Bosch GRL160DHV Operating/safety Instructions Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

For English Version Version française Versión en español

See page 6 Voir page 22 Ver la página 38

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

GRL160DHV

-2-

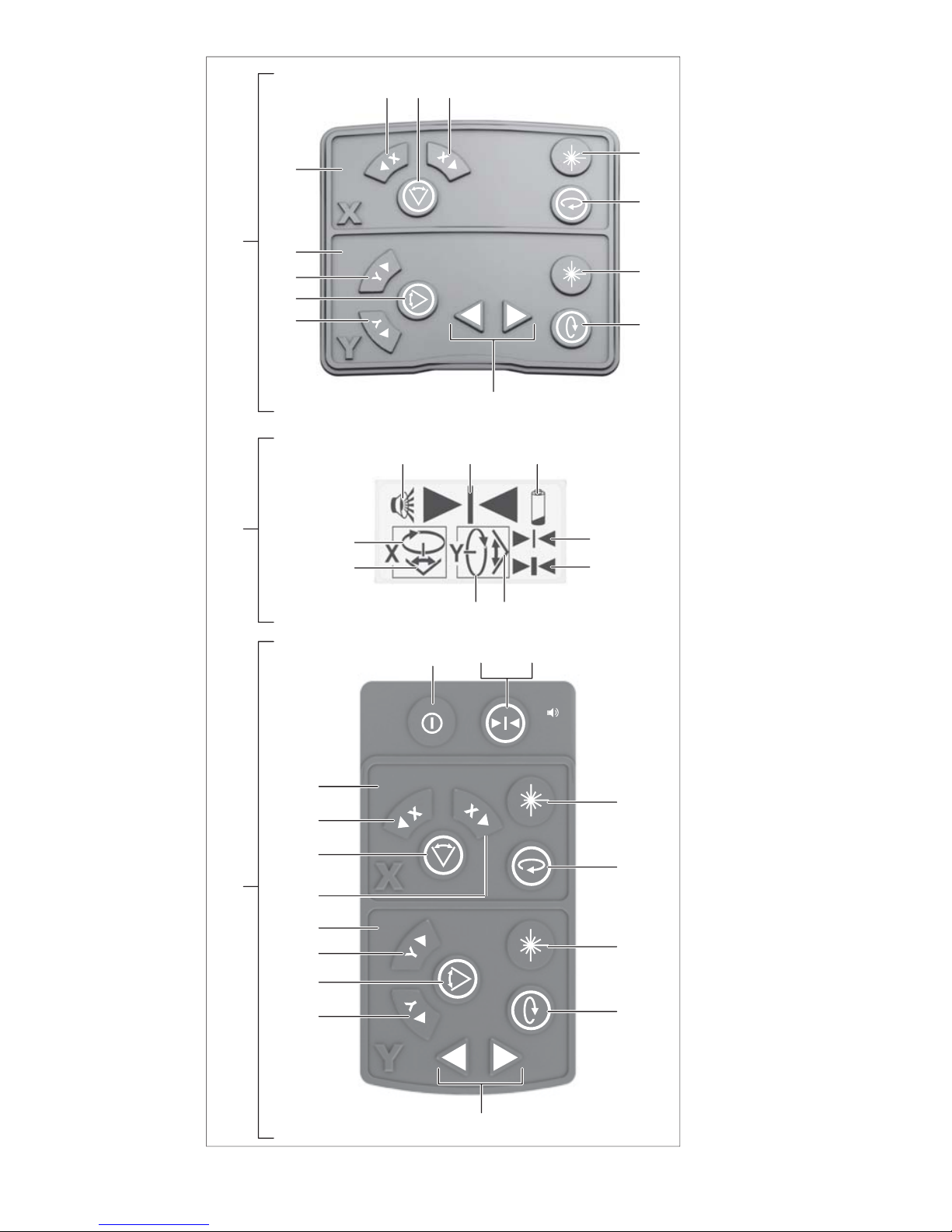

4

3

2

1

5

6

6

11

12

7

8

10

9

-3-

13

14

15

19181716

21 20

-4-

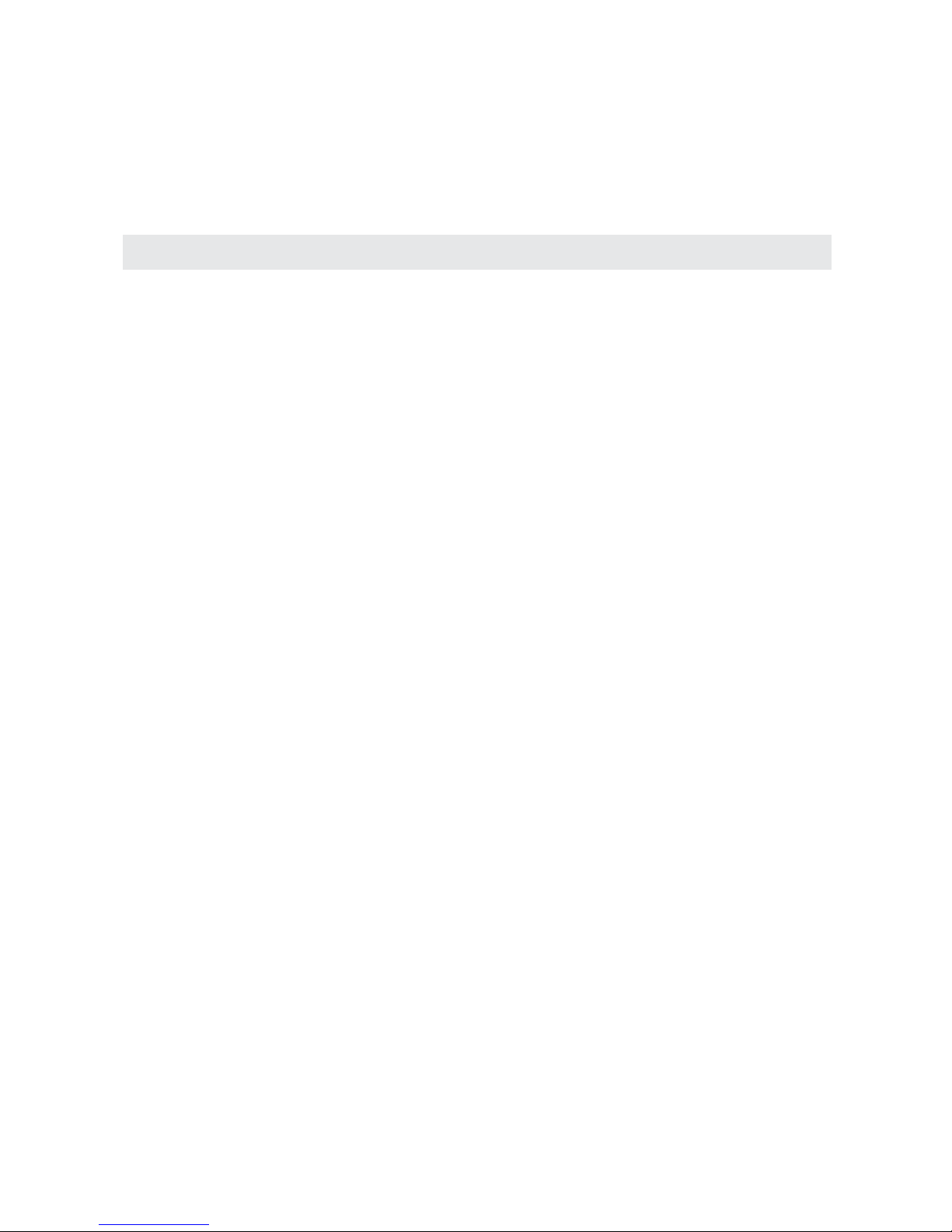

22

26

34

27

33

26

27

34

33

38

39

28

3

29

31

22

23

29

31

24

30

28

43

42

30

23

35

44 45 46

3736

32

2524

32

41 40

16

17

25

47

48

49

50

51

-6-

Read all instructions. Failure to follow all instructions listed below may

result in hazardous radiation exposure, electric shock, fire and/or

serious injury. The term “tool” in all of the warnings listed below refers to your mains-operated

(corded) tool or battery-operated (cordless) tool.

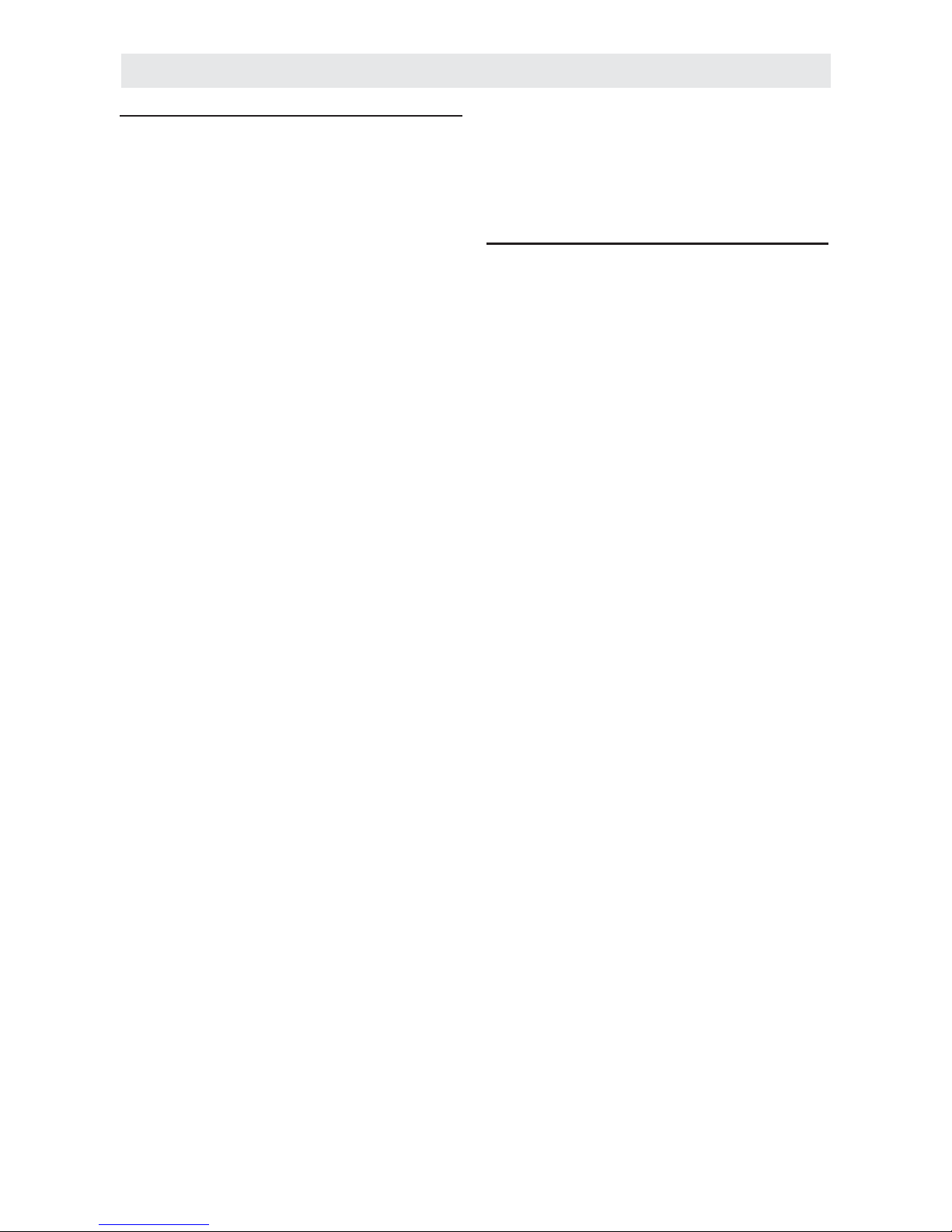

The following labels are on your laser tool for your convenience and

safety. They indicate where the laser light is emitted by the tool.

ALWAYS BE AWARE of their location when using the tool.

Do not direct the laser beam at persons or animals and do not stare into the

laser beam yourself. This tool produces laser class IIIa laser radiation. This can

lead to persons being blinded.

DO NOT remove or deface any warning or caution labels. Removing labels

increases the risk of exposure to laser radiation.

Use of controls or adjustments or performance of procedures other than those specified in this

manual, may result in hazardous radiation exposure.

ALWAYS make sure that any bystanders in the vicinity of use are made aware of the dangers

of looking directly into the laser tool.

DO NOT place the laser tool in a position that may cause anyone to stare into the laser beam

intentionally or unintentionally. Serious eye injury could result.

ALWAYS position the laser tool securely. Damage to the laser tool and/or serious injury to the

user could result if the laser tool fails.

ALWAYS use only the accessories that are recommended by the manufacturer of your laser

tool. Use of accessories that have been designed for use with other laser tools could result in

serious injury.

DO NOT use this laser tool for any purpose other than those outlined in this manual. This could

result in serious injury.

DO NOT leave the laser tool “ON” unattended in any operating mode.

DO NOT disassemble the laser tool. There are no user serviceable parts inside. Do not modify

the product in any way. Modifying the laser tool may result in hazardous laser

radiation exposure.

DO NOT use the laser viewing glasses as safety goggles. The laser viewing glasses are used

for improved visualization of the laser beam, but they do not protect against laser radiation.

DO NOT use the laser viewing glasses as sun glasses or in traffic. The laser viewing glasses

do not afford complete UV protection and reduce color perception.

DO NOT use any optical tools such as, but not limited to, telescopes or transits to view the

laser beam. Serious eye injury could result.

DO NOT stare directly at the laser beam or project the laser beam directly into the eyes of

others. Serious eye injury could result.

SAVE THESE INSTRUCTIONS

General Safety Rules

!

WARNING

!

WARNING

-7-

FCC Statement

This product has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Consult the dealer or an experienced radio/TV technician for help.

SAVE THESE INSTRUCTIONS

Work area safety

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

DO NOT operate the laser tool around

children or allow children to operate the

laser tool. Serious eye injury could result.

Electrical safety

Batteries can explode or

leak, cause injury or fire.

To reduce this risk, always follow all

instructions and warnings on the battery label

and package.

DO NOT short any battery terminals.

DO NOT charge alkaline batteries.

DO NOT mix old and new batteries. Replace

all of them at the same time with new

batteries of the same brand and type.

DO NOT mix battery chemistries.

Dispose of or recycle batteries per

local code.

DO NOT dispose of batteries in fire.

Keep batteries out of reach of children.

Remove batteries if the device will not be

used for several months.

Personal safety

Stay alert, watch what you are doing and

use common sense when operating a

tool. Do not use a tool while you are tired

or under the influence of drugs, alcohol

or medication. A moment of inattention

while operating a tool may result in serious

personal injury or incorrect

measurement results.

Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

Use and care

Use the correct tool for your application.

The correct tool will do the job better

and safer.

Do not use the tool if the switch does not

turn it on and off. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Store idle tool out of the reach of children

and do not allow persons unfamiliar with

the tool or these instructions to operate

the tool. Tools are dangerous in the hands

of untrained users.

Maintain tools. Check for misalignment or

binding of moving parts, breakage of

parts and any other condition that may

affect the operation. If damaged, tool

repaired before use. Many accidents are

caused by poorly maintained tools.

Use the tool, accessories, etc., in

accordance with these instructions and in

the manner intended for the particular

type of tool, taking into account the

working conditions and the work to be

performed. Use of the tool for operations

different from those intended could result in a

hazardous situation.

Service

Have your tool serviced by a qualified

repair person using only identical

replacement parts. This will ensure that the

safety of the tool is maintained.

Develop a periodic maintenance schedule

for tool. When cleaning a tool be careful

not to disassemble any portion of the tool

since internal wires may be misplaced or

pinched or may be improperly mounted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

SAVE THESE INSTRUCTIONS.

!

WARNING

-8-

This tool projects rotating, dithering lasers and is intended for accurate transfer and alignment of

plumb, level, and 90-degree lines.

• Plumbing (Making vertical) — Use the Vertical Spin or Line Dither/Scan laser for indoor

and outdoor plumb and alignment applications, such as plumbing framing or

aligning conduit.

• Leveling — Use the Horizontal Spin or Line Dither/Scan laser for indoor and out door level

applications, such as leveling cabinetry, setting concrete forms, or leveling electrical outlets.

• Grading — Use the tool at a sloped angle for indoor and outdoor level applications, such

as grading driveways or swimming pools.

• Squaring— Use both lasers simultaneously to generate a crosshair for level and plumb

alignment applications, such as aligning cabinetry or tiling.

Intended Use

Preparation

Inserting/Replacing the Battery

ALWAYS turn off the laser and the main

power switch before removing and replacing

the batteries.

Alkaline batteries are recommended for

the tool.

The battery compartment is located at the

bottom of the unit, below the power switch

and AC/DC port. Open the compartment and

replace the batteries. Note that the two pairs

of batteries are stacked.

When inserting, pay attention to the correct

polarity according to the representation on

the inside of the battery compartment.

To open the battery lid, slide lid toward the

back of the tool.

Always replace all batteries at the same time.

Only use batteries from one brand and with

the identical capacity.

• Remove the batteries from the

tool when not using it for extended

periods. When storing for extended

periods, the batteries can corrode and

discharge themselves.

Low Battery Indicator

The LED flashes yellow when 25 percent of

battery life remains (approximately five

hours). The LED flashes, and continues to

flash in a pattern of three seconds on/one

second off, until the batteries are replaced

or fail.

-9-

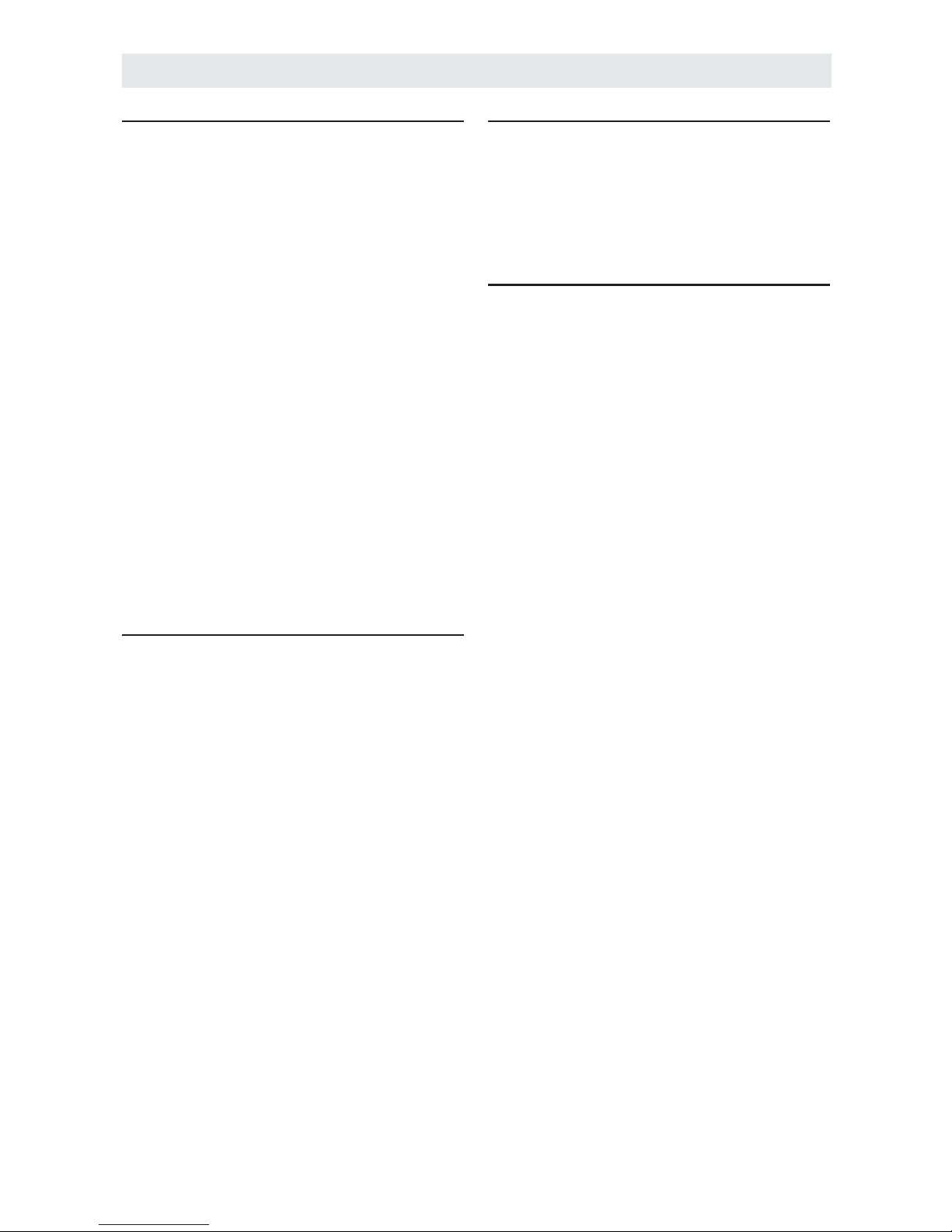

The numbering of the product features shown

refers to the illustration of the tool

on page 2.

Rotational Laser Level

1 On/off switch for rotational laser level

2 LED for operating condition

3 Control panel of the rotational laser level

4 Handle

5 Warning label, laser radiation

exit opening

6 Outlet opening of the horizontal laser

beam (X-axis)

7 Horizontal laser beam (X-axis)

8 Outlet opening of the vertical laser

beam (Y-axis)

9 Vertical laser beam (Y-axis)

10 Calibration screw, front (only for service

personnel)

11 Laser warning label

12 Calibration screw, sideward (only for

service personnel)

13 Serial number of the rotational laser level

14 Tripod mount 5/8- 11

15 Battery compartment, rotational

laser level

Detector/Remote Control

16 Control panel, laser receiver

17 Display

18 Reception area for the laser beam

19 Center mark

20 Serial number of laser receiver

21 Battery compartment, laser receiver

Operating controls, rotational laser level

22 Control Panel, Horizontal Laser

Beam (X-axis)

23 Button for positioning of the laser line in

counter-clockwise direction (horizontal

laser beam)

24 Button for line operation button and

selection of line length (horizontal

laser beam)

25 Button for positioning of the laser line in

clockwise direction (horizontal

laser beam)

26 On/Off button (horizontal laser beam)

27 Button for rotational operation and

selection of the rotational speed

(horizontal laser beam)

28 Control Panel, Vertical Laser

Beam (Y-axis)

29 Button for positioning of the laser line in

clockwise direction (vertical laser beam)

30 Button for line operation and selection of

line length (vertical laser beam)

31 Button for positioning of the laser line in

counter-clockwise direction (vertical

laser beam)

32 Leveling buttons (vertical laser beam)

33 Button for rotational operation and

selection of the rotational speed (vertical

laser beam)

34 On/Off button (horizontal laser beam)

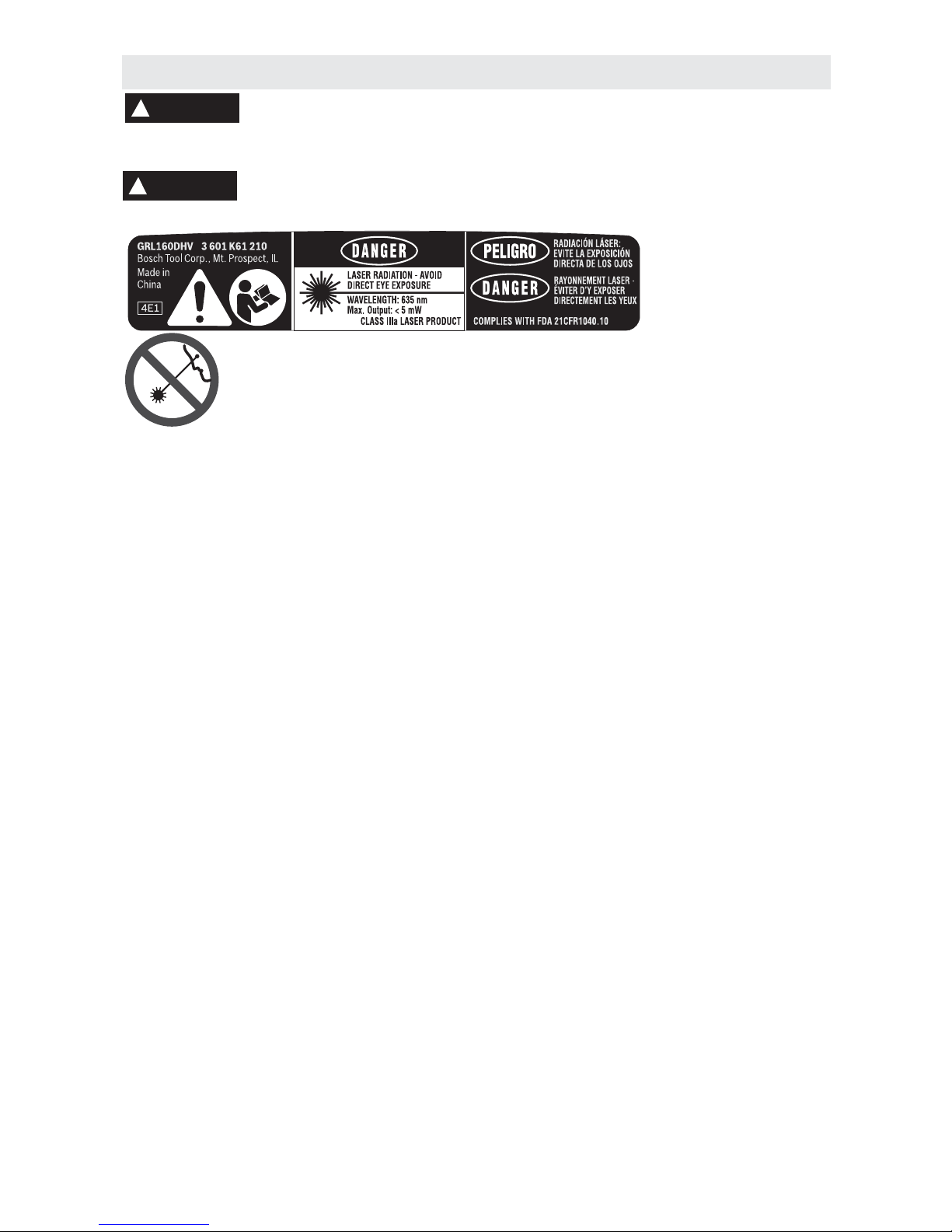

Display Indications 17 on the Detector

35 Indicator for audio signal

36 Direction indicator for positioning of the

laser receiver

37 Battery indication

38 Indicator for measuring accuracy “(fine)”

39 Indicator for measuring accuracy

“(coarse)”

40 Line operation indicator (vertical

laser beam)

41 Rotational operation indicator (vertical

laser beam)

42 Line operation indicator (horizontal

laser beam)

43 Rotational operation indicator (horizontal

laser beam)

Operating Controls, Detector/Remote

Control

44 On/Off button for laser receiver

45 Button for adjustment of the

measuring accuracy

46 Audio signal button

22 Control Panel, Horizontal Laser

Beam (X-axis)

23 Button for positioning of the laser line in

counter-clockwise direction (horizontal

laser beam)

24 Button for line operation button and

selection of line length (horizontal

laser beam)

25 Button for positioning of the laser line in

clockwise direction (horizontal

laser beam)

26 On/Off button (horizontal laser beam)

27 Button for rotational operation and

selection of the rotational speed

(horizontal laser beam)

28 Control Panel, Vertical Laser

Beam (Y-axis)

29 Button for positioning of the laser line in

clockwise direction (vertical laser beam)

30 Button for line operation and selection of

line length (vertical laser beam)

Features

-10-

Article number . . . . . . . . . . . . . . 3601K61210

Number of laser points . . . . . . . . . . . . . . .

2 rotating beams, (level and plumb), with

independent and simultaneous operation.

Working Range (Diameter)

With Laser Receiver . . . .up to 1000ft(305m)

Self Leveling Range

Horizontal and Vertical . . . . . . Up to +/- 6°

Leveling Accuracy

Level (horizontal):

Minimum Factory

Accuracy . . . . . . . . . . . . . . . . . ±0.167mm/m

(±0.002004in/ft)

Typical Horizontal

Accuracy . . . . . . . . . . . . up to ±1/8”@ 100ft

(±3mm at 30m)

Plumb (vertical):

Minimum Factory

Accuracy . . . . . . . . . . . . . . . . ±0.167mm/m

(±0.002004in/ft)

Typical Vertical

Accuracy . . . . . . . . . . . . up to ±1/4”@ 100ft

(±6.4mm at 30m)

Rotation Speeds

Three Discrete Speeds: . . . . .350/600/1200

rpm +/- 10%

Dithering Settings . . . . . . . . . . . .3/10/30/45/

90/ 120°

Positioning, horizontal or vertical

(for line operation) . . . . . . . . . . . . . . . . .360°

Laser Class . . . . . . . . . . . . . . . . . .Class IIIa

Laser Type . . . . . . . . . . .635nm, <5mW max.

IP Protection . . . . . . . . . . . . . . . . . . . .IP 5X

Power . . . . . . . . . . . . . . . . . . . . . . . . . . .4 ‘D’

alkaline batteries

Weight . . . . . . . . . . . . . . . . . . . . . . . . 6.7lb

(3.05 kg)

(including 4 `D’ alkaline batteries)

Operating

Temperature Range . . . . . .14°F to + 122°F

(-10°C to + 50°C)

Storage

Temperature Range. . . . . . . .-4°F to + 158°F

(-20°C to +70°C)

Battery Life . . . . . . . . . . . . . . . 40 hrs (min)

Tripod Mount . . . . . . . . . . . . . . . . . . . .5/8-11

Remote Control with Laser

Receiver-detector

Working Range (Radius)

Laser Receiver with

Rotational Laser Level . .up to 5250ft (160m)

Remote Control . . . . . . . . up to 300ft (91m)

Measuring Accuracy

Fine Adjustment . . . . . . . +/- 1/16in @ 30ft

(+/- 1.5mm @ 10m)

Coarse Adjustment . . . . . . . +/- 1/8in@ 30ft

(+/- 3mm @ 10m)

Operating

Temperature Range . . . . . .14°F to + 122°F

(-10°C to + 50°C)

Storage

Temperature Range. . . . . . . .-4°F to + 158°F

(-20°C to +70°C)

Power . . . . . . . . . . . . .1 x 9V alkaline battery

Battery Life . . . . . . . Approximately 2000 hrs.

Stand by Operation . . . . . . . . . .after 20 min.

Remote Control

IP Protection: . . . . . . . . . . . . . . . . . . . .IP 51

Please observe the article number on the

type plate of your tool. The trade names of

the individual tools may vary.

Technical Data

31 Button for positioning of the laser line in

counter-clockwise direction (vertical

laser beam)

32 Leveling buttons (vertical laser beam)

33 Button for rotational operation and

selection of the rotational speed (vertical

laser beam)

34 On/Off button (horizontal laser beam)

Other Features

47 Laser viewing glasses

48 Laser target plate

49 Holder for laser receiver

50 Tripod*

51 Protective Case

52 Wall Mount

*The accessories illustrated or described are

not included as standard delivery.

-11-

Initial Operation

• Protect the tool against moisture and

direct sun irradiation.

• Do not subject the tool to extreme

temperatures or variations in

temperature.

As an example, do not leave it in vehicles

for longer periods. In case of large

variations in temperature, allow the tool to

adjust to the ambient temperature before

putting it into operation. In case of extreme

temperatures or variations in temperature,

the accuracy of the tool can be impaired.

• Avoid heavy impact or and prevent the

tool from falling. After heavy exterior

impact on the tool, an accuracy check

should always be carried out before

continuing to work (see “Leveling

Accuracy”).

• Switch the tool off during transport.

Switch off the leveling unit, which can be

damaged in the case of intense movement.

Setting Up the Tool

1. Place the tool on a flat surface, or set it on

a standard surveyor’s tripod, using the

built-in 5/8-11 tripod mount (located on the

bottom of the unit).

Note: Due to the high leveling accuracy, the

tool reacts sensitively to ground vibrations and

position changes. Therefore, pay attention that

the position of the tool is stable in order to

avoid operational interruptions due

to re-leveling.

Turning on the Tool

1. Turn on the tool with its power switch. The

tool immediately starts the automatic

leveling. During the leveling, LED 2 flashes

green. The tool is leveled in as soon as the

LED 2 continuously lights up green.

2. To switch on the horizontal and/or vertical

laser beam, press the On/Off button 26

and/or 34 on the control panel of the

rotational laser level 3.

Note: Each time after switching on, the tool is

in rotational operation mode with the lowest

rotational speed.

Turning off the Tool

1. To switch off the horizontal and/or vertical

laser beam, press the On/Off button 26

and/or 34 again.

2. To switch off the tool, push the On/Off

switch 1 into position O. The LED 2

goes out.

• ALWAYS turn off the laser and the main

power switch before transporting or storing

the unit.

Power Standby Mode

When commands are not received for 20

minutes, the GRL160DHV automatically

enters the power standby mode to save

battery life. The LED 2 flashes green, once

per second, to indicate power standby mode.

The timer is reset each time a button is

pressed. The power automatically turns off

after eight hours in Power Standby mode.

When the tool enters power standby mode, it

"remembers" the settings that were in effect,

and returns to these settings when a

command is issued and power returns.

Current settings are not retained when power

is turned off with the main power switch.

• To override power standby mode, press

and hold the on/off button 26 or 34 for three

seconds. The unit emits a beep and two

"chirps," confirming that automatic power

standby is disabled. After automatic power

standby is disabled, the unit continues to

operate for a maximum period of

eight hours.

• To re-enable automatic power standby,

press and hold the button 26 or 34 for three

seconds. A beep and a single "chirp"

confirm the command.

Charge-control Indicator

When the LED 2 flashes yellow, the tool can still

be operated for approx. 5h. The LED continues

to flash until the batteries are replaced or

discharged.

Working with Automatic Leveling

Position the tool on a level and firm support,

or attach it to the tripod 50.

After switching on, the automatic leveling

function automatically compensates

irregularities within the self-leveling range up

to ±6°. The leveling is finished as soon as

the tool stops beeping, the LED turns green,

and the laser beams stop flashing.

If the automatic leveling function is not

possible, e.g. because the surface on which

the tool stands deviates by more than 6° the

tool beeps, the LED flashes red once per

second, and the laser beams flash once

per second.

Operation

-12-

In this case, bring the tool to the level

position and wait for the self-leveling to take

place. As soon as the tool is within the selfleveling range of ±6° respectively, the tool

stops beeping, the LED turns green, and the

laser beams stop flashing.

In case of ground vibrations or position

changes during operation, the tool is

automatically leveled in again. To avoid

errors by moving the tool, check the position

of the laser beams with regard to the

reference points upon re-leveling.

The GRL160DHV rotary laser tool has two

basic operating modes for both the

Horizontal and Vertical laser beams. These

modes are the Rotation Mode and the Line

Dithering/Scan Mode.

Rotation Mode

The laser beam is dispersed throughout the

level or plumb plane. Rotation mode is used

under conditions where laser beam visibility

is poor or nonexistent (for example, outdoors

in daylight). It is not always possible to easily

see a rotating laser beam. A laser receiverdetector makes it possible to detect and

correctly position the rotation mode indoors

or outdoors. The Rotation Mode is the default

mode when the tool is turned on.

When the laser is first turned on, it is rotating

at 350 rpms. Press the keypad rotation mode

button 27 (Horizontal laser beam) or button

33 (Vertical laser beam) to cycle through the

medium and fast speeds, then back to slow

speed. Decrease speed to improve laser

beam visibility, especially for indoor

applications.

Note: To enter rotation mode from line

dithering/scan mode, press the keypad

rotation mode button.

Line Dithering/Scan Mode

The dithering line is a laser dot that moves

rapidly back and forth (dithers), producing a

shorter, beam that is brighter than beams in

the rotation mode. Because of the brighter

laser beam in the dithering mode, a laser

receiver-detector may not be required. The

dithering line length can easily be changed

according to application requirements in

either the level or plumb applications. The

line dithering/scan mode is normally used for

indoor applications.

A choice of six dithering line lengths are

available. The laser beam is less visible at

the longer line length. In some situations, it

may be necessary to use a laser receiverdetector to accurately locate

the beam.

When the laser is first turned on, it is rotating

at 350 rpms. To enter Line Dithering/Scan

Mode, press the keypad Line Dithering/Scan

Mode button 24 (horizontal laser beam) or 30

(vertical laser beam). Continue pressing the

Line Dithering/Scan Mode buttons to cycle

through six different line lengths. The laser

line dither can be positioned through a 360°

range in the level or plumb plane by pressing

the line position control buttons 23 or 25

(horizontal laser line) or buttons 29 or

31(vertical laser line).

Vertical Laser Beam Alignment

During rotational operation, the vertical laser

beam can be aligned on the rotational axis

(X-axis) within the range of ± 2,5°. The

default setting is vertical to the

rotational axis.

1. Press the respective button 32 until the

requested alignment is reached.

Note: If the setting range is exceeded, the

tool emits an audio signal until the laser

beam is returned back within the permitted

setting range.

Working Advice

• Always use the center of the laser point for

marking. The size of the laser point

changes with the distance.

• Working with the remote control. When

pressing the operating controls it is

possible to bring the tool out of its level

position, so that the rotation is briefly

interrupted. This effect can be prevented

by applying the laser receivers’

Remote-control function.

When working with the remote control, pull

the antenna out of the laser receiver.

Operating Modes - Rotation and Line Dithering/Scan Mode

-13-

Out of Level Indication

Out-of-level indicators alert you if the unit is

not on a level surface or if it is out of selfleveling range:

• The LED flashes red once per second

• The laser beam stops rotating (if in rotation

mode) or dithering (if in dithering/dot mode)

and flashes a laser dot in sync with the LED

• The beeper sounds in sync with the laser

beam and LED

Reposition the tool to ensure that it is within the

self-leveling range of ±6°. Once the unit is

within self-leveling range, it stops beeping, the

LED turns green, and the laser beam stops

flashing. The tool resumes the mode of the last

command issued.

Note: When the laser beam is switched off,

the alert is indicated only by the flashing LED

and the audio signal.

Note: The out-of-level indicator overrides all

other indicators. If the laser tool is in low

battery or power standby mode and becomes

out of level, the out-of-level indicator overrides

the low battery or power standby mode

indicator.

Influences on Accuracy

The ambient temperature has the greatest

influence. Especially temperature differences

occurring from the ground upward can divert

the laser beam.

As thermal fluctuation is largest close to the

ground, the tool, if possible, should be

mounted on a commercially available tripod

and placed in the center of the working area.

Apart from exterior influences, device specific

influences (such as heavy impact or drop) can

lead to deviations. Therefore, check the

accuracy of the tool each time before starting

your work.

Should the tool exceed the maximum

deviation during one of the tests, see

recalibration procedure or have it recalibrated

by a Bosch after-sales service center.

Leveling

In the level position, the tool automatically

self-levels within ±6°. When the tool is turned

on. Once the tool is level, the LED turns to a

steady green, and the beeping stops. Press

button 27 (Horizontal laser beam) or button

33 (Vertical laser beam) the laser then begins

rotating at a slow speed.

Calibration

Although the GRL 160DHV laser tools are

calibrated to specification before leaving the

factory, they contain many precision-machined

parts that may be affected if subject to abuse.

Therefore, if a unit is dropped or sustains

significant impact, check its calibration. It is

also recommended that the tool be

periodically calibrated, as a normal

maintenance procedure.

To Calibrate the GRL160DHV:

1. Select a site for calibration that allows the

unit to be placed about 50 ft. (15m) away

from a smooth vertical surface, such as a

wall. Use an Allen wrench to remove the

calibration port covers on the side and

front of the unit. Store the calibration port

covers in a safe place.

2. Set the unit on a level surface at one end

of the range. Place the unit with the side

facing the wall. Ensure the calibration

port faces away from the wall.

3. Turn on the unit with its power switch 1,

then press the keypad laser level

(horizontal) on/off button 26. Select Line

Dither/Scan mode (at the shortest line

length) for best laser beam visibility. If the

beam is not visible, use the laser detector

to locate the beam.

Leveling Accuracy

-14-

4. Mark the laser beam height (center) on the

vertical surface of the wall, as A.

5. Rotate the tool 180°, taking care not to

change its height. The tool should be

positioned with its opposite side facing the

same vertical wall as in step 2. Use the

level (horizontal) Line Dither/Scan position

arrows 23 and 25 to position the laser

beam on the original wall.

6. Mark the height of the laser beam on the

same vertical surface, as B. If B is

positioned at the same height as A,

proceed to step 11. Otherwise, continue to

step 7. The goal of the next few steps is to

position the level laser beam at a height

halfway between A and B

7. Turn off the laser beam and the tool.

Caution: The laser beam must be turned off

and the main power switch in the off position

before proceeding to the next step

8. Insert an Allen wrench into the side

calibration port and locate the calibration

screw. Rotate it clockwise to lower the

beam, or counterclockwise to raise

the beam.

9. Remove the Allen wrench from the

calibration port. Turn on the power, turn on the

level laser beam, then check the height of the

laser beam. Repeat steps 7 and 8 until the

beam is at a height exactly halfway between

A. and B.

Caution: The Allen wrench must be removed

from the calibration port before turning on

the power.

10. Mark this calibrated point on the vertical

surface, as C.

11. Repeat steps 3-7 to confirm the position of

C, then proceed to step 12.

12. Rotate the base unit 90° and position it

with the front facing the vertical surface.

Mark the height of the laser beam, as D.

13. Compare the height of D with C. If the

height of D matches the height of C,

calibration is complete. Turn the power

switch to the off position. Reattach the

calibration port covers, then resume

normal operation. If the height of D does

not match the height of C, proceed to

step 14.

14. Turn off the laser beam and power to the

unit.

Caution: The laser beam must be turned off

and the power switch in the off position before

proceeding to the next step.

15. Insert an Allen wrench into the front

calibration port and locate the calibration

screw. Rotate it clockwise to lower the

beam, or counterclockwise to raise

the beam.

50 ft. (15m)

A

*

50 ft. (15 m)

50 ft. (15m)

Y

B

*

50 ft. (15 m)

50 ft. (15m)

B

A

C

*

Y

50 ft. (15 m)

50 ft. (15m)

*

D

C

50 ft. (15 m)

-15-

16. Remove the Allen wrench from the

calibration port. Turn on the power, turn on

the level laser beam, then check the

height of the laser beam. Repeat steps 14

and 15 until the beam is at the height of C.

Caution: The Allen wrench must be removed

from the calibration port before turning on

the power.

Calibration is complete.

17. Turn the power switch to the off position.

Reattach the calibration port covers, then

resume normal operation.

Note: Complete calibration of the level laser

beam automatically calibrates the plumb laser

beam. Separate calibration of the plumb laser

beam is not required.

Using the Remote Control / Receiver-Detector

The GRL160DHV can also

be operated using the

RCR1 Remote Control /

Receiver. Its receiving

(detecting) function

responds better to the

GRL160DHV laser tools

rather than any other laser

receiver-detector. The

RCR1 allows accurate laser

beam detection outdoors or

under other conditions

when the beam is difficult to

see. The following diagram

illustrates the RCR1

remote control.

The following diagram illustrates RCR1’s LCD

display icon.

Starting Operation of the Laser Receiver

• Protect the laser receiver against moisture.

• Do not subject the laser receiver to extreme

temperatures or variations in temperature.

As an example, do not leave it in vehicles for

longer periods. In case of large variations in

temperature, allow the laser receiver to adjust to

the ambient temperature before putting it into

operation. In case of extreme temperatures or

variations in temperature, the accuracy of the

laser receiver can be impaired.

Under unfavorable light conditions (bright

environment, direct sunlight) and for larger

distances, use the laser receiver for improved

finding of the laser beam. When working with the

laser receiver, select rotational operation with the

highest rotational speed.

Position the laser receiver at least 50cm away

from the rotational laser level. Position the laser

receiver in such a manner that the laser beam

can reach the reception area 18. Set the highest

rotational speed on the rotational laser level.

Attaching the RCR1 to the Bracket

The RCR1 can be attached to the its bracket

with either a level or plumb allocation

depending on whether it is being used to

locate the level or plumb laser beam.

The bracket’s clamp is used to attach it to a

grade/leveling rod.

X

Y

Low Battery

Indicator

Beeper On/Off

Level Line

Dither/Scan Mode

Level Spin Mode/

Speed Select

Plumb Spin Mode/

Speed Select

Fine Resolution

Coarse Resolution

Plumb Line

Dither/Scan Mode

Detector Laser

Beam Locator

Detector LCD Display

50 ft. (15m)

D

C

50 ft. (15 m)

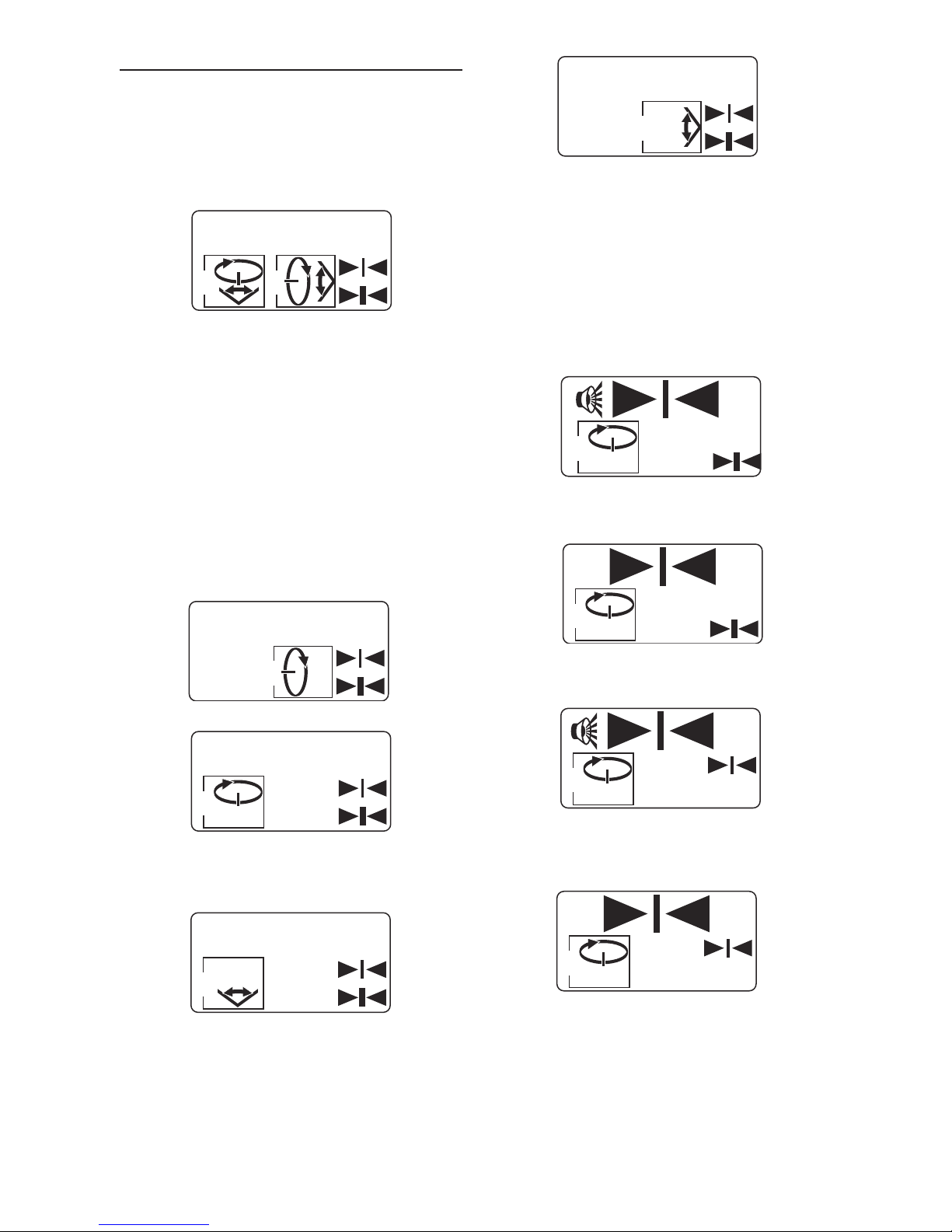

Operation

1. Activate the RCR1 by pressing its power

on/off button. The unit emits a single beep,

and icons in the lower portion of the LCD

display appear, showing all available

options. This confirms that the unit is

activated, but the GRL160DHV and RCR1

have not been turned on.

RF remote control / Laser detector activated

2. Turn on the tool by pressing the laser

on/off button from the keypad. As soon as

one or both of the lasers are turned on,

the displayed icons confirm the selected

laser(s) (level, plumb, or both) and mode

(Spin or Line Dither/Scan). The level and

plumb lasers start up in Spin mode, at the

slowest speed.

Note: The LCD display shows the laser modes

for commands transmitted to the tool from the

RF remote control. Commands made from the

tool controls are not shown on the RF remote

control/laser receiver-detector LCD display.

Plumb laser, Spin mode, Detector off

Level laser, Spin mode, Detector off

Press the Line Dither/Scan button 24 or 30

again to change to Line Dither/Scan mode.

Level laser, Line Dither/Scan Mode,

Detector off

Plumb laser, Line Dither/Scan Mode,

Detector off

3. Laser Detection To turn on the laser

detector, press the Coarse/Fine Select

button 45. On startup, the laser detector

resolution is coarse, with the beeper on

indicated by the icons on LCD display.

Continue pressing the Coarse/Fine 45

Select button to cycle through the following

options:

Beeper on, Laser detector on, Coarse

resolution, Level laser, Spin mode

Beeper off, Laser detector on, Coarse

resolution, Level laser, Spin mode

Beeper on, Laser detector on, Fine resolution,

Level laser, Spin mode

Beeper off, Laser detector on, Fine resolution,

Level laser, Spin mode

-16-

X

Y

Y

X

X

Y

X

X

X

X

-17-

Laser detector power off, Level laser,

Spin mode

4. Locate the laser beam, using the red

sensor panel on the RCR1. As the laser

beam is approached, a single arrow points

in the direction of the beam. The base unit

emits sounds to aid in locating the laser

beam:

• Rapid beep - Indicates that the laser

detector is pointed overly high or far to

the left or right.

• Continuous tone - Indicates that the

laser detector is pointed directly toward

the laser beam.

5. Center the beam by moving the laser

detector in the direction of the arrow.

When the beam is aligned with the center

of the detector panel, both arrows on the

LCD display are lit and the beep is

continuous, indicating that it is properly

centered.

Note: Laser detector orientation depends on

whether it is being used to locate the level or

plumb laser beam.

6. To turn off the RCR1, press its power

On/Off button. There is a double beep for

confirmation, the LCD display becomes

blank, and the lasers shut off.

Charge-control Indicator

When the symbol for the battery indication 37

is indicated on the display 17, the laser

receiver can still be operated for approx. 4

hours.

X

Level laser detection

Plumb laser detection

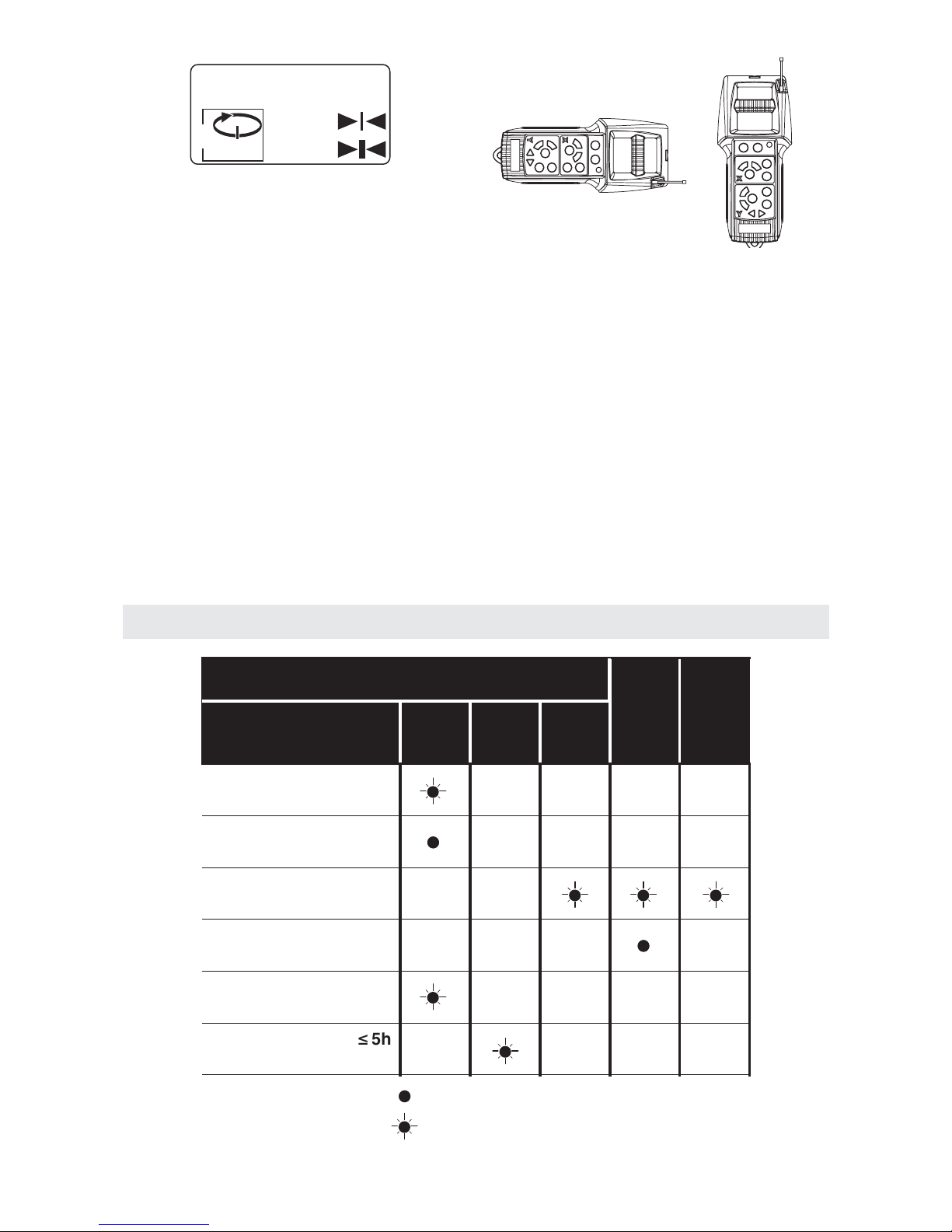

LED Indications

Switching on the tool

Tool leveled in/ready

for operation

Battery voltage for ² 5h

operation

Self-Leveling range

exceeded

Leveling range of the

vertical laser exceeded

Tool In stand-by

operation

Audio Signal

Laser Beam

Continuous lighting and audio signal

Flashing and single audio signals

Green RedYellow

LED

Loading...

Loading...