Honeywell UDC2300 User Manual

51-52-03-27 8/99

Page 1 of 12

UDC2300

Universal Digital Controller Specification

Overview

The UDC 2300 Universal Digital Controller is a new low priced addition to Honeywell’s LeaderLine family.

This controller introduces new features in the popular low priced ¼ DIN size while retaining all the reliability, cost effectiveness, simplicity, and popular HMI of Honeywell’s UDC 2000.

The UDC 2300 monitors and controls temperatures and other variables in applications such as environmental chambers, plastic processing machines, furnaces and ovens, and packaging machinery. The standard features include AccutuneII™ and the popular single display, automatic mode model. A Dual Display model with Automatic/Manual control modes is optional. A Limit Control model is also available.

ALM 12 |

|

|

PV |

||

|

|

F |

|||

OUT 1 |

|

|

|

C |

|

2 |

2300 MA |

||||

|

|||||

|

SP 2300 |

R L |

|||

|

|

||||

FUNCTION |

DISPLAY |

MAN-AUTO |

SET UP |

||

RESET |

|||||

|

|

|

|

||

AUTO |

|

|

|

RUN |

|

TUNE |

|

|

|

HOLD |

|

Figure 1—UDC 2300 Controller has a sealed faceplate suitable for hosedown applications

The UDC 2300 provides a low priced, 1/4 DIN sized alternative for many applications. Its new features include:

Universal AC power supply, RS485 ASCII or Modbusâ RTU communications option, Input/Output isolation, and Isolated Auxiliary Current output.

These features when combined with the new AccutuneIIä tuning with Fuzzy Logic overshoot suppression, result in price/performance leadership in the performance segment positioned below the

UDC 3300 Controller.

For the many thousands of satisfied UDC 2000 users, UDC 2300 is downward compatible with existing UDC 2000 applications and installations. It even uses the same case; therefore, it can be easily inserted into existing panel installations.

âModbus is a trademark of AEG Modicon

Features/Options |

|

Features/Options, continued |

High Accuracy—Typically ±0.25% of full scale input with a typical resolution of 15 bits.

Analog Inputs—Two inputs are available. The first input accepts all thermocouple, RTD, mA, mV, and voltage types (See Table 1.). Alternatively, the second input is a high level input and can be used as a remote setpoint, for data acquisition, a parameter to be alarmed on. All input types are configurable. All inputs are sampled six times per second (every 166 ms). These two inputs are isolated from all other inputs and outputs, but not from each other.

Dual Setpoints - Simple push-button selection allows quick switchover from primary to alternate setpoint with minimal operator confusion.

Manual/Automatic Modes—

Bumpless, balanceless transfer between control modes. Available with a Dual Display option and SP Programming option.

Accutune II™ —This standard feature provides a new, truly plug and play tuning algorithm, which will, at the touch of a button or through a digital input, accurately identify and tune any process including those with deadtime and integrating processes. This speeds up and simplifies start-up plus allows retuning at any setpoint.

Fuzzy Logic—This standard feature uses fuzzy logic to suppress process variable overshoot due to SP changes or externally induced process disturbances. It operates independently from AccutuneIIä tuning. It does not change the PID constants, but temporarily modifies the internal controller response to suppress overshoot. This allows more aggressive tuning to co-exist with smooth PV response. It can be enabled or disabled depending on the application or the control criteria.

CE Mark—Conformity with 73/23/EEC, Low Voltage Directive and 89/336/EEC, the EMC Directive as a standard feature.

Industrial Automation and Control, 1110 Virginia Drive, Fort Washington, PA 19034

Printed in U.S.A. ■ © Copyright 1999—Honeywell Inc.

51-52-03-27 Page 2

Features/Options, continued

Auxiliary Output* (Optional)—This isolated Auxiliary Output can be scaled from 4-20 mA for 0 to 100% for any range. It can be configured to represent Input 1, Input 2, PV, active Setpoint, Local SP1, Deviation, or the Control Output..

Communications* (Optional)—

Provides a communications link between the UDC 2300 and host computer or PLC via the RS422/485 ASCII or Modbus® RTU communications option.

Digital Input* (Optional)—Provides isolated digital input for remote dry contact closure to select one of the following actions:

•Manual control mode

•Local setpoint 1

•Local setpoint 2

•Direct controller action

•Hold SP Ramp/Programming

•Select PID set 2

•To Run - SP Ramp/Program

•External program reset

•Disable PID integral action

•Manual mode, failsafe output

•Disable keyboard

•Start Timer

•Initiate Tuning

•Initiate PV Hot Start

•Output tracks Input 2

•To Remote Setpoint

•To Latching Manual Mode

Also the digital input can allow one of the following selections to be combined with one of the above selections:

•Select PID set 2

•Direct controller action

•Local setpoint 2

•Local setpoint 1

•To Run

New Alarm Function Features

•Alarms can be configured as latching or non-latching.

•Alarm blocking is also available which allows start-up without alarm energized until after it first reaches the operating region.

•PV rate of change alarm

•Loop break alarm

•Timer output reset

Universal Switching Power —

Operates on any line voltage from 90 to 264 Vac 50/60 Hz without jumpers. 24 Vac/dc instrument power is available as an option.

*Auxiliary Output, Digital Input, and

Features/Options, continued

Moisture Protection —IP65/NEMA 3 rated front face permits use in applications where it may be subjected to moisture, dust, or hosedown conditions.

Limit Control—Provides a latching relay , which is activated whenever the PV goes above or below a preset setpoint value. An alarm indicator will light when the output is activated. Reset is through a key on the front of the controller or an external switch. A FM approved model is available.

Approval Body Options—FM approval and CSA certification are available options. A UL listing applies to regulatory use only and is a standard feature.

Timer—This standard feature provides a configurable time period of 0 to 99 hours, 59 minutes or units of minutes and seconds. It can be started via the keyboard, alarm 2, or by a digital input. The timer output is Alarm 1 which energizes at the end of the Timer Period. Alarm 1 can be automatically reset. The Timer Period can be changed between each batch. Status is shown on the lower display.

Heat/Cool Capability—Provides split range control with independent PID tuning constants—one for heating, one for cooling—plus mixed output forms.

Setpoint Ramp/Soak Programming (Optional)—Enables you to program and store six Ramp and six Soak segments for setpoint programming. Run or Hold of program is keyboard or remote digital switch selectable.

Setpoint Rate—Lets you define a ramp rate to be applied to any local setpoint change. A separate upscale or downscale rate is configurable. A single setpoint ramp is also available as an alternative.

Thermocouple Failsafe—

Configurable upscale or downscale burnout and failsafe output level.

Decimal Point Location—

Configurable for none, one, or two places.

Indicator Model—A single display indicator model is available. Optional features include: 2 alarms plus Auxiliary Output or Communications.

Features/Options, continued

Dedicated Keys—Provide direct access setpoint modes and setpoint program status to simplify and speed operation.

Two Sets of Tuning Constants—

Two sets of PID parameters can be configured for each loop and automatically or keyboard selected.

Alarm Selection—None, one, or two relays to activate external equipment when preset high/low setpoints are reached. There is an indicator for each alarm. For Duplex or 3 Position Step operation, only one alarm is available.

Data Security—Five levels of keyboard security protect tuning, configuration, and calibration data, accessed by a configurable 4-digit code. Nonvolatile EEPROM memory assures data integrity during loss of power.

Diagnostic/Failsafe Outputs -

Continuous diagnostic routines detect failure modes, trigger a failsafe output value and identify the failure to minimize troubleshooting time.

High Noise Immunity - The controller is designed to provide reliable, errorfree performance in industrial environments that often affect highly noise-sensitive digital equipment.

Quality/Support—The UDC 2300 is covered by a 2-year warranty and backed up by a toll-free phone number for technical assistance.

Transmitter Power—Provides up to 30 volts dc to power a 2-wire transmitter. (Requires use of alarm 2 open collector output selection or auxiliary output.).

Physical Description

The controller is housed in a 4.2-inch deep, black metal case with a dark gray elastomer bezel, that can be panel mounted in a 1/4 DIN cutout. (See Figure 5.) The plug-in chassis allows easy access to the controller board and its various option boards. All power, input, and output wiring are connected to screw terminals on the rear panel. (See Figure 6.) Blue and tan elastomer bezels are optionally available.

Communications are mutually exclusive.

Configuration

You decide how the controller is to interact with the process by selecting, through simple keystrokes, the functions you want.

Multi-language prompts guide the operator step-by-step through the configuration process assuring quick and accurate entry of all configurable parameters. Five languages are available via configuration: English, French, German, Spanish and Italian.

Inputs

The analog inputs are sampled six times a second.

The UDC 2300 is available with one or two inputs. The first input, or Process Variable input, can be one of the various thermocouple, RTD, Radiamatic or linear actuations. Linear actuations have thermocouple, RTD, and Radiamatic transmitter characterization capability as a standard feature.

The optional second input is a high level input and accepts ranges of 0-5V, 1-5V, 0-20mA, or 4-20mA.

All actuations and characterizations are keyboard configurable. Cold junction compensation is provided for thermocouple type inputs. Upscale or downscale sensor break protection is keyboard configurable. A configurable digital filter of 0 to 120 seconds provides input signal damping.

Output Types

The following output types are available per the model selection guide:

•Current Output

•Electromechanical Relays (5 amps)

•Solid State Relays (1 amp)

•Solid State Relays (10 amps) externally mounted (optional)

•Open Collector Outputs

•Auxiliary Current Output (optional)

Output Algorithms

The UDC 2300 is available with one or more of the following output algorithms:

Time Proportional—Provides On-Off or Time Proportional (Relay) output.

Current Proportional—Supplies proportional direct current output for final control elements which require a 4-20 mA signal.

Current Proportional Duplex—

Similar to current proportional but provides a second set of tuning parameters and a split range current output or a second current output via the Auxiliary output option, for the heat and cool zones.

Time Proportional Duplex—

Depending on which control algorithm you select, this duplex output algorithm can provide On-Off Duplex, Time Proportional Duplex, or Three Position Step Control. The time proportional duplex output provides independent PID tuning constants and two time proportional outputs; one for heat zone above the 50% output, and one for cool zone below 50% output.

Current/Relay Duplex (Relay = Heat)—A variation of Duplex with Current active for 0 to 50% output (PID Set 2) and Relay 2 active 50 to100% output (PID Set 1). Note that only one alarm is available.

Relay/Current Duplex (Relay = Cool)—A variation of Duplex with Current active for 50 to 100% output and Relay 2 is active for 0 to 50% output. Not that only one alarm is available.

Universal Output Model—Flexibility of the output algorithms allows the current output with two alarms model (DC230B-CE) to also be configured for current simplex, current duplex, and time simplex. A relay output model with auxiliary output option (DC230B-CE-2) can also be configured for these output algorithms. Note that only current simplex and current duplex can have 2 alarms.

51-52-03-27 Page 3

Control Algorithms

Depending on the output algorithms specified, the controller can be configured for the following control algorithms:

•On-Off

•PID-A

•PID-B

•PD with Manual Reset

•Three Position Step Control

The Three Position Step Control algorithm allows the control of a valve (or other actuator), with an electric motor driven by two controller output relays; one to move the motor upscale, the other downscale without a feedback slidewire linked to the motor shaft.

Control Modes

The controller is capable of operating in three different control modes:

1.Manual

2.Automatic with Local Setpoint

3.Automatic with Remote Setpoint The manual and automatic control modes with local and remote setpoint, and bumpless, balanceless transfer between modes.

Alarms

Alarm output terminals are located at the rear terminal panel. One or two electromechanical alarm relays are available to activate external equipment when preset alarm setpoints are reached. Each of the two alarms can be set to monitor two independent setpoints. Each alarm setpoint can be either high or low alarm. The alarm type can be selected to be either of the inputs, the Process Variable, Deviation, Output, Shed from communications, PV rate of change, or to alarm on manual mode. It can also be used as an On or Off event at the beginning or end of a Ramp/Soak segment. The alarm hysteresis is configurable from 0 to 100% of range.

Configurable alarm features include:

•Alarm latching or non-latching

•Alarm blocking

•PV rate of change alarm

•Loop break alarm (Future)

•Timer reset

51-52-03-27 Page 4

Upper Display - Four digits

•Normal operation - Process Variable

•Configuration mode - displays parameter value or selection

ALM - Alarm |

ALM 12 |

|

|

PV |

||

conditions exist |

|

|

||||

|

|

F |

||||

OUT - Control |

OUT 1 |

|

|

|

C |

|

2 |

2300 MA |

|||||

Relay |

|

|||||

1 or 2 on |

|

|

|

|

R |

|

|

|

SP 2300 |

L |

|||

|

|

|

||||

|

FUNCTION |

DISPLAY |

MAN-AUTO |

SET UP |

||

Keys- |

RESET |

|||||

|

|

|

|

|||

|

|

|

|

|

||

See |

|

|

|

|

|

|

Figure 3 |

AUTO |

|

|

|

RUN |

|

|

TUNE |

|

|

|

HOLD |

|

F - °Fahrenheit being used

C - °Centigrade being used M or A - Manual/Auto display

R - Remote or Local SP2 setpoint active

L - Local setpoint active

Lower Display - Six alpha-numeric characters

•Normal operation - displays operating parameters and values (four numeric digits)

•Configuration mode - displays functions and parameters

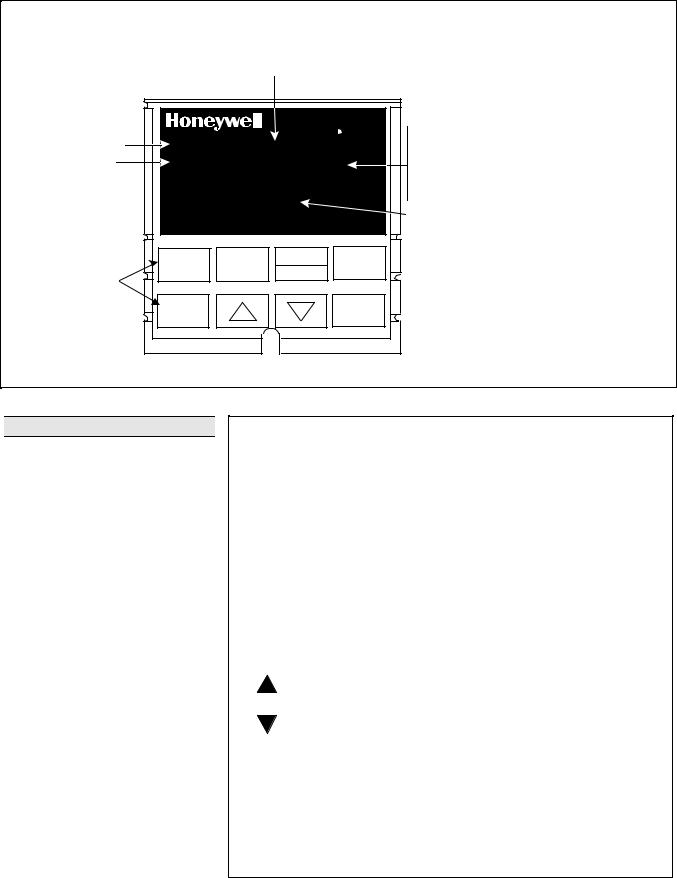

Figure 2—Operator Interface

Operator Interface (Figure2)

Indicators—Provide alarm, control mode, and temperature unit indication. There is also indication of when Remote Setpoint is active, the status of the control relays, and whether a setpoint program is in Run or Hold mode.

Displays—A 4-digit upper display is dedicated to the process variable during normal operation with alternate information displayed when in the configure mode. The upper display is also dedicated to the single display model operation and also shows Setpoint output or Deviation on demand. The Indicator model uses the Upper Display only.

During normal operation of the dual display model, the six character alphanumeric lower display shows keyselected operating parameters such as Output, Setpoints, Inputs, Deviation, active Tuning Parameter Set, Timer Status, or minutes remaining in a setpoint ramp. It also provides guidance, through language prompts, for the operator during controller configuration.

Eight keys enable complete configuration and operation

FUNCTION |

Selects functions within each configuration group. |

|

|||

Selects 2nd Setpoint or Remote Setpoint. |

|

||||

|

|

|

|

||

|

|

|

Returns Controller to normal display from Set Up mode. |

||

|

|

|

|||

DISPLAY |

|||||

Toggles various operating parameters for display. |

|

||||

|

|

|

|

||

|

|

|

Selects Manual or Auto mode. |

|

|

MAN-AUTO |

|

||||

Resets the latching Limit Controller relay. |

|

||||

|

RESET |

|

|||

|

|

|

In Set Up mode, used to restore original value or selection. |

||

|

|

|

|||

|

|

|

Scrolls through the configuration groups. |

|

|

SET UP |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

AUTO |

Initiates Limit Cycle Tuning. |

|

||

TUNE |

|

||||

|

|

||||

|

|

|

Increases setpoint or output value. Increases the |

|

|

|

|

|

|

||

|

|

|

|

||

|

|

|

configuration values or changes functions in Configuration mode groups. |

||

|

|

|

Decreases setpoint or output value. Decreases the |

||

|

|

|

|||

|

|

|

configuration values or changes functions in Configuration mode groups. |

||

|

|

|

Enables Run/Hold of the SP Ramp or Program |

|

|

|

RUN |

|

|

||

|

HOLD |

plus Timer start. |

22350.ppt |

||

|

|

|

|||

|

|

|

|

||

Figure 3—Key Functions

Loading...

Loading...