Honeywell TP970-72, TP970-74, TP9600, TP9630 Installation Instructions

TP970-72, TP970-74, TP9600, and TP9630

Pneumatic Sensors, Humidistats,

and Thermostats |

|

INSTALLATION INSTRUCTIONS |

|

|

Contents |

INTRODUCTION ............................................................................................................................ |

2 |

BEFORE INSTALLATION ............................................................................................................................ |

2 |

Tools and Accessories ........................................................................................ |

2 |

General ............................................................................................................... |

2 |

Dimensions ......................................................................................................... |

4 |

Covers ................................................................................................................ |

5 |

General ............................................................................................................... |

5 |

Removing and Replacing Covers ....................................................................... |

6 |

Installing Cover Inserts ....................................................................................... |

7 |

Painting (Beige Plastic Covers Only) .................................................................. |

7 |

INSTALLATION ............................................................................................................................ |

9 |

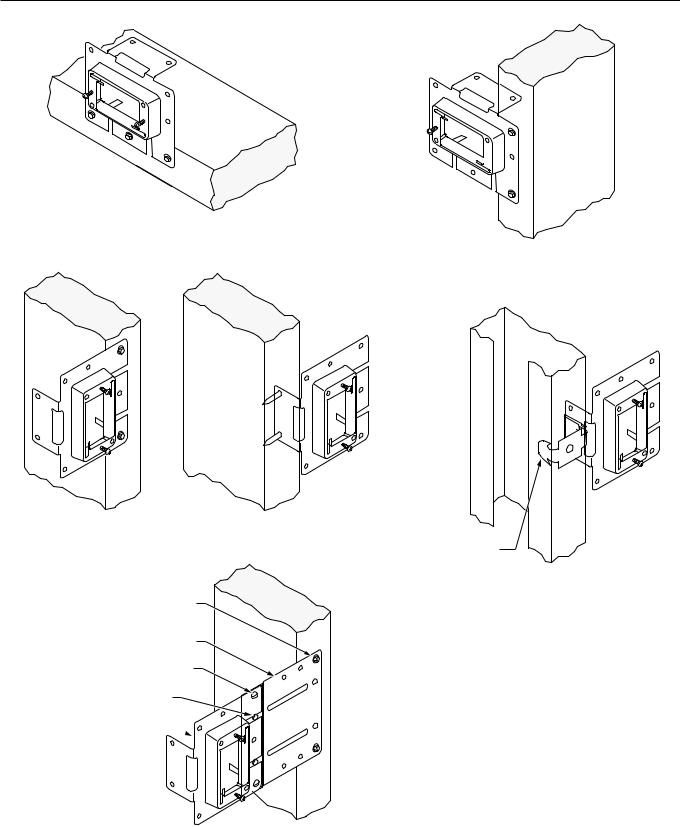

Installation with Recessed Tubing ...................................................................... |

9 |

Hollow-Core Studded Wall ................................................................................. |

9 |

Block or Brick Wall ............................................................................................ |

28 |

Concrete Pour .................................................................................................. |

34 |

Mullion .............................................................................................................. |

38 |

Installation with Surface-Mounted Tubing ........................................................ |

40 |

Piping ................................................................................................................ |

45 |

CALIBRATION .......................................................................................................................... |

45 |

Tools Required ................................................................................................. |

45 |

Humidistat/Humidity Sensor ............................................................................. |

45 |

General ............................................................................................................. |

45 |

Setpoint Lock .................................................................................................... |

46 |

Throttling Range Adjustment (HP970 and HP972) ........................................... |

46 |

Calibration Check ............................................................................................. |

46 |

Recalibration .................................................................................................... |

46 |

Thermostat/Temperature Sensor ...................................................................... |

47 |

General ............................................................................................................. |

47 |

Throttling Range Adjustment ............................................................................ |

47 |

Calibration Check ............................................................................................. |

47 |

Recalibration .................................................................................................... |

47 |

APPENDIX: BACKPLATES .......................................................................................................................... |

48 |

General ............................................................................................................. |

48 |

Removing Stat from Conventional Backplate ................................................... |

48 |

Removing Stat from Quick-Mount Backplate.................................................... |

48 |

® U.S. Registered Trademark |

|

Copyright © 1998 Honeywell Inc. • All Rights Reserved |

95-5597-1 |

TP970-72, TP970-74, TP9600, AND PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

INTRODUCTION

The BEFORE INSTALLATION section shows tools and accessories used during installation and calibration, dimensions of major accessories, and procedures for preparing thermostat and humidistat covers. The INSTALLATION section shows how to install thermostats, humidistats, sensors, and fittings and shows connections for oneand two-pipe applications. The CALIBRATION section describes calibration and adjustment procedures.

For information on how to remove a stat body from a stat backplate, refer to APPENDIX: BACKPLATES.

BEFORE INSTALLATION

Tools and Accessories

General

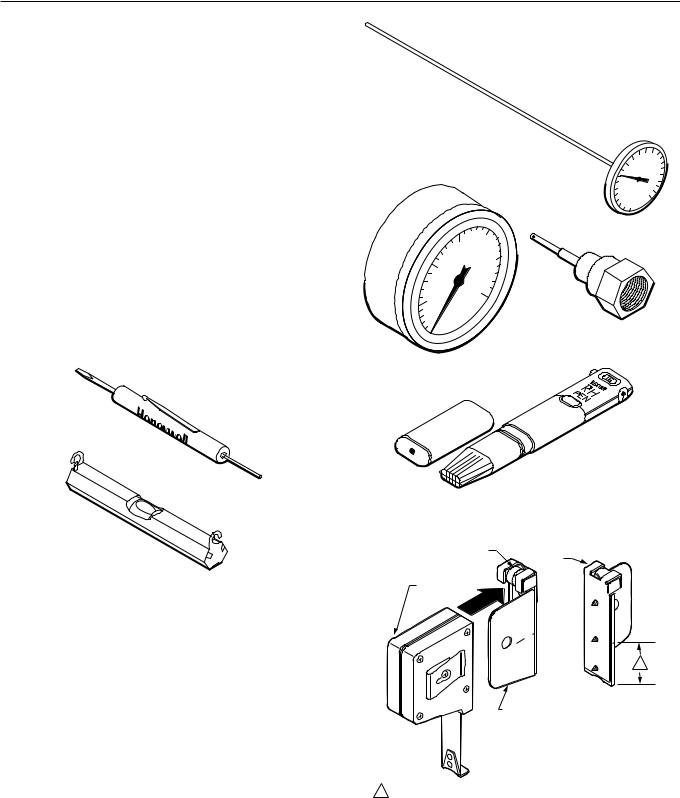

Figure 1 shows tools used for stat installation. Figure 2 shows tools used during calibration check. Figures 3 through 8 show accessories used for several mounting methods.

THERMOSTAT TOOL

POCKET LEVEL CCT348

C3150-1

Fig. 1. Installation Tools Used for All Mounting Methods.

TEST THERMOMETER |

|

100 |

120140 |

|

CCT902 |

|

160 |

||

80 |

||||

|

180 |

|||

|

60 |

|

||

|

|

200 |

||

|

40 |

|

||

|

|

220 |

||

|

20 |

|

||

|

0 |

|

||

20

15

25

10

30

5

0

GAGE 305965

0-30 PSI (0-207 kPa)

GAGE PORT NEEDLE (CCT729A CAN BE USED TO

CONNECT TO 5/32 IN. AND 1/4 IN. POLYETHYLENE TUBING)

DIGITAL RELATIVE

HUMIDITY INDICATOR

PEN CCT915

C3928

Fig. 2. Calibration Tools.

LEVEL |

BACK |

|

VIEW |

TAPE

MEASURE

C

L

1

THERMOSTAT

MOUNTING

GUIDE TOOL

11—1/2 IN. (38 MM) FROM BOTTOM OF TAPE MEASURE TO CENTER MARK CORRESPONDING TO CENTER OF STAT.

C3151

Fig. 3. Tape Measure CCT422 and Thermostat

Mounting Guide Tool CCT690.

95-5597—1 |

2 |

TP970-72, TP970-74, TP9600, AND TP9630 PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

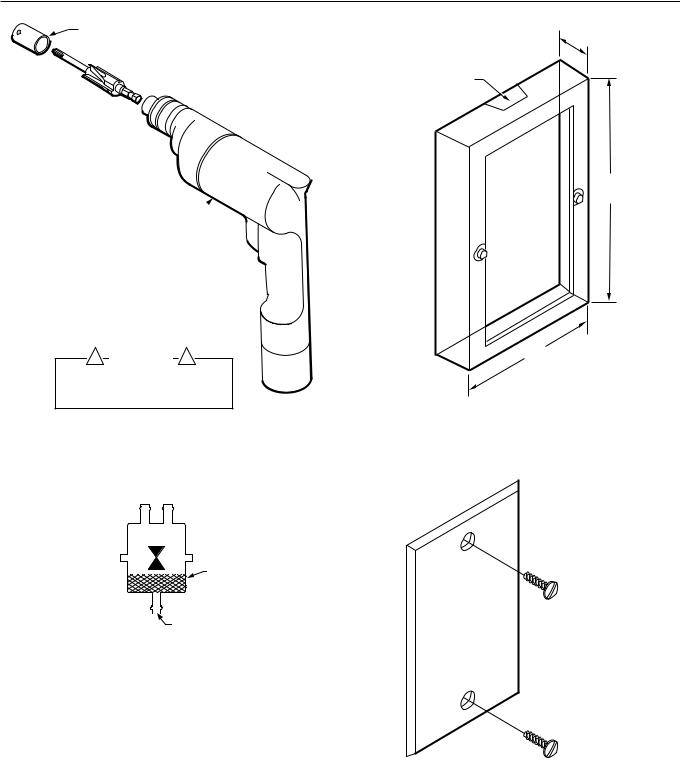

PROTECTIVE SLEEVE FOR BORE

REPLACEMENT PROTECTIVE SLEEVES

ARE AVAILABLE. ORDER CCT691A.

THERMOSTAT STEP/BORING TOOL

THERMOSTAT STEP/BORING TOOL

CORDLESS DRILL

! WARNING |

! |

TO AVOID BODILY INJURY AND PROTECT |

|

BORE, LEAVE PROTECTIVE SLEEVE ON |

|

STEP/BORING TOOL EXCEPT WHEN |

|

DRILLING WITH BORE. |

C3152 |

Fig. 4. Thermostat Step/Boring Tool CCT691

and Cordless Drill CCT713.

SEE CHART FOR BARB SIZE

A B

|

|

|

|

|

|

|

|

FILTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INLET |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

ALL INLET BARBS |

|

|

|

|

|

|

|

|

|

1/4 IN. (6 MM) |

|

|

|

REMOTE RESTRICTORS |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BARB SIZE |

|

PART NO. |

ORIFICE |

|

BODY |

IN INCHES (MM) |

|||||

14002913– |

SIZE IN INCHES |

|

COLOR |

A |

B |

||||

|

|

|

|

|

|

|

|

|

|

–001* |

0.005 |

|

|

|

|

|

Blue |

1/4 (6) |

5/32 (4) |

|

|

|

|

|

|

|

|

|

|

–004 |

0.005 |

|

|

|

|

|

Blue |

5/32 (4) |

5/32 (4) |

|

|

|

|

|

|

|

|

|

|

* ONE BARB CAP 14003567-001 FURNISHED WITH RESTRICTOR

C3931-1

Fig. 5. Remote Restrictors Used for Piping.

1/2

(13)

REMOVABLE WEB (CUT AWAY WITH POCKET KNIFE)

3-17/32

(90)

2-5/16

(59)

C3153

Fig. 6. Wall Mounting Ring 14004458-001 for Flush or Surface Mounting to Brick or Block Wall or to Wall with Surface-Mounted Tubing.

NOTE: USE FOR APPLICATION WITH RECESSED TUBING WHEN STAT IS TO BE MOUNTED AT A LATER DATE

C3154

Fig. 7. Wall Plate Bag Assembly 14001905-001.

3 |

95-5597—1 |

TP970-72, TP970-74, TP9600, AND PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

Dimensions

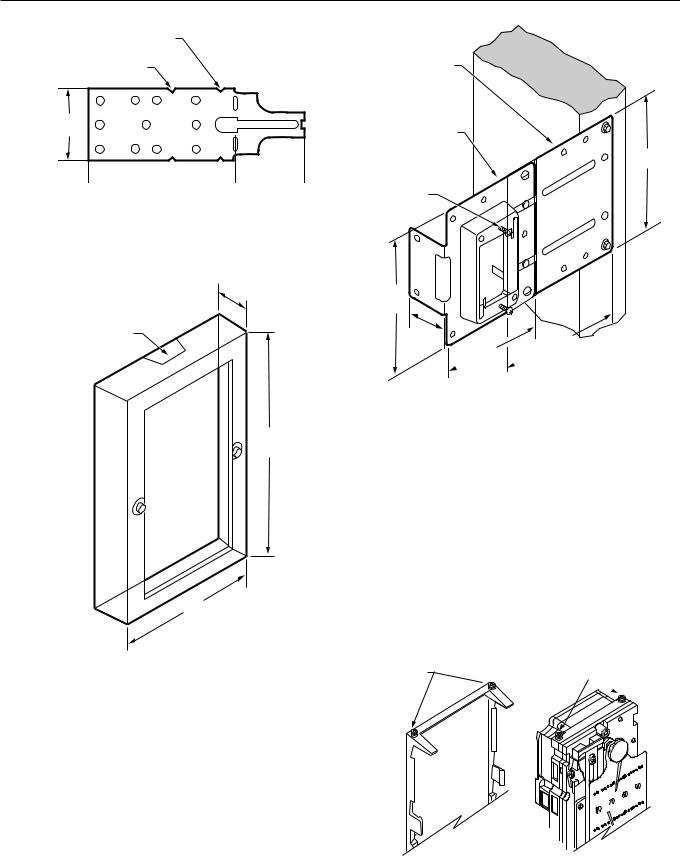

Figures 9 through 13 show dimensions of major installation accessories.

4-5/8

(117)

2-3/4 (70)

C5532

Fig. 7A. Wall Plate Bag Assembly 14002136-004.

TWIN TUBE

AK3240 (5/32 IN. O.D. X 0.030 IN. WALL) OR

AK3241 (1/4 IN. O.D. X 0.040 IN. WALL)

BUNDLED TUBING AK3168 (5/32 IN. O.D. X 0.030 IN. WALL)

C3155

Fig. 8. Twin Tube AK3240 (5/32 in. O.D. x 0.030 in. wall) or AK3241 (1/4 in. O.D. x 0.040 in. wall) and Bundled Tubing AK3168 (5/32 in. O.D. x 0.030 in. wall).

4-1/2

(115)

2-7/8

(73)

|

2-1/4 |

|

(57) |

1-11/16 |

|

(43) |

|

NO. 6-32 X 1/2 IN. |

|

MOUNTING SCREW (2) |

|

PROVIDED WITH |

C3180 |

SHALLOW WALLPLATE |

Fig. 9. Shallow Wall Plate 14001614-001

Dimensions in Inches (Millimeters).

KNOCKOUT FOR 1/2 IN. CONDUIT OR

FITTING SNAP RING (BOTH SIDES,

BACK, TOP AND BOTTOM)

3/16 (5) |

TAPPED HOLE (2) 6 x 32 |

|||

(6 PLACES) |

MOUNTING SCREWS |

|||

|

|

|

6 x 32 - 1/2 (PROVIDED) |

|

TAPPED HOLE |

ALIGNMENT |

|||

8 x 32 (2 PLACES) |

FOR FINISHED WALL |

|||

|

|

|

1/4 (6) |

|

GUIDES FOR |

1/2 (13) |

|||

|

||||

MOUNTING |

3/4 (19) |

|||

BRACKET |

||||

|

||||

|

|

|

|

|

2-5/8

(67)

2-9/16 (65) |

1-7/16 |

(37)

C3930

Fig. 10. Deep Wall Box 14001355-001

Dimensions in Inches (Millimeters).

95-5597—1 |

4 |

TP970-72, TP970-74, TP9600, AND TP9630 PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

1 IN. (25 MM) OFFSET FOR BOX

2 IN. (51 MM) OFFSET FOR BOX

1-1/2

(38)

3-1/16 (78)

3-1/16 (78)

1-7/16 (37)

1-7/16 (37)

C3179

Fig. 11. Deep Wall Box Mounting Bracket 14001354-001

Dimensions in Inches (Millimeters).

1/2

(13)

REMOVABLE WEB (CUT AWAY WITH POCKET KNIFE)

3-17/32

(90)

2-5/16

(59)

C3153

Fig. 12. Wall Mounting Ring 14004458-001

Dimensions in Inches (Millimeters).

EXTENSION

PLATE

STUD-MOUNTED STAT PLATE (ALIGN OVER ELECTRICAL BOX)

NO. 6-32 X 1/2 IN.

MOUNTING SCREW (2)

PROVIDED WITH

STUD-MOUNTED

STAT PLATE

3-15/16

(100)

1-1/16

(27)

3-1/16  (78)

(78)

3-15/16

(100)

3-9/16  (91)

(91)

C3933

Fig. 13. Stud-Mounted Stat Plate 14004610-001

and Extension Plate 14004656-001

Dimensions in Inches (Millimeters).

Covers

General

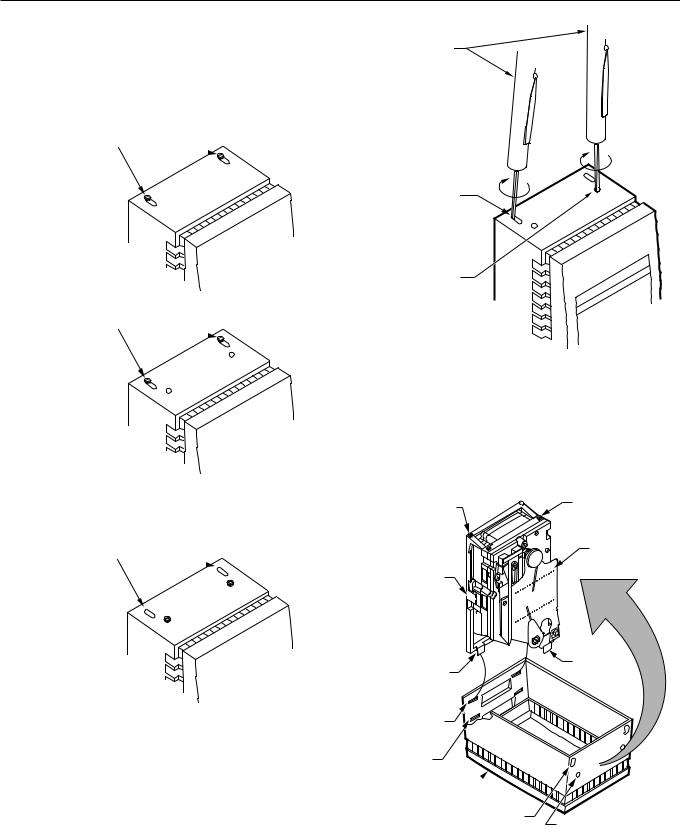

This section shows how to remove and replace thermostat and humidistat covers and how to install Inserts over the setpoint and DAY/AUTO slots at the bottom of covers. This section also lists recommended paints for covers that can be painted and describes painting procedures.

Cover assembly and disassembly differs between conventional and Quick-Mount stats. On a conventional stat the cover mounts to setscrews in the backplate, while on a Quick-Mount stat the cover mounts to setscrews in the stat body (Fig. 14).

CONVENTIONAL STAT

SETSCREWS QUICK-MOUNT STAT  SETSCREWS

SETSCREWS

STAT BACKPLATE |

STAT BODY |

|

C3569 |

Fig. 14. Setscrew Locations for Conventional and Quick-Mount Stats.

5 |

95-5597—1 |

TP970-72, TP970-74, TP9600, AND PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

To determine the cover mounting method, look at the holes at

the top of the cover (Fig. 15). If the setscrews are raised

THERMOSTAT TOOL

against the back pair of slots (toward the wall), the setscrews are in the backplate and the stat is a conventional stat. If the setscrews are raised into the front pair of holes, the setscrews are in the stat body and the stat is a Quick-Mount stat.

CONVENTIONAL STAT

SETSCREWS VISIBLE

CONVENTIONAL STAT

SETSCREW SLOT (2)

SPECIAL COVER

QUICK-MOUNT STAT

SETSCREW HOLE (2)

COVER

SETSCREWS VISIBLE

90 80 70

60 Honeywell

C3158

STANDARD COVER

Fig. 16. Removing Cover.

Use the following procedure to replace a cover:

1.Hook slots at bottom of cover over two bottom tabs of stat (Fig. 17). Setpoint adjustment will align with setpoint slot.

QUICK-MOUNT STAT

SETSCREWS VISIBLE

STANDARD COVER

C3157

Fig. 15. Conventional and Quick-Mount Stats.

Removing and Replacing Covers

Cover assembly/disassembly requires Thermostat Tool CCT735A (MQT735A). Use the following procedure to remove a cover:

1.Locate setscrews in cover (back pair of slots for conven tional stat, front pair of holes for Quick-Mount stat).

2.Place Allen wrench end of Thermostat Tool through slot/ hole and into setscrew (Fig. 16).

3.Rotate Thermostat Tool clockwise until setscrew no longer touches cover. Repeat for other setscrew.

4.Pull Cover out and down.

CONVENTIONAL STAT

SETSCREW LOCATION (2)  QUICK-MOUNT STAT SETSCREW LOCATION (2)

QUICK-MOUNT STAT SETSCREW LOCATION (2)

STAT

STAT

BACKPLATE

|

90 |

|

80 |

|

70 |

|

60 |

CONVENTIONAL |

QUICK-MOUNT |

STAT TAB (2) |

STAT TAB (2) |

CONVENTIONAL STAT

MOUNTING SLOT (2)

QUICK-MOUNT STAT

MOUNTING SLOT (2)

COVER

CONVENTIONAL STAT

SETSCREW SLOT (2)

QUICK-MOUNT STAT

SETSCREW HOLE (2)

C4110

Fig. 17. Replacing Cover.

95-5597—1 |

6 |

TP970-72, TP970-74, TP9600, AND TP9630 PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

2.Swing cover up and over stat.

3.Place Allen wrench end of Thermostat Tool through setscrew slot and into setscrew.

4.Rotate Thermostat Tool counterclockwise until setscrew holds cover securely onto stat backplate (conventional stat) or stat body (Quick-Mount stat). Repeat for other setscrew.

Installing Cover Inserts

The following Cover Inserts are available for the setpoint and DAY/AUTO lever slots on stat covers:

|

|

|

|

|

|

|

|

Applicable |

|

Part No. |

Finish |

Covers |

Slot |

|

|

|

|

|

|

14004437 |

-001 |

Satin |

14004406-XXX |

DAY/AUTO |

|

|

Chrome |

Standard Covers* |

|

|

|

|

|

|

|

-002 |

Beige |

14004407-XXX |

|

|

|

Plastic |

Standard Covers* |

|

|

|

|

|

|

14004438 |

-001 |

Satin |

14004406-XXX |

Setpoint |

|

|

Chrome |

Standard Covers* |

|

|

|

|

|

|

|

-002 |

Beige |

14004407-XXX |

|

|

|

Plastic |

Standard Covers* |

|

|

|

|

|

|

14004442 |

-001 |

Black |

14002132-XXX |

DAY/AUTO |

|

|

|

Special Covers† |

Setpoint |

|

|

|

|

|

*See HP970 and TP970 Series Standard Covers and Accessories Specification Data 77-1003.

†See HP970 and TP970 Series Standard Covers Specification Data 77-9828.

Cover Inserts are removable. Covers ship with setpoint and DAY/AUTO lever slots “open” (without Insert) or “closed” (with Insert present) as follows:

—Setpoint slot: Open or closed as ordered (see HP970 and TP970 Series Standard Covers and Accessories Specification Data 77-1003 and HP970 and TP970 Series Special Covers and Accessories Specification Data 77-9828)

—DAY/AUTO lever slot:

•No Insert on vertical stat covers

•Insert present on horizontal stat covers

Figures 18 and 19 show how to install Inserts.

COVER

UNUSED

SLOT

SLOT

COVER

INSERT

M10828

Fig. 18. Installing DAY/AUTO Cover Insert

14004437-001/-002.

COVER

COVER

|

SETPOINT |

|

SLOT |

SETPOINT |

|

COVER |

M10827 |

INSERT |

Fig. 19. Installing Setpoint Cover Insert

14004438-001/-002.

Painting (Beige Plastic Covers Only)

Beige Plastic Covers can be painted with recommended paints before or after Covers are installed.

Recommended Paints

If a non-latex paint is required, use Rust-Oleum Enamel (a fish-oil type enamel). No primer is needed.

If a latex paint is required, use one of the following as a primer and follow with any latex wall paint:

—Sears Anti-Rust Enamel (a soya-alkyd type enamel in a spray can)

—True Value Tru-Test X-O Stain Primer/Sealer Stain Killer XOS-1 White (a white-pigmented, shellac type primer)

Painting Procedures

Painting Cover before Window is Installed

Order the following equipment:

—Cover Assembly 14004402-002

—DAY/AUTO Cover Insert 14004437-002 (optional)

—Setpoint Cover Insert 14004438-002 (optional)

—Window 14004405-XXX according to the following table:

1.Remove or add Inserts to Cover Assembly as required (see INSTALLING COVER INSERTS).

2.Wash Cover Assembly with mild dish detergent solution.

3.Dry with paper towel.

4.Paint with approved paint.

5.Allow to dry.

6.When Window has been assembled to Cover, disassembly may damage Window. Before installing Window, note the following:

a.Check that Window display is correct for job requirements.

b.Check Window orientation to cover. Cover setpoint and DAY/AUTO lever slots should be on the bottom (vertical mounting) or to the right (horizontal mounting).

7.Remove liner from adhesive on back of Window. Slide Window into Cover opening (Fig. 20) and press in place.

7 |

95-5597—1 |

TP970-72, TP970-74, TP9600, AND PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

90 80

70

60

90 80

70

60

COVER

WINDOW CURVED FOR INSTALLATION

C3156

Painting Cover after Window is Installed

Order the following equipment:

—Cover Assembly 14004407-XXX (select from HP970 and TP970 Series Standard Covers and Accessories Spec Data 77-1003)

—Paint Mask 14002193-001

—DAY/AUTO Cover Insert 14004437-002 (optional)

—Setpoint Cover Insert 14004438-002 (optional)

1.Remove or add Inserts to Cover Assembly as required (see INSTALLING COVER INSERTS).

2.Wash Cover Assembly with mild dish detergent solution. Do not immerse.

3.Dry with paper towel.

4.Apply Paint Mask to window. Trim around window as needed.

5.Paint with approved paint.

6.Allow to dry.

7.Remove Paint Mask.

Fig. 20. Installing Window.

|

|

|

|

|

|

|

|

|

Window 14004405-XXX |

|

Stat |

|

|

|

|

||

Silver |

Beige |

Orientation |

Honeywell |

Display (Unit) |

|

|||

Background |

Background |

Vert. |

|

Horiz. |

Logo |

Setpoint |

|

Thermometer |

-001 |

-101 |

X |

|

|

X |

None |

|

None |

|

|

|

|

|

|

|

|

|

-002 |

-102 |

|

|

X |

X |

None |

|

None |

-003 |

-112 |

X |

|

X |

|

None |

|

None |

-004 |

-113 |

X |

|

|

|

60-90 (F) |

|

60-90 (F) |

|

|

|

|

|

|

|

|

|

-005 |

-103 |

X |

|

|

X |

60-90 (F) |

|

60-90 (F) |

-006 |

N/A |

X |

|

|

X |

40-70 (F) |

|

40-70 (F) |

-007 |

-104 |

X |

|

|

X |

15-30 (C) |

|

15-30 (C) |

|

|

|

|

|

|

|

|

|

-008 |

-106 |

X |

|

|

X |

60-90 (F) |

|

None |

-009 |

N/A |

X |

|

|

X |

40-70 (F) |

|

None |

-010 |

N/A |

X |

|

|

X |

15-30 (C) |

|

None |

|

|

|

|

|

|

|

|

|

-011 |

N/A |

X |

|

|

X |

None |

|

60-90 (F) |

-012 |

N/A |

X |

|

|

X |

None |

|

15-30 (C) |

-013 |

N/A |

|

|

X |

|

60-90 (F) |

|

60-90 (F) |

|

|

|

|

|

|

|

|

|

-014 |

N/A |

|

|

X |

X |

60-90 (F) |

|

60-90 (F) |

-015 |

-105 |

|

|

X |

X |

15-30 (C) |

|

15-30 (C) |

-016 |

-107 |

X |

|

|

X |

20-80 (% rh) |

|

None |

|

|

|

|

|

|

|

|

|

-017 |

N/A |

|

|

X |

X |

20-80 (% rh) |

|

None |

-018 |

N/A |

X |

|

|

X |

COOLER/WARMER |

|

None |

-019 |

N/A |

X |

|

|

X |

HEAT RANGE/COOL RANGE |

|

60-90 (F) |

|

|

|

|

|

|

60-90 (F) |

|

|

N/A |

-110 |

X |

|

|

X |

15-30 (C) |

|

60-90 (F) |

-021 |

N/A |

|

|

X |

X |

40-70 (F) |

|

40-70 (F) |

|

|

|

|

|

|

|

|

|

95-5597—1 |

8 |

TP970-72, TP970-74, TP9600, AND TP9630 PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

INSTALLATION

This section categorizes stat installation according to the following factors:

—Location of tubing: recessed or surface-mounted

—Type of wall: hollow-core studded, block or brick, concrete, or mullion

—Condition of wall: rough-in or finished

Installation with Recessed Tubing

Examples of installations with recessed tubing include: hollow-core stud walls, block or brick walls, concrete walls, and mullions.

Hollow-Core Studded Wall

A hollow-core studded wall requires either rough-in mounting or finished-wall installation.

Rough-In Installation

Rough-in installation is done to a stud before the wall is drywalled or to lath before the wall is plastered.

NOTE: If the wall is already drywalled or plastered, see FINISHED WALL INSTALLATION.

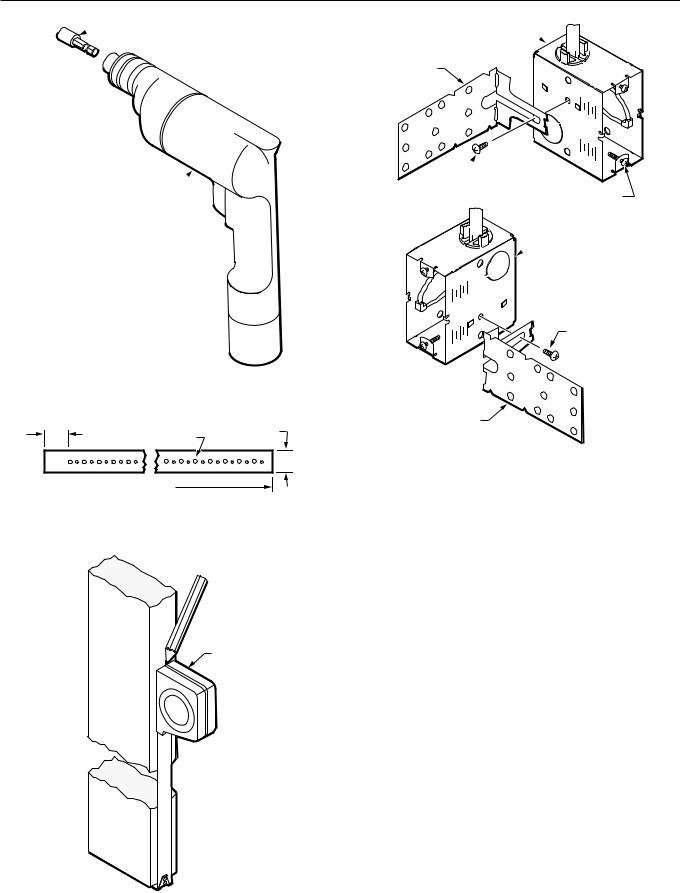

Mounting to Stud with Stud-Mounted Stat Plate

Mounting to a stud using a Stud-Mounted Stat Plate requires the following equipment:

—Stud-Mounted Stat Plate 14004610-001 (Fig. 21)

—Extension Plate 14004656-001 (optional) (Fig. 21)

—Tape Measure CCT422

—No. 8 sheet metal screws

—Cordless Drill CCT713 (Fig. 22)

—TEK Drill Adapter Screwdriver CCT240 (Fig. 22)

—No. 8 x 1/2 in. TEK Screws CCT2444 (two per stat)

—Stud Mount Box Clip CCT2642 for mounting StudMounted Stat Plate to metal stud (Fig. 23) (optional)

—Thermostat Tool CCT735A (MQT735A)

SCREWS |

|

|

PROVIDED |

|

|

STUD-MOUNTED |

EXTENSION PLATE |

|

STAT PLATE |

|

|

NOTE: MAXIMUM EXTENSION IS 2-3/4 IN. (70 MM) USING |

C3932 |

|

ONE PLATE, 5-3/8 IN. (137MM) USING TWO PLATES. |

||

Fig. 21. Stud-Mounted Stat Plate and

Optional Extension Plate.

TEK DRILL ADAPTER

TEK DRILL ADAPTER

SCREWDRIVER

CORDLESS DRILL

C3167

Fig. 22. TEK Drill Adapter Screwdriver and Cordless Drill.

C3181

Fig. 23. Stud Mount Box Clip.

TAPE

MEASURE

C3162

1. Measure and mark approximate stat location on stud.

9 |

95-5597—1 |

TP970-72, TP970-74, TP9600, AND PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

HORIZONTAL MOUNTING TO HORIZONTAL STUD

HORIZONTAL MOUNTING TO VERTICAL STUD

OR VERTICAL MOUNTING TO HORIZONTAL STUD

OR

OR

VERTICAL MOUNTING TO VERTICAL STUD

TEK SCREW (2)

EXTENSION PLATE

SHEET METAL SCREW (2)

EXTENSION PLATE

BUTTON (2)

STUD-MOUNTED

STAT PLATE

STUD MOUNT

BOX CLIP

MOUNTING TO METAL STUD

(REQUIRES STUD MOUNT BOX CLIP CCT2642)

NOTE:

TO ATTACH STUD-MOUNTED STAT PLATE TO EXTENSION PLATE:

A.FIT TWO BUTTONS ON EXTENSION PLATE INTO SLOTS ON STUD-MOUNTED STAT PLATE.

B.ALIGN TWO OUTER HOLES AND/OR SINGLE CENTER HOLES ON TWO PLATES.

C.FASTEN PLATES TOGETHER WITH NO. 8 x 1/2 IN. SHEET METAL SCREWS.

D.FASTEN EXTENSION PLATE TO STUD USING NO. 8 x 1/2 IN. TEK SCREWS.

C3937

TYPICAL MOUNTING WITH EXTENSION PLATE

2.Attach Stud-Mounted Stat Plate, using Extension Plate if required to center stat over electrical box. Use Cordless Drill and TEK Screwdriver Drill Adapter to drive No. 8 x 1/2 in. TEK screws, or use Stud Mount Box Clip as required.

95-5597—1 |

10 |

TP970-72, TP970-74, TP9600, AND TP9630 PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

TUBING

STUD-MOUNTED

STAT PLATE

TAB

TAB

C3934

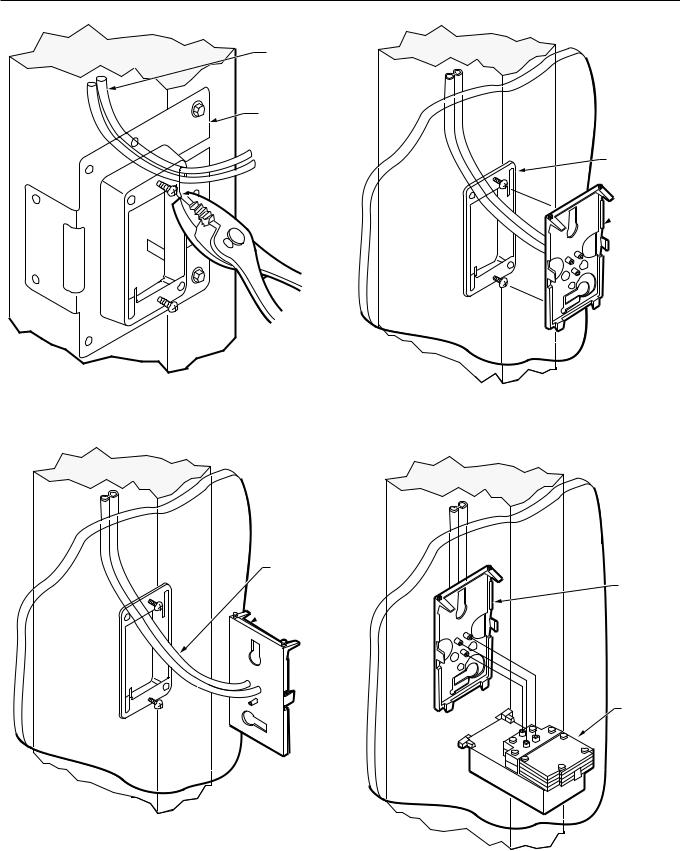

3.Fish tubing through Stud-Mounted Stat Plate. Anchor tubing in upper-right or lower-left corner of Plate by crimping Plate tab with pliers.

TUBING

STAT

STAT

BACKPLATE

C3935

4.After drywall or plaster is up, release tubing from corner of Plate. Connect tubing to barbs on stat backplate.

STUD MOUNTED

STAT PLATE

STAT

STAT

BACKPLATE

C3936

5.Hook keyhole slots of stat backplate over backed-out screws on Stud-Mounted Stat Plate. Level stat backplate and tighten screws.

STAT

BACKPLATE

STAT

C3573

6. Mount stat to stat backplate.

11 |

95-5597—1 |

TP970-72, TP970-74, TP9600, AND PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

SETSCREWS

STAT

BACKPLATE

STAT

TAB (2)

COVER

SETSCREW

SLOTS

C4116

7.Hook slots on stat cover over bottom tabs on stat backplate. Swing stat cover up and over stat. Use Thermostat Tool to raise stat backplate setscrews into setscrew slots on top of cover.

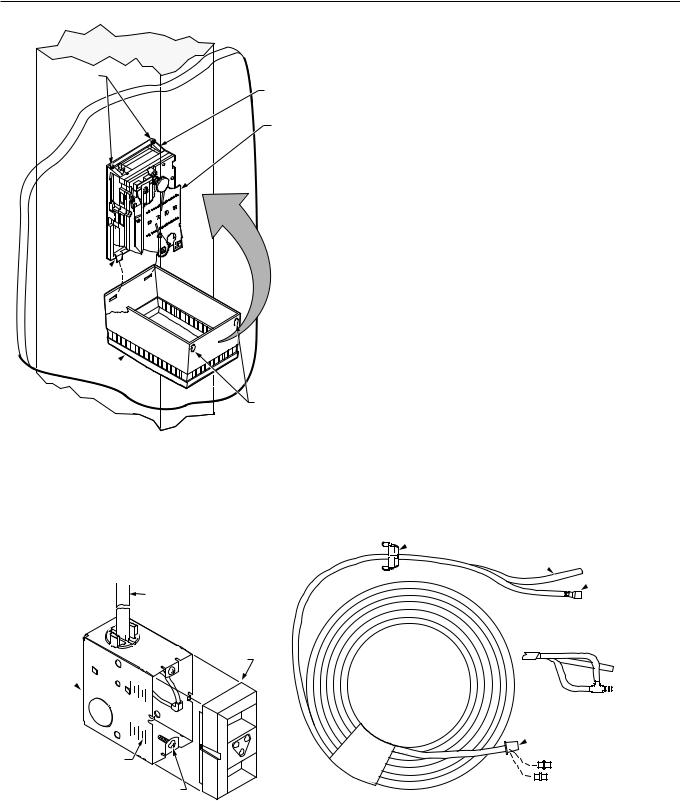

PROTECTOR CAP

PROTECTOR CAP

PLASTIC CABLE

ASSEMBLY 8 FT (2.5 M)

BUSHING

BUSHING

FITTING

FINDER

DEEP WALL

BOX

ALIGNMENT GUIDE

FOR FINISHED WALL

NO. 6–32 X 1/2 IN. SCREW (2)

PROVIDED WITH DEEP WALL BOX

Mounting to Stud with Deep Wall Box

Mounting to a stud using a Deep Wall Box requires the following equipment:

—Deep Wall Box Assembly 14001492-001 (includes two pipe plastic cable assembly, see Fig. 24) or separate parts for oneand three-pipe applications as follows:

•Deep Wall Box 14001355-001

•Fitting Finder 14000706-001 (optional)

•One of the following:

14001491-001 one-pipe or -003 three-pipe Plastic Cable Assembly

or

14001494-001 one-pipe, -002 two-pipe, or -003 three-pipe Copper Cable Assembly

—Barb Couplings CCT1606B (MJP1606B) (5/32 x 1/4 in.) or CCT1628B (MJP1628B) (5/32 x 5/32 in.) for plastic tubing (one, two, or three Couplings required according to application)

—Tape Measure CCT422

—Cordless Drill CCT713 (Fig. 25)

—TEK Drill Adapter Screwdriver CCT240 (Fig. 25)

—The following items according to mounting method:

•Directly to stud:

Two No. 8 x 2 in. Pan Head Sheet Metal Screws CCT2310 (MVH2310)

or

Two 6d 2 in. (51 mm) nails

•Between two studs:

Universal Strap CCT2630 (MVP2630) (Fig. 26) Two No. 8 x 1/2 in. TEK Screws CCT2444

One No. 8-32 x 1/2 in. Round Head Screw CCT2410

•Offset from stud (e.g., to center over electrical box): Deep Wall Box Mounting Bracket 14001354-001 One No. 8-32 x 1/4 in. Round Head Screw CCT2408 Two No. 8 x 1/2 in. TEK Screws CCT2444

—Thermostat Tool CCT735A (MQT735A)

BUSHING

BUSHING

MAIN

BARB CAP

BARB CAP

BRANCH

ONE-PIPE ASSEMBLY

SWITCH

MAIN

BRANCH |

BARB TEE |

THREE - PIPE ASSEMBLY

PROTECTOR CAP

PROTECTOR CAP

BARB

COUPLINGS

FOR PLASTIC

TUBING C3562

CABLE ASSEMBLY

Fig. 24. Deep Wall Box Assembly and Cable Assemblies.

95-5597—1 |

12 |

TP970-72, TP970-74, TP9600, AND TP9630 PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

TEK DRILL ADAPTER

TEK DRILL ADAPTER

SCREWDRIVER

CORDLESS DRILL

C3167

DEEP WALL BOX

MOUNTING

BRACKET

NO. 8–32 X 1/4 IN.

NO. 8–32 X 1/4 IN.

SCREW

NO. 6–32 X 1/2 IN.

SCREW (2) PROVIDED

DEEP WALL BOX

DEEP WALL BOX

NO. 8–32 X 1/4 IN.

SCREW

Fig. 25. TEK Drill Adapter Screwdriver and Cordless Drill.

1 (25) |

3/4 (19) |

|

NO. 8–32 |

||

|

24 (610)

24 (610)

C3161

Fig. 26. Universal Strap.

MOUNTING

BRACKET

C3566

2.If offset from stud is required (e.g., to center stat over electrical box), attach Deep Wall Box to Deep Wall Box Mounting Bracket with No. 8-32 x 1/4 in. Round Head Screw.

TAPE

MEASURE

C3162

1. Measure and mark approximate stat location on stud.

13 |

95-5597—1 |

TP970-72, TP970-74, TP9600, AND PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

STUD

CABLE

ASSEMBLY

DEEP WALL BOX

DEEP WALL BOX

NO. 8 x 2 IN.

SHEET METAL SCREWS

OR 6d 2 IN. (51 MM) NAILS

MOUNTING DEEP WALL BOX DIRECTLY TO STUD

NO. 8 x 1/2 IN. TEK SCREW

UNIVERSAL STRAP

DEEP WALL BOX

8-32 x 1/2 IN. ROUND HEAD SCREW (INSTALL FROM INSIDE BOX)

NO. 8 x 1/2 IN.

TEK SCREW

MOUNTING DEEP WALL BOX BETWEEN STUDS

USING UNIVERSAL STRAP

DEEP WALL BOX |

DEEP WALL BOX |

NO. 8 TEK |

|

NO. 8 TEK |

|

SCREWS (2) |

|

||

|

SCREWS (2) |

||

|

|

||

DEEP |

|

DEEP |

|

WALL BOX |

|

||

MOUNTING |

|

WALL BOX |

|

BRACKET |

|

MOUNTING |

|

1 (25) |

2 (51) |

BRACKET |

|

OFFSET |

|

||

|

OFFSET |

|

|

ALIGN BRACKET NOTCH |

C3939 |

||

WITH EDGE OF STUD |

|||

|

|||

USING DEEP WALL BOX MOUNTING BRACKET

3.Mount Deep Wall Box to stud so that front of Box will be flush with finished wall.

BARB |

PROTECTOR CAP |

|

|

COUPLINGS |

|

|

PLASTIC CABLE |

|

ASSEMBLY 8 FT (2.5 M) |

FITTING FINDER |

C3561 |

(IF WALL IS TO BE PLASTERED) |

4.Remove protector cap from Cable Assembly. Attach tubing to Cable with 5/32 x 1/4 in. or 5/32 x 5/32 in. Barb Couplings. If wall is to be plastered, snap Fitting Finder onto Deep Wall Box.

TUBING

STAT

STAT

BACKPLATE

C3590

5.After drywall or plaster is up, remove Fitting Finder, if used, from box. Cut elbow from end of Cable Assembly. Connect tubing to barbs on stat backplate.

95-5597—1 |

14 |

TP970-72, TP970-74, TP9600, AND TP9630 PNEUMATIC SENSORS, HUMIDISTATS, AND THERMOSTATS

DEEP WALL

BOX

STAT

BACKPLATE

KEYHOLE

SLOTS

C3587

6.Back screws out of Deep Wall Box. Hook stat backplate keyhole slots onto backed-out screws. Level stat backplate and tighten screws.

STAT

BACKPLATE

STAT

STAT

C3575

7. Mount stat onto stat backplate.

SETSCREWS

STAT

BACKPLATE

STAT

TAB (2)

COVER

SETSCREW

SLOTS

C4115

8.Hook slots on stat cover over bottom tabs on stat backplate. Swing stat cover up and over stat. Use Thermostat Tool to raise stat backplate setscrews into setscrew slots on top of cover.

Mounting to Stud with Standard Electrical Box

Mounting to a stud using a standard electrical box requires the following equipment:

—Standard Utility Conduit Box CCT2967 (MVE2967) or Standard 4 x 4 in. Electrical Box CCT2960 (Fig. 27)

—One of the following (Fig. 28):

•Plastic Cable Assembly 14001491-001 (one pipe), -002 (two pipe), or -003 (three pipe) and Barb Couplings CCT1606B (MJP1606B) (5/32 x 1/4 in.) or CCT1628B (MJP1628B) (5/32 x 5/32 in.)

•Copper Cable Assembly 14001494-001 (one pipe), -002 (two pipe), or -003 (three pipe)

•1/2 in. emt conduit and 1/2 in. TW Setscrew Connector CCT2900 (MVE2900)

—Tape Measure CCT422

—No. 10 x 3 Pan Head Sheet Metal Screws CCT2317 (MVH2317) or 2-1/2 in. (64 mm) nails (two per stat)

—Stud Mount Box Clip CCT2642 for Standard Utility Conduit Box (Fig. 29)

—MFS Clip CCT2649E for Standard 4 x 4 in. Electrical Box (Fig. 29)

—If wall is to be plastered:

•Standoff Ring 14000885-001

•Fitting Finder 14000706-001

—Thermostat Tool CCT735A (MQT735A)

15 |

95-5597—1 |

Loading...

Loading...