Yaskawa GPD 515-G5 User Manual

GPD 515/G5 Modbus

®

RTU

Technical Manual

Technical References

Refer to the following publications for further information about the GPD 515/G5:

• GPD 515/G5 Technical Manual

Publication TM 4515

• GPD 515/G5 RS-232C/485 Interface Card Installation Sheet

Publication 02Y00025-0401

Refer to the following Modicon publication for technical information on Modbus RTU protocol:

• Modicon Modbus Protocol Reference Guide

Publication PI-MBUS-300 Rev. D

Technical Support

Technical Support Center-

Provide telephone assistance related to installation, start-up, programming, and

troubleshooting drives and communication products. For technical phone support

call 1-800-541-0939.

Technical References / Technical Support i

CONTENTS

Technical References / Technical Support i

Contents 1

Chapter 1 GPD 515/G5 and Serial Communication 1-1

Introduction to GPD 515 Modbus RTU Communication 1-2

Standard RS-232D Serial Communication 1-2

The RS-232D to RS-485 Converter Board 1-3

Figure 1-1. The CM085 Board 1-3

Chapter 2 RS-232D Serial Communication 2-1

RS-232D Serial Communication 2-2

Figure 2-1. RS-232D Pin-out at 6CN Connector 2-2

Chapter 3 Installation of CM085 Board 3-1

Installation Procedure 3-2

Figure 3-1. Position of the CM085 Board

on the GPD 515 Drive 3-2

Chapter 4 Wiring of the CM085 Board 4-1

Connection of Multiple Drives 4-2

Figure 4-1. Interconnection Diagram 4-2

Wiring Instructions 4-3

Figure 4-2. Twisted Shielded Wire Termination 4-3

Table 4-1. Functions of Terminal Block TC1 4-3

Table 4-2. Applicable Wire Sizes for Terminal Block TC1 4-3

Terminating Resistors 4-4

Figure 4-3. SW1 Location on the CM085 Board 4-4

Chapter 5 Setting GPD 515 Parameters for Communication 5-1

Run/Stop and Frequency Selection 5-2

Communication Set up Parameters 5-3

“ENTER” Command 5-5

Chapter 6 The Message Format 6-1

Message Functions 6-2

Read Multiple Registers - 03h 6-3

Loop-back Test - 08h 6-6

Write Multiple Registers - 10h 6-8

No Response Message 6-11

CRC-16 6-11

Chapter 7 Registers 7-1

Simultaneous Broadcast Registers 7-2

Command Registers 7-3

Monitor Registers 7-4

Drive Parameter Registers 7-7

Special Registers 7-17

Contents 1

Chapter 8 Error Codes and Troubleshooting 8-1

Communication Error (CE) 8-2

Modbus Error Codes 8-2

Figure 8-1. Response Message (Fault) 8-2

GPD Failure Codes 8-3

Chapter 9 Command Priority 9-1

Command Priority 9-2

Table 9-1. Set up for Serial Communication Control 9-3

Table 9-2. Set up for External Terminals Control 9-4

Table 9-3. Set up for Digital Operator Control 9-5

Table 9-4. Set up for Option Board Control 9-6

Appendix A Product Specifications A-1

Appendix B Spare Parts List B-1

Contents 2

Chapter 1

GPD 515/G5 and Serial Communication

• Introduction to GPD 515/G5 Modbus RTU Communication

• Standard RS-232D Serial Communication

• Figure 1-1. The CM085 Board

Note: The AC Drive referenced in this manual may be named GPD

515, G5, or GPD 515/G5. These are physically the same drive. This

manual will use the name GPD 515 hereafter.

• The RS-232D to RS-485 Converter Board

GPD 515 and Serial Communication 1-1

Introduction to GPD 515 Modbus RTU Communication

This manual describes the set-up and protocol for Modbus Communication. The GPD 515 offers

RS-232D serial communication as a standard, and RS-485 as an option.

The Modbus RTU protocol requires that the controller communicates using a master-slave

technique, in which only one device (the master) can initiate transactions. The other devices (the

slaves) respond by supplying the requested data to the master, or by taking the action requested.

The GPD 515 drive must act in the slave mode.

A complete understanding of drive programming and operation is required before attempting

serial communication operation. A full discussion of programming and operation is covered in the

GPD 515 technical manual TM 4515.

GPD 515 / Modbus RTU Specifications

The data that may be sent or received from the drive consists of:

-Run Command

-Frequency Reference

-Fault Contents

-Drive Status

-Drive Parameter Settings

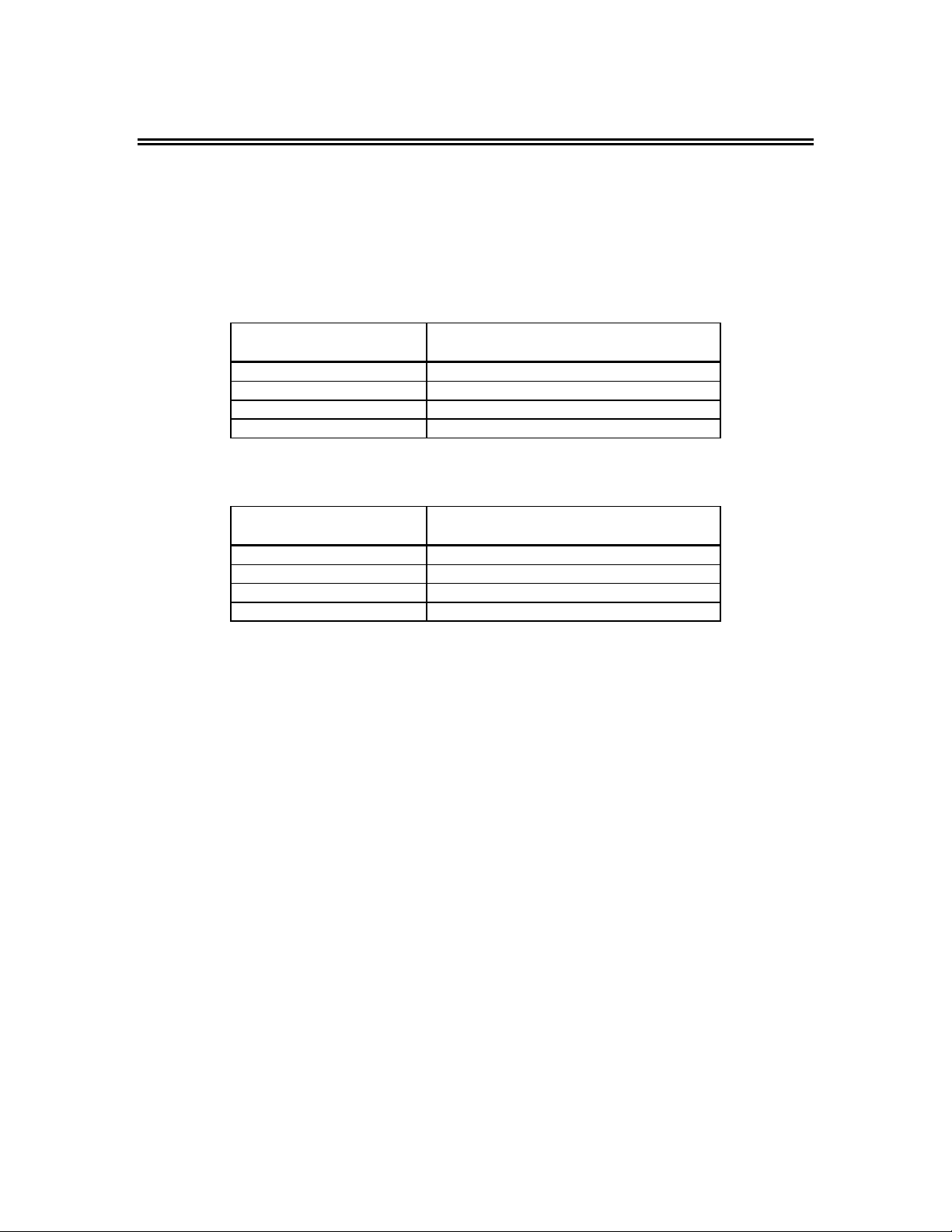

The following table illustrates whether the serial communication specifications are fixed or user

selectable. If the specification is fixed, the fixed value is shown in the last column. If the

specification is selectable, the range of allowed values is shown in the last column.

Communication Specification Fixed or Selectable Range

Baud Rate Selectable 2400, 4800, or 9600 bps

Data Bit Fixed 8

Parity Selectable None, Even, or Odd

Stop Bit Fixed 1

Nodes RS-232D point-to-point only

Nodes Selectable for RS-485 maximum of 31 nodes

Standard RS-232D Serial Communication

The GPD 515 drive offers RS-232D serial communications as a standard feature of the drive.

RS-232D has a maximum transmission distance of 50 feet. RS-232D only allows point-to-point

communications. The specifications for wiring and pin outs for RS-232D are given in Chapter 2.

1-2 GPD 515 and Serial Communication

The RS-232D to RS-485 Converter Board

The GPD 515 offers RS-485 serial communications as an option. RS-485 allows a maximum

transmission distance of 4000 feet. RS-485 allows multidrop (multiple devices) communication.

To obtain RS-485 communications an optional converter board must be purchased. This

RS-232D to RS-485 Converter Board is represented by the MagneTek part number CM085.

Read this manual thoroughly before installation, operation, maintenance, and inspection of the

CM085 Option Board.

The CM085 option board employs CMOS technology which may be damaged by static electricity.

Use proper electrostatic discharge (ESD) procedures when handling this board.

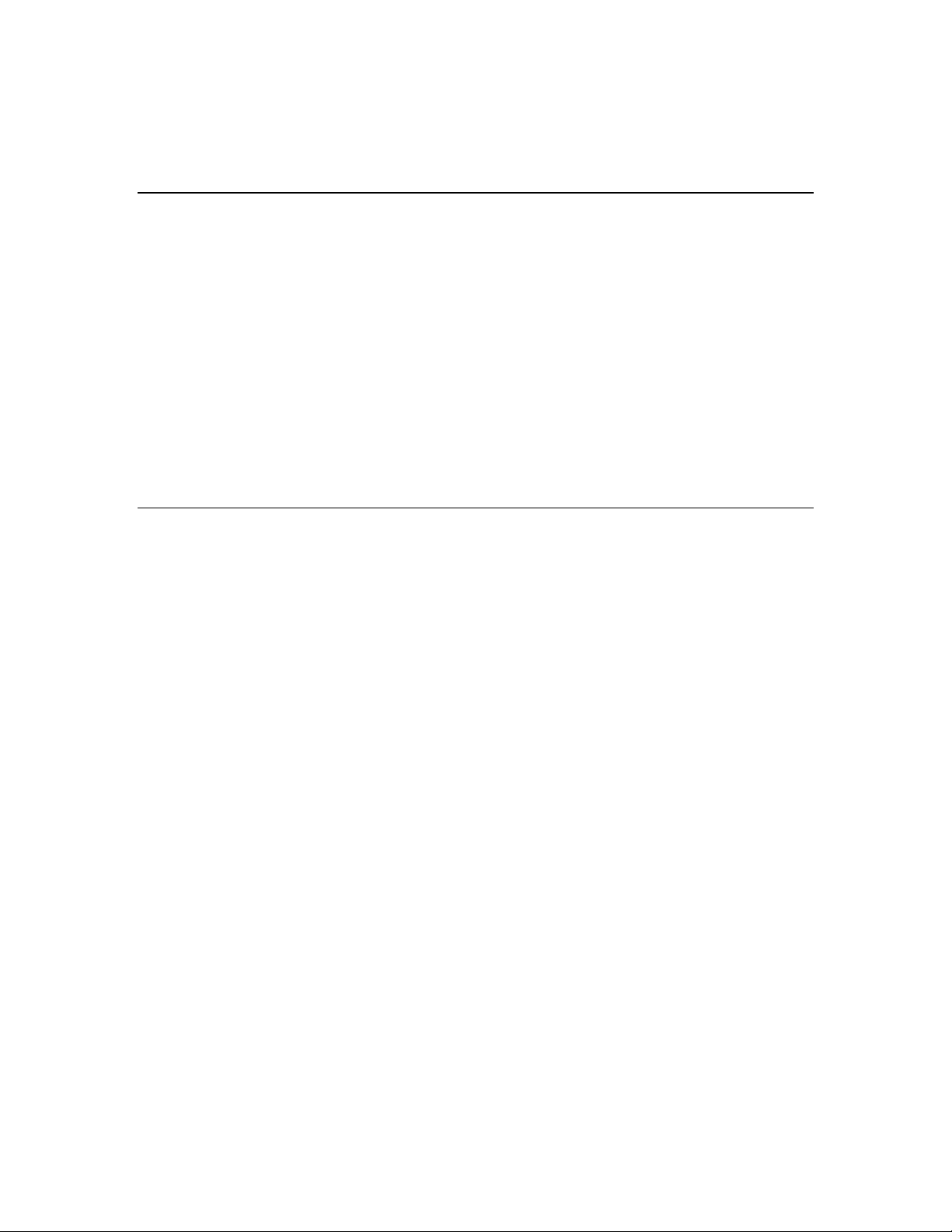

The CM085 board is used to convert the drive’s RS-232D standard function to offer RS-485

interface. The following diagram illustrates the CM085 board. (The figure is not actual size.)

CAUTION

Figure 1-1. The CM085 Board

GPD 515 and Serial Communication 1-3

Chapter 2

RS-232D Serial Communication

RS-232D Serial Communication

•

•

Figure 2-1. RS-232D Pin-out at 6CN Connector

RS-232D Serial Communication 2-1

RS-232D Serial Communication

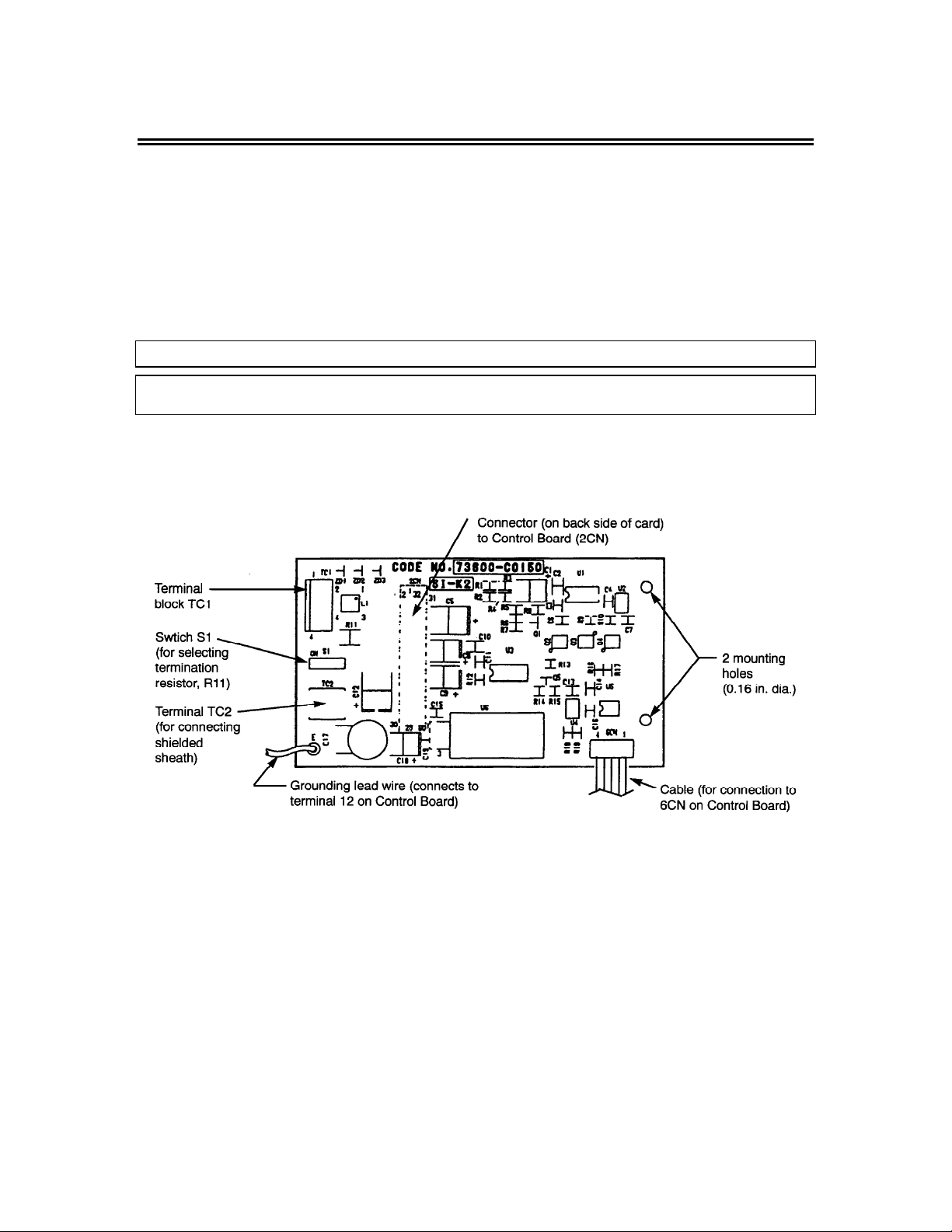

RS-232D Serial Communication is accessed through connector 6CN on the GPD 515ís control

board. Pin 1 on the 6CN connector is for the transmission of data, Pin 2 is for the receipt of data,

and pin 4 is for the ground connection. The RS-232D pin out is shown in the diagram below.

GPD515

2CN

Connector

1CN

Connector

Cable Specifications:

-cable should be a shielded, thin twisted wire 22-28 AWG

-cable pinout is as follows:

Computer - 9 Pin Female

6CN

Connector

Figure 2-1. RS-232D Pin-out at 6CN Connector

GPD 515 Connector for 6CN

D shell

3 - Tx 2 - Rx

2 - Rx 1 - Tx

5 - GND 4 - GND

1

2

3

4

Tx

Rx

GND

-pinout for devices other than a computer (PC), such as a PLC, may vary.

2-2 RS-232D Communication

Chapter 3

Installation of the CM085 Board

Installation Procedure

•

• Figure 3-1. Position of the CM085 Board on the

GPD 515 Drive

Installation of the CM086 Board 3-1

Installation Procedure

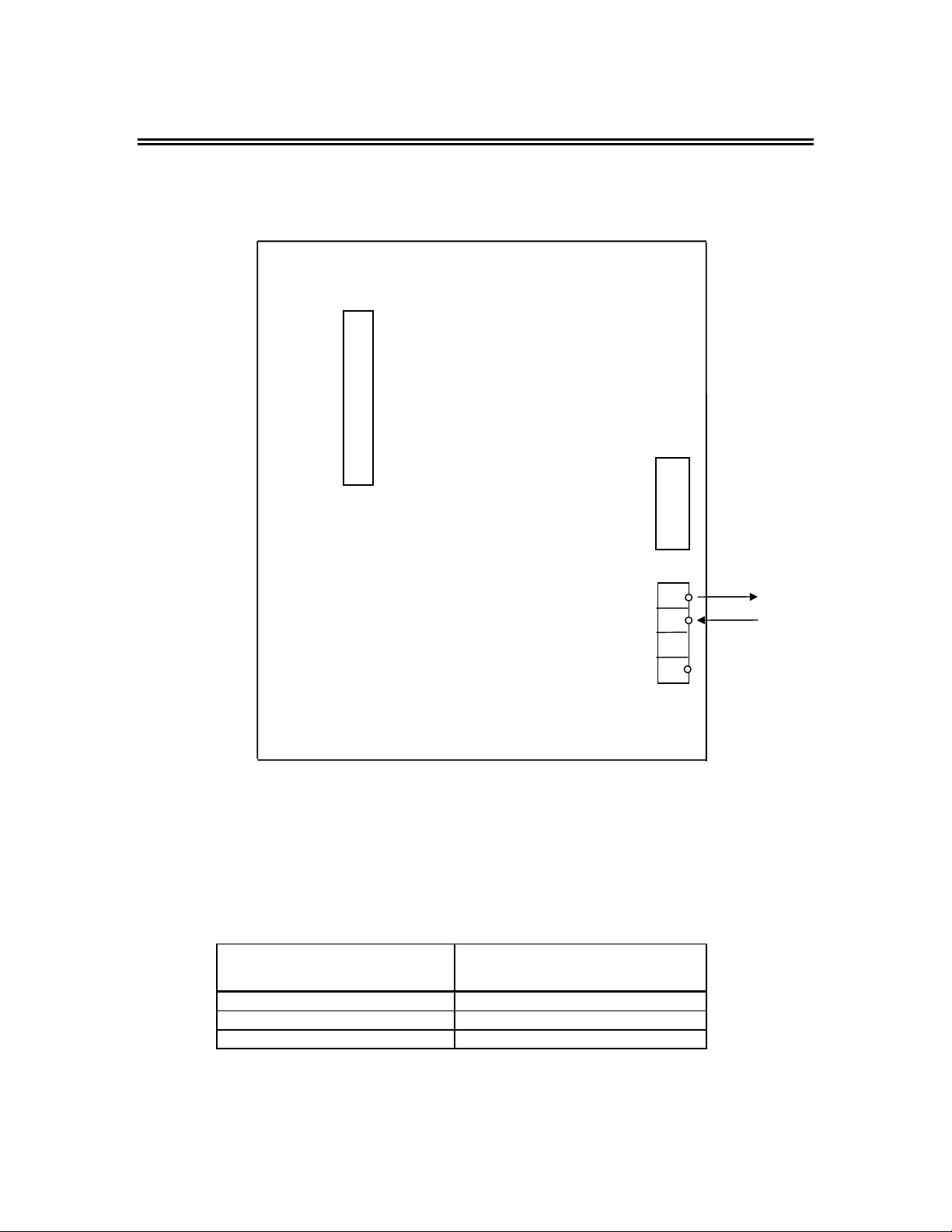

These procedures should be followed when installing the CM085 board into the GPD 515 drive.

1. Turn the main power OFF to the drive. Remove the front cover of the drive to verify that the

CHARGE lamp is off.

2. Position the CM085 board onto the control board of the drive, lining up the 2CN connector on

the CM085 board with the 2CN connector on the control board of the drive.

3. Position the two spacer holes on the right side of the CM085 board with the plastic stand-offs

on the control board. Snap the CM085 board onto the stand-offs tightly.

4. Plug the 6CN cable from the CM085 board into location 6CN on the control board.

5. Connect the green wire (labeled ëEí) from the CM085 board to terminal 12 on the drive.

6. After installing the CM085 board onto the drive, connect with peripheral devices and replace

the cover of the drive.

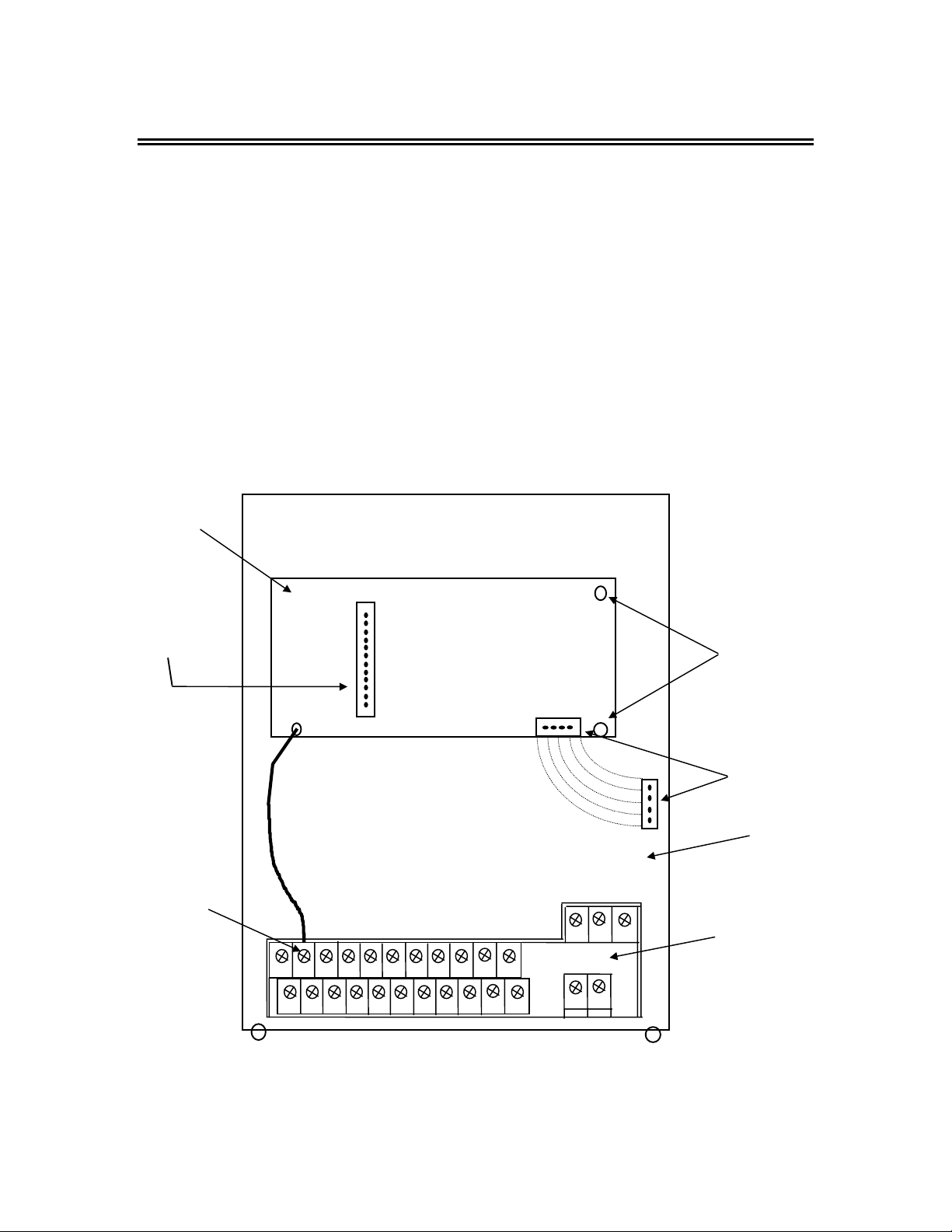

CM085

Board

2CN

Connector

Ground

Terminal

Spacer Holes

inserted onto

stand-offs

E

6CN

Connection

Drive Control

Board

Main Control

Terminals

Terminal Block

Figure 3-1. Position of the CM085 Board on t he GPD 515 Drive

3-2 Installation of CM086 Board

Chapter 4

Wiring of the CM085 Board

Connection of Multiple Drives

•

• Figure 4-1. CM085 Connection Diagram

Wiring Instructions

•

• Figure 4-2. Shielded Wire Termination

• Table 4-1. Functions of Terminal Block TC1

• Table 4-2. Applicable Wire Sizes for Terminal

Block TC1

Terminating Resisto r

•

• Figure 4-3. SW1 Location on the CM085 Board

Wiring of the CM085 Board 4-1

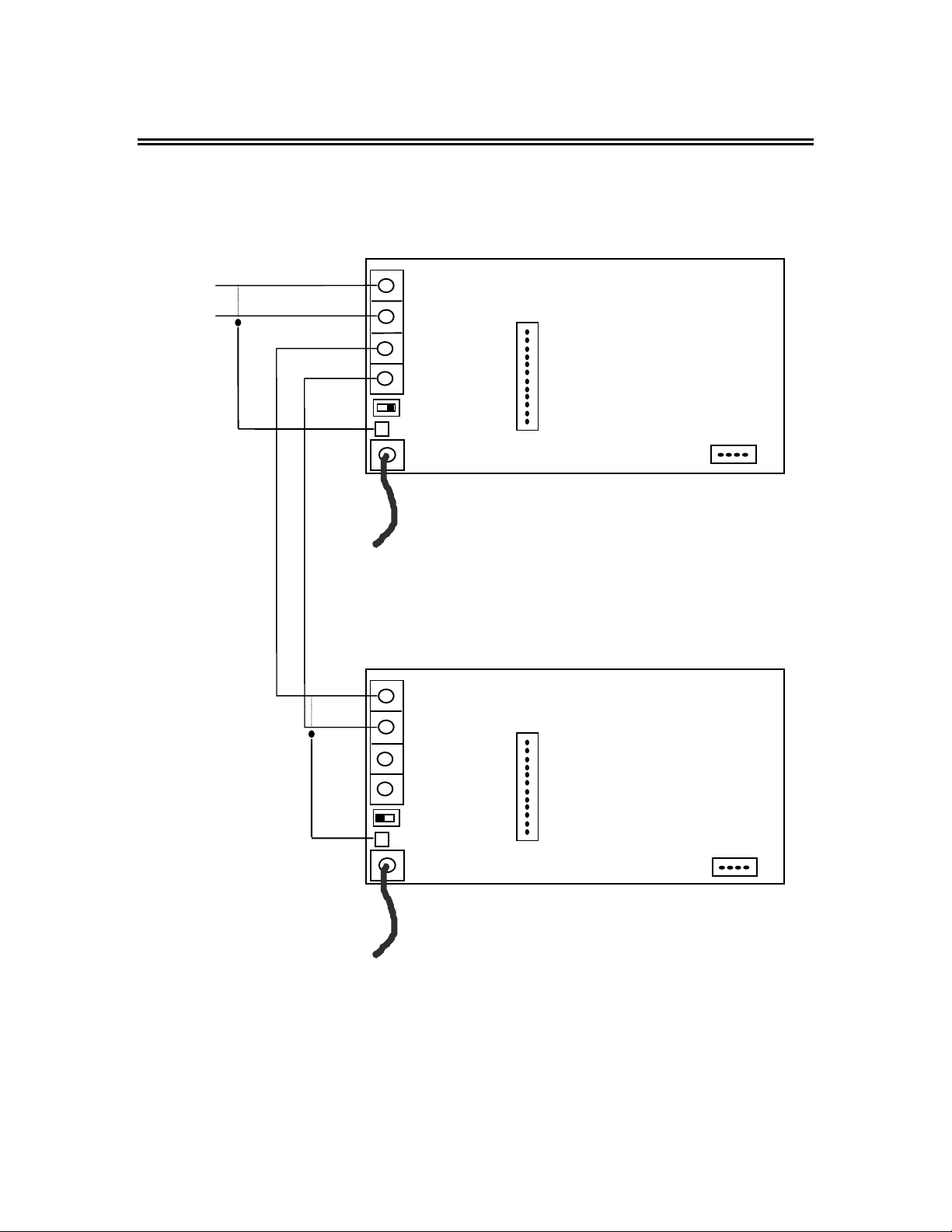

Connection of Multiple Drives

With the RS-485/RS-422 Conversion Board (CM085) multiple drives may be connected together

for a multiple drive communication system. The following diagram illustrates the connection

between multiple CM085 boards.

(+)

RS-485

(-)

Shielded Sheath

Connection

S/R (+)

S/R (-)

S/R (+)

S/R (-)

S/R (+)

S/R (-)

TC1

1

2

3

4

SW1

TC2

Ground

Connection

TC1

1

2

2CN

CM085

BOARD

6CN

2CN

Shielded Sheath

Connection

Figure 4-1. Interconnection Diagram

4-2 Wiring of the CM085 Board

3

4

SW1

TC2

Ground

Connection

CM085

BOARD

6CN

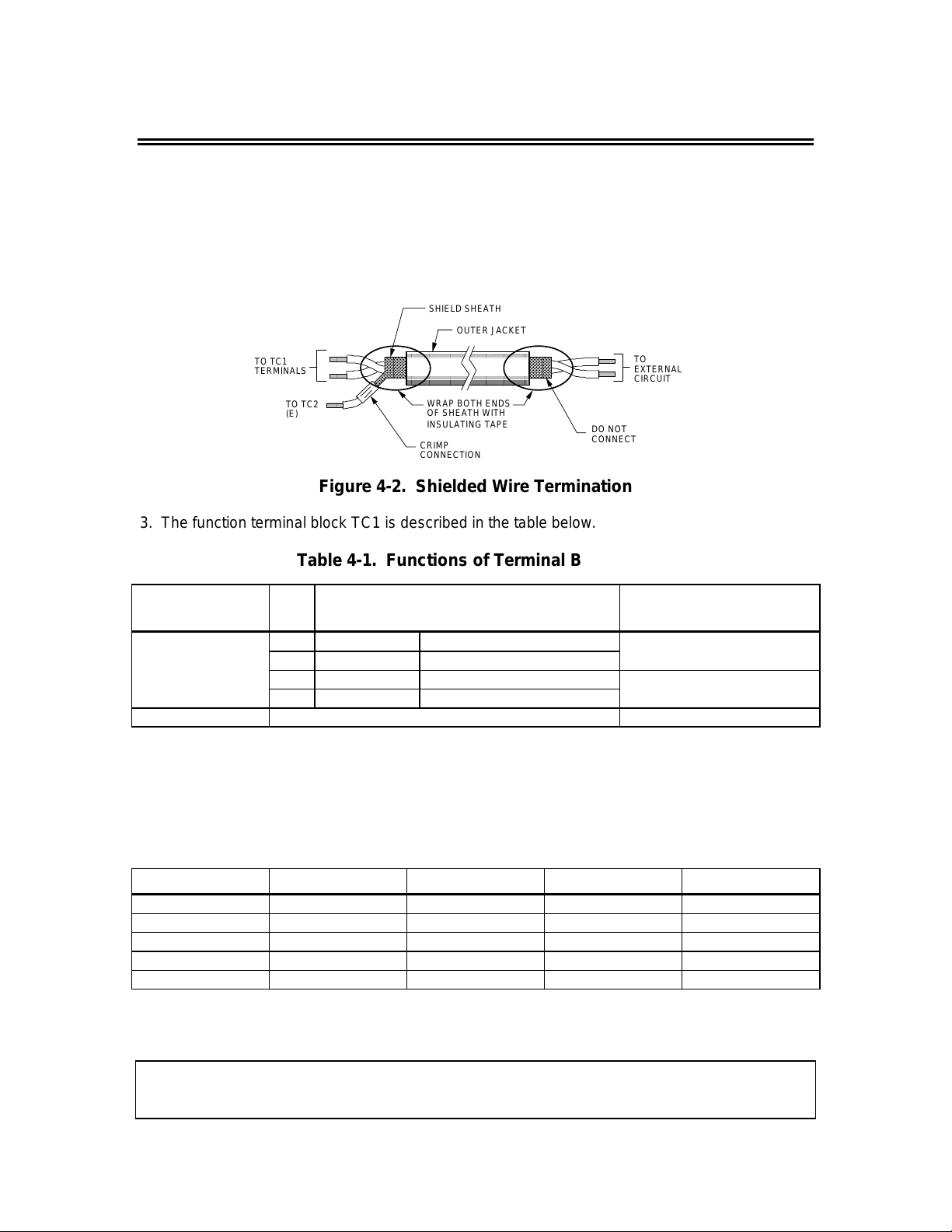

Wiring Instructions

1. Locate terminal block at TC1 on the CM085 board. (See Figure 1-1 in this manual.)

TC1 should have 4 terminal locations (1, 2, 3 and 4) on it.

2. A twisted shielded wire should be used for connection to TC1. The shielded wire should

be separated and connected per the drawing below to eliminate interference due to

noise.

SHIELD SHEATH

OUTER JACKET

DO NOT

CONNECT

TO

EXTERNAL

CIRCUIT

TO TC1

TERMINALS

TO TC2

(E)

WRAP BOTH ENDS

OF SHEATH WITH

INSULATING TAPE

CRIMP

CONNECTION

Figure 4-2. Shielded Wire Termination

3. The function terminal block TC1 is described in the table below.

Table 4-1. Functions of Terminal Block TC1

Terminal Block

Symbol

TC1 2 S/R (-) RS-485 input/output (-) parallel connection

TC2 Shield connection terminal -

4. It is important that an appropriate wire size is selected. When the wire gauge is too thick,

it may apply pressure to the CM085 board and cause failure. When the wire gauge is too

thin, it may lead to imperfect contact or a break in the wire. The table below indicates

the suggested wire size to be used at TC1.

Pin

Functions Remarks

No.

1 S/R (+) RS-485 input/output (+) Use as input at

3 S/R (+) RS-485 input/output (+) Use as output at

4 S/R (-) RS-485 input/output (-) parallel connection

Table 4-2. Applicable Wire Sizes for Terminal Block TC1

[mm2] AWG I [A] VAC [V]

Twisted wire 1.0 16 12 125

Single wire 1.5 16 12 125

UL - 22-16 10 300

CSA - 28-16 10 300

CSA - 28-16 10 150

5. When stripping the wire end to be connected at TC1, approximately 5.5 mm of wire

should be exposed to make a good connection.

Note: Avoid sources of electric interference capable of inducing noise into the cable.

Communication and signal wiring should be kept separate from power wiring. If communication

or signal wiring must cross power wiring, it must cross at a right angle.

Wiring of the CM085 Board 4-3

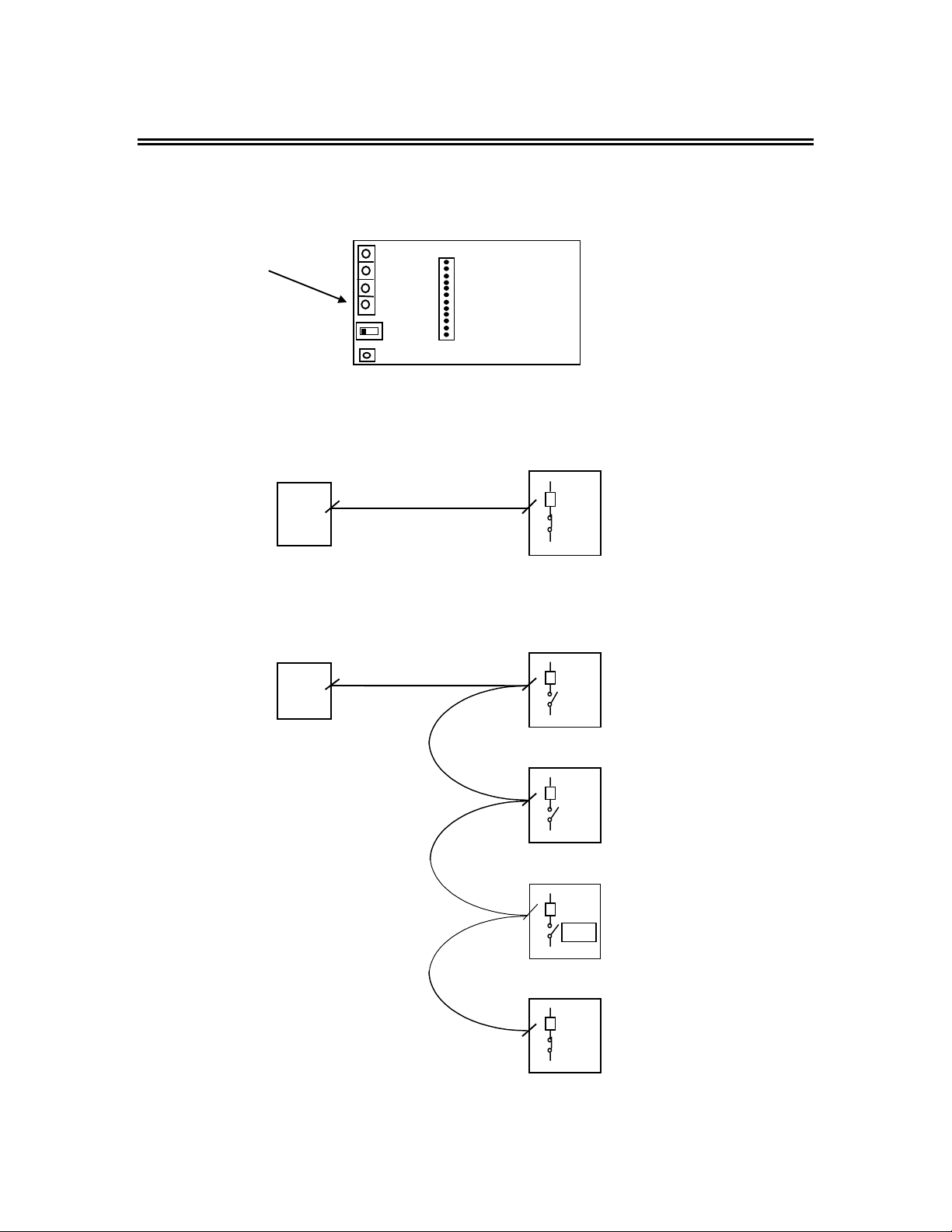

Terminating Resistor

Dip Switch SW1 is located on the lower right hand corner of the CM085 board. (See Figure 4-3

below) When SW1 is on, a termination resistor (100 Ohms) is connected between S/R (+) and

S/R (-).

TC1

1

2

3

4

on

SW1

TC2

Figure 4-3. SW1 Location on the CM085 Board

For one-to-one connections of the CM085 card and a master device set SW1 to ON as shown

below.

RS-485

2CN

CM085

BOARD

ON

Master Device

CM085 Board

If multiple CM085 cards are connected to a master device, set SW1 on the last CM085 board to

ON as shown below.

RS-485

OFF

Master Device

CM085 Board

OFF

CM085 Board

OFF

CM085 Board

4-4 Wiring of the CM085 Board

ON

CM085 Board

Chapter 5

Setting GPD 515 Parameters for

Communication

Run/Stop and Frequency Selection

•

Communication Set up Parameters

•

ìENTERî C ommand

•

Setting GPD 515 Parameters for Communication 5-1

Run/Stop and Frequency Selection

The run/stop commands and frequency reference command can originate from serial

communication, the Digital Operator, the external terminals, or an option board. The origin of the

run/stop command does not have to be the same as the origin for the frequency reference

command. Parameter b1-01 (Reference Selection) allows you to set up the origin of the

frequency reference, and parameter b1-02 (Operatoin Mode Selection) sets the origin of the

run/stop commands. Parameter b1-01 is Modbus register number 180h, and b1-02 is Modbus

register 181h. The charts shown below illustrate the possible frequency reference and run/stop

selections.

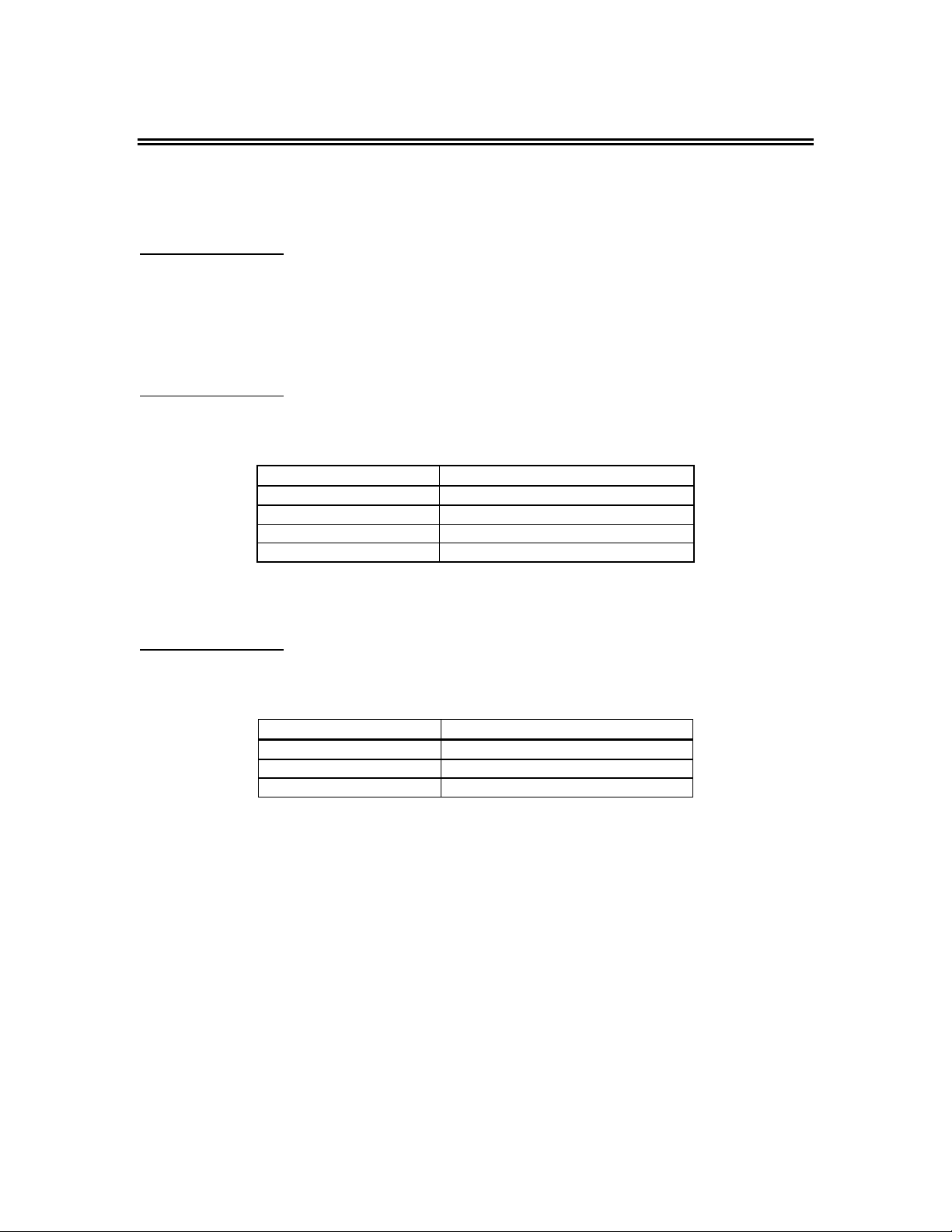

Parameter b1-01 (180h)

Setting

0 Digital Operator

1 External Terminals

2 Serial Communication

3 Option board

The default setting of parameter b1-01 is ë1í.

Parameter b1-02 (181h)

Setting

0 Digital Operator

1 External Terminals

2 Serial Communication

3 Option board

The default setting of parameter b1-02 is ë1í.

Frequency Reference Selection

Operation Method Selection

(Run/Stop)

5-2 Setting GPD 515 Parameters for Communication

Serial Communication Set up Parameters

The GPD 515 has parameters used for the set up of serial communication. These

communication set up parameters are H5-01 through H5-05 and o2-09.

Parameter H5-01 - Serial Communication Station Address

Parameter H5-01 (or Modbus Register 41Ch) is used to set the Modbus slave address of the GPD

515 drive. The slave address can be any number from 1 to 1F in hexadecimal (or 1 to 31

decimal). Two nodes may not have the same address. The default setting for parameter H5-01

is ë1Fíh.

Parameter H5-02 - Serial Communication Baud Rate Selection

Parameter H5-02 (or Modbus Register 41Dh) is used to select the baud rate. The table below

indicates the baud rates that may be selected.

Setting Value (in hex) Baud Rate Selection

0 1200 bps

1 2400 bps

2 4800 bps

3 9600 bps

The default setting of parameter H5-02 is ë3í.

Parameter H5-03 - Serial Communication Parity Selection

Parameter H5-03 (or Modbus Register 41Eh) is used to select the parity . The table below

indicates the parity that may be selected.

Setting Value (in hex) Parity Selection

0 No parity

1 Even parity

2 Odd parity

The default setting of parameter H5-03 is ë0í.

Communication Error (CE)

A communication error can occur only after communication has been established between the

master and the drive. The drive waits for the master to initiate communication.

The message data is always checked for CRC, parity, overrun, framing, and overflow. If the data

has discrepancies in any of these areas a communication error will occur. If the drive does not

receive a message (addressed to its appropriate slave address set up in H5-01) within a period of

2 seconds, a time-out occurs. A time-out can also cause a communication error if it is enabled

(see parameter H5-05).

Parameters H5-04 and H5-05 are the set up parameters that determine how the drive will respond

to a communication error.

Setting GPD 515 Parameters for Communication 5-3

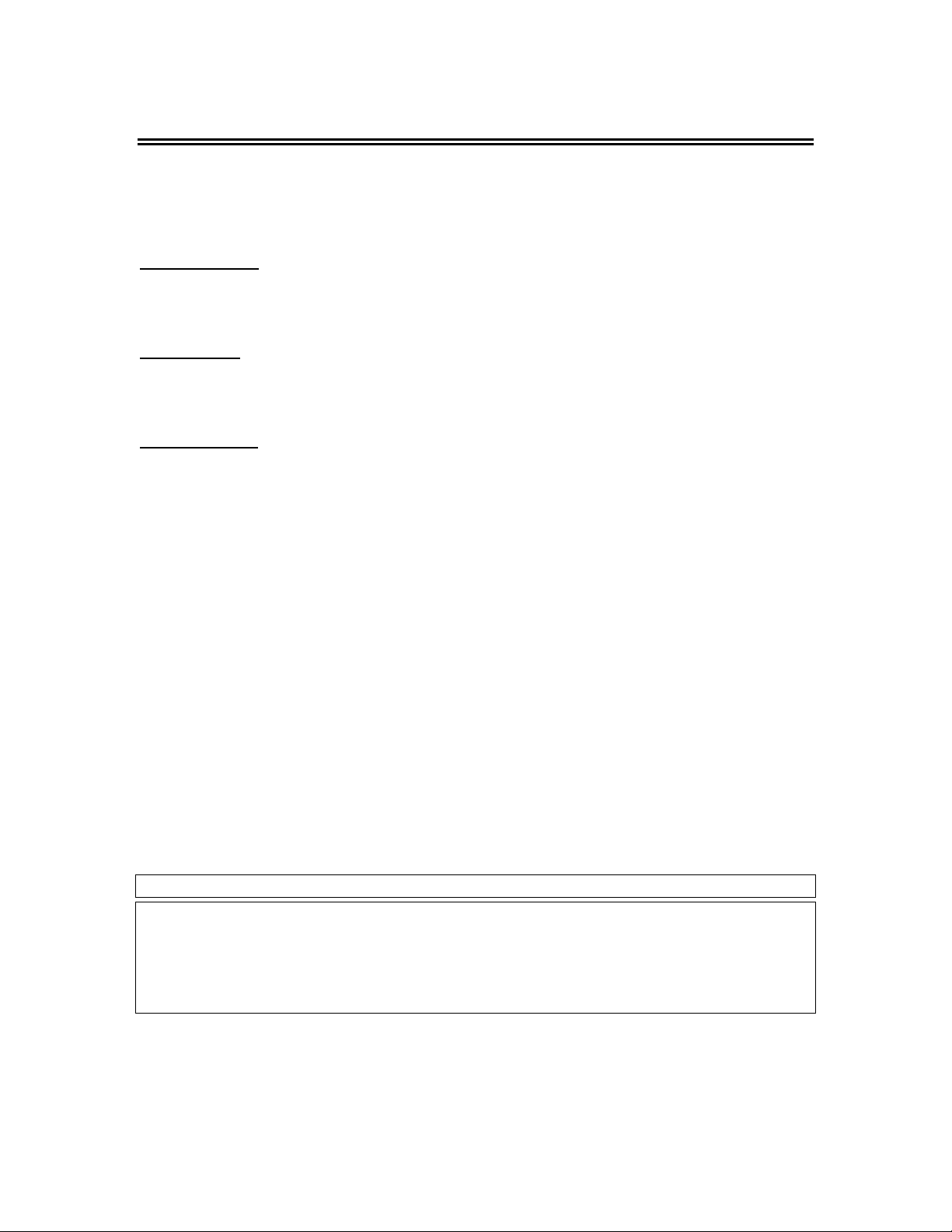

Parameter H5-04 - Stopping Method after Serial Communication Error

Parameter H5-04 (or Modbus Register 41Fh) is used to determine the method of stopping the

motor if there is a communication error. The table below indicates the stopping methods that can

be used when a communication error occurs.

Setting Value (in hex) Stopping Method

0 Decelerate to stop

1 Coast to stop

2 Fast Stop

3 Alarm Only / Continue Operation

The default setting of parameter H5-04 is ë3í.

Parameter H5-05 - Serial Fault Detection Selection

Parameter H5-05 (or Modbus Register 420h) is used to enable or disable the Time-out detection.

The table below indicates how to enable or disable the communication error.

Setting Value (in hex) Time-out Detection Selection

0 disabled

1 enabled

The default setting of parameter H5-05 is ‘1’.

Parameter o2-09 - Initial Mode Select

Parameter o2-09 (or Modbus Register 50Dh) determines the Modbus Register Address of the

operational signals register and frequency reference register. Set this parameter to ë1í so that the

Modbus Register Addresses of the Operation Signal register is 001h and the Frequency

Reference register is 002h. The Modbus Register Address for Operation Signals is 00h and the

Frequency Reference register is 01h for flach software versions previous to ‘1024’ and CPU

version ‘20’.

The default setting for parameter o2-09 is ‘0’.

Note: Power must be cycled to the drive,

to make the serial communication set up parameters effective.

5-4 Setting GPD 515 Parameters for Communication

ìENTERî Command

The GPD 515 has two types of memory: ëVolatileí and ëNon-Volatileí. Data held in the Volatile

memory will be lost when power is removed from the drive. Data held in Non-Volatile memory will

be retained when power is removed from the drive. Different types of registers are stored in

different areas of memory.

Command Data:

The command registers (000h to 00Fh) are stored in Volatile memory. When writing to a

command register the new data becomes active immediately. In the case of a power loss all data

stored in these registers will not be retained.

Monitor Data:

The monitor registers (010h to 01Fh) are stored in Volatile memory. These registers can not be

written to (read only registers). Any data read from the monitor registers will not be retained

during a power loss situation.

Parameter Data:

The parameter registers (100h to 50Dh) are stored in Non-Volatile memory. When writing new

data to parameter registers, an ëENTERí command must be given for the new data to become

active.

There are two different types of ëENTER’ commands, ‘ACCEPT’ and ‘ENTER’. For an ‘ACCEPT’,

write the value ‘0’ to Modbus register FFDDh. This causes data to become “active”. If a power

loss occurs, the data will not be retained. For an ‘ENTER’, write the value ‘0’ to Modbus register

FFFDh. This causes data to become “active” and saves the date to Non-Volatile memory. If a

power loss occurs, the data will be retained.

Some Parameter Data registers may be written to while the drive is running. These parameters

are called run operative parameters. For a list of these paremeters, refer to Appendix A, Table

A1-11 of the GPD 515 technical manual (TM 4515).

All other Parameter Data registers may only be written to when the drive is stopped. These are

called non-run operative parameters.

If new data is written to any parameter serially, and is not followed by an ‘ENTER’ command, a

“Busy Write Protected” message will flash on the Digital Operator display if an attempt is then

made to change a parameter using the Digital Operator.

The same message will be displayed if an attempt is made to change a parameter via the Digital

Operator while the contents of the ‘ENTER’ command register is any value other than ‘0’.

NOTE

Use the ‘ENTER’ (FFFDh) command only when necessary!

The life of the EEPROM (Non-Volatile memory) on the GPD 515 will support a finite number of

operations. This means that the ‘ENTER’ command, value ‘0’ written to

register FFFDh, can only be used a maximum of a 100,000 times to store data in the EEPROM.

After the specified number of operations, the EEPROM may fault

control board to be replaced.

(ERR)

requiring the GPD 515

Setting GPD 515 Parameters for Communication 5-5

Chapter 6

The Message Format

Message Functions

•

Read Multiple Registers

•

Loop Back Test

•

Write Multiple Registers

•

No Response Message

•

CRC-16

•

The Message Format 6-1

Message Functions

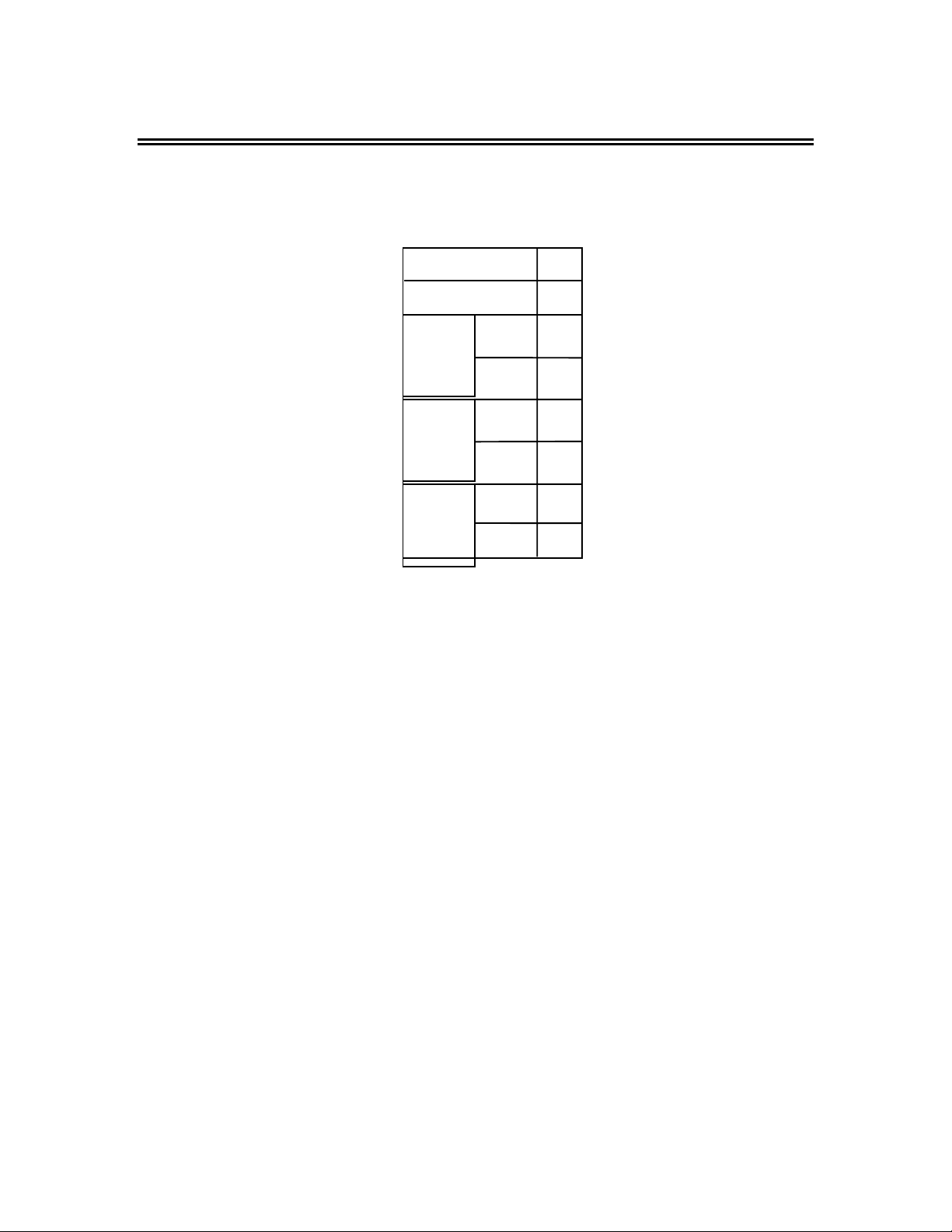

In communicating to the GPD 515 drive via Modbus RTU, there are three message functions

available. The master specifies the function to be executed by the slave according to the function

code. The following table shows the types of function codes available, and the length (quantity)

and contents of the message according to the function.

Function

Code (hex)

3 Read Multiple Registers 8 8 7 37

8 Loop-back test 8888

10 Write Multiple Registers 11 41 8 8

The message format varies depending upon the function of the message. For each function,

there is a command message from the master and a response message initiated from the slave.

The following sections review the format of the command message and the response message

for each function.

Function

Command

Message

min.

(bytes)

max.

(bytes)

Response

Message (Normal)

min.

(bytes)

max.

(bytes)

6-2 The Message Format

Read Multiple Registers - 03h

N

The multiple register read function (03h) allows the master to request information from the slave.

The command message of a multiple register read is structured as shown below.

Command Message

SLAVE ADDRESS

FUNCTION CODE

STARTING

REGISTER

O.

UPPER

LOWER

UPPER

03h

00h

20h

00h

QTY.

LOWER

LOWER

04h

45h

CRC-16

UPPER

F0h

Each GPD 515ís slave address is set in advance by the drive parameter H5-01. Valid slave

addresses must be in the range of 1 to 31 decimal (1 to 1F hex). No two slaves may have the

same address. The master addresses the slave by placing the slave address in the address field

of the message. In the command message above, the slave is addressed at 2.

The function code of this message is 03h (read multiple registers).

The starting number is the first register to be read. In the command message above the starting

register is 20h, indicating that the first register is the Frequency Reference. A listing of the GPD

515ís registers is shown in Chapter 7, Registers.

The quantity indicates how many consecutive registers are to be read. The quantity may range

from 1 to 16 registers. If the quantity is greater than 16, an error code of ë3í is returned in the

fault response message. In this command message there is four consecutive registers to be

read: 20h-Frequency Reference, 21h-Output Frequency, 22h-Output Current, and 23h-Control

Method.

A CRC-16 value is generated from a calculation using the values of the address, function code,

and data sections of the message. The procedure for calculating a CRC-16 is described at the

end of this chapter. When the slave receives the command message it calculates a CRC-16

value and compares it to the one in CRC-16 field of the command message. If these two CRC-16

values are the same the slave has received the proper command message. If the two CRC-16

values are not the same the slave will not respond.

If the command message has a valid slave address, function code, starting register, and quantity

value, the slave will respond with a normal response message. If the command message has an

invalid slave address, function code, starting register, and/or quantity the slave will respond with a

fault response message.

The Message Format 6-3

6-4 The Message Format

Loading...

Loading...