Bosch GSB 10 Professional, GSB 10 RE Professional, GSB 13 Professional, GSB 13 RE Professional, GSB 16 Professional User guide [ml]

...

OBJ_DOKU-929-005.fm Page 1 Tuesday, June 28, 2011 2:38 PM

Robert Bosch GmbH

Power Tools Division

70745 Leinfelden-Echterdingen

Germany

www.bosch-pt.com

1 609 929 M43 (2011.06) O / 54 ASIA

GSB Professional

10 | 10 RE | 13 | 13 RE | 16 | 16 RE

|

|

|

en Original instructions |

vi |

BΩng hõëng dÿn nguy›n bΩn |

cn |

fr |

Notice originale |

tw |

ar |

ΔϴϠλϷ ϞϴϐθΘϟ ΕΎϤϴϠόΗ |

ko |

fa |

̶Ϡλ έΎ̯ ίήσ ̵ΎϤϨϫέ |

th

id Petunjuk-Petunjuk untuk Penggunaan Orisinal

OBJ_BUCH-61-006.book Page 2 Tuesday, June 28, 2011 2:41 PM

2 |

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

Page 6 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 15 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

Bahasa Indonesia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Halaman

Tiøng Vi·t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Trang

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. Page |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

ΔΤϔλ |

vÝ—U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

ϪΤϔλ |

29

34

39

48

53

|

|

1 609 929 M43 | (28.6.11) |

|

|

Bosch Power Tools |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 3 Tuesday, June 28, 2011 2:41 PM

GSB 16 RE:

2 608 180 009 (DP 500)

GSB 16 RE:

2 608 030 053 (MS 65)

2 608 030 055 (MS 80)

2 602 025 094

2 603 001 009

2 609 160 112

| 3

1 607 950 045

GSB 10/GSB 10 RE:

2 608 571 078

GSB 13/GSB 13 RE/ GSB 16/GSB 16 (RE):

2 608 571 079

GSB 13/GSB 13 RE/ GSB 16/GSB 16 (RE):

2 608 571 080

2 607 990 050 (S 41)

|

|

Bosch Power Tools |

|

|

1 609 929 M43 | (28.6.11) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 4 Tuesday, June 28, 2011 2:41 PM

4 |

|

1 |

4 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

2 |

|

|

|

|

|

|

|

5 |

|

|

|

8 |

7 6 |

|

|

|

|

|

|

|

|

9 |

|

|

|

10 |

|

|

12 |

|

11 |

|

|

|

|

|

|

13 |

GSB 16 RE |

|

|

|

11 |

Professional |

|

|

|

|

|

|

|

|

|

A |

|

B |

|

3 |

|

|

|

|

2 |

X |

10 |

9 |

|

|

|

|

|

||

12 |

|

11 |

|

|

1 609 929 M43 | (28.6.11) |

|

|

|

Bosch Power Tools |

OBJ_BUCH-61-006.book Page 5 Tuesday, June 28, 2011 2:41 PM

| 5

C |

14 |

D |

|

||

|

|

16 |

|

|

17 |

|

|

15 |

E |

|

F |

18 |

1 |

19 |

19 |

1 |

18 |

G |

|

|

H |

|

|

|

8 |

|

|

|

8 |

|

|

|

|

|

|

Bosch Power Tools |

|

|

|

|

1 609 929 M43 | (28.6.11) |

OBJ_BUCH-61-006.book Page 6 Tuesday, June 28, 2011 2:41 PM

6 | English

English

Safety Notes

General Power Tool Safety Warnings

|

Read all safety warnings and all in- |

|

WARNING |

||

structions. Failure to follow the warnings |

||

|

and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

fKeep work area clean and well lit. Cluttered or dark areas invite accidents.

fDo not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

fKeep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

fPower tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

fAvoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is earthed or grounded.

fDo not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

fDo not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges and moving parts. Damaged or entangled cords increase the risk of electric shock.

fWhen operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

fIf operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

Personal safety

fStay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

fUse personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

fPrevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

fRemove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

fDo not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

fDress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

fIf devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

Power tool use and care

fDo not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

fDo not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

fDisconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

fStore idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

fMaintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

fKeep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

fUse the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a hazardous situation.

Service

fHave your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

|

|

1 609 929 M43 | (28.6.11) |

|

|

Bosch Power Tools |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 7 Tuesday, June 28, 2011 2:41 PM

Safety Warnings for Drills

GSB 13/GSB 13 RE/GSB 16/GSB 16 RE

fUse auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

fWhen working with the machine, always hold it firmly with both hands and provide for a secure stance. The power tool is guided more secure with both hands.

GSB 10/GSB 10 RE/GSB 13/GSB 13 RE/GSB 16/ GSB 16 RE

fWear ear protectors when impact drilling. Exposure to noise can cause hearing loss.

fHold power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

fUse suitable detectors to determine if utility lines are hidden in the work area or call the local utility company for assistance. Contact with electric lines can lead to fire and electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property damage or may cause an electric shock.

fSwitch off the power tool immediately when the tool insert jams. Be prepared for high reaction torque that can cause kickback. The tool insert jams when:

—the power tool is subject to overload or

—it becomes wedged in the workpiece.

fSecure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

fAlways wait until the machine has come to a complete stop before placing it down. The tool insert can jam and lead to loss of control over the power tool.

Products sold in GB only: Your product is fitted with a

BS 1363/A approved electric plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible shock hazard and should never be inserted into a mains socket elsewhere.

Products sold in AUS and NZ only: Use a residual current device (RCD) with a rated residual current of 30 mA or less.

English | 7

Product Description and Specifications

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Intended Use

The machine is intended for impact drilling in brick, concrete and stone as well as for drilling in wood, metal and plastic. Machines with electronic control and right/left rotation are also suitable for screwdriving and thread-cutting.

Product Features

The numbering of the product features refers to the illustration of the machine on the graphics page.

1Keyless chuck*

2Front sleeve

3Rear sleeve

4“Drilling/Impact Drilling” selector switch

5Lock-on button for On/Off switch

6On/Off switch

7Thumbwheel for speed preselection (GSB 16 RE)

8Rotational direction switch

(GSB 10 RE/GSB 13 RE/GSB 16 RE)

9Button for depth stop adjustment*

10Wing bolt for adjustment of auxiliary handle*

11Auxiliary handle (insulated gripping surface)*

12Depth stop*

13Handle (insulated gripping surface)

14Chuck key*

15Key type drill chuck*

16Universal bit holder*

17Screwdriver bit*

18Allen key**

19Open-end spanner**

*Accessories shown or described are not part of the standard delivery scope of the product. A complete overview of accessories can be found in our accessories program.

**Commercially available (not included in the delivery scope)

Technical Data

Impact Drill |

GSB ... |

10 |

10 RE |

13 |

13 RE |

16 |

16 RE |

|

Professional |

|

|

|

|

|

|

Article number |

3 601 ... |

B16 0.. |

B16 1.. |

B17 0.. |

B17 1.. |

B18 0.. |

B18 1.. |

|

|

|

|

|

|

|

|

Rated power input |

W |

500 |

500 |

600 |

600 |

701 |

701 |

|

|

|

|

|

|

|

|

Output power |

W |

250 |

250 |

301 |

301 |

351 |

351 |

|

|

|

|

|

|

|

|

No-load speed |

min-1 |

2600 |

0 – 2600 |

2800 |

0 – 2800 |

3000 |

0 – 3000 |

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary. Please observe the article number on the type plate of your machine. The trade names of the individual machines may vary.

|

|

Bosch Power Tools |

|

|

1 609 929 M43 | (28.6.11) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 8 Tuesday, June 28, 2011 2:41 PM

8 | English

Impact Drill |

GSB ... |

10 |

10 RE |

13 |

13 RE |

16 |

16 RE |

|

Professional |

|

|

|

|

|

|

Rotational speed under load, max. |

min-1 |

1610 |

1610 |

1570 |

1570 |

1640 |

1640 |

Impact rate |

min-1 |

25700 |

25700 |

25070 |

25070 |

26270 |

26270 |

Rated torque |

Nm |

1.5 |

1.5 |

1.8 |

1.8 |

2.0 |

2.0 |

|

|

|

|

|

|

|

|

Speed preselection |

|

– |

– |

– |

– |

– |

z |

|

|

|

|

|

|

|

|

Right/left rotation |

|

– |

z |

– |

z |

– |

z |

Spindle collar dia. |

mm |

43 |

43 |

43 |

43 |

43 |

43 |

Max. drilling dia. |

|

|

|

|

|

|

|

– Concrete |

mm |

10 |

10 |

13 |

13 |

16 |

16 |

– Steel |

mm |

8 |

8 |

10 |

10 |

12 |

12 |

– Wood |

mm |

20 |

20 |

25 |

25 |

30 |

30 |

Chuck clamping range |

mm |

1.5 – 10 |

1.5 – 10 |

1.5 – 13 |

1.5 – 13 |

1.5 – 13 |

1.5 – 13 |

Weight according to EPTA-Procedure |

|

|

|

|

|

|

|

01/2003 |

kg |

1.5 |

1.5 |

1.7 |

1.7 |

1.9 |

1.9 |

Protection class |

|

/II |

/II |

/II |

/II |

/II |

/II |

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary. Please observe the article number on the type plate of your machine. The trade names of the individual machines may vary.

Assembly

fBefore any work on the machine itself, pull the mains plug.

Auxiliary Handle (see figure A)

(GSB 13/GSB 13 RE/GSB 16/GSB 16 RE)

fOperate your machine only with the auxiliary handle 11.

The auxiliary handle 11 can be set to any position for a secure and low-fatigue working posture.

Turn the wing bolt for adjustment of the auxiliary handle 10 in anticlockwise direction and set the auxiliary handle 11 to the required position. Then tighten the wing bolt 10 again in clockwise direction.

Adjusting the Drilling Depth (see figure A)

The required drilling depth X can be set with the depth stop

12.

Press the button for the depth stop adjustment 9 and insert the depth stop into the auxiliary handle 11.

Pull out the depth stop until the distance between the tip of the drill bit and the tip of the depth stop correspond with the desired drilling depth X.

Changing the Tool

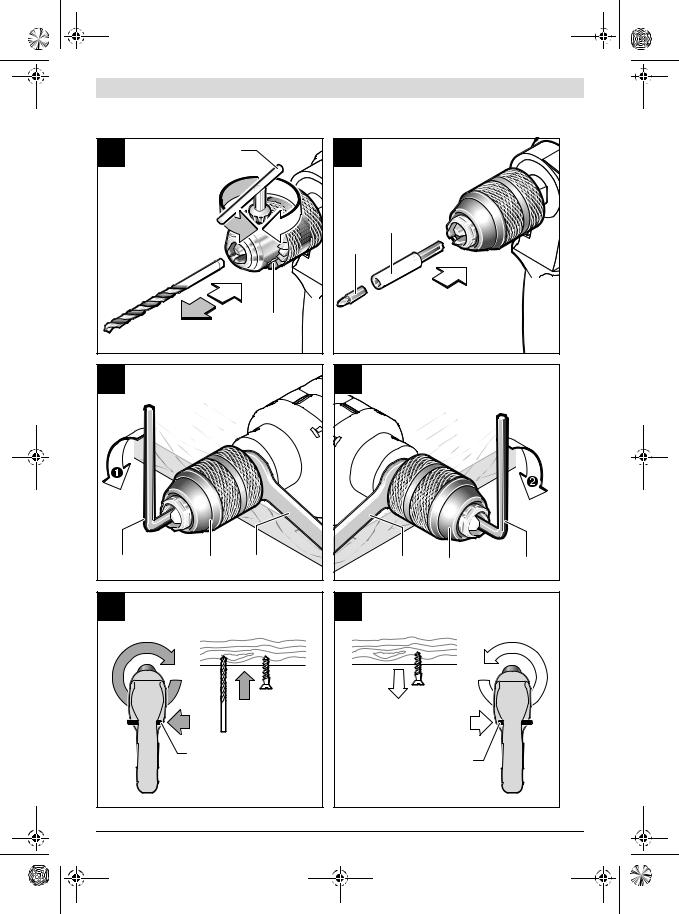

Keyless Chuck (see figure B)

Hold the rear sleeve 3 of the keyless chuck 1 tight and turn the front sleeve 2 in rotation direction n, until the tool can be inserted. Insert the tool.

Hold the rear sleeve 3 of the keyless chuck 1 tight and firmly turn the front sleeve 2 in rotation direction oby hand until the locking action is no longer heard. This automatically locks the drill chuck.

The locking is released again to remove the tool when the front sleeve 2 is turned in the opposite direction.

Key Type Drill Chuck (see figure C)

fWear protective gloves when changing the tool. The drill chuck can become very hot during longer work periods.

Open the key type drill chuck 15 by turning until the tool can be inserted. Insert the tool.

Insert the chuck key 14 into the corresponding holes of the key type drill chuck 15 and clamp the tool uniformly.

Screwdriver Tools (see figure D)

When working with screwdriver bits 17, a universal bit holder 16 should always be used. Use only screwdriver bits that fit the screw head.

For driving screws, always position the “Drilling/Impact Drilling” selector switch 4 to the “Drilling” symbol.

Replacing the Drill Chuck

Removing the Drill Chuck (see figure E)

To dismount the keyless chuck 1, clamp an Allen key 18 into the keyless chuck 1 and position an open-end spanner 19 (size 12 mm) against the spanner flats of the drive spindle. Place the machine on a firm support, e.g., a workbench. Hold the open-end spanner 19 firmly and loosen the keyless chuck 1 by turning the Allen key 18 in rotation direction n. Loosen a tight seated keyless chuck by giving the long end of the Allen key 18 a blow. Remove the Allen key from the keyless chuck and completely unscrew the keyless chuck.

The key type drill chuck 15 is removed in the same manner as the keyless chuck.

Mounting the Drill Chuck (see figure F)

The keyless chuck/key type drill chuck is mounted in reverse order.

The drill chuck must be tightened with a tightening torque of approx. 30–35 Nm.

|

|

1 609 929 M43 | (28.6.11) |

|

|

Bosch Power Tools |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 9 Tuesday, June 28, 2011 2:41 PM

Dust/Chip Extraction

fDusts from materials such as lead-containing coatings, some wood types, minerals and metal can be harmful to one’s health. Touching or breathing-in the dusts can cause allergic reactions and/or lead to respiratory infections of the user or bystanders.

Certain dusts, such as oak or beech dust, are considered as carcinogenic, especially in connection with wood-treat- ment additives (chromate, wood preservative). Materials containing asbestos may only be worked by specialists.

–Provide for good ventilation of the working place.

–It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the materials to be worked.

fPrevent dust accumulation at the workplace. Dusts can easily ignite.

Operation

Starting Operation

fObserve correct mains voltage! The voltage of the power source must agree with the voltage specified on the nameplate of the machine. Power tools marked with 230 V can also be operated with 220 V.

Reversing the Rotational Direction (see figures G–H) (GSB 10 RE/GSB 13 RE/GSB 16 RE)

The rotational direction switch 8 is used to reverse the rotational direction of the machine. However, this is not possible with the On/Off switch 6 actuated.

Right Rotation: For drilling and driving in screws, push the rotational direction switch 8 left to the stop.

Left Rotation: For loosening and unscrewing screws and nuts, press the rotational direction switch 8 through to the right stop.

Setting the Operating Mode

Drilling and Screwdriving

Set the selector switch 4 to the “Drilling” symbol.

Impact Drilling

Set the selector switch 4 to the “Impact drilling” symbol.

The selector switch 4 engages noticeably and can also be actuated with the machine running.

Switching On and Off

To start the machine, press the On/Off switch 6 and keep it pressed.

To lock the pressed On/Off switch 6, press the lock-on button

5.

To switch off the machine, release the On/Off switch 6 or when it is locked with the lock-on button 5, briefly press the On/Off switch 6 and then release it.

English | 9

Adjusting the Speed/Impact Frequency (GSB 10 RE/GSB 13 RE/GSB 16 RE)

The speed/impact rate of the switched on power tool can be variably adjusted, depending on how far the On/Off switch 6 is pressed.

Light pressure on the On/Off switch 6 results in low speed/impact rate. Further pressure on the switch increases the speed/impact rate.

Preselecting the Speed/Impact Frequency (GSB 16 RE)

With the thumbwheel for speed preselection 7, the required speed/impact frequency can be preselected even during operation.

The required speed/impact frequency depends on the material and the working conditions, and can be determined through practical testing.

Working Advice

fApply the power tool to the screw/nut only when it is switched off. Rotating tool inserts can slip off.

After longer periods of working at low speed, allow the machine to cool down by running it for approx. 3 minutes at maximum speed with no load.

For drilling in tiles, set the selector switch 4 to the “Drilling” symbol. Do not switch over to the symbol “Impact Drilling” or work with impact until after drilling through the tile.

Use carbide tipped drill bits when working in concrete, masonry and brick wall.

For drilling in metal, use only perfectly sharpened HSS drill bits (HSS=high-speed steel). The appropriate quality is guaranteed by the Bosch accessories program.

Twist drills from 2.5–10 mm can easily be sharpened with the drill bit sharpener (see accessories).

GSB 16 RE

We recommend the use of a drill stand (see accessories) for work where greater precision is particularly required.

The machine vice, which is available as an accessory, enables secure clamping of workpieces. This prevents the workpiece from turning and any accidents this would cause.

Maintenance and Service

Maintenance and Cleaning

fBefore any work on the machine itself, pull the mains plug.

fFor safe and proper working, always keep the machine and ventilation slots clean.

If the machine should fail despite the care taken in manufacturing and testing procedures, repair should be carried out by an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always include the 10-digit article number given on the type plate of the machine.

|

|

Bosch Power Tools |

|

|

1 609 929 M43 | (28.6.11) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 10 Tuesday, June 28, 2011 2:41 PM

10 | English

After-sales Service and Customer Assistance

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare parts. Exploded views and information on spare parts can also be found under:

www.bosch-pt.com

Our customer service representatives can answer your questions concerning possible applications and adjustment of products and accessories.

People’s Republic of China

China Mainland

Bosch Power Tools (China) Co., Ltd. 567, Bin Kang Road

Bin Jiang District 310052 Hangzhou, P.R.China

Service Hotline: 400 826 8484 Fax: +86 571 8777 4502

E-Mail: contact.ptcn@cn.bosch.com www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Hong Kong Co. Ltd. 21st Floor, 625 King’s Road North Point, Hong Kong

Customer Service Hotline: +852 (21) 02 02 35 Fax: +852 (25) 90 97 62

E-Mail: info@hk.bosch.com www.bosch-pt.com.hk

Indonesia

PT. Multi Mayaka

Kawasan Industri Pulogadung Jalan Rawa Gelam III No. 2 Jakarta 13930

Indonesia

Tel.: +62 (21) 46 83 25 22

Fax: +62 (21) 46 82 86 45/68 23 E-Mail: sales@multimayaka.co.id www.bosch-pt.co.id

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers, 3rd Avenue corner 31st Street, Fort Bonifacio Global City, 1634 Taguig City, Philippines Tel.: +63 (2) 870 3871

Fax: +63 (2) 870 3870 matheus.contiero@ph.bosch.com www.bosch-pt.com.ph

Bosch Service Center: 9725-27 Kamagong Street San Antonio Village Makati City, Philippines Tel.: +63 (2) 899 9091 Fax: +63 (2) 897 6432

rosalie.dagdagan@ph.bosch.com

Malaysia

Robert Bosch (S.E.A.) Pte. Ltd. No. 8A, Jalan 13/6

G.P.O. Box 10818

46200 Petaling Jaya

Selangor, Malaysia

Tel.: +60 (3) 7966 3194

Fax: +60 (3) 7958 3838 cheehoe.on@my.bosch.com Toll-Free: 1800 880 188 www.bosch-pt.com.my

Thailand

Robert Bosch Ltd. Liberty Square Building No. 287, 11 Floor Silom Road, Bangrak Bangkok 10500

Tel.: +66 (2) 6 31 18 79 – 18 88 (10 lines) Fax: +66 (2) 2 38 47 83

Robert Bosch Ltd., P. O. Box 2054 Bangkok 10501, Thailand

Bosch Service – Training Centre 2869-2869/1 Soi Ban Kluay

Rama IV Road (near old Paknam Railway) Prakanong District

10110 Bangkok Thailand

Tel.: +66 (2) 6 71 78 00 – 4 Fax: +66 (2) 2 49 42 96 Fax: +66 (2) 2 49 52 99

Singapore

Robert Bosch (SEA) Pte. Ltd. 11 Bishan Street 21 Singapore 573943

Tel.: +65 6571 2772

Fax: +65 6350 5315 leongheng.leow@sg.bosch.com Toll-Free: 1800 333 8333 www.bosch-pt.com.sg

Vietnam

Robert Bosch Vietnam Co. Ltd 10/F, 194 Golden Building 473 Dien Bien Phu Street Ward 25, Binh Thanh District 84 Ho Chi Minh City

Vietnam

Tel.: +84 (8) 6258 3690 ext. 413 Fax: +84 (8) 6258 3692 hieu.lagia@vn.bosch.com www.bosch-pt.com

|

|

1 609 929 M43 | (28.6.11) |

|

|

Bosch Power Tools |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 11 Tuesday, June 28, 2011 2:41 PM

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd. Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center Inside Australia:

Phone: +61 (01300) 307 044 Fax: + 61 (01300) 307 045 Inside New Zealand:

Phone: +64 (0800) 543 353 Fax: +64 (0800) 428 570 Outside AU and NZ:

Phone: +61 (03) 9541 5555 www.bosch.com.au

Disposal

The machine, accessories and packaging should be sorted for environmental-friendly recycling.

Do not dispose of power tools into household waste!

Subject to change without notice.

!

" "

f 事故。

f 气体。

f 会使你失去对工具的控制。

f 未经改装的插头和相配的插座将减少电击危险。

f 动工具将增加电击危险。

| 11

件。

f 软线。

fRCD RCD

f 疏忽会导致严重人身伤害。

f/

f 发可能会卷入运动部件中。

f 引起的危险。

f 须进行修理。

f 的。

f 护不良的电动工具引发。

|

|

Bosch Power Tools |

|

|

1 609 929 M43 | (28.6.11) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 12 Tuesday, June 28, 2011 2:41 PM

12 |

f 的刀具不易卡住而且容易控制。

f 些与其用途不符的操作可能会导致危险。

f 进行修理。

GSB 13/GSB 13 RE/GSB 16/GSB 16 RE

f 控可能导致伤害。

f 固。

GSB 10/GSB 10 RE/GSB 13/GSB 13 RE/GSB 16/ GSB 16 RE

f 力损伤。

f 成操作者触电。

f 住如果

f 用手持握工件更牢固。

f 具。

並且/

速装备和正/ /

1 *

2

3

4 " / "

5

6

7 (GSB 16 RE)

8 (GSB 10 RE/GSB 13 RE/GSB 16 RE)

9 *

10*

11*

12*

14*

15*

16*

17*

18**

19**

*

**

|

|

|

GSB ... |

10 |

|

10 RE |

13 |

13 RE |

16 |

16 RE |

|

|

||||

|

|

|

|

Professional |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 601 ... |

B16 0.. |

B16 1.. |

B17 0.. |

B17 1.. |

B18 0.. |

B18 1.. |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 |

500 |

600 |

600 |

701 |

701 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

250 |

250 |

301 |

301 |

351 |

351 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/ |

2600 |

0 – 2600 |

2800 |

0 – 2800 |

3000 |

0 – 3000 |

|

|

|||||

|

|

230 V |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 609 929 M43 | (28.6.11) |

|

|

|

|

|

|

|

|

Bosch Power Tools |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 13 Tuesday, June 28, 2011 2:41 PM

| 13

|

GSB ... |

10 |

10 RE |

13 |

13 RE |

16 |

16 RE |

|

Professional |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/ |

1610 |

1610 |

1570 |

1570 |

1640 |

1640 |

|

/ |

25700 |

25700 |

25070 |

25070 |

26270 |

26270 |

|

|

1,5 |

1,5 |

1,8 |

1,8 |

2,0 |

2,0 |

|

|

– |

– |

– |

– |

– |

z |

/ |

|

– |

z |

– |

z |

– |

z |

|

|

43 |

43 |

43 |

43 |

43 |

43 |

|

|

|

|

|

|

|

|

– |

|

10 |

10 |

13 |

13 |

16 |

16 |

|

|||||||

– |

|

8 |

8 |

10 |

10 |

12 |

12 |

– |

|

20 |

20 |

25 |

25 |

30 |

30 |

|

|

1,5 – 10 |

1,5 – 10 |

1,5 – 13 |

1,5 – 13 |

1,5 – 13 |

1,5 – 13 |

EPTA-Procedure |

|

|

|

|

|

|

|

01/2003 |

|

1,5 |

1,5 |

1,7 |

1,7 |

1,9 |

1,9 |

|

|

/II |

/II |

/II |

/II |

/II |

/II |

|

|

|

|

|

|

|

|

230 V

f 出插头。

A

(GSB 13/GSB 13 RE/GSB 16/GSB 16 RE)

f 11.

11

1011 10

A

12 X

9 11

和需要的钻深X

B

1 3 n 2

1 3 o2

2

C

f 十分炽热。

15

14 15

D

17 16

/ 4

E

1 181 19 1219 n18 118

15

F

/

30–35

30–35

|

|

Bosch Power Tools |

|

|

1 609 929 M43 | (28.6.11) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 14 Tuesday, June 28, 2011 2:41 PM

14 |

/

f 病。

含石棉的物料。

–P2

f

f 标示的电压一致。

G–H

(GSB 10 RE/GSB 13 RE/GSB 16 RE)

86

8

/ 8

4

4

4

/

6

5 6

65 6

/

(GSB 10 RE/GSB 13 RE/GSB 16 RE)

6/

6 / /

/ (GSB 16 RE)

7 //

/

f/

上滑开。

3

4

头。

HSSHSS =

2,5–10

GSB 16 RE

f 出插头。

f 高工作品质和安全性。

的顾客服务处修理。

10

|

|

1 609 929 M43 | (28.6.11) |

|

|

Bosch Power Tools |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 15 Tuesday, June 28, 2011 2:41 PM

护和备件的问题。以下的网页中有爆炸图和备件的资 料

www.bosch-pt.com

设定本公司产品及附件的问题。

询。

滨江区滨康路567

310052400 826 8484+86 571 8777 4502contact.ptcn@cn.bosch.com www.bosch-pt.com.cn

x 625 21

+852 (21) 02 02 35

+852 (25) 90 97 62

info@hk.bosch.comwww.bosch-pt.com.hk

邮箱号码100156

70745 Leinfelden-Echterdingen -

Deutschland

和废弃的包装材料。

!

" "

| 15

f 事故。

f 氣體。

f 會使你失去對工具的控制。

f 未經改裝的插頭和相配的插座將減少電擊危險。

f 果你身體接地會增加電擊危險。

f 動工具將增加電擊危險。

件。

f,

fRCD RCD

f 疏忽會導致嚴重人身傷害。

f 如適當條件下使用防塵面具、防滑安全鞋、安全帽、 聽力防護等裝置能減少人身傷害。

f/

f 留在電動工具旋轉零件上的扳手或鑰匙會導致人身傷 害。

f 樣在意外情況下能很好地控制電動工具。

f 髮可能會捲入運動部件中。

f 引起的危險。

|

|

Bosch Power Tools |

|

|

1 609 929 M43 | (28.6.11) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-61-006.book Page 16 Tuesday, June 28, 2011 2:41 PM

16 |

f 選用適當設計的電動工具會使你工作更有效、更安 全。

f 須進行修理。

f 種防護性措施將減少工具意外起動的危險。

f 的。

f 護不良的電動工具引發。

f 的刀具不易卡住而且容易控制。

f 些與其用途不符的操作可能會導致危險。

f 性。

GSB 13/GSB 13 RE/GSB 16/GSB 16 RE

f 控可能導致傷害。

f 固。

GSB 10/GSB 10 RE/GSB 13/GSB 13 RE/GSB 16/

GSB 16 RE

f 力損傷。

f 成操作者觸電。

f 住如果

f 用手持握工件更牢固。

f 具。

並且/

速裝備和正/ /

1 *

2

3

4 " / "

5

6

7 (GSB 16 RE)

8 (GSB 10 RE/GSB 13 RE/GSB 16 RE)

9 *

10*

11*

12*

14*

15*

16*

17*

18**

19**

*

**

|

|

1 609 929 M43 | (28.6.11) |

|

|

Bosch Power Tools |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...