JLG 4394RT Service Manual

Service & Maintenance Manual

Models

3394RT

4394RT

Prior to S/N 0200191606

excluding S/N’s:

0200186972,

0200187002,

0200187013

3121133

October 6, 2008

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

A.A GENERAL

This section contains the general safety precautions

which must be observed during maintenance of the

aerial platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to

themselves or others, or damage to the equipment.

A maintenance program must be followed to ensure

that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT

APPROVAL BY JLG INDUSTRIES INC., IS A SAFETY

VIOLATION.

The specific precautions to be observed during

maintenance are inserted at the appropriate point in

the manual. These precautions are, for the most

part, those that apply when servicing hydraulic and

larger machine component parts.

Relieve system pressure by cycling the applicable

control several times with the engine stopped and

ignition on, to direct any line pressure back into the

reservoir. Pressure feed lines to system components

can then be disconnected with minimal fluid loss.

A.C MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS

LISTED IN THIS SECTION MAY RESULT IN MACHINE

DAMAGE, PERSONNEL INJURY OR DEATH AND IS A

SAFETY VIOLATION.

• No smoking is mandatory. never refuel during electrical

storms. ensure that fuel cap is closed and secure at all other

times.

• Remove all rings, watches and jewelry when performing any

maintenance.

• Do not wear long hair unrestrained, or loose-fitting clothing

and neckties which are apt to become caught on or entangled

in equipment.

Your safety, and that of others, is the first consideration when engaging in the maintenance of equipment. Always be conscious of weight. Never attempt

to move heavy parts without the aid of a mechanical

device. Do not allow heavy objects to rest in an

unstable position. When raising a portion of the

equipment, ensure that adequate support is provided.

SINCE THE MACHINE MANUFACTURER HAS NO

DIRECT CONTROL OVER THE FIELD INSPECTION

AND MAINTENANCE, SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPERATOR.

A.B HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems operate at extremely high potentially dangerous pressures. Every effort should be made to

relieve any system pressure prior to disconnecting

or removing any portion of the system.

• Observe and obey all warnings and cautions on machine and in

service manual.

• Keep oil, grease, water, etc. wiped from standing surfaces and

hand holds.

• Use caution when checking a hot, pressurized coolant system.

• Never work under an elevated sizzor until platform has been

safely restrained from any movement by blocking or overhead

sling, or boom safety prop has been engaged.

• Before making adjustments, lubricating or performing any

other maintenance, shut off all power controls.

• Battery should always be disconnected during replacement of

electrical components.

• Keep all support equipment and attachments stowed in their

proper place.

• Use only approved, nonflammable cleaning solvents.

3121133 – JLG Lift – a

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

REVISION LOG

Original Issue - April 12, 2002

Revised - May 10, 2002

Revised - August 30, 2002

Revised - October 14, 2002

Revised - March 6, 2003

Revised - October 24, 2003

Revised - April 28, 2004

Revised - August 18, 2004

Revised - August 12, 2005

Revised - October 4, 2005

Revised - March 1, 2006

Revised - May 11, 2006

Revised - October 31, 2006

Revised - April 3, 2007

Revised - October 12, 2007

Revised - January 23, 2008

Revised - March 17, 2008

Revised - October 6, 2008

b – JLG Lift – 3121133

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A.A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-a

A.B Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-a

A.C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-a

SECTION 1 - SPECIFICATIONS

1.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 Machine Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.7 Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.8 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.9 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.10 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.11 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.12 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.13 Operator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

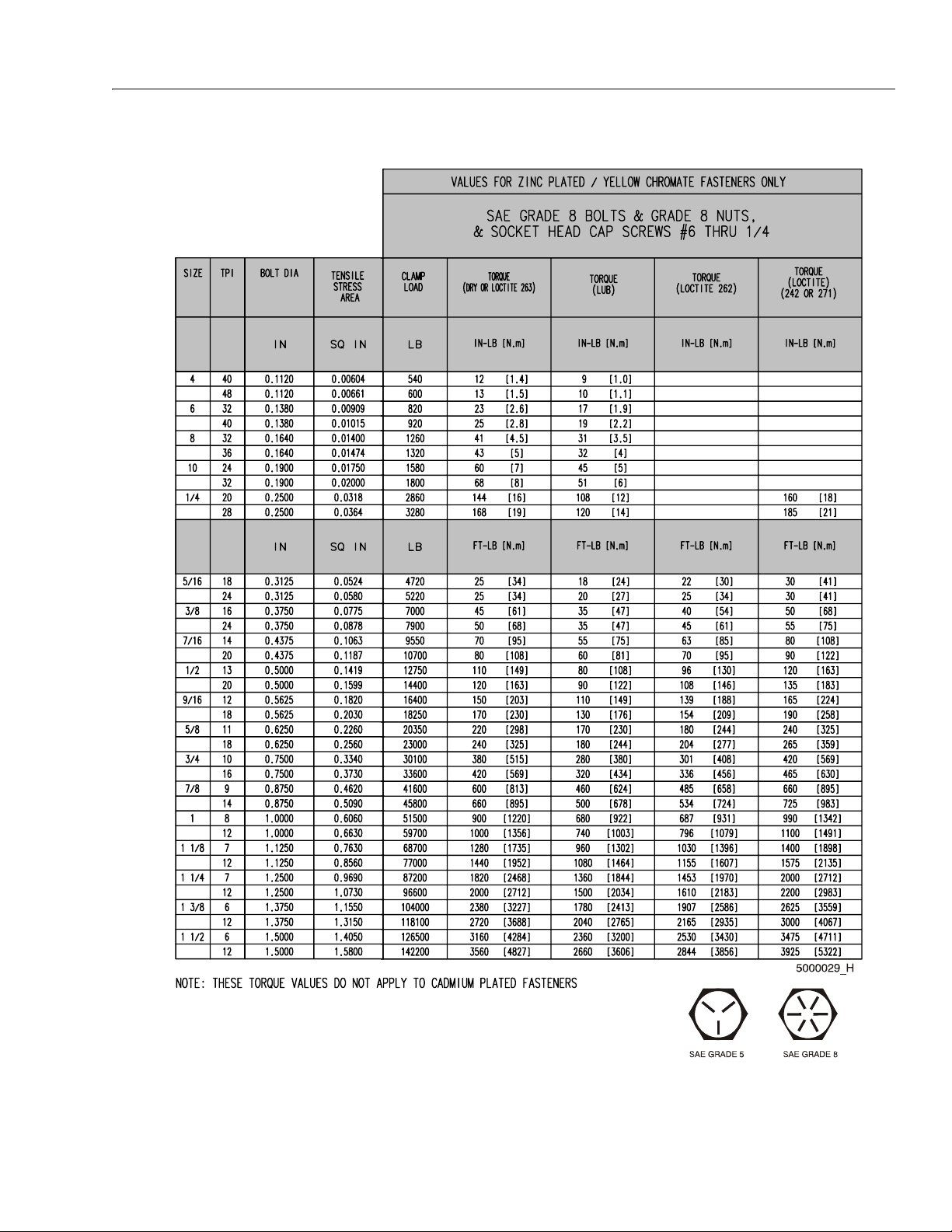

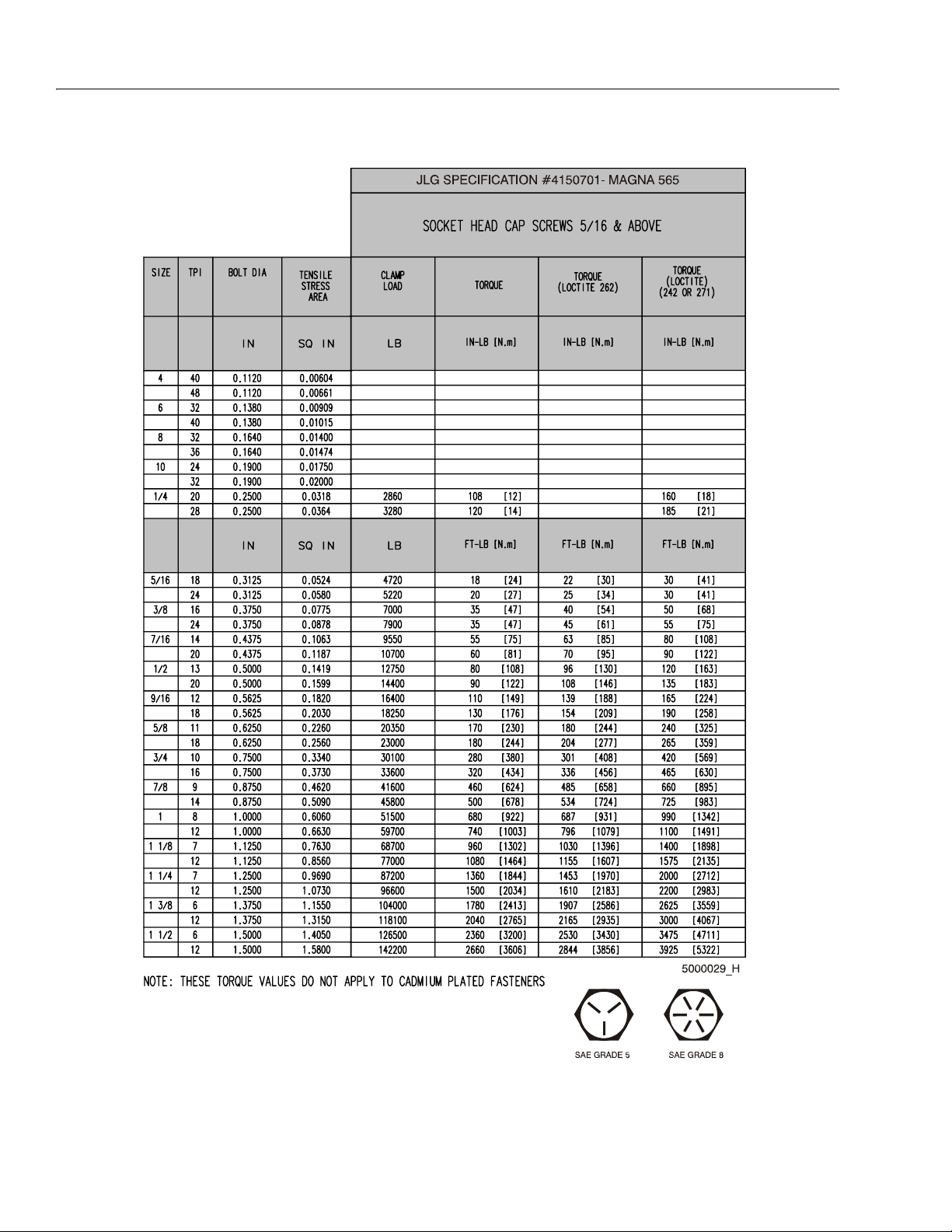

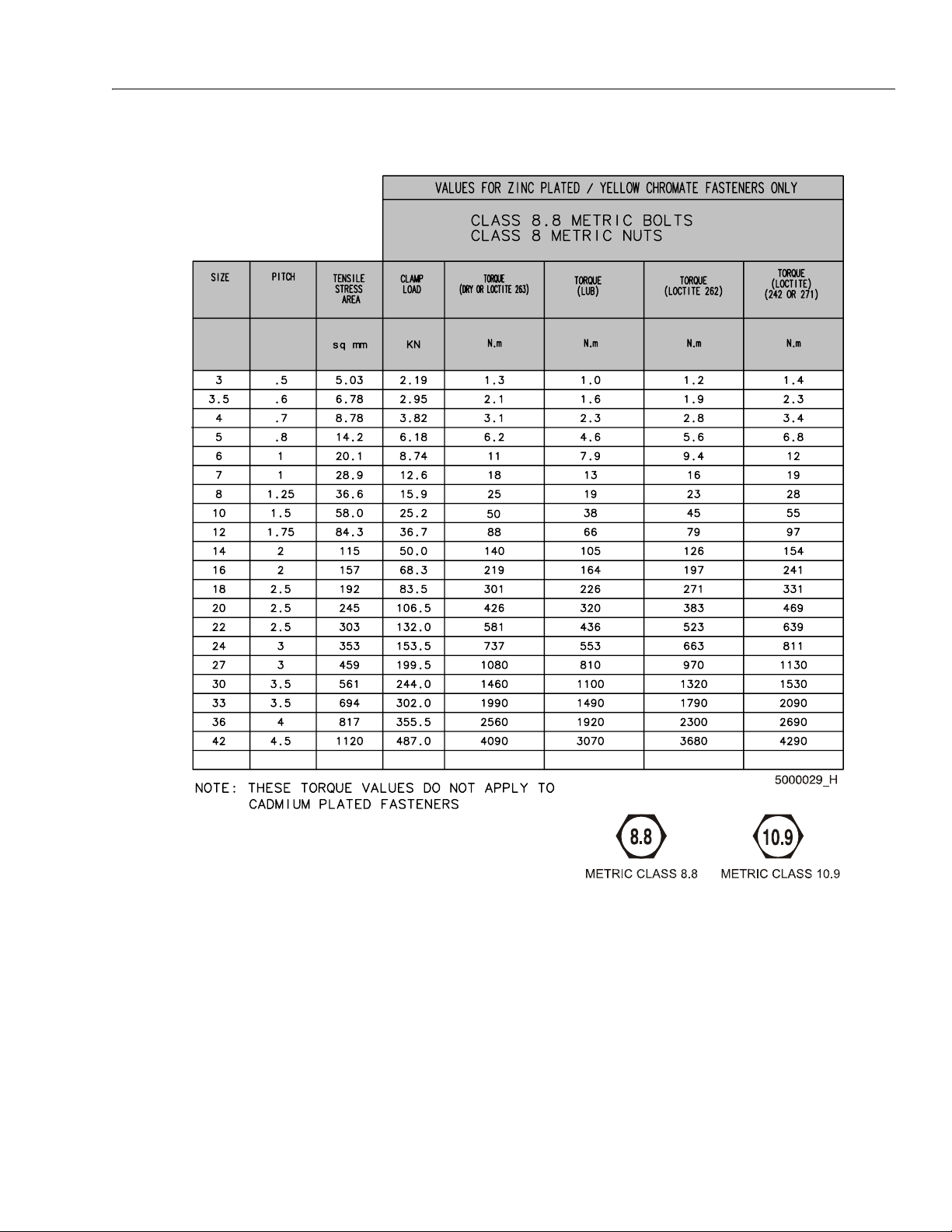

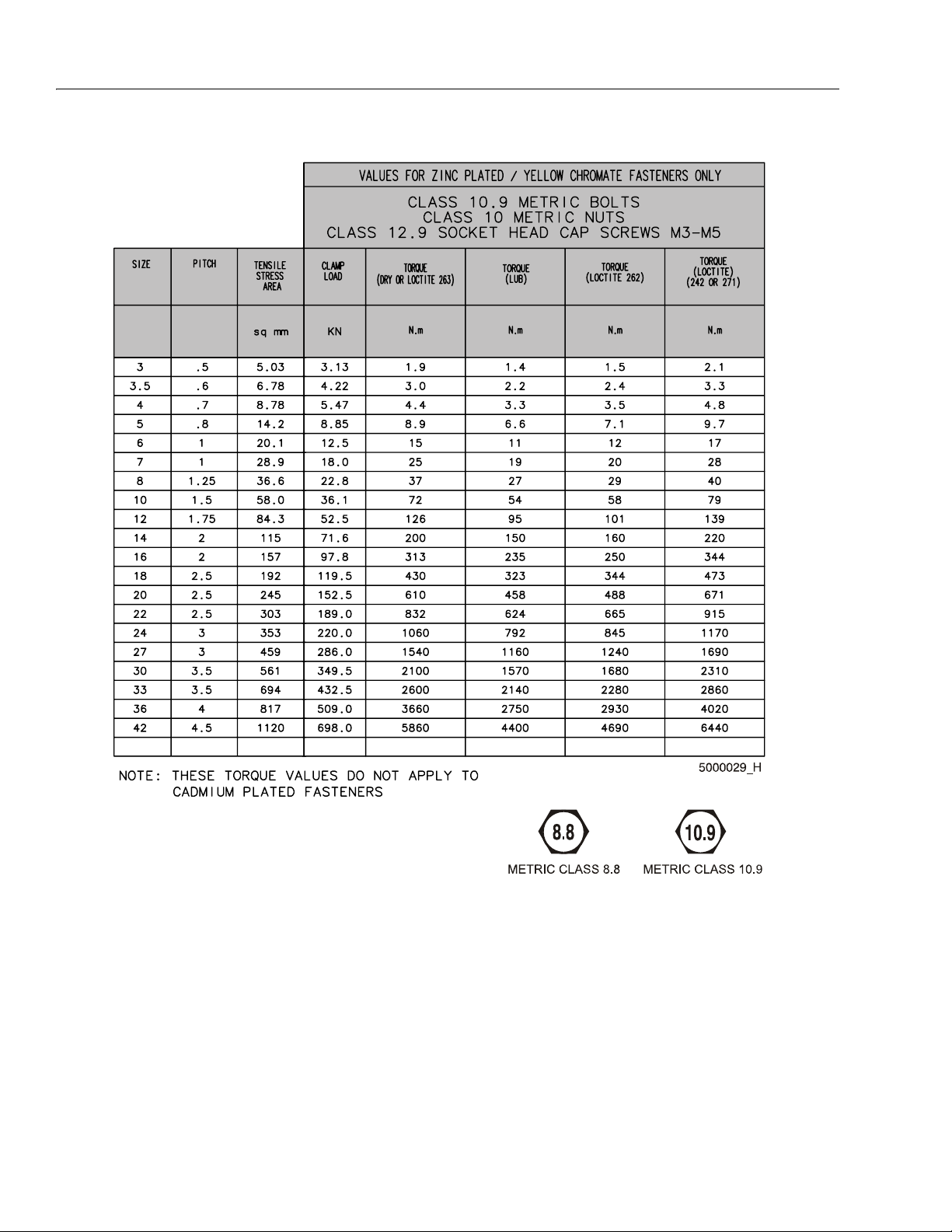

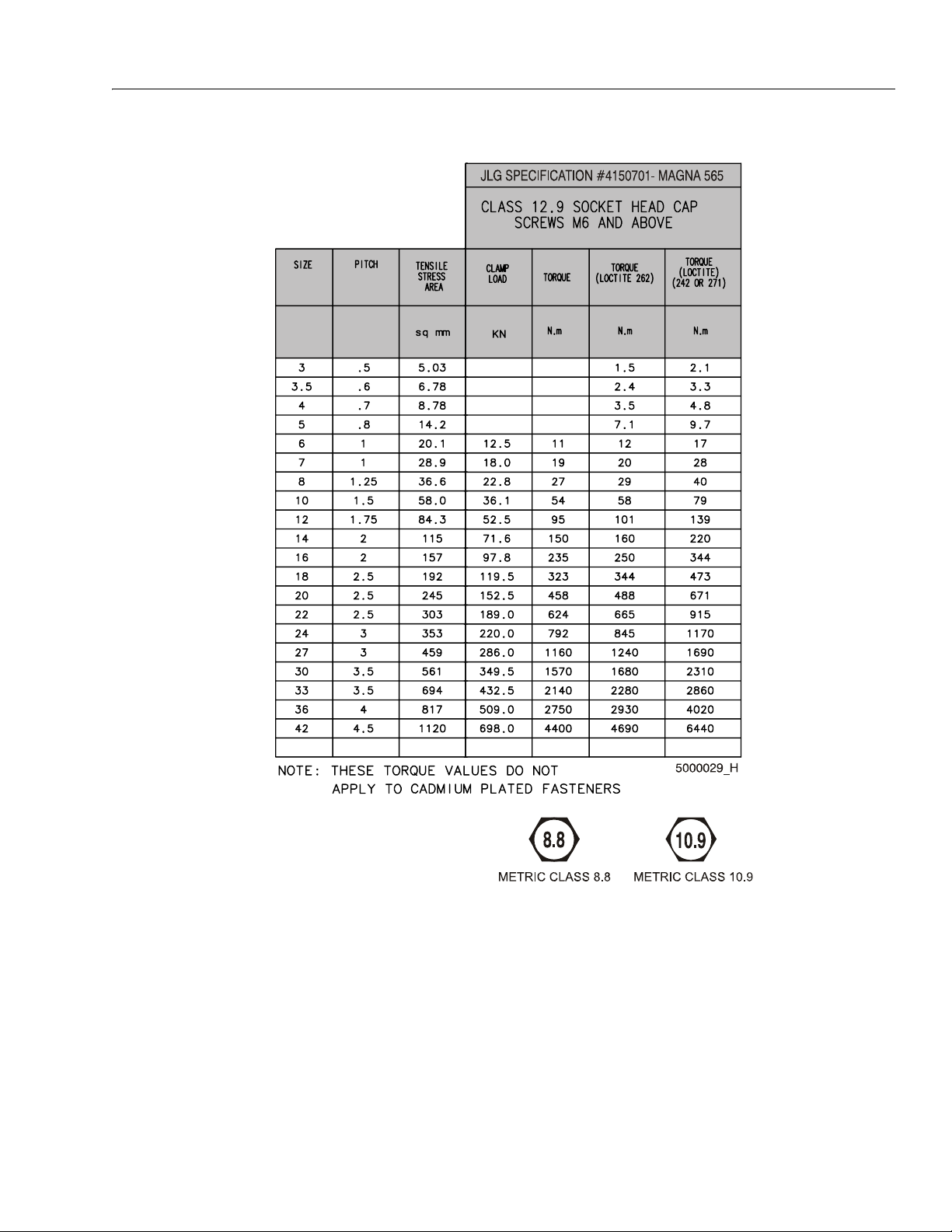

1.14 Torque Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

SECTION 2 - GENERAL

2.1 Machine Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Service and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 Lubrication and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.4 Cylinder Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.5 Pins and Composite Bearing Repair Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.6 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

SECTION 3 - CHASSIS & SCISSOR ARMS

3.1 Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Level Sensor and Analyzer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.4 Integrated Torque/drive hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.5 Dual Fuel/LPG System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

3.6 Ford EFI Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

3.7 Generator - Ford Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-43

3.8 Deutz EMR 2 (S/N 0200138634 to Present) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-44

3.9 Generator - Duetz Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3.10 GM Engine General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-58

3.11 Generator - GM Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-60

3.12 GM Engine Dual Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

3.13 GM Engine Fuel System Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-66

3.14 GM Engine LPG Fuel System Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-72

3.15 Joystick Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-76

SECTION 4 - HYDRAULICS

4.1 Cylinders - Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Valves - Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Component Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.4 Cylinder Checking Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.5 Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.6 Drive Pump Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

3121133 – JLG Lift – i

TABLE OF CONTENTS

4.7 Hydraulic Component Start-Up Procedures and Recommendations . . . . . . . . . . . . . . . . . . . . . .4-10

4.8 Hydraulic Gear Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.9 Main Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.10 Drive Header Valve (2WD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.11 Drive Header Valve (4WD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.12 Header Valves (4WD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.13 dIRECTIONAL vALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

4.14 pOWER dECK sANDWICH vALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.15 Power Deck Manifold Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4.16 Hydraulic Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.17 Cylinder Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

SECTION 5 - JLG CONTROL SYSTEM

5.1 Hand Held Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Flash Codes and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

SECTION 6 - GENERAL ELECTRICAL INFORMATION & SCHEMATICS

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Multimeter Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 Applying Silicone Dielectric Compound To Amp Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.4 Working With Deutsch Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.5 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6.6 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

ii – JLG Lift – 3121133

TABLE OF CONTENTS

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. Serial Number Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-2. Operator Maintenance and Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3. Filter Lock Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1-4. Torque Chart (SAE Fasteners - Sheet 1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1-5. Torque Chart (SAE Fasteners - Sheet 2 of 3)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1-6. Torque Chart (SAE Fasteners - Sheet 3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1-7. Torque Chart (METRIC Fasteners - Sheet 1 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1-8. Torque Chart (METRIC Fasteners - Sheet 2 of 3)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

1-9. Torque Chart (METRIC Fasteners - Sheet 3 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

2-1. Engine Operating Temperature Specifications - Deutz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-2. Engine Operating Temperature Specifications - Ford . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-3. Engine Operating Temperature Specifications - GM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

3-1. Limit Switch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2. Level Sensor and Analyzer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-3. Tilt Sensor Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3-4. Tilt Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3-5. Tilt Sensor Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-6. Tilt Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-7. Integrated Torque/Drive Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-8. Drive Motor/Hub Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-9. Drive Hub Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3-10. EFI Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

3-11. Typical Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

3-12. Generator (Ford Engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3-13. EMR 2 Engine Side Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

3-14. Deutz EMR 2 Troubleshooting Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-46

3-15. Deutz EMR 2 Vehicle Side Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-47

3-16. Deutz EMR 2 Engine Side Connection Diagram - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

3-17. Deutz EMR 2 Engine Side Connection Diagram - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3-18. EMR 2 Engine Plug Pin Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-50

3-19. EMR 2 Vehicle Plug Pin Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-51

3-20. EMR2 Fault Codes - Sheet 1 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-52

3-21. EMR2 Fault Codes - Sheet 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3-22. EMR2 Fault Codes - Sheet 3 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-54

3-23. EMR2 Fault Codes - Sheet 4 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-55

3-24. EMR2 Fault Codes - Sheet 5 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-56

3-25. Generator (Deutz Engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-57

3-26. Engine Oil Dip Stick. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-59

3-27. Generator (GM Engine). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-60

3-28. Electric Fuel Lock Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-61

3-29. EPR Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

3-30. Low Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-62

3-31. Air Fuel Mixer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-63

3-32. ETC throttle control device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-63

3-33. LPG Engine Control Unit (ECM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

3-34. ECM Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64

3-35. Heated Exhaust Gas Oxygen Sensor (HEGO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64

3-36. Gasoline Fuel Pressure and Temperature Manifold Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

3-37. Filter Lock Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-66

3-38. EPR Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

3-39. Pressure Regulator Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-68

3-40. (TMAP) Sensor & Electronic Throttle Control (ETC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-68

3-41. Mixer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-70

3-42. EPR Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

3121133 – JLG Lift – iii

TABLE OF CONTENTS

3-43. Joystick Controller - (JLG P/N 1600308) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-76

3-44. Joystick Controller - (JLG P/N 1600403) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-77

4-1. Lift Cylinder Holding Valve and Fitting Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4-2. Cylinder Barrel Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4-3. Lift Cylinder Cap Screw Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4-4. Cylinder Rod Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4-5. Tapered Bushing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4-6. Bushing Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4-7. Rod Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-8. Poly-Pak Piston Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-9. Wiper Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-10. Installation of Head Seal Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-11. Piston Seal Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-12. Tapered Bushing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4-13. Seating the Tapered Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4-14. Rod Assembly Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4-15. Main Valve Torque Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4-16. Main Valve Hydraulic Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-17. Drive Header Valve (2wd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4-18. Drive Header Valve (4wd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4-19. Header Valve (Fix) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4-20. Header Valve (Osc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4-21. Directional Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

4-22. Power Deck Sandwich Valve (Dual Deck Extension Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4-23. Power Deck Manifold Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4-24. Pump Pressure Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4-25. Auxiliary Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4-26. Steer Cylinder - Prior to S/N 137518. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

4-27. Steer Cylinder - S/N 137518 to Present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4-28. Lift Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4-29. Lift Cylinder Valve Cartridge Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4-30. Oscillating Axle Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

4-31. Oscillating Axle Valve Cartridge Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

4-32. Leveling Jack Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

4-33. Deck Extension Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4-34. Oscillating Axle Bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

5-1. Hand Held Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5-2. Analyzer Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5-3. Analyzer Flow Chart - SW P1.X - Sheet 1 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5-4. Analyzer Flow Chart - SW P1.X - Sheet 2 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5-5. Analyzer Flow Chart - SW P1.X - Sheet 3 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

6-1. Voltage Measurement (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6-2. Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-3. Continuity Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-4. Current Measurement (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-5. AMP Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6-6. Connector Assembly (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-7. Connector Assembly (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-8. Connector Assembly (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-9. Connector Assembly (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-10. Connector Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-11. Connector Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

6-12. DT/DTP Contact Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-13. DT/DTP Contact Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6-14. HD/HDP Contact Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6-15. HD/HDP Locking Contacts Into Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6-16. HD/HDP Contact Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6-17. HD/HDP Unlocking Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

iv – JLG Lift – 3121133

6-18. Electrical Schematic - Dual Fuel - Sheet 1 of 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6-19. Electrical Schematic - Dual Fuel - Sheet 2 of 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-20. Electrical Schematic - Dual Fuel - Sheet 3 of 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-21. Electrical Schematic Diesel (Prior to S/N 138634) - Sheet 1 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

6-22. Electrical Schematic Diesel (Prior to S/N 138634) - Sheet 2 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

6-23. Electrical Schematic Diesel (Prior to S/N 138634) - Sheet 3 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

6-24. Electrical Schematic - Dual Fuel GM - Sheet 1 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

6-25. Electrical Schematic - Dual Fuel GM - Sheet 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

6-26. Electrical Schematic Dual Fuel - GM - Sheet 3 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

6-27. Electrical Schematic Dual Fuel - GM - Sheet 4 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

6-28. Electrical Schematic Dual Fuel - GM - Sheet 5 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

6-29. Electrical Schematic Diesel (S/N 138634 to Present) - Sheet 1 of 3 . . . . . . . . . . . . . . . . . . . . . . .6-28

6-30. Electrical Schematic Diesel (S/N 138634 to Present) - Sheet 2 of 3 . . . . . . . . . . . . . . . . . . . . . . .6-29

6-31. Electrical Schematic Diesel (S/N 138634 to Present) - Sheet 3 of 3 . . . . . . . . . . . . . . . . . . . . . . .6-30

6-32. Hydraulic Schematic 4WD - Sheet 1 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

6-33. Hydraulic Schematic 4WD - Sheet 2 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

6-34. Hydraulic Schematic 4WD - Sheet 3 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

6-35. Hydraulic Schematic 4WD - Sheet 4 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

6-36. Hydraulic Schematic 2WD - Sheet 1 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-36

6-37. Hydraulic Schematic 2WD - Sheet 2 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

6-38. Hydraulic Schematic 2WD - Sheet 3 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

6-39. Hydraulic Schematic 2WD - Sheet 4 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-39

6-40. Hydraulic Diagram - (2WD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-40

6-41. Hydraulic Diagram - (4WD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

6-42. Hydraulic Diagram - (Leveling Jacks) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

6-43. Hydraulic Diagram - Deck Extension (Single) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-43

6-44. Hydraulic Diagram - Deck Extension (Dual) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-44

6-45. Hydraulic Diagram - Deck Extension (Dual Megadeck) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

6-46. Electrical Components Installation - Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-46

6-47. Electrical Components Installation - Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-47

TABLE OF CONTENTS

3121133 – JLG Lift – v

TABLE OF CONTENTS

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Operating Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-2 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-3 Ford LRG-425 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-4 Deutz F3M2011 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-5 GM 3.0L Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-6 Tire Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-7 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-8 High Drive Cut-Out Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-9 Tilt Sensor Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-10 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-11 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-12 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-13 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-14 Mobil DTE 13M Specs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-15 Mobil EAL 224H Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2-1 Inspection and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-2 Cylinder Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-3 Preventive Maintenance and Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3-1 Tilt Sensor Harness Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-2 Tilt Sensor Harness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-3 Torque/Drive Hub Specs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-4 Gearbox Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-5 ECM Diagnostic Trouble Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

3-6 Generator Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3-7 Generator Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3-8 Generator Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

3-9 LPF Fuel System Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

3-10 Joystick Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-76

3-11 Joystick Plug Loading Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-76

3-12 Joystick Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-77

3-13 Joystick Plug Loading Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-77

3-14 Symptom Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-78

3-15 DTC to SPN/FMI Cross Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-86

4-1 Cylinder Piston Nut Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4-2 Holding Valve Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4-3 Pump Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

5-1 Fault Code Listing - Software P1.X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5-2 Machine Model Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5-3 Machine Configuration Programming Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-4 Machine Tilt Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

vi – JLG Lift – 3121133

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

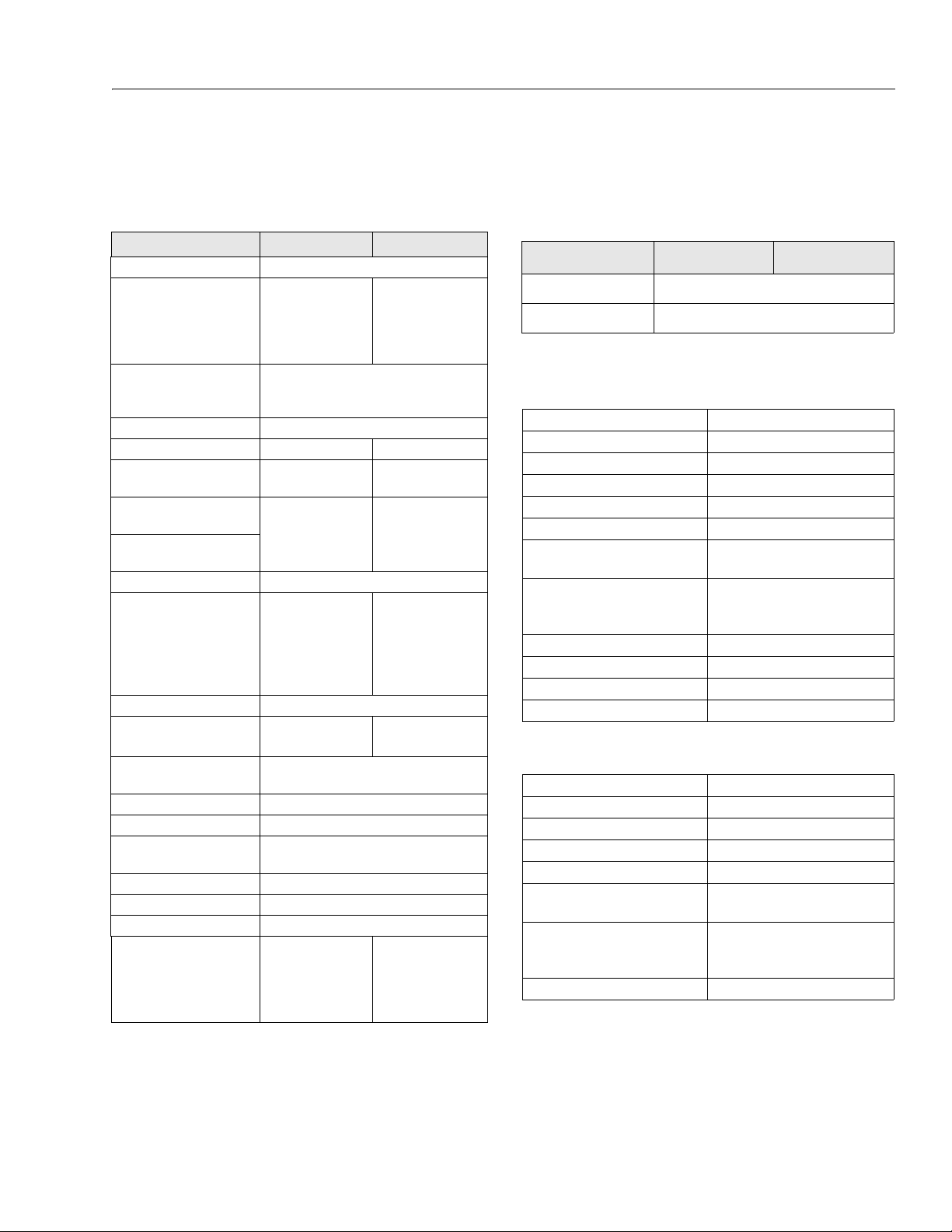

1.1 SPECIFICATIONS 1.2 CAPACITIES

Table 1-1. Operating Specifications

Description 3394RT 4394RT

Maximum Occupants 6

Maximum Workload

(Capacity):

Single Extension:

D ua l Ex t en s i on :

Extension Only:

Maximum Travel Grade :

2 WD

4 WD

Maximum Travel Grade : 3°

Maximum Platform Height 33 ft 43 ft

Maximum Drive Speed 2 WD

Maximum Drive Speed 4WD

LIft Up Speed (Stowed to Full

Height)

Lift Down Speed (Full Height

to Stowed)

Maximum Wind Speed 28 mph (12.5 m/s)

Maximum Horizontal Manual

Side Force:

Single Extension

D ua l Ex t en s i on

Single Extension (CE/AUS)

D ua l Ex t en s i on ( CE / AU S )

Maximum Tire Load 4400 lbs (1996 kg)

Ground Bearing Pressure

w/Standard tires

Leveling Jack Bearing

Pressure

Wheelbase 9.67 ft (2.95 m)

Ground Clearance 12 in (30 cm)

Maximum Hydraulic System

Pressure

Electrical System Voltage 12 Volt

Inside Turning Radius 14 ft 5 in (4.39 m )

Outside Turning Radius 20 ft 1 in (6.12 m)

Gross Vehicle Weight w/ One

Extension

Note: Cer tain options or

country standards increase

weight.

2250 lbs (1020 kg)

2000 lbs (905 kg)

500 lbs (230 kg)

3.0 mph (4.8 kph)

3.5 mph (5.6 kph)

29 - 31 sec 40 - 45 sec

335 lb force (1490 N)

300 lb force (1335 N)

90 lb force (400 N)

90 lb force (400 N)

49 psi

(3.45 kg/cm

69 psi (4.9 kg/cm

3000 psi (207 bar)

11,910 lbs

(5,402 kg)

1500 lbs (680 kg)

1250 lbs (565 kg)

500 lbs (230 kg)

35%

45%

3.0 mph (4.8 kph)

3.5 mph (5.6 kph)

300 lb force (1335 N)

300 lb force (1335 N)

90 lb force (400 N)

90 lb force (400 N)

2

)

(3.94 kg/cm2)

56 psi

2

)

15,300 lbs

(6,940 kg)

Description 3394RT 4394RT

Fuel Tank 31.5 gal (119 l)

Hydraulic Tank 40 gal (151 l)

1.3 ENGINES

Table 1-3. Ford LRG-425 Specifications

Fuel Gasoline

Oil Capacity 4.5 Quar ts (4.25 L) w/Filter

Idle RPM 1000

Low RPM 1800

High RPM 2800

Alternator 40 Amp, Belt Drive

Battery 112 Amphour, 950 Cold Cranking

Fuel Consumption

L ow R P M

H ig h R PM

Horsepower 54 @ 2400 RPM, full load

Cooling System 16 Quarts (15.14 L)

Spark Plug AWSF-52-C

Spark Plug Gap 0.044 in. (1.117 mm)

Table 1-4. Deutz F3M2011 Specifications

Fuel DIesel

Oil Capacity 8.5 Quarts (8 L) w/Filter

Low RPM 900

High RPM 2800

Alternator 95 Amp, Belt Drive

Battery 112 Amphour, 950 Cold Cranking

Fuel Consumption

Low RPM

H ig h R P M

Horsepower 48 @ 2800 RPM, full load

Table 1-2. Capacities

Amps, 12 VDC

3.45 GPH (13.06 lph)

4.60 GPH (17.41 lph)

Amps, 12 VDC

1.3 GPH (4.9 lph)

1.6 GPH (6.0 lph)

3121133 – JLG Sizzor – 1-1

SECTION 1 - SPECIFICATIONS

Table 1-5. GM 3.0L Specifications

Fuel Gasoline or Gasoline/LP Gas

No. of Cylinders 4

BHP

Gasoline

L P

Bore 4.0 in. (101.6 mm)

Stroke 3.6 in. (91.44 mm)

Displacement 181 cu.in. (3.0 L, 2966 cc)

Oil Capacity w/filter 4.5 qts. (4.25 L)

Minimum Oil Pressure

at i dl e

Ho t

Compression Ratio 9.2:1

Firing Order 1-3-4-2

Max. RPM 2800

83 hp @ 3000 rpm

75 hp @ 3000 rpm

6 psi (0.4 Bar) @ 1000 rpm

18 psi (1.2 Bar) @ 2000 rpm

1.4 TIRES

Table 1-6. Tire Specifications

Size

12 x 16.5

Pneumatic

Ply

Rating

10 90 psi (6 bar)

Inflation

Pressure

Wheel Nut

Torq ue (Dr y )

170 ft lbs

(238 Nm)

1.5 MACHINE DIMENSIONS

Description 3394RT 4394RT

Machine Height

(rails down)

Machine Width 7ft 10in (2.4 m)

Machine Length 13 ft (4 m)

61.75 in (1.6 m) 70.4 in (1.8 m)

1.6 PRESSURE SETTINGS

Table 1-7. Pressure Settings

Description 3394RT 4394RT

Main Relief 3000 psi (207 bar)

Steer Relief 2800 psi (193 bar)

Lift 2700 psi (186 bar)

Leveling Jack Relief 2500 psi (172 bar)

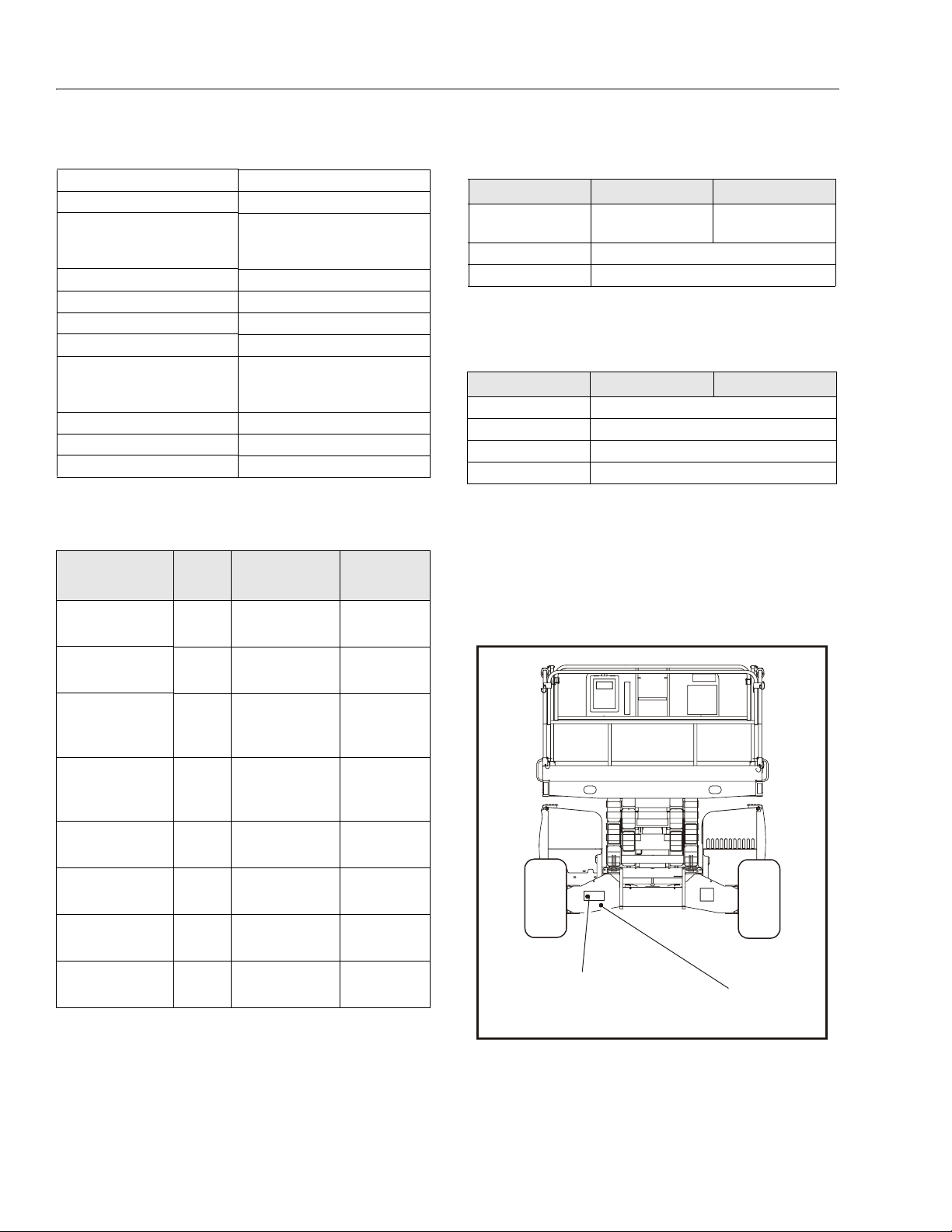

1.7 SERIAL NUMBER LOCATIONS

For machine identification, a serial number plate is affixed

to the machine. The plate is located at the rear of the

machine on the left side of the axle. In addition, should the

serial number plate be damaged or missing, the machine

serial number is stamped directly under the serial number

plate.

12 x 16.5

Foam Filled

12 x 16.5

Pneumatic

(Non-Marking)

12 x 16.5

Foam Filled

(Non-Marking)

33/1550 x 16.5

Pneumatic

33/1550 x 16.5

Foam Filled

33/16LLx16.1

Foam Filled - Sand

31 x 15.50-15

Grass Master

10

10 90 psi (6 bar)

10

14 90 psi (6 bar)

14

10

10 60 psi (4 bar)

Foam Fill to

90 psi (6 bar)

Foam Fill to

90 psi (6 bar)

Foam Fill to

90 psi (6 bar)

Foam Fill to

50 psi (3.4 bar)

170 ft lbs

(238 Nm)

170 ft lbs

(238 Nm)

170 ft lbs

(238 Nm)

170 ft lbs

(238 Nm)

170 ft lbs

(238 Nm)

170 ft lbs

(238 Nm)

170 ft lbs

(238 Nm)

SERIAL NUMBER

PLATE

Figure 1-1. Serial Number Location

SERIAL NUMBER

STAMPED

1-2 – JLG Sizzor – 3121133

SECTION 1 - SPECIFICATIONS

1.8 SENSORS

The machine is equipped with the following limit switches:

Elevation Switch/Rotary Position Sensor - High drive

speed is cut out when platform is raised above the preset

heights listed in Table 1-8, High Drive Cut-Out Height.

Table 1-8. High Drive Cut-Out Height

Model Feet Meters

3394RT 6-9 1.8 - 2.7

4394RT 7-10 2.1 - 3

Tilt Alarm - An alarm sounds and a warning light is illuminated when the machine is operated on a slope that

exceeds the values in Table 1-9, Tilt Sensor Indicators.

The lift and drive functions will cut out at these set heights.

NOTE: Alarm only sounds when above elevation.

If the machine is operated beyond the specified

slope, with the platform completely lowered, only the

warning light is illuminated.

Table 1-9. Tilt Sensor Indicators

Model Front To Back Side To Side

3394RT

(ANSI, ANSI Expor t, Aus)

4394RT

(ANSI, ANSI Expor t, Aus)

3394RT/4394RT

(CSA)

3394RT/4394RT

(CE)

5° to full height

5° to full height

3° to full height 3° to full height

5° to full height 3° to full height

5° to 26 ft (8 m)

4° to 30 ft (9 m)

3° to 33 ft (10 m)

5° to 26 ft (8 m)

4° to 30 ft (9 m)

3° to 43 ft (13 m)

1.9 CYLINDER SPECIFICATIONS

Table 1-10. Cylinder Specifications

Description Bore Stroke Rod Dia

Lift Cylinder

Leveling Jack Cylinder

Lockout Cylinder

(Oscillating Axle)

Power Deck Extension

Cylinders

Steer Cylinder

4.5 in

(11.4 cm)

3 in

(7.6 cm)

2.5 in

(6.4 cm)

1.5 in

(3.8 cm)

2.5 in

(6.4 cm)

83 in

(211 cm)

21.5 in

(54.6 cm)

6.0 in

(15.2 cm)

48 in

(122 cm)

4.6 in

(11.2 cm)

1.10 MAJOR COMPONENT WEIGHTS

Table 1-11. Major Component Weights

Component Weight

Fixed Platform 1070 lbs (485 kg)

Platform Extension 440 lbs (200 kg)

Arm Assembly- (Includes Lift Cylinder)

3394RT

4394RT

Chassis with Pneumatic Tires

3394RT

4394RT

Chassis with Foam Filled Tires

3394RT

4394RT

3600 lbs (1633 kg)

4550 lbs (2064 kg)

6790 lbs (3080 kg)

9080 lbs (4119 kg)

7788 lbs (3533 kg)

9086 lbs (4121 kg)

3.5 in

(8.9 cm)

2 in

(5 cm)

1.75 in

(4.4 cm)

1 in

(2.5 cm)

1.75 in

(4.4 cm)

3121133 – JLG Sizzor – 1-3

SECTION 1 - SPECIFICATIONS

1.11 CRITICAL STABILITY WEIGHTS

DO NOT REPLACE ITEMS CRITICAL TO STABILITY WITH ITEMS

OF DIFFERENT WEIGHT OR SPECIFICATION (FOR EXAMPLE:

FILLED TIRES, ENGINE) DO NOT MODIFY UNIT IN ANY WAY TO

AFFECT STABILITY.

Table 1-12. Critical Stability Weights

Component Weight

Tires

12 x 16.5 Pneumatic

12 x16.5 Foam Filled

33/1550-16.5 Pneumatic

33/1550-16.5 Foam Filled

33/16LL x 16.1 Foam Filled - Sand

Engine (Ford) 324 lbs (147 kg)

Engine (Deutz) 441 lbs (200 kg)

Engine (GM) 341 lbs (155 kg)

132 lbs (60 kg)

352 lbs (160 kg)

162 lbs (73 kg)

410 lbs (186 kg)

426 lbs (193 kg)

1.12 LUBRICATION SPECIFICATIONS

Table 1-13. Hydraulic Oil

HYDRAULIC SYSTEM

OPERATING

TEMPERATURE RANGE

0°F to +23°F

(-18°C to -5°C)

0°F to +210°F

(-18°C to +100°C)

+50°F to +210°F

(+10°C to +100°C)

SAE VISCOSITY GRADE

10W

10W-20,10W-30

20W-20

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system service. JLG Industries recommends Mobilfluid 424

hydraulic oil, which has an SAE viscosity index of

152 .

Table 1-14. Mobil DTE 13M Specs

ISO Viscosity Grade #32

Specific Gravity 0.877

Pour Point, Max -40°F (-40°C)

Flash Point, Min. 330°F (166°C)

Viscosity

at 40° C 33cSt

at 100° C 6.6 cSt

at 100° F 169 SUS

at 210° F 48 SUS

c p a t - 20 ° F 6, 2 00

Viscosity Index 140

NOTE: Must be stored above 32°F (14°C)

Table 1-15. Mobil EAL 224H Specs

Ty pe Synthetic Biodegradable

ISO Viscosity Grade 32/46

Specific Gravity 0.922

Pour Point, Max -25°F (-32°C)

Flash Point, Min. 428°F (220°C)

Operating Temp. 0°F to 180°F (-17°C to 162°C)

Viscosity

at 40°C 37 cSt

at 100°C 8 .4 cSt

Viscosity Index 213

1-4 – JLG Sizzor – 3121133

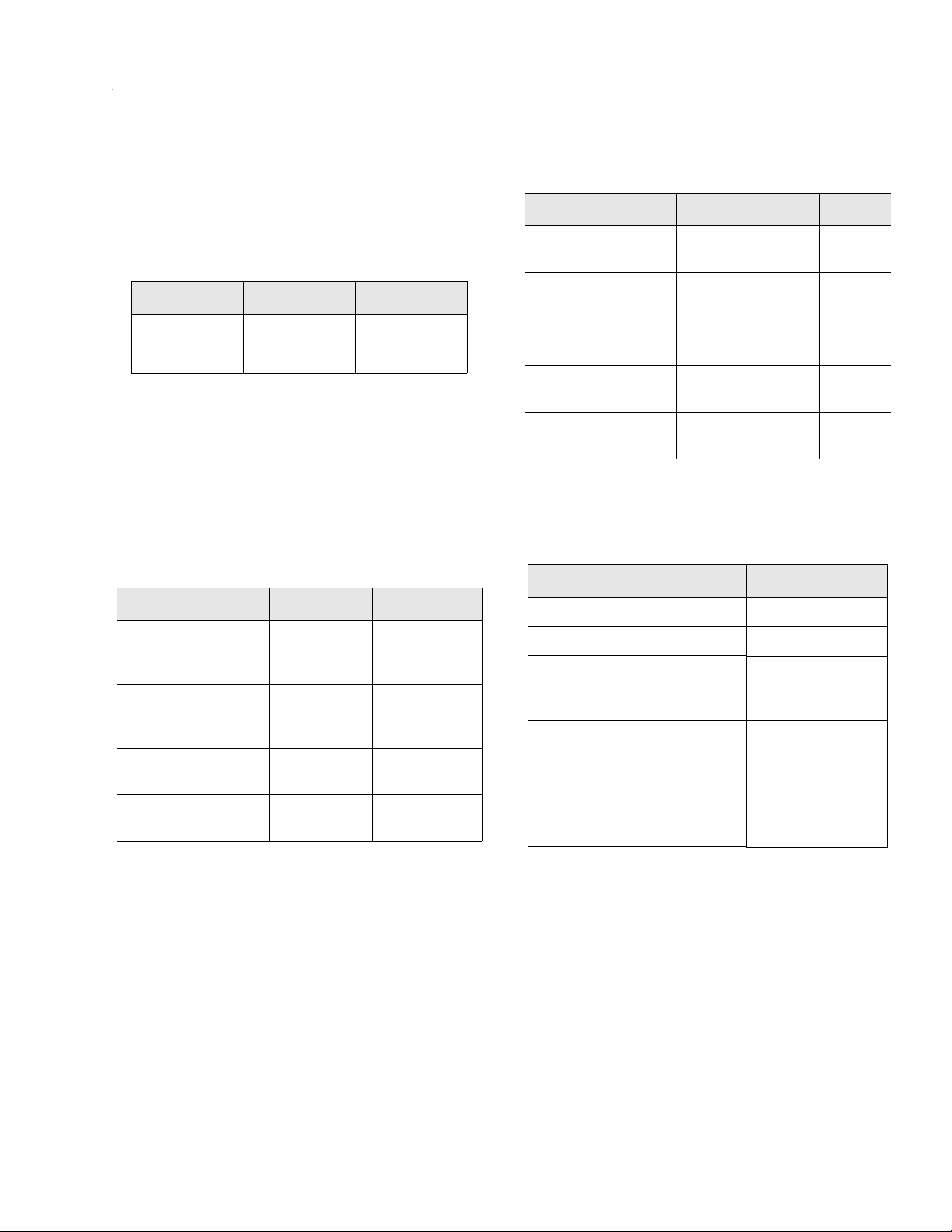

1.13 OPERATOR MAINTENANCE

SECTION 1 - SPECIFICATIONS

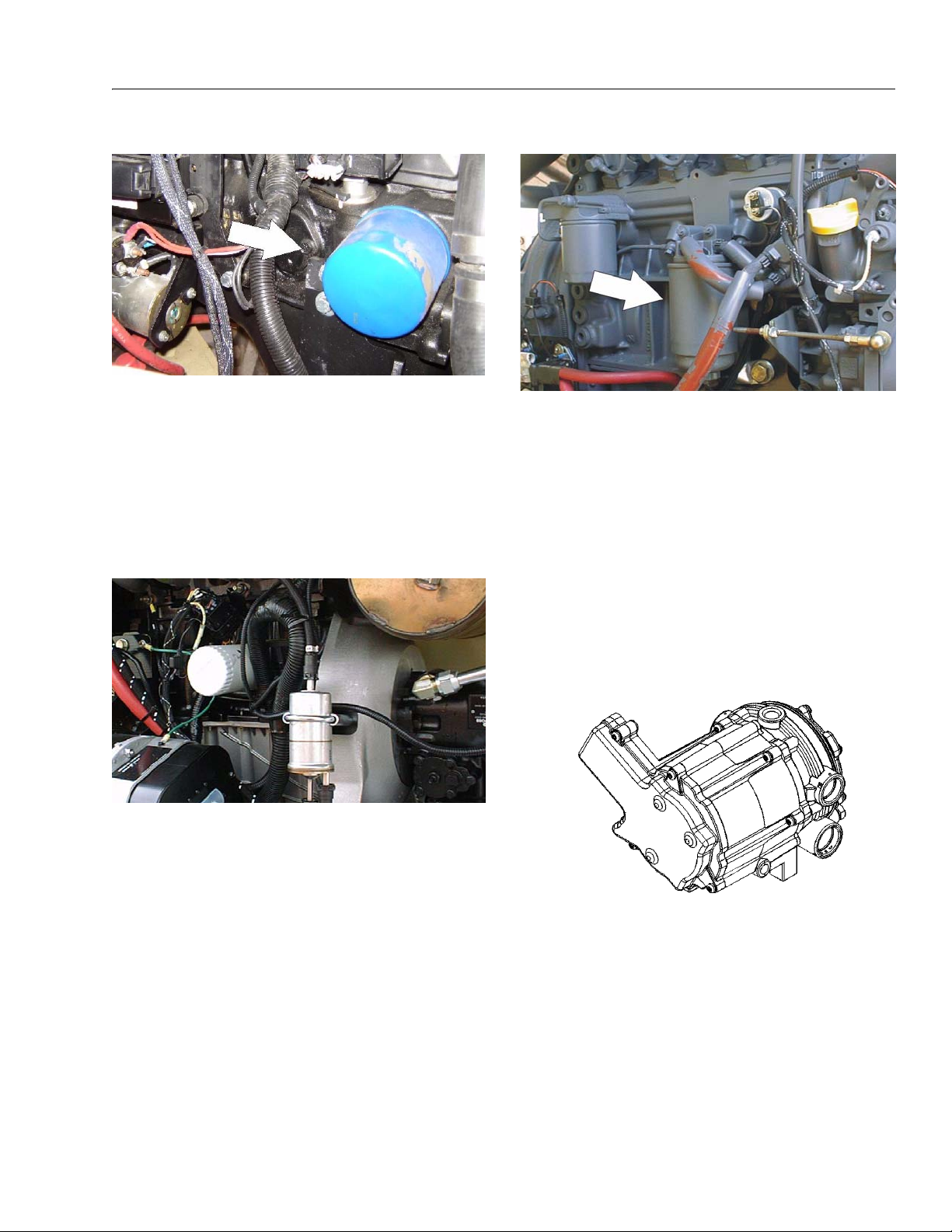

1. Fuel Tank

2. Drive Hubs

3. Hydraulic Oil Tank

4. Sliding Wear Pads

5. Oil Change w/Filter - Ford

6. Oil Change w/Filter - Deutz

7. Oil Change w/Filter - GM

8. Fuel Filter - Ford

9. Fuel Filter - Deutz

10. Fuel Filter (Gasoline) - GM

11. Air Filter

12. Electronic Pressure Regulator (LP Only)

13. Fuel Filter (Propane) - GM

NOTE: Item #5 through #13 are on the opposite

side of the machine and not shown.

Figure 1-2. Operator Maintenance and Lubrication Diagram

TO AVOID PERSONAL INJURY, USE SAFETY PROP FOR ALL

MAINTENANCE REQUIRING PLATFORM TO BE ELEVATED.

NOTE: Be sure to lubricate like items on each side.

NOTE: Recommended lubricating intervals are based on

machine operations under normal conditions. For

machines used in multi-shift operations and/or

exposed to hostile environments or conditions, lubrication frequencies must be increased accordingly.

Operate hydraulic functions through one complete

cycle before checking hydraulic oil level in tank. Oil

should be visible in ADD sight window on hydraulic

tank. If oil is not visible, add oil until oil is visible in

both ADD and FULL sight windows on tank. Do not

overfill tank.

Any time the pump coupling is removed, coat splines

of coupling with Texaco Code 1912 grease prior to

assembly.

1. Fuel Tank

• Fuel - Diesel or Gasoline

• Capacity - 31.5 gal (119 l)

3121133 – JLG Sizzor – 1-5

SECTION 1 - SPECIFICATIONS

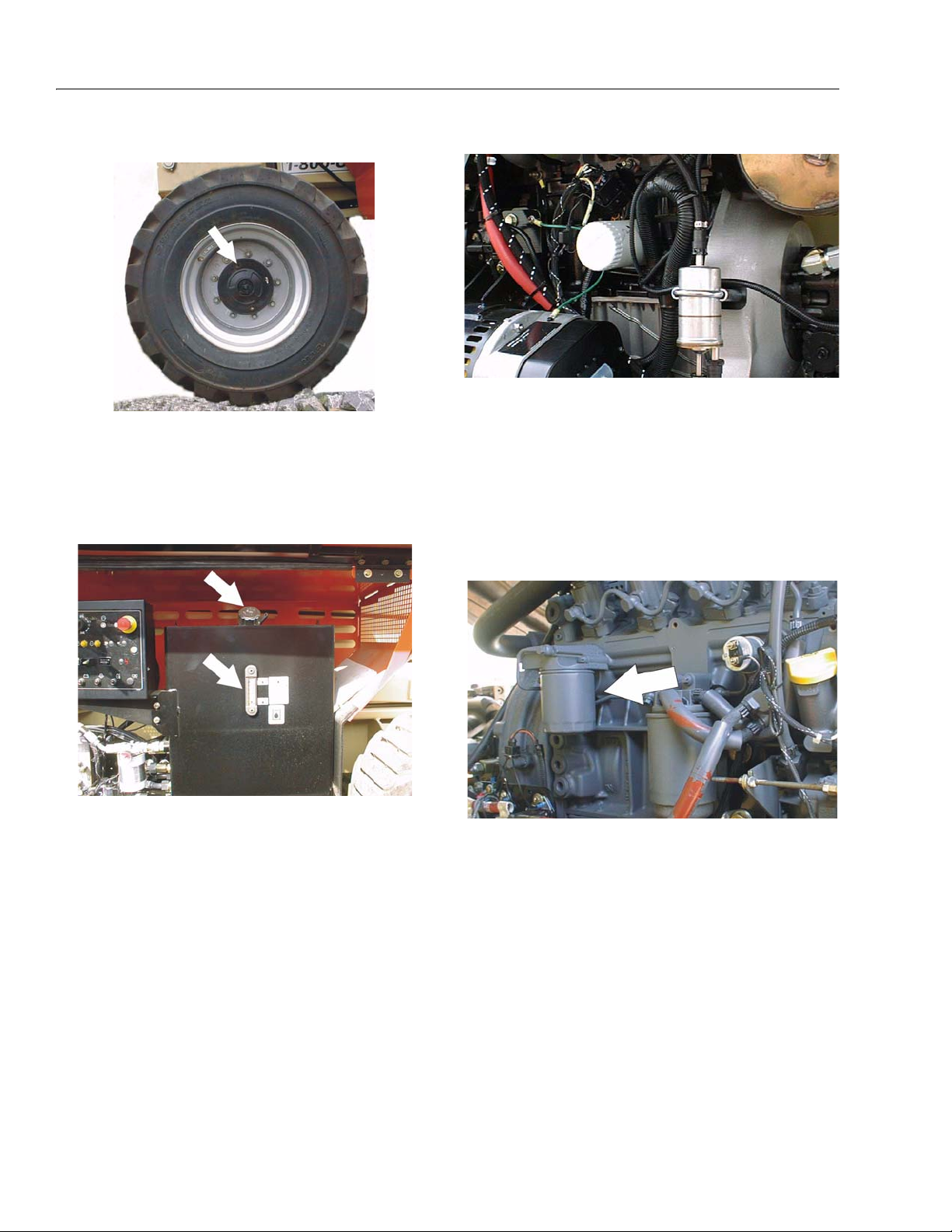

2. Drive Hub

• Lube Points - Fill Plugs (4)

•Lube - EPGL

• Interval - Every 2 years or 1200 hours

3. Hydraulic Oil

5. Oil Change w/Filter - Ford

• Lube Point(s) - Fill Cap/Spin-on Element

(JLG P/N 7014501)

• Capacity - 4.5 qt. (4.25 L)

•Lube - EO

• Interval - 3 Months or 150 hours of operation

• Comments - Check level daily/Change in accordance

with engine manual.

6. Oil Change w/Filter - Deutz

• Lube Point - Fill Cap/Fill Level

•Lube - HO

• Interval - Check oil every 10 hours of operation;

change oil every 2 years or 1200 hours of operation.

4. Sliding Wear Pads

• Lube Points - 8 Sliding Wear Pads

•Lube - MPG

• Interval - Every month or 50 hours.

• Lube Point(s) - Fill Cap/Spin-on Element

(JLG P/N 7016331)

• Capacity - 6.3 qt. (5.9 L) engine only

•Lube - EO

• Interval - Every Year or 600 hours of operation

• Comments - Check level daily/Change in accordance

with engine manual.

1-6 – JLG Sizzor – 3121133

SECTION 1 - SPECIFICATIONS

7. Oil Change w/Filter - GM

• Lube Point(s) - Fill Cap/Spin-on Element

(JLG P/N 7027965)

• Capacity - 4.5 qt. (4.25 L) w/filter

•Lube - EO

• Interval - 3 Months or 150 hours of operation

• Comments - Check level daily/Change in accordance

with engine manual.

8. Fuel Filter - Ford

9. Fuel Filter - Deutz

• Lube Point(s) - Replaceable Element

• Interval - Every Year or 600 hours of operation

10. Fuel Filter (Gasoline) - GM

• Lube Point(s) - Replaceable Element

• Interval - Every 6 months or 300 hours of operation

11. Air Filter

• Lube Point(s) - Replaceable Element

• Interval - Every 6 months or 300 hours of operation or

as indicated by the condition indicator

• Lube Point(s) - Replaceable Element

• Interval - Every Year or 600 hours of operation

12. Electronic Pressure Regulator (LP only)

• Interval - 3 Months or 150 hours of operation

• Comments - Drain oil build up. Refer to Draining Oil

Build Up From The Propane Regulator

3121133 – JLG Sizzor – 1-7

SECTION 1 - SPECIFICATIONS

13. Fuel Filter (Propane) - GM

• Interval - 3 Months or 150 hours of operation

• Comments - Replace filter. Refer to Propane Fuel Filter

Replacement

Draining Oil Build Up From The Propane Regulator

During the course of normal operation oils may build

inside the primary and secondary chambers of the propane pressure regulator. These oils may be a result of

poor fuel quality, contamination of the fuel supply chain,

or regional variation in the make up of the fuel. If the build

up of the oil is significant this can effect the operation of

the fuel control system. Refer to Section 1.13, Operator

Maintenance for maintenance intervals. More frequent

draining may be required if the fuel supply has been contaminated.

5. Disconnect the electrical connection to the LPG fuel

temperature sensor in the auxiliary fuel port of the

EPR.

6. Remove the retainer clip for the LPG fuel temperature sensor and remove the sensor from the regulator body.

NOTICE

FOR BEST RESULTS WARM THE ENGINE TO OPERATING TEMPERATURE BEFORE DRAINING. THIS WILL ALLOW THE OILS TO

FLOW FREELY FROM THE REGULATOR.

1. Move the equipment to a well ventilated area.

Ensure there are no external ignition sources.

2. Start the engine and bring to operating temperature.

3. With the engine running, close the manual tank

valve and run the engine out of fuel.

4. Push in the Emergency Switch once the engine

stops.

NOTE: Have a small container ready to collect oil that will

drain freely from the regulator at this point.

7. Once all of the oil has been drained, reinstall the

LPG fuel temperature sensor and reconnect the

electrical connector.

8. Open the fuel tank manual valve.

9. Start the engine and verify all connections are

secure.

10. Dispose of any drained oil per local regulations in a

safe and proper fashion.

1-8 – JLG Sizzor – 3121133

SECTION 1 - SPECIFICATIONS

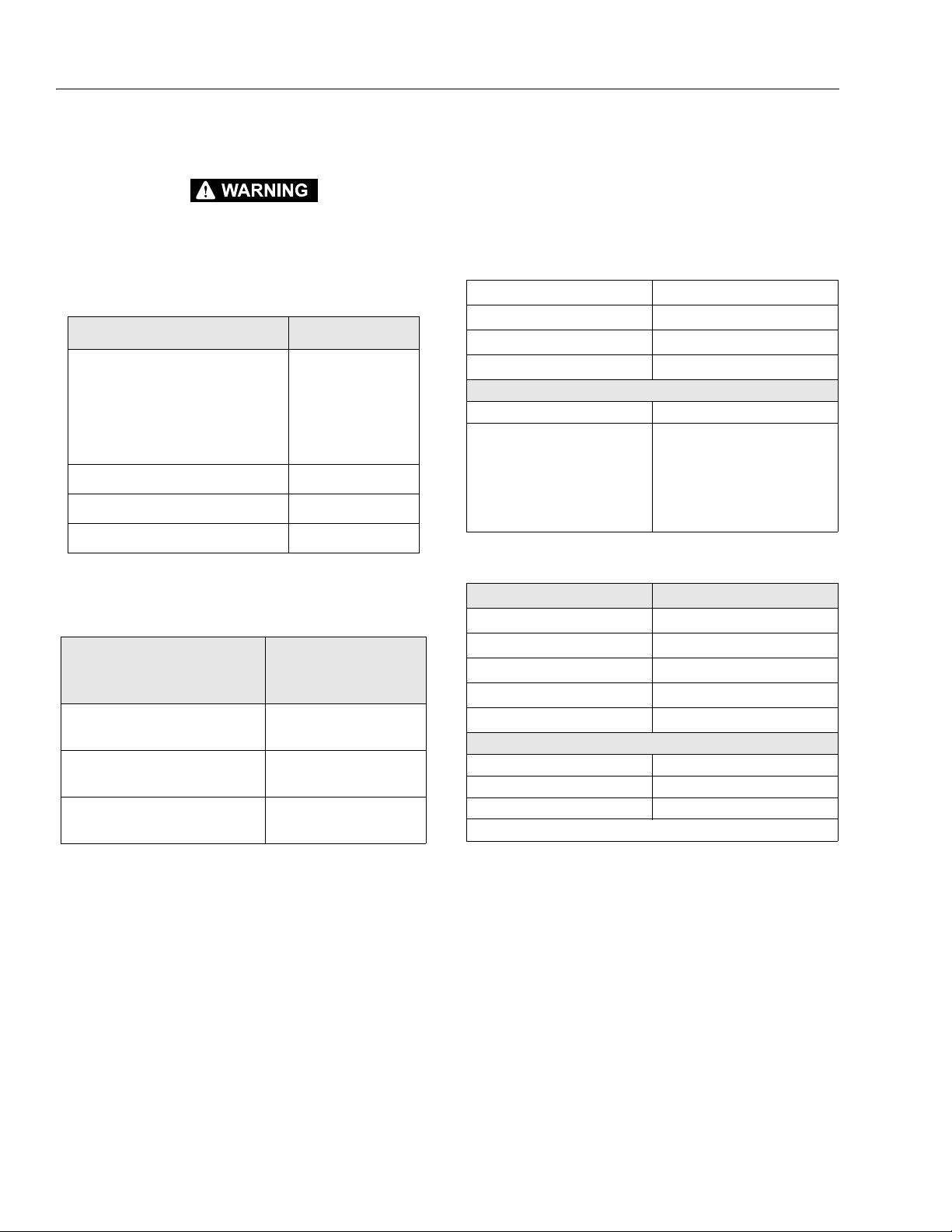

Propane Fuel Filter Replacement

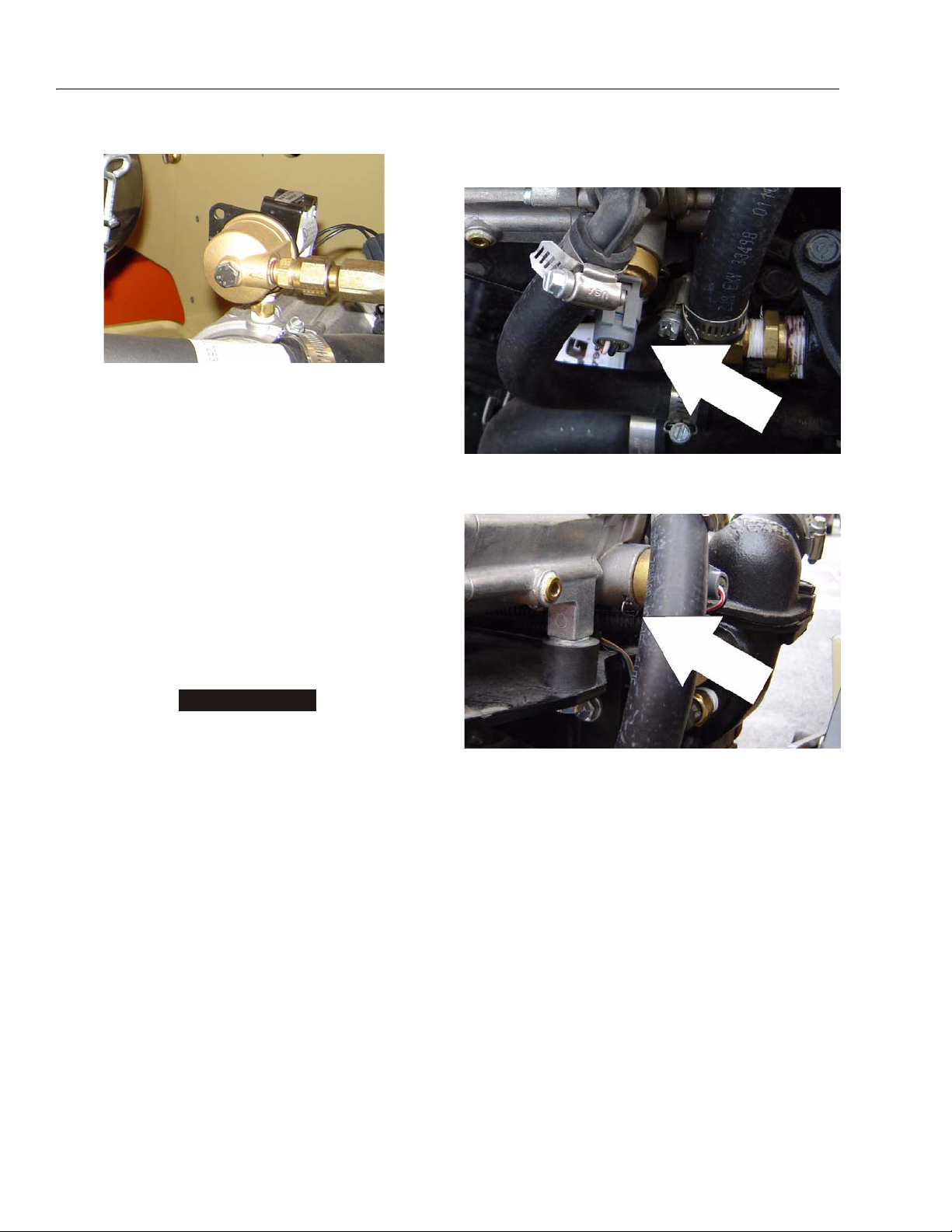

1. Electric Lock Off Solenoid

2. Mounting Plate

3. Housing Seal

4. Filter Magnet

5. Filter Housing

6. Seal

Figure 1-3. Filter Lock Assembly

7. Electrical Connector

8. Fuel Outlet

9. O-ring

10. Filter

11. Fu el In le t

12. Retaining Bolt

INSTALLATION:

NOTICE

BE SURE TO REINSTALL THE FILTER MAGNET INTO THE HOUSING BEFORE INSTALLING NEW SEAL.

1. Install the mounting plate to lock off O-ring seal.

2. Install the retaining bolt seal.

3. Install the housing seal.

4. Drop the magnet into the bottom of the filter housing.

5. Install the filter into the housing.

6. Install the retaining bolt into the filter housing.

7. Install the filter up to the bottom of the electric lock

off.

8. Tighten the filter retaining bolt to 106 in lbs (12 Nm).

9. Open manual shut-off valve. Start the vehicle and

leak check the propane fuel system at each serviced

fitting. Refer to Propane Fuel System Leak Test.

Propane Fuel System Pressure Relief

REMOVAL:

1. Relieve the propane fuel system pressure. Refer to

Propane Fuel System Pressure Relief.

2. Disconnect the negative battery cable.

3. Slowly loosen the Filter housing retaining bolt and

remove it.

4. Pull the filter housing from the Electric lock off

assembly.

5. Locate Filter magnet and remove it.

6. Remove the filter from the housing.

7. Remove and discard the housing seal.

8. Remove and discard the retaining bolt seal.

9. Remove and discard mounting plate to lock off O-

ring seal.

THE PROPANE FUEL SYSTEM OPERATES AT PRESSURES UP TO

312 PSI (21.5 BAR). TO MINIMIZE THE RISK OF FIRE AND PERSONAL INJURY, RELIEVE THE PROPANE FUEL SYSTEM PRESSURE (WHERE APPLICABLE) BEFORE SERVICING THE

PROPANE FUEL SYSTEM COMPONENTS.

To relieve propane fuel system pressure:

1. Close the manual shut-off valve on the propane fuel

tank.

2. Start and run the vehicle until the engine stalls.

3. Turn the ignition switch OFF.

RESIDUAL VAPOR PRESSURE WILL BE PRESENT IN THE FUEL

SYSTEM. ENSURE THE WORK AREA IS WELL VENTILATED

BEFORE DISCONNECTING ANY FUEL LINE.

3121133 – JLG Sizzor – 1-9

SECTION 1 - SPECIFICATIONS

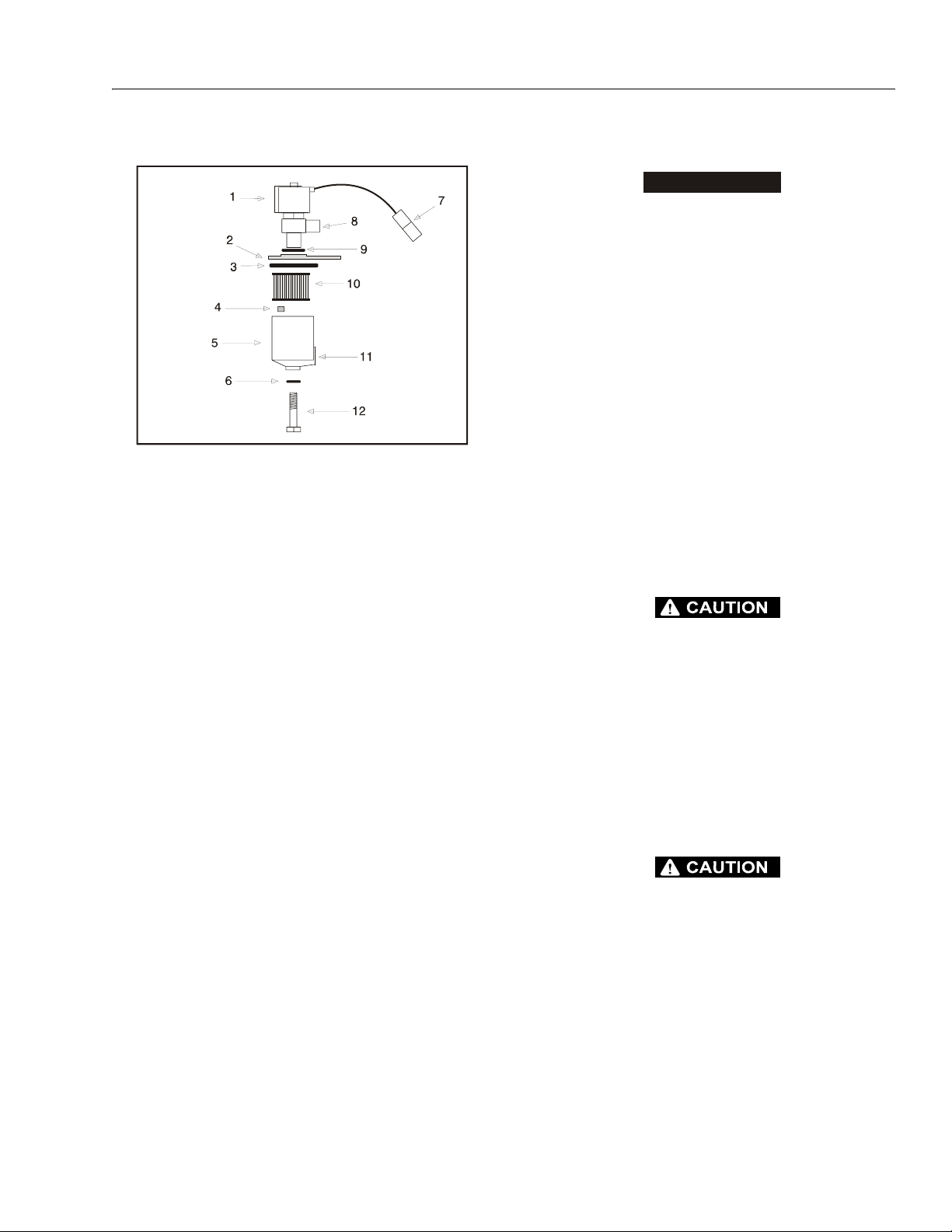

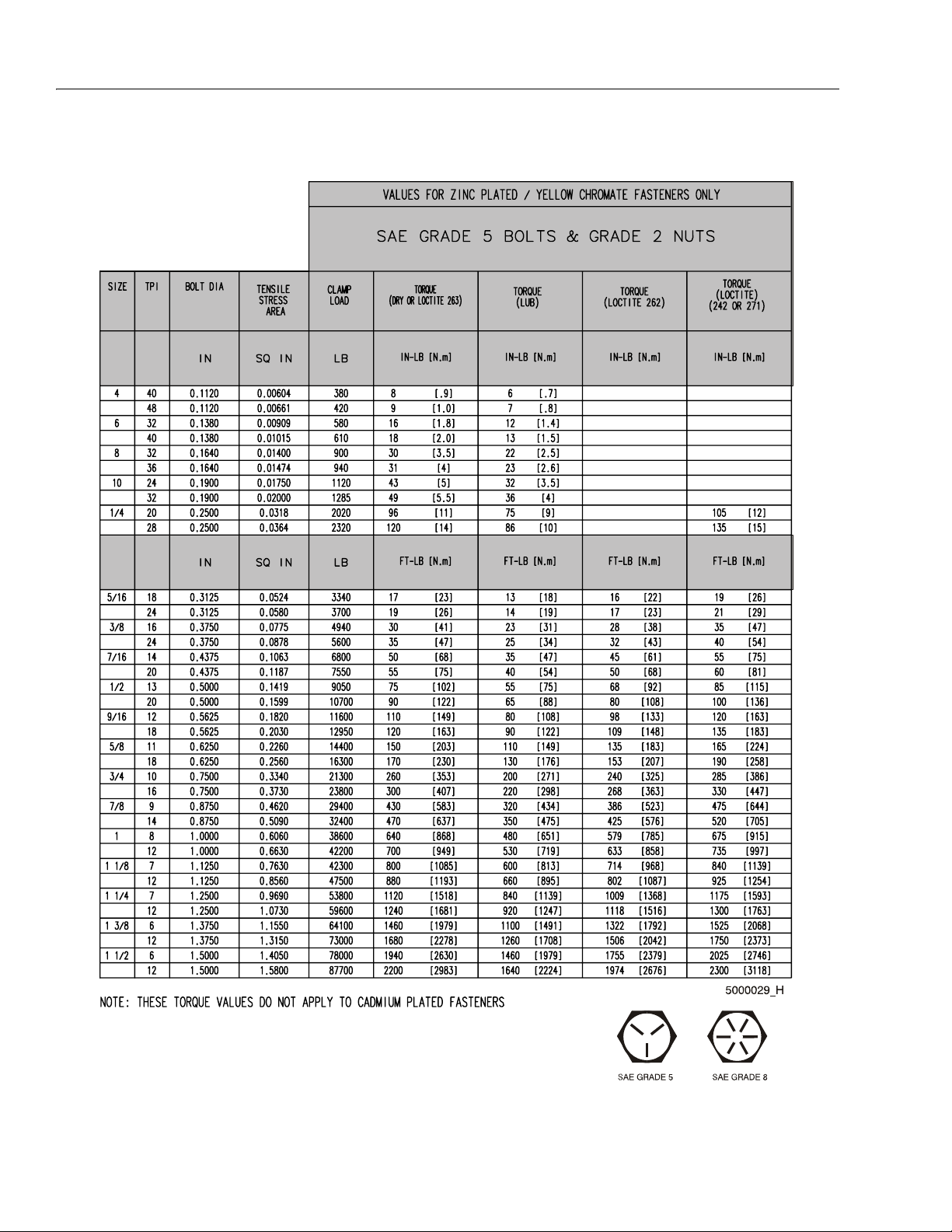

1.14 TORQUE CHARTS

Figure 1-4. Torque Chart (SAE Fasteners - Sheet 1 of 3)

1-10 – JLG Sizzor – 3121133

SECTION 1 - SPECIFICATIONS

Figure 1-5. Torque Chart (SAE Fasteners - Sheet 2 of 3))

3121133 – JLG Sizzor – 1-11

SECTION 1 - SPECIFICATIONS

Figure 1-6. Torque Chart (SAE Fasteners - Sheet 3 of 3)

1-12 – JLG Sizzor – 3121133

SECTION 1 - SPECIFICATIONS

Figure 1-7. Torque Chart (METRIC Fasteners - Sheet 1 of 3)

3121133 – JLG Sizzor – 1-13

SECTION 1 - SPECIFICATIONS

Figure 1-8. Torque Chart (METRIC Fasteners - Sheet 2 of 3))

1-14 – JLG Sizzor – 3121133

SECTION 1 - SPECIFICATIONS

Figure 1-9. Torque Chart (METRIC Fasteners - Sheet 3 of 3)

3121133 – JLG Sizzor – 1-15

SECTION 1 - SPECIFICATIONS

NOTES:

1-16 – JLG Sizzor – 3121133

SECTION 2. GENERAL

SECTION 2 - GENERAL

2.1 MACHINE PREPARATION, INSPECTION, AND MAINTENANCE

General

This section provides the necessary information needed

by those personnel that are responsible to place the

machine in operation readiness and maintain its safe

operating condition. For maximum service life and safe

operation, ensure that all the necessary inspections and

maintenance have been completed before placing the

machine into service.

Preparation, Inspection, and Maintenance

It is important to establish and conform to a comprehensive inspection and preventive maintenance program. The

following table outlines the periodic machine inspections

and maintenance recommended by JLG Industries, Inc.

Consult your national, regional, or local regulations for further requirements for aerial work platforms. The frequency

of inspections and maintenance must be increased as

environment, severity and frequency of usage requires.

Pre-Start Inspection

It is the User’s or Operator’s primary responsibility to perform a Pre-Start Inspection of the machine prior to use

daily or at each change of operator. Reference the Operator’s and Safety Manual for completion procedures for the

Pre-Start Inspection. The Operator and Safety Manual

must be read in its entirety and understood prior to performing the Pre-Start Inspection.

Pre-Delivery Inspection and Frequent Inspection

The Pre-Delivery Inspection and Frequent Inspection shall

be performed by a qualified JLG equipment mechanic.

JLG Industries, Inc. recognizes a qualified JLG equipment

mechanic as a person who, by possession of a recognized degree, certificate, extensive knowledge, training, or

experience, has successfully demonstrated the ability and

proficiency to service, repair, and maintain the subject

JLG product model.

The Pre-Delivery Inspection and Frequent Inspection procedures are performed in the same manner, but at different times. The Pre-Delivery Inspection shall be performed

prior to each sale, lease, or rental delivery. The Frequent

Inspection shall be accomplished for each machine in service for 3 months or 150 hours (whichever comes first);

out of service for a period of more than 3 months; or when

purchased used. The frequency of this inspection must be

increased as environment, severity and frequency of

usage requires.

Reference the JLG Pre-Delivery and Frequent Inspection

Form and the Inspection and Preventative Maintenance

Schedule for items requiring inspection during the performance of these inspections. Reference the appropriate

areas of this manual for servicing and maintenance procedures.

Annual Machine Inspection

JLG recommends that an annual machine inspection be

performed by a Factory-Certified Service Technician on an

annual basis, no later than thirteen (13) months from the

date of the prior Annual Machine Inspection. JLG Industries, Inc. recognizes a Factory-Certified Service Technician as a person who has successfully completed the JLG

Service Training School for the subject JLG product

model. Reference the machine Service and Maintenance

Manual and appropriate JLG inspection form for performance of this inspection.

Reference the JLG Annual Machine Inspection Form and

the Inspection and Preventative Maintenance Schedule for

items requiring inspection during the performance of this

inspection. Reference the appropriate areas of this manual for servicing and maintenance procedures.

For the purpose of receiving safety-related bulletins, it is

important that JLG Industries, Inc. has updated ownership

information for each machine. When performing each

Annual Machine Inspection, notify JLG Industries, Inc. of

the current machine ownership.

Preventative Maintenance

In conjunction with the specified inspections, maintenance shall be performed by a qualified JLG equipment

mechanic. JLG Industries, Inc. recognizes a qualified JLG

equipment mechanic as a person who, by possession of a

recognized degree, certificate, extensive knowledge, training, or experience, has successfully demonstrated the

ability and proficiency to service, repair, and maintain the

subject JLG product model.

Reference the Preventative Maintenance Schedule and

the appropriate areas of this manual for servicing and

maintenance procedures. The frequency of service and

maintenance must be increased as environment, severity

and frequency of usage requires.

3121133 – JLG Lift – 2-1

SECTION 2 - GENERAL

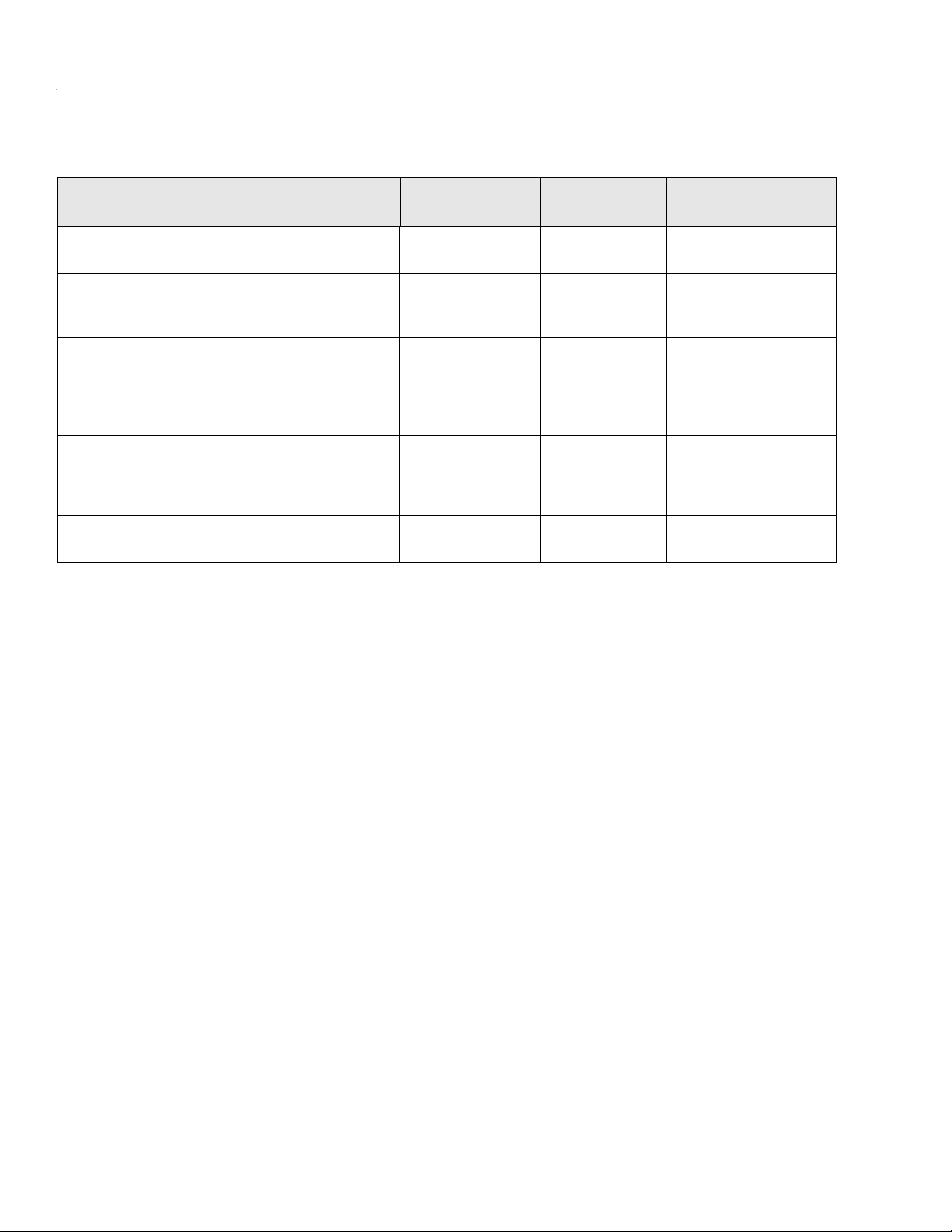

Table 2-1. Inspection and Maintenance

Typ e Frequency

Pre-Start Inspection

Pre-Delivery

Inspection

Frequent Inspection

Annual Machine

Inspection

Preventative

Maintenance

Prior to use each day; or

At each Operator change.

Prior to each sale, lease, or

rental delivery.

In service for 3 months or 150 hours,

whichever comes first; or

Out of service for a period of more than 3

months; or

Purchased used.

Annually, no later than 13 months from the

date of the prior inspection.

At intervals as specified in the Service and

Maintenance Manual.

2.2 SERVICE AND GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this book.

Safety and Workmanship

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

Cleanliness

1. The most important single item in preserving the

long service life of a machine is to keep dirt and foreign materials out of the vital components. Precautions have been taken to safeguard against this.

Shields, covers, seals, and filters are provided to

keep air, fuel, and oil supplies clean; however, these

items must be maintained on a scheduled basis in

order to function properly.

Primary

Responsibility

User or Operator User or Operator Operator and Safety Manual

Owner, Dealer, or User

Owner, Dealer, or User

Owner, Dealer, or User

Owner, Dealer, or User

2. At any time when air, fuel, or oil lines are disconnected, clear adjacent areas as well as the openings

and fittings themselves. As soon as a line or component is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their containers until they are ready to be used.

Service

Qualification

Qualified JLG

Mechanic

Qualified JLG

Mechanic

Factory-Certified

Service Technician or

a Qualified JLG

Mechanic

Qualified JLG

Mechanic

Reference

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual

Components Removal and Installation

1. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpendicular as possible to top of part being

lifted.

2. Should it be necessary to remove a component on

an angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between

the supporting structure and the component

becomes less than 90°.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc., have been

removed and that no adjacent parts are interfering.

2-2 – JLG Lift – 3121133

SECTION 2 - GENERAL

Component Disassembly and Reassembly

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure-Fit Parts

When assembling pressure-fit parts, use an anti-seize or

molybdenum disulfide base compound to lubricate the

mating surface.

Bearings

1. When a bearing is removed, cover it to keep out dirt

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bearing.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored, or burned.

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

unwrap reusable or new bearings until they are

ready to install.

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bearing is to be installed on a shaft, apply pressure to the

inner race.

Gaskets

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat-treated bolts, studs, and steel nuts, in accordance with recommended shop practices. (See

Torque Chart Section 1.)

Hydraulic Lines and Electrical Wiring

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System

1. Keep the system clean. If evidence of metal or rubber particles are found in the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

Lubrication

Service applicable components with the amount, type,

and grade of lubricant recommended in this manual, at

the specified intervals. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

Battery

Clean battery, using a non-metallic brush and a solution of

baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry battery and coat terminals with

an anti corrosion compound.

Lubrication and Servicing

Components and assemblies requiring lubrication and

servicing are shown in the Lubrication Chart in Section 1.

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand-fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location, as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

3121133 – JLG Lift – 2-3

SECTION 2 - GENERAL

2.3 LUBRICATION AND INFORMATION

Hydraulic System

1. The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various

means, e.g., using inadequate hydraulic oil, allowing

moisture, grease, filings, sealing components, sand,

etc., to enter when performing maintenance, or by

permitting the pump to cavitate due to insufficient

system warm-up or leaks in the pump supply (suction) lines.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty operation. Every precaution must be taken to keep

hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced as necessary, at the specified intervals required in the Lubrication Chart in

Section 1. Always examine filters for evidence of

metal particles.

3. Cloudy oils indicate a high moisture content which

permits organic growth, resulting in oxidation or corrosion. If this condition occurs, the system must be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing components.

Hydraulic Oil

1. Refer to Section 1 for recommendations for viscosity

ranges.

3. The only exception to the above is to drain and fill

the system with Mobil DTE 13 oil or its equivalent.

This will allow start up at temperatures down to -20°F

(-29°C). However, use of this oil will give poor performance at temperatures above 120° (49°C). Systems

using DTE 13 oil should not be operated at temperatures above 200°F (94°C) under any condition.

Changing Hydraulic Oil

1. Use of any of the recommended hydraulic oils eliminates the need for changing the oil on a regular

basis. However, filter elements must be changed

after the first 50 hours of operation and every 300

hours thereafter. If it is necessary to change the oil,

use only those oils meeting or exceeding the specifications appearing in this manual. If unable to obtain

the same type of oil supplied with the machine, consult local supplier for assistance in selecting the

proper equivalent. Avoid mixing petroleum and synthetic base oils. JLG Industries recommends changing the hydraulic oil annually.

2. Use every precaution to keep the hydraulic oil clean.

If the oil must be poured from the original container

into another, be sure to clean all possible contaminants from the service container. Always clean the

mesh element of the filter and replace the cartridge

any time the system oil is changed.

3. While the unit is shut down, a good preventive maintenance measure is to make a thorough inspection

of all hydraulic components, lines, fittings, etc., as

well as a functional check of each system, before

placing the machine back in service.

Lubrication Specifications

Specified lubricants, as recommended by the component

manufacturers, are always the best choice, however,

multi-purpose greases usually have the qualities which

meet a variety of single purpose grease requirements.

Should any question arise, regarding the use of greases in

maintenance stock, consult your local supplier for evaluation. Refer to Section 1 for an explanation of the lubricant

key designations appearing in the Lubrication Chart.

2. JLG recommends Mobilfluid 424 hydraulic oil, which

has an SAE viscosity of 10W-30 and a viscosity

index of 152.

NOTE: Start-up of hydraulic system with oil temperatures

below -15°F (-26°C) is not recommended. If it is necessary to start the system in a sub-zero environment, it will be necessary to heat the oil with a low

density, 100VAC heater to a minimum temperature of

-15°F (-26°C).

2-4 – JLG Lift – 3121133

Loading...

Loading...