JLG 3969 Service Manual

Service and Maintenance Manual

Models

3369electric

3969electric

3120768

March 10, 2004

ANSI

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

A.A GENERAL

This section contains the general safety precautions

which must be observed during maintenance of the

aerial platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to

themselves or others, or damage to the equipment.

A maintenance program must be followed to ensure

that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY A RESPONSIBLE AUTHORITY THAT THE

MACHINE IS AT LEAST AS SAFE AS ORIGINALLY

MANUFACTURED, IS A SAFETY VIOLATION.

The specific precautions to be observed during

maintenance are inserted at the appropriate point in

the manual. These precautions are, for the most

part, those that apply when servicing hydraulic and

larger machine component parts.

Your safety, and that of others, is the first consideration when engaging in the maintenance of equipment. Always be conscious of weight. Never attempt

to move heavy parts without the aid of a mechanical

device. Do not allow heavy objects to rest in an

unstable position. When raising a portion of the

equipment, ensure that adequate support is provided.

SINCE THE MACHINE MANUFACTURER HAS NO

DIRECT CONTROL OVER THE FIELD INSPECTION

AND MAINTENANCE, SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPERATOR.

Relieve system pressure by cycling the applicable

control several times with the engine stopped and

ignition on, to direct any line pressure back into the

reservoir. Pressure feed lines to system components

can then be disconnected with minimal fluid loss.

A.C MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS

LISTED IN THIS SECTION MAY RESULT IN MACHINE

DAMAGE, PERSONNEL INJURY OR DEATH AND IS A

SAFETY VIOLATION.

• NO SMOKING IS MANDATORY. NEVER REFUEL DURING ELECTRICAL STORMS. ENSURE THAT FUEL CAP

IS CLOSED AND SECURE AT ALL OTHER TIMES.

• REMOVE ALL RINGS, WA TCHES AND JE WELRY WHEN

PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE-FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS ON MACHINE AND IN SERVICE MANUAL.

• KEEP OIL, GREASE, WATER, ETC. WIPED FROM

STANDING SURFACES AND HAND HOLDS.

• USE CAUTION WHEN CHECKING A HOT, PRESSURIZED COOLANT SYSTEM.

• NEVER WORK UNDER AN ELEVATED SIZZOR UNTIL

PLATFORM HAS BEEN SAFELY RESTRAINED FROM

ANY MOVEMENT BY BLOCKING OR OVERHEAD

SLING, OR BOOM SAFETY PROP HAS BEEN

ENGAGED.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT OFF

ALL POWER CONTROLS.

• BATTERY SHOULD AL WA YS BE DISCONNECTED DURING REPLACEMENT OF ELECTRICAL COMPONENTS.

A.B HYDRAULIC SYSTEM SAFETY

• KEEP ALL SUPPOR T EQUIPMENT AND ATTACHMENTS

It should be noted that the machines hydraulic systems operate at extremely high potentially dangerous pressures. Every effort should be made to

relieve any system pressure prior to disconnecting

or removing any portion of the system.

3120768 – JLG Sizzor – a

STOWED IN THEIR PROPER PLACE.

• USE ONLY AP PROVED, NONFLAMMABLE CLEANING

SOLVENTS.

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

REVISON LOG

March 25, 1999 - Original Issue (This manual was part of complete manual 3120597)

Updated November 24, 1999 - page 1-2

Updated November 24, 1999 - page 2-11

Updated March 10, 2004 - page 2-11

b – JLG Sizzor – 3120768

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A.A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .a-a

A.B Hydraulic System Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . a-a

A.C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .a-a

SECTION 1 - SPECIFICATIONS

1.1 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Component Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.5 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.7 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.8 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.9 critical stability weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.10 Relays/Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.11 Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SECTION 2 - PROCEDURES

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Servicing and Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Lubrication Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 Cylinders - Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5 Valves - Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.6 Component Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.7 Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.8 Motor Controller - Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.9 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.10 CYlinder Checking Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.11 Cylinder Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.12 Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.13 Tilt Switch Indicator Leveling Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2.14 Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2.15 Pressure Setting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2.16 Drive Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.17 Drive Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.18 Free Wheeling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.19 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

SECTION 3 - TROUBLESHOOTING

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Troubleshooting Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 Hydraulic Circuit Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3120768 – JLG Sizzor – i

TABLE OF CONTENTS (Continued)

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

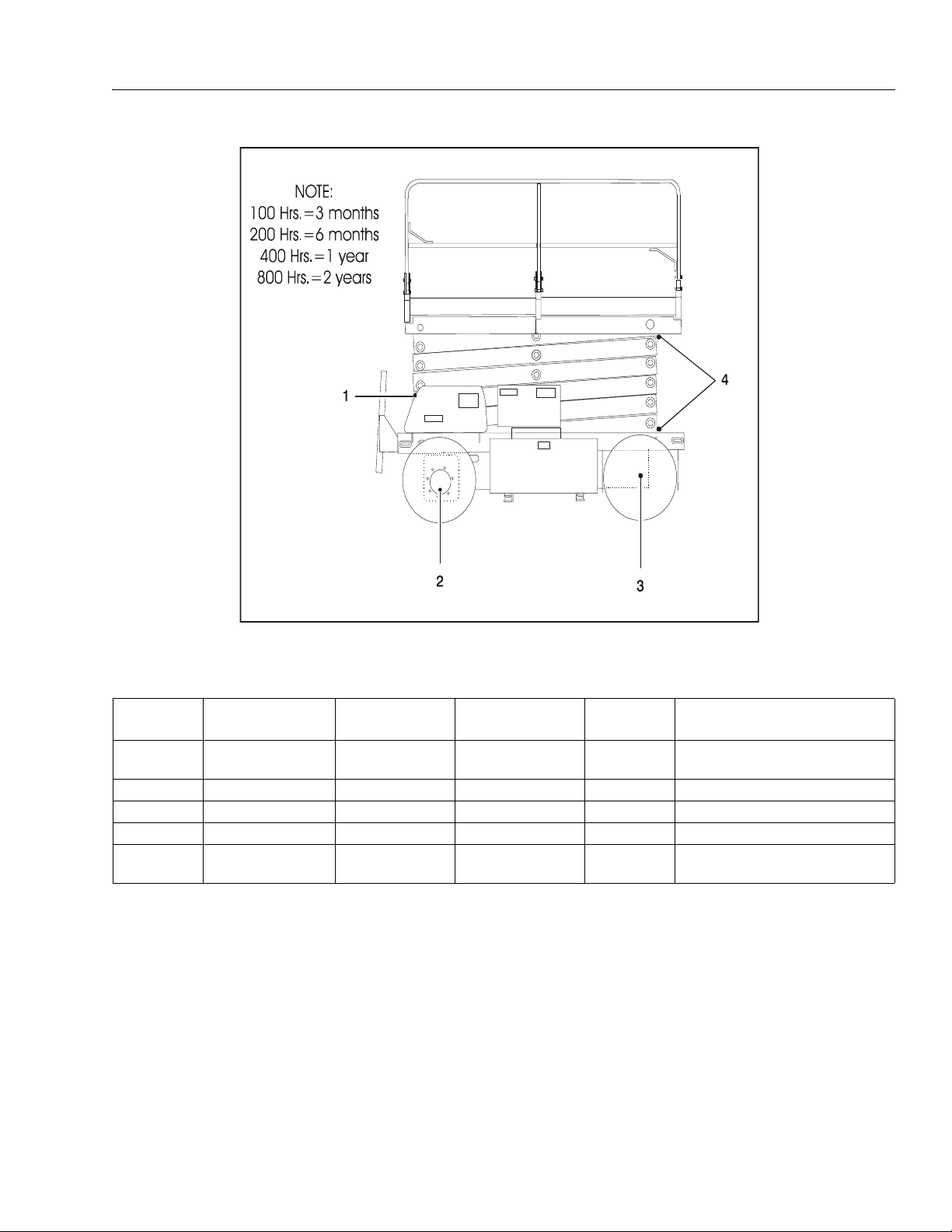

1-1. Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-2. Serial Number Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

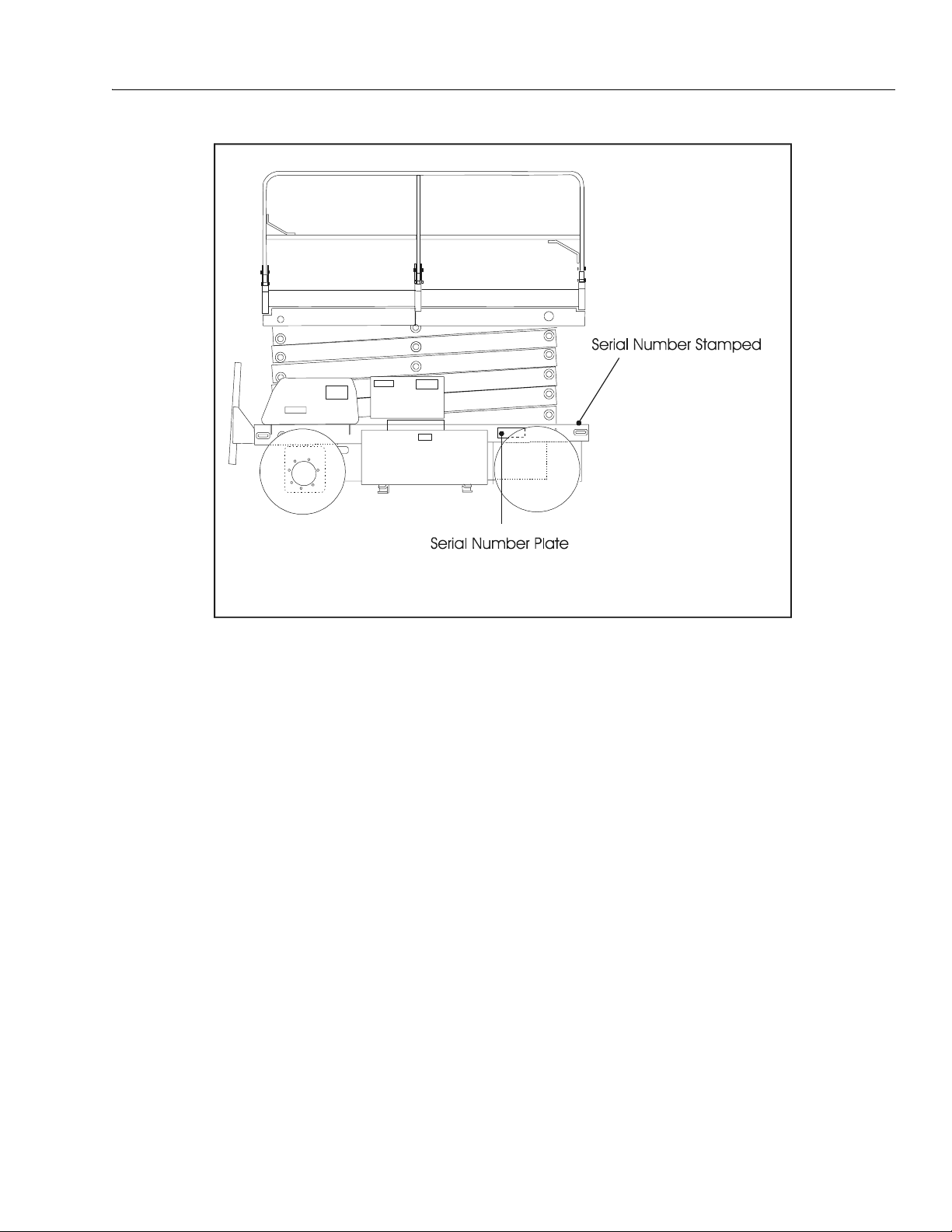

1-3. Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

2-1. Barrel Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-2. Capscrew Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-3. Rod Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-4. Tapered Bushing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-5. Oil-lite Bearing Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-6. Rod Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-7. Wiper Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-8. Installation of Head Seal Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-9. Piston Seal Kit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-10. Tapered Bushing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-11. Poly-Pak Piston Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-12. Rod Assembly Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-13. Pressure Setting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-14. Drive Torque Hub Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-15. Drive Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

3-1. Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3-2. Platform Wiring Diagram (Sheet 1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-2. Platform wiring Diagram (Sheet 2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-3. Ground Control Wiring Diagram (Sheet 1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3-3. Ground Control Wiring Diagram (Sheet 2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-3 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-4 Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-5 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-6 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-7 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2-1 Flash Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-2 Cylinder Piston Nut Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-3 Holding Valve Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-4 Preventive Maintenance and Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

3-1 Platform Assembly Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2 Chassis Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-3 Hydraulic System Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3-4 Electrical System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-5 Flash Code Troubleshooting Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

ii – JLG Sizzor – 3120768

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

1.1 CAPACITIES

Hydraulic Oil Tank

11.0 gallons (41.6 liters)

Hydraulic System

Approximately 13.2 gallons (50.0 liters)

Tor q u e H u b s ( 2 )

17 ounces (0.5 liters)

1.2 COMPONENT DATA

Battery Charger

Input, 110 VAC,60 HZ

Output, 48 VDC (23 Amp)

Batteries (8)

6 Volt, 245 AmpHour

Drive System

Drive Motor - 36 VDC, 4.1 H.P. @ 1880 rpm. continuous,

rotation - reversible

Drive Brake- 24 VDC, spring-applied, electrically released

Steer System

Tires - ST205 75R15, Load Range C, 6 Ply Rating, Poly

Filled

1.3 PERFORMANCE DATA

Travel Speed

3369/3969 electric - 3.0 mph (4.8 kmh)

High Drive for/rev (sec/50 ft) - 11-13 sec

Creep Drive for/rev (sec/50 ft) - 50-60 sec

Gradeability

25%

Turning Radius (Inside)

3369 electric - 60 in (1.52 m)

3969 electric - 60 in (1.52 m)

Turni ng Rad ius (O u tsid e )

3369 electric - 149 in (3.81 m)

3969 electric - 149 in (3.81 m)

Platform Lift Speed

3369 electric - Lift Up - 75 - 80 seconds

3369 electric - Lift Down - 50 - 60 seconds

3969 electric - Lift Up - 75 - 80 seconds

3969 electric - Lift Down - 50 - 60 seconds

Platform Capacity

3369 electric - 1000 lbs (454 kg)

3969 electric - 750 lbs (340 kg)

Platform Extension Capacity

3369 electric - 500 lbs (227 kg)

Toe-In - Adjust to 1/4 inch (6.4 mm) overall

Hydraulic Filter

Return, 25 Micron

Hydraulic Pump/Electric Motor Assembly

Motor - 48 VDC, 5.5 H.P. @ 2500 rpm

Pump - 0.098 in.[3]/rev. (1.6 cm[3]/rev.)

Pump Output - 1.09 gpm (4.13 lpm) @ 2000 psi (137.9

Bar)

3969 electric - 500 lbs (227 kg)

Machine Weight

3369 electric - 8,000 lbs (3629 kg)

3969 electric - 8,800 lbs (3992 kg)

Machine Height (w/rails folded down)

3369 electric - 73 in (1.85 m)

3969 electric - 79 in (2.01 m)

Machine Length (stowed)

3369 electric - 109 in (2.77 m)

3969 electric - 109 in (2.77 m)

3120768 – JLG Sizzor – 1-1

SECTION 1 - SPECIFICATIONS

Machine Width

3369 electric - 69 in (1.80 m)

3969 electric - 69 in. (1.80 m)

Wheelbase

3369 electric - 77 in (1.98 m)

3969 electric - 77 in (1.98 m)

Ground Clearance

3369 electric - 7 in (17.8 cm)

3969 electric - 7 in (17.8 cm)

Maximum Tire Load

3369 electric - 3060 lb (1388 kg)

3969 electric - 3145 lb (1427 kg)

Maximum Bearing Pressure

3369 electric - 56 psi (3.9 bar)

3969 electric - 58 psi (3.9 bar)

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system service. JLG Industries recommends Mobilfluid 424

hydraulic oil, which has an SAE viscosity index of

152.

When temperatures remain consistently below 2° F

(-7 ° C), JLG recommends the use of Mobil DTE 11.

NOTE: Aside from JLG recommendations, it is not advisable

to mix oils of different brands or types, as they may

not contain the same required additives or be of

comparable viscosities.

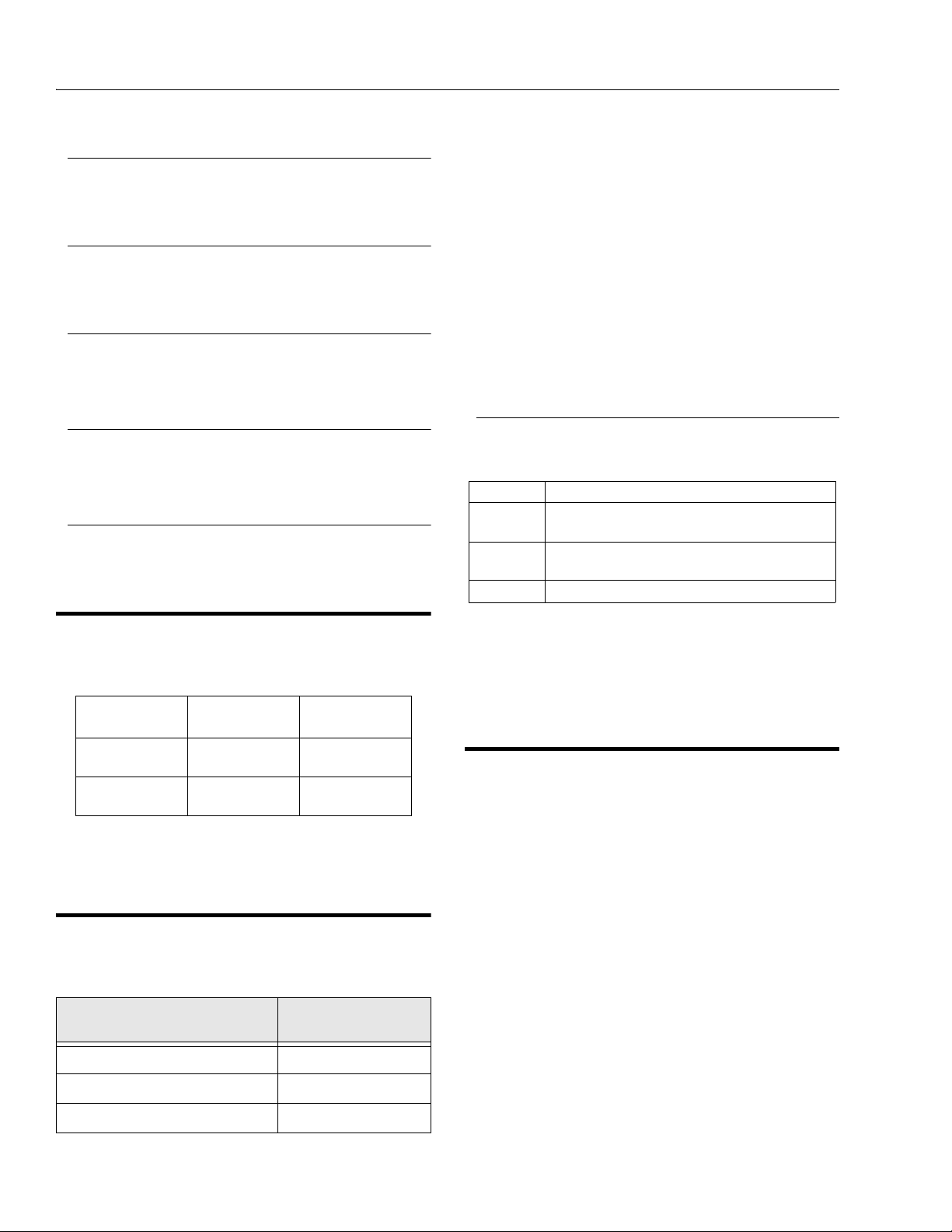

Lubrication Specifications

Table 1-3. Lubrication Specifications

KEY SPECIFICATIONS

EPGL Extreme Pressure Gear Lub e (oil) meeting API service

classification GL- 5 or MIL-Spec MIL-L-2105

HO Hydraulic Oil. API service classification Gl-3, BP Energo l

SHS46.

LL Synthetic Lithium Lub ricant, Gredag 741 Grease.

1.4 TORQUE SPECIFICATIONS

Ta b l e 1 - 1 . To r qu e S pe ci f i c a t i o n s

DESCRIPTION

Torque Hub 75 ft. lbs.

Wheel Bolts 90 ft. lbs.

NOTE: When maintenance becomes necessary or a fas-

tener has loosened, refer to the Torque Chart to

determine proper torque value.

TORQUE VALUE

(DRY)

102 (NM)

(122 NM)

INTERVAL HOURS

500

50

1.5 LUBRICATION

Ta b l e 1 - 2 . Hy dr au li c O i l

Hydraulic System Operating Temper-

ature Ra nge

0° F to 23° F (-18°C to -5°C) 10W

SAE Viscosit y Grade

*MPG may be substituted for these lubricants, if necessary, but service intervals will be reduced.

NOTE: Refer to Lubrication Chart for specific lubrication pro-

cedures.

1.6 PRESSURE SETTINGS

Lift Up Relief - 3369ES - 2500 psi (172 bar)

3969ES - 2700 psi (186 bar)

Lift Down Relief - 1000 psi (69 bar)

Steer Relief - 1200 psi (82.74 bar)

NOTE: Main Relief at Pump - 2700 psi (186.2 bar)

0° F to 210° F (-18°C to +99°C) 10W-20, 10W- 0

50° F to 210° F (+10°C to +99°C) 20W-20

Updated 11/24/99

1-2 – JLG Sizzor – 3120768

SECTION 1 - SPECIFICATIONS

Figure 1-1. Lubrication Chart

Table 1-4. Lubrication Chart

INDEX

NUMBER

1 Hydraulic Oil Fill Cap/Drain P lug HO-Kendall Hyken 05 2 8/800 Check oil every 8 hours of operation.

2 Torque Hub Fill Plug/Half Full EPGL-SAE 90 2000 Check oil level at side plug on hub.

3 Wheel Bearings N/A MPG - Repac k 800 2 years

4 Sliding P ads Wear Pads (8) MPG - Brush 50 N/A

5 (not s hown) Hydraulic Filter Element N/A Replaceab le Element 40/250 Replace fil ter element after first 40 hours of

KEY TO LUBRICANTS:

HO - Hydraulic Oil -Kendall Hyken 052

EPGL - Extreme Pressure Gear Lube

COMPONENT

NO/TYPE LUBE

POINTS

LUBE/METHOD

NOTE: Be sure to lubricate like items on each side of the

INTERVAL

HOURS

Change oil every 800 hours of operation.

operation then ever y 250 hours thereafter.

machine.

Recommended lubricating intervals are based on

machine operations under normal conditions. For

machines used in multi-shift operations and/or

exposed to hostile environments or conditions, lubricating frequencies must be increased accordingly

COMMENTS

3120768 – JLG Sizzor – 1-3

SECTION 1 - SPECIFICATIONS

1.7 CYLINDER SPECIFICATIONS

NOTE: All dimensions are given in inches (in.), with the met-

ric equivalent, centimeters (cm), given in parentheses. .

Table 1-5. Cylinder Specifications

DESCRIPTION BORE STROKE ROD DIA.

Lift Cylinder 4.00

(10.16)

Steer Cylinder

(Double Rod)

NOTE: All dimensions are given in inches (in.), with the met-

ric equivalent, centimeters (cm), given in parentheses.

2.00

(5.08)

14.68

(37.29)

3.00

(7.62)

each direction

2.50

(6.35)

1.25

(3.18)

each rod

1.8 MAJOR COMPONENT WEIGHTS

Table 1-6. Major Component Weights

COMPONENT 3369 ELECTRIC 3969 ELECTRIC

LBS. KG. LBS. KG.

Platform 761 345 761 345

Platform Extension 320 145 320 145

Arm Assembly (Inc ludes Lift

Cylinders)

Chassis (Includes Batt ery

Box and Foam filled Tires)

Machine Complete (G VW) 8000 3629 8800 3992

3393 1539 3903 1770

3662 1661 3662 1661

1.9 CRITICAL STABILITY WEIGHTS

Table 1-7. Critical Stability Weights

COMPONENT 3369/3969 ELECTRIC

LBS. KG.

Platform 761 345

Platform Extension 320 145

Foam Filled Tires 150 68

Battery (Each) 77 35

1.10 RELAYS/CIRCUIT BREAKERS

Console Box

Relay - Potter & Brumfield P/N K10P-11D15-48 48VDC.

Circuit Breaker - Wood Electric Corp. P/N W58 x BIA4 A-5.

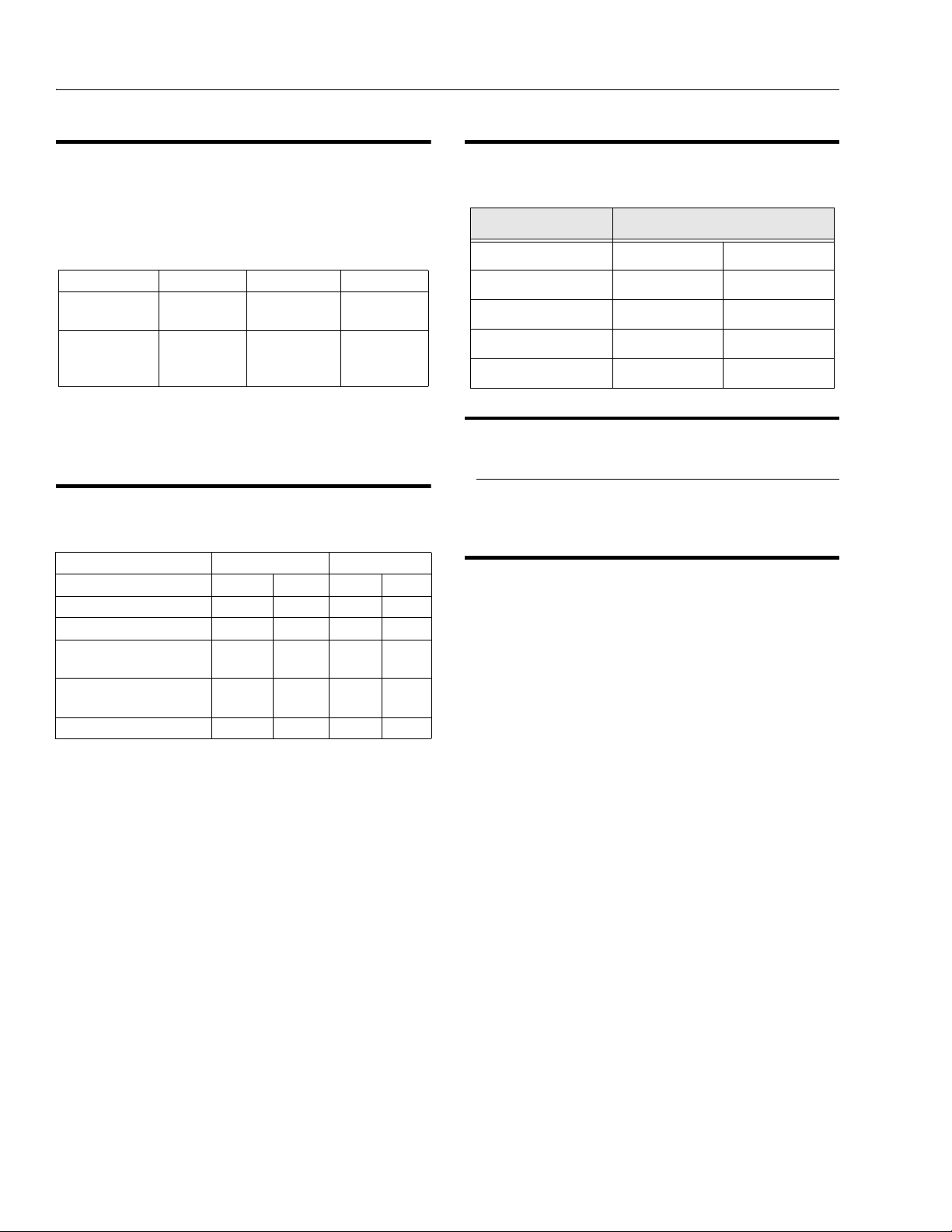

1.11 SERIAL NUMBER LOCATIONS

For machine identification, a serial number plate is affixed

to the front of the frame. If the serial number plate is damaged or missing, the machine serial number is stamped

on the right front of the machine frame.

1-4 – JLG Sizzor – 3120768

SECTION 1 - SPECIFICATIONS

Figure 1-2. Serial Number Location

3120768 – JLG Sizzor – 1-5

SECTION 1 - SPECIFICATIONS

Figure 1-3. Torque Chart

1-6 – JLG Sizzor – 3120768

SECTION 2. PROCEDURES

SECTION 2 - PROCEDURES

2.1 GENERAL

1. This section provides information necessary to perform maintenance on the sizzor lift. Descriptions,

techniques and specific procedures are designed to

provide the safest and most efficient maintenance

for use by personnel responsible for ensuring the

correct installation and operation of machine components and systems.

WHEN AN ABNORMAL CONDITION IS NOTED AND PROCEDURES

CONTAINED HEREIN DO NOT SPECIFICALLY RELATE TO THE

NOTED IRREGULARITY, WORK SHOULD BE STOPPED AND

TECHNICALLY QUALIFIED GUIDANCE OBTAINED BEFORE WORK

IS RESUMED.

2. The maintenance procedures included consist of

servicing and component removal and installation,

disassembly, and assembly, inspection, lubrication

and cleaning. Information on any special tools or

test equipment is also provided where applicable.

2.2 SERVICING AND MAINTENANCE

GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this chapter.

Safety and Workmanship

Your safety and that of others is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

2. At any time when hydraulic oil lines are disconnected, clear adjacent areas as well as the openings

and fittings themselves. As soon as a line or component is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their containers until they are ready to be used.

Component Removal and Installation

1. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpendicular as possible to top of part being

lifted.

2. Should it be necessary to remove a component on

an angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between

the supporting structure and the component

becomes less than 90 degrees.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc. have been

removed and that no adjacent parts are interfering.

Component Disassembly and Reassembly

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure Fit Parts

When assembling pressure fit parts, use an “anti-seize” or

molybdenum disulfide base compound to lubricate the

mating surface.

Cleanliness

1. The most important single item in preserving the

long service life of a machine is to keep dirt and foreign materials out of the vital components. Precautions have been taken to safeguard against this.

Shields, covers, seals and filters are provided to

keep oil supplies clean; however, these items must

be maintained on a scheduled basis in order to function properly.

Bearings

1. When a bearing is removed, cover it to keep out dirt

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bearing.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored or burned.

3120768 – JLG Sizzor – 2-1

SECTION 2 - PROCEDURES

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

unwrap reusable or new bearings until they are

ready to be installed.

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bearing is to be installed on a shaft, apply pressure to the

inner race.

Gaskets

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat treated bolts, studs and steel nuts, in accordance with recommended shop practices.

Hydraulic Lines and Electrical Wiring

Batteries

Clean batteries using a non-metallic brush and a solution

of baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry batteries and coat terminals with

an anti-corrosion compound.

Lubrication and Servicing

Components and assemblies requiring lubrication and

servicing are shown in Section 1.

2.3 LUBRICATION INFORMATION

Hydraulic System

1. The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various

means, e.g.; inadequate hydraulic oil, allowing moisture, grease, filings, sealing components, sand, etc.

to enter when performing maintenance, or by permitting the pump to cavitate due to insufficient system warm-up.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty operation. Every precaution must be taken to keep

hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced at the specified intervals

required in Section 1. Always examine filters for evidence of metal particles.

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System

1. Keep the system clean. If evidence of metal or rubber particles are found in the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

3. Cloudy oils indicate a high moisture content which

permits organic growth, resulting in oxidation or corrosion. If this condition occurs, the system must be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing components.

Hydraulic Oil

Lubrication

Service applicable components with the amount, type,

and grade of lubricant recommended in this manual, at

the specified interval. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

2-2 – JLG Sizzor– 3120768

1. Refer to Lubrication Specification Table for recommendations for viscosity ranges.

2. JLG recommends Kendall Hyken 052 Hydraulic Oil,

which has an SAE viscosity of 10W-20 and a viscosity index of 152.

Loading...

Loading...