5)Sticker with handling instructions for insulating cover plate

6)Metal dividing plate intrinsically safe and non-intrinsically safe terminals

7)Cable gland (size M20x1.5 or Pg13.5) or cable adapter (e.g. M20x1.5 to ½ inch NPT)

8)PE/FE U-clamp terminal size M5

9)Indication sticker for intrinsically safe signal in-/output terminals (MODIS)

10)External U-clamp terminal size M5 for equipotential bonding cable.

Terminal compartment of MODIS versions

10 |

UFM 3030 |

Loading...

Loading...