Ingersoll-Rand FA5, FA5T User Manual

Form MHD56037

PARTS, OPERATION AND MAINTENANCE MANUAL

MODEL FA5 AND FA5T

(Dwg. MHP2107)

READ THIS MANUAL BEFORE USING THESE PRODUCTS. This manual contains important safety, installation, operation and maintenance information. Make this manual available to all persons responsible for the installation, operation and maintenance of these products.

WARNING

WARNING

Do not use this winch for lifting, supporting, or transporting people unless winch is approved for Man RiderTM applications. Do not lift or support loads over people.

Always operate, inspect and maintain this winch in accordance with American Society of Mechanical Engineers Standards Safety Code (ASME B30.7) and any other applicable safety codes and regulations.

Form MHD56037 Edition 5

May 2006 71062103

© 2006 Ingersoll Rand Company

TABLE OF CONTENTS

Description |

Page No. |

Safety Information

Danger, Caution, Warning and Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Safe Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Warning Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications

Model Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Performance Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Traceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Wire Rope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Air Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Constant Tension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Initial Operating Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation

Winch Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Underwound Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Emergency Stop and Overload System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Overload Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Winch Overload Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Constant Tension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Winch Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Drum Locking Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Lubrication

Recommended Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Component Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inspection

Records and Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Frequent Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Winches not in Regular Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Inspection and Maintenance Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Troubleshooting

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Maintenance

Maintenance Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 K5C2 Control Valve Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Cleaning, Inspection and Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 K5C2 Control Valve Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 K5C2E Control Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Parts Information

FA5 Winch Assembly Drawings Reference Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 FA5 Winch Drawings and Parts Lists Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 FA5 Winch Drawings and Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40-76 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2 |

MHD56037 - Edition 5 |

SAFETY INFORMATION

This manual provides important information for all personnel involved with the safe installation, operation and proper maintenance of this product. Even if you feel you are familiar with this or similar equipment, you should read this manual before operating the winch.

Danger, Warning, Caution and Notice

Throughout this manual there are steps and procedures which, if not followed, may result in a hazard. The following signal words are used to identify the level of potential hazard.

Danger is used to indicate the presence of  DANGER a hazard which will cause severe injury,

DANGER a hazard which will cause severe injury,

death, or substantial property damage if the warning is ignored.

WARNING

WARNING

CAUTION

CAUTION

Warning is used to indicate the presence of a hazard which can cause severe injury, death, or substantial property damage if the warning is ignored.

Caution is used to indicate the presence of a hazard which will or can cause injury or property damage if the warning is ignored.

Notice is used to notify people of NOTICE installation, operation, or maintenance

information which is important but not hazard-related.

Safety Summary

WARNING

WARNING

•Do not use this winch for lifting, supporting, or transporting people unless winch is approved for Man RiderTM applications. Do not lift or support loads over people.

•The supporting structures and load-attaching devices used in conjunction with this winch must provide an adequate safety factor to handle the rated load, plus the weight of the winch and attached equipment. This is the customer’s responsibility. If in doubt, consult a registered structural engineer.

Ingersoll Rand winches are manufactured in accordance with the latest ASME B30.7 standards.

The National Safety Council, Accident Prevention Manual for Industrial Operations, Eighth Edition and other recognized safety sources make a common point: Employees who work near suspended loads or assist in hooking on or arranging a load should be instructed to keep out from under the load. From a safety standpoint, one factor is paramount: conduct all lifting or pulling operations in such a manner that if there were an equipment failure, no personnel would be injured. This means keep out from under a raised load and keep out of the intended path of any load.

The Occupational Safety and Health Act of 1970 generally places the burden of compliance with the user, not the manufacturer. Many OSHA requirements are not concerned or connected with the manufactured product but are, rather, associated with the final installation. It is the owner’s and user’s responsibility to determine the suitability of a product for any particular use. It is recommended that all applicable industry, trade association, federal, state and local regulations be checked. Read all operating instructions and warnings before operation.

Rigging: It is the responsibility of the operator to exercise caution, use common sense and be familiar with proper rigging techniques. Refer to ASME B30.9 for rigging information, American Society of Mechanical Engineers, Three Park Avenue, New York, NY 10015.

This manual has been produced by Ingersoll Rand to provide dealers, mechanics, operators and company personnel with information required to install, operate, maintain and repair the products described herein.

It is extremely important that mechanics and operators be familiar with servicing procedures of these products, or like or similar products, and are physically capable of conducting the procedures. These personnel shall have a general working knowledge that includes:

1.Proper and safe use and application of mechanics common hand tools as well as special Ingersoll Rand or recommended tools.

2.Safety procedures, precautions and work habits established by accepted industry standards.

Ingersoll Rand cannot know of, or provide all the procedures by which product operations or repairs may be conducted and the hazards and/or results of each method. If operation or maintenance procedures not specifically recommended by the manufacturer are conducted, it must be ensured that product safety is not endangered by the actions taken. If unsure of an operation or maintenance procedure or step, personnel should place the product in a safe condition and contact supervisors and/ or the factory for technical assistance.

MHD56037 - Edition 5 |

3 |

SAFE OPERATING INSTRUCTIONS

The following warnings and operating instructions have been adapted in part from American Society of Mechanical Engineers (Safety) Standard ASME B30.7 and are intended to avoid unsafe operating practices which might lead to injury or property damage.

Ingersoll Rand recognizes that most companies who use winches have a safety program in force at their facility. In the event that some conflict exists between a rule set forth in this publication and a similar rule already set by an individual company, the more stringent of the two should take precedence.

Safe Operating Instructions are provided to make an operator aware of dangerous practices to avoid and are not necessarily limited to the following list. Refer to specific sections in the manual for additional safety information.

1.Only allow personnel trained in safety and operation of this product to operate and maintain this winch.

2.Only operate a winch if you are physically fit to do so.

3.When a “DO NOT OPERATE” sign is placed on winch, or controls, do not operate winch until sign has been removed by designated personnel.

4.Before each shift, check winch for wear and damage. Never use a winch that inspection indicates is worn or damaged.

5.Never lift a load greater than rated capacity of the winch. Refer to labels attached to winch or to “SPECIFICATIONS” section.

6.Keep hands, clothing, etc., clear of moving parts.

7.Never place your hand in the throat area of a hook or near wire rope spooling onto or off of winch drum.

8.Always rig loads properly and carefully.

9.Be certain the load is properly seated in saddle of hook. Do not support load on tip of hook.

10.Do not “side pull” or “yard”.

11.Always ensure that you, and all other people, are clear of the path of the load. Do not lift a load over people.

12.Never use the winch for lifting or lowering people, and never allow anyone to stand on a suspended load.

13.Ease slack out of wire rope when starting a lift or pull. Do not jerk the load.

14.Do not swing a suspended load.

15.Do not leave a suspended load unattended.

16.Never operate a winch with twisted, kinked or damaged wire rope.

17.Pay attention to the load at all times when operating the winch.

18.Never use the winch wire rope as a sling.

19.After use, or when in a non-operational mode, winch should be secured against unauthorized and unwarranted use.

WARNING LABEL

Each unit is shipped from the factory with warning label shown. If the label is not attached to your unit, order a new label and install it. Refer to the parts list for part number. Label is shown smaller than actual size.

(Dwg. 71060529)

4 |

MHD56037 - Edition 5 |

SPECIFICATIONS

Model Code Explanation |

|

|

|

|

|

|

|

Example: FA5-24MK320P |

FA5 |

- |

24 |

M |

K |

320 |

P |

Series (Capacity)

FA5 = Air Powered Winch (5 metric ton / 11,000 lbs.) Drum Flange Height or Man Rider®:

- = Standard flange: 27 inch (660 mm) diameter

T |

= |

Tall flange: 35 inch (890 mm) diameter |

MR |

= |

Man RiderTM (Refer to FA5 Man RiderTM Supplement Form #MHD56042) |

Drum Length (Distance between drum flanges):

12 = 12 inch (306 mm)

16 = 16 inch (406 mm)

24 = 24 inch (610 mm) (Standard)

30 = 30 inch (760 mm)

36 = 36 inch (915 mm) Tall Flange Winch only

Drum Brake:

A = Automatic Drum Brake

M = Manual Drum Brake

X = None

Disc Brake:

K = Automatic Disc Brake

X = None

Control:

|

1 |

= Winch mounted lever throttle. (Standard) |

|

* |

2XX |

= Remote full flow lever throttle (XX = Specify hose length (feet). Maximum 20 ft. (6 metres)) |

|

* |

3XX |

= Remote pilot pendant throttle (XX = Specify hose length (feet). Maximum 50 ft. (15 metres)) |

|

* |

4XX |

= |

|

Remote pilot lever throttle (XX = Specify length (feet). Maximum 50 ft. (15 metres)) |

|||

* |

5XX |

= |

Remote electric over air throttle† |

Options: **

|

7 |

= |

Drum Grooving (Number = wire rope size in sixteenths, e.g. 7/16 inch) † |

** |

C |

= |

Low Temperature Components; specify -10° C (14° F) or -20° C (-4° F) |

D= Drum Divider Flange and additional wire rope anchor †

E= Construction Cage†

|

G |

= |

Drum Guard |

|

|

|

L |

= |

Drum Locking Pin |

|

|

** |

M1 |

= Material Traceability (typical material results) †† |

|

|

|

** |

M2 |

= Material Traceability (actual material results) †† |

|

|

|

** |

M3 |

= Material Traceability (actual material results for these parts in finished, as-delivered condition) †† |

|||

|

N |

= |

Type Approval – Specify: |

|

|

|

A = American Bureau of Shipping (ABS); N = Det Norske Veritas (DNV); R = Lloyd’s Register of Shipping (LRS) |

||||

|

P |

= Marine Grade Corrosion Preventative Finish |

|

|

|

|

Q |

= |

|

|

|

|

Special paint |

U |

= Underwound wire rope operation † |

||

|

S |

= |

Limit Switch (upper and lower) |

V |

= Press Roller |

|

T |

= |

Tensioning Manifold |

W |

= Witness; please specify ** |

|

Z |

= |

Sandblast and Carbozinc Primer |

X |

= Testing; please specify |

|

-E |

= Compliance with European Machinery Directive (includes Emergency Stop and Overload Protection) |

|||

Notes: * Remote throttles are provided with 10 feet (3 metres) of hose. Specify hose lengths greater than 10 feet. For lengths greater than 20 ft. (6 metres) with the Remote Full Flow Throttle, or 50 ft. (15 metres) with the Remote Pilot Lever and Remote Pilot Pendant Throttles contact your Ingersoll Rand distributor or the factory for control acceptability. Metric lengths are provided for reference only, order lengths in feet.

**Documentation, witness testing and material traceability available; must be requested at time of order. Specify options or contact the factory or your nearest Ingersoll Rand distributor for information.

† Not covered in this manual.

†† Refer to ‘Traceability’on page 8 for a description of the differences between M1, M2 and M3.

MHD56037 - Edition 5 |

5 |

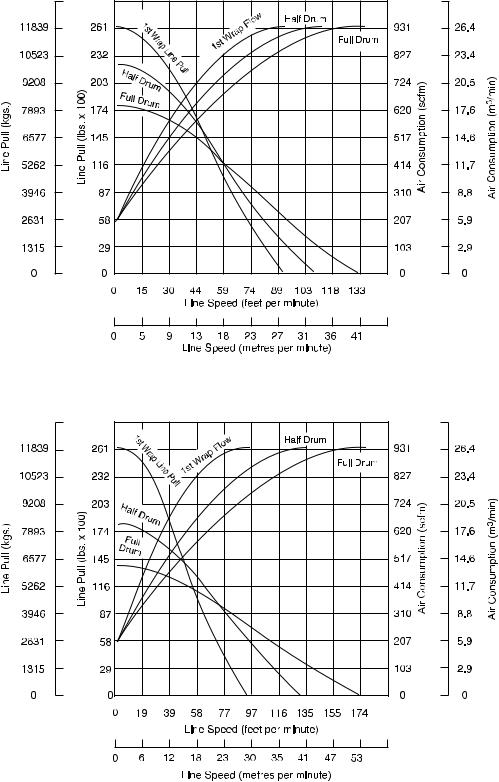

Performance Graphs

FA5 Winch

(Dwg. MHP1890)

FA5T Winch

(Dwg. MHP1891)

6 |

MHD56037 - Edition 5 |

General Specifications: |

|

|

Model |

|

||

|

FA5 |

FA5T |

||||

|

|

|

||||

|

|

|

|

|

|

|

|

Rated Operating Pressure |

|

|

90 psig (6.3 bar) |

|

|

Air System |

|

|

|

|

|

|

Air Consumption |

700 scfm |

|

20 cu.m/min. |

700 scfm |

20 cu.m/min. |

|

|

(at rated pressure and load) |

|

||||

|

|

|

|

|

|

|

|

Full Drum Line Pull |

11,000 lbs |

|

4,490 kgs |

8,400 lbs |

3,810 kgs |

Rated Performance |

Mid Drum Line Speed |

65 fpm |

|

20 m/min. |

80 fpm |

24 m/min. |

Max Stall Pull - 1st Layer |

24,000 lbs |

|

10,886 kgs |

24,000 lbs |

10,886 kgs |

|

(at rated pressure / volume) |

|

|||||

FA5-24MX1 Ship Weight |

1,920 lbs |

|

873 kgs |

- - - |

- - - |

|

|

|

|||||

|

FA5T-24MX1 Ship Weight |

- - - |

|

- - - |

2,115 lbs |

961 kgs |

Air Motor Pipe Inlet Size |

1.25 inch |

|

32 mm |

1.25 inch |

32 mm |

|

Minimum Air System Hose Size |

1.5 inch |

|

38 mm |

1.5 inch |

38 mm |

|

Drum Barrel Diameter |

15 inches |

|

381 mm |

15 inches |

381mm |

|

Drum Flange Diameter |

27.25 inches |

|

692 mm |

35.25 inches |

895 mm |

|

|

Drum Length (inches) |

|

|

Wire Rope Diameter |

|

|

|

|

|

|

|

|

|

|

0.625 inch |

|

16 mm |

|

|

|

|

|

|

|

|

||

|

12 |

874 ft |

|

266 m |

0.625 inch (16 mm) diameter |

|

|

16 |

1181 ft |

|

360 m |

wire rope not recommended for |

|

|

24 (Standard) |

1795 ft |

|

547 m |

use on FA5T winches. |

|

|

|

|

|

|||

|

30 |

2256 ft |

|

688 m |

|

|

|

|

0.75 inch |

|

18 mm |

0.75 inch |

18 mm |

* Drum Wire Rope |

12 |

550 ft |

|

168 m |

1240 ft |

378 m |

16 |

746 ft |

|

227 m |

1681 ft |

512 m |

|

Storage Capacity |

|

|||||

24 (Standard) |

1138 ft |

|

347 m |

2564 ft |

782 m |

|

(feet / metres) |

|

|||||

|

30 |

1431 ft |

|

436 m |

3225 ft |

983 m |

|

36 (Tall flange only) |

- - - |

|

- - - |

3887 ft |

1185 m |

|

|

0.875 inch |

|

20 mm |

0.875 inch |

20 mm |

|

12 |

400 ft |

|

122 m |

886 ft |

270 m |

|

16 |

544 ft |

|

166 m |

1204 ft |

367 m |

|

24 (Standard) |

832 ft |

|

254 m |

1841 ft |

561 m |

|

30 |

1047 ft |

|

319 m |

2318 ft |

706 m |

|

36 (Tall flange only) |

- - - |

|

- - - |

2796 ft |

852 m |

|

|

|

|

|

|

|

*Wire rope storage capacity based on wire rope top layer located a minimum of 1/2 inch (13 mm) below drum flange and meets ASME B30.7. The wire rope storage capacities listed may vary from figures stated elsewhere.

Description of Operation

FA5 winches are air powered, planetary geared units designed for lifting and pulling applications. FA5 winches are available with either an internal automatic disc brake, a manual or automatic band brake, or a combination of both.

The output from an externally mounted piston air motor is transmitted through a coupling and shaft to the planetary reduction gear assembly.

The output from planetary reduction gear assembly is connected to the wire rope drum through the output shaft.

FA5 winches can be provided with an optional disc brake assembly consisting of friction plates splined to a hub which in turn is connected to the drive shaft from the air motor. Brake friction plates are clamped to the drum shaft through a spring applied piston. The brake remains applied until the winch control valve is operated and winch payout or haul-in occurs. Air is introduced into the brake piston chamber, which is formed between brake piston and brake housing, causing the brake piston to react, compressing brake springs and releasing friction plates allowing motor shaft to rotate. A power failure or sudden loss of air will immediately cause the spring applied brake to engage.

The drum band brake operates by applying a friction force between drum brake band and winch drum. The manual brake requires an operator to engage and disengage brake using a lever located on top of brake band. The automatic drum band brake operation is similar to disc brake operation; they are both fully disengaged in the haul-in and payout direction.

MHD56037 - Edition 5 |

7 |

Traceability

Load bearing parts are documented to provide traceability. The documentation includes chemical and physical properties of raw material, heat treating, hardening, tensile and charpy tests as required for the part.

Units with M1, M2 or M3 in the model code have traceable load bearing components.

M1–Material Traceability certificates according to EN 10204 (Ex DIN 50049) 2.2 on load bearing parts. Conformity documents affirm (by manufacturer) that parts are in compliance with requirements of order based on non-specific inspection and testing (i.e. results are typical material properties for these parts).

M2–Material Traceability certificates according to EN 10204 (Ex DIN 50049) 3.1b on load bearing parts. Conformity documents affirm (by a department independent of the manufacturing department) that the actual parts are in compliance with the requirements of the order based on specific inspection and testing (i.e. results are actual material properties for these parts).

M3–Material Traceability certificates according to EN 10204 (Ex DIN 50049) 3.1b on load bearing parts. Conformity documents affirm (by a department independent of the manufacturing department) that the actual parts used in the product are in compliance with the order based on specific inspection and testing (i.e. results are actual material properties for these parts in a finished, as delivered condition).

Components with part numbers ending in CH or CHA are charpy parts for use under extreme cold conditions. Traceability requirements must be stated when reordering these parts for continued certification.

INSTALLATION

Prior to installing winch, carefully inspect it for possible shipping damage.

Winches are supplied fully lubricated from the factory. Before operation check oil levels and adjust as necessary. Use the proper type of oil as recommended in “LUBRICATION” section.

CAUTION

CAUTION

• Owners and users are advised to examine specific, local or other regulations, including American Society of Mechanical Engineers Standards and/or OSHA Regulations which may apply to a particular type of use of this product before installing or putting winch to use.

Mounting

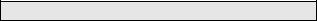

Refer to Dwg. MHP0133 and Table 1 on page 8, and Table 2 on page 9.

Care must be taken when moving, positioning or mounting the winch. In most cases, lifting lugs have been provided to assist in handling the winch. If lug locations are improper for your specific installation, great care should be taken to ensure that winch, when lifted, will be properly balanced. Determine weight of your winch by referring to “SPECIFICATIONS” section. Lift winch 3 to 4 inches (75 to 100 mm) off ground.

Verify winch is balanced and secure before continuing lift. Mount winch so axis of drum is horizontal and that motor vent cap is not more than 15° off top vertical center. If winch is to be mounted in an inverted position, motor case must be rotated to position vent cap at top.

1.The winch mounting surface must be flat and of sufficient strength to handle rated load plus weight of winch and attached equipment. An inadequate foundation may cause distortion or twisting of winch uprights and side rails resulting in winch damage.

2.Make sure mounting surface is flat to within 0.005 inch (0.127 mm) per inch of drum length. Shim if necessary. Refer to Table 1.

3.Mounting bolts must be 3/4 inch (18 mm) Grade 8 or better. Use self-locking nuts or nuts with lockwashers.

4.Tighten 3/4 inch (18 mm) mounting bolts evenly and torque to 380 ft lbs (515 Nm) for dry thread fasteners. If fasteners are plated, lubricated or a thread locking compound is used, torque to 280 ft lbs (380 Nm).

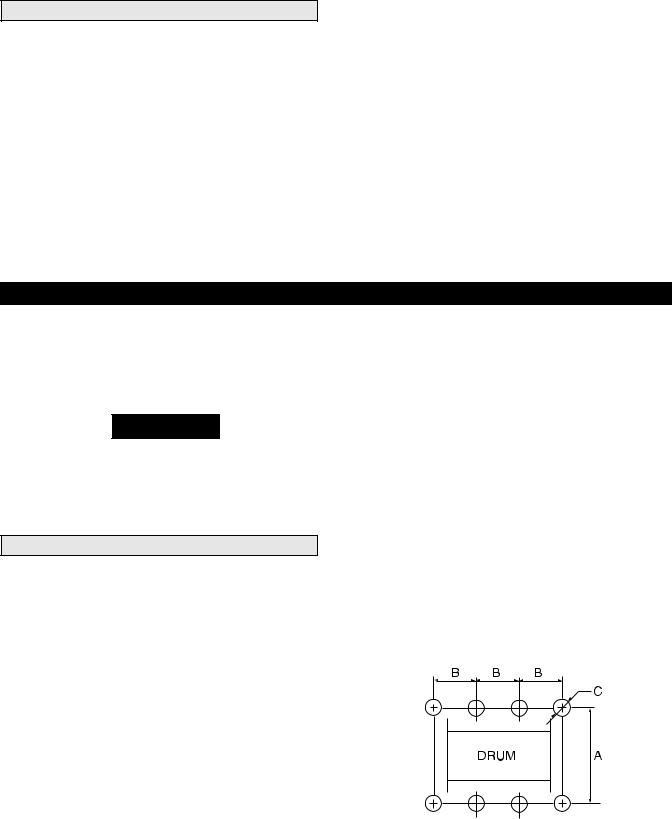

5.Maintain a fleet angle between sheave and winch of no more than 1-1/2°. The lead sheave must be on a center line with drum and, for every inch (25 mm) of drum length, be at least 1.6 feet (0.5 metre) from the drum. Refer to Dwg. MHP2123 on page 9.

6.Do not weld any part of winch.

Table 1–Mounting Surface Tolerance

Drum |

Mounting Surface Minimum Flatness |

||

Length |

|

|

|

inch |

mm |

||

|

|||

12 |

0.06 |

1.52 |

|

16 |

0.08 |

2.03 |

|

24 |

0.12 |

3.05 |

|

30 |

0.15 |

3.81 |

|

36 |

0.18 |

4.57 |

|

|

|

|

|

Winch Bolt Hole Mounting Dimension Drawing

(Dwg. MHP0133)

8 |

MHD56037 - Edition 5 |

Table 2–Winch Bolt Hole Mounting Dimensions

Dimension |

|

|

Drum Length (inches) |

|

||||

|

|

|

|

|

|

|

||

|

12 |

16 |

|

24 |

30 |

36* |

||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

“A” FA5 |

|

inch |

|

31.25 |

|

- - - |

||

|

|

|

|

|

|

|

||

|

mm |

|

|

794 |

|

|||

|

|

|

|

|

|

|||

“A” FA5T |

|

inch |

|

|

34.25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

mm |

|

|

870 |

|

|

||

|

|

|

|

|

|

|||

“B” (with |

|

inch |

7.5 |

9 |

|

10.5 |

10 |

11.5 |

Drum Brake) |

|

mm |

190 |

229 |

|

267 |

254 |

292 |

“B” (without |

|

inch |

6 |

6.25 |

|

9 |

12 |

14 |

Drum Brake) |

|

mm |

152 |

159 |

|

229 |

305 |

356 |

“C” |

|

inch |

|

|

13/16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

mm |

|

|

20 |

|

|

||

|

|

|

|

|

|

|||

Bolt Hole Qty each |

|

4 |

|

|

|

5 |

||

Side Rail |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

* 36 inch drum length applies to FA5T (tall flange) only.

Wire Rope

CAUTION

CAUTION

•Maintain at least 3 tight wraps of wire rope on drum at all times.

•Install wire rope to come off drum for overwind operation. (normal application.) Refer to Dwg. MHP2124 on page 9.

(Dwg. MHP2124)

(Dwg. MHP2123)

‘A’ = 1.6 feet (0.5 metre) per inch of drum length: ‘A’ = 19.2 feet (5.85 metres) for 12 inch drum. ‘A’ = 25.6 feet (7.80 metres) for 16 inch drum. ‘A’ = 38.4 feet (11.7 metres) for 24 inch drum. ‘A’ = 48.0 feet (14.6 metres) for 30 inch drum. ‘A’ = 57.6 feet (17.5 metres) for 36 inch drum.

Notes:

1.Maintain a minimum of 3 tight wraps of wire rope on drum at all times.

2.Ensure wire rope does not exceed top layer requirement. Refer to “SPECIFICATIONS” section.

NOTICE

• For underwound applications order the “U” option or contact factory prior to operation.

Wire Rope Selection

Consult a reputable wire rope manufacturer or distributor for assistance in selecting appropriate type and size of wire rope and, where necessary, a protective coating. Use a wire rope which provides an adequate safety factor to handle actual working load and that meets all applicable industry, trade association, federal, state and local regulations.

When considering wire rope requirements the actual working load must include not only static or dead load but also loads resulting from acceleration, retardation and shock load. Consideration must also be given to the size of winch wire rope drum, sheaves and method of reeving. Wire rope construction should be 6 X 19 or 6 X 37 IWRC EIPS right regular lay. Refer to Table 3 on page 9 for minimum and maximum recommended wire rope sizes.

Table 3–Minimum and Maximum Wire Rope Size

Model |

Minimum |

Maximum |

|||

|

|

|

|

||

inch |

mm |

inch |

mm |

||

|

|||||

FA5 |

5/8 |

16 |

7/8 |

22 |

|

FA5T |

3/4 |

20 |

|||

|

|

||||

|

|

|

|

|

|

Note: Maximum wire rope diameter is limited by size of wire rope anchor hole. Refer to parts list for correct wire rope anchor part numbers.

MHD56037 - Edition 5 |

9 |

Installing Wire Rope

CAUTION

CAUTION

• To avoid disc brake damage when installing wire rope pressurize brake with a minimum of 60 psi (4.1 bar) air from an auxiliary source.

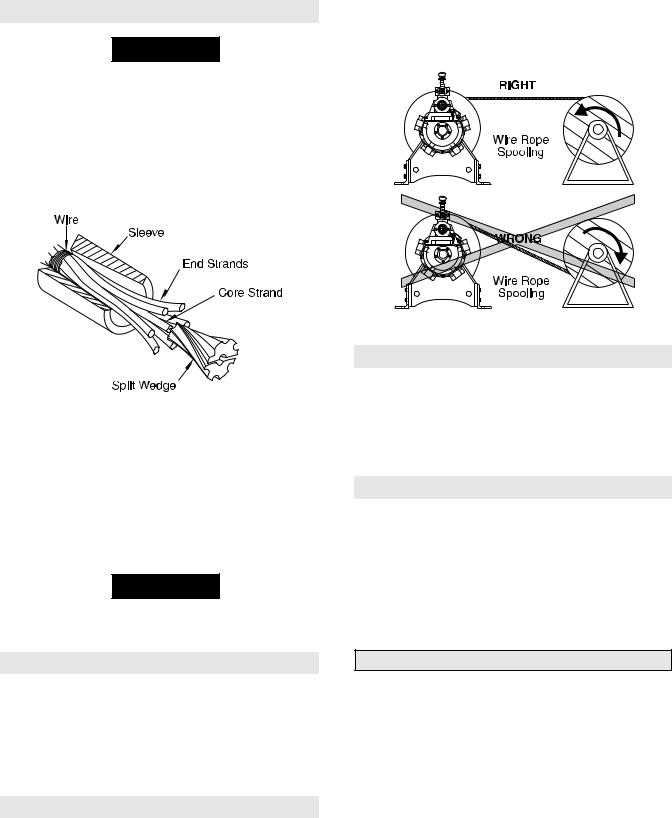

Refer to Dwg. MHP0166 on page 10.

1.Cut wire rope to length in accordance with wire rope manufacturer’s instructions.

2.Feed end of wire rope into wire rope anchor hole in drum and pull through approximately one foot (305 mm) of wire rope.

(Dwg. MHP0166)

3.Wrap wire rope with wire a distance from the end equal to wedge length plus one inch (25 mm).

4.Slide sleeve over end of wire rope so larger diameter of taper bore is nearest the end of wire rope.

5.Spread end strands of wire rope and insert split wedge until it is below the end of wire rope.

6.Pull sleeve over wire rope end until tight. Check that wire rope strands stay in the slots located on split wedge.

7.Pull wire rope anchor into position in drum anchor pocket.

CAUTION

CAUTION

• Make sure first wrap of wire rope is tight and lays flush against drum flange.

Safe Wire Rope Handling Procedures

1.Always use gloves when handling wire rope.

2.Never use wire rope which is frayed or kinked.

3.Never use wire rope as a sling.

4.Always ensure wire rope is correctly spooled and the first layer is tight against drum.

5.Always follow wire rope manufacturers’ recommendation on use and maintenance of wire rope.

Wire Rope Spooling

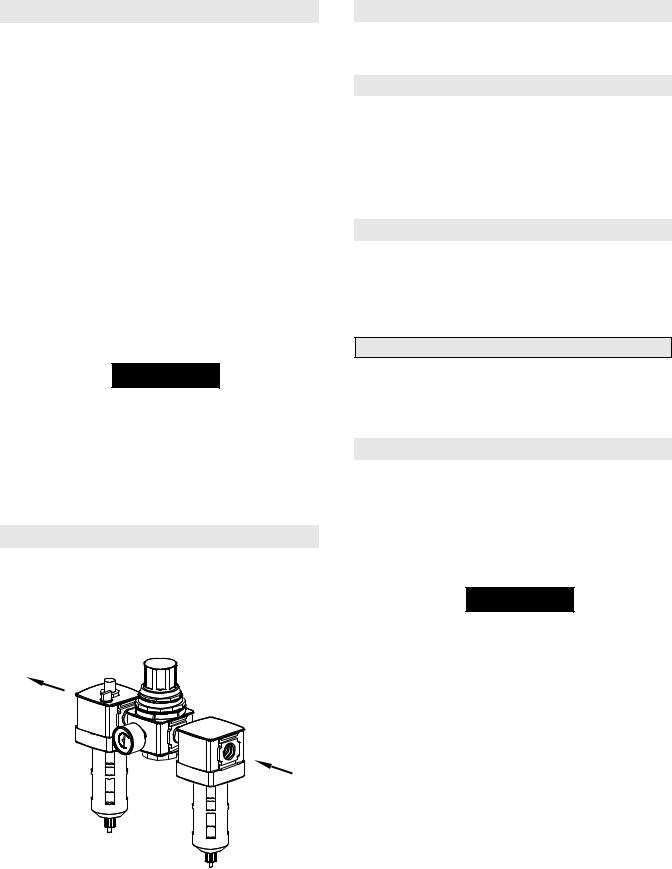

Refer to Dwg. MHP2125 on page 10.

To compensate for uneven spooling and decrease in line pull capacity as drum fills up, use as short a wire rope as practical. When rewinding apply tension to the end of wire rope to eliminate slack. This helps achieve level winding and tight spooling.

Support wire rope spool and have wire rope come off top of spool and over top of winch drum. This will prevent damage to wire rope.

Spooling Wire Rope onto Winch Drum

(Dwg. MHP2125)

Rigging

Make sure all wire rope blocks, tackle and fasteners have a sufficient safety margin to handle required load under all conditions. Do not allow wire rope to contact sharp edges or make sharp bends which will cause damage to wire rope, use a sheave. Refer to wire rope manufacturer’s handbook for proper sizing, use and care of wire rope.

Safe Installation Procedures

1.Do not use wire rope as a ground (earth) for welding.

2.Do not attach a welding electrode to winch or wire rope.

3.Never run wire rope over a sharp edge. Use a correctly sized sheave.

4.When a lead sheave is used, it must be aligned with center of drum. The diameter of lead sheave must be at least 18 times diameter of wire rope. Refer to Dwg. MHP2123 on page 9.

5.Always maintain at least three full, tight wraps of wire rope on drum.

Air Supply

The air supply must be clean, free from moisture and lubricated to ensure optimum motor performance. Foreign particles, moisture and lack of lubrication are the primary causes of premature motor wear and breakdown. Using an air filter, lubricator and moisture separator will improve overall winch performance and reduce unscheduled down time.

Air consumption for the FA5 and FA5T air motor is 700 scfm (20 cu. m/min.) at rated operating pressure of 90 psig (6.3 bar) at winch motor inlet. If air supply varies from recommended, then winch performance will change.

10 |

MHD56037 - Edition 5 |

Air Lines

Inside diameter of winch air supply lines must not be less than sizes shown in Table 4 on page 11. Before making final connections, all air supply lines should be purged with clean, moisture free air or nitrogen before connecting to winch inlet. Supply lines should be as short and straight as installation conditions will permit. Long transmission lines and excessive use of fittings, elbows, tees, globe valves etc. cause a reduction in pressure due to restrictions and surface friction in lines.

Table 4–Minimum Allowable Air Supply Line Sizes

Model |

inch |

mm |

|

FA5 |

1-1/2 |

38 |

|

|

|||

FA5T |

|||

|

|

||

|

|

|

|

Air Line Lubricator |

|

|

|

|

|

|

Refer to Dwg. MHP0191 on page 11.

Always use an air line lubricator with these motors. The lubricator must have an inlet and outlet at least as large as inlet on motor. Install air line lubricator as close to air inlet on motor as possible.

CAUTION

CAUTION

•Lubricator must be located no more than 10 ft. (3 m) from motor.

•Shut off air supply before filling air line lubricator.

The air line lubricator should be replenished daily and set to provide 6 to 9 drops per minute of ISO VG 32 (SAE 10W) oil. A fine mist will be exhausted from throttle control valve when air line lubricator is functioning properly.

Air Line Filter

Refer to Dwg. MHP0191 on page 11.

It is recommended that an air line strainer/filter be installed as close as practical to motor air inlet port, but before lubricator, to prevent dirt from entering valve and motor. The strainer/filter should provide 20 micron filtration and include a moisture trap. Clean the strainer/filter periodically to maintain its operating efficiency.

Air Out

Regulator

Air In

Lubricator

Filter

(Dwg. MHP0191)

Air Pressure Regulator

If an air pressure regulator is used, install between lubricator and filter. Refer to Dwg. MHP0191 on page 11.

Moisture in Air Lines

Moisture that reaches the air motor through air supply lines is a primary factor in determining the length of time between service overhauls. Moisture traps can help to eliminate moisture. Other methods, such as an air receiver which collects moisture before it reaches motor or an aftercooler at compressor that cools air to condense and collect moisture prior to distribution through supply lines are also helpful.

Mufflers

Make sure mufflers are installed in winch exhaust manifold and control valve exhaust port. An additional muffler is used on winches equipped with an emergency stop and overload device. Check mufflers periodically to ensure they are functioning correctly.

Motor

For optimum performance and maximum durability of parts, provide an air supply of 90 psig at 700 scfm (6.3 bar/630 kPa at 20 cu. m/m) as measured at motor inlet. The air motor should be installed as near as possible to compressor or air receiver.

Emergency Stop and Overload System (optional feature)

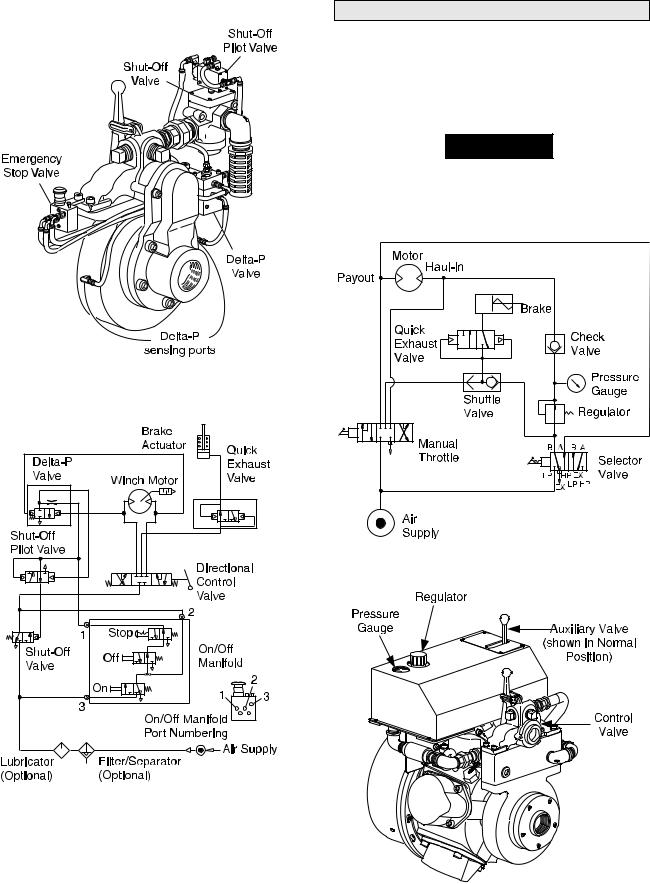

Refer to Dwg. MHP1492 on page 12. old style

The air supply line is connected to the shutoff valve which is connected to the air control valve. When Emergency Stop valve is activated, a pilot signal is sent to the shut off pilot valve which directs shutoff valve to cut off air to winch, immediately stopping all winch movement.

CAUTION

CAUTION

• If winch continues to move (payout load) after shutoff valve activates, brake(s) are not holding load and need to be adjusted or repaired.

The overload system also activates shutoff valve. When Delta-P valve senses a preset pressure difference between the two ports, located on rotary housing, it directs a pilot signal to shutoff pilot valve activating the shutoff valve. Refer to Dwg. MHP1491 on page 12.

MHD56037 - Edition 5 |

11 |

Emergency Stop and Overload System Components (old style)

(Dwg. MHP1492)

Air Schematic–Emergency Stop and Overload System (old style)

(Dwg. MHP1491)

Constant Tension (optional feature)

Refer to Dwg. MHP1865 on page 12 and Dwg. MHP1176 on page 12.

The air supply line is connected to one of the two top ports on the control valve. This will allow air to supply either the normal control valve or the auxiliary valve.

CAUTION

CAUTION

• Use only one control valve to operate winch at any time. Attempting to OVER-RIDE one control valve with the other will result in total loss of winch control.

Air Schematic–Constant Tension Winches

(Dwg. MHP1176)

Constant Tension Components

(Dwg. MHP1865)

12 |

MHD56037 - Edition 5 |

Initial Operating Checks

Winches are tested for proper operation prior to leaving factory. Before winch is placed into service the following initial operating checks should be performed.

1.When first running motor inject some light oil into inlet connection to provide initial lubrication.

2.When first operating winch it is recommended that motor be operated slowly in both directions for a few minutes.

For winches that have been in storage the following start-up procedures are required.

1.Give the winch an inspection conforming to requirements of “Winches Not in Regular Use” in the “INSPECTION” section.

2.Pour a small amount of ISO VG 32 (SAE 10W) oil in motor inlet port.

3.Operate motor for 10 seconds in both directions to flush out any impurities.

4.The winch is now ready for normal use.

OPERATION

The four most important aspects of winch operation are:

1.Follow all safety instructions when operating winch.

2.Allow only people trained in safety and operation of this winch to operate this equipment.

3.Subject each winch to a regular inspection and maintenance procedure.

4.Be aware of winch capacity and weight of load at all times.

CAUTION

CAUTION

• To avoid damage to rigging, the structure supporting rigging and winch, do not “two-block” the end of wire rope.

* Two blocking occurs when winch wire rope is multi-reeved using two separate sheave blocks which are allowed to come into contact with each other during winch operation. When this occurs extreme forces are exerted on wire rope and sheave blocks which may result in equipment and or rigging failure.

Operators must be physically competent. Operators must have no health condition which might affect their ability to act, and they must have good hearing, vision and depth perception. The winch operator must be carefully instructed in his duties and must understand the operation of winch, including a study of the manufacturers’ literature. The operator must thoroughly understand proper methods of hitching loads and must have a good attitude regarding safety. It is the operator’s responsibility to refuse to operate winch under unsafe conditions.

WARNING

WARNING

• Winch is not designed or suitable for lifting, lowering or moving persons. Never lift loads over people.

Winch Controls

The spring loaded, motor mounted, live air manual throttle control valve is supplied as a standard feature on this winch. Optional remote throttle controls are available. Reference model code on the winch nameplate and compare it to the “SPECIFICATIONS” section, on page 5 of this manual, to determine your configuration. The throttle controls provide operator control of motor speed and direction of drum rotation.

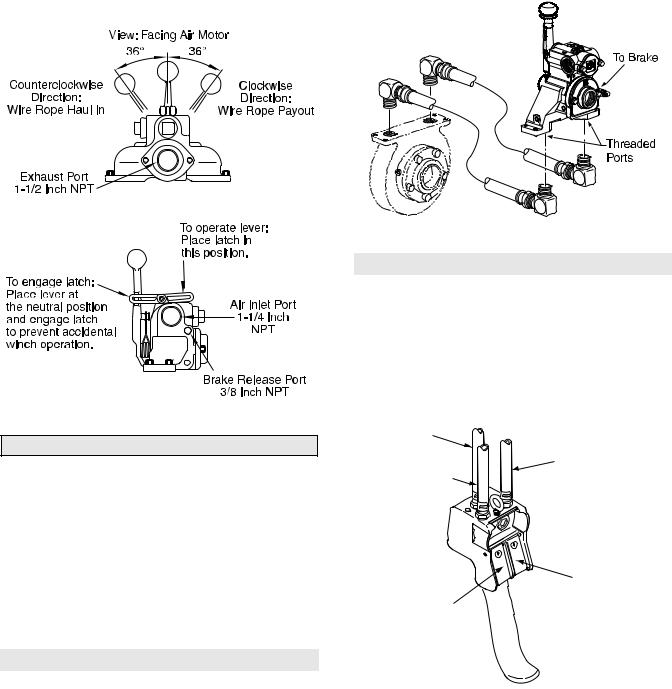

Winch Mounted Air Throttle (standard feature)

New Style

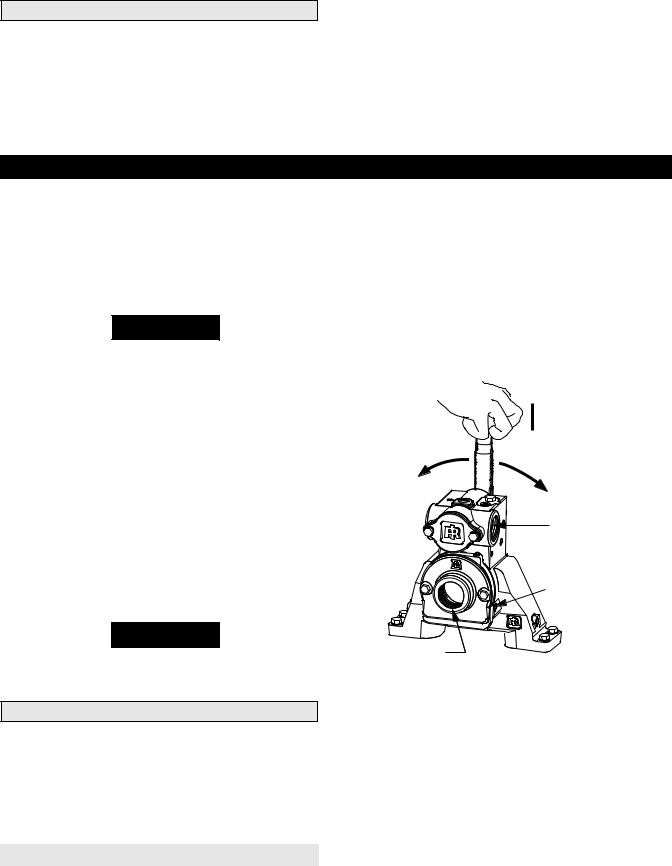

Refer to Dwg. MHP1809 on page 13.

The spring loaded, live air, manual control throttle valve mounts to the rotary housing.

To operate control valve, place palm of hand on control knob and wrap fingers around flange of sliding handle. Squeeze fingers, lifting sliding handle up to unlock control lever. Shift control lever in desired direction to payout or haul-in wire rope.

As viewed from the air motor end, move the control throttle handle to the right (clockwise) to payout wire rope and to the left (counterclockwise) to haul-in wire rope. Avoid sudden movements of the control valve to ensure smooth operation of the winch. When released, handle will return to the neutral or center position. The sliding handle will drop down to engage and lock the control handle in place.

Winch Mounted Throttle Control Valve Operation

Lift Slider

Lift Slider

Handle

UP to

Unlock

Haul-In

Payout

Air Inlet Port

1-1/4 NPT

Brake Release Port

1/4 NPT

Exhaust Port

1-1/2 NPT

(Dwg. MHP1809)

old style

Refer to Dwgs. MHP0165 on page 54 and MHP0566 on page 14. The spring loaded, live air, manual control throttle valve mounts to air motor.

As viewed from air motor end, move control throttle handle to the right (clockwise) to payout wire rope and to the left (counterclockwise) to haul-in wire rope. Avoid sudden movements of control valve to ensure smooth operation of winch.

When winch is not in use, engage latch to prevent inadvertent movement of control throttle.

MHD56037 - Edition 5 |

13 |

Winch Mounted Throttle Control Valve Operation (old style)

Dwg. MHP0566)

Underwound Operation (optional feature)

Underwound operation is where wire rope haul-in or payout is off the bottom of drum. This is a special operation and requires a winch specifically designed for this usage.

Underwound operation requires a reverse bias valve installed in the control valve.

Control valve operation will be opposite as shown in Dwg. MHP1809 on page 13. As viewed from air motor end, lift slider handle up to unlock control lever. Move control throttle handle to the left (counterclockwise) to payout, and to the right (clockwise) to haul-in.

Remote Live Air Throttle (optional feature)

Refer to Dwgs. MHP2043 on page 14.

Provides for remote mounting of winch control at a fixed location at up to 20 feet (6 metres) away from winch motor. Air hoses connect throttle to winch motor to provide winch operation.

Move control throttle handle to the right (clockwise) to payout wire rope and to the left (counterclockwise) to haul-in wire rope. Avoid sudden movements of control valve to ensure smooth operation of winch.

14

(Dwg. MHP2043)

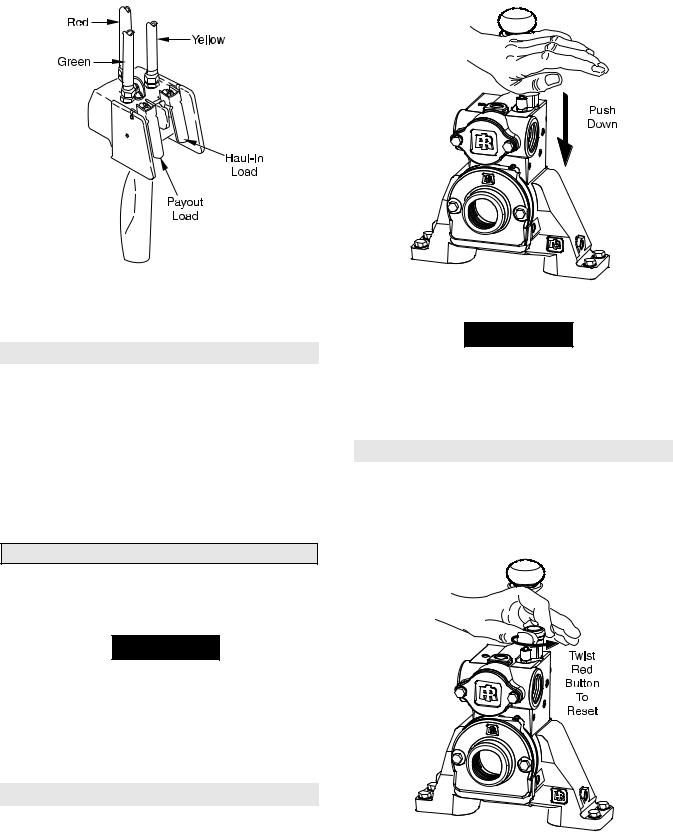

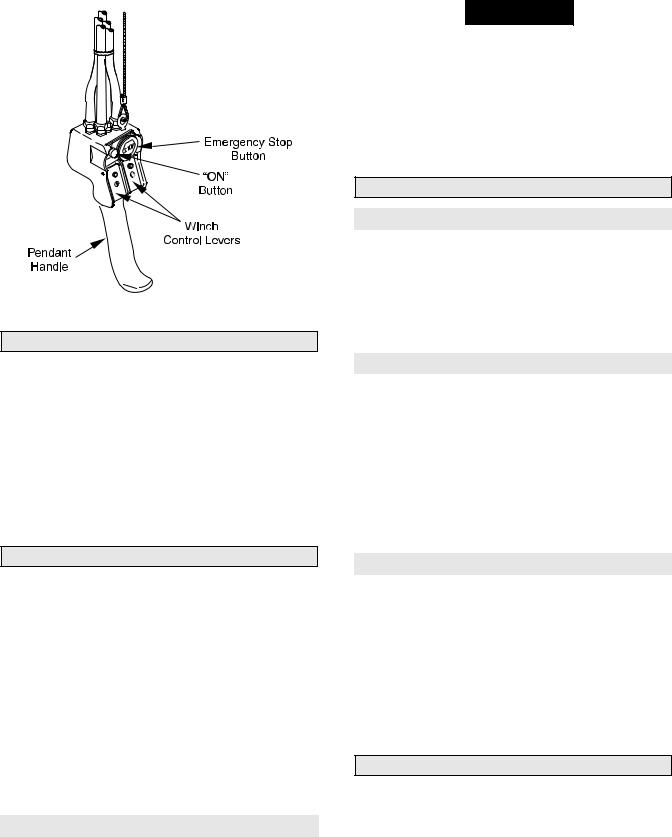

Remote Pilot Pendant Throttle (optional feature)

Refer to Dwg. MHP2233 on page 14 and MHP1311 on page 15. Provides for remote winch control at distances of up to 50* feet (15 metres) away from winch. The pendant pilot control throttle is a two lever movable control station for winch operation. Pilot pressure from pendant pilot control throttle activates winch control valve. The winch control valve, located on winch motor, controls motor speed and direction of drum rotation. Direction of rotation is determined by the pendant lever depressed.

Pendant Hose and Operating Levers (new style)

Red

Yellow

Green

Haul-In

Load

Payout

Load

(Dwg. MHP2233)

MHD56037 - Edition 5

Pendant Hose and Operating Levers (old style) |

Emergency Stop Operation |

(Dwg. MHP1311)

* For distances greater than 50 feet (15 metres) contact Ingersoll Rand Technical Sales for control suitability.

Remote Pilot Lever Throttle (optional feature)

Refer to Dwg. MHP0167 on page 56, item 358.

Provides for remote winch control at distances of up to 50* feet (15 metres) away from winch. The lever pilot control throttle is a fixed mount lever control station for winch operation. Pilot pressure from lever pilot control throttle activates winch control valve. The winch control valve, located on winch motor, controls motor speed and direction of drum rotation. Direction of rotation is determined by direction in which lever is shifted.

* For distances greater than 50 feet (15 metres) contact Ingersoll Rand Technical Sales for control suitability.

Emergency Stop and Overload System

Refer to Dwg. MHP2180 on page 52.

Air supply line is connected to air control valve. When emergency stop or overload valve is activated, all winch movement will stop.

CAUTION

CAUTION

• If winch continues to move (payout load) after emergency stop activates, brake(s) are not holding load and may require adjustment or repair.

When control valve senses a preset pressure difference between ports, a pilot signal is sent to stop flow of air, all winch movement will stop.

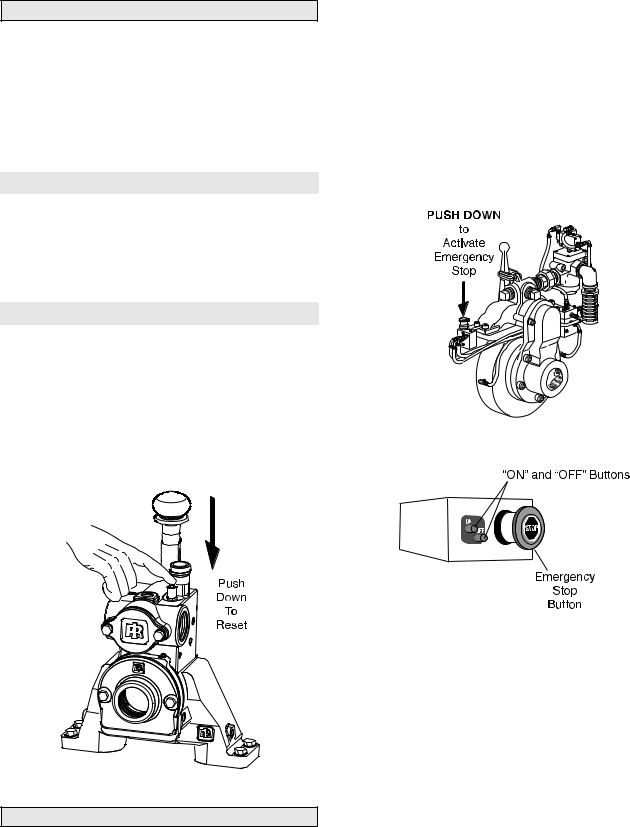

Emergency Stop (optional feature)

Refer to Dwg. MHP2047on page 15.

Emergency stop device is located on the control valve. When activated, winch drum rotation will immediately cease. To activate emergency stop, conduct the following:

1.Depress (push down) red palm valve, located on top of control valve.

(Dwg. MHP2047)

NOTICE

•If winch overload occurs, overload device, if equipped, also stops winch. To operate winch after an overload, reduce load and reset overload.

•Cannot be added to old style control valve. Refer to

Dwg. MHP2036 on page 50.

Emergency Stop Reset

Refer to Dwg. MHP2048 on page 15.

1.Rotate red stop button, in counterclockwise direction until red stop button ‘pops’ up.

2.Winch is ready to resume operation.

Emergency Stop Reset

(Dwg. MHP2048)

MHD56037 - Edition 5 |

15 |

Overload Device

An overload device is available on winches with the emergency shutoff option. Overload device operation is based on differential pressure between air motor inlet and exhaust. The overload device is factory preset to actuate at 150% (± 25%) of winch rated capacity. When an overload condition is sensed, the valve poppet closes, to cut off supply air to winch, stopping winch operation. If an overload shutoff occurs, winch load must be reduced. Reset the overload valve and operate winch in payout direction to lower load. Refer to ‘Emergency Stop Reset’ section.

Checking Overload Valve Setting

1.Attach load line to a load that is calibrated to maximum load for which winch is rated.

2.Move control lever to haul-in position. If winch does not lift load, adjust the adjustment screw. Refer to ‘Overload Valve Adjustment’ section“Overload Valve Adjustment (optional feature)” on page 26.

Setting the Overload

Refer to MHP2049 on page 16 and MHP2216 on page 27. Attach load line to a load that is calibrated to 150% of winch rated capacity. Shift control lever to haul-in position.

1.If overload valve activates, reset overload valve. Winch is ready for normal operation.

2.If winch lifts load, lower load. Turn adjustment screw counterclockwise in 1/4 turn increments until overload valve activates when control lever is shifted to haul-in position. After each 1/4 turn, retest winch.

Overload Valve Reset

(Dwg. MHP2049)

Emergency Stop (optional feature)

Refer to Dwgs. MHP1485, MHP0754 on page 16 and MHP1892 on page 17.

The emergency stop device is located at air inlet of winch on local control models, and on pendant on remote control models. When activated, winch drum rotation will immediately cease.

1.To start winch operation depress the ‘ON’ button.

2.To operate winch, depress appropriate ‘Haul-in’ or ‘Payout’ lever.

3.In event of an emergency all winch operation can be stopped by pushing the emergency stop button. This will prevent air from reaching winch motor, engage winch automatic brake(s) and stop winch haul-in or payout movement.

4.If depressed, the ‘OFF’ button will also stop winch operation.

5.To reset Emergency Stop Valve:

a.Locate serrated ring directly below emergency stop button. Rotating serrated ring clockwise, will cause emergency stop button to ‘pop up’.

b.Depress emergency stop valve ‘ON’ button.

Emergency Stop Operation (old style)

(Dwg. MHP1485)

Local Control Emergency Stop Valve Operation

(Dwg. MHP0754)

16 |

MHD56037 - Edition 5 |

Remote Pendant Emergency Stop Valve Operation

(Dwg. MHP1892)

Winch Overload Device (optional feature)

The overload device is integrated into winch air motor control air system and prevents winch from lifting a load greater than overload value. Refer to “INSPECTION” section on page 21. If an overload is detected, inlet supply air is stopped and winch will not operate.

If overload device is activated load must be lowered and reduced. To lower load and reset emergency stop valve:

1.Locate serrated ring directly below emergency stop button. Rotating serrated ring clockwise, causes emergency stop button to ‘pop up’.

2.Depress emergency stop valve ‘ON’ button.

3.Operate winch control in payout direction.

Constant Tension (optional feature)

Refer to Dwg. MHP1865 on page 12.

With auxiliary valve in the NORMAL position, winch provides normal operation. Placing valve selector in TENSIONING position allows winch to automatically operate to haul-in slack wire rope to maintain tension.

Auxiliary valve provides preset air pressure to air motor and disc brake. This allows brake to be released and winch to overhaul during TENSIONING operations. In this position, winch will maintain constant tension on wire rope.

Auxiliary valve is pre-set at zero from the factory. Specific adjustments must be made in the field. Adjustments can be modified at anytime to accommodate the load conditions. Refer to ‘Regulator Adjustment’ in the “MAINTENANCE” section for specific procedure.

Constant Tension (operation)

1.Place auxiliary valve in NORMAL position.

2.Operate winch normally to position end of load line.

3.Connect load line to load.

MHD56037 - Edition 5

WARNING

WARNING

• Ensure slack load line is taken up by operating winch control valve with selector in NORMAL position. If selector lever is placed in TENSION position the winch will immediately attempt to establish line tension causing line to ‘snap’ resulting in injury or damage to property.

4.Operate winch normally to remove slack from load line.

5.Actuate valve to TENSION position to set winch to automatically haul-in load line and maintain line tension.

Winch Brakes

Manual Drum Brake

Refer to Dwg. MHP0153 on page 48.

The manual drum brake may be applied by pushing down on handle (104) and released by pulling up. If handle is pushed down fully, it should lock in that position and prevent drum rotation, until released by operator. The brake must be kept properly adjusted to hold required load. Refer to ‘Adjustments’ on page 26 in “MAINTENANCE” section for adjustment instructions.

Automatic Drum Brake (optional feature)

Refer to Dwg. MHP0153 on page 48.

The automatic drum brake is a spring applied, air released brake which utilizes an air actuated, spring loaded cylinder (110), that automatically disengages brake when motor is operated. Air pressure in cylinder overcomes spring pressure to release brake. When control valve is placed in neutral position, air in cylinder (110) is vented and spring automatically engages brake to prevent drum rotation.

The cylinder clevis (107) must be kept properly adjusted to hold required load.

Automatic Disc Brake (optional feature)

Refer to Dwg. MHP0152 on page 46.

The automatic disc brake is a spring applied, air released brake. Using an air actuated, spring loaded piston (10), the brake automatically disengages when motor is operated and engages when throttle is returned to neutral position.

Air pressure ported through brake housing (21) overcomes spring

(9) pressure and moves piston (10) which releases brake. When control valve is placed in neutral position, air is vented, spring pressure overcomes air pressure and spring (9) pressure moves piston, engages brake and prevents drum rotation.

Drum Locking Pin (optional feature)

Refer to Dwg. MHP0155 on page 61.

The drum locking pin is mounted to winch on outboard upright, opposite motor. It should be engaged if a load is left suspended. The drum lock is operated by rotating a pin between a shallow groove (disengaged) and a deep groove (engaged).

To Engage:

1.Rotate drum (80) to align one of the holes in flange with locking pin (136). Pull out, straight away from outboard upright, pull rod (140) and rotate counterclockwise 90°, aligning pin (135) with deep groove in gland (138). Release

17

pull rod and ensure locking pin engages and is seated in drum hole and gland deep groove.

WARNING

WARNING

•Ensure that all braking mechanisms are engaged and all personnel are clear of winch load and rigging before disengaging locking pin.

•Extremely difficult locking pin release is an indication that load is held by locking pin and braking mechanisms are not functioning properly. Do not release locking pin until load control is established.

To Disengage:

1.Pull out, straight away from outboard upright, pull rod (140) and rotate clockwise 90°. Align pin (135) with the shallow groove in gland (138) and release pull rod. Ensure locking pin (136) is clear of the drum (80) flange and pin is seated in gland shallow groove.

Limit Switch (optional feature)

Pre-set limit switch settings prevent winch wire rope payout and haul-in by stopping air flow to the winch motor when a defined set point has been reached. It is the owner’s and operator’s responsibility to adjust winch operating limits prior to using winch.

To adjust set points refer to ‘Adjustments’ in “MAINTENANCE” section.

WARNING

WARNING

• Ensure limit switch set points are established and operating properly before using winch.

18 |

MHD56037 - Edition 5 |

LUBRICATION

To ensure continued satisfactory operation of winch, all points requiring lubrication must be serviced with correct lubricant at proper time interval as indicated for each assembly.

The lubrication intervals recommended in this manual are based on intermittent operation of winch eight hours each day, five days per week. If winch is operated almost continuously or more than the eight hours each day, more frequent lubrication will be required. Also, lubricant types and change intervals are based on operation in an environment relatively free of dust, moisture, and corrosive fumes. Use only those lubricants recommended. Other lubricants may affect winch performance. Approval for use of other lubricants must be obtained from your Ingersoll Rand distributor. Failure to observe this precaution may result in damage to winch and/or its associated components.

INTERVAL |

LUBRICATION CHECKS |

|

|

Start of each shift |

Check flow and level of air line lubricator |

|

(approximately 6 to 9 drops per minute |

|

required at maximum motor speed). |

|

|

|

Check winch motor oil level. |

|

|

Monthly |

Lubricate components supplied by grease |

|

fittings. |

|

|

|

Inspect and clean or replace air line filter. |

|

|

|

Check reduction gear oil level. |

|

|

Yearly |

Drain and refill winch reduction gear oil. |

|

|

|

Drain and refill winch motor oil. |

|

|

Note: Intervals are based on winch operation in a normal environment as described in the “INSPECTION” section. In ‘Heavy’ or ‘Severe’ operating conditions adjust lubrication intervals accordingly.

Recommended Lubricants

Reduction Gear Recommended Lubricant

Temperature |

Type Oil |

|

|

Below 32° F (0° C) |

ISO VG 68 (2 EP) |

|

|

32° to 80° F (0° to 27° C) |

ISO VG 100 (3 EP) * |

|

|

Above 80° F (27° C) |

ISO VG 150 (4 EP) |

|

|

* Units are shipped from factory with ISO VG 100 (3 EP) lubricant. Reduction gear capacity is approximately 2 quarts (1.9 litres).

Air Motor and Disc Brake Recommended Lubricant

Temperature |

Type Oil |

|

|

Below 32° F (0° C) |

ISO VG 32 (SAE 10W) |

|

|

32° to 80° F (0° to 27° C) |

ISO VG 68 (SAE 20W) * |

|

|

Above 80° F (27° C) |

ISO VG 100 (SAE 30W) |

|

|

* Units are shipped from factory with ISO VG 68 (SAE 20W) lubricant. Motor oil capacity is approximately 3 quarts (2.8 litres).

Recommended Grease

Temperature |

Type Oil |

|

|

-20° to 50° F |

EP 1 multipurpose |

(-30° to 10° C) |

lithium based grease |

|

|

30° to 120° F |

EP 2 multipurpose |

(-1° to 49° C) |

lithium based grease |

|

|

NOTICE

• Do NOT use synthetic lubricants in air motor. Synthetic lubricants will result in oil blowing by piston rings.

Component Lubrication

General Lubrication

Correct lubrication is one of the most important factors in maintaining efficient winch operation.

1.The recommended grade of oil must be used at all times. Use of unsuitable oil may result in excessive temperature rise, loss of efficiency and possible damage to lubricated components. Refer to ‘Recommended Lubricants’ section.

2.Drain and replace oil in motor, disc brake and reduction gear after the first 50 hours of initial winch operation. Thereafter, drain and replace oil according to operating environment (yearly in NORMAL and HEAVY; quarterly in SEVERE), or more frequently if desired.

3.Always inspect removed oil for evidence of internal damage or contamination (metal shavings, dirt, water, etc.). If indications of damage are noted, investigate and correct before returning winch to service.

4.After winch operation, allow oil to settle before topping off.

5.Always collect lubricants in suitable containers and dispose of in an environmentally safe manner.

Motor

Refer to Dwg. MHP2126 on page 20.

The motor is splash lubricated by oil in motor housing and has no other means of lubrication. It is therefore important to use only good quality, non-detergent motor oil to ensure maximum performance and minimum downtime for repairs. Refer to ‘Recommended Lubricants’ section.

Oil capacity for the K5B-546 motor is 3 quarts (2.8 litres). Add oil through filler opening until oil flows from level plug hole. Add oil slowly to prevent spilling.

The motor should be level-checked daily or at the start of each shift after any accumulated water has been drained off. When motors are operated in temperatures below freezing, wait long enough at end of shift for water to separate from oil but not long enough for it to freeze. Drain water then refill to level plug (225), located on side of motor housing (217). If desired, all oil may be drained at end of shift and motor refilled with new oil.

MHD56037 - Edition 5 |

19 |

K5B Motor Lubrication Locations

(Dwg. MHP2126)

Air Throttle

Refer to Dwg. MHP0165 on page 54. Periodically, depending on winch usage and severity of environment, lubricate lever air throttle (local and remote) with recommended grease at grease fitting (246).

Wire Rope

Follow wire rope manufacturer’s instructions. At a minimum, observe the following guidelines.

1.Clean with a brush or steam to remove dirt, rock dust or other foreign material on surface of wire rope.

CAUTION

CAUTION

• Do not use an acid-based solvent. Only use cleaning fluids specified by wire rope manufacturer.

2.Apply Ingersoll Rand LUBRI-LINK-GREEN or ISO VG 100 (SAE 30W) oil as a wire rope lubricant.

3.Brush, drip or spray lubricant weekly, or more frequently, depending on severity of service.

Reduction Gear Assembly

Refer to Dwg. MHP0140 on page 20.

It is recommend that the first oil change be done after approximately 50 hours initial operation. Always inspect removed oil for evidence of internal damage (metal shavings, dirt, water, etc.).

The reduction gear is filled to the correct levels prior to shipment from the factory. Check oil level before initial winch operation. This component is splash lubricated by oil in the housing and has no other means of lubrication. It is therefore important to use high quality Extreme Pressure (EP) rust and oxidation inhibited gear oil to ensure maximum performance and minimum down time for repair.

CAUTION

CAUTION

• Do not over fill. Excess oil will reduce operating efficiency and increase oil temperature.

To ensure correct performance, highest efficiency and long life, it is essential that lubricating oil be maintained at correct level. Rotate drum until fill plug is located at top dead center then add oil up to level plug hole. Oil capacity for reduction gear assembly is 4 quarts (3.8 litres).

Reduction Gear Lubrication Plug Locations

(Dwg. MHP0140)

Disc Brake (optional feature)

Refer to Dwg. MHP1348 on page 20.

The friction plates and drive plates are in a self contained oil bath and have no other means lubrication. After an oil change or winch overhaul remove the breather plug (22) and pour a small amount of oil [4 to 6 ounces (0.2 litres)] through breather hole in brake housing. Allow oil to fully settle between fillings.

NOTICE

• If too much oil is added excess oil will be discharged through breather plug when control valve is actuated.

(Dwg. MHP1348)

Seals and Bearings

If winch is disassembled, clean all parts thoroughly and coat bearings and seals with clean grease. Refer to ‘Recommended Lubricants’ section. Use sufficient grease to provide a good protective coat. Lubricate grease fittings monthly with 2 or 3 pumps of a grease gun.

20 |

MHD56037 - Edition 5 |

Drum Locking Pin (optional feature)

Refer to Dwg. MHP0155 on page 61.

Lubricate at least once every month, depending on environment and duty cycle, through grease fitting (139) located in gland (138) with 2 or 3 pumps of a grease gun.

If drum locking pin is disassembled, clean all parts thoroughly and coat with clean grease. Refer to ‘Recommended Lubricants’ section. Use sufficient grease to provide a good protective coat.

Lubrication will help to prevent rust and allow easier locking pin operation.

INSPECTION

Inspection information is based in part on American Society of Mechanical Engineers Standards Safety Codes (ASME B30.7).

WARNING

WARNING

•All new or repaired equipment should be inspected and tested by personnel instructed in safety, operation and maintenance of this equipment to ensure safe operation at rated specifications before placing equipment in service.

•Never use a winch that inspection indicates is damaged.

Frequent and periodic inspections should be performed on equipment in regular service. Frequent inspections are visual examinations performed by operators or personnel trained in safety and operation of this equipment and include observations made during routine equipment operation. Periodic inspections are thorough inspections conducted by personnel trained in safety, operation and maintenance of this equipment. ASME B30.7 states inspection intervals depend upon the nature of critical components of the equipment and severity of usage. The inspection intervals recommended in this manual are based on intermittent operation of winch eight hours each day, five days per week, in an environment relatively free of dust, moisture, and corrosive fumes. If winch is operated almost continuously, or more than eight hours each day, more frequent inspections will be required.

Careful inspection on a regular basis will reveal potentially dangerous conditions while still in the early stages, allowing corrective action to be taken before condition becomes dangerous. Deficiencies revealed through inspection, or noted during operation, must be reported to designated personnel instructed in safety, operation and maintenance of this equipment.

A determination as to whether a condition constitutes a safety hazard(s) must be decided, and correction of noted safety hazard(s) accomplished and documented by written report before placing equipment in service.

Records and Reports

Inspection records, listing all points requiring periodic inspection should be maintained for all load bearing equipment. Written reports, based on severity of service, should be made on condition of critical parts as a method of documenting periodic inspections. These reports should be dated, signed by the person who performed inspection, and kept on file where they are readily available for authorized review.

Wire Rope Reports

Records should be maintained as part of a long-range wire rope inspection program. Records should include the condition of wire rope removed from service. Accurate records will establish a relationship between visual observations noted during frequent inspections and actual condition of wire rope as determined by periodic inspections.

MHD56037 - Edition 5

Frequent Inspection

On equipment in continuous service, frequent inspection should be made by operators at the beginning of each shift. In addition, visual inspections should be conducted during regular operation for indications of damage or evidence of malfunction (such as abnormal noises).

1.WINCH. Prior to operation, visually inspect winch housings, controls, brakes, side rails and drum for indications of damage. Do not operate winch unless the wire rope feeds onto drum smoothly. Any discrepancies noted must be reviewed and inspected further by authorized personnel instructed in operation, safety and maintenance of this winch.

2.WIRE ROPE. Visually inspect all wire rope which can be expected to be in use during the day’s operations. Inspect for wear and damage indicated by distortion of wire rope such as kinking, “birdcaging,” core protrusion, main strand displacement, corrosion, broken or cut strands. If damage is evident, do not operate winch until the discrepancies have been reviewed and inspected further by personnel knowledgeable on wire rope safety and maintenance procedures.

NOTICE

• The full extent of wire rope wear cannot be determined by visual inspection. At any indication of wear inspect wire rope in accordance with instructions in “Periodic Inspection.”

3.AIR SYSTEM. Visually inspect all connections, fittings, hoses and components for indication of air leaks. Repair any leaks or damage.

4.PENDANT (optional feature). Ensure operation of pendant levers is smooth and winch is responsive to pendant control. Pendant levers must spring return to the neutral position when released.

5.MANUAL THROTTLE LEVER. Ensure operation of manual throttle lever is smooth and winch is responsive to lever movement. Lever must return to neutral and lock in place when released. If winch responds slowly or controls stick, do not operate winch until all problems have been corrected.

6.BRAKES. During winch operation test brakes. Brakes must hold load without slipping. Automatic brakes must release when winch motor throttle is operated. If brakes do not hold load, or do not release properly, brakes must be adjusted or repaired.

7.WIRE ROPE REEVING. Check reeving and ensure wire rope is properly secured to the drum. Do not operate winch unless wire rope feeds onto drum smoothly.

8.LUBRICATION. Refer to “LUBRICATION” section for recommended procedures and lubricants.

9.LIMIT SWITCHES (optional feature). If equipped, ensure limit switches engage and prevent operation at the required set point and with drum rotating in correct direction. Ensure limit switch properly resets.

21

10.MOTOR. During operation check motor housing for excess heat build up. Housing should not be hot to touch. Listen for grinding or knocking noises. Ensure lubricated air supply provides 6 to 9 drops per minute of ISO VG 32 (SAE 10W) oil when winch is operated at rated capacity. Operate winch slowly in both directions to verify operation.

Periodic Inspection

Periodic inspection intervals for winch use under various conditions is listed below:

NORMAL |

HEAVY |

SEVERE |

yearly |

semiannually |

quarterly |

Disassembly may be required as a result of frequent inspection findings or in order to properly inspect individual components. Refer to “MAINTENANCE” section on page 26. Maintain written records of periodic inspections to provide an accumulative basis for continuing evaluation. Inspect all items listed in “Frequent Inspection.” Also inspect the following:

1.SIDE RAILS AND UPRIGHTS. Check for deformed, cracked or corroded main components. Replace damaged parts.

2.FASTENERS. Check retainer rings, split pins, capscrews, nuts, and other fasteners on winch, including mounting bolts. Replace if missing or damaged and tighten if loose.

3.DRUM AND SHEAVES. Check for cracks, wear or damage. Replace if necessary.

4.WIRE ROPE. In addition to “Frequent Inspection” requirements, also inspect for the following:

a.Build-up of dirt and corrosion. Clean with steam or a stiff wire brush to remove dirt and corrosion if necessary.

b.Loose or damaged end connection. Replace if loose or damaged.

c.Check wire rope anchor is secure in drum.

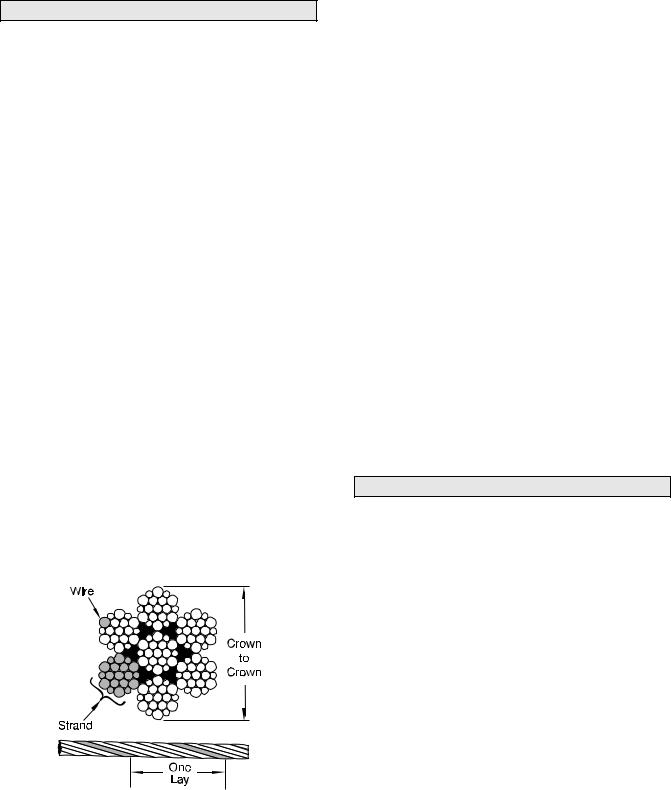

d.Verify wire rope diameter. Measure diameter of wire rope from crown-to-crown throughout life of wire rope. Recording of actual diameter should only be done with wire rope under equivalent loading and in same operating section as accomplished during previous inspections. If actual diameter of wire rope has decreased more than 1/64 inch (0.4 mm) a thorough examination of wire rope should be conducted by an experienced inspector to determine suitability of wire rope to remain in service. Refer to Dwg. MHP0056 on page 22.

(Dwg. MHP0056)

5.ALL COMPONENTS. Inspect for wear, damage, distortion, deformation and cleanliness. If external evidence indicates damage, disassemble as required to conduct a detailed inspection. Inspect gears, shafts, bearings, sheaves, springs and covers. Replace worn or damaged parts. Clean, lubricate and reassemble.

6.BRAKES. Individually test brakes installed to ensure proper operation. Brakes must hold a 125% rated load at mid drum without slipping. If indicated by poor operation or visual damage, disassemble and repair brake(s). Check all brake surfaces for wear, deformation or foreign deposits. If brake lining thickness is less than minimum as described in “MAINTENANCE” section replace brakes. Clean and replace components as necessary. Adjustments cannot be made to disc brake. The disc brake must be repaired as described in “MAINTENANCE” section.

7.FOUNDATION OR SUPPORTING STRUCTURE. Check for distortion, wear and continued ability to support winch and rated load. Ensure winch is firmly mounted and that fasteners are in good condition and tight.

8.LABELS AND TAGS. Check for presence and legibility of labels. Replace if damaged or missing.