Epson Stylus Pro GS6000 Service Manual. Field Repair Guide

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 1.

Table of Contents

Table of Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Control Panel Map - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Component Replacement - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Board (Heater Control) Removal - - - - - - - - - - - - - - - - - - - - - - - - - 13

Board (Heater Relay) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Board (Main) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Board (Main) Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

Board (Power Supply) Removal - - - - - - - - - - - - - - - - - - - - - - - - - 35

Board (P/S Term) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Board (Sub B) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Board (Sub C) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Board Sub D (Left) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Board Sub D (Right) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - 47

Cap Assy Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

Cleaner Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Cover (Control Panel) Removal - - - - - - - - - - - - - - - - - - - - - - - - - 57

Cover (Front Left) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Cover (Ink Bay Left) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Cover (Ink Bay Right) Removal - - - - - - - - - - - - - - - - - - - - - - - - - 68

Cover (Rear) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 72

Cover (Side Left) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

Cover (Side Right) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - 76

Cover (Top Left) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - 79

Cover (Top Right) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 2.

Flushing Box Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

Heater Assembly (Platen) Removal - - - - - - - - - - - - - - - - - - - - - - - 86

Heater Assembly (Post) Removal - - - - - - - - - - - - - - - - - - - - - - - - 90

Heater Assembly (Pre) Removal - - - - - - - - - - - - - - - - - - - - - - - - - 98

Media Holder Assembly Removal - - - - - - - - - - - - - - - - - - - - - - - -102

Print Head (Left) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - -103

Print Head (Left) Installation - - - - - - - - - - - - - - - - - - - - - - - - - - -122

Print Head (Right) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - -138

Print Head (Right) Installation - - - - - - - - - - - - - - - - - - - - - - - - - -159

Pump Assembly Removal - - - - - - - - - - - - - - - - - - - - - - - - - - - -177

Sensor (Rear AD) Removal - - - - - - - - - - - - - - - - - - - - - - - - - - -182

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 185

Error Codes (Service) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -186

Sub Tank Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - -196

Adjustments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 198

All Counter Clear - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -199

Check Network Communication - - - - - - - - - - - - - - - - - - - - - - - - -200

CR Motor Life Counter Save & Reset - - - - - - - - - - - - - - - - - - - - - -204

Head Slant (CR) Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - -207

Feed Adj.+Side Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - -213

Head L [M,C,K,Y] Life Counter Save & Reset - - - - - - - - - - - - - - - - - -215

Head R [O,G,Lc,Lm] Life Counter Save & Reset - - - - - - - - - - - - - - - - -218

Head Rank Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -221

Head Wiping Counter Reset - - - - - - - - - - - - - - - - - - - - - - - - - - -224

Ink Discharge - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -227

Initial Ink Charge Flag - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -230

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 3.

Input Serial Number - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -233

NVRAM.EXE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -236

PF Motor Life Counter Save & Reset - - - - - - - - - - - - - - - - - - - - - -245

Pump Motor 1 [Front] Life Counter Reset - - - - - - - - - - - - - - - - - - - -248

Pump Motor 2 [Rear] Life Counter Reset - - - - - - - - - - - - - - - - - - - -251

RTC & USB ID Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - -254

Washing Sequence Flag - - - - - - - - - - - - - - - - - - - - - - - - - - - - -257

Component Pictures - - - - - - - - - - - - - - - - - - - - - - - - - - - 260

Board (Heater Control) Picture - - - - - - - - - - - - - - - - - - - - - - - - -261

Board (Heater Relay) Picture - - - - - - - - - - - - - - - - - - - - - - - - - -262

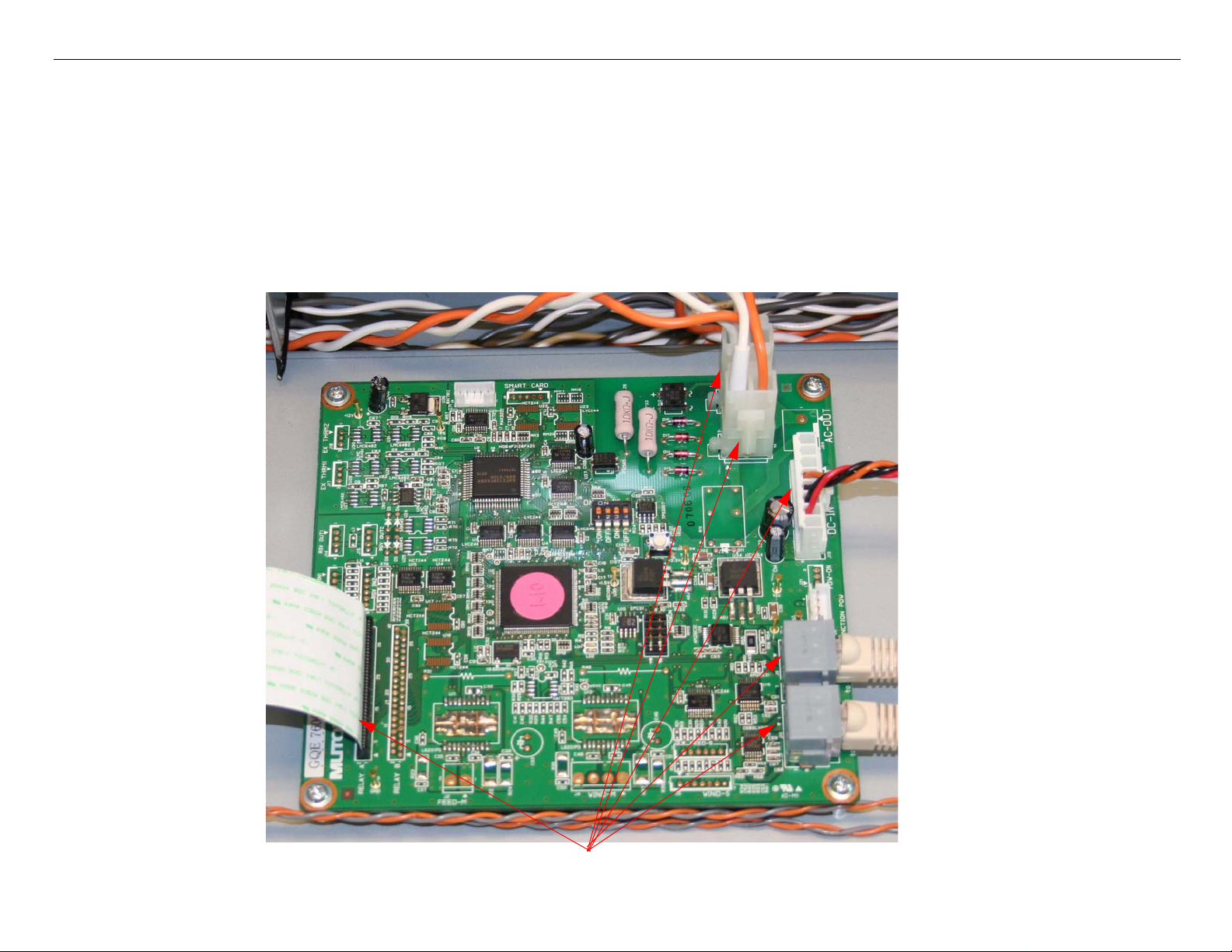

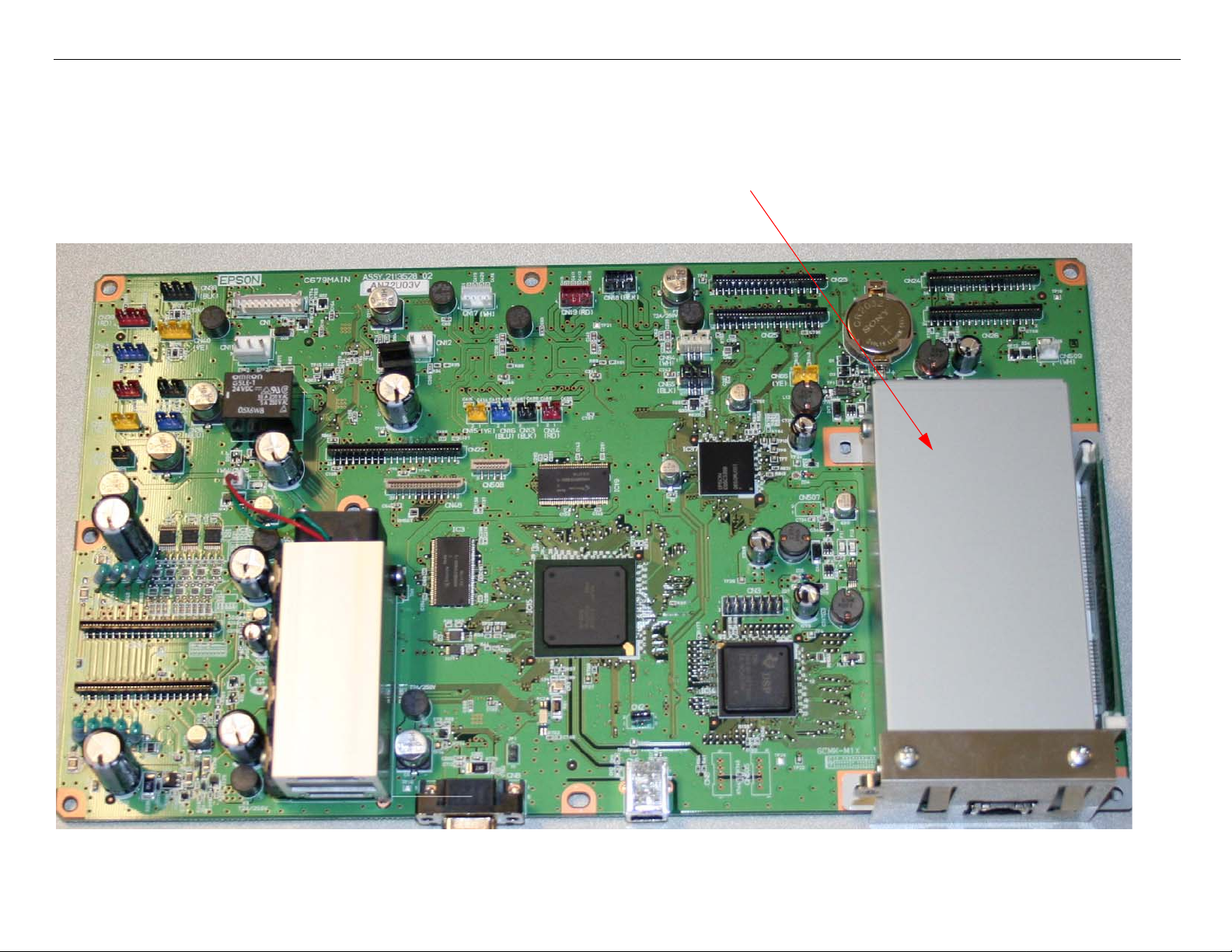

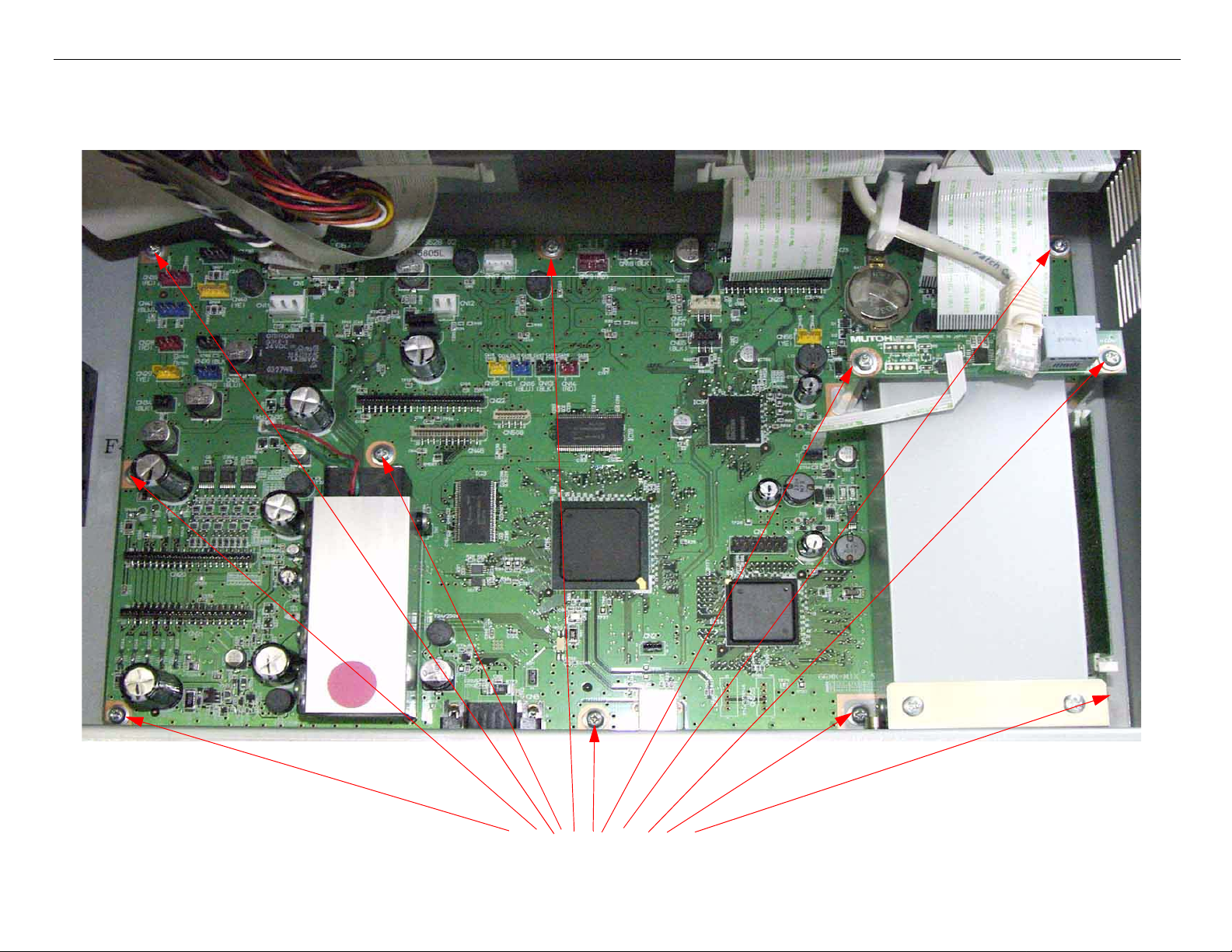

Board (Main) Picture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -263

Board (Power Supply) Picture - - - - - - - - - - - - - - - - - - - - - - - - - -264

Board (P/S Term) Picture - - - - - - - - - - - - - - - - - - - - - - - - - - - -265

Board (Sub-B) Picture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -266

Board (Sub C) Picture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -267

Board (Sub-D) Picture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -268

Cap Assembly Picture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -269

Control Panel Pictures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -270

Flushing Box Picture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -271

Print Head Pictures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -272

Pump Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -274

Sensor (Rear AD) Picture - - - - - - - - - - - - - - - - - - - - - - - - - - - -275

Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 276

Accessories List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -277

Carriage Release (Manual) - - - - - - - - - - - - - - - - - - - - - - - - - - - -278

Cleaning Supplies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -279

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 4.

Color Order - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -280

Connectors / Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -282

Consumable/Service Parts List - - - - - - - - - - - - - - - - - - - - - - - - -292

Firmware History - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -294

Firmware Update Procedure Using FWUpdate.exe - - - - - - - - - - - - - - -295

Glossary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -296

Ink Draining and Flushing Procedure - - - - - - - - - - - - - - - - - - - - - -302

Revision History - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -304

Sensors, Motors, Solenoids, and Fans - - - - - - - - - - - - - - - - - - - - -305

Service Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -308

Utilities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 309

FWUpdate.exe - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -310

Servprog.exe - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -314

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 5.

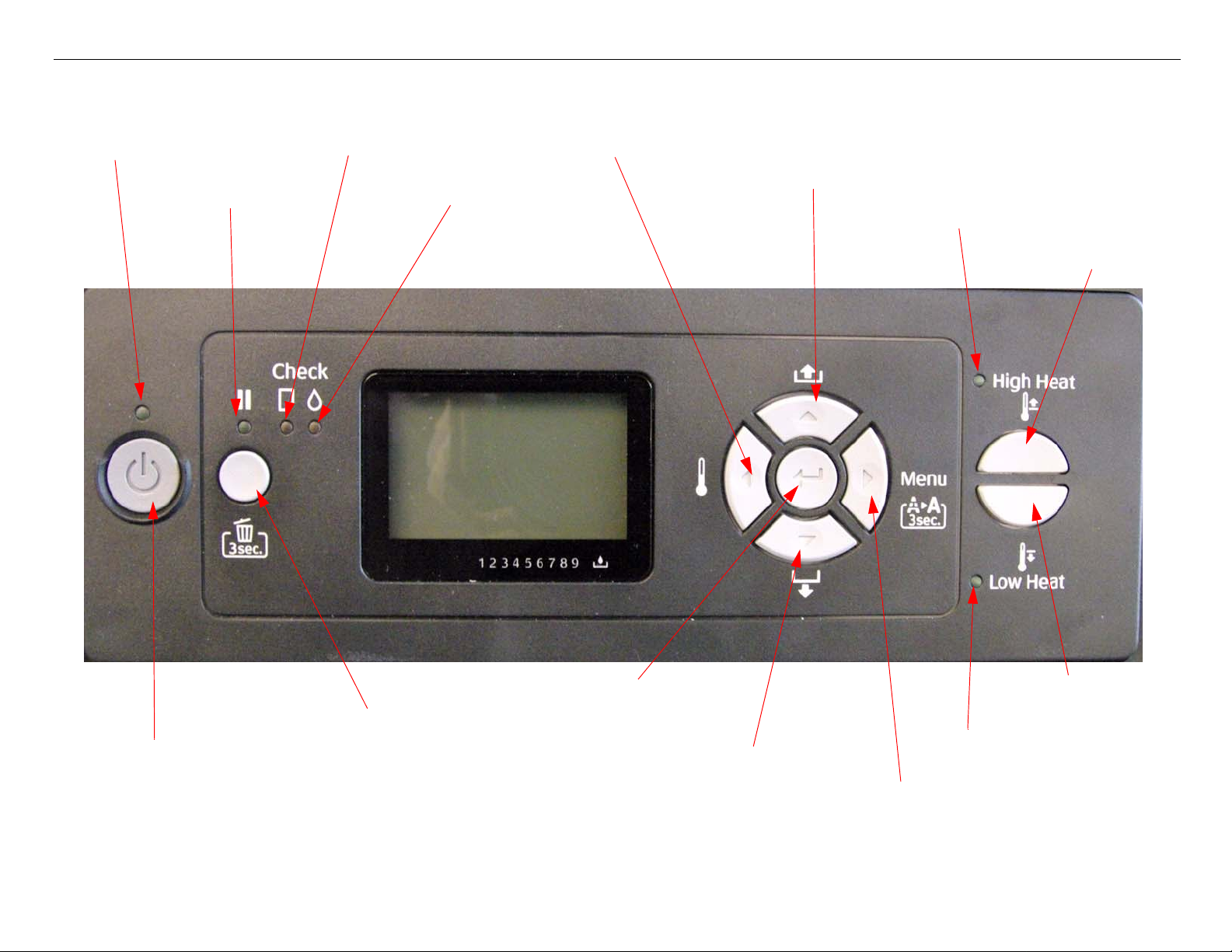

Control Panel Map

Power Light

Paper Check Light

Ink Check Light

Heater and Left Arrow

Paper Feed (Reverse) and Up Arrow

Pause and Reset

Paper Feed (Forward) and Down Arrow

Pause Light

Low Heat Light

Power Button

Enter

Low Heat

High Heat Light

High Heat

Menu and Right Arrow

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 6.

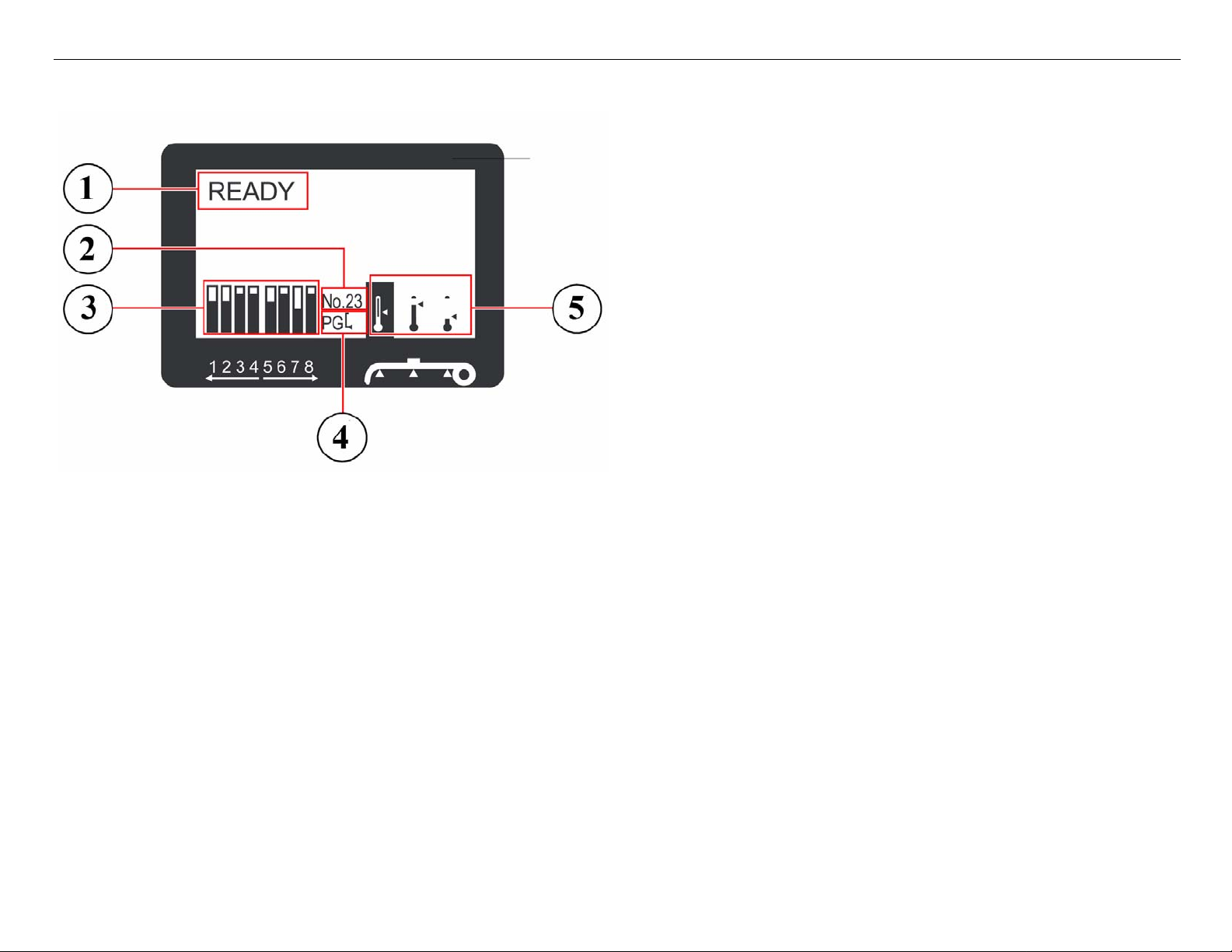

Printers LCD Display

1. Messages

2. Paper Type

3. Ink Cartridge Status Icon

4. Platen Gap Icon

5. Heater Icon

Maintenance Mode: Pause, at power on.

F/W DOWNLOAD MODE: Up, Down, Left, and Right, at power on.

Parameter Backup and Restore Mode: Down, Right, and Pause, at power on.

SERVICEMAN MODE: Down, Right, and Pause, at power on.

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 7.

User Menu: Press the Menu button when the printer displays Ready

1. PRINTER SETUP.

Side Margin: *5mm-25mm(*0.2inch-1.00inch)

Paper Size Check: *ON, OFF

Paper Skew Check: *ON, OFF

Print Nozzle Pattern: *OFF, On: Every PageOn: Every 10 Pages

Heating Time: Off, *10min-240min

Flush onto Paper: *Yes, No

Flushing Frequency: 1Pass-*5Pass-999Pass

Paper Origin Setup: *0mm-800mm, *0-32inches

Auto Take-Up Reel: *On, Off

Head Fan: *ON, OFF

Regular Cleaning: Off, 1h-*6h, 9h, 12h, 18h, 24h

Initialize Settings: Execute

2. Paper Setup

Paper Type: *Standard, No. 1 - 30

Paper Setup: *Standard, No. 1-30: Print Mode: *Speed 2, Speed 1-3, Quality 1-3, Max Quality

Paper Feed Adjust: Line Feed Adjust: 100mm, 250mm, 500mm: Print

Print Sample Pattern

Head Alignment: Bi-D All

Pre Heater: *50C, Off, 30-50C

Platen Heater: *50C, Off, 30-50C

After Heater: *50C, Off, 30-50C

M/W Adjust: *High A, High A-D, Extra High A-B, Low A-B, Medium A-D

Paper Suction: *High, Low

Drying Time: *0.0sec, 0-10.0 sec.

Carriage Movement: *Date Width, Printer Full Width

Print Multiple Layer: *Off, 2-8

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 8.

Maintenance Mode: Press and hold the Pause button and turn on the Printer.

LANGUAGE: *ENGLISH, JAPANESE, FRENCH, GERMAN, ITALIAN, PORTUGUE, SPANISH, DUTCH

(Panel Language)

UNIT: *FEET/INCH, METER (Set’s the unit of measure that the printer displays)

Thermometer Unit: *C, F (Set the Unit for Temperature of Heaters)

DEFAULT PANEL: EXEC (Resets to Factory Default all of the User Menus

3. Maintenance

Cleaning (Very Light): Execute

Cleaning (Light): Execute

Cleaning (Medium): Execute

Cleaning (Heavy): Execute

Head Washing: Execute

Carriage Maintenance: Execute

Clocking Setting: MM/DD/YY HH MM

Contrast Adjustment: -20 - *0 - 20

4. Test Print

Nozzle Check: Print

Status Print: Print

Network Status Sheet: Print

Job Information: Print

Custom Paper: Print

5. Printer Status

Version: T0xxxx-xx xx IBCC

Printable Page: (ink color) nnnnn Pages

Ink Level: (ink colors) nn%

Usage Counter: Ink xxxxx.x ml, Paper xxxxx.x cm

Clear Usage Count: Ink: Execute

Paper: Execute

Job History

Total Print: nnnnnn Pages

EDM Status: *Not Started, Enabled, Disabled

Last Uploaded

MM/DD/YY HH/MM

6. Network Setup

Network Setup: *Disable, Enable

IP Address Setting:*Auto, Panel

IP, SM, DG Setting: IP Address:*192.168.192.168

Subnet Mask:*255.255.255.000

Default Gateway:

*255.255.255.255

Bonjour: *On, Off

Init Network Setting: Execute

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 9.

ServiceMan Mode: Press and hold the Down, Right, and Pause buttons, and turn on the Printer

Note: SERVICEMAN MODE turns on the USB Port even if there is an error condition.

SELF TESTING:

Test:

Version: F/W, Boot, Pram1, Pram 2, Serial No., USB, Serial No.

Panel: Key, LCD, LED, Printer Check LED(Button, LCD, and LED tests for the control panel)

Sensor: Paper Lever: Down, Up (Paper Release Sensor test)

MTank: On, ON, ON(CSIC Contact Test)

Carriage NOT: 1,2,3,4,5,6,7,8 (Ink Cartridge Sensor test for 9 Ink Bays)

RearAD: (nnn nnn) (Rear Paper Sensor test)

Head Temp: (nn)C (Displays the current Print Head temperature in degrees centigrade)

Drv. Temp: (nn)C (Displays the current Print Head Driver temperature in degrees centigrade)

PG: (High, Low) (Platen Gap Sensor Test)

CR Origin: (Home Position Sensor Test)

Edge AD: (Edge Detector Sensor Test)

Encoder: CR (nnnn) (Carriage Encoder test. Counts up, moving away from home position)

PF (nnnn) (Paper Feed Encoder test. Counts up, as the paper advances.)

Fan: Paper(ALL): (Fan test for all paper suction fans)

Paper(Duty): (200% - 0%) (Tests the fan suction for all paper suction fans)

Paper1: (Fan test for paper suction fan #1 (Right Side Fan))

Paper2: (Fan test for paper suction fan #2

Paper3: (Fan test for paper suction fan #3

Paper4: (Fan test for paper suction fan #4

HT Fan: (Fan test for the Head Driver Cooling Fan)

Head Fan 1: (Fan Test for the Carriage Fan 1)

Head Fan 2: (Fan Test for the Carriage Fan 2)

Actuator: CrLock Sol (Carriage Lock Solenoid Test)

Ctrl Test: Ctrl Ver: Ctrl AP, Ctrl PCB

Ctrl Sns: Tank: 1 H/L/V - 8 H/L/V

Etc: Maint Cover, Ink Cover, Front Cover, Pre Heater 1/2, Platen Heater 1/2, After

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 10.

Heat 1/2

Ctrl Fan: Mist Fan: Mist Fan All, Mist Fan 1, Mist Fan 2, Mist Fan 3

Box Fan

Ctrl Heater: Pre Heater: Pre Heater 1/2

Platen Heater: Platen Heater 1/2

After Heater: After Heater 1/2

Ctrl Actuator: Tank Valve

Ink Valve: Valve1 On, Valve2 On, Valve3 On, Valve4 On

Ink Pump

Wiper

Error History (list of past errors)

Edge Sns Lvl: [Enter], Start (Sets the black level of the Edge Detector)

Adjustment

CR Origin Adjust: Exec. (Sets the “Capped” position for the Carriage Assembly.)

Platen Adjust: Exec.(Turns on the Platen Heater).

Heater Temp: Pre Heater Temp: 0-58 C (Sets the Pre Heater Temperature for service printing)

Platen Heater Temp:0-58 C (Sets the Platen Heater Temperature for service printing)

After Heater: 0-58 C (Sets the Post Heater Temperature for service printing)

RearAD: [Enter]Start (nnn nnn nnn) (For adjusting the Rear Paper Sensor)

Init.Fill: [Enter]Start (Starts a initial fill)

Nozzle Check: Output Pattern:(Nozzle Check pattern for checking vertical deflections)

Nozzle Alignment: Output Pattern: (Nozzle Check pattern for checking horizontal deflections)

Head Slant : CR Head Slant, PF Head Slant: Adjust, Confirm(Adjust Print head mechanical alignments)

Skew Check: Please Set Paper (Tests for Paper Skewing)

Feed Adj.+ Side: [Enter] Print(Performs the 980mm and Side Margin adjustments)

Gap Adj: Uni-D Low, Bi-D Low, Uni-D High, Bi-D High:

VSD1 400, VSD3 320, VSD3 400, All: Rough Adjust, Fine Adjust (Perform All, Rough, to com-

pletely adjust the Bi and Uni directional adjustments.)

Print Adj. Variable: [Enter] Print (Prints the numeric adjustment variables currently set and head rank)

All Pattern: (Print All Adjustment Patterns)

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 11.

Life(?)

CR Motor: Speed CW, Speed CCW, Page Size, Head Fan, LifeCount (?)

PF Motor: Feed Amount, LifeCount(?)

Pump: Pump Speed, LifeCount(?)

Head Fan: Head Fan 1 ON Time, Head Fan 1 OFF Ti me, Head Fan 2 O N Time, Head Fan 2 OFF Time,

LifeCount(?)

CR Lock: Wait Time (sec.), LifeCount(?)

Ink Valve: Valve1 On, Valve2 On, Valve3 On, Valve4 On, Valve All On(?)

Tank Valve: Valve1 On, Valve2 On, Valve3 On, V alve4 On, Valve5 On, V alve6 On, Valve7 On, V alve8 on,

Valve All On(?)

Feed(?)

Key: Backward(?)

Key: Forward(?)

Status(?)

GS6000 Field Repair Guide 10/10/08

Printer Component, Software Item, LCD Display, Printer Button Page 12.

Component

Replacement

GS6000 Field Repair Guide 10/10/08

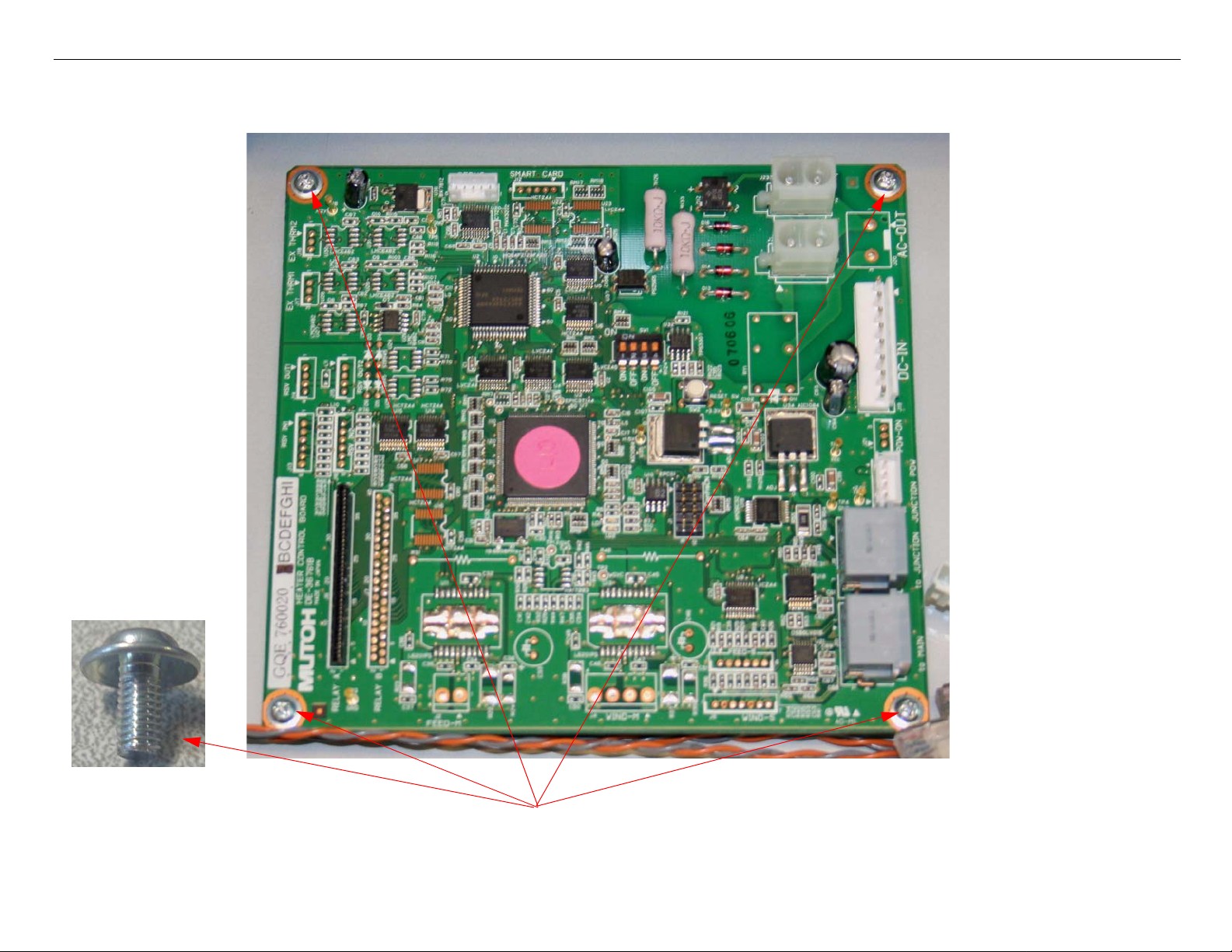

Board (Heater Control) Removal Printer Component, Software Item, LCD Display, Printer Button Page 13.

Board (Heater Control) Removal

1. Turn off the Printer and UNPLUG from AC.

2. Remove the Heater Assembly (Post).

3. Unplug the 6 Cables that attach the Heater Control Board to the Printer.

Unplug 6 Cables.

GS6000 Field Repair Guide 10/10/08

Board (Heater Control) Removal Printer Component, Software Item, LCD Display, Printer Button Page 14.

4. Remove 4 Screws that fasten the Heater Control Board to the Printer.

Remove 4 Screws.

GS6000 Field Repair Guide 10/10/08

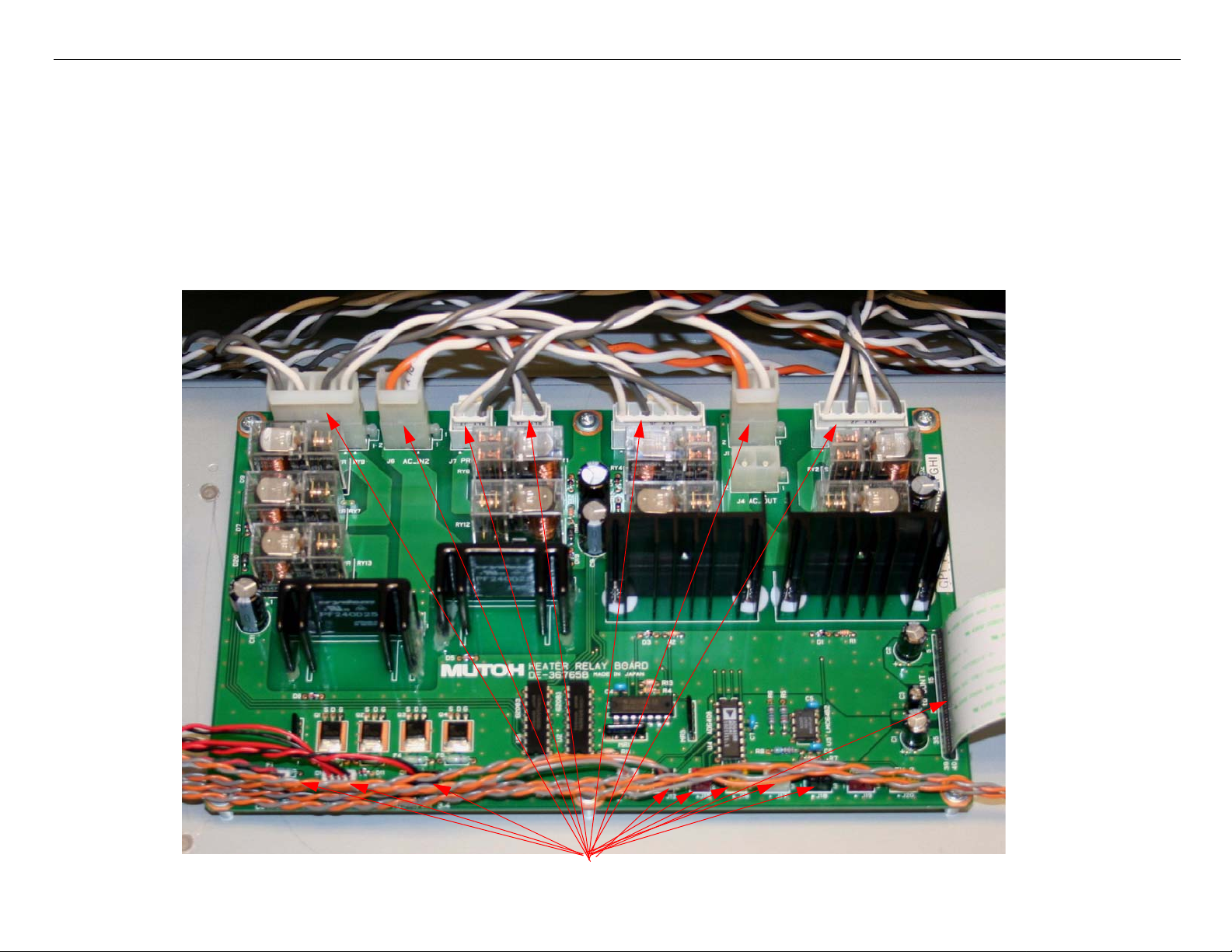

Board (Heater Relay) Removal Printer Component, Software Item, LCD Display, Printer Button Page 15.

Board (Heater Relay) Removal

1. Turn off the Printer and UNPLUG from AC.

2. Remove the Heater Assembly (Post).

3. Unplug the 17 Cables that attach the Heater Relay Board to the Printer.

Unplug 17Cables.

GS6000 Field Repair Guide 10/10/08

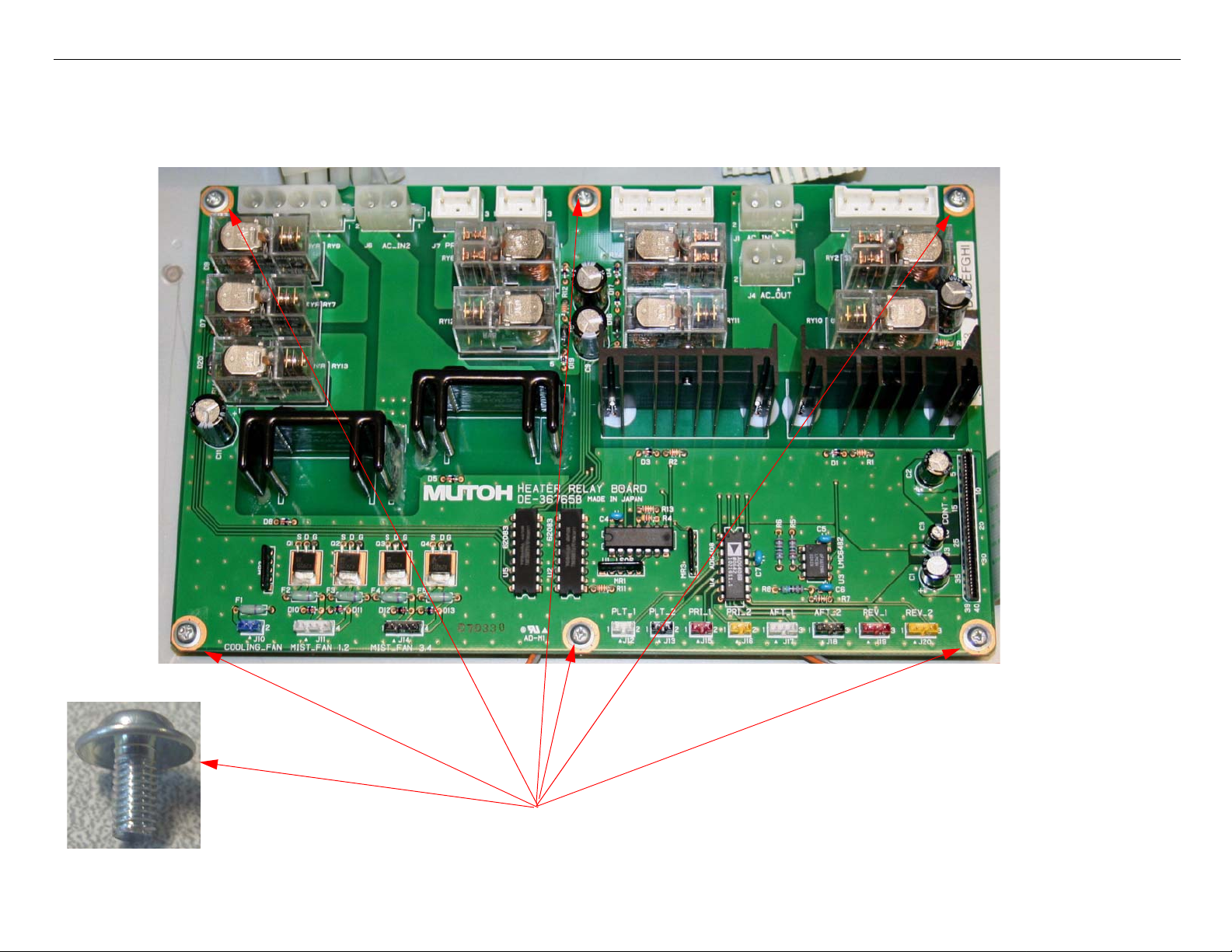

Board (Heater Relay) Removal Printer Component, Software Item, LCD Display, Printer Button Page 16.

4. Remove 6 Screws that fasten the Heater Relay Board to the Printer.

Remove 6 Screws.

GS6000 Field Repair Guide 10/10/08

Board (Main) Removal Printer Component, Software Item, LCD Display, Printer Button Page 17.

Board (Main) Removal

Note: GS6000 Main Board Part # 2121641 (the part # is stamped on the board)

Main Board Removal (Overview)

• Back up the Printer’s Parameters.

• Release the Mainboard (Box) Cover.

• Unplug the Cables.

• Remove the Screws.

• Remove the Ethernet Cover from the Main Board.

• Remove the Main Board

Main Board Removal (Detail)

1. Re-Install the Printer’s parameters using the NV-Ram Backup Utility feature of the servprog.exe utility.

1.1 Perform the RTC & USBID Adjustment located in the servprog.exe utility.

Note: If the Printer’s parameters can not be “backed up”, print out the Print Head Calibration value

(Head Rank). The Print Head Calibration value is included when the Adjustment variables are printed.

(ServiceMan Mode: Self Testing: Adjustment: Print Adj. Variable).

2. Turn off the Printer and UNPLUG from AC.

GS6000 Field Repair Guide 10/10/08

Board (Main) Removal Printer Component, Software Item, LCD Display, Printer Button Page 18.

3. Release the Mainboard Cover.

Remove 5 screws securing the

Mainboard Cover to the Printer.

Remove 2

screws

Be sure to hold the Mainboard Cover

when removing the last screw as the

cover will drop down.

GS6000 Field Repair Guide 10/10/08

Board (Main) Removal Printer Component, Software Item, LCD Display, Printer Button Page 19.

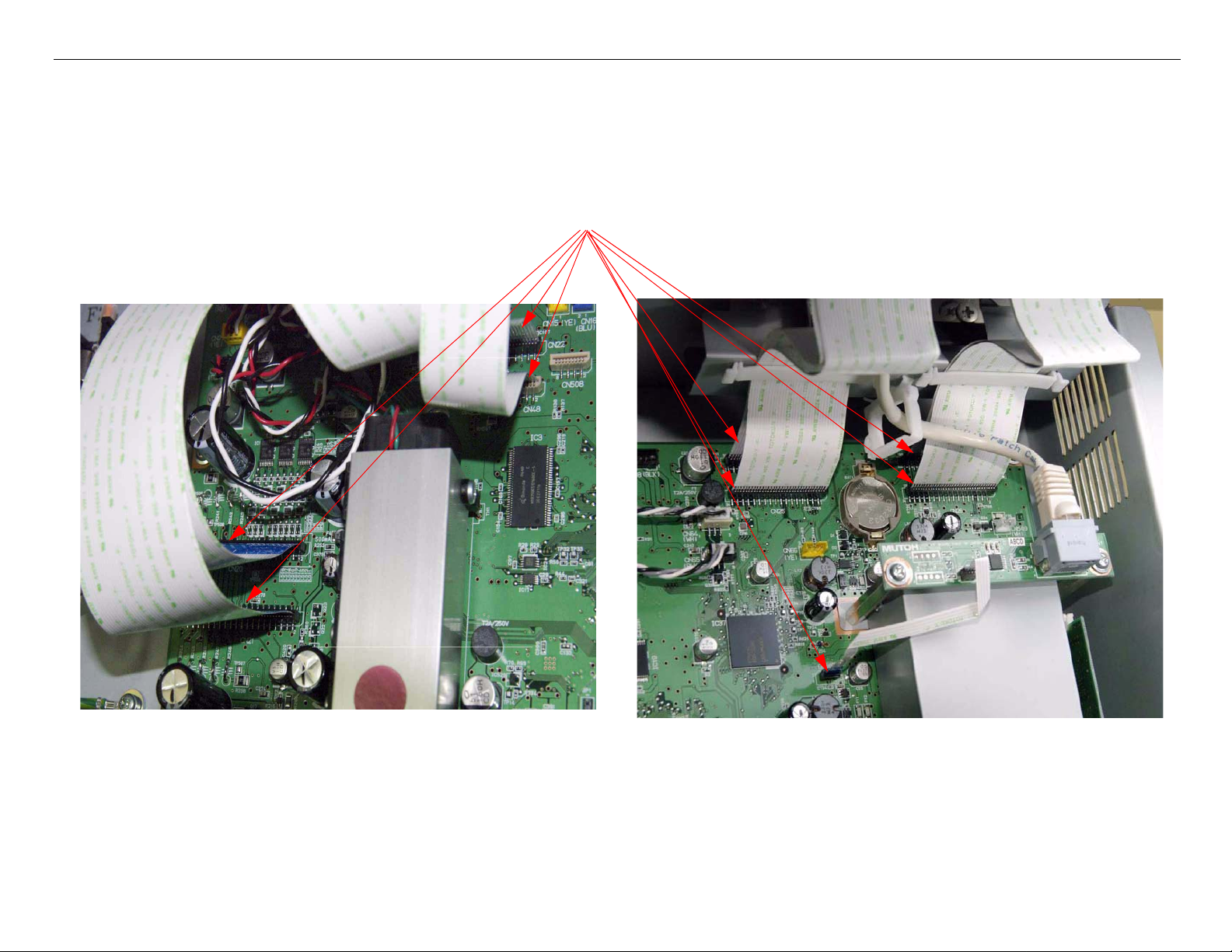

4. Unplug the 9 Foil Cables that attach the Main Board to the Printer

Unplug 9 Foil Cables

GS6000 Field Repair Guide 10/10/08

Board (Main) Removal Printer Component, Software Item, LCD Display, Printer Button Page 20.

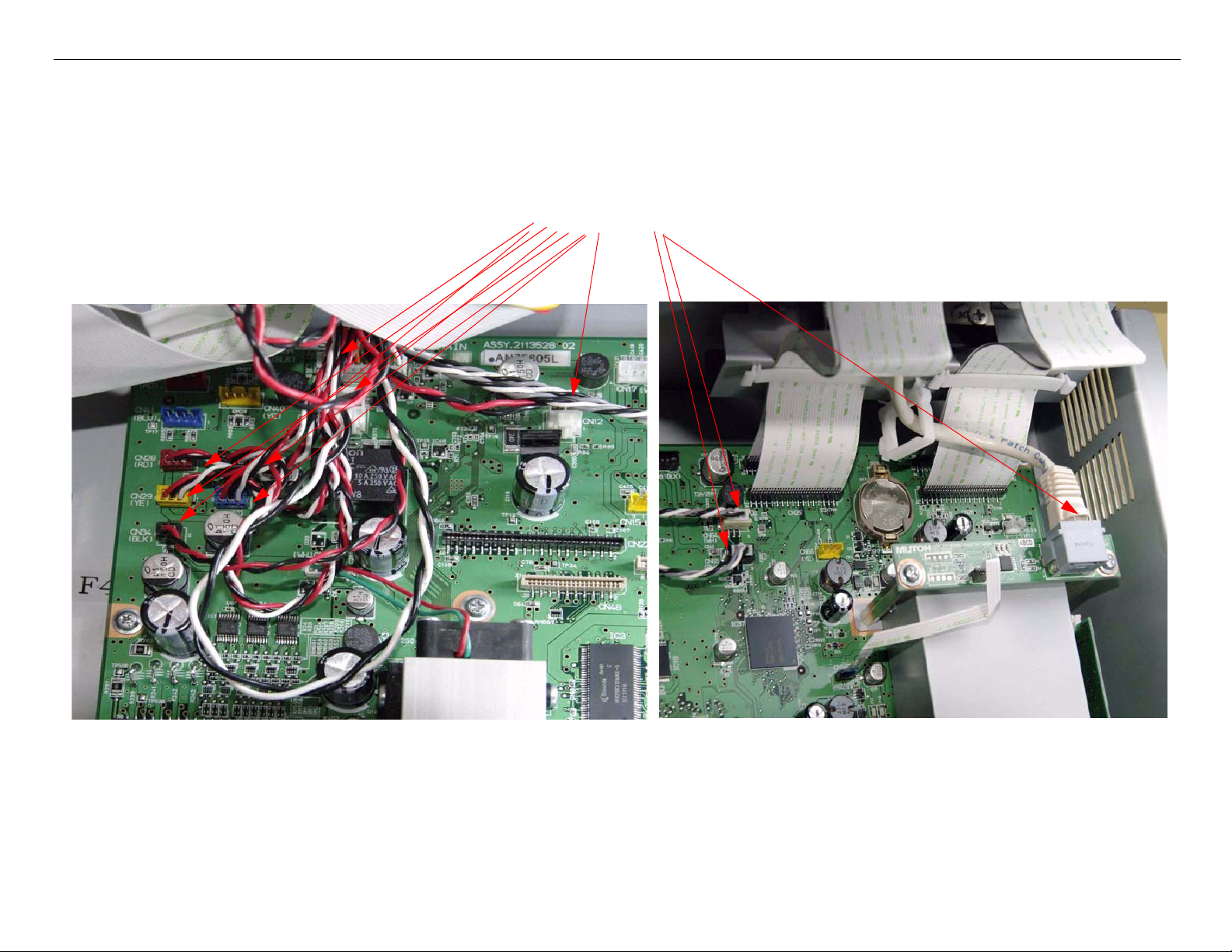

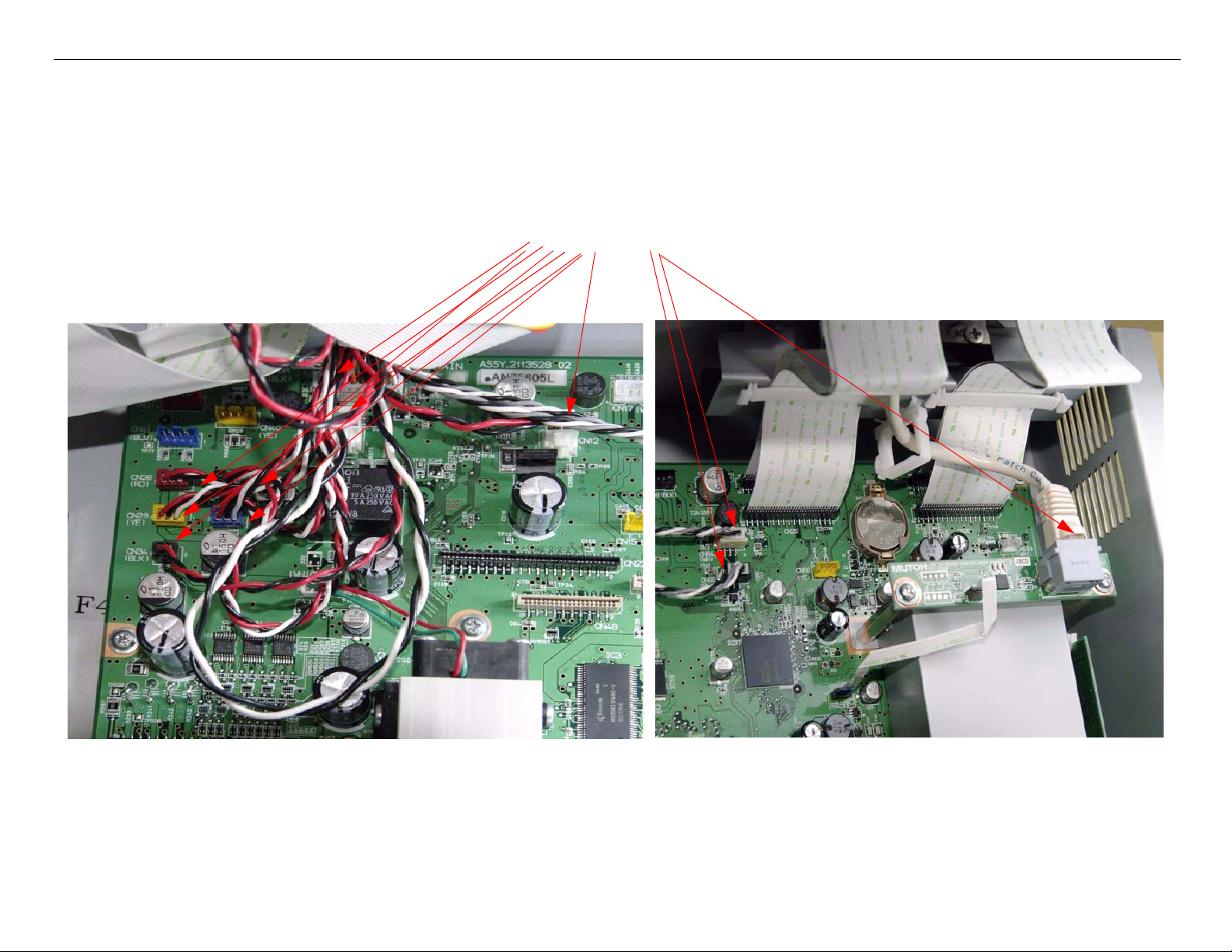

5. Unplug the 11 Wired Cables that attach the Main Board to the Printer.

Unplug 11 Wire Cables

GS6000 Field Repair Guide 10/10/08

Board (Main) Removal Printer Component, Software Item, LCD Display, Printer Button Page 21.

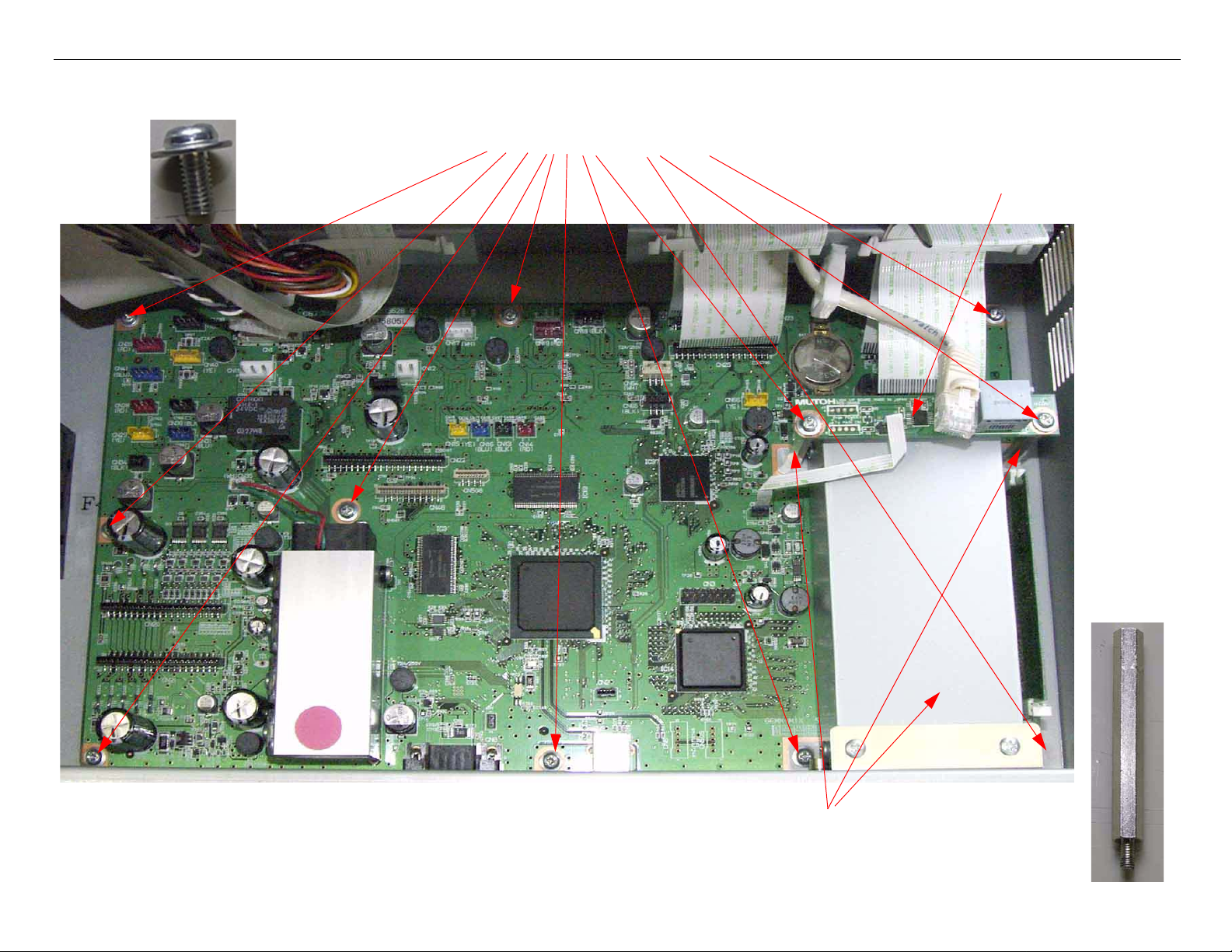

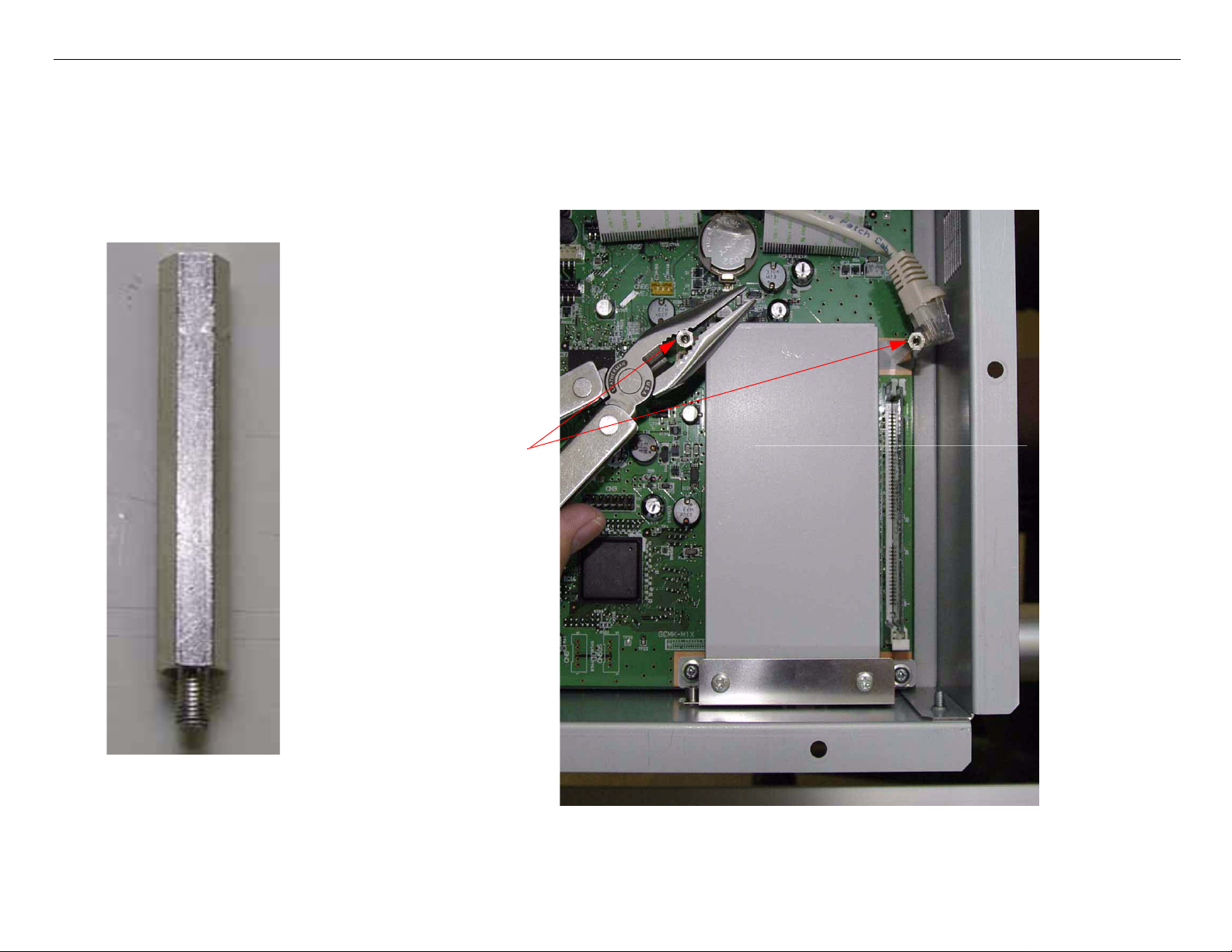

6. Remove 11 Screws and 2 Metal Support Rods and remove the LVDS Board.

1. Remove 11 Screws

2.Remove the LVDS Board

3.Use pliers to remove 2 Metal Support

Rods and remove the Ethernet Cover.

GS6000 Field Repair Guide 10/10/08

Board (Main) Removal Printer Component, Software Item, LCD Display, Printer Button Page 22.

7. Lift out the Main Board.

GS6000 Field Repair Guide 10/10/08

Board (Main) Removal Printer Component, Software Item, LCD Display, Printer Button Page 23.

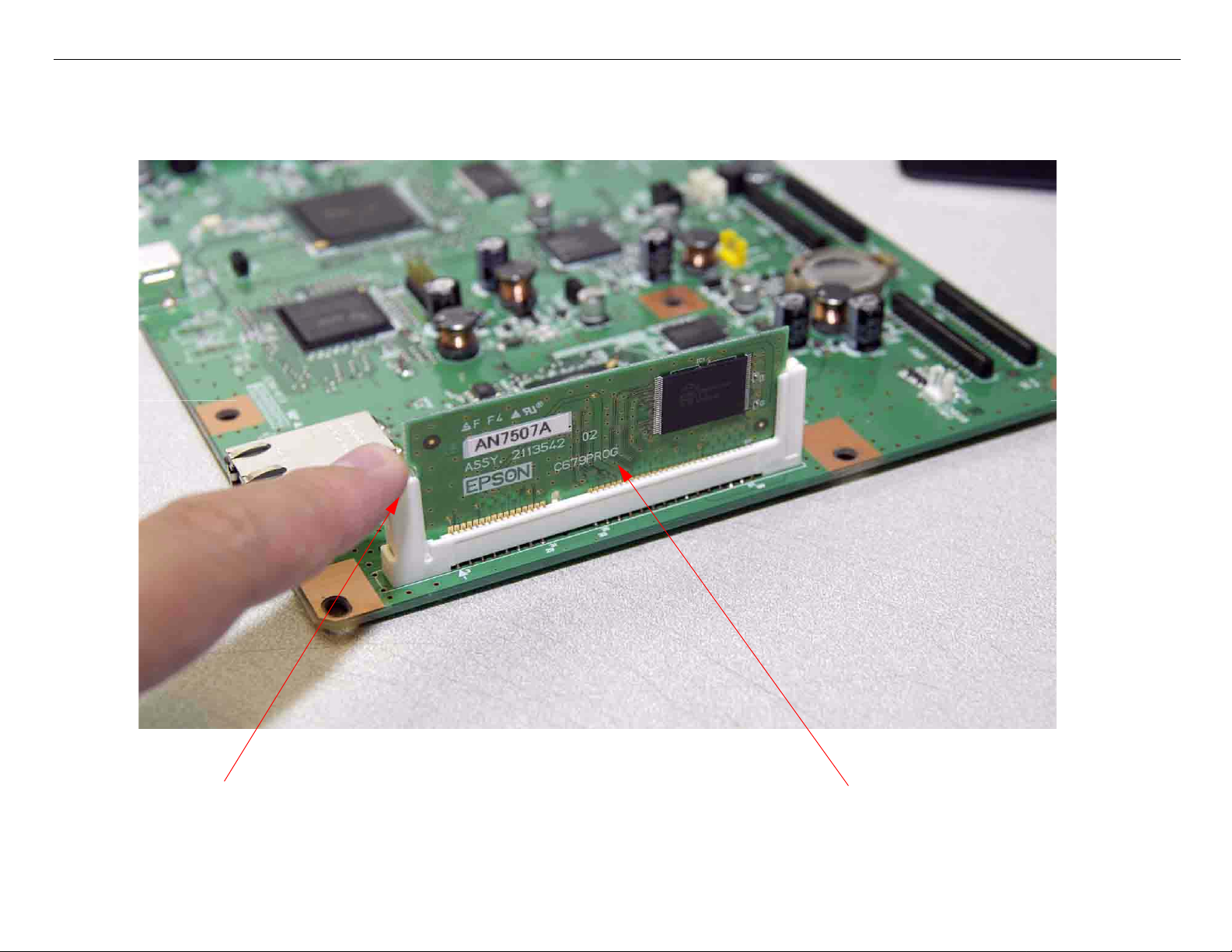

8. Remove the EDM SIMM from the Main Board.

1. Press here to release the EDM SIMM.

2. Lift out the EDM SIMM.

GS6000 Field Repair Guide 10/10/08

Board (Main) Installation Printer Component, Software Item, LCD Display, Printer Button Page 24.

Board (Main) Installation

Note: GS6000 Main Board Part # 2121641 (the part # is stamped on the board)

Main Board Installation (Overview)

• Install the EDM SIMM on the New Main Board

• Install the Main Board.

• Install the Ethernet Cover onto the Main Board.

• Install the Screws.

• Plug in the Cables.

• Close the Rear Cover.

• Upload Firmware.

• Install the Printer’s Parameters.

• Perform the RTC & USB ID Adjustment.

Main Board Installation (Detail)

1. Compare the New Main Board to the Old Main Board. Verify that the Components, Brackets,

and Part Numbers match.

GS6000 Field Repair Guide 10/10/08

Board (Main) Installation Printer Component, Software Item, LCD Display, Printer Button Page 25.

2. Install the EDM SIMM onto the Main Board.

Install the EDM SIMM.

GS6000 Field Repair Guide 10/10/08

Board (Main) Installation Printer Component, Software Item, LCD Display, Printer Button Page 26.

3. Install the Main Board into the Printer, and place the Ethernet Cover in position.

1. Drop in the Main Board.

2. Place the Ethernet Cover in position

GS6000 Field Repair Guide 10/10/08

Board (Main) Installation Printer Component, Software Item, LCD Display, Printer Button Page 27.

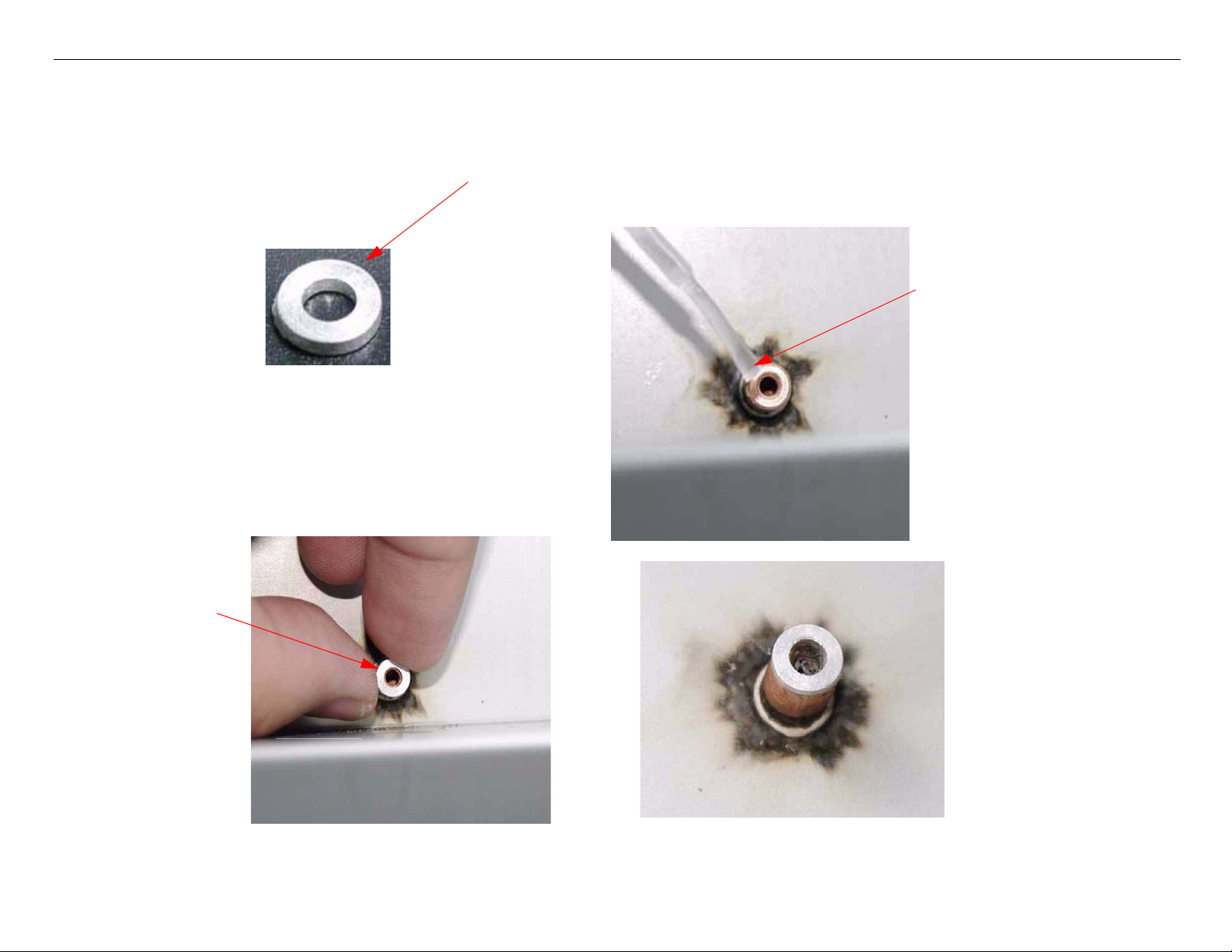

4. Make sure all screw stands have the washer on them.

During Mainboard removal or installation, this washer may come off it s screw

stand. Glue it back in place, making sure no glue leak into the thread of the

stand.

Brush a small amount of

glue on the outer edge of

the screw stand.

Install washer.

GS6000 Field Repair Guide 10/10/08

Board (Main) Installation Printer Component, Software Item, LCD Display, Printer Button Page 28.

5. Install 2 Metal Support Rod that fasten the Main Board and Ethernet Cover to the Printer.

Install 2 Metal Support

Rods, do not over-tighten.

GS6000 Field Repair Guide 10/10/08

Board (Main) Installation Printer Component, Software Item, LCD Display, Printer Button Page 29.

6. Install 11 screws that fasten the Main Board to the Printer.

Install 11 screws.

GS6000 Field Repair Guide 10/10/08

Board (Main) Installation Printer Component, Software Item, LCD Display, Printer Button Page 30.

7. Plug in 11 Wire cables

Plug in 11 Wire Cables

Loading...

Loading...