Honeywell W7750A User Manual

Excel 10

W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

SYSTEM ENGINEERING |

|

|

Contents |

Introduction .................................................................................................................................. |

6 |

Description of Devices.......................................................................................... |

6 |

Control Application ............................................................................................... |

7 |

Control Provided................................................................................................... |

7 |

Products Covered................................................................................................. |

8 |

Organization of Manual ........................................................................................ |

8 |

Applicable Literature............................................................................................. |

8 |

Product Names..................................................................................................... |

9 |

Agency Listings .................................................................................................... |

9 |

Abbreviations and Definitions............................................................................... |

10 |

Construction ......................................................................................................... |

11 |

Controllers ...................................................................................................... |

11 |

PERFORMANCE SPECIFICATIONS ......................................................... |

13 |

LONMARK® Functional Profile ..................................................................... |

17 |

Inputs/Outputs: ............................................................................................... |

18 |

ANALOG INPUTS:...................................................................................... |

18 |

DIGITAL INPUTS: ....................................................................................... |

19 |

TRIAC OUTPUTS ON THE (W7750B,C MODELS ONLY):........................ |

19 |

DIGITAL OUTPUTS: ................................................................................... |

19 |

Wall Modules .................................................................................................. |

20 |

Duct Sensor .................................................................................................... |

20 |

Configurations ...................................................................................................... |

22 |

General ........................................................................................................... |

22 |

Allowable Heating and Cooling Equipment Configurations ............................ |

24 |

STAGED HEATING/COOLING CONTROL ................................................ |

24 |

MODULATING HEATING/COOLING CONTROL ....................................... |

24 |

HEAT PUMP CONTROL............................................................................. |

24 |

ECONOMIZER CONTROL ......................................................................... |

25 |

PNEUMATIC ACTUATOR CONTROL ........................................................ |

25 |

MIXED-OUTPUT-TYPE CONTROL ........................................................... |

26 |

Occupancy Sensor ......................................................................................... |

26 |

Window Open/Closed Digital Input ................................................................. |

26 |

Wall Module Options ....................................................................................... |

26 |

Dirty Filter Monitor .......................................................................................... |

27 |

Indoor Air Quality (IAQ) Override ................................................................... |

27 |

Smoke Control ................................................................................................ |

27 |

Freeze Stat ..................................................................................................... |

27 |

Modes of Operation .............................................................................................. |

27 |

Application Steps .................................................................................................................................. |

29 |

Overview .............................................................................................................. |

29 |

Step 1. Plan the System....................................................................................... |

29 |

Step 2. Determine Other Bus Devices Required .................................................. |

29 |

Step 3. Lay Out Communications and Power Wiring ........................................... |

30 |

LONWORKS® Bus La yout ................................................................................ |

30 |

Power Wiring .................................................................................................. |

32 |

POWER BUDGET CALCULATION EXAMPLE .......................................... |

32 |

LINE LOSS ................................................................................................. |

33 |

Step 4. Prepare Wiring Diagrams......................................................................... |

35 |

® U.S. Re gistered Trademark |

|

Copyright © 2000 Hone ywell Inc. • All Rights Reserved |

74-2958- 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

General Considerations .................................................................................. |

35 |

W7750 Controllers .......................................................................................... |

36 |

FACTORY DEFAULT DIGITAL OUTPUTS: ................................................ |

37 |

LONWORKS® Bus Termination Module ........................................................... |

43 |

Step 5. Order Equipment ..................................................................................... |

45 |

Step 6. Configure Controllers............................................................................... |

48 |

Step 7. Troubleshooting ....................................................................................... |

48 |

Troubleshooting Excel 10 Controllers and Wall Modules ............................... |

48 |

Temperature Sensor and Setpoint Potentiometer Resistance Ranges .......... |

49 |

Alarms ............................................................................................................ |

49 |

Broadcasting the Service Message ................................................................ |

50 |

W7750 Controller Status LED ........................................................................ |

50 |

T7770C,D Wall Module Bypass Pushbutton and Override LED ..................... |

51 |

T7560A,B Digital Wall Module Bypass Pushbutton and LCD Display Occupancy |

|

Symbols .......................................................................................................... |

51 |

Appendices .................................................................................................................................. |

51 |

Appendix A. Using E-Vision to Commission a W7750 Controller......................... |

51 |

Sensor Calibration .......................................................................................... |

51 |

Setting the Pid Parameters ............................................................................ |

51 |

Appendix B. Sequences of Operation. ................................................................. |

52 |

Common Operations ...................................................................................... |

53 |

Room Temperature Sensor (RmTemp)....................................................... |

54 |

Remote Setpoint (RmtStptPot) ................................................................... |

55 |

Setpoint Limits (LoSetptLim and HiSetptLim)............................................. |

55 |

Bypass Mode (StatusOvrd and StatusLed) ................................................ |

55 |

BYPASSTIME............................................................................................. |

55 |

OverrideType .............................................................................................. |

55 |

OverridePriority........................................................................................... |

55 |

Cycles per Hour (ubHeatCph and ubCoolCph) .......................................... |

55 |

T7770C,D or T7560A,B Wall Module Bypass Pushbutton Operation......... |

55 |

Standby Mode (StatusOcySen) .................................................................. |

56 |

Continuous Unoccupied Mode ................................................................... |

56 |

Occupancy Mode and Manual Override Arbitration.................................... |

56 |

Time Clock (Occ_Time_Clock) ................................................................... |

57 |

Schedule Master (Sched_Master) .............................................................. |

57 |

Setpoint Ramping ....................................................................................... |

57 |

Recovery Ramping for Heat Pump Systems .............................................. |

57 |

Fan Operation............................................................................................. |

58 |

Window Sensor (StatusWndw)................................................................... |

58 |

Smoke Control............................................................................................ |

58 |

Demand Limit Control (DLC) ...................................................................... |

58 |

Dirty Filter Monitor ...................................................................................... |

59 |

Start-Up ...................................................................................................... |

59 |

Temperature Control Operations .................................................................... |

59 |

Staged Cooling Control .............................................................................. |

60 |

Staged Heating Control .............................................................................. |

60 |

Cascade Control of Modulating Cooling/Heating........................................ |

61 |

Series 60 Modulating Control ..................................................................... |

61 |

Pulse Width Modulating (PWM) Control ..................................................... |

61 |

Outdoor Air Lockout of Heating/Cooling ..................................................... |

61 |

Economizer Damper Control ...................................................................... |

61 |

Indoor Air Quality (IAQ) Override ............................................................... |

62 |

Freeze Stat ................................................................................................. |

62 |

Discharge Air Low Limit Control ................................................................. |

62 |

Economizer Enable/Disable Control........................................................... |

62 |

Appendix C. Complete List of Excel 10 W7750 Controller User Addresses. ....... |

62 |

User Address Indexes (all in alphabetical order) ............................................ |

63 |

Mappable User Addresses and Table Number ............................................... |

64 |

Failure Detect User Addresses and Table Number ........................................ |

65 |

Appendix D. Q7750A Excel 10 Zone Manager Point Estimating Guide............... |

109 |

Approximate Memory Size Estimating Procedure. ......................................... |

109 |

Appendix E. Sensor Data for Calibration. ............................................................ |

110 |

Resistance Sensors. ...................................................................................... |

110 |

Voltage/Current Sensors. ............................................................................... |

112 |

72-2958— 1 |

2 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER |

|

List of Figures |

|

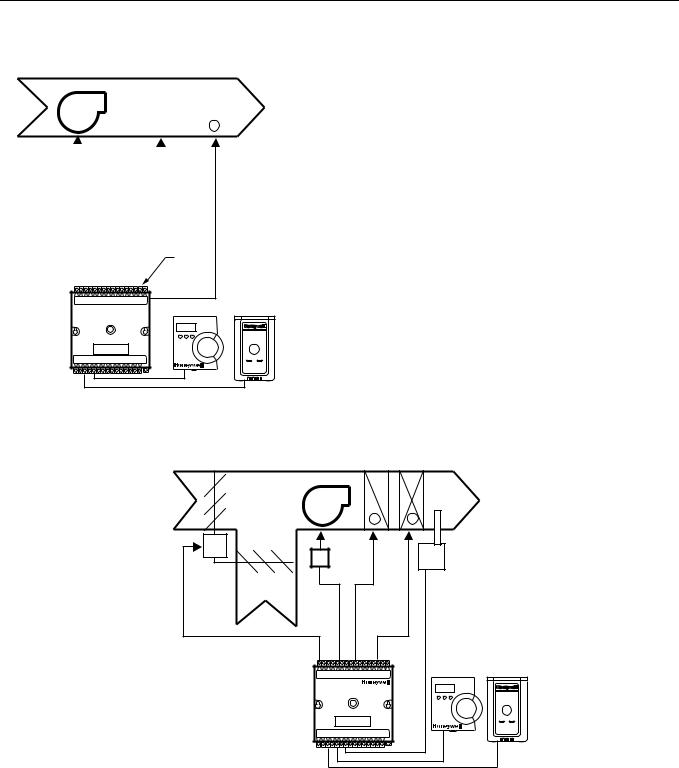

Fig. 1. Typical system overview. ................................................................................................................................................ |

6 |

Fig. 2. Typical W7750 control application. ................................................................................................................................. |

7 |

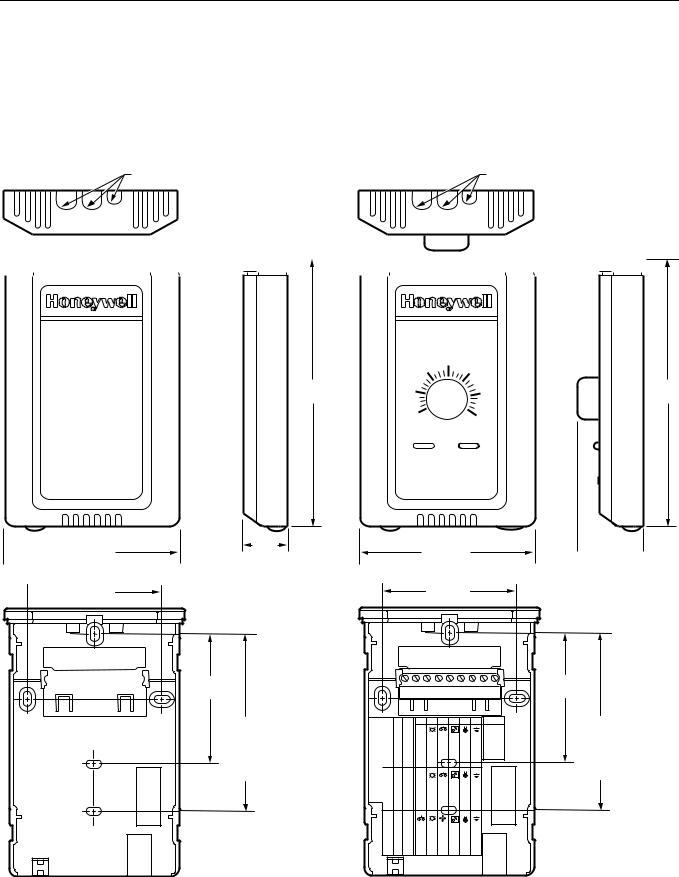

Fig. 3. Excel 10 W7750A Constant Volume AHU Controller. ..................................................................................................... |

12 |

Fig. 4. W7750A construction in in. (mm). ................................................................................................................................... |

13 |

Fig. 5. Excel 10 W7750B Constant Volume AHU Controller. ..................................................................................................... |

14 |

Fig. 6. Excel 10 W7750C Constant Volume AHU Controller. .................................................................................................... |

15 |

Fig. 7. W7750B,C construction in in. (mm). W7750C (shown) has three 4 to 20 mA analog outputs.) ..................................... |

16 |

Fig. 8. DIN rail adapters. ............................................................................................................................................................ |

17 |

Fig. 9. Functional profile of LONMARK® RTU object details (variables not implemented in Excel 10 CVAHU |

|

are greyed)........................................................................................................................................................................ |

18 |

Fig. 10. T7770A,B,C,D construction in in. (mm). ....................................................................................................................... |

20 |

Fig. 11. T7560A,B construction in in. (mm). ............................................................................................................................... |

21 |

Fig. 12. C7770A construction in in. (mm). .................................................................................................................................. |

21 |

Fig. 13. Fan with two stages of heating and two stages |

|

of cooling........................................................................................................................................................................... |

24 |

Fig. 14. Fan, modulating heating and modulating cooling. ......................................................................................................... |

24 |

Fig. 15. Heat pump with two compressors and auxiliary heat stage(s)....................................................................................... |

25 |

Fig. 16. Economizer control. ...................................................................................................................................................... |

25 |

Fig. 17. Modulating heat with pneumatic valve actuator............................................................................................................. |

26 |

Fig. 18. Connecting the portable operator terminal |

|

to the LONWORKS® Bus..................................................................................................................................................... |

29 |

Fig. 19. Wiring layout for one doubly terminated daisy-chain LONWORKS® Bus segment. ........................................................ |

31 |

Fig. 20. Wiring layout for two singly terminated LONWORKS® Bus segments............................................................................. |

32 |

Fig. 21. NEMA class 2 transformer voltage output limits. ........................................................................................................... |

34 |

Fig. 22. Power wiring details for one Excel 10 per transformer. ................................................................................................. |

34 |

Fig. 23. Power wiring details for two or more Excel 10s per transformer. .................................................................................. |

34 |

Fig. 24. Transformer power wiring details for one Excel 10 used in UL 1995 equipment (U.S. only)......................................... |

35 |

Fig. 25. Attaching two or more wires at terminal blocks.............................................................................................................. |

36 |

Fig. 26. W7750B High-Side/Low-Side selectable switching and jumper location....................................................................... |

36 |

Fig. 27. Typical W7750A Controller AHU application wiring diagram. (For more information on note 2, |

|

refer to Fig. 25.)................................................................................................................................................................ |

38 |

Fig. 28. Typical W7750A Controller with separate transformer application wiring diagram. |

|

(For more information on note 2, refer to Fig. 25.) ............................................................................................................ |

38 |

Fig. 29. W7750A Controller floating economizer damper wiring diagram. (For more information on note 2, refer to Fig. 25.)... |

39 |

Fig. 30. Typical W7750B Controller with staged heating and cooling wiring diagram. (For more information on note 2, refer to Fig. 25.) .................................................................................................................................................................................... 40 Fig. 31. W7750B Controller with floating heating, cooling and economizer wiring diagram. (For more information on note 2, refer

to Fig. 25.) ......................................................................................................................................................................... |

40 |

Fig. 32. W7750B,C Controller PWM damper actuator wiring diagram. (For more information on note 2, refer to |

|

Fig. 25.) ............................................................................................................................................................................. |

41 |

Fig. 33. W7750B,C wiring diagram with 4 to 20 mA enthalpy sensors and digital inputs. (For more information on note 2, refer to

Fig. 25.) ............................................................................................................................................................................. |

41 |

Fig. 34. W7750B,C wiring diagram with C7600C 4 to 20 mA solid state humidity sensor. (For more information on note 2, refer to

Fig. 25.) ............................................................................................................................................................................. |

42 |

Fig. 35. W7750C Controller with 4-to-20 mA heating, cooling and economizer wiring diagram. AOs must use terminals 16, 17 or

18. The AOs can be set to be reverse acting. (For more information on note 2, refer to Fig. 25.).................................... |

42 |

|

Fig. 36. Pneumatic transducer to W7750B,C |

|

|

(B shown, see triangle note 4). ......................................................................................................................................... |

43 |

|

Fig. 37. RP7517,B pneumatic transducer to W7750C. ............................................................................................................... |

43 |

|

Fig. 38. Typical doubly terminated daisy-chain LONWORKS® Bus segment termination module wiring diagram. ..................... |

44 |

|

Fig. 39. LONWORKS® Bus termination wiring options. ............................................................................................................... |

45 |

|

Fig. 40. Temperature sensor resistance plots............................................................................................................................. |

49 |

|

Fig. 41. Location of the Service Pin Button................................................................................................................................. |

50 |

|

Fig. 42. LED location on W7750. ................................................................................................................................................ |

51 |

|

Fig. 43. The T7770C,D Wall Modules LED and Bypass pushbutton locations........................................................................... |

51 |

|

Fig. 44. |

The T7560A,B Digital Wall Module Bypass pushbutton location................................................................................... |

51 |

Fig. 45. |

LED and Bypass pushbutton operation. ....................................................................................................................... |

56 |

Fig. 46. |

Setpoint ramping parameters with ramp rate calculation............................................................................................... |

57 |

Fig. 47. |

Setpoint ramping parameters with setpoint calculation.................................................................................................. |

58 |

3 |

74-2958— 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER |

|

|

Fig. 48. Setpoint ramping parameters with ramp rate calculation............................................................................................... |

58 |

|

Fig. 49. Schematic diagram for a typical W7750B Unit. ............................................................................................................. |

59 |

|

Fig. 50. Staged output control versus PID Error. ....................................................................................................................... |

60 |

|

Fig. 51. Point capacity estimate for Zone Manager. .................................................................................................................. |

109 |

|

Fig. 52. Graph of Sensor Resistance versus Temperature......................................................................................................... |

110 |

|

Fig. 53. Graph of Sensor Resistance versus Temperature......................................................................................................... |

110 |

|

Fig. 54. Graph of Sensor Resistance versus Temperature......................................................................................................... |

111 |

|

Fig. 55. Graph of Sensor Resistance versus Temperature......................................................................................................... |

111 |

|

Fig. 56. Graph of Sensor Resistance versus Temperature......................................................................................................... |

112 |

|

Fig. 57. Graph of Sensor Voltage versus Humidity..................................................................................................................... |

112 |

|

Fig. 58. C7600C output current vs. humidity............................................................................................................................... |

112 |

|

Fig. 59. Graph of Sensor Current versus Enthalpy (volts). ......................................................................................................... |

113 |

|

Fig. 60. Partial psychometric chart for a C7400A Solid State Enthalpy Sensor. ........................................................................ |

114 |

|

Fig. 61. |

C7400A Solid State Enthalpy Sensor output current vs. relative humidity. ................................................................... |

114 |

Fig. 62. |

Graph of Sensor Voltage versus CO2 concentration..................................................................................................... |

115 |

Fig. 63. |

Graph of Sensor Voltage versus input Voltage to A/D.................................................................................................. |

115 |

Fig. 64. |

Graph of Sensor Voltage (Vdc) versus Pressure (Inw).................................................................................................. |

116 |

74-2958— 1 |

4 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER |

|

List of Tables |

|

Table 1. Agency Listing. ............................................................................................................................................................. |

9 |

Table 2. List of Differences in W7750A and W7750B,C Controllers........................................................................................... |

11 |

Table 3. Common Configuration Options Summary For W7750A,B,C Controllers..................................................................... |

22 |

Table 4. Configuration Options Summary For W7750A,B,C Controllers. ................................................................................... |

23 |

Table 5. Modes Of Operation For The Excel 10 W7750 Controller . .......................................................................................... |

27 |

Table 6. Application Steps. ......................................................................................................................................................... |

29 |

Table 7. LONWORKS® Bus Configuration Rules And Device Node Numbers. ............................................................................ |

30 |

Table 8. VA Ratings For Transformer Sizing. ............................................................................................................................. |

33 |

Table 9. Field Wiring Reference Table (Honeywell listed as AK#### or equivalent).................................................................. |

36 |

Table 10. W7750A Version I/O Description. ............................................................................................................................... |

37 |

Table 11. Excel 10 W7750 Controller Ordering Information. ...................................................................................................... |

46 |

Table 12. Excel 10 Alarms.......................................................................................................................................................... |

49 |

Table 14. Common Configuration Options Summary For W7750A,B,C Controllers................................................................... |

53 |

Table 15. Configuration Options Summary For W7750A,B,C Controllers. ................................................................................. |

54 |

Table 16. Bypass Pushbutton Operation. ................................................................................................................................... |

55 |

Table 17. Interstage Minimum Times.......................................................................................................................................... |

60 |

Table 18. Excel 10 W7750 Controller User |

|

Address Point Types................................................................................................................................................................... |

62 |

Table 20. Input/Output Points. .................................................................................................................................................... |

67 |

Table 21. Control Parameters..................................................................................................................................................... |

73 |

Table 22. Energy Management Points........................................................................................................................................ |

78 |

Table 23. Status Points............................................................................................................................................................... |

81 |

Table 24. Calibration Points........................................................................................................................................................ |

93 |

Table 25. Configuration Parameters. .......................................................................................................................................... |

94 |

Table 26. LONMARK® /Open System Points. ............................................................................................................................... |

97 |

Table 27. Direct Access And Special Points............................................................................................................................... |

106 |

Table 28. Data Share Points....................................................................................................................................................... |

108 |

Table 29. Sensor Resistance Versus Temperature.................................................................................................................... |

110 |

Table 30. Sensor Resistance Versus Temperature.................................................................................................................... |

110 |

Table 31. Sensor Resistance Versus Temperature.................................................................................................................... |

111 |

Table 32. Sensor Resistance Versus Temperature.................................................................................................................... |

111 |

Table 33. Sensor Resistance Versus Temperature.................................................................................................................... |

111 |

Table 34. Sensor Voltage Versus Humidity. ............................................................................................................................... |

112 |

Table 35. Sensor Voltage Versus Humidity. ............................................................................................................................... |

112 |

Table 36. Sensor Current Versus Enthalpy (volts)...................................................................................................................... |

113 |

Table 37. Sensor Voltage Versus CO2 Concentration. .............................................................................................................. |

115 |

Table 38. Sensor Voltage Versus Input Voltage To A/D............................................................................................................. |

115 |

Table 39. Sensor Voltage (Vdc) Versus Pressure (Inw). ............................................................................................................ |

116 |

5 |

74-2958— 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

INTRODUCTION

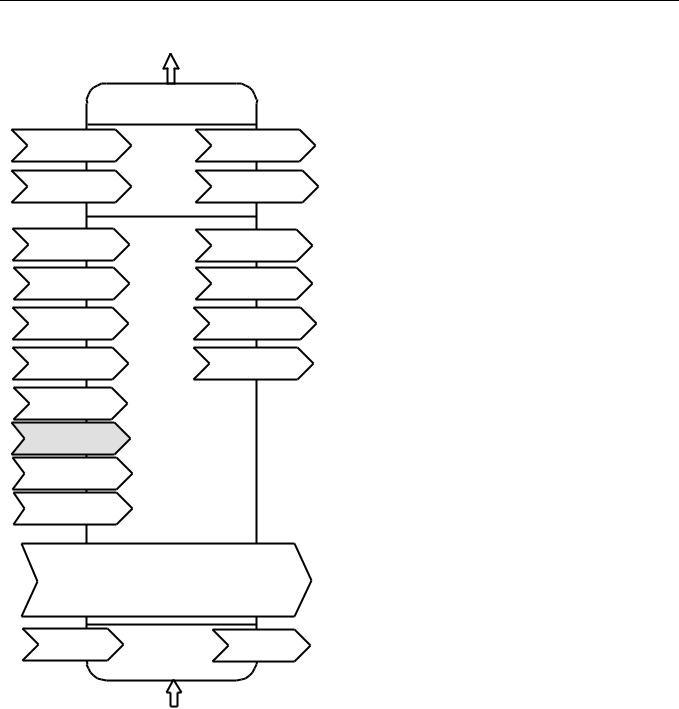

LONWORKS network (LONWORKS Bus) for communications, and conforms with the LONMARK HVAC Interoperability standard for Roof Top Unit Controllers (see Fig. 9).

Description of Devices

The W7750 is the Constant Volume Air Handling Unit (CVAHU) Controller in the Excel 10 product line family. The CVAHU is a LONMARK compliant device designed to control single zone and heat pump air handlers. W7750 systems control the space temperature in a given zone by regulating the heating and cooling equipment in the air handler that delivers air to that space. The W7750 air handler is typically an all-in-one constant air volume packaged unit, located on the roof of the building. In addition to standard heating and cooling control, the W7750 provides many options and advanced system features that allow state-of-the-art commercial building control. The W7750 Controller is capable of stand-alone operation; however, optimum functional benefits are achieved when the network communication capabilities are used. The W7750 utilizes the Echelon

The T7770 or T7560 direct-wired Wall Modules are used in conjunction with W7750 Controllers. The zone controlled by the W7750 Controller typically can use a T7770A through D or a T7560A,B Wall Module. Additional features available in T7770A through D models include analog setpoint input knob, override digital input pushbutton, override status LED and LONWORKS Bus network access jack. Additional features available in T7560A,B models include analog setpoint input knob, override digital input pushbutton, humidity sensor (T7650B model), override status LCD and digital display.

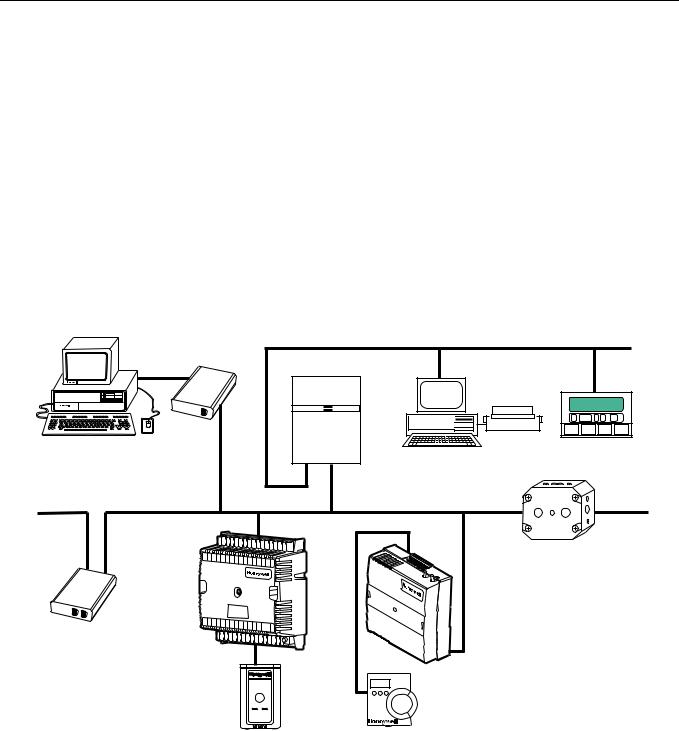

The Q7750A Excel 10 Zone Manager is a communications interface that allows devices on the LONWORKS Bus network to communicate with devices on the standard EXCEL 5000 System C-Bus. Fig. 1 shows an overview of a typical system layout. The Q7750A also provides some control and monitoring functions.

Q7752A |

|

|

|

|

|

|

|

|

|

|

C-BUS COMMUNICATION NETWORK |

|

|||||

LONWORKS BUS |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

||||||||||||

SERIAL |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

ADAPTER |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXCEL 10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q7750A |

|

|

PERSONAL COMPUTER TOOLS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ZONE |

|

EXCEL 500 |

E-VISION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MANAGER |

EXCEL BUILDING SUPERVISOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

CARE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C-BUS TO LONWORKS BUS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INTERFACE DEVICE |

Q7740A |

|

LONWORKS-BUS COMMUNICATIONS NETWORK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-WAY |

||

|

|

|

|

|

|

|

|

|

|

|

|

LONWORKS BUS COMMUNICATIONS NETWORK |

REPEATER |

||||

31 |

30 |

29 |

28 |

27 |

26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

24 |

23 |

22 |

21 |

20 |

19 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

18 |

17 |

16 |

|

|

|||||

|

EXCEL 10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXCEL 10 W7751F |

|

W7750B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CVAHU |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PANEL PLENUM |

|

CONTROLLER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOUNT VERSION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VARIABLE AIR VOLUME |

Q7751A |

1 |

|

|

|

|

|

|

|

|

10 |

11 |

12 |

13 |

14 |

15 |

CONTROLLER |

|

2 |

3 |

4 |

5 |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

8 |

9 |

|

|

|

|

|

|

|

|||||

FTT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LONWORKS BUS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ROUTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXCEL 10 T7770 |

|

|

|

|

|

|

|

|

EXCEL 10 T7560A, B |

||||||

|

WALL MODULE |

|

|

|

|

|

|

|

|

WALL MODULE |

||||||

M17487

Fig. 1. Typical system overview.

74-2958— 1 |

6 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

Control Application

W7750 systems in commercial buildings typically incorporate a packaged air handler system that delivers a constant volume of air at preconditioned temperatures to the zone being served. Each zone is usually serviced by a separate AHU; however, sometimes two or more AHUs service the same zone. Note that the W7750 is not designed to control Variable Air Volume (VAV) air handlers or Multi-Zone air handlers, where one air handler simultaneously controls the space temperature in many zones.

OA TEMP

The W7750 can control staged or modulating heating and cooling coils, mixed air economizer dampers, and the system fan. Control of heat pump units, where the compressor(s) is used for both cooling and heating, is also provided. The zone the W7750 services can use a T7770 or T7650 for space temperature sensing and an LONWORKS Bus network access for users. Fig. 2 shows a typical W7750 control application.

|

COOL |

HEAT |

FILTER |

COIL |

COIL |

|

FAN |

|

OUTDOOR |

|

|

AIR |

- |

+ |

|

||

M |

|

|

EXCEL 10

W7750

CVAHU

DA TEMP

RA TEMP |

ROOF |

CEILING

OCCUPANCY

SENSOR

RETURN |

T7770 OR T7560A,B |

DISCHARGE |

M17488 |

|

AIR |

AIR |

|||

|

WINDOW CONTACT

Fig. 2. Typical W7750 control application.

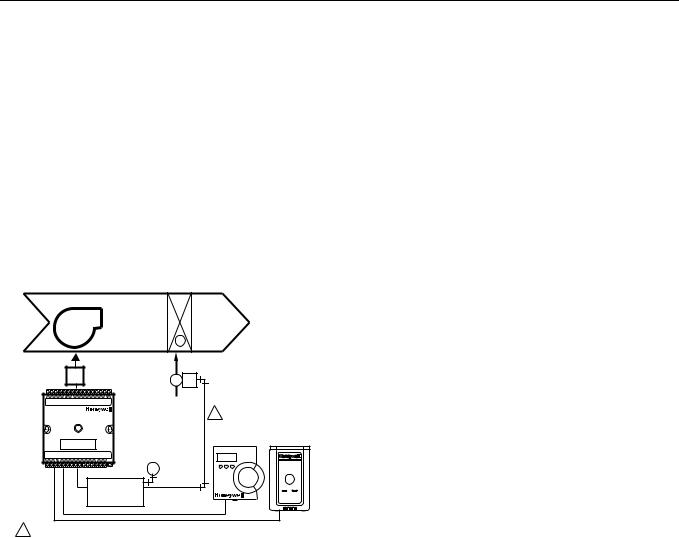

Control Provided

The W7750 Controller is designed to control a single air handler to maintain the units space temperature at the current setpoint. Heating and cooling control is provided for either staged or modulating equipment. Up to four stages of mechanical cooling and up to four stages of heating are allowed. Modulating outputs can be either floating type such as a Series 60 control, or Pulse Width Modulated (PWM W7750B,C only) control.

The economizer dampers can be controlled directly with floating or PWM outputs, or indirectly using a digital output as an enable/disable signal to a packaged economizer controller. The economizer enable function, which decides when to allow outdoor air to be used for free cooling, can be configured to

one of ten strategies based on the inputs. For more details, see Appendix B— Sequences of Operation. When the economizer position is controlled from the W7750, the minimum position setting (for ventilation requirements) can be adjusted based on indoor air quality (IAQ) needs in the space. IAQ monitoring is provided through either a CO2 sensor or a digital input from a space-mounted IAQ limit switch.

For heat pump configurations, up to four compressors can be controlled, along with up to four stages of auxiliary heat, and a heat/cool change over valve. Including the supply fan, the combination of these items may not exceed eight outputs if a W7750B,C is used, or six outputs for a W7750A. (The eight outputs on the W7750C consist of five digital and three analog outputs.)

7 |

74-2958— 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

Like the W7751 VAV Box Controller, the W7750 Controller can |

Form No. |

Title |

||

monitor a space-mounted occupancy sensor, and a door/ |

|

|

||

window contact. These inputs affect the operational mode of |

74-2956 |

Excel 10 W7750A,B,C Controller Specification |

||

the controller (see Table 5 for a list of all possible modes of |

|

Data |

||

operation). |

74-2697 |

Excel 10 T7770A,B,C,D,E,F,G Wall Module |

||

The W7750 Controller allows other controllers in the system to |

||||

|

Specification Data |

|||

use the W7750s physical inputs and outputs. A digital input |

|

|

||

and an analog input can be configured to read switch states |

74-3097 |

T7560A,B Digital Wall Module Specification |

||

and voltage sensor values, respectively, and send them out |

|

Data |

||

over the LONWORKS Bus network. The Q7750A Zone |

|

|

||

Manager can use these values in custom control strategies. |

74-2950 |

Excel 10 Q7750A, Zone Manager Specification |

||

Additionally, two of the W7750 digital outputs are available for |

|

Data |

||

control program use. These outputs only respond to signals |

|

|

||

sent over the network, and are not controlled by the W7750 |

74-2952 |

Excel 10 Q7751A,B Router Specification Data |

||

internal control algorithms. |

74-2954 |

Excel 10 Q7752A Serial Interface Specification |

||

|

|

|||

Products Covered |

|

Data |

||

|

|

|||

This System Engineering Guide describes how to apply the |

74-3067 |

Q7752B PCMCIA LONWORKS PCC-10 Card |

||

Excel 10 family of W7750 CVAHU Controllers and related |

|

Specification Data |

||

accessories to typical applications. The specific devices |

74-2858 |

Excel 10 Q7740A,B FTT Repeaters |

||

covered include: |

||||

• |

W7750A,B,C Controllers. |

|

Specification Data |

|

74-2951 |

Excel 10 Q7750A Zone Manager Checkout |

|||

• T7770A through D Wall Modules. |

||||

• |

T7560A,B Wall Modules. |

|

and Test Manual |

|

• Q7750A Excel 10 Zone Manager. |

95-7521 |

Excel 10 W7750A,B,C Controller Installation |

||

• Q7751A,B Router (FTT to FTT and TPT to FTT). |

||||

• |

Q7752A Serial Interface. |

|

Instructions |

|

• Q7740A,B Repeaters (2-way and 4-way). |

95-7538 |

Excel 10 T7770A,B,C,D,E,F,G Wall Module |

||

• 209541B FTT Termination Module. |

||||

|

|

|

Installation Instructions |

|

Organization of Manual |

95-7620 |

T7560A,B Digital Wall Module Installation |

||

This manual is divided into three basic parts: the Introduction, |

|

Instructions |

||

the Application Steps, and the Appendices that provide |

95-7509 |

Excel 10 Q7750A Zone Manager Installation |

||

supporting information. The Introduction and Application |

||||

Steps 1 through 5 provide the information needed to make |

|

Instructions |

||

accurate material ordering decisions. Application Step 6 and |

95-7510 |

Excel 10 Q7751A,B Router Installation |

||

the Appendices include configuration engineering that can be |

||||

started using Excel E-Vision PC Software after the devices |

|

Instructions |

||

and accessories are ordered. Application Step 7 is |

95-7511 |

Excel 10 Q7752A Serial Interface Installation |

||

troubleshooting. |

||||

The organization of the manual assumes a project is being |

|

Instructions |

||

95-7613 |

Q7752B PCMCIA LONWORKS PCC-10 Card |

|||

engineered from start to finish. If an operator is adding to, or is |

||||

changing an existing system, the Table of Contents can |

|

Installation Instructions |

||

provide the relevant information. |

|

|

||

Applicable Literature

95-7555 Excel 10 Q7740A,B FTT Repeaters Installation

Instructions

The following list of documents contains information related to |

95-7554 |

Excel 10 209541B Termination Module |

the Excel 10 W7750 CVAHU Controller and the EXCEL 5000 |

|

Installation Instructions |

OPEN SYSTEM in general. |

74-2588 |

Excel E-Vision User’s Guide |

|

||

|

74-5587 |

CARE User’s Manual |

|

74-1392 |

CARE Excel 10 Zone Manager User’s Guide |

|

74-5577 |

CARE Icon Guide |

|

74-2039 |

XBS User’s Manual |

|

74-5018 |

XBS Application Guide |

74-2958— 1 |

8 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

Product Names

The W7750 Controller is available in three models:

•W7750A Constant Volume AHU Controller - W7750A Version.

•W7750B Constant Volume AHU Controller - W7750B Version.

•W7750C Constant Volume AHU Controller - W7750C

Version.

The T7770 Wall Module is available in four models. The T7770 Wall Modules will work with all Excel 5000 and Excel 10 Controllers (except the W7751A,C,E,G):

•T7770A1xxx Wall Module with nonlinearized 20 Kohm NTC sensor only.

•T7770A2xxx Wall Module with nonlinearized 20 Kohm NTC sensor and LONWORKS Bus jack.

•T7770B1xxx Wall Module with nonlinearized 20 Kohm NTC sensor, 10 Kohm setpoint, and LONWORKS Bus jack.

•T7770C1xxx Wall Module with nonlinearized 20 Kohm NTC sensor, 10 Kohm setpoint, bypass button and LED, and LONWORKS Bus jack.

•T7770D1xxx Wall Module with nonlinearized 20 Kohm NTC sensor, bypass button and LED, and LONWORKS Bus jack.

NOTE: The T7770B,C Models are available with a absolute 55 to 85°F (10 to 85°C) or a relative scale plate adjustable in E-Vision to ± 18°F (± 5°C).

The T7560A,B Wall Module is available in two models:

•T7560A Wall Module displays and provides space temperature, setpoint, Occ/Unocc override, override status LCD and digital display.

•T7560B Wall Module displays and provides space temperature, humidity sensor, setpoint, Occ/Unocc override, override status LCD and digital display.

Other products:

•Q7750A Excel 10 Zone Manager.

•Q7751A,B Bus Router.

•Q7752A Serial Adapter.

•Q7740A,B FTT Repeaters.

•209541B FTT Termination Module.

Refer to Table 11 in Application Step 5. Order Equipment for a complete listing of all available part numbers.

NOTE: The Q7750A Zone Manager is referred to as (E-Link) in internal software and CARE.

Agency Listings

Table 1 provides information on agency listings for Excel 10 products. Be sure to always follow Local Electrical Codes.

|

|

Table 1. Agency Listing. |

|

|

|

|

|

Device |

Agency |

|

Comments |

|

|

|

|

W7750A,B,C Controllers |

UL |

Tested and listed under UL916 (file number E87741). The CVAHU W7750A,B,C |

|

|

|

Controllers are UL94-5V listed and suitable for plenum mounting. |

|

|

|

|

|

|

cUL |

Listed (E87741). |

|

|

|

|

|

|

CE |

General Immunity per European Consortium Standards EN50081-1 (CISPR 22, Class B) |

|

|

|

and EN 50082-1:1992 (based on Residential, Commercial, and Light Industrial). |

|

|

|

EN 61000-4-2: |

IEC 1000-4-2 (IEC 801-2) Electromagnetic Discharge. |

|

|

EN 50140, EN 50204: IEC 1000-4-3 (IEC 801-3) Radiated Electromagnetic Field. |

|

|

|

EN 61000-4-4: |

IEC 1000-4-4 (IEC 801-4) |

|

|

|

Electrical Fast Transient (Burst). Radiated Emissions and |

|

|

|

Conducted Emissions: |

|

|

EN 55022: |

1987 Class B. |

|

|

CISPR-22: |

1985. |

|

|

|

|

|

FCC |

Complies with requirements in FCC Part 15 rules for a Class B Computing Device. |

|

|

|

Operation in a residential area can cause interference to radio or TV reception and require |

|

|

|

the operator to take steps necessary to correct the interference. |

|

|

|

|

|

T7770A,B,C,D and |

UL |

(Not applicable.) |

|

T7560A,B Wall Modules |

|

|

|

|

|

|

|

|

cUL |

(Not applicable.) |

|

|

|

|

|

|

FCC |

(Not applicable.) |

|

|

|

|

|

Q7750A Excel 10 |

|

|

|

|

|

|

|

Zone Manager |

UL |

Tested and listed under UL916, file number S4804 (QVAX, PAZY). |

|

|

|

|

|

|

CSA |

Listing pending. |

|

|

|

|

|

|

FCC |

Complies with requirements in FCC Part 15 rules for a Class A Computing Device. |

|

|

|

Operation in a residential area can cause interference to radio or TV reception and require |

|

|

|

the operator to take steps necessary to correct the interference. |

|

|

|

|

|

Q7740A,B FTT |

UL |

UL1784. |

|

Repeaters, Q7751A,B |

|

|

|

Routers and |

|

|

|

Q7752A Serial Adapter |

|

|

|

CSA |

Listed. |

|

|

|

|

|

|

|

FCC |

Complies with requirements in FCC Part 15 rules for a Class B Computing Device. |

|

|

|

|

|

9 |

74-2958— 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

Abbreviations and Definitions

AHU Air Handling Unit; the central fan system that includes the blower, heating equipment, cooling equipment, ventilation air equipment, and other related equipment.

CO Carbon Monoxide. Occasionally used as a measure of indoor air quality.

CO2 Carbon Dioxide. Often used as a measure of indoor air quality.

CARE Computer Aided Regulation Engineering; the PC based tool used to configure C-Bus and LONWORKS Bus devices.

C-Bus Honeywell proprietary Control Bus for communications between EXCEL 5000 System controllers and components.

CPU Central Processing Unit; an EXCEL 5000 OPEN SYSTEM controller module.

cUL Underwriters Laboratories Canada

CVAHU Constant Volume AHU; refers to a type of air handler with a single-speed fan that provides a constant amount of supply air to the space it serves.

DDF Delta Degrees Fahrenheit.

D/X Direct Expansion; refers to a type of mechanical cooling where refrigerant is (expanded) to its cold state, within a heat-exchanging coil that is mounted in the air stream supplied to the conditioned space.

Echelon The company that developed the LONWORKS Bus and the Neuron chips used to communicate on the LONWORKS Bus.

Economizer Refers to the mixed-air dampers that regulate the quantity of outdoor air that enters the building. In cool outdoor conditions, fresh air can be used to supplement the mechanical cooling equipment. Because this action saves energy, the dampers are often referred to as economizer dampers.

EMI Electromagnetic Interference; electrical noise that can cause problems with communications signals.

E-Link Refers to the Q7750A Zone Manager. This name is used in internal software and in CARE software.

EMS Energy Management System; refers to the controllers and algorithms responsible for calculating optimum operational parameters for maximum energy savings in the building.

EEPROM Electrically Erasable Programmable Read Only Memory; the variable storage area for saving user setpoint values and factory calibration information.

Enthalpy The energy content of air measured in BTUs per pound (KiloJoules per Kilogram).

EPROM Erasable Programmable Read Only Memory; the firmware that contains the control algorithms for the Excel 10 Controller.

Excel 10 Zone Manager A controller that is used to interface between the C-Bus and the LONWORKS Bus. The Excel 10 Zone Manager also has the functionality of an Excel 100 Controller, but has no physical I/O points.

NOTE: The Q7750A Zone Manager can be referred to as E-Link in the internal software, CARE.

E-Vision User interface software used with devices that operate via the FTT LONWORKS Bus communications protocol.

Firmware Software stored in a nonvolatile memory medium such as an EPROM.

Floating Control Refers to Series 60 Modulating Control of a valve or damper. Floating Control utilizes one digital output to pulse the actuator open, and another digital output to pulse it closed.

FTT Free Topology Transceiver.

IAQ Indoor Air Quality. Refers to the quality of the air in the conditioned space, as it relates to occupant health and comfort.

I/O Input/Output; the physical sensors and actuators connected to a controller.

I x R I times R or current times resistance; refers to Ohms Law: V = I x R.

K Degrees Kelvin.

Level IV Refers to a classification of digital communication wire. Formerly known as UL Level IV, but not equivalent to Category IV cable. If there is any question about wire compatibility, use Honeywell-approved cables (see Step 5 Order Equipment section).

LONWORKS Bus Echelons LONWORKS network for communication among Excel 10 Controllers.

LONWORKS Bus Segment An LONWORKS Bus section containing no more than 60 Excel 10s. Two segments can be joined together using a router.

NEC National Electrical Code; the body of standards for safe field-wiring practices.

NEMA National Electrical Manufacturers Association; the standards developed by an organization of companies for safe field wiring practices.

Node A Communications Connection on a network; an Excel 10 Controller is one node on the LONWORKS Bus network.

NV Network Variable; an Excel 10 parameter that can be viewed or modified over the LONWORKS Bus network.

PC An Personal Computer with Pentium processor capable of running Microsoft Windows 95.

Pot Potentiometer. A variable resistance electronic component located on the T7770B,C or T7560A,B Wall Modules; used to allow user-adjusted setpoints to be input into the Excel 5000 or Excel 10 Controllers.

74-2958— 1 |

10 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

PWM Pulse Width Modulated output; allows analog modulating control of equipment using a digital output on the controller.

RTD Resistance Temperature Detector; refers to a type of temperature sensor whose resistance output changes according to the temperature change of the sensing element.

Subnet A LONWORKS Bus segment that is separated by a router from its Q7750A Zone Manager.

TOD Time-Of-Day; the scheduling of Occupied and Unoccupied times of operation.

TPT Twisted Pair Transceiver.

VA Volt Amperes; a measure of electrical power output or consumption as applies to an ac device.

Vac Voltage alternating current; ac voltage rather than dc voltage.

VAV Variable Air Volume; refers to either a type of air distribution system, or to the W7751 Excel 10 VAV Box Controller that controls a single zone in a variable air volume delivery system.

VOC Volatile Organic Compound; refers to a class of common pollutants sometimes found in buildings. Sources include out-gassing of construction materials, production-line by-products, and general cleaning solvents. A VOC is occasionally used as a measure of indoor air quality.

W7750 The model number of the Excel 10 CVAHU Controllers (also see CVAHU).

W7751 The model number of the Excel 10 VAV Box Controllers (also see VAV).

Wall Module The Excel 10 Space Temperature Sensor and other optional controller inputs are contained in the T7770 or the T7560A,B Wall Modules. See Application Step 5. Order Equipment for details on the various models of Wall Modules.

XBS Excel Building Supervisor; a PC based tool for monitoring and changing parameters in C-Bus devices.

Construction

Controllers

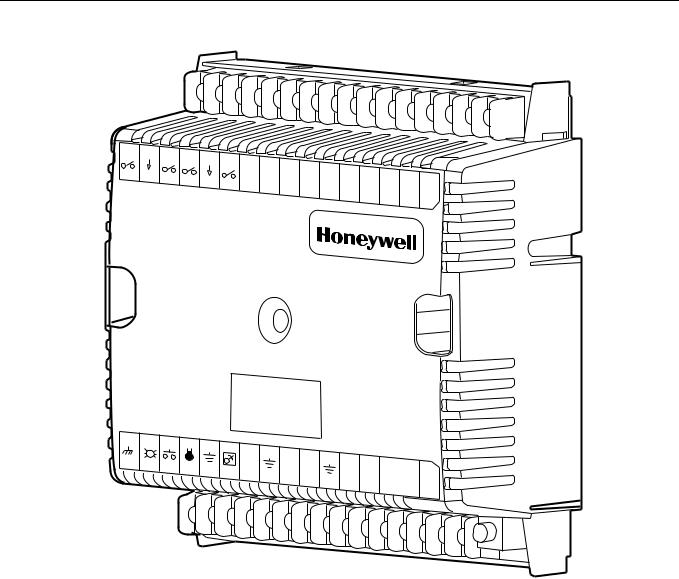

The Excel 10 W7750 Controller is available in three different models. The W7750A Model, which is a low cost controller made for simple single zone air handlers and heat pump controls. The W7750B,C Models are intended for more complex applications.

The W7750B,C Models use Triacs for their digital outputs, where as the W7750A Model uses dry-contact relays. The W7750C Model also has three analog outputs available on terminals 16, 17 and 18.

All wiring connections to the controller are made at screw terminal blocks. Connection for operator access to the LONWORKS Bus is provided by plugging the SLTA connector cable into the LONWORKS Bus communications jack.

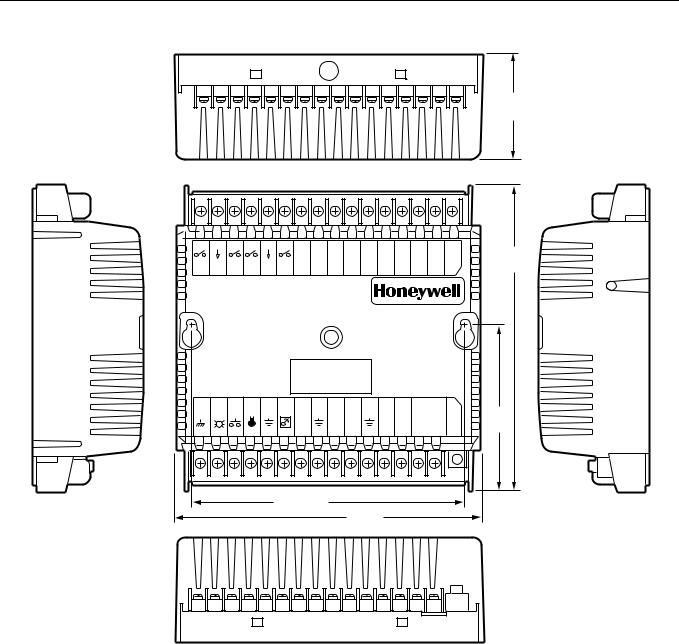

The W7750A,B,C Models consist of a single circuit board that is mounted in a sheet metal subbase and protected by a factory snap-on cover. The three controllers have the same physical appearance except for terminals 16 through 20 (W7750A) and different labels next to the wiring terminals (see Fig. 3, 5 or 6). Wires are attached to the screw terminal blocks on both sides of the controller. The controllers mount with two screws (see Fig. 4 or 7). The W7750 can also be mounted using DIN rail. To mount the W7750 on DIN rail, purchase two DIN rail adapters (obtain locally) part number TKAD, from Thomas and Betts, see Fig. 8, then snap onto standard EN 50 022 35 mm by 7.5 mm (1-3/8 in. by 5/16 in.) DIN rail. DIN rail is available through local suppliers.

A channel in the cover allows the controller status LED to be visible when the cover is in place. There are no fieldserviceable parts on the circuit board and, therefore, it is intended that the cover never be removed.

The W7750A,B,C can be mounted in any orientation. Ventilation openings were designed into the cover to allow proper heat dissipation regardless of the mounting orientation. See Fig. 4 and 7.

The input/output and control differences between the two models are summarized in Table 2. The I/O points in Table 2 are the free I/O points that are not reserved for Wall Module use.

Table 2. List of Differences in W7750A and W7750B,C Controllers.

|

|

|

|

W7750A Model |

W7750B,C Models |

|

|

|

Digital Outputs |

Six Relay Outputs |

Eight Triac Outputs |

|

|

|

Digital Inputs |

Two |

Four |

|

|

|

Wall Module |

One* |

One* |

|

|

|

Analog Outputs |

None |

Three 4 to 20 mA Outputs (W7750C only) |

|

|

|

Analog Inputs |

One (Resistive Input Only) |

Four (Two Resistive and two Voltage/Current Inputs) |

|

|

|

DC Power |

None |

20 Vdc available to power optional sensors |

|

|

|

Floating (Series 60) Control |

Economizer Only |

Heating, Cooling, and/or Economizer |

|

|

|

PWM Control |

None |

Heating, Cooling, and/or Economizer |

|

|

|

*The T7770 or the T7560 Wall Modules includes I/O points for two analog inputs for the space temperature and the setpoint knob, a digital input for the Bypass pushbutton, and a digital

output for the LED Bypass Indicator. These W7750 I/O points are configurable, but are normally used for the Wall Module.

11 |

74-2958— 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

W7750A

31 |

30 |

29 |

28 |

27 |

26 |

25 |

|

|

|

|

|

24 |

23 |

|

|

||||||

|

|

|

22 |

21 |

||||||

|

|

|

|

|

|

|||||

W1 |

W2 |

Y1 |

|

|

NETWORK |

|||||

Y2 |

G |

|

|

|

24 |

|||||

|

|

|

24 |

|||||||

|

|

|

|

DO |

Rc |

Rh |

VAC |

|||

|

|

|

|

|

VAC |

|||||

|

|

|

|

|

|

|

|

|

COM |

|

|

|

|

|

|

|

|

|

|

|

|

20

NOT USED

19 |

18 |

17 |

16 |

|

|

||

NOT |

|

|

|

NOT |

NOT NOT |

||

USED USED USED USED |

|||

E GND

1

LED 2

BYPASS 3

SNSR 4

GND 5

SET PT 6

AI-1 |

GND |

DI-1 |

GND |

GND |

|

|

OHM |

DI-2 |

|||||

|

||||||

|

|

|||||

|

|

|

||||

7 |

8 |

9 |

10 |

11 |

12 |

|

|

||||||

|

|

|||||

|

|

|

|

NOT USED

13

L |

|

ONW |

|

|

ORKS |

BUS |

|

14 |

15 |

|

|

LON

JACK

J3

Fig. 3. Excel 10 W7750A Constant Volume AHU Controller.

74-2958— 1 |

12 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

2-1/8

(54)

31 |

30 |

29 |

28 |

27 |

26 |

25 |

24 |

23 |

22 |

21 |

20 |

19 |

18 |

17 |

16 |

|

|

|

|

|

NEYWORK |

|

|

24 |

24 |

|

|

|

|

|

|

WI |

W2 |

Y1 |

Y2 |

G |

|

DO |

Rc |

Rh |

VAC |

NOT |

NOT |

NOT |

NOT |

NOT |

|

|

|

VAC |

COM |

USED |

USED |

USED |

USED |

USED |

|||||||

5-5/8

(143)

E |

LED |

BYPASS |

SNSR |

GND |

SET PT |

AI-1 |

GND |

DI-1 |

GND |

GND |

DI-2 |

NOT |

LONWORKS |

LON |

3-1/16 |

|

GND |

|

|

|

|

|

OHM |

|

|

|

|

|

USED |

|

BUS |

JACK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

J3 |

(77) |

|

||||||||||||||||

|

|

|

|

|

5-3/16 (132) |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

6 (152) |

|

|

|

|

|

|

|

M10098B

Fig. 4. W7750A construction in in. (mm).

PERFORMANCE SPECIFICATIONS

Power:

24 Vac with a minimum of 20 Vac and a maximum of 30 Vac at either 50 or 60 Hz. The W7750A power consumption is 6 VA maximum at 50 or 60 Hz. The W7750B,C power consumption is 12 VA maximum at 50 or 60 Hz.The W7750A,B,C is a NEC Class 2 rated device. This listing imposes limits on the amount of power the product can consume or directly control to a total of 100 VA.

Special Note for the W7750B,C Unit:

The individual Triac outputs incorporate an internal common connection with the input power transformer. The Triacs provide a switched path from the hot side (R) of the transformer through the load to the common of the transformer. The W7750B,C Controller design must use the same power transformer for any loads connected to that controller; see Fig. 30.

Each individual Triac is rated 1A at 30 Vac maximum. Under all operating conditions, the maximum load/source power budget for the W7750B,C Controller is 100 VA. Actual allowable Triac current is 500 mA MAX.

13 |

74-2958— 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

31

DI-4

30

DI GND

29

DI-3

28

DI-2

27

DI GND

26 |

25 |

24 |

23 |

22 |

21 |

|

|

||||||

|

|

|||||

|

|

VAC |

|

|

||

|

VAC |

|

|

|

||

DI-1 |

24 |

1 |

|

|

||

24 |

2 |

|

||||

COM |

3 |

|||||

|

OUT |

|||||

|

|

OUT |

||||

|

|

|

OUT |

|||

|

|

|

|

20

4 OUT

19 |

18 |

17 |

16 |

|

|

|

|||

|

|

|

||

5 |

6 |

7 |

|

|

OUT |

OUT |

8 |

||

OUT |

||||

|

OUT |

|||

|

|

|||

|

|

|

E |

LED |

BYPASS |

|

|

GND |

SNSR |

|||

|

||||

|

|

|||

1 |

2 |

3 |

4 |

|

|

||||

|

|

|||

|

|

|

AI GND

5

SET PT |

AI-1 |

|

OHM |

6 |

7 |

|

AI GND

8

A1-2 |

AI-3 |

OHM |

V/mA |

|

|

9 |

10 |

AI GND

11

AI-4 |

20VDC |

V/mA |

OUT |

|

|

12 |

13 |

LONWORKS |

|

|

BUS |

14 |

15 |

LON

JACK

J3

M6854B

Fig. 5. Excel 10 W7750B Constant Volume AHU Controller.

CPU:

Motorola or Toshiba 3150 Neuron processor, containing three eight-bit CPUs. Each Neuron has a unique 48-bit network identification number.

Memory Capacity:

64K ROM/PROM (6K reserved for network operations, 58K usable for control algorithm code).

512 bytes EEPROM.

2K RAM.

Specified Space Temperature Sensing Range:

45 to 99°F (7 to 37°C) with an allowable control setpoint range from 50 to 90°F (10 to 32°C) when initiated from the network and 55 to 85°F (13 to 29°C) when configured and connected to T7770 or T7560 Wall Modules.

74-2958— 1 |

14 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

31

DI-4

30

DI GND

29

DI-3

28

DI-2

27

DI GND

26 |

25 |

24 |

23 |

22 |

21 |

|

|

||||||

|

|

|||||

|

|

VAC |

|

|

||

|

VAC |

|

|

|

||

DI-1 |

24 |

1 |

|

|

||

24 |

2 |

|

||||

COM |

3 |

|||||

|

OUT |

|||||

|

|

|

OUT |

OUT |

||

|

|

|

|

20

4 OUT

19 |

18 |

17 |

16 |

|

|

|

|||

|

|

|

||

5 |

A0 |

A0 |

|

|

OUT |

A0 |

|||

1 |

||||

2 |

||||

|

|

3 |

||

|

|

|

E |

LED |

BYPASS |

|

|

GND |

SNSR |

|||

|

||||

|

|

|||

1 |

2 |

3 |

4 |

|

|

||||

|

|

|||

|

|

|

AI GND

5

SET PT |

AI-1 |

|

OHM |

6 |

7 |

|

AI GND

8

A1-2 |

AI-3 |

OHM |

V/mA |

|

|

9 |

10 |

AI GND

11

AI-4 |

20VDC |

|

V/mA |

||

OUT |

||

|

||

12 |

13 |

LONWORKS |

|

|

BUS |

14 |

15 |

LON

JACK

J3

M17489

Fig. 6. Excel 10 W7750C Constant Volume AHU Controller.

15 |

74-2958— 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

2-1/8

(54)

31 |

30 |

29 |

28 |

27 |

26 |

25 |

24 |

23 |

22 |

21 |

20 |

19 |

18 |

17 |

16 |

|

|

|

|

|

|

|

VAC |

VAC |

1 |

2 |

3 |

4 |

5 |

A0 |

A0 |

A0 |

5-5/8 |

|

DI |

|

|

DI |

|

24 |

(143) |

|||||||||

DI-4 GND DI-3 DI-2 GND |

DI-1 24 |

COM OUT OUT OUT OUT OUT |

1 |

2 |

3 |

|

||||||||||

E |

LED |

BYPASS SNSR |

AI |

SET PT |

AI-1 |

AI |

AI-2 AI-3 |

AI |

AI-4 |

20VDC |

LONWORKS |

LON |

|

|||

GND |

|

|

|

GND |

|

OHM GND OHM V/mA GND V/mA |

OUT |

|

BUS |

JACK |

3-1/16 |

|||||

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

J3 |

(77) |

|

||||||||||||||||

5-3/16 (132)

6 (152)

M17490

Fig. 7. W7750B,C construction in in. (mm). W7750C (shown) has three 4 to 20 mA analog outputs.)

Communications:

The W7750A,B,C Controller uses a Free Topology Transceiver (FTT) transformer-coupled communications port running at 78 kilobits per second (kbps). Using the transformer-coupled communications interface offers a much higher degree of common-mode noise rejection while ensuring dc isolation.

Approved cable types for LONWORKS Bus communications wiring is Level IV 22 AWG (0.34 mm2) plenum or nonplenum rated unshielded, twisted pair, solid conductor wire. For nonplenum areas, use Level IV 22 AWG (0.34 mm2) such as U.S. part AK3781 (one pair) or U.S. part AK3782 (two pair). In plenum areas, use plenum-rated Level IV, 22 AWG (0.34 mm2) such as U.S. part AK3791 (one pair) or U.S. part AK3792 (two pair). (See Tables 9 and 11 for part numbers.) Contact Echelon Corp. Technical Support for the recommended vendors of Echelon approved cables.

74-2958— 1 |

16 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

2

2

3

3

1

M6857

Fig. 8. DIN rail adapters.

The FTT supports polarity insensitive free topology wiring. This frees the system installer from wiring using a specific bus topology. T-tap, star, loop, and mixed wiring topologies are all supported by this architecture. The maximum LONWORKS Bus length when using a combination of T-tap, star, loop, and bus wiring (singly terminated) is 1640 ft. (500m) with the maximum node-to-node length of 1312 ft. (400m). In the event that the total wire length is exceeded, then a Q7740A 2-Way Repeater or a Q7740B 4-Way Repeater can be used to allow the number of devices to be spread out as well as increasing the length of wire over which they communicate. The maximum number of repeaters per segment is one (on either side of the router). A Q7751A,B LONWORKS Bus Router can also be used to effectively double the maximum LONWORKS Bus length. The advantage of using the router is that it segregates traffic to a segment while when using the repeater, all traffic is repeated on each segment. When utilizing a doubly terminated LONWORKS Bus structure, use a continuous daisy-

chain with no stubs or taps from the main backbone, The maximum LONWORKS Bus length is 4593 ft. (1400m) with the maximum node-to-node length of 3773 ft. (1150m).

FTT networks are very flexible and convenient to install and maintain, but it is imperative to carefully plan the network layout and create and maintain accurate documentation. This aids in compliance verification and future expansion of the FTT network. This also keeps unknown or inaccurate wire run lengths, node-to-node (device-to-device) distances, node counts, total wire length, inaccurate repeater/router locations, and misplaced or missing terminations minimized. Refer to LONWORKS Bus Wiring Guidelines form, 74-2865 for complete description of network topology rules.

LONMARK® FUNCTIONAL PROFILE

W7750 Controllers support the LONMARK Functional Profile number 8030 Roof Top Unit Controller, version 1.0

(see Fig. 9).

17 |

74-2958— 1 |

EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

Hardware

Output

Roof Top Unit

Controller number 8030

nv1 |

|

nviSpaceTemp |

|

nv3 |

|

nvoSpaceTemp |

||

|

SNVT_temp_p |

Mandatory |

|

SNVT_ temp_p |

||||

|

|

|

|

|||||

|

|

|

|

Network |

|

|

|

|

nv2 |

|

nviSetPoint |

Variables |

nv4 |

|

nvoUnitStatus |

||

|

SNVT_temp_p |

|

|

SNVT_hvac_status |

||||

nv5 |

|

nviApplicMode |

|

nv10 |

|

nvoEffectSetPt |

||

|

|

|

||||||

|

|

|

||||||

|

SNVT_hvac_mode |

|

|

SNVT_ temp_p |

||||

|

|

|

|

|

||||

nv6 |

|