EPSON TM-H6000II service manual

TM-H6000II

Technical Reference

guide

EPSON |

English |

|

404367000

TM-H6000II Technical Reference Guide

CAUTIONS

This document shall apply only to the product(s) identified herein.

No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Seiko Epson Corporation.

The contents of this document are subject to change without notice. Please contact us for the latest information.

While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation's operating and maintenance instructions.

Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options or any consumable products other than those designated as Original EPSON Products or EPSON Approved Products by Seiko Epson Corporation.

TRADEMARKS

EPSON® and ESC/POS® are registered trademarks of Seiko Epson Corporation.

General Notice: Other product and company names used herein are for identification purposes only and may be trademarks of their respective companies.

ESC/POS Proprietary Command System

EPSON took the initiative by introducing ESC/POS, a proprietary POS printer command system including patented commands and enabling versatile POS system construction with high scalability. Compatible with all types of EPSON POS printers and displays, this proprietary control system also offers the flexibility to easily make future upgrades. Its popularity is worldwide.

Revision Information

Revision |

Page |

Altered Items and Contents |

|

|

|

Rev. A |

all page |

newly authorized |

|

|

|

Rev. A |

i |

About This Manual

Aim of the Manual

This manual was created to provide the information on the TM-H6000II printer for anyone who is developing hardware, installations, or programs. Programmers will also want to consult other documents.

Contents of the Manual

Chapter 1, “General Information.” |

General description of features plus |

|

specifications. |

Chapter 2, “System Planning.” |

Contains introduction of control methods and |

|

each connection form. |

Chapter 3, “Setup.” |

Contains information on such matters as DIP |

|

switches, memory switches, error processing for |

|

using TM-H60000II. |

Chapter 4, “Maintenance & |

Contains useful information for using. |

Troubleshooting.” |

|

Chapter 5, “Application Development |

Contains useful information for programming. |

Information for OPOS.” |

|

Chapter 6, “Application Development |

Contains useful information for programming. |

Information for APD.” |

|

ii |

Rev. A |

|

|

TM-H6000II Technical Reference Guide |

Related Software and Documents |

|

|

|

Related software and documents |

|

|

|

|

|

Software/document name |

Description |

|

|

|

|

ESC/POS Application Programming Guide |

This provides descriptions in Acrobat format of the commands |

|

|

used by each TM printer, along with sample programs and other |

|

|

information about the printers |

|

|

|

|

TM-H6000II User’s Manual/ |

This provides basic handling procedures for the end user of the |

|

|

printer |

|

|

|

|

EPSON OPOS ADK |

This is an OCX driver |

|

|

|

|

EPSON OPOS ADK Manual |

This provides information for anyone who is programming using |

|

|

OPOS |

|

|

|

|

EPSON Advanced Printer Driver |

This is a Window driver |

|

|

|

|

EPSON Advanced Printer Driver Manual |

This provides information for anyone who is programming using |

|

|

APD (EPSON Advanced Printer Driver) |

|

|

|

Rev. A |

iii |

iv |

Rev. A |

TM-H6000II Technical Reference Guide

Safety Precautions

EMC and Safety Standards Applied

Product Name: TM-H6000II

Type Name: M147B or M147C

The following standards are applied only to the printers that are so labeled. (EMC is tested using the EPSON PS-170 or PS-180 power supply.)

Europe: |

CE marking |

|

Safety: EN 60950 |

North America: |

EMI: FCC/ICES-003 Class A |

|

Safety: UL 1950/CSA C22.2 No. 950 |

Japan: |

EMC: VCCI Class A |

|

JEIDA-52 |

Oceania: |

EMC: AS/NZS 3548 |

|

M147B: Class B |

|

M147C: Class A |

WARNING

The connection of a non-shielded printer interface cable to this printer will invalidate the EMC standards of this device.

You are cautioned that changes or modifications not expressly approved by Seiko Epson could void your authority to operate the equipment.

CE Marking

The printer conforms to the following Directives and Norms

Directive 89/336/EEC

EN 55022

M147B: Class B

M147C: Class A

EN 55024

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-5

IEC 61000-4-6

IEC 61000-4-8

IEC 61000-4-11

Directive 90/384/EEC

EN45501

WARNING

M147C is a Class A product. In a domestic environment these products may cause radio interference in which case the user may be required to take adequate measures.

Rev. A |

v |

FCC Compliance Statement

For American Users

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user will be required to correct the interference at his own expense.

For Canadian Users

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

GEREÄUSCHPEGEL

Gemäß der Dritten Verordnung zum Gerätesicherheitsgesetz (Maschinenlärminformations- Verordnung-3. GSGV) ist der arbeitsplatzbezogene Geräusch-Emissionswert kleiner als 70 dB(A) (basierend auf ISO 7779).

Key to Symbols

The following symbols are used in the documentation for this product. See the specific warnings and cautions at appropriate points throughout this guide.

WARNING:

WARNING:

Warnings must be followed carefully to avoid serious bodily injury.

CAUTION:

CAUTION:

Cautions must be observed to avoid minor injury to yourself or damage to your equipment.

Note:

Note:

Notes have important information and useful tips on the operation of your printer.

vi |

Rev. A |

TM-H6000II Technical Reference Guide

Safety Precautions

This section presents important information to ensure safe and effective use of this product. Please read this section carefully and store it in an accessible location.

WARNING:

WARNING:

Shut down your equipment immediately if it produces smoke, a strange odor, or unusual noise. Continued use may lead to fire or electric shock. Immediately unplug the equipment and contact your dealer or a Seiko Epson service center for advice.

Never attempt to repair this product yourself. Improper repair work can be dangerous.

Never disassemble or modify this product. Tampering with this product may result in injury, fire, or electric shock.

Be sure to use the specified power source. Connection to an improper power source may cause fire or shock.

Never insert or disconnect the power plug with wet hands. Doing so may result in severe shock.

Do not allow foreign matter to fall into the equipment. Penetration of foreign objects may lead to fire or shock.

If water or other liquid spills into this equipment, unplug the power cord immediately, and then contact your dealer or a Seiko Epson service center for advice. Continued usage may lead to fire or shock.

Do not place multiple loads on the power outlet (wall outlet). Overloading the outlet may lead to fire.

Always supply power directly from a standard domestic power outlet.

Handle the power cord with care. Improper handling may lead to fire or shock.

•Do not modify or attempt to repair the cord.

•Do not place any object on top of the cord.

•Avoid excessive bending, twisting, and pulling.

•Do not place cord near heating equipment.

•Check that the plug is clean before plugging it in.

•Be sure to push the prongs all the way in.

If the cord becomes damaged, obtain a replacement from your dealer or a Seiko Epson service center.

Rev. A |

vii |

CAUTION:

CAUTION:

Do not connect cables other than as described in this manual. Different connections may cause equipment damage and burning.

Be sure to set this equipment on a firm, stable, horizontal surface. Product may break or cause injury if it falls.

Do not use in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage, fire, or shock.

Do not place heavy objects on top of this product. Never stand or lean on this product. Equipment may fall or collapse, causing breakage and possible injury.

To ensure safety, please unplug this product prior to leaving it unused for an extended period.

Do not touch either the thermal or the dot matrix print head or the paper feed motor. Wait for the heads and the motor to cool. The head and the motor can be very hot after printing for a long time. Touching them may cause burns.

viii |

Rev. A |

TM-H6000II Technical Reference guide

Chapter 1 General Information

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1-1 |

1.1.1 Slip Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1-1 |

1.1.2 Receipt Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1-1 |

1.1.3 Both Receipt and Slip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

1.1.4 About control method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

1.2 Product Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

1.2.1 Standard Parts Included with the Printer . . . . . . . . . . . . . . . . . . . . |

1-2 |

1.2.2 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

1.3 Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

1.3.1 Ribbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

1.3.2 Roll paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

1.4 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-4 |

1.5 Printing and paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

1.5.1 Slip Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

1.5.1.1 Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

1.5.1.2 Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

1.5.1.3 Ribbon Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-10 |

1.5.2 Endorsement Section (Factory Option) . . . . . . . . . . . . . . . . . . . . . |

1-10 |

1.5.2.1 Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-10 |

1.5.2.2 Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-11 |

1.5.2.3 Ribbon Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-11 |

1.5.2.4 Notes on Using the Endorsement Print Mechanism . . . . . . . |

1-12 |

1.5.3 MICR Reader (When the Printer is Used with the MICR Reader) |

. 1-12 |

1.5.3.1 Reading method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-12 |

1.5.3.2 Recognition rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-12 |

1.5.3.3 Inserting direction and endorsement printing . . . . . . . . . . . |

1-12 |

1.5.3.4 Notes on using the MICR reader . . . . . . . . . . . . . . . . . . . . . . |

1-14 |

1.5.4 Receipt Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-15 |

1.5.4.1 Autocutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-16 |

1.5.4.2 Paper Roll Supply Device Section . . . . . . . . . . . . . . . . . . . . . |

1-17 |

1.5.4.3 Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-18 |

1.5.4.4 Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

1.5.4.5 Printing and Cutting Positions . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

1.6 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.6.1 Paper Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.6.1.1 Receipt section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.6.1.2 Slip section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.6.2 Printer Cover Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1.6.2.1 Receipt section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1.6.2.2 Slip section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1.7 Other Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1.7.1 Internal Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1.7.2 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1.7.3 EMI and Safety Standards Applied . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.7.4 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.7.4.1 Slip printer section: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.7.4.2 Endorsement print mechanism section: . . . . . . . . . . . . . . . . 1-24

1.7.4.3 Receipt printer section: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.7.5 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

1.7.6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

1.8 External Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

1.9 Maintenance Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

1.10 Comparison Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Chapter 2 System Planning |

|

2.1 Control Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-1 |

2.1.1 Windows Driver (EPSON Advanced Printer Driver) . . . . . . . . . . |

. . 2-1 |

2.1.1.1 General Features of the EPSON Advanced Printer Driver |

. 2-1 |

2.1.1.2 EPSON Advanced Printer Driver Components . . . . . . . . |

. . 2-2 |

2.1.1.3 EPSON Advanced Printer Driver Support Environment . . |

. . 2-2 |

2.1.2 EPSON OPOS ADK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-3 |

2.1.2.1 General Features of EPSON OPOS ADK (OPOS Control) |

. . 2-3 |

2.1.2.2 EPSON OPOS ADK Contents . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-4 |

2.1.2.3 EPSON OPOS ADK Supported Environment . . . . . . . . . . . |

. . 2-5 |

2.1.3 ESC/POS Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-5 |

2.1.4 How to Get a Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-5 |

2.2 Connection Form and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-5 |

2.2.1 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-5 |

2.3 Serial Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-6 |

2.3.1 Stand alone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2-8 |

2.3.2 Y-connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2-8 |

2.3.3 Pass-through connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2-9 |

2.4 Parallel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2-9 |

2.5 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2-10 |

Chapter 3 Setup

3.1 Part Name and Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

3.1.1 part name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

3.1.1.1 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

3.1.2 The Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

3.1.2.1 LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

3.1.2.2 Control Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-3 |

3.2 Setup Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

3.3 Printer setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-5 |

3.3.1 Installing or Replacing the Ribbon Cassette . . . . . . . . . . . . . . . . . |

3-6 |

3.3.2 Installing or Replacing |

|

the Optional Endorsement Ribbon Cassette . . . . . . . . . . |

3-9 |

3.3.3 Installing or Replacing the Paper Roll . . . . . . . . . . . . . . . . . . . . . . . |

3-10 |

3.3.4 Connecting the Printer to the Host PC / POS Terminal . . . . . . . . . |

3-12 |

3.3.4.1 Serial interface model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-12 |

3.3.4.2 Parallel Interface Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-13 |

3.3.4.3 USB Interface Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-13 |

3.3.4.4 Connecting a Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-15 |

3.3.5 Connecting the Power Supply Unit (PS-180/ 170) . . . . . . . . . . . . . |

3-15 |

3.4 Customizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-16 |

3.4.1 How to Confirm Current Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-17 |

3.4.2 Adjusting the Roll Paper Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-17 |

3.4.3 Adjusting the Roll Paper Near End Detector . . . . . . . . . . . . . . . . . |

3-18 |

3.4.4 Adjusting the DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-19 |

3.4.4.1 Changing the DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . |

3-19 |

3.4.4.2 Serial interface model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-21 |

3.4.4.3 Parallel / Ethernet interface model . . . . . . . . . . . . . . . . . . . |

3-22 |

3.4.4.4 USB interface model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-23 |

3.4.4.5 When Using Original Paper . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-24 |

3.4.5 Memory Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-24 |

3.4.6 How to Use Two-Color Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-25 |

3.5 Install a Printer Driver in the Host PC / POS Terminal . . . . . . . . . . . . . . . . . . . |

3-25 |

3.5.1 OPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-25 |

3.5.1.1 Installing and Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-25 |

3.5.1.2 Package contents of EPSON OPOS ADK. . . . . . . . . . . . . . . 3-28 |

|

3.5.2 Advanced Printer Driver (APD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

3.5.2.1 Installing and Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.6 Self Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3.6.1 Running the Self Test on Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . 3-31 3.6.2 Running the Self Test with Slip Paper . . . . . . . . . . . . . . . . . . . . . . . . 3-31 3.6.3 Running the Self Test with the Optional Endorsement Function . . 3-32

Chapter 4 Maintenance & Troubleshooting

4.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Cleaning the Thermal Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 4.1.2 Cleaning the MICR Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 4.1.2.1 Cleaning frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 4.1.2.2 Cleaning sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 4.1.2.3 Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 4.1.2.4 Self mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 4.1.2.5 Command mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.1 Removing a Paper Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 4.2.2 Autocutter Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 4.2.3 LED Blinking Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 4.2.3.1 Error Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 4.2.4 Printer prints “?“ or Incorrect Data With Serial Interface . . . . . . . . 4-6 4.2.5 Hexadecimal Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3 Thermal Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.3.1 Specified Monochrome Thermal Paper: NTP080-80 . . . . . . . . . . . 4-8 4.3.2 Other Qualified Suppliers for Thermal Paper . . . . . . . . . . . . . . . . . 4-8 4.3.3 Specified Two-color Thermal Paper: ENTPB080080 . . . . . . . . . . . . 4-9

Chapter 5 Application Development Information for OPOS

5.1 Bitmap Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Explanation of Bitmap Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 5.1.2 Supplementary Explanation of Function . . . . . . . . . . . . . . . . . . . . . 5-2 5.1.2.1 LetterQuality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 5.1.2.2 Setting of printing position by escape sequence . . . . . . . . 5-2 5.1.2.3 Color bitmap printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 5.1.3 Printable bitmap format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2 Slip & MICR Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.1 Recommended Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 5.2.2 Sample Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 Cash Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.3.1 Drawer Open/Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6 5.3.2 Checking Drawer Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Chapter 6 Application Development Information for APD

6.1 Slip & MICR Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Recommended procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Bitmap Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.1 Explanation of Bitmap Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 6.2.2 Color bitmap printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 6.2.3 Printable bitmap format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 Two-Dimensional Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 6.4 Drawer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4.1 Drawer Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 6.4.2 Checking Drawer Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Appendix A Character Code Tables

A.1 Page 0 (PC437: USA, Standard Europe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1 A.2 Page 1 (Katakana) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2 A.3 Page 2 (PC850: Multilingual) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3 A.4 Page 3 (PC860: Portuguese) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4 A.5 Page 4 (PC863: Canadian-French) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5 A.6 Page 5 (PC865: Nordic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6 A.7 Page 16 (WPC1252) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7 A.8 Page 17 (PC866: Cyrillic2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8 A.9 Page 18 (PC852: Latin2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9 A.10 Page 19 (PC858: Euro) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10 A.11 Page 254 (Space Page) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11 A.12 Page 255 (Space Page) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12 A.13 International Character Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

TM-H6000II Technical Reference Guide

Chapter 1

General Information

1.1 Features

TheTM-H6000II is a high-quality POS printer that can print on slip and receipt paper (paper roll).

1.1.1Slip Section

An optional Magnetic Ink Character Recognition (MICR) reader that enables the printer to perform consecutive reading and processing of MICR characters

An optional endorsement printer (E/P) that enables single-pass high speed printing of endorsements

Single-pass processing for checks eliminates the need to reverse the check paper for printing an endorsement.

High throughput using bidirectional, minimum distance printing.

Mechanical form stopper for stable slip printing

Page mode for flexibility in printing formats

1.1.2Receipt Section

High-speed printing with batch processing

High-speed graphic printing

Autocutter provides easy user operation

Easy drop-in paper roll loading

PDF417 symbols (2-dimensional code) printing is possible

Two-color printing is possible with two-color paper

1.1.3Both Receipt and Slip

Small footprint and simple design

Selectable receive buffer size (45 bytes or 4 KB)

NV (Non-volatile) bit image buffer (384 KB) (*1)

NV (Non-volatile) user memory (1 KB) (*1)

(*1) The memory size can be set by ESC/POS command

Rev. A |

General Information 1-1 |

A counter function that allows checking the printer by remote maintenance

Several interface models (USB, RS-232C, bidirectional parallel) are supported

1.1.4About control method

Command protocol based on the ECS/POS® Proprietary Command System.

Automatic Status Back (ASB) function that automatically transmits changes in the printer status

Windows® printer driver is provided. (Advanced Printer Driver, and OPOS.)

1.2 Product Structure

1.2.1 Standard Parts Included with the Printer

This printer is packed with the materials listed below.

User’s Manual

Roll paper (diameter 40 mm {1.57"}) 1 roll

I/F fixing screws (hexagonal millimeter screws)

Power switch cover (using this cover enables you to prevent accidental turning off of the power)

Exclusive ribbon cassette ERC-32

Endorsement ribbon cassette (only for printers equipped with the optional endorsement print mechanism)

1.2.2Options

The options for this printer are provided as below.

EPSON power supply unit, PS-170, PS-180

MICR reader (factory-installed option) (available only for serial interface model)

Endorsement printer (factory-installed option) (available only for MICR model)

Direct connection customer display DM-D105/D205 or DM-D106/DM-D206 (available only for serial interface model or the USB model)

Paper-width spacer for 58 mm or 60 mm {2.3 or 2.4"} PG-58

Special tray for TM-H6000 / H6000II (PT-6000, DPR-6000, TA-6000)

1-2 General Information |

Rev. A |

TM-H6000II Technical Reference Guide

1.3 Consumables

1.3.1 Ribbons

This printer needs a ribbon cassette to print on slip (and endorsement). We provide 4 ribbon cassettes:

EPSON ribbon cassette, ERC-32 (P) (Life: 6,000,000 characters / Color: Purple)

EPSON ribbon cassette, ERC-32 (B) (Life: 4,000,000 characters / Color: Black)

EPSON ribbon cassette ERC-41 (P) (Life: 1,000,000 characters) (for the optional endorsement print mechanism)

EPSON ribbon cassette ERC-41 (B) (Life: 800,000 characters) (for the optional endorsement print mechanism)

1.3.2Roll paper

We provide roll paper for this printer. The widths are 80 mm / 60 mm / 58 mm {3.15"/2.36"/ 2.28"}.

Rev. A |

General Information 1-3 |

1.4 Product Specifications

|

Slip: 9-pin serial impact dot matrix |

|

|

|

Wire pitch approximately 0.353 mm {1/72"} |

|

|

|

E/P: 8-pin shuttle impact dot matrix |

|

|

|

Wire pitch approximately 0.353 mm {1/72"} |

|

|

|

Receipt: Thermal line |

|

|

Print method |

0.141 dots/mm × 0.141 dots/mm (180 dpi × 180 dpi) |

|

|

|

|

|

|

|

Slip & E/P: 68mm to 230mm × 68mm to 297mm |

|

|

|

|

NOTE: The minimum size is 68mm × 152mm |

|

|

Receipt: |

80 mm / 60 mm / 58 mm {3.15"/2.36"/2.28"} |

|

|

|

NOTE: default setting is 80 mm {3.15"}. |

|

|

|

58 mm {2.28"} or 60 mm {2.36"} paper width can be selected using |

|

Paper width |

|

the paper roll spacer. |

|

|

|

|

|

Cut type (Receipt) |

Partial cut (cutting with one point on left edge left uncut) |

|

|

|

|

|

|

|

Slip: 95 alphanumeric, 37 international characters, graphics: 128 × |

12 pages. |

|

|

(including two space pages) |

|

|

|

Multilingual character model supports printing with one of the |

|

|

|

following character sets: |

|

|

|

Simplified Chinese (GB2312): 7580 |

|

|

|

Traditional Chinese (Big 5): 13494 |

|

|

|

Receipt: 95 alphanumeric, 37 international characters, graphics: 128 × 11 pages. |

||

|

(including a space page) |

|

|

|

Multilingual character model supports printing with one of the |

|

|

|

following character sets: |

|

|

|

Simplified Chinese (GB2312): 7580 |

|

|

|

Traditional Chinese (Big 5): 13494 |

|

|

Character sets |

E/P: 95 alphanumeric, 37 international characters, graphics: 128 × |

11 pages. |

|

(including a space page) |

|

||

|

|

|

|

Interface |

RS-232C / Bidirectional parallel |

|

|

(compatible) |

Dealer options: RS-485, USB, 10Base-T I/F |

|

|

|

|

|

|

|

Receive buffer: 4KB/45 bytes |

|

|

|

|

||

|

User-defined buffers (both for user-defined characters and user-defined bit images) |

||

|

For Receipt: 12KB |

|

|

|

For Slip: Approximately 3KB |

|

|

|

|

|

|

|

Macro buffer: 2KB |

|

|

|

|

|

|

|

Non-volatile graphics data buffer: |

|

|

|

384KB |

|

|

|

192KB (Multilingual character model) |

|

|

Buffer |

|

|

|

User NV memory: 1KB |

|

||

|

|

|

|

Power supply |

Power supplied by an AC adapter — the PS-170 or PS-180 (option) |

|

|

|

|

|

|

Operating voltage |

+24 VDC ± 10% (optional power supply: EPSON PS-170, PS-180) |

|

|

|

|

|

|

|

Slip: |

Operating: Mean:Approximately 1.7A |

|

Current |

|

(Character font A α -N, all columns printing) |

|

|

Peak: Approximately 5.5A |

|

|

consumption |

Receipt: |

Operating:Mean:Approximately 1.8A |

|

(at 24V except for |

|

(Character font A α -N, all columns printing) |

|

drawer kickout |

|

Peak: Approximately 7.7A |

|

driving) |

Standby: |

Mean: Approximately 0.2A |

|

|

|

|

|

1-4 General Information |

Rev. A |

|

TM-H6000II Technical Reference Guide |

|

|

Temperature |

Operating:5 to 45 °C {41 to 113 °F} |

Storage: –10 to 50 °C {14 to 122 °F} (except for paper and ribbon) |

|

|

|

Humidity |

10 to 90% |

|

|

Weight (mass) |

Approximately 5.8 kg {12.76 lb} |

|

|

1.5 Printing and paper Specifications

1.5.1 Slip Section

Printing method: |

Serial impact dot matrix |

Head wire |

9-pin vertical line, 0.353 mm {1/72-inch} wire pitch |

configuration: |

|

Printing direction: |

Bidirectional, minimum distance printing |

Printing speed |

Approximately 5.14 LPS (printing 40 columns per line with 17.8 CPI |

|

when the head energizing time is set to normal mode.) |

Number of characters: Alphanumeric characters: 95 International characters: 37

Extended graphics: 128 × 12 pages (including two space pages)

Multilingual character model supports printing with one of the following character sets:

Simplified Chinese (GB2312): 7580

Traditional Chinese (Big 5): 13494

Character structure |

Font A: 5 × |

9 (total 270 dots horizontally) |

|

Font B: 7 × |

9 (total 540 half dots horizontally) |

|

Kanji: 16 × |

16 (two-pass printing font) |

Characters per line |

Refer to “Character size and print speed.” |

|

Characters per inch |

Refer to “Character size and print speed.” |

|

Character size and print speed

|

Character |

|

|

|

|

|

|

|

structure |

|

|

|

Character |

||

|

(horizontal dots |

|

Characte |

Character |

size |

|

|

Font |

× |

|

Character |

rs |

s |

(width× heigh |

|

vertical dots) |

spacing |

per inch |

per line |

t) |

|

||

|

|

|

|

|

|

|

|

A |

5 × |

9 |

1 dot |

13.3 |

45 |

1.56 × |

3.1 |

(default) |

|

|

|

|

|

mm |

|

|

|

|

|

|

|

|

|

B |

7 × |

9 |

2 half-dots |

17.8 |

60 |

1.24 × |

3.1 |

|

|

|

|

|

|

mm |

|

|

|

|

|

|

|

|

|

Kanji |

16 × |

16 |

2 half-dots |

13.0 |

30 |

2.7 × |

2.9 mm |

|

|

|

|

|

|

|

|

Rev. A |

General Information 1-5 |

Note:

Note:

Kanji character spacing by default setting is 2 half dots. (Kanji character spacing can be changed by ESC/ POS command.) Printing speed for Kanji characters shown in table above is in the case of full column printing with two-pass printing.

1.5.1.1 Paper Specifications

1.Cut sheet

Paper type:Normal paper, pressure-sensitive paper, carbon copy paper Paper size:70 - 148 mm (W) × 150 - 210 mm (L) (2.8 - 5.8”(W) × 5.9 - 8.3”(L)) Copy capability and paper thickness:

•Normal paper (single-ply):0.09 to 0.2 mm (0.0035 to 0.0079 in.)

•Carbon copy paper

combination:4 sheets maximum (original + 2 copies)

Backing paper: |

0.07 to 0.12 mm (0.0028 to 0.0047 in.) |

Copy and original: |

0.04 to 0.07 mm (0.0016 to 0.0028 in.) |

Carbon paper: |

Approximately 0.035 mm (0.0014 in.) |

Total thickness: |

0.09 to 0.31 mm (0.0035 to 0.0122 in.) |

•Example: one original + 2 copies,

Original paper |

0.04 mm |

Carbon paper |

0.07 mm (0.035 mm × 2 sheets) |

Copy paper |

0.04 mm |

Backing paper |

0.07 mm |

|

|

Total thickness |

0.22 mm (0.0087 in.) |

Ambient temperature and copy capability:

Copy capability is greatly influenced by the ambient temperature, so printing must be performed under the conditions described in the table below.

Relationship between ambient temperature and number of copies

Number of copies |

Ambient temperature |

|

|

Original + 3 copies |

10 to 40 °C (50 to 104°F) |

|

|

Original + 1 copy |

5 to 45 °C (41 to 113 °F) |

|

|

1-6 General Information |

Rev. A |

TM-H6000II Technical Reference Guide

2.Notes on slip paper

•The slip paper must be flat, without curls or wrinkles, especially at the top edges. Otherwise, the paper may rub against the ribbon and become dirty.

•There must be no glue on the bottom edge of slip paper. Choose slip paper carefully when the glue is on the right or top edge, since paper feeding and insertion are affected by gluing conditions (e.g., glue quality, method, and length) and glue location (refer to the figure on the next page). Be especially careful when slip paper is wide and has the glue on the left edge, since skew may occur.

OK to use |

|

Do not use |

|

Use carefully |

Use carefully |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Paper feed |

Glued area |

direction |

|

Slip paper glued area

•Since the slip BOF sensor uses a photo sensor, do not use paper that has holes at the sensor position, or is translucent.

•Since the slip TOF sensor uses a reflective photo sensor and it detects from the back of slip paper, do not use paper that has holes or dark portions with low reflection (less than 40% reflection) at the sensor position.

•Since the slip paper ejection sensor uses a reflective photo sensor and it detects from the surface of the paper roll, do not use paper that has holes or dark portions with low reflection (less than 40% reflection) at the sensor position.

Rev. A |

General Information 1-7 |

•Use thinner paper (N30 or equivalent) between the top and bottom sheets of multi-ply paper. If thick paper is used, the copy capability is lowered.

30

15 |

20 |

10

Area where paper holes are prohibited and reflection rate for the back on paper should be 40% or more.

Paper feed direction

Area where paper holes are prohibited and reflection rate for the surface on paper should be 40% or more.

Paper holes and translucence prohibited in this area.

[Units: mm (All the numeric values are typical.)]

Prohibited area for paper holes and low reflection

1-8 General Information |

Rev. A |

TM-H6000II Technical Reference Guide

1.5.1.2 Printable Area

*2 The length from the form stopper to the tip of the paper.

*3 The length from the tip of the paper to the first printing line position.

*4 The printable area after the slip BOF sensor detects the end of the paper. (The bottom margin must be considered for a real printable area.)

*5 Bottom margin (calculated value).

Form stopper

5

Paper inserting direction

Paper inserting direction

18.4

(Min)

8685.2.4(Max) 45..86

70 (Min)

Printable area (for slip paper)

Rev. A |

General Information 1-9 |

1.5.1.3 Ribbon Cassette

Exclusive ribbon cassette for slip |

|

Type: |

ERC-32(P) |

Color: |

Purple |

Ribbon life: |

6,000,000 characters (at 25 °C ( 77 °F), continuous printing) |

1.5.2 Endorsement Section (Factory Option)

Printing method: |

Shuttle impact dot matrix |

|

Head wire |

8 print solenoids in a horizontal line |

|

configuration |

|

|

Characters per line: |

40 columns |

|

Print speed: |

Approximately 1.9 LPS |

|

Number of characters: |

Alphanumeric characters: |

95 |

|

International characters: |

37 |

|

Extended graphics: 128 × 11 pages (including one space page) |

|

Character structure |

5 × 7 (total 240 dots horizontally) |

|

Character size |

1.1 × 2.42 mm (W × H) |

|

Note:

Note:

Character dot spacing can be changed by ESC/POS command.

1.5.2.1 Paper Specifications

Cut sheet |

|

|

Paper type: |

Normal paper |

|

Paper size: |

70-148 mm (W) × |

150-210 mm (L) |

|

(2.8-5.8 in. (W) × |

5.9-8.3 in. (L) |

Paper thickness: |

Single-ply (copy paper cannot be used) 0.09 mm - 0.2 mm |

|

|

(0.0035 - 0.0079 in.) |

|

1-10 General Information |

Rev. A |

TM-H6000II Technical Reference Guide

1.5.2.2 Printable Area

The print head consists of 8 print solenoids (A, B, C, D, E, F, G, and H) arranged in a horizontal line. The print head moves from the left (from the standby position) to the right, printing at 30 positions as each print solenoid is energized, so that one dot line is formed. The total number of dots per dot line is 240 (30 positions × 8 solenoids).

Slip paper feeding roller position

Endorsement printing

Forward paper feed direction |

Reverse paper feed direction |

MIN. 70

Form stopper position

Approx. 26.8 |

(152 steps) |

|

|

(20 steps)

Approx. 92.3 |

(523 steps) |

|

|

BOF sensor position

E/P printable area (for endorsement printing)

1.5.2.3 Ribbon Cassette

Exclusive ribbon cassette for E/P |

|

Type: |

ERC-41 (P) |

Color: |

Purple |

Ribbon life: |

1,000,000 characters (at 25 °C (77 °F), continuous printing) |

Rev. A |

General Information 1-11 |

1.5.2.4 Notes on Using the Endorsement Print Mechanism

The endorsement print mechanism (abbreviated as E/P) enables printing of endorsements as part of a sequence that is automatically processed: MICR reading, printing an endorsement on the back side of a personal check, and printing on the surface of it. Once the end of the paper exceeds the E/P print head position, reverse paper feeding to the front side is not possible.

When the endorsement printing is executed after a MICR reading, the printer feeds the paper forward automatically after receiving a command to print the endorsement; then the printer starts printing up to approximately 7.0 mm (0.28 in.) from the end of the check paper by using reverse paper feeding.

Since the E/P printing format is assumed to print an endorsement on a U.S. personal check, the print begins on the back side of the paper. (As viewed from the front of the printer, the endorsement printing characters are upside down.)

The printing sequence for slip paper is different, depending on whether an endorsement print mechanism is installed. That is, when the E/P is installed, once the printing exceeds the E/P printable area and the slip paper is fed forward, reverse paper feeding must be prohibited. Consider this when developing application programs.

The E/P printing must be not performed on copy paper. Otherwise, a paper jam may occur or the E/P may be broken. Because E/P printing feeds the paper in a reverse paper feed direction, the paper may be wrinkled.

In some case paper feeding may not be accurate when E/P printing is performed on check paper. This may depend on the width of the check paper. Therefore, it is recommended for the user to check in advance whether the check paper prints correctly or not.

1.5.3MICR Reader (When the Printer is Used with the MICR Reader)

1.5.3.1 Reading method

Magnetic bias

1.5.3.2 Recognition rating

98% or more (at 25 °C, 77 °F)

Recognition rating is defined as follows

Recognition rating (%)= |

Total number of checks − (number of sheets misread or not identified.) |

× 100 |

|

Total number of checks |

|||

|

|

•Check paper used for test is EPSON standard check paper.

•Checks must be flat, without curls, folds, or wrinkles.

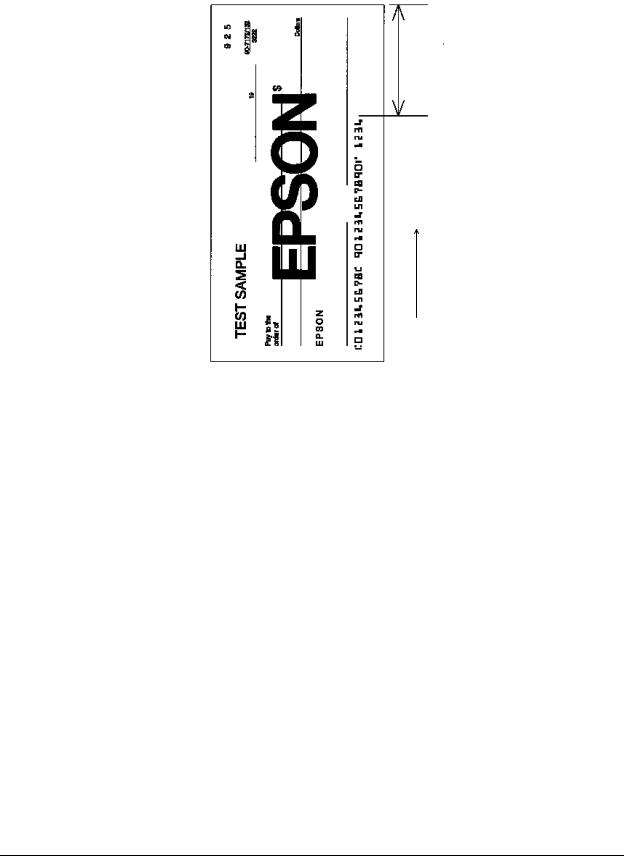

1.5.3.3Inserting direction and endorsement printing

Insert the check with the surface printed with the magnetic ink upward, following the slip side guide.

1-12 General Information |

Rev. A |

TM-H6000II Technical Reference Guide

The printer can perform endorsement printing.

|

is |

|

(1.93”) |

recognition |

|

49.0 |

where |

impossible. |

|

Area |

Inserting direction

Area of personal check where MICR character recognition is impossible

To print endorsements in the specified area (within 38.1 mm {1.5”} from the top), set the print position for the last line so that it is printed at least 3 mm {0.118”} above the bottom of the printable area (Especially when the printer is used near the display device, the user is required to check the recognition rate of the MICR).

Rev. A |

General Information 1-13 |

Notes:

1.Do not install the printer near any magnetic fields, because this may cause MICR reading errors. (Be sure to check the MICR recognition rate when the printer is used near a display device.)

2.MICR characters may not be recognized when impact or vibration is applied to the printer.

Specified printing area

38.1

[Units: mm (All numeric values are typical.)]

Endorsement printing

1.5.3.4 Notes on using the MICR reader (only when the printer is used with MICR)

The personal checks must be flat, without curls, folds, or wrinkles (especially at the edges). Otherwise, the check may rub against the ribbon and become ink-stained.

Do not insert checks that have clips or staples. These may cause paper jams, MICR reading errors, and damage to the MICR head.

Let go of the check immediately as soon as the printer starts feeding it. Otherwise, the paper is not fed straight, causing paper jams and MICR reading errors.

1-14 General Information |

Rev. A |

|

|

TM-H6000II Technical Reference Guide |

1.5.4 Receipt Section |

|

|

Printing method: |

Thermal line printing |

|

Dot density: |

180 dpi × 180 dpi [the number of dots per 25.4 mm {1"}] |

|

Printing direction: |

Unidirectional with friction feed |

|

Printing width: |

72 mm {2.83"}, 512 dot positions |

|

Paper width: |

80 mm / 60 mm / 58 mm {3.15"/2.36"/2.28"} |

|

|

NOTE: default setting is 80 mm {3.15"}. |

|

|

58 mm {2.28"} or 60 mm {2.36"} paper width can be selected using |

|

|

the roll paper spacer. |

|

Characters per line: |

42 (font A, default) 56 (font B) (When using 80mm width paper) |

|

Character spacing: |

0.28 mm {.01"} (2 dots) (font A, default) |

|

|

0.28 mm {.01"} (2 dots) (font B) |

|

|

Programmable by control command. |

|

Print speed: |

Normal: 54 lps maximum (computed value for 1/8" feed) |

|

|

170 mm/s maximum {Approximately 6.7"/s} |

|

|

(at 24 V, density level 2) |

|

|

* For the model with paper width 58 mm {2.28"}, 150 mm/s |

|

|

{5.9"/s} maximum. |

|

|

Ladder barcode/2-dimensional code printing: |

|

|

114 mm/s maximum |

|

|

Two-color print mode: |

|

|

56.4 mm/s maximum |

|

|

(at 24V, density level 2) |

|

Paper feed speed: |

Approximately 170 mm/second {approximately 6.7"/second} |

|

|

continuous feeding |

|

Line spacing (default): |

4.23 mm {1/6"}, programmable by control commands. |

|

Number of characters: |

Alphanumeric characters: |

95 |

|

International characters: |

37 |

Extended graphics: 128 × 11 pages (including one space page) Multilingual character model supports printing with one of the following character sets:

Simplified Chinese (GB2312): 7580

Traditional Chinese (Big 5): 13494

Rev. A |

General Information 1-15 |

Character structure: Font A: 12 × 24 (including 2-dot spacing in horizontal) Font B: 9 × 17 (including 2-dot spacing in horizontal) Kanji: 24 × 24

Font A is the default

Character size, characters per line

|

|

|

|

|

|

|

|

Double-width/ |

|

|

|

Standard |

|

Double-height |

|

Double-width |

|

Double-height |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

W x H in mm |

|

W x H in mm |

|

|

W x H in mm |

|

W x H in mm |

|

|

|

{inches} |

CPL |

{inches} |

|

CPL |

{inches} |

CPL |

{inches} |

|

CPL |

|

|

|

|

|

|

|

|

|

|

|

Font A |

1.41 x 3.39 |

42 |

1.41 x 6.77 |

|

42 |

2.82 x 3.39 |

21 |

2.82 x 6.77 |

|

21 |

12 x 24 |

{.06 x .13"} |

|

{.06 x .27"} |

|

|

{.11 x .13"} |

|

{.11 x .27"} |

|

|

|

|

|

|

|

|

|

|

|

|

|

Font B |

0.99 x 2.40 |

56 |

0.99 x 4.80 |

|

56 |

1.98 x 2.40 |

28 |

1.98 x 4.80 |

|

28 |

9 x 17 |

{.04 x .09"} |

|

{.04 x .19"} |

|

|

{.08 x .09"} |

|

{.08 x .19"} |

|

|

|

|

|

|

|

|

|

|

|

|

|

Kanji |

3.39 x 3.39 |

21 |

3.39 x 6.77 |

|

42 |

6.77 x 3.39 |

10 |

6.77 x 6.77 |

|

21 |

12 x 24 |

{.13 x .13"} |

|

{.13 x .27"} |

|

|

{.27 x .13"} |

|

{.11 x .27"} |

|

|

|

|

|

|

|

|

|

|

|

|

|

*CPL = characters per line

*Space between characters is not included

*Characters can be scaled up to 64 times the standard size.

*When using Font B in a font mode such as emphasized mode, some words may be hard to read. Check the font mode in advance when using Font B.

1.5.4.1 Autocutter

Partial cut: Cutting with one point left uncut

NOTES:1.To prevent dot displacement, after cutting, feed paper approximately 1 mm (14/360 inches) or more before printing.

2.If the printer is stopped, you must feed paper over 40 mm (1.58 in.) before cutting

1-16 General Information |

Rev. A |

Loading...

Loading...