Yaskawa MX 3 User Manual

YASNAC MX3

CNC SYSTEM FOR MACHINING CENTERS

Before initial operation, read these instructions thoroughly, and retam for future reference

YASKAWA

|

|

|

|

|

|

|

|

|

|

|

|

CONTENTS |

|

|

|

|

|

|

|

|

|

|

1. |

|

OUTLINE |

1 |

|

|

|

|

|

|

|

|

7. |

SETTING |

AND |

ADJUSTMENT |

FOR |

MODULE |

bO |

|

|||

1.1 |

COMPONENT |

ARRANGEMENT |

|

|

|

7.1 |

MU20 |

BOARD |

60 |

|

|

|

|

|

|

|||||||

1.2 |

CONSTRUCT! ON |

3 |

|

|

|

|

|

7.2 |

SP20 |

BOARD |

61 |

|

|

|

|

|

|

|||||

1.3 |

MAJOR COMPONENTS |

4 |

|

|

|

|

7.3 |

SR20 |

BOARD |

SR20 |

- [--------161 |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~. -- ---~ |

|

|

|

||

2. |

|

ROUTINE |

INSPECTION SCHEDULE |

7 |

|

7.4 |

1021 |

61 |

|

|

|

|

|

|

|

|||||||

|

|

7.5 |

AREA |

NO SETTING |

AND |

I/O ADDRESS PORT |

63 |

|||||||||||||||

2.1 |

|

TAPE READER 8 |

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

2.2 |

|

CONTROL PANEL |

|

8 |

|

|

|

|

|

8. |

NC DATA |

HANDLING |

64 |

|

|

|

|

|

||||

2.3 |

|

AC SERVOMOTOR |

|

9 |

|

|

|

|

|

8.1 |

SYSTEM |

NO. SETTING |

(<<6219) |

64 |

|

|

||||||

2.4 |

|

BATTERY |

9 |

|

|

|

|

|

|

|

|

8.2 |

DISPLAYING |

AND WRITING PARAMETERS |

64 |

|

||||||

3. |

|

MAINTENANCE |

INSTRUMENTS |

10 |

|

|

8.3 |

DISPLAYING |

AND WRITING |

KEEP_MEMORY |

66 |

|

||||||||||

|

|

|

8.4 |

TAPE INPUT OF SETTING DATA AND PARAMETER |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

4. |

|

TROUBLESHOOTING |

|

11 |

|

|

|

|

|

DATA |

66 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

8.5 |

PUNCHING-OUT OF SETTING DATA AND |

|

|

||||||||||||

4.1 |

|

TROUBLE |

IDENTIFICATION |

11 |

|

|

|

|

||||||||||||||

|

|

|

PARAMETER |

DATA |

67 |

|

|

|

|

|

|

|||||||||||

4.2 |

|

TROUBLESHOOTING |

BY |

ALARM CODES |

12 |

8.6 |

SUMMARY OF STORING DATA AND EDITING |

|

|

|||||||||||||

4.3 |

|

TROUBLESHOOTING |

WITHOUT |

ALARM CODES |

OPERATIONS |

|

67 |

|

|

|

|

|

|

|

||||||||

|

30 |

|

|

|

|

|

|

|

|

|

|

|||||||||||

4.4 |

|

MAINTENANCE OF |

ACGC |

49 |

|

|

|

9. |

APPENDIX |

69 |

|

|

|

|

|

|

|

|||||

4.5 |

|

SUPPLY VOLTAGE |

CHECK |

51 |

|

|

|

9.1 |

ALARM NO. LIST |

69 |

|

|

|

|

|

|||||||

4.6 |

|

STATUS DISPLAY BY ON-LINE DIAGNOSTICS |

9.2 |

LIST OF SETTING |

NUMBERS |

102 |

|

|

||||||||||||||

FUNCTION (DGN) |

52 |

|

|

|

|

|

|

|

9.3 |

LIST OF |

PARAMETER NUMBERS |

108 |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

5. |

ADJUSTMENTS |

UPON |

|

INSTALLATION |

54 |

|

9.4 |

STORED |

LEADSCREW |

ERROR COMPENSATION |

130 |

|||||||||||

6. |

MODULE/UNIT |

REPLACEMENT |

PROCEDURE |

57 |

9,5 |

LIST OF |

STANDARD |

INPUT/OUTPUT SIGNALS |

134 |

|||||||||||||

9.6 |

LIST OF |

ADDRESS CHARACTERS |

143 |

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

6.1CPU UNIT 57

6.2OPERATOR'S PANEL 58

6.3OPTIONAL MODULES 59

|

|

|

|

|

|

|

|

|

|

|

|

|

|

'r |

|

|

|

|

|

|

|

|

|

|

INDEX |

|

|

|

|

|

Subject |

|

|

|

|

|

|

|

|

|

|

Chapter |

Section |

Page |

A |

AC SERVOMOTOR |

|

|

|

|

|

|

|

|

|

2 |

2.3 |

9 |

|

|

AOGC ALARM |

INDICATION |

|

|

|

|

|

|

|

4 |

4.4.2 |

49 |

||

|

AOGC TROUBLESHooTI NG • |

|

|

|

|

|

|

|

4 |

4.4.1 |

49 |

|||

|

ADJUSTMENTS UPON INSTALLATION |

|

|

|

5 |

|

54 |

|||||||

|

ALARM 075. 076. 077 (RS232C Faulty) |

|

|

4 |

4.2.3 |

14 |

||||||||

|

ALARM 170. 172. 173. 174 AND |

175 |

(Memory |

Error) |

|

4 |

4.2.4 |

17 |

||||||

|

ALARM 179 (Temperature Alarm inside the Panel) • |

|

4 |

4.2.5 |

18 |

|||||||||

|

ALARM 310 (Servo Power Supply Not Applied) • |

|

4 |

4.2.9 |

22 |

|||||||||

|

ALARM 320 (Control Not Ready) |

. • . •• |

|

|

4 |

4.2.10 |

23 |

|||||||

|

ALARM 325 (Servo CPU Error) |

• • • • • • |

|

|

4 |

4.2.16 |

28 |

|||||||

|

ALARM 329 (Bui It·in |

Type PC CPU Error! • |

|

|

4 |

4.2.17 |

28 |

|||||||

|

ALARM 330 (Emergency Stop) • • • • |

|

|

4 |

4.2.11 |

23 |

||||||||

|

ALARM 820 (ROM/RAM Check Error) |

|

|

|

4 |

4.2.18 |

29 |

|||||||

|

ALARM NO. LIST· ••••••••• |

|

|

|

9 |

9.1 |

69 |

|||||||

|

ALARMS 010 |

AND 011 |

(Parity Error) |

|

|

|

4 |

4.2.2 |

13 |

|||||

|

ALARMS 231. 232. 234 AND 235 (Zero Point Return Area |

|

|

|

||||||||||

|

Error! • • • • • • • • • • • • • • • • • • • • • • • • |

4 |

4.2.6 |

19 |

||||||||||

|

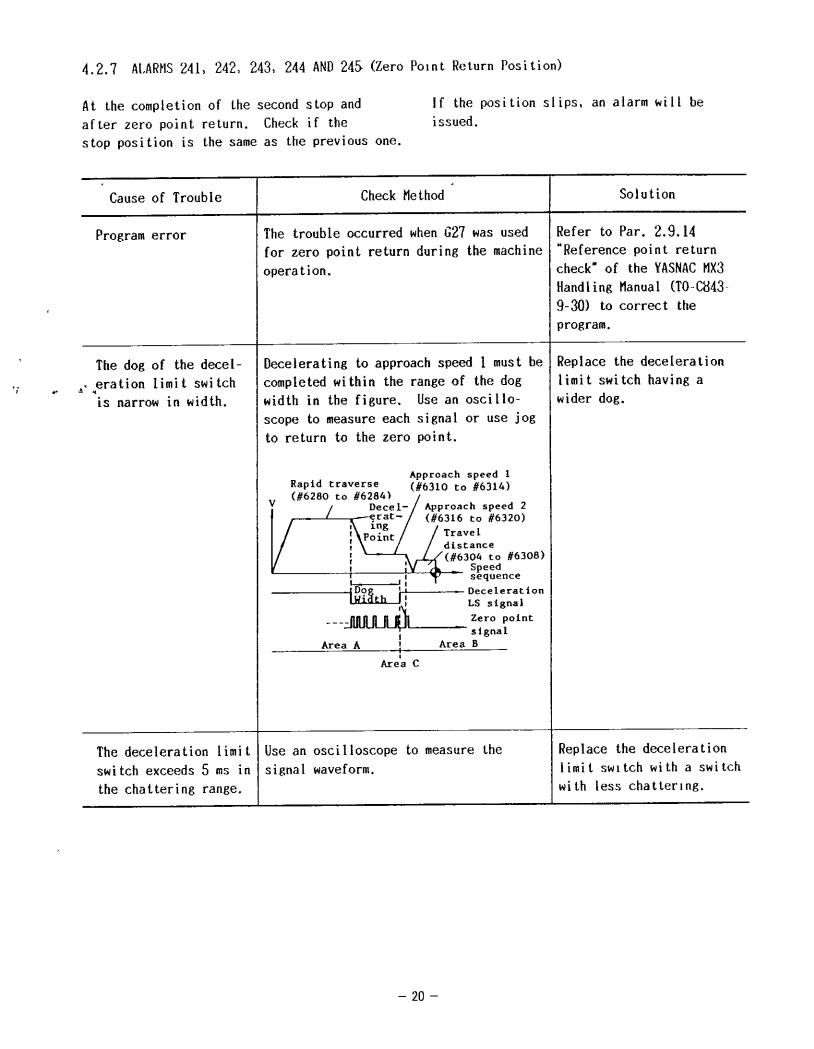

ALARMS 241. 242. 243. 244 |

AND 245 (Zero Point Return |

|

|

|

|||||||||

|

Area Error! |

• • • . |

. • |

• |

• |

• . . • • • |

• • • • |

. • . |

4 |

4.2.7 |

20 |

|||

|

ALARMS 271. 272. 273. 274 |

AND 275 |

(P-SET |

Error) |

••• |

4 |

4.2.8 |

22 |

||||||

|

AbARMS 331. 332. 333. 334 AND 335 (Servo Fuse Blown) . |

4 |

4.2.12 |

24 |

||||||||||

|

ALARMS 341. 342. 343. 344. 345 AND 346 (Servo Error) . |

4 |

4.2.13 |

25 |

||||||||||

|

ALARMS 351. 352. 353. 354 |

AND 355 |

(Motor Overload) . |

4 |

4.2.14 |

26 |

||||||||

|

ALARMS 361. 362. 363. 364. 365 AND 366 |

|

|

|

4.2.15 |

27 |

||||||||

|

(PG 0 i sconnec ti on |

Error) . |

. |

. . . |

• . |

|

|

4 |

||||||

|

APPENDIX· • . • • • |

• |

. • |

• • . • •• |

|

|

9 |

|

69 |

|||||

|

AREA NO SETTING AND 110 ADDRESS PORT· |

|

|

7 |

7.5 |

63 |

||||||||

B |

BATTERy··········· |

|

|

|

2 |

2.4 |

9 |

|||||||

C |

CHECK AC POWER SUPPLY |

VOLTAGE |

|

|

|

4 |

4.5.1 |

51 |

||||||

|

CHECK DC POWER SUPPLY VOLTAGE |

|

|

|

4 |

4.5.3 |

52 |

|||||||

|

COMPONENT ARRANGEMENT |

|

|

|

|

|

|

|

1 |

1.1 |

1 |

|||

|

CONSTRUCT ION· • • |

• |

• |

• |

• |

• |

• |

|

|

|

1 |

1.2 |

3 |

|

|

CONTROL PANEL . . |

• |

. |

• |

• |

• |

• |

|

|

|

2 |

2.2 |

8 |

|

|

'CPU ERROR" |

DISPLAY |

(Without |

Alarm Codes) |

|

|

4 |

4.3.3 |

31 |

|||||

|

CPU UNIT· • . • . ••• . • |

|

|

|

|

6 |

6.1 |

57 |

||||||

|

CRT SCREEN DOES NOT DISPLAY |

|

|

|

|

4 |

4.3.4 |

32 |

||||||

|

CYCLE START FAILURE |

•••• |

|

|

|

|

4 |

4.3.9 |

39 |

|||||

o |

0ISPLAY METHOD· . • |

. • |

• |

• |

|

|

|

|

4 |

4.2.1 |

12 |

|||

|

DISPLAYING AND WRITING KEEP MEMORY· |

|

|

8 |

8.3 |

66 |

||||||||

|

DISPLAYING |

AND WRITING |

PARAMETERS |

|

|

|

8 |

8.2 |

64 |

|||||

E |

EDIT DOES NOT FUNCTION· |

••••• |

|

|

|

4 |

4.3.13 |

44 |

||||||

F |

FAULTS NOT |

DISPLAYED AOGC |

ALARM INDICATION· |

|

4 |

4.4.3 |

49 |

|||||||

|

"FIN" WAIT MODE BY SPINDLE RELATED INSTRUCTION· |

|

4 |

4.3.15 |

46 |

|||||||||

H |

HANDLE MODE OPERATION FAULTY· ••••• . •• |

|

4 |

4.3.5 |

32 |

|||||||||

|

INDICATION |

LAMP OF |

POWER SUPPLY UNIT· . . •• |

|

4 |

4.5.2 |

52 |

|||||||

|

INITIAL DIAGNOSTIC ERROR DISPLAY AT POWER ON· |

|

4 |

4.3.2 |

31 |

|||||||||

|

1021' . . . . . . . . . |

|

|

. . •• ..... |

|

7 |

7.4 |

61 |

||||||

II

INDEX (Con t' d)

Subject

LLIST OF ADDRESS CHARACTERS ... • . L[ST OF PARAMETER NUMBERS . . . . . .

L[ST OF SETT[NG NUMBERS . . . . . . .

L[ST OF STANDARD [NPUT/OUTPUT S[GNALS

MMA[NTENANCE [NSTRUMENTS . . . . .

MA[NTENANCE OF ACGC . . . . . • . . MAJOR COMPONENTS' . . • . . . . . .

MANUAL JOG MODE OPERATION FAULTY· . MANUAL RAP[D MODE OPERATION FAULTY·

MANUAL ZERO RETURN OPERAT[ON FAULTY MB20 BOARD· . • ... •• ....

MODULE/UNIT REPLACEMENT PROCEDURE

NNC DATA HANDLING' ....... .

9" CRT SCREEN [S DARK. . . . . . .

oOPERAT[NG PROCEDURE TO DISPLAY [NPUT/OUTPUT SIGNALS

OPERATION IS NOT AVAILABLE WITH Gal, G02 OR G03 • OPERATOR'S PANEL' . . . . . . . . • • • . . OPTIONAL MODULES' . . .. • .

OUTLINE ..... .

OUTL[NE OF DISPLAYS

PPARAMETER DATA DISPLAY' PARAMETER TYPES . . . .

POWER CANNOT BE SUPPLI ED .

PUNCHING~OUT OF SETTING DATA AND PARAMETER DATA

RRECOGNITION OF NC SYSTEM· .. RECOGNITION OF TROUBLE STATUS

RS232C DOES NOT FUNCTION WELL

ROUTI NE INSPECTION SCHEDULE •

SSETTING AND ADJUSTMENT FOR MODULE . . SKIP FUNCTION (G31) OPERATION FAILURE

SOFTWARE VERSION INDICATION SP20 BOARD· .... • .

SPINDLE DOES NOT ROTATE .......... • ..

SR20 BOARD |

SR20 |

~ |

~ ~ ~ . . |

. • . . . |

. . . . . • . |

STATUS DISPLAY |

BY ON~LINE |

DIAGNOSTICS FUNCTION (UGN) . |

|||

STORED LEADSCREW ERROR COMPENSATI ON |

• . • • . . |

||||

SUMMARY OF |

STORING DATA AND EDITING OPERATIONS, |

||||

SUPPLY VOLTAGE CHECK· . . . . . . . |

. . . . . • |

||||

SYSTEM NO. |

SETTING |

(16219) . . . . . . . . . . |

|||

TTAPE INPUT OF SETTING DATA AND PARAMETER DATA TAPE MODE OOES NOT FUNCTION

TAPE READER . . . . . .

TROUBLE IDENT[FICATION' . . . .

TROUBLESHooTl NG . . . . . . . .

TROUBLESHOOTING BY ALARM CODES'

TROUBLESHOOT[NG WITHOUT ALARM CODES

W WR[TING PARAMETER DATA • ... • .

Chapter Section Page

9 |

9.6 |

· 143 |

9 |

9.3 |

· 108 |

9 |

9.2 |

• 102 |

9 |

9.5 |

• 134 |

3 |

|

10 |

4 |

4.4 |

49 |

1 |

1.3 |

4 |

4 |

4.3.6 |

34 |

4 |

4.3.7 |

36 |

4 |

4.3.8 |

37 |

7 |

7.1 |

60 |

6 |

|

57 |

8 |

|

64 |

4 |

4.3.12 |

43 |

4 |

4.6.2 |

53 |

4 |

4.3.10 |

40 |

6 |

6.2 |

58 |

6 |

6.3 |

59 |

1 |

|

1 |

4 |

4.6.1 |

52 |

8 |

8.2.2 |

65 |

8 |

8.2.1 |

65 |

4 |

4.3.1 |

30 |

8 |

8.5 |

67 |

4 |

4.1.2 |

11 |

4 |

4.1.1 |

11 |

.. 4 |

4.3.14 |

45 |

2 |

|

7 |

7 |

|

60 |

4 |

4.3.16 |

47 |

4 |

4.4.4 |

50 |

7 |

7.2 |

61 |

4 |

4.3.1 |

41 |

7 |

7.3 |

61 |

4 |

4.6 |

52 |

9 |

9.4 |

••• 130 |

8 |

8.6 |

67 |

4 |

4.5 |

51 |

8 |

8.1 |

64 |

8 |

8.4 |

66 |

4 |

4.3.17 |

48 |

2 |

2.1 |

8 |

4 |

4.1 |

11 |

4 |

|

11 |

4 |

4.2 |

12 |

4 |

4.3 |

30 |

8 |

8.2.3 |

65 |

ill

This manual is primarily intended to give operators maintenance instructions for YASNAC MX3.

The information contained in manual does not provide all details to be met concerning maintenance and troubleshooting. If uncertainties be encountered for particular maintenance operation, refer to the following YASNAC MX3 documents for additional information:

YASNAC LX3/MX3 PC SYSTEM (TOE-C843-9.1) YASNAC MX3 SPECIFICATIONS (SIE-C843-9.30) YASNAC MX3 OPERATOR'S MANUAL (TOE-C843-9.30) YASNAC MX3 CONNECTING MANUAL (TOE-C843-9.32)

1. OUTLINE

The YASNAC MX3 provides you with an internal self-diagnosis function (DGN). System maintenance can easily be accomplished with DGN and other main functions as listed below;

(1) Microprocessor always monitors the machine operations internally and can display the status with function keys. If any failure occurs, NC immediatelY stops with the blinking of alarm displays. Also the same precedure

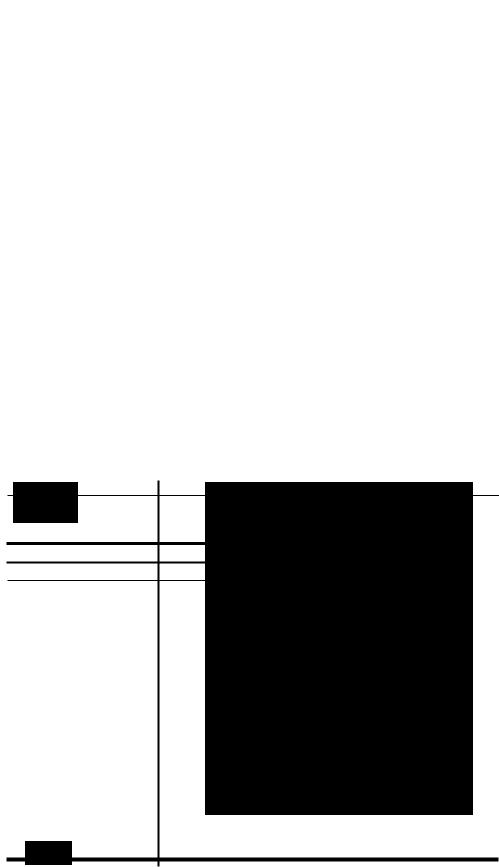

1.1 COMPONENT ARRANGEMENT

can be executed on machine sequence for the application of built-in type programmable controller.

(2)ON/OFF SIGNAL of input to NC/Output from NC can be displayed with DGN.

(3)Setting value of various parameters such as accel/decel time constant and rapid speed.

|

|

MACHINE |

|

~ |

|

|

9" CRT |

|

|

|

|

ACGC |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

0 _ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

Zo |

|

|

|

|

|

|

|

|

, |

|

|

|

|

|

|

|

|

|

|

|

|

CONTROL |

|

|

|

|

|

|

|

PANEL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

i::~ |

|

|

|

|

|

(OPTIONAL) |

|

|

|

|

|

|

||||||||||

|

|

STATION |

|

.. |

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

w |

~ t |

|

|

|

|

|

|

AC SERVO |

|

|

|

'X-AXIS |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

"' ... |

|

|

|

|

|

|

|

|

|

|

|

DRIVE |

|

-<2; MOTOR |

|||||

|

|

|

|

|

|

|

|

|

"' |

|

|

|

|

|

|

|

r-- ~ |

|

|

|

=J |

|

||||||

|

|

|

|

|

|

|

|

|

"s |

|

|

|

|

|

|

UNIT |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

o~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

...w ,.. |

CONTROL UNIT |

r- |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

~ ... |

|

|

|

|

|

|

I- |

- |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

~o. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

00 . |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

o.=> |

|

|

|

|

|

|

|

|

AC SERVO |

|

|

|

Y-AXIS |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

0"'~ |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

u |

|

|

|

|

|

|

|

|

DRIVE |

|

|

|

|

||||||

|

|

POWER |

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

|

UNIT |

|

~!~J MOTOR |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

~ |

INPUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

UNIT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

GENERAL |

|

|

~f-- |

|

AC SERVO |

|

|

M |

Z-AXIS |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

PURPOSE |

|

|

|

|

|

|

DRIVE |

|

|

~j |

MOTOR |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

I/O MODULE |

|

|

|

l-. |

|

UNIT |

~ |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPINDLE |

|

|

|

SPINDLE |

||

|

|

|

|

|

|

|

|

|

CONTROL CABINET |

|

|

|

|

|

|

DRIVE |

|

" |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNIT |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

Fig. |

|

1.1 Component Arrangement of |

YASNAC MX3 |

|

|

|

|

||||||||||||||||

- 1 -

1.1 COMPONENT |

ARRANGEMENT |

(Conl'd) |

|

YASNAC· MX~J==== |

:c:-: :-:: , |

||

Ii: |

-CPS-l0N"SUl',--,PL~YCi'UNIf,'~CNl -f1iTf--'4-~~----- |

||

|

poWER |

|

|

. ! |

eN 12'(}-::!---==--- |

{A) |

|

t)!1 |

l |

|

|

1 |

:~'7""'!.""-1'.!C~N!!li·39-"T-=--- |

||

< |

"- |

|

|

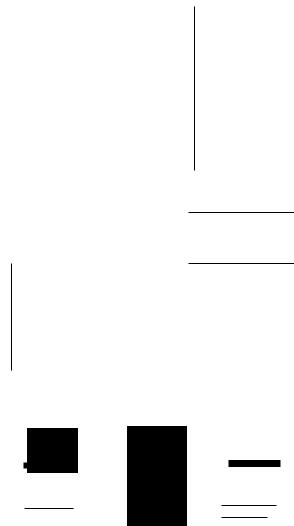

HANDLE TYPE

OPTIONAL ENCODER

(OPTIONAL)

NOTE: Circled "e" values shows cable No. (Refer to YASNAC

MX3 Connecting Manual:

TOE-<:843-9. 32).

III |

8 |

POIIITS |

III 40 PQIIITS |

OUT 4 |

pOlIlTS |

OUT |

~ |

POUltS |

|

(REED |

lEUY) |

Fig. 1.2 Conneclion Diagram

- 2 -

1.2 CONSTRUCTION

586-176

Approx |

|

|

|

POWER SUPPLY UNIT |

Weight: 10 kg |

|

|

|

|

|

|

" ---- PC20 BOARD |

||

|

|

|

||

|

|

|

|

BOARD |

|

|

|

|

|

|

|

L------------------I020 BOARD |

||

|

L-________________________________,M":on MAIN BOARD |

|||

|

||||

|

Fig. 1.3 CPU Module |

|||

(2)

KEYBOARD UNIT

¢ ~ ~

CRT UNIT

MDI MODULE

Fig. 1.4 g"eRT |

Unit |

Fig. 1.5 Tape Reader Unit |

(rear |

view) |

|

- 3 -

1.2 CONSTRUCTION |

(Cont'd) |

(3) |

RELAY UNIT |

|

SPINDLE |

|

DRIVE UNIT |

•

\ |

--CPU |

MODULE |

|

A |

|

9" CRT UNIT

.1

I

MACHINE

PANEL

.1F~

,-

586--173

Fig. 1.6 Example of Uni t Assembly wi th IIigh Vol tage Uni ts

1.3 MAJOR COMPONENTS

(1) YASNAC MAJOR COMPONENTS

Table 1.1 YASNAC Major Components

Tape Reel

Memory Board for EKtension

Control Stalron..

SP |

Board |

|

|

|

|

SR |

20 Board |

|

|

|

|

Manual Pulse |

|

|

OTN5520 |

(Option) |

|

(SiMultaneous 3-axls Cont- |

JANCD-SP21 |

||||

-4-

(2) |

ACGC Major |

Components |

Table 1.2 ACGC Major Components |

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Name |

|

|

|

|

|

Type |

|

|

|

Code No. |

|

|

|

Remarks |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14" CRT |

Unit |

|

|

|

|

|

C-5470YE |

|

CRT6 |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

Keyboard |

|

|

Un i t |

|

|

|

|

HMK-9993-02 |

|

SI-I677 |

|

Main |

key |

(Hoci zon ta I) |

|

|||||||||

|

|

|

Keyboard |

|

|

Un i t |

|

|

|

|

IlMK-2293-03 |

|

SI-I678 |

|

Main |

key |

(Vertical) |

|

|||||||||

|

|

|

Keyboard |

|

|

Unit |

|

|

|

|

HMK-9993-20 |

|

SI-I679 |

|

Soft |

key |

|

|

|

|

|

|

|||||

|

|

|

Power Supply |

Unit |

|

|

VST-5-522/ST |

|

AVR738 |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

CPU Module |

|

|

|

|

JANCO-CGOlD |

|

OTN5390 |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

Graphic |

|

Module |

|

|

JANCO-CG02 |

|

OTN4290 |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

Memory |

Module |

|

|

JZNC-I1UL lU -t:J |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

JANCO-CG03 |

|

OTN5100 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

Memory |

Unit |

|

|

|

|

JANCO-CG04 |

|

OTN5110 |

|

These units are incor- |

||||||||||||||

|

|

|

|

|

|

|

JANCO-CG05 |

|

OTN5120 |

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

JANCO-CG06 |

|

OTN5130 |

|

porated |

into memory module |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

JANCO-CG09 |

|

OTN5510 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

Ba ttery |

|

Un i t |

|

|

|

|

JZNC-BAT02 |

|

DUN13060 |

|

|

|

|

|

|

|

|

|

||||||

(3) |

AC Servo Units |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table |

1.3 |

|

AC Servo Units |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Servopack |

|

|

|

|

|

App lied Mo tor |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

Code |

No. |

|

|

|

Optical |

Encoder |

||||||||||||

|

|

|

|

|

|

|

|

|

Type |

|

|

Motor Type |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

p/rev |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR05SBIAF |

|

DUAI5920 |

|

USAFED-05FAl |

|

|

6000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR05SBIBF |

|

DUA16020 |

|

USAFED-05FBl |

|

|

5000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR05SBIDF |

|

DUA16120 |

|

USAFED-05FOl |

|

|

4000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SRIOSBIAF |

|

DUAI5940 |

|

USAFED-09FAl |

|

|

6000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SRIOSBIBF |

|

DUA16040 |

|

USAFED-09FBl |

|

|

5000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SRIOSBIOF |

|

OUA16140 |

|

USAFEO-09FOl |

|

|

4000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR15SBIAF |

|

DUA15950 |

|

USAFEO-13FAl |

|

|

6000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

CACR-SR15SBIBF |

|

DUA16050 |

|

USAFEO-13FBl |

|

|

5000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

CACR-SR15SBlDF |

|

OUA16150 |

|

USAFEO-13FDl |

|

|

4000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

CACR-SR20SBIAF |

|

DUA15960 |

|

USAFEO-20FAl |

|

|

6000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR20SBIBF |

|

OUA16060 |

|

USAFEO-20FBI |

|

|

5000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR20SBlDF |

|

DUA16160 |

|

USAFEO-20FDl |

|

|

4000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR30SBIAF |

|

OUAI5970 |

|

USAFEO-30FAl |

|

|

6000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR30SBIBF |

|

DUA16070 |

|

USAFEO-30FBl |

|

|

5000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR30SBIOF |

|

OUA16170 |

|

USAFEO-30FDl |

|

|

4000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR44SBIAF |

|

OUA15980 |

|

USAFEO-44FAl |

|

|

6000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR44SBIBF |

|

DUAI6080 |

|

USAFEO-44FBl |

|

|

5000 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

CACR-SR44SBIOF |

|

OUA16180 |

|

USAFEO-44FDl |

|

|

4000 |

|

|

|

|

|

|||||||

- 5 -

1.3 MAJOR COMPONENTS (Cont'd) |

|

|

|

|

|

|

|

||||

(4) Spindle Drive Units VS-626l1T ill |

|

|

|

|

|

|

|

||||

|

|

Table 1.4 |

Spindle Drive Units |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dri ve Un i t Type |

|

l1otor Type |

Installation |

||||||

|

|

CIl1R-MT ill -3. 7K |

UAASKA-04CAI |

Flange l10unted |

|

||||||

|

|

UAASKA-04CA3 |

Foot l10unted |

||||||||

|

|

|

|

|

|||||||

|

|

CIl1R-I1Till-5.5K |

UAASKA-06CAI |

Flange Mounted |

|

|

|||||

|

|

||||||||||

|

|

UAASKA-06CA3 |

Foot l10unted |

||||||||

|

|

|

|

|

|||||||

|

|

CIMR-MTill-7.5K |

|

UAASKA-08CAI |

Flange Mounted |

|

|

||||

|

|

|

UAASKA-08CA3 |

Foot Mounted . |

|||||||

|

|

||||||||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||

|

|

CIMR-MTill -11K |

|

UAASKA-llCAI |

Flange Mounted |

|

|||||

|

|

|

UAASKA-llCA3 |

Foot Mounted |

|||||||

|

|

|

|

|

|||||||

|

|

CIMR-I1Till-15K |

|

|

UAASKA-15CAI |

Flange l10unted |

|

||||

|

|

|

|

UAASKA-15CA3 |

Foot Mounted |

|

|||||

|

|

|

|

|

|||||||

- 6 -

2. ROUTINE INSPECTION SCIIEDULE

The following table shows the minimum requirements to be observed for maintenance time in

order to keep the equipment in optimum condilion for an exlended period.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 2.1 |

Inspection |

Schedule |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wi th |

Wi th |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Items |

|

|

|

|

|

|

|

Frequency |

the |

the |

|

|

Remarks |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

system- |

sys tem- |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

off |

on |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

Cleaning of |

reading |

As |

required |

|

0 |

|

|

|

Including light source |

|

||||||||||||

|

|

|

|

|

|

|

|

head |

|

|

|

|

|

|

|

|

|

|

|

part. |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

Tape |

Cleaning of |

tape |

As |

required |

|

0 |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

Reader |

tumble box |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

Lubrica ting of tension |

As |

required |

|

0 |

|

|

|

|

|

, |

|

|

||||||||||

|

|

|

|

|

|

|

|

arm shaf tend |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

Tight closing of doors |

Dai Iy |

|

|

|

0 |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

Control |

|

Checking |

for |

|

|

loose fit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

Panel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

and gaps of side plates |

Monthly |

|

0 |

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

'and worn |

door |

gaskets |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

AC |

Vibration |

and |

noise |

Dai Iy |

|

|

|

|

|

|

0 |

Feel |

by |

hand, and do |

|

||||||||||||

|

|

|

|

|

|

|

|

|

the |

audible inspection. |

|

|||||||||||||||||||

|

|

|

Servo- |

Mo tor con tam i na ti on |

Dai Iy |

or |

|

0 |

|

|

0 |

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

motor |

|

|

|

Inspect |

visually. |

|

|||||||||||||||||||||

|

|

|

and breakage |

|

|

|

|

|

as |

required |

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

Battery |

|

|

|

|

|

At |

POWER ON |

|

0 |

|

|

0 |

See if alarm for BATTERY |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

is displayed on CRT screen. |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Except for those checks which can be made with the NC in the energized state, such as checks for external cleanliness, vibration, and noise, be sure to turn off the power supply to the NC before starting to undertake routine maintenance service.

For this, turning off the power supply by pushing the POWER OFF button on lhe NC operator's station is nol sufficient, because after this button is pushed, still several areas in the housing are energized, and are potenlially dangerous.

- 7 -

2.1 TAPE READER

(1)Cleaning the tape reader head (As required)

(a)Remove tape rubbish and dust from the glass with a blower brush. If the glass is stained with oil or oily dust, wipe it using agauze or soft cloth with absolute alcohol. Also clean the tape guide and the tape retainer.

(b)Remove the dust, if any, on LED (light

source) on top with a blower brush.

(2) Cleaning of tape tumble box (As required) Clean the braided nylon leading tape with a clean, soft cloth.

(3) Lubricating of tension arm shaft(As required)

For the control with 6-inch or 8-inch diameter reels, lubricate the shaft end of tension arm, when the tension arm does not move smoothly.

LUBRICATING

Q

TENSION ARM

\

(In the case of 8-inch diameter reel)

Fig. 2.1

NOTE

When trouble occurs in feeding or winding tape with 8-inch diameter reels, open the front door and brush away dust around the photo-coupler by using a blower brush.

2.2 CONTROL PANEL

(1)Checks on doors for tight closing (Daily)

(a)The control panel is constructed as a dustproof, sheet-steel enclosure with gasketed

doors so as to keep off dust and oil mists. Keep each door tightly closed at all times. Tension arm shaft available as an option.

(b) After inspecting the control with door open, close the door and fasten door locks (2 per door) securely using the key provided (No. YE001). When opening or closing, insert the key all the way into the keyhole and turn

until it clicks (approximately a quarter-turn). The key can be removed from an open or closed position.

|

|

|

|

@J |

|

||

~5~ii~ON~~ |

|

|

CLOSED |

||||

~-CLOSED |

|||||||

CWSED |

"-.::! |

~ |

POSITION |

||||

|

|

|

|

||||

OPEN |

POS ITION |

|

|

|

|

||

Wi th |

the door |

Wi th |

the door |

|

|||

lock |

on |

righ t |

lock |

on |

left |

|

|

side of |

the |

side of |

the |

|

|||

door |

(Lef t- hand |

door |

(Right-hand |

||||

Hinged |

Door) |

Hinged |

Door) |

|

|||

|

|

|

Fig. |

2.2 |

|

|

|

|

|

|

NOTE |

|

|

|

|

If the optional door interlocking |

|

||||||

switch is provided, opening the door |

|

||||||

shuts |

off |

the main |

power supply and |

|

|||

stops |

all operations. |

|

|

|

|||

(2) Checks |

gaps or i mpa irmen t 0 f |

to ta II y- |

|||||

enclosed structure.

(a) Check gaskets on the rims of front and

rear doors.

(b)See if the inside of enclosure IS dusty. Clean it, if necessary.

(c)Check for any opening In the door base with the doors shut tightly.

YASNAC control panel can be used stably for a longer period by executing the above procedures.

-8-

2.3 AC SERVOMOTOR

(1) Vibration and noise (Daily or as required)

Vibration can be checked by resting the hand on the motors, and for noise, using a listening stick is recommended. If any abnormality is found, contact maintenance personnel immediately.

(2) Motor contamination and impairment (Daily or as required)

Check the motor exterior visually. If dirt or damage should be observed, inspect the motor by removing the machine cover. Refer to the machine tool builder's manual.

2.4 BATTERY

Make sure that "BAT" or "AlB" on the rightlow position of CRT screen is not displayed. If it is displayed, the battery must be replaced within a month.

When replacing, never remove the old battery with power OFF, otherwise the data stored in memory are cleared. Battery cannot be obtained in the market. Contact your YASKAWA representative.

Replacing Procedure

(1) Depress POWER OFF pushbutton to shut off the power supply to the operator's station.

(2) Turn OFF the door inter lock sw itch key when a door interlock switch is provided. Then the power supply can be turned ON with the door opened.

(3) Open the door and remove the CPU module cover (type JANCD-MB20) so that the module can be seen.

(4) Depress POWER ON pushbutton (only for primary power supply).

(5) Check to see if lLED on memory board is illuminated. Fig. 2.3 shows the arrangement of LED and the battery. If illuminated, replace the battery with new one.

Battery Type: JZNC-GBAOI

(6)With the power on, remove the old battery.

(7)Put the new battery in the holder and set the connector. See Fig. 2.4. Battery connection.

(8)With the power on, make sure that blink display of CRT screen or LEDl goes off. IF they are still illuminated, it is due to the improper battery connection or defective battery.

JANCD-MB20D

LEDI

f:j

eJOo

Fig. 2.3 Arrangement of LED and Battery

o 0

CORRECT |

CORRECT |

WRONG |

Fig. |

2.4 Battery Connection |

|

-9-

3. MAINTENANCE INSTRUMENTS

(1) Measuring instruments

Name |

Allowable measuring range |

|

|

Purpose |

|

|

|||

|

|

|

|

|

|

|

|

||

|

|

10 to 30 VAC (at 40 to 100 Hz) |

To |

measure |

AC power |

voltages |

|||

|

|

Tolerance : |

±2% or |

less |

|

|

|

|

|

Tester |

|

Several mV to 100 VDC |

|

To |

measure |

DC power |

voltages |

||

or |

|

||||||||

Multi-purpose |

Tolerance : |

±2% or |

less |

|

|

|

|

|

|

digital meter |

|

|

|

|

|

|

|

|

|

Several >2 to approx. multiple of 10M>2 To measure currents flowing

Tolerance : ±5% or less through DC motors, etc.

.

(2) Tools

Phillips screwdrivers; large, medium and small Standard screwdrivers; medium and small

(3) Chemicals

Cleaning agent for tape reader (absolute alcohol)

-10-

4.TROUBLESHOOT! NG

4.1 TROuBLE IDENTIFICATION

Try to fully analyze the circumstances in which the trouble occurred. This is necessary for identifying the trouble and/or for having your YASKAWA representative called in to correct the trouble. Verifying the following poin ts will minimize the down time of your system:

4.1.1 RECOGNITION OF TROUBLE STATUS

(1)What operation will cause the trouble? (Is other operation performed normally?)

(2)When does the trouble occur: every time or frequently?

(3)Was there no external disturbance such as power interruption or lightning when trouble occurred?

(4)Did it occur during or after operation of mode switches such as EDIT or memory. or function such as IP~M I(parameter) orl DGN I(diagnose) or key switch on C~T panel?

(5)Ensure the following points if the trouble occurred as related to feed and/or spindle operation:

Check of LED on the drive unit ON/OFF check of fuse or MCCB

Time of trouble occurrence such as at power application.

at acceleration. at deceleration.

at steady-state runnine.

(6) Does it depend on part program?

If so. record also part program. offset and coordinate system settings.

4.1.2 RECOGNITION OF NC SYSTEM

recognize the status of machine and equipment regardless of the detail of trouble.

The NC unit is provided with an interlock

swi tch. When the operator opens the door. the NC unit power supply is tripped by MCCB and the interlock switch is released.

Do not start the check operation unLil the interlock switch is released.

(I) Name of machine manufacturer

(2)Time of delivery

(3)Name and type of machine

(4)Name and type of NC unit and others (Example)

NC unit

Servo drive

Servo motor

Spindle drive

Spindle motor

(5) System No. of NC software Check procedure

Keep depressinglORGlbutton on operator's panel at the time of power application. Then. the screen as shown in Fig. 4.1 appears on the CRT.

YASNAC MX3

~Servo system No.

II I I III I I

ain system No.

III I II I II

I I I I I I I I I /---PC system No.

L-______________~

Fig. 4.1 NC Screen at Power Application

(6) Ensure that the parameters are the same as Ensure the following points so as to correctly those specified in the list attached to the NC

uni t.

- 11 -

4.2 TROUBLESHOOTING BY ALARM CODES

This description covers the troubles displayed by alarm codes that were recognized by diagnostic function of NC unit during normal operation.

Refer to Appendix 1 "List of Alarm Codes.' Some additional explanations are given for especially difficult troubles.

4.2.1 |

DISPLAY |

METHOD |

|

|||

If |

an alarm condition occurs, a display "ALM" |

|||||

or |

"A/B" |

(for |

battery alarm) blinks on the |

|||

bottom |

line of |

the CRT screen regardless of |

||||

the mode or function. |

In this case, detailed |

|||||

information of |

the alarm condition will be |

|||||

displayed by the following operations: |

||||||

Depress |

the (ALM) |

key. |

|

|||

This will |

cause up |

to |

4 pairs of alarm codes |

|||

and alarm messages to appear in order of importance, with the most serious one at the top. Note: In an alarm state, the alarm screen

appears taking priority over any other display. There is no need to operate the (PAGE) key.

Alarm disp lay area diagnosed

f by He unit.

Alarm and message disp lay area by

fmach~ne sequence

Fig. 4.2 Alarm Codes and Messages

Eliminate the cause of the alarm and depress thelRESETlkey, and the alarm state and the alarm display will be reset. Notice that the alarm code "820" is displayed regardless of the selected function key.

The alarm codes are categorized as in Table

4.1.

|

|

|

|

|

|

|

|

|

|

Table 4.1 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type of |

Alarm |

|

|

|

|

|

|

Alarm No. |

Spindle OperatIon |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

000 |

to 099 |

Stop at |

block end |

Tape format errOr alarm |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

100 |

to 199 |

Stop at |

block |

end |

Macro, |

operation, external |

input/output |

||||||||||

|

|

error, |

sequence error |

(1) |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

200 |

to 299 |

Decelerated |

to |

stop |

Overtravel. |

reference |

poInt |

return. |

|||||||||

|

|

po~ltlonlng, |

MHOY |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

300 |

to 399 |

Decelerated |

to |

slop |

Servo, emergency stop, overload FG,RPG |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

400 |

to 499 |

Decelerated |

to |

stop |

Sequence error (2) |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

500 |

to 599 |

|

|

|

|

|

Unused |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

600 |

to 699 |

|

|

|

|

|

Sequencer message |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

700 |

to 799 |

|

|

|

|

|

Unused |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

800 |

to 899 |

NC |

sys tem stop |

|

CPU error, RAM error, |

ROM error |

|

||||||||||

|

|

|

Contact |

your |

YASKAWA representative. |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

900 |

to 999 |

|

|

-- |

|

|

Off-line error (for our maintenance) |

||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

NOTE: |

Alarm |

No. |

180: |

sequence error |

(I), 400: sequence error (2) |

and 600 to |

||||||||||

699: sequencer ~essages are the troubles concerned with machine sequence.

Refer to the maintenance manual prepared by machine manufacturer for details.

- 12 -

4.2.2 |

ALARMS 010 |

AND 011 |

(Parity Error) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Cause of Trouble |

|

|

|

|

Check |

l1ethod |

|

|

|

|

|

|

|

|

Solution |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Alarm 010 |

|

1) |

In |

case of |

tape |

operation: |

|

|

|

|

• Clean |

|

|

tape |

reader. |

|

||||||

|

(TH |

error) |

|

The number |

of data holes for each |

|

|

Check tape itself if the |

|

||||||||||||||

|

|

|

|

character is checked on the NC tape. |

|

feed hole is faulty and/or |

|

||||||||||||||||

|

|

|

|

An alarm is issued when the number is: |

|

the nap is raised on the |

|

||||||||||||||||

|

|

|

|

Even: |

For |

EIA |

tape |

|

|

|

|

|

|

|

hole. |

|

|

|

|

|

|

|

|

|

|

|

|

Odd: |

For |

ISO |

tape |

|

|

|

|

|

|

|

Failure of |

tape reader |

|

||||||

|

|

|

|

(The description that follows applies |

|

itself |

|

|

|

|

|

|

|||||||||||

|

|

|

|

to |

the |

EIA |

code.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

o |

0~.. ~..•~~0./. :~ |

|

0.(~ |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

000 |

|

|

|

0 |

0 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

o |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

.••• |

••••.• |

••• •.• |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

•• f •••••••.• |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

o |

o |

0 0 |

0 |

|

000 |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

0 |

00 |

0 |

|

0 |

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

0 |

000 |

00 |

0 |

0 |

|

0 |

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

F.COICN IGOX 12 J |

456C |

MJOlE |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

I.SK -ji |

|

\,",,--~)' |

|

|

|

It" |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

'" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

But |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

2) |

Failure of machining program area |

|

Failure of I1B20 board or |

|

|||||||||||||||

|

|

|

|

in case of memory operation or at time |

|

of expansion memory board |

|

||||||||||||||||

|

|

|

|

of |

EDIT. |

|

|

|

|

|

|

|

|

|

(111121 |

|

|

board) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. |

|

|

item 4.3.14 • |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Refer to |

|

|||||||

|

|

|

|

3) |

RS232C communication error |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

• Framing error |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

. Overrun |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

Alarm 011 |

|

In |

case of |

tape operation: |

|

|

|

|

|

If the tape cannot perform |

|

|||||||||||

|

(TV |

error) |

|

The |

tape should be capable of TV check. |

|

TV check, use it |

by setting |

|

||||||||||||||

|

|

|

|

(Number of characters for one block |

|

ISETI16002 D. = 0 (TV check |

|

||||||||||||||||

|

|

|

|

should |

be |

even, including |

EOB.) |

|

|

|

OFF) or make it so that it |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

can perform |

TV check. |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

Others |

|

1) |

Disagreement between |

numbers |

of |

|

|

Check |

|

the |

specification of |

|

||||||||||

|

Alarm 010 |

|

RS232C baud rates and stop bits |

|

|

|

RS232C |

equipment. |

|

||||||||||||||

|

|

|

|

2) Communication error of RS232C |

|

|

Check |

|

parameters. |

|

|||||||||||||

|

|

|

|

(e.a. |

too |

high |

noise level) |

|

|

|

|

Refer |

|

to Par. |

4.3.14. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check |

|

|

cable grounding. |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 13 -

4.2.3ALARM 075, 076, 077 (RS232C Faulty)

075:RS232C interface; disagreement between number of bits and number of baud rates

RS232C

No effect with

• 0 9999· keyedin and depressing

IOUTI key.

Setting da ta wri tten

correct! ?

YES

Parameter written proper I ?

076:RS232C interface; transmission failure

077:RS232C interface; 10 characters or more were read after stop code was issued.

NO |

#6003 |

|

||

D.=L |

D5=0 OUT |

|||

|

|

|||

|

|

Do=L |

D.=O IN |

|

|

|

|

|

|

|

|

#6028 |

(OUT) |

|

NO |

#6026 |

(IN) |

||

Baud |

rate setting. |

|||

|

|

|||

|

|

Stop |

bi t set ting. |

|

Control code setting.

Cable

NO

connections Check wiring. correct?

YES

Detailed investigation is required.

(Contact your YASKAWA representative.)

Fig. 4.3

- 14-

· Setting of _Appl icdble Jnterface

Set the data trdnsmlSSlon baud rate, stop bil length and control code sending command specificatIons wilh parameters as shown in Tables 4.3 and 4.4.

(a) Selection of RS232C Interface Porl

Select the port of RS232C inlerface by selting 16003.

Isl RS232C and 2nd RS232C cannot be selected

simuI taneously. |

|

|

|

|

|

|

|||

|

Table 4.2 Seleclion of RS232C |

Inlerface Port |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Interface |

Input |

|

Outpu l |

|||

|

|

|

1st RS232C |

«6003D. |

|

«6003D. |

|

|

|

|

|

|

2nd RS232C |

«6003D, |

|

16003D5 |

|

||

Select above bits by parametler selting "I".

(b) 1st RS232C Interface

Baud rate val~e setting for 1st RS232C interface is shown in Table 4.3.

|

|

Table 4.3 Baud Rate Value Setting |

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input |

|

|

|

|

#602t |

|

|

#602t |

|

|

B602E |

16026 |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

D3 |

|

|

D. |

|

|

D, |

|

|

D. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

Output |

|

|

|

|

B602~ |

|

|

#602f |

|

|

B6021 |

#6028 |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D3 |

|

|

D. |

|

|

D, |

|

|

D. |

|||

|

|

|

|

50 |

|

|

0 |

0 |

0 |

0 |

|

|

||||||||||||||

|

|

|

|

100 |

|

|

0 |

|

|

0 |

0 |

1 |

|

|

||||||||||||

|

|

|

|

|

|

1I0 |

|

|

|

|

0 |

|

|

0 |

1 |

0 |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Baud |

|

150 |

|

|

|

|

|

|

0 |

|

|

0 |

1 |

1 |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|