Ingersoll-Rand 651616-X User Manual

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

INCLUDE MANUALS: 66516-X FOLLOWER PLATE (PN 97999-854), 67195-X FOLLOWER PLATE (PN 97999-841) &

S-635 GENERAL INFORMATION (PN 97999-635)

651616-X

RELEASED: 6-6-02

REVISED: 3-4-10

(REV. L)

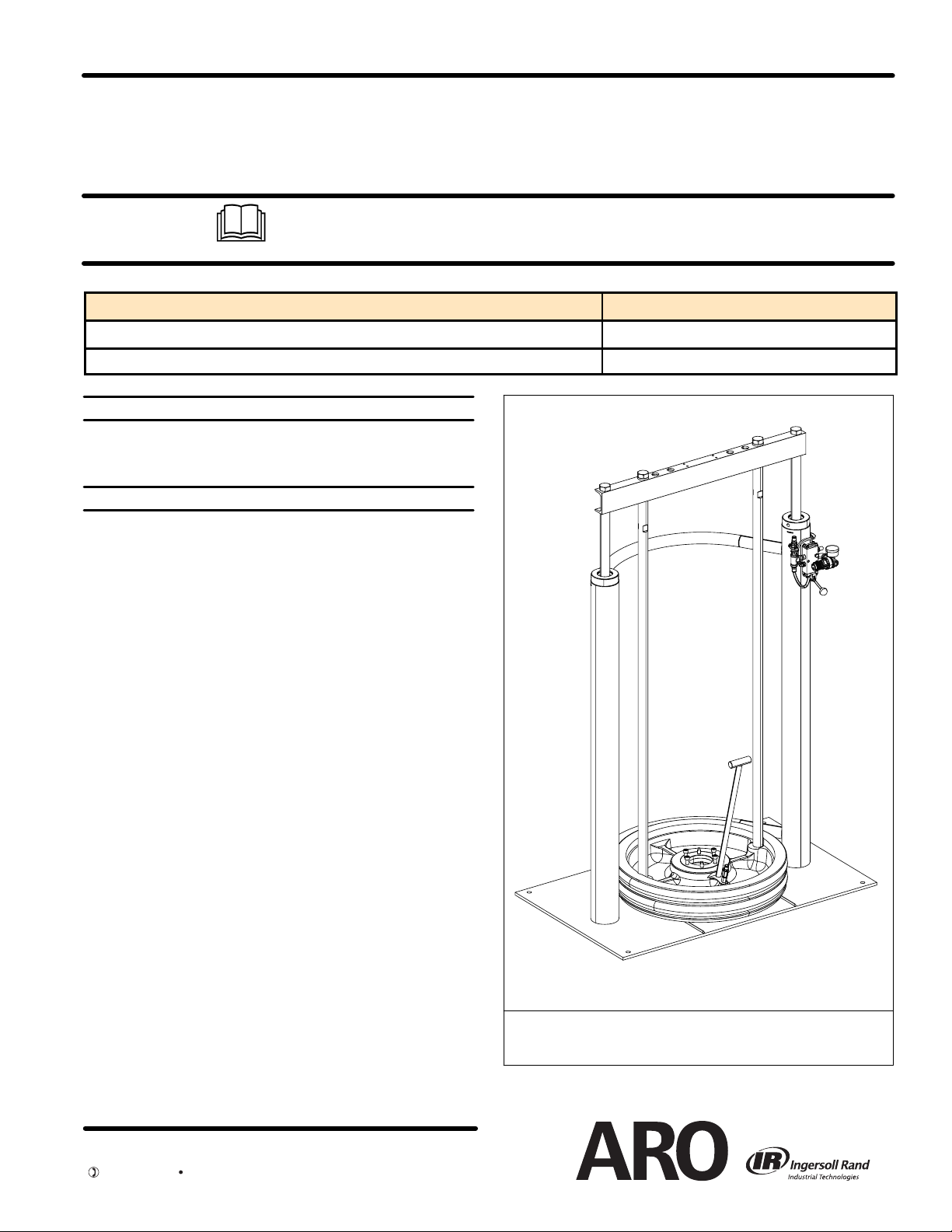

TWO POST LIFT / RAM

(67081 BASIC LIFT / RAM PLUS FOLLOWER PLATE)

For use with 5 - 55 Gallon Drums

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

THIS MANUAL COVERS THE FOLLOWING MODELS (COMPLETE FOLLOWER DATA ON PAGE 3)

MODEL (See Page 3 for Follower Plate)

651616-1, -2, -3, -7, -8, -9, -13, -14, -15, -19, -51, -52, -53, -57, -58, -59, -63 3-1/4’’ TO 6’’ AIR MOTORS (TIE ROD PUMPS)

651616-4, -5, -6, -10, -11, -12, -16, -17, -18, -20, -54, -55, -56, -60, -61, -62, -64 8’’ TO 12’’ AIR MOTORS (TIE ROD PUMPS)

SERVICE KITS

116772 for repair of E512LM valve.

104302 for repair of R37121-100 miniature regulator.

GENERAL DESCRIPTION

TYPICAL PUMP APPLICATION

The ARO Model 651616-X Two Post Lift / Ram uses two 3-1/2’’ air-powered cylinders connected by tubular steel cross member and is welded

to a heavy gauge base plate. It is normally used to raise and lower a fluid

handling pump and follower in and out of a standard 55 - gallon drum, or

when used as a ram it can force high viscosity flowable material into the

pump inlet. It is offered with several follower plate options (see page 4)

which will accommodate most of the ARO Fluid Handling Industrial

pumps and allow connection directly to the pump lower end. There are

also mounting locations on the horizontal beam for the vertical rods allowing use with 5 - gallon containers. Pump air controls (F-R-L) can be

mounted on the top horizontal support beam using the holes provided.

Cast aluminum followers are fitted with a dual lip seal or dual ‘‘O” ring

seal to wipe the drum clean and seal off the material from the atmosphere. Several material options are available for the follower plate outer seal. Select a compatible seal for the material being pumped. The

model chart above shows the pump motors they will generally accommodate.

When properly secured, this unit has the ability to raise a pump to clear a

standard 55 - gallon drum. The operator is then able to easily remove the

pump from the drum.

This Lift / Ram uses a hand lever 4-way control valve which controls the

air necessary to raise and lower the lift. This unit includes an auxiliary

manual air valve which is used to supply a controlled amount of air pressure to the bottom of the follower plate. When the control valve is in the

‘‘UP’’ position, a small amount of air pressure applied under the follower

plate will help to raise the follower plate, pump and lift by relieving the

vacuum (refer to page 5).

Refer to page 2 for optional accessories available for pump stabilization

and drum hold down.

651616-1

FIGURE 1

BASE DIMENSIONS: 39-1/2’’ (1003.3 mm) x 24’’ (609.6 mm)

HEIGHT: LOWERED 61-17/32’’ (156.3 cm), RAISED: 99-5/32’’ (251.9 cm)

TWOPOSTLIFT/RAM

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

© 2010

CCN 99445348

OPERATING AND SAFETY PRECAUTIONS

Z Read and heed all Warnings, Cautions and Safety Precautions

before operating.

Z Use only genuine ARO replacement partsto assurecompatible

pressure rating and longest service life.

WARNING

CRETE FLOOR. An improperly secured lift could be unsafe. Do

not attempt to use the lift until all possible measures have been

taken to insure that the lift has been properly installed and the

base has been secured. It is the duty of the installer to provide an-

chor bolts / studs (not included) and for them to be securely embedded in concrete which is more than 2’’ thick.

WARNING

above the lift is clear of electrical fixtures, devices and w iring.

Examine the working area and take necessary action to assure adequate clearance for the lift and pump assembly to raise to the fullest

limit and function properly.

ANCHOR THE LIFT BASE SECURELY TO A CON-

Shock hazard.

Striking electrical

fixtures can cause

injury.

Keep the area

overhead clear of

electrical devices.

PREVENT ELECTRIC SHOCK. Be certain the area

Pinch hazard.

Follower can descend

quickly causing injury.

Keep hands clear

when aligning with

container.

WARNING

PINCH HAZARD. Follower can descend quickly,

causing injury. Keep hands clear when aligning with container.

In the raising and lowering function, the lift could get hung up or the

descent could be temporarily restricted. The lift could, in some situations, drop suddenly and be hazardous. If the follower plate does not

enter the drum properly, DO NOT ATTEMPT TO REPOSITION IT

WITH YOUR HANDS; release the downward pressure, raise the lift,

realign the drum and restart.

WARNING

STANDCLEAR. When raising or lowering the lift,

keep clear and operate from a safe position.

Hazardous pressure.

Can result in injury or

property damage.

WARNING

HAZARDOUS PRESSURE. Do not exceed maxi-

Do not exceed maximum inlet air pressure.

mum inlet air pressure of 150 psi (10.3 bar). Operating lift at higher pressure may cause lift damage and / or personal injury and / or

property damage. Do not service or clean pump, hoses or dispensing valve while the system is pressurized.

WARNING

DO NOT EXCEED DRUM PRESSURE LIMITS.

Know the pressure limitations of the drum and regulate the air pressure within safe limits when supplying air to the follower plate.

CAUTION

Be certain all operators of this equipment have

been trained for safe working practices, understand it’s limitations and wear their safety goggles / equipment as required.

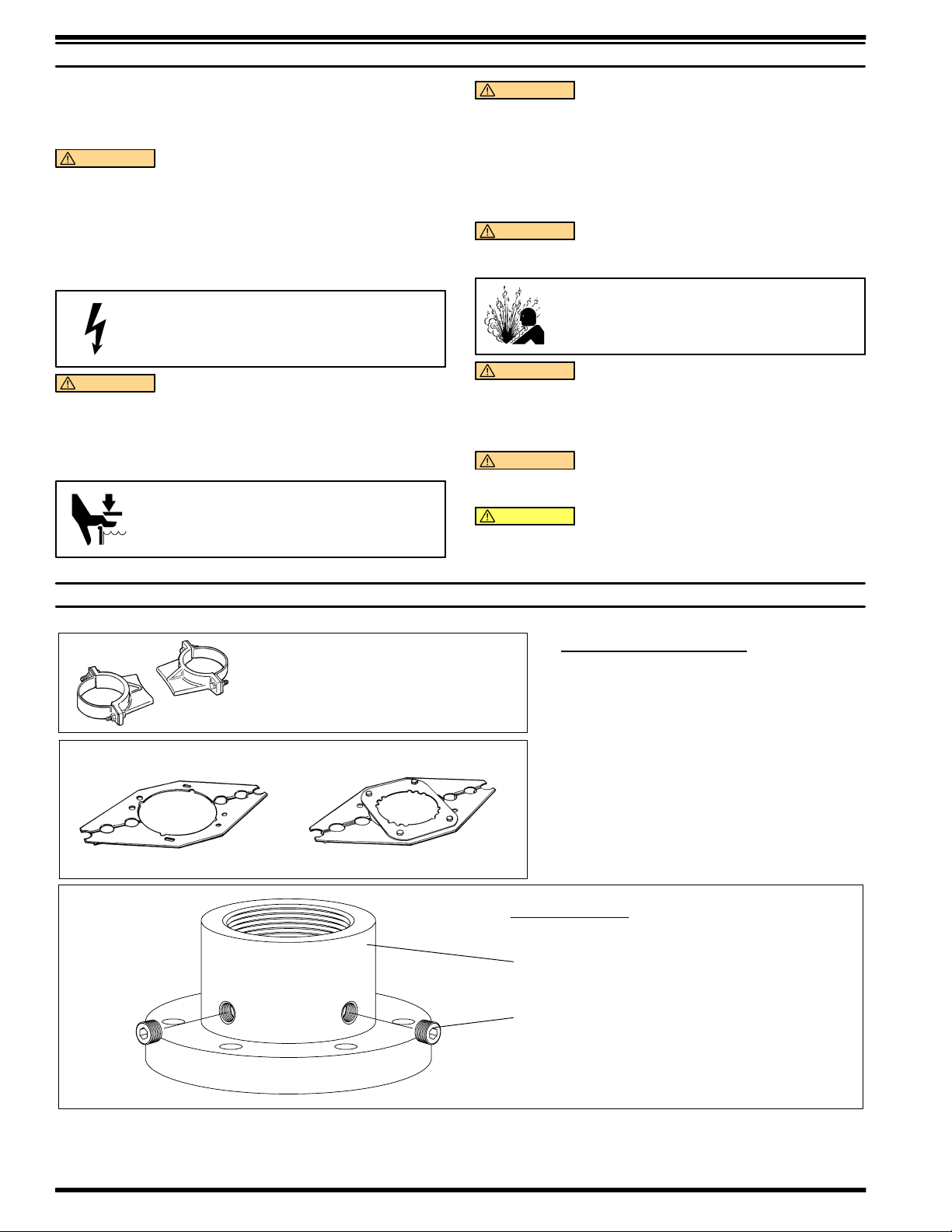

Pump Stabilizing Bracket Kit (includes hardware)

66353-1 for 8’’, 10’’, 12” Motors

OPTIONAL EQUIPMENT

67133 Drum Hold Down Bracket Kit

Includes (2 of each): Brackets, Clamps,

Screws, Nuts.

66354-1 for 3-1/4’’, 4-1/4’’, 6’’ Motors

H Filter-Regulator-Lubricators

4-1/4’’, 6-1/4’’ - 65940 HD FRL w / Bracket

8’’ - 651730 HD FRL w / Bracket

10’’, 12’’ - 651729 HD FRL w / Bracket

H Polyethylene Follower Plate seal

protector sheets

91364-10 Pkg of 10 - 20’’ dia. (5 Gal. drum)

91363-10 Pkg of 10 - 32’’ dia. (55 Gal. drum)

67136 Adapter Kit

67136 Adapter Kit Assembly

Y17-50-S Pipe Plug (2) ~

~ Included in 67136 Adapter Kit Assembly.

651616-XPAGE 2 OF 8

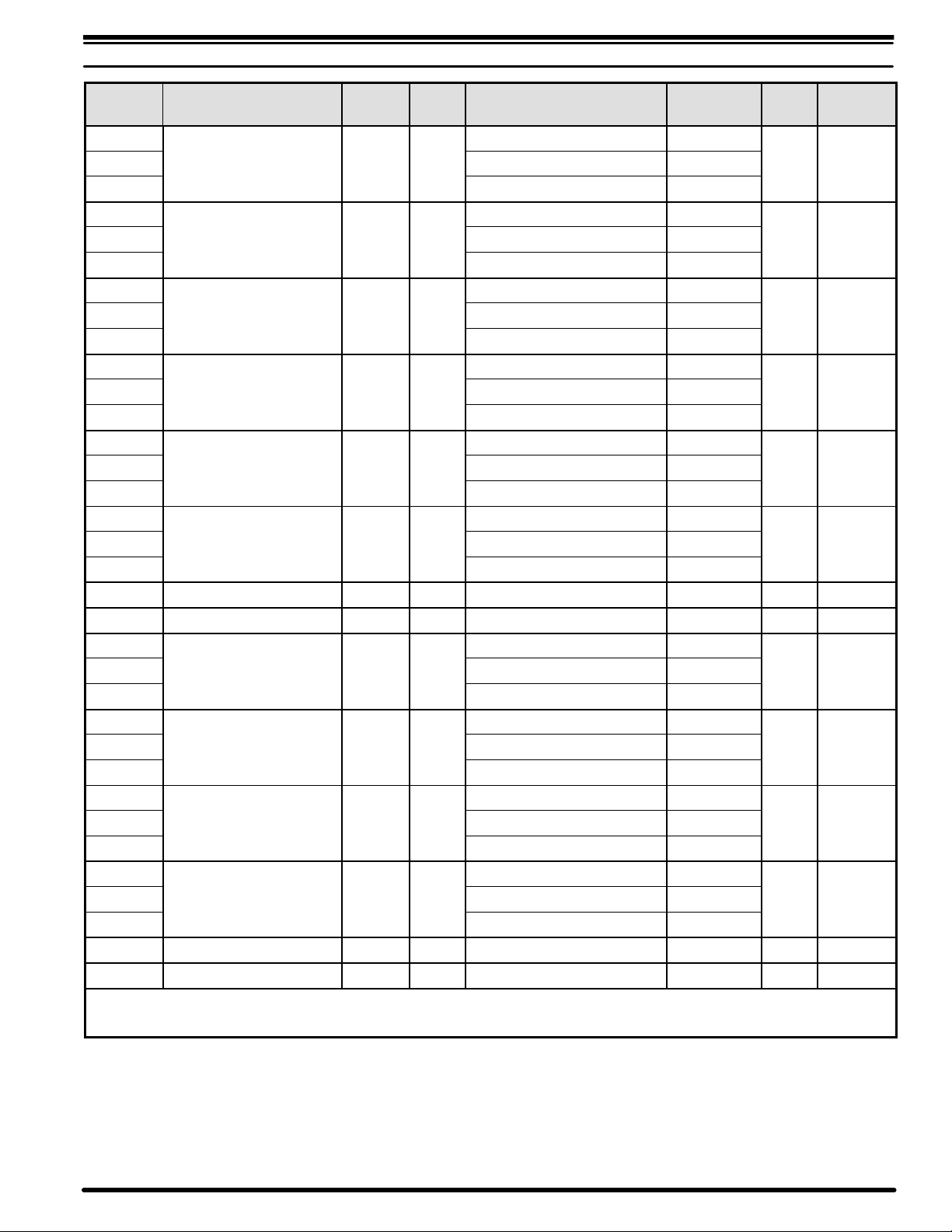

MODEL DESCRIPTION / FOLLOWER PLATE OPTIONS

MODEL DESCRIPTION

PLATE

STYLE

PUMP

SIZE

D’BL LIP FOLLOWER SEAL

MATERIAL, PART #

COLOR

FOLLOWER

PLATE (Pg.4)

ROD

POS’N

BASIC

RAM/LIFT

651616-1 Nitrile, 92334 D 66516

651616-2 Standard Duty Flat Small Polyurethane, 92122 ~ 66516-1 A 67081

651616-3 EPR, 92132 D 66516-2

651616-4 Nitrile, 92334 D 66517

651616-5 High Volume Flat Large Polyurethane, 92122 ~ 66517-1 B 67081

651616-6 EPR, 92132 D 66517-2

651616-7 Nitrile, 92334 D 66667

651616-8 High Viscosity Tapered Small Polyurethane, 92122 ~ 66667-1 A 67081

651616-9 EPR, 92132 D 66667-2

651616-10 Nitrile, 92334 D 66668

651616-11 High Volume High Viscosity Tapered Large Polyurethane, 92122 ~ 66668-1 B 67081

651616-12 EPR, 92132 D 66668-2

651616-13 EPR, 360-009 D (TUBE TYPE) 67195-2

651616-14 Any Viscosity Tapered Small Neoprene, 360-008 D (TUBE TYPE) 67195-1 A 67081

651616-15 Viton, 360-008V D (TUBE TYPE) 67195-3

651616-16 EPR, 360-009 D (TUBE TYPE) 67196-2

651616-17 High Volume Any Viscosity Tapered Large Neoprene, 360-008 D (TUBE TYPE) 67196-1 B 67081

651616-18 Viton, 360-008V D (TUBE TYPE) 67196-3

651616-19 Any Viscosity Tapered Small Neoprene, 360-008-1 D (TUBE TYPE) 67195-8 A 67081

651616-20 High Volume Any Viscosity Tapered Large Neoprene, 360-008-1 D (TUBE TYPE) 67196-8 B 67081

651616-51 Nitrile, 92334 D 66516-5 =

651616-52 Standard Duty Flat Small Polyurethane, 92122 ~ 66516-6 = A 67081

651616-53 EPR, 92132 D 66516-7 =

651616-54 Nitrile, 92334 D 66517-5 =

651616-55 High Volume Standard Duty Flat Large Polyurethane, 92122 ~ 66517-6 = B 67081

651616-56 EPR, 92132 D 66517-7 =

651616-57 EPR, 360-009 D (TUBE TYPE) 67195-6 =

651616-58 Any Viscosity Tapered Small Neoprene, 360-008 D (TUBE TYPE) 67195-5 = A 67081

651616-59 Viton, 360-008V D (TUBE TYPE) 67195-7 =

651616-60 EPR, 360-009 D (TUBE TYPE) 67196-6 =

651616-61 High Volume Any Viscosity Tapered Large Neoprene, 360-008 D (TUBE TYPE) 67196-5 = B 67081

651616-62 Viton, 360-008V D (TUBE TYPE) 67196-7 =

651616-63 Any Viscosity Tapered Small Neoprene, 360-008-1 D (TUBE TYPE) 67195-9 = A 67081

651616-64 High Volume Any Viscosity Tapered Large Neoprene, 360-008-1 D (TUBE TYPE) 67196-9 = B 67081

SMALL = 3-1/4’’, 4-1/4”, 6’’ Motors, 2-Ball, 8” 44:1, 38:1 2-Ball ~ RED D BLACK

LARGE = 8’’, 10’’, 12’’ Extrusion pumps, (Except 8” 44:1, 38:1)

= Follower plate is PTFE coated.

651616-X

PAGE 3 OF 8

Loading...

Loading...