Honeywell TR40, TR42 Installation Instructions

Zio® Lite TR40/42 LCD and non-LCD Wall Modules

INSTALLATION INSTRUCTIONS

BEFORE INSTALLATION

—For information on Sylk bus distance limitations, see Table 1 on page 2.

—All wiring is polarity insensitive.

INSTALLATION

Mount the wall module on an inside wall approximately 54 in. (1372 mm) from the floor (or in the specified location), to allow exposure to the average zone temperature. Do not mount the wall module on an outside wall, on a wall containing water pipes, or near air ducts. Avoid locations that are exposed to discharge air from registers or radiation from appliances, lights, or the sun.

The wall module can be mounted on a wall, on a standard utility conduit box using No. 6 (3.5 mm) screws or on a 60 mm wall outlet box (see Fig. 3). When mounting directly on a wall, use the type of screws appropriate for the wall material.

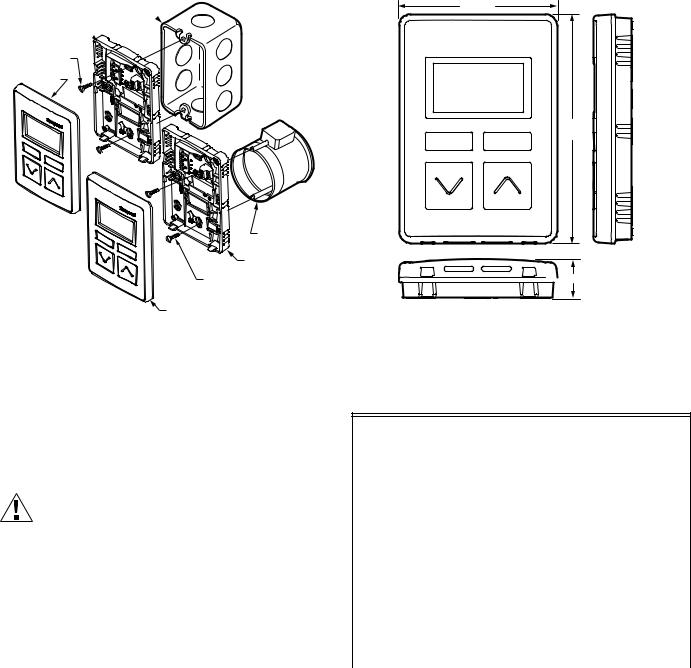

Fig. 1. LCD Wall Module.

CAUTION

Erratic System Operation Hazard.

Failure to follow proper wiring practices can introduce disruptive electrical interference (noise).

Keep wiring at least one foot away from large inductive loads such as motors line starters, lighting ballasts, and large power distribution panels.

Shielded cable is required in installations where these guidelines cannot be met.

Ground the shield only to the grounded controller case.

2-3/8 (60) |

|

|

4-41/64 |

|

(118) |

|

3-1/4 |

|

(83) |

|

2-3/8 |

|

(60) |

2-3/8 (60) |

|

3-11/64 (81) |

M34633 |

IMPORTANT

All wiring must comply with local electrical codes and ordinances or as specified on installation wiring diagrams.

Fig. 2. Subbase mounting holes and locking tabs.

62-0467-05

ZIO® LITE TR40/42 LCD AND NON-LCD WALL MODULES

STANDARD UTILITY

CONDUIT BOX

SUBBASE

NO. 6 SCREW

WALL

MODULE

|

60 mm WALL |

|

OUTLET BOX |

|

SUBBASE |

3.5 mm SCREW |

|

WALL MODULE |

M34634 |

|

|

Fig. 3. Mounting on standard utility conduit box or 60 mm wall outlet box.

Wiring

All terminal connections can be made to the backside of the module. There are no field adjustable/replaceable components inside the module.

Attach the wires from the programmable controller and network to the appropriate wall module terminals, as indicated in Fig. 6 on page 3.

CAUTION

Improper Electrical Contact Hazard.

Screw-type terminal blocks are designed to accept no more than one 14AWG (2.5mm sq) conductor.

Connect multiple wires that are 14AWG (2.5mm sq) with a wire nut. Include a pigtail with this wire group and attach the pigtail to the individual terminal block.

Wiring Wall Modules

Wire the terminal block shown in Fig. 6 as follows:

1.For single wires, strip 3/16 in. (5 mm); for multiple wires going into one terminal, strip 1/2 in. (13 mm) insulation from the conductor. See Fig. 5 for wiring multiple TR40/42s.

2.Insert the wire in the required terminal location and tighten the screw to complete the termination.

3.Review and verify the terminal connection wiring illustrated in Fig. 6.

3-5/16 (84)

4-49/64

(121)

53/64 (21)

53/64 (21)

M34635

Fig. 4. LCD Wall Module dimensions in inches (mm).

Table 1.

Recommended maximum distance from controller to any Sylk device

|

|

|

Standard |

|

|

|

|

thermostat wire, |

|

|

|

|

(non-twisted), |

|

|

Single twisted pair, |

shielded or non- |

||

|

non-shielded, |

shielded, stranded |

||

Quantity and type |

stranded or solidb |

or solidc,d |

||

of devicea |

|

|

|

|

18-22 AWG |

24 AWG |

18-24 AWG |

||

10 wall modules, |

500 ft |

400 ft |

100 ft |

|

any type |

(150 m) |

(120 m) |

(30 m) |

|

|

|

|

|

|

4 Sylk field devices |

400 ft |

300 ft |

100 ft |

|

of any type |

||||

(120 m) |

(100 m) |

(30 m) |

||

(including Zelix) |

||||

|

|

|

||

|

|

|

|

|

10 Sylk field |

400 ft |

300 ft |

100 ft |

|

devices of any type |

||||

(120 m) |

(100 m) |

(30 m) |

||

(excluding Zelix) |

||||

|

|

|

||

|

|

|

|

|

aFor Spyders, use the Resource Usage View in the Spyder Tool to determine the maximum number of devices. For ComfortPoint™ Open controllers, there is a maximum of 3 TR40/42s.

bAs a rule of thumb, single twisted pair (2 wires per cable only), thicker gauge, non-shielded cable yields best results for longer runs.

cThe 30 m distance for standard thermostat wire is conservative, but meant to reduce the impact of any sources of electrical noise (including but not limited to VFDs, electronic ballasts, etc). Shielded cable recommended only if there is a need to reduce the effect of electrical noise.

dThese distances also apply for shielded twisted pair.

62-0467—05 |

2 |

Loading...

Loading...