Yaskawa GPD503 User Manual

Magne

Tek

GPD 503

Technical Manual

- i -

GPD 503 SIMPLIFIED START-UP PROCEDURE

This procedure will quickly get you up and running by Digital Operator keypad or user supplied

remote operator control. It assumes that the GPD 503 and motor are correctly wired (see pages

1-8 thru 1-15), and start-up is to be performed without any changes to factory set constants.

Detailed information on the many other features of this drive will be found in later sections of this

manual.

INSTALLATION

1. Be certain your input voltage source, motor, and drive name plates are all marked either 230V,

460V, or 575V. Other voltages can be used, but require additional programming, see Section

2.

2. Mount drive on a vertical surface with adequate space for air circulation.

3. Remove front cover, fit conduit to bottom plate, and connect power and ground wires as

shown.

CAUTION

Be certain you connect input power to terminals L1, L2, and L3 only, or serious damage

will result. Connect motor to terminals T1, T2, and T3 only.

KEYPAD OPERATION

1. Replace cover and apply input power - keypad display shows "

F00.00

"; DRIVE, FWD, and

STOP lampS are on. Press and hold JOG key, noting direction of motor rotation. If it is

incorrect, remove power, wait for “CHARGE” light to go out, then switch wires between

terminals T1, and T2. Replace cover, and apply input power.

2. Run, Stop, and Frequency (Speed) - Here, the terms frequency and speed are used

interchangeably. A value of 60.00 (Hz) in the “

F00.00

” display equals full speed (frequency)

for common motors. Press RUN key; RUN lamp lights, STOP lamp flashes (to indicate drive is

running at zero speed). Note flashing "0" in “

F00.00

” display. Press “up arrow” key one time

to increase display frequency value to 10.00. Press DATA/ENTER key to enter speed data,

noting that motor shaft begins to turn. Repeat this procedure using “up arrow”, “down arrow”

and “right arrow” (RESET) keys to introduce various speeds, noting that the drive responds to

each new value only after the DATA/ENTER key is pressed. The “

F00.00

” display indicates

the frequency command the drive is looking at, whether it is running or not.

3. Reversing - can be selected while stopped, or while running. With the drive stopped, press

FWD/REV key and note the REV lamp lights and FWD lamp goes out. If drive is running

when this key is pressed, the drive will decelerate the motor to 0 Hz, then accelerate the

motor to the same speed in the opposite direction. You can try this while running, provided

your machine can be operated in reverse direction without damage.

4. Displays - With drive stopped, each time the DISPL (display) key is pressed, a different

function appears. The first function on power up is the “

F00.00

” display, discussed above.

Press DISPL and “

0.00

” appears; this is a display of output frequency (speed) and is

recognized as the only display without alpha characters. The next is

“

0.0A

”; the “A” indicates

this display is output amps. For other display information, refer to Section 3.

5. Faults - If an unacceptable operating condition such as code Ou (over voltage), Uu (under

voltage), OC (over current), etc. occurs, the drive will trip, and the motor will coast to a stop.

The appropriate fault code will be displayed. Examine fault code; consult Sections 6 & 7 for

fault correction procedure.

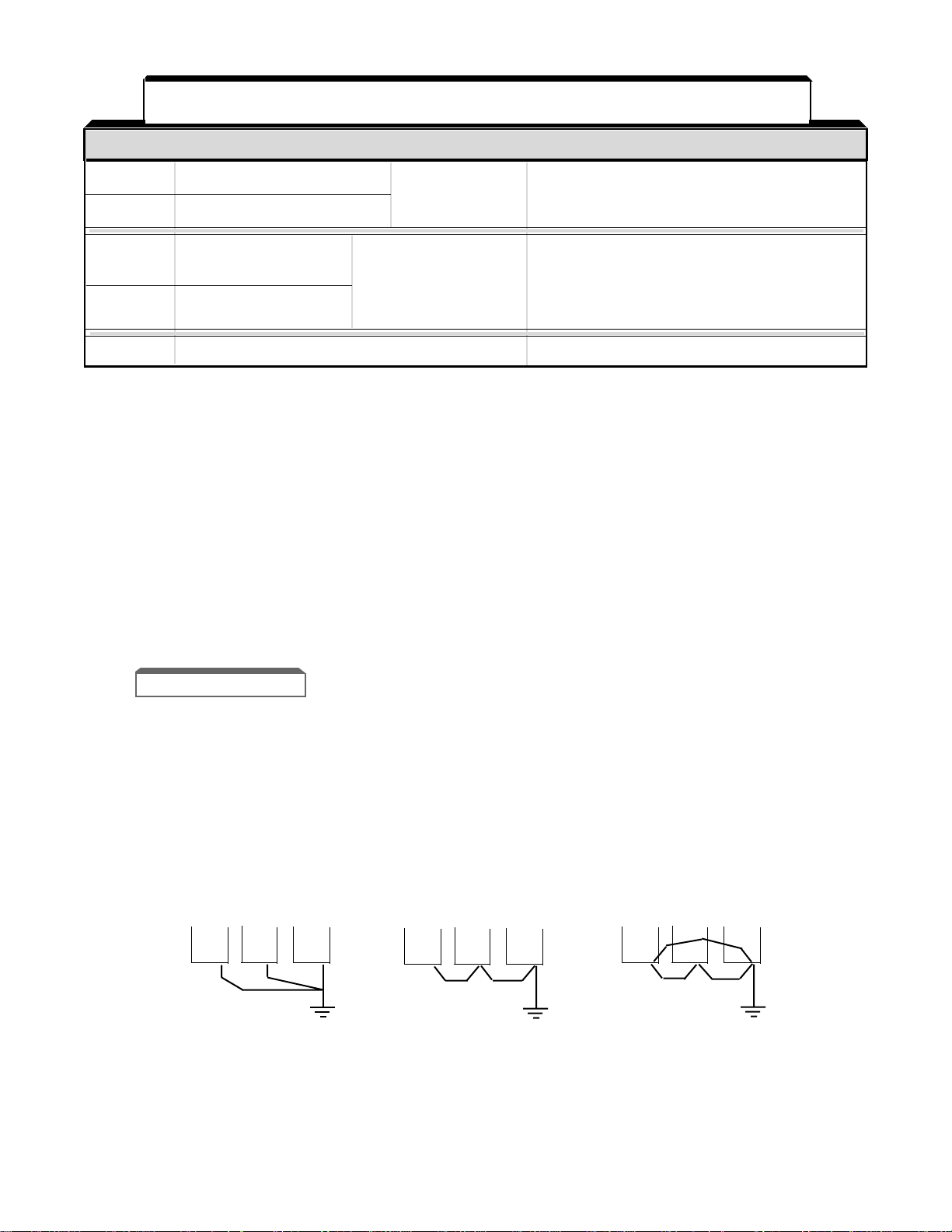

INSTALLATION OF EXTERNAL RUN/STOP SWITCH AND SPEED POTENTIOMETERS

IMPORTANT: Complete the INSTALLATION and KEYPAD OPERATION instructions before

attempting external control.

1. Disconnect power, remove cover, and wait for “CHARGE” light to go out.

2. Refer to the diagram below and connect a switch to terminals 1 and 11 using two conductor

shielded wire. This circuit is 24Vdc, very low current; use a quality rotary or toggle switch

(all wire should be 14-18AWG). Connect the shield to terminal 12 on the drive end only.

3. Install a single conductor “jumper” wire between drive terminals 5 and 11.

4. Connect a manual speed potentiometer rated 2000-3000 ohms, 1 watt minimum, using

three conductor shielded wire, with shield connected at terminal 12. Connect wires to the

potentiometer as shown, viewing potentiometer from the back. Trace wire shown closest to

the top in diagram (right side of potentiometer) and connect to terminal 17. Trace center

wire of potentiometer through and connect to terminal 16. The remaining wire will be

connected to the trim pot in step 5.

5. Connect a trim potentiometer rated 2000-3000 ohms, 1 watt minimum, as close to the drive

terminals as possible. Viewing the potentiometer from the back, connect a single conductor

wire from the left terminal to terminal 15 of the drive. Connect a short jumper wire between

the center and left terminals. Connect remaining wire from manual speed pot as shown.

- ii -

11 12 13 14 15 16 17 25 26 27

1 2 3 4 5 6 7 8 21 22

1R

Trim Pot

S1

STOP

RUN

SHIELD

WIRES

1RH

MANUAL SPEED

POTENTIOMETER

(REAR VIEW)

Shield wire

termination

GPD 503

Control Board

terminals

"Jumper

wire"

IMPORTANT: Programming is required to set up the drive for operation from external

terminals.

6. Replace cover, make sure remote switch S1 is in “Stop” position, then apply power. Note that

the DRIVE lamp is on. Press DRIVE/PROGRAM key, noting the DRIVE lamp goes out,

indicating drive is in the “Program mode”. The display will show “

Sn-01

”, which is a constant

(address). Press the “up arrow” (RESET) key three times to change constant to “

Sn-04

”.

Press the DATA/ENTER key; the display will show “

0011

”, and the left 0 will be flashing.

Using the same procedure used in setting the speed in “KEYPAD OPERATION”, move to the

first 1 and change it to 0; then move to the remaining 1 and also change it to 0. The display

should now read “

0000

”. Press the DATA/ENTER key to change the contents of constant

Sn-04 to this new value. Display will momentarily show

"

End

".

7. Press DRIVE/PROGRAM key, noting DRIVE lamp turns on; you have returned to the “Drive

mode”.

8. Calibrate manual speed pot for maximum speed at maximum rotation. With switch S1 in the

“Stop” position, press DISPL key repeatedly, stopping at the “

FXX.XX

” display. The display

will be indicating the combined setting of the trim, and manual speed pots. Turn manual

speed pot (as viewed from the front) to the right (maximum) setting. Turn trim pot slowly

until “

F59.00

” is displayed, then advance just enough to display “

F60.00

”.

9. Press DISPL key to move to output frequency display, turn switch S1 to “Run”, and adjust

motor speed with manual speed pot.

- iii -

- iv -

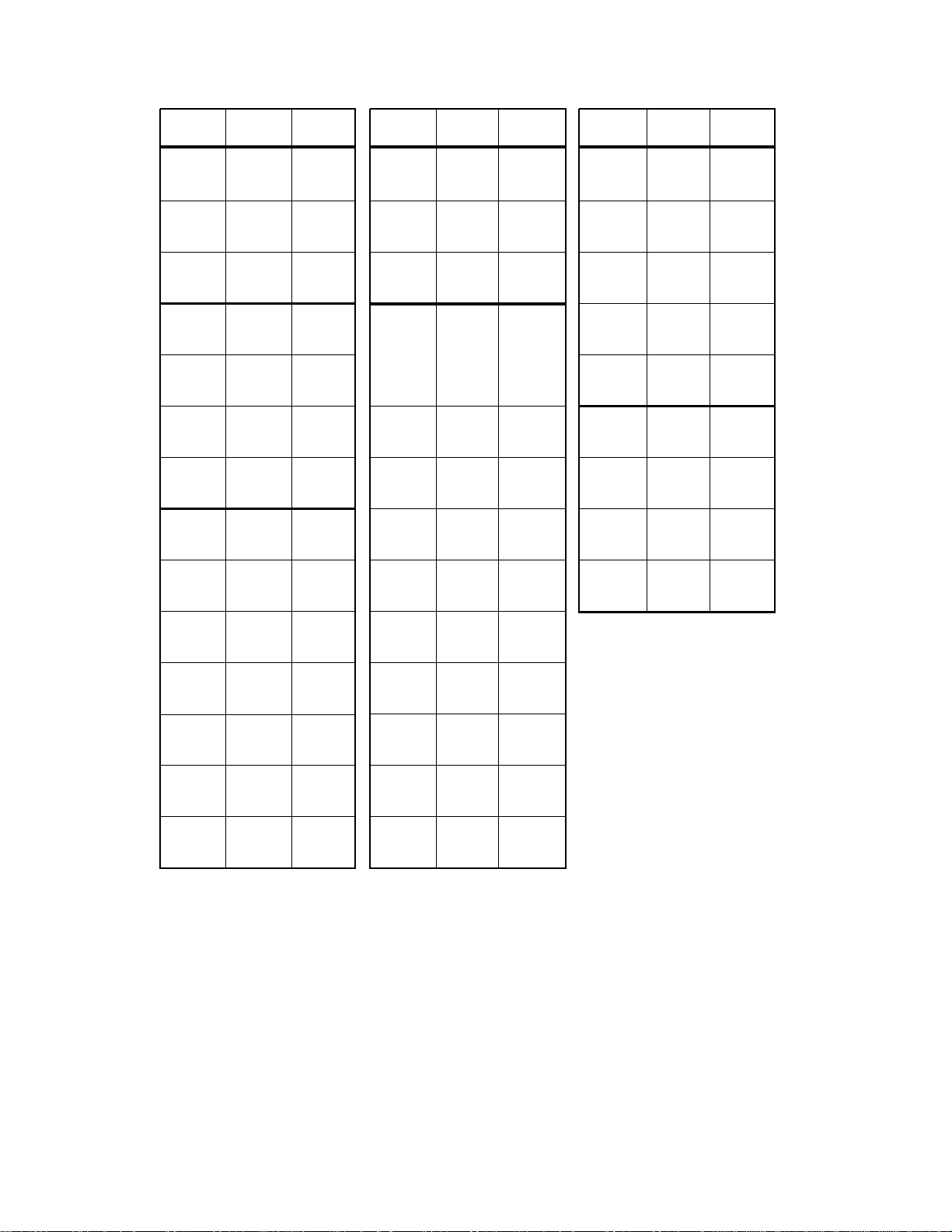

Cn-29 50

Cn-30 160

Cn-31

(4)

Cn-32

(4)

Cn-33

(4)

Cn-34 30

(3)

Cn-35 2.0

Cn-36 0

Cn-37

(4)

Cn-38 150

Cn-39 2.0

(4)

Cn-40

(4)

Cn-41 100

Cn-42 0.3

Un-01 N/A N/A

Un-02 N/A N/A

Un-03 N/A N/A

Un-04 N/A N/A

Un-05 N/A N/A

Un-06 N/A N/A

Un-07 N/A N/A

Un-08 N/A N/A

Un-09 N/A N/A

Un-10 N/A N/A

Sn-22 02

Sn-23 00

Sn-24 00

Sn-25 0000

Sn-26 0000

Sn-27 0010

Sn-28 0100

Cn-01 230.0

(230V)

or 460.0

(460V)

or 575.0

(575V)

Cn-02

(2)

Cn-03

(2)

Cn-04

(2)

Cn-05

(2)

Cn-06

(2)

Cn-07

(2)

Cn-08

(2)

Cn-09

(1)

Cn-10 1.5

(2)

Cn-11 50

Cn-12 0.0

Cn-13 0.0

Cn-14 100

Cn-15 0

Cn-16 0.0

Cn-17 0.0

Cn-18 0.0

Cn-19 1.0

Cn-20 0

Cn-21 0.0

Cn-22 2.0

Cn-23

(4)

Cn-24

(4)

Cn-25 00

Cn-26 160

Cn-27 0.1

Cn-28 170

An-01 0.00

An-02 0.00

An-03 0.00

An-04 0.00

An-05 0.00

An-06 0.00

An-07 0.00

An-08 0.00

An-09 6.00

bn-01 10.0

bn-02 10.0

bn-03 10.0

bn-04 10.0

bn-05 100.0

bn-06 0

bn-07 1.0

bn-08 0.0

bn-09 80

bn-10 1

bn-11 1.00

bn-12 0.50

Sn-01

(1)

Sn-02 01

Sn-03 0000

Sn-04 0011

Sn-05 0000

Sn-06 0000

Sn-07 0000

Sn-08 0100

Sn-09 0000

Sn-10 0000

Sn-11 0000

Sn-12 0100

Sn-13 0100

Sn-14 0000

Sn-15 03

Sn-16 04

Sn-17 06

Sn-18 08

Sn-19 00

Sn-20 00

Sn-21 01

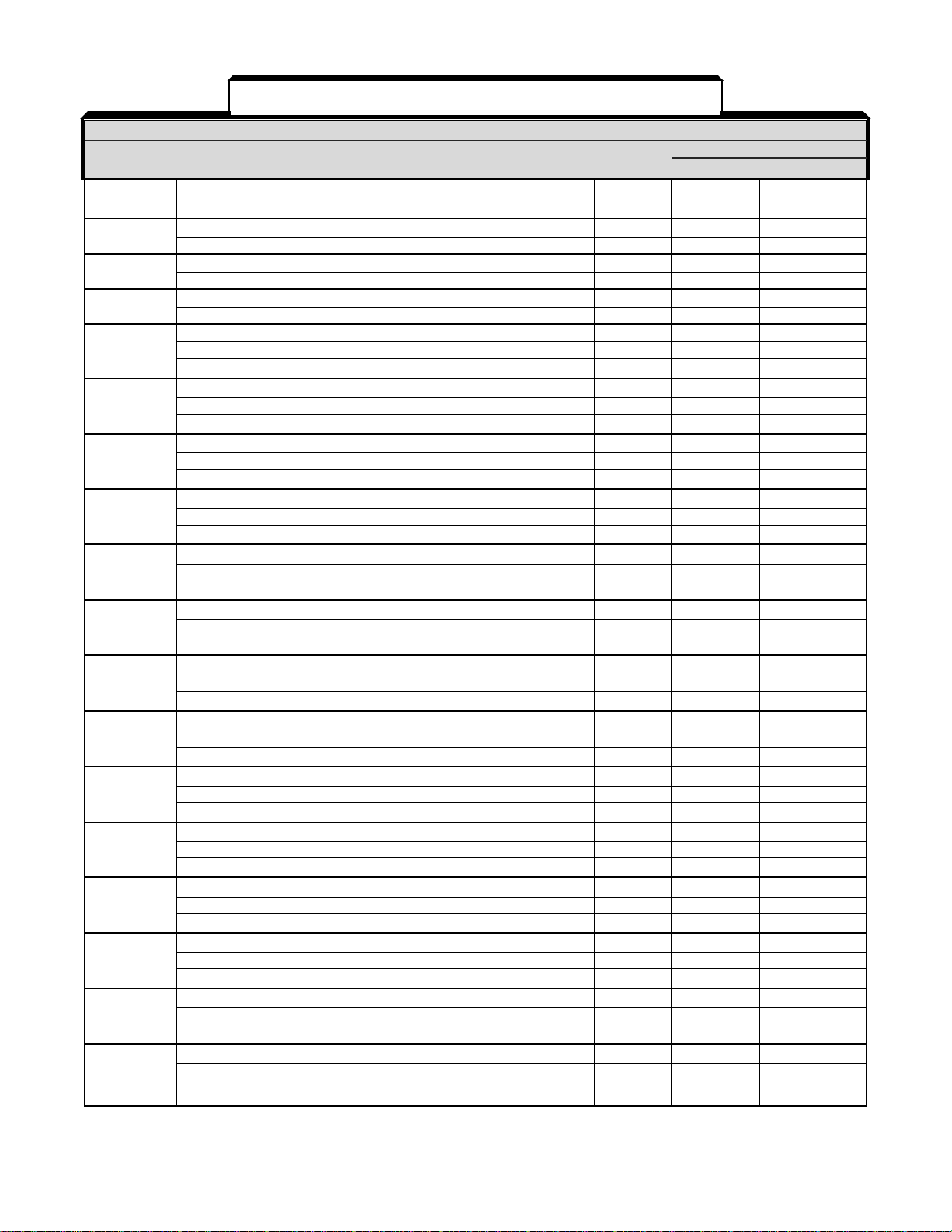

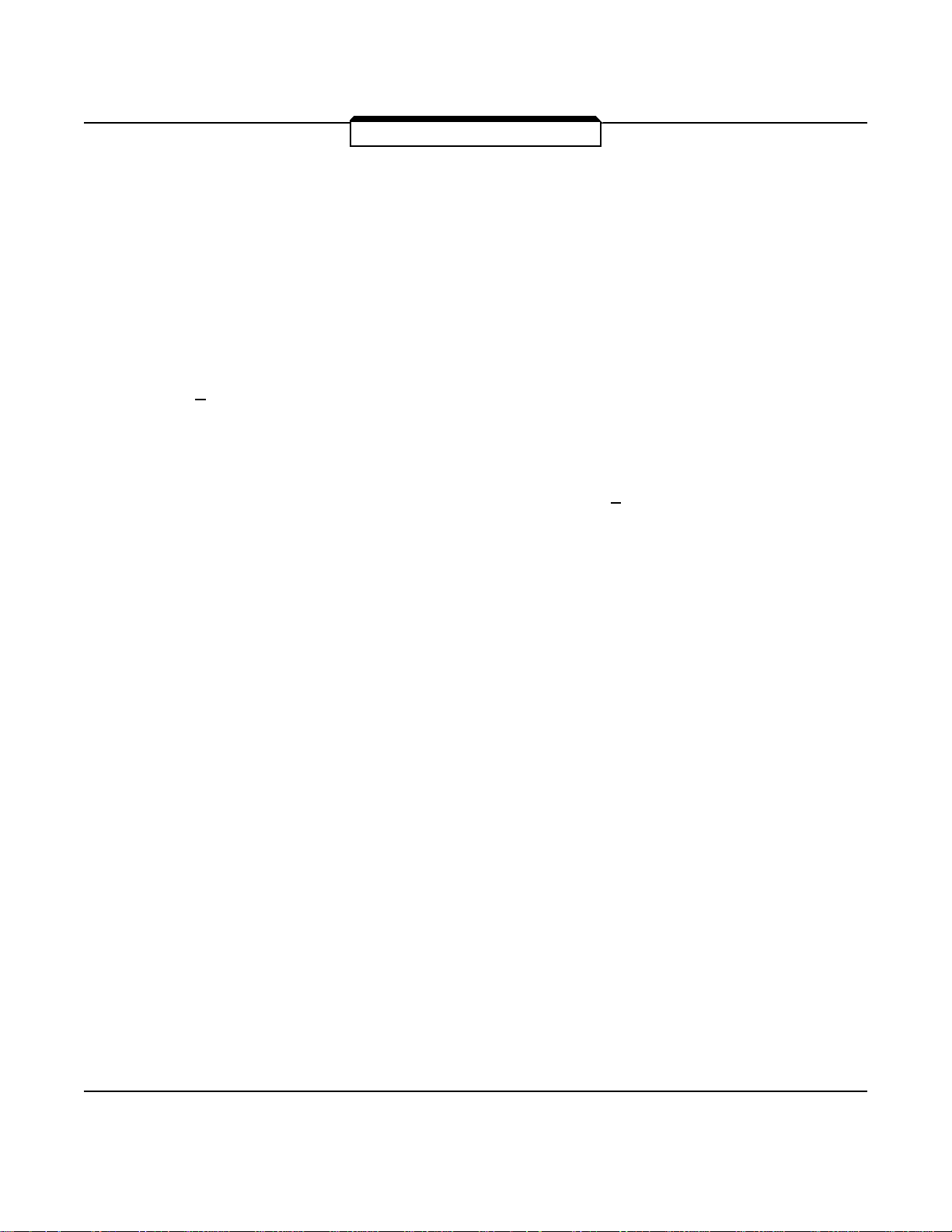

QUICK REFERENCE FOR GPD 503 CONSTANTS (FACTORY SET)

CONSTANT FACTORY USER CONSTANT FACTORY USER CONSTANT FACTORY USER

NUMBER SETTING SETTING NUMBER SETTING SETTING NUMBER SETTING SETTING

(1)

Setting depends on GPD 503 rating. See Table A3-1.

(2)

Initial value is related to V/f curve selected by Sn-02 setting.

(3)

Motor rated current (Cn-09) is set at 100% level. Setting range: 10

to 200% of GPD 503 rated capacity.

(4)

Initial value differs depending on GPD 503 capacity.

-v-

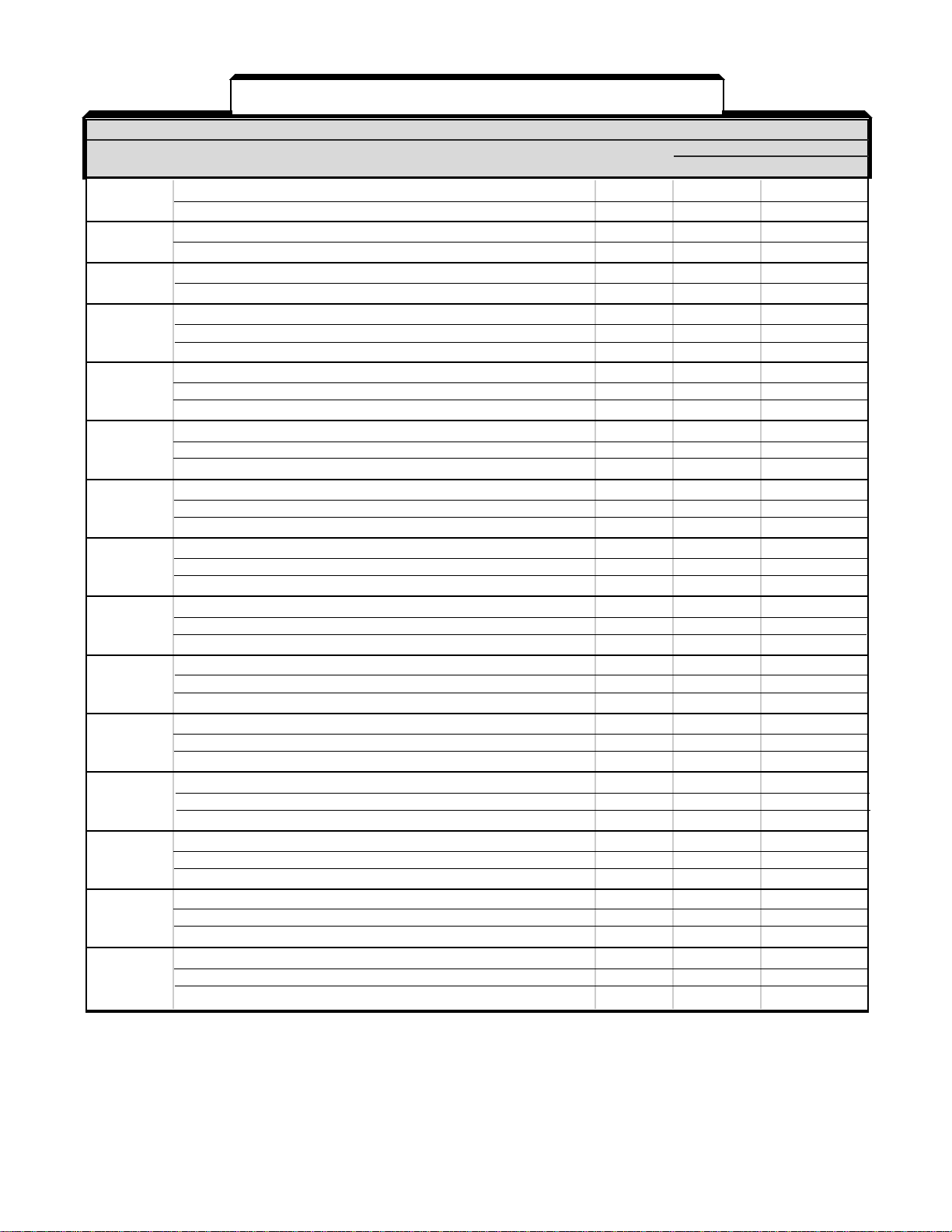

Horsepower Range

RATED

HORSEPOWER

MODEL

INPUT

CT (150% OL) VT (125% OL)

NO.

1 1 DS305

2 2 DS302

3 3 DS306

5 5 DS307

7.5 7.5/10 DS308

2 10 15 DS309

3 15 20 DS310

0 20 25 DS311

V 25 30 DS322

30 40 DS323

40 50 DS2040

40/50 50 GPD503-2L40

50 60 DS2050

60 60 GPD503-2L50

60 75 DS2060

60 75 GPD503-2L60

75 100 DS2075

75 100 GPD503-2L75

100 150 DS2100

100 125 GPD503-2L100

1 1 DS313

2 2 DS304

3 3 DS314

5 5 DS315

7.5 7.5/10 DS316

10 15 DS317

4 15 20 DS318

6 20 25 DS326

0 25 30 DS325

V 30 40 DS330

40 50 DS340

50 60 DS350

60 75 DS360

75 100 DS075

75/100 100 GPD503-4L75

100 150 DS100

100 150 GPD503-4L100

150 200 DS150

150 200 GPD503-4L150

200 250 DS200

200 250 GPD503-4L200

250 300 DS250

300 400 DS303

400 500 DS400

2 3 DS5003

3 3 DS5004

5 5 DS5006

7.5 7.5 DS5009

10 10 DS5012

15 15 DS5017

5 20 20 DS5022

7 25 25 DS5027

5 30 30 DS5032

V 40 40 DS5043

50 50 DS5054

60 60 DS5064

75 75 DS5081

100 100 DS5112

125 150 DS5130

150 200 DS5172

200 200 DS5202

( "L" ) (04/27/95)

-vi-

WARNING

Do not touch circuit components until main input power has been turned off and

“CHARGE” lamp is extinguished. The capacitors are still charged and can be

quite dangerous.

Do not connect or disconnect wires and connectors while power is applied to the

circuit.

CAUTION

Know your application before using either Initialization function of Sn-03. This

constant must be set to 0000 for Drive mode operation. (See paragraph 2.25 for

additional information.)

1110 = Factory 2-Wire Control Initialization (Maintained RUN Contact)

1111 = Factory 3-Wire Control Initialization (Momentary START/STOP Contact)

Entering either Initialization code resets all constants EXCEPT Sn-01 AND Sn-02 to

factory settings, and automatically returns Sn-03 setting to 0000. If the GPD 503 is

connected for 3-Wire control and this constant is set to 1110 (2-Wire Control

Initialization), the motor may run in reverse direction WITHOUT A RUN COMMAND

APPLIED. Equipment damage or personal injury may result.

IMPORTANT

Always ground the GPD 503 using ground terminal G ( E ). See paragraph 1.4.3,

"Grounding".

Never connect main circuit output terminals T1, T2, and T3 to AC main circuit power

supply.

All constants have been factory set. Do not change their settings unnecessarily.

Do not perform a “HIPOT” voltage test on any part of the GPD 503. Equipment uses semi-

conductors and is vulnerable to high voltage.

The Control PCB employs CMOS ICs which are easily damaged by static electricity. Use

proper electrostatic discharge (ESD) procedures when handling the Control PCB.

CONTENTS

SUBJECT PAGE

GPD 503 SIMPLIFIED START-UP PROCEDURE ...................... i

HORSEPOWER RANGE ........................................................... v

WARNING/CAUTION STATEMENTS ....................................... vi

1 INSTALLATION ...................................................................... 1-1

1.1 General .................................................................................. 1-1

1.2 Receiving ................................................................................ 1-1

1.3 Physical Installation ............................................................... 1-1

1.4 Electrical Installation ............................................................. 1-2

1.4.1 Main Circuit Input/Output ................................................. 1-2

1.4.2 Control Circuit ................................................................... 1-4

1.4.3 Grounding .......................................................................... 1-6

1.4.4 Auxiliary Input and Output Power Option Devices .............. 1-7

Figure 1-3. 230V or 450V Interconnections - 2-Wire Control .. 1-9

Figure 1-4. 230V or 460V Interconnections - 3-Wire Control . 1-11

Figure 1-5. 575V Interconnections - 2-Wire Control .............. 1-13

Figure 1-6. 575V Interconnections - 3-Wire Control .............. 1-15

2 PROGRAMMABLE FEATURES .............................................. 2-1

2.1 General .................................................................................. 2-1

2.2 Accel/Decel Time ................................................................... 2-3

2.3 Auto Reference Characteristics ............................................... 2-4

2.4 Auto Reference - Loss Detection ............................................. 2-5

2.5 Auto-restart ........................................................................... 2-7

2.7 Critical Frequency Rejection ................................................... 2-8

2.8 DC Injection Braking .............................................................. 2-9

2.9 Digital Display Selection ........................................................ 2-12

2.10 Display - Monitor (at Power-up) Selection .............................. 2-13

2.11 Energy Saving Operation ....................................................... 2-14

2.12 External Fault Terminal ........................................................ 2-15

2.13 Frequency (Auto) Command Bias/Gain ................................. 2-17

2.14 Frequency Command Upper & Lower Limits .......................... 2-18

2.15 Jog Reference ........................................................................ 2-19

2.16 Momentary Power Loss Ride-thru ......................................... 2-20.2

2.17 Monitor Display (Digital Operator) ......................................... 2-21

2.18 Multi-function Analog Input (Term. 16) .................................. 2-22

2.19 Multi-function Input Terminals (Term. 5-8) ........................... 2-24

2.20 Multi-function Analog Monitor Output (Term. 21 & 22) .......... 2-29

2.21 Multi-function Output Terminals (Term. 9 & 10; 25-27) ........ 2-30

2.22 Overtorque Detection ............................................................. 2-31

2.23 Speed Coincidence ................................................................ 2-34

2.24 Remote/Local and Reference Selection .................................. 2-35

2.25 Reset Codes (2-Wire, 3-Wire Initialization) ............................. 2-40

2.26 Slip Compensation ................................................................ 2-41

2.27 Soft Start (S-Curve) Characteristics ....................................... 2-42

2.28 Speed Search ........................................................................ 2-42

2.29 Stall Prevention ..................................................................... 2-44

-vii-

Revision Date 12/01/94

-viii-

(THIS PAGE INTENTIONALLY BLANK)

CONTENTS - Continued

SUBJECT PAGE

- ix -

2.30 Thermal Motor Overload Protection ....................................... 2-46

2.31 Torque Compensation .......................................................... 2-46.2

2.32 V/f Pattern - Standard ......................................................... 2-46.2

2.33 V/f Pattern - Custom ............................................................. 2-48

2.34 Up/Down Frequency Setting ................................................. 2-50

2.35 Slip Compensation Primary Time Delay ................................. 2-51

2.36 Carrier Frequency ................................................................. 2-52

3 DIGITAL OPERATOR ............................................................. 3-1

3.1 General .................................................................................. 3-1

3.2 Display and Keypad ................................................................ 3-1

3.3 Comparison of Program Mode and Drive Mode ........................ 3-4

3.4 Program Mode Operation ........................................................ 3-5

3.5 Drive Mode Operation ............................................................. 3-7

4 INITIAL START-UP (“LOCAL” CONTROL) ............................. 4-1

4.1 Pre-power Checks ................................................................... 4-1

4.2 Test Run Using Digital Operator ("Local" Control) ................... 4-2

4.3 Pre-operation Considerations ................................................. 4-4

4.4 Storage Function .................................................................... 4-4

5 OPERATION AT LOAD ........................................................... 5-1

6 FAILURE INDICATION AND DETAILS ................................... 6-1

6.1 General .................................................................................. 6-1

6.2 Displaying Fault Sequence ..................................................... 6-4

7 TROUBLESHOOTING ............................................................ 7-1

App. 1 LISTING OF CONSTANTS...................................................... A1-1

Frequency Reference Memory Settings (An-XX) ...................... A1-1

Run Operative Settings (bn-XX) ............................................. A1-2

System Constants (Sn-XX) .................................................... A1-3

Control Constants (Cn-XX) ................................................... A1-11

Monitor Displays (Un-XX) ..................................................... A1-15

App. 2 SPECIFICATIONS ................................................................. A2-1

App. 3 GPD 503 CAPACITY (Sn-01) ................................................. A3-1

App. 4 DIODE AND TRANSISTOR MODULE RESISTANCE TEST .... A4-1

App. 5 DIMENSIONS ........................................................................ A5-1

App. 6 SPARES ................................................................................ A6-1

App. 7 DYNAMIC BRAKING CONNECTIONS ................................... A7-1

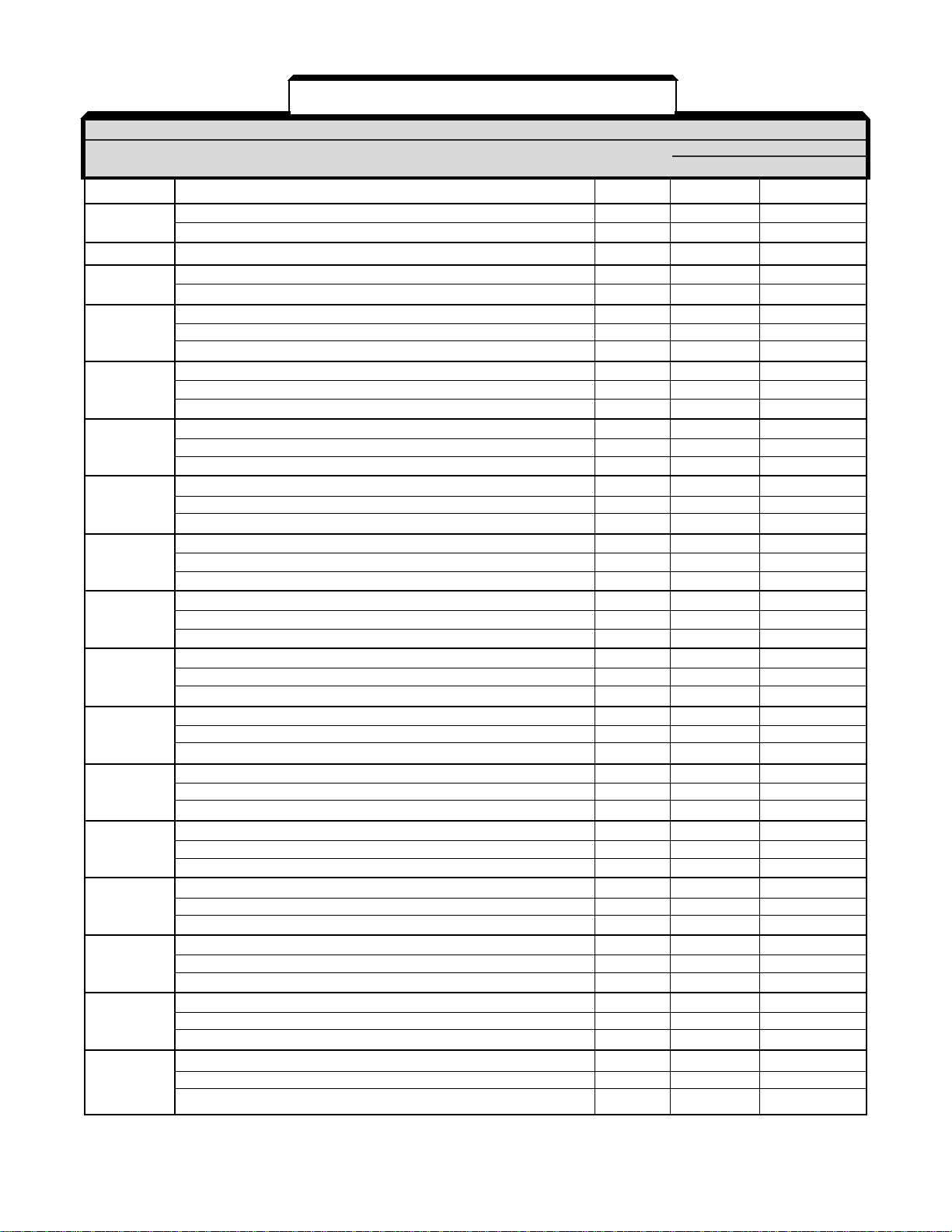

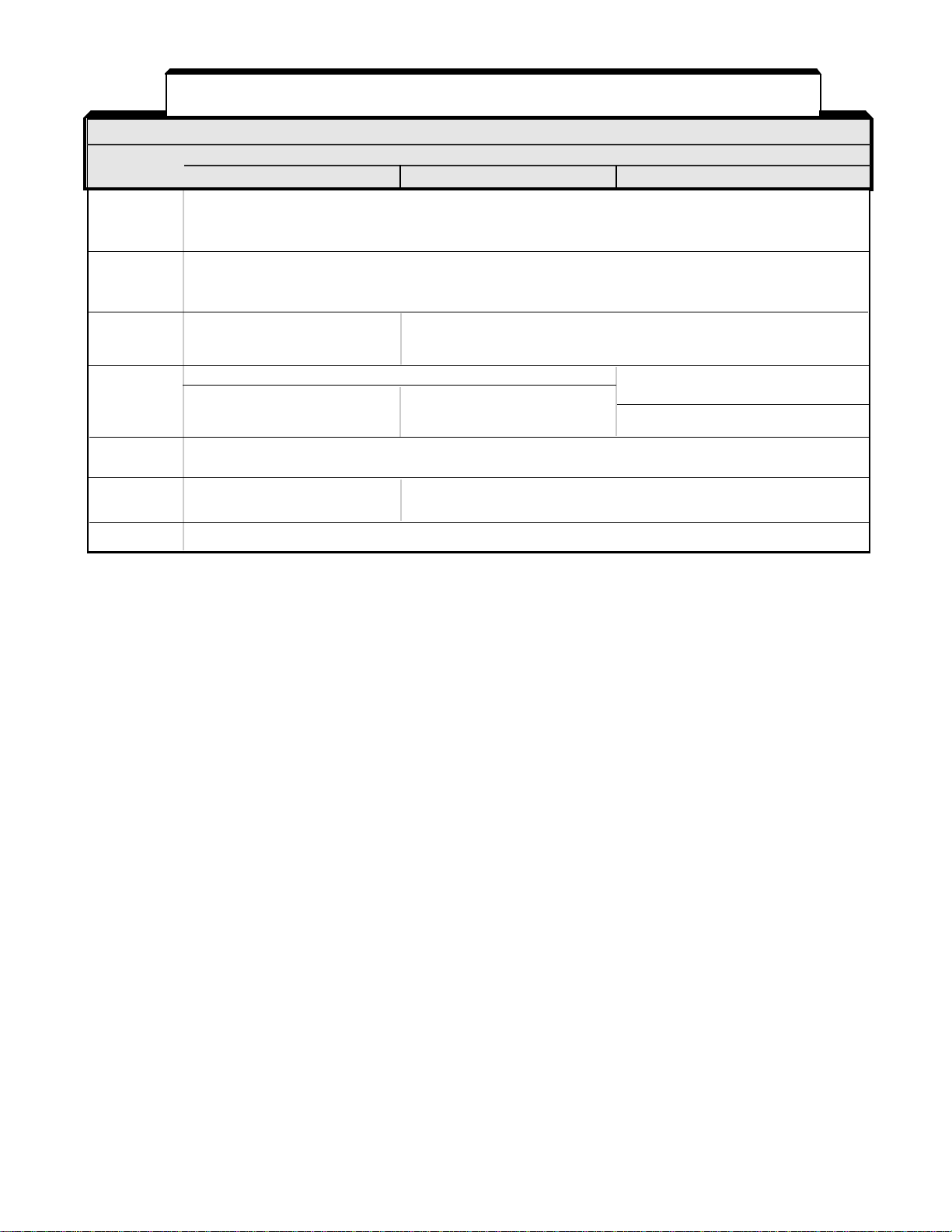

INSTALLATION REFERENCE SHEET

• Drive Information: • Motor Nameplate Information:

Model Number ______________ Full Load Amps ______________

Specification ______________ Voltage ______________

Voltage ______________ Horsepower ______________

kW ______________ Poles ______________

Number ______________ RPM ______________

Location ______________ Service Factor ______________

Drive Rated Amps NEMA Design ______________

Variable Torque – 125% OL ______ Insulation Class ______________

Constant Torque – 150% OL ______ TEFC ___ or TENV ___

EPROMs ______________ Disconnect at Motor _______

I/O Boards ______________ Single/Multiple Motor _________

V/Hz Pattern ______________ Pulse Generator ______________

Speed/Torque Regulation _______ Location ______________

Pulse Generator Input __________ Number ______________

Thermal Motor Overload

Protection – Sn-14 ______

Motor Rated Current – Cn-09 _______

• Load / Machine: • Control:

Torque Requirements as % of Controlled Variable (Pressure, Flow, Temp,

Full Load Torque: Level, etc.) ______________

Breakaway ______ Sensor ______________

Running ______ Location ______________

Peak ______ Number ______________

Speed Range ______________ Output ______________

Gear/Pulley Ratio _____________ Run/Stop:

Speed/Torque Controlled ________ 2-Wire ___ or 3-Wire ___ Contro

Accuracy Required _____________ Location(s) ______________

Inertia ______________ Numbers ______________

Location ______________ Speed Reference: 0-10 Vdc ___

Number ______________ or 4-20 mA ___

• Power Supply: • Auxiliary Devices:

Circuit Breaker / Amps __________ Reactors

Disconnect / Fused __________ Input _______

Location _______________ Outptu _______

Number _______________ Filters

Source _______________ Input _______

Voltage _______________ Output _______

Frequency _______________ Bypass _______

Quality _______________

- x -

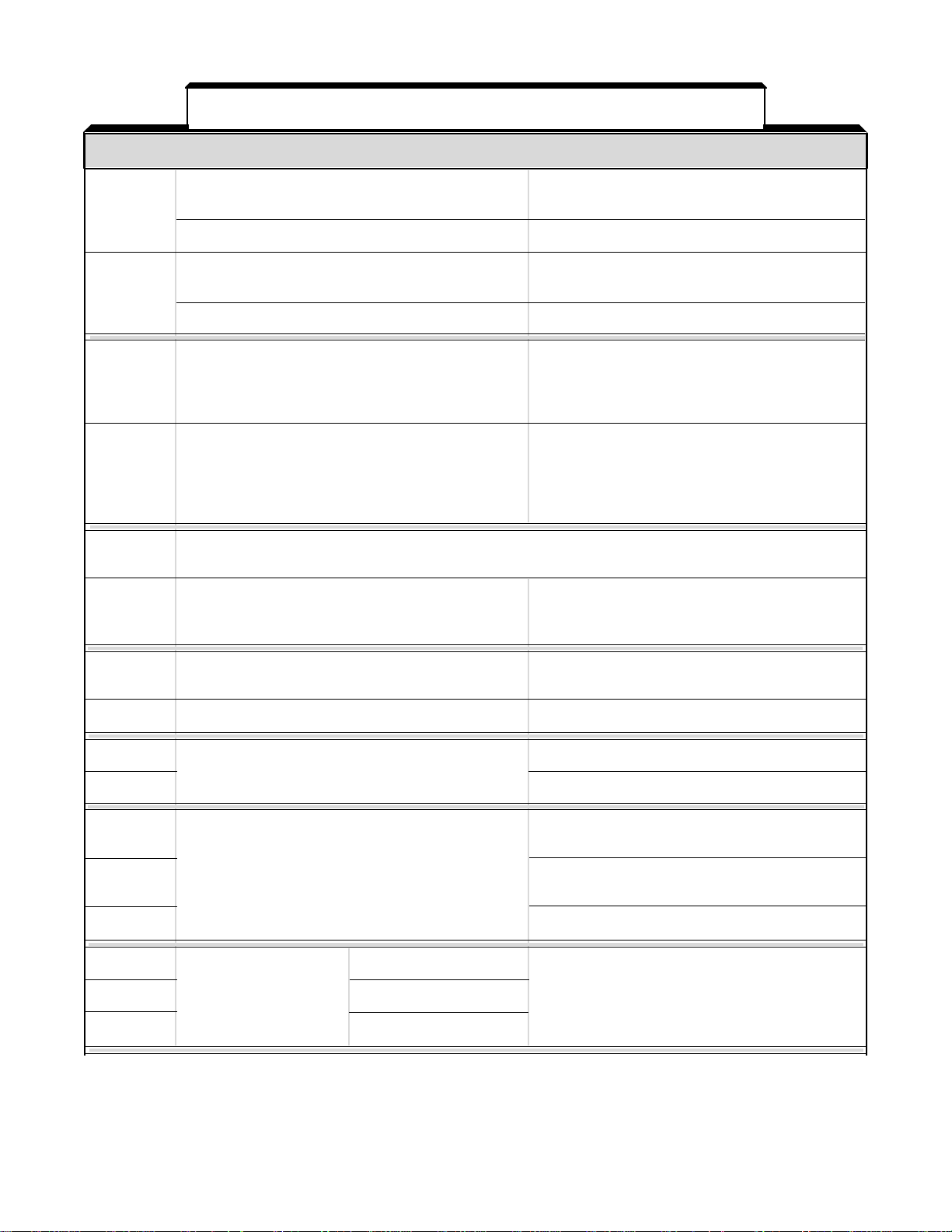

TROUBLESHOOTING / MAINTENANCE REFERENCE SHEET

• Fault Code History:

Date Fault Cause Solution

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

_______ _________ ____________________ ___________________________

• Preventive Maintenance Log:

Date Action Person

_______ _____________________________ ___________________________

_______ _____________________________ ___________________________

_______ _____________________________ ___________________________

_______ _____________________________ ___________________________

_______ _____________________________ ___________________________

_______ _____________________________ ___________________________

_______ _____________________________ ___________________________

_______ _____________________________ ___________________________

_______ _____________________________ ___________________________

- xi -

Section 1. INSTALLATION

1.1 GENERAL

The GPD 503 is a high performance sine-coded pulse width modulated AC motor drive

which generates an adjustable voltage/frequency three phase output for complete speed

control of any conventional squirrel cage induction motor. Automatic stall prevention and

voltage boost prevents nuisance tripping during load or line side transient conditions. The

GPD 503 will not induce any voltage line notching distortion back to the utility line and

maintains a displacement power factor of not less than 0.95 throughout its speed range.

When properly installed, operated and maintained, the GPD 503 will provide a lifetime of

service. It is mandatory that the person who operates, inspects, or maintains this

equipment thoroughly read and understand this manual before proceeding.

This manual primarily describes the GPD 503, but contains basic information for the

operator control station as well. For details of the operation of other units in the drive

system, refer to their respective manuals.

1.2 RECEIVING

The GPD 503 is thoroughly tested at the factory. After unpacking, verify the part numbers

with the purchase order (invoice). Any damages or shortages evident when the equipment

is received must be reported immediately to the commercial carrier who transported the

equipment. Assistance, if required, is available from your sales representative.

1.3 PHYSICAL INSTALLATION

Location of the GPD 503 is important to achieve proper performance and normal operating

life. The unit should be installed in an area where it will be protected from:

• Direct sunlight, rain or moisture.

• Corrosive gases or liquids.

• Vibration, airborne dust or metallic particles.

For effective cooling as well as proper maintenance, a wall mount style GPD 503 must be

installed vertically to the ground using four mounting screws. There MUST be a MINIMUM

6 in. clearance above and below the GPD 503. A MINIMUM 2 in. clearance is required on

each side on the GPD 503.

A free-standing style GPD 503 must be installed with enough clearance for opening the

door of the cabinet; this will ensure sufficient air space for cooling.

1-1

1.4 ELECTRICAL INSTALLATION

All basic interconnections (using the Digital Operator) are shown in Figures 1-3

through 1-6.

1.4.1 Main Circuit Input/Output

Complete wiring interconnections for the main circuit according to Tables 1-1 and 1-2,

while observing the following:

CAUTION

Use only factory supplied instructions to install dynamic braking

resistors. Failure to do so may cause equipment damage or

personal injury.

• Use 600 V vinyl-sheathed wire or equivalent. Wire size should be determined

considering voltage drop of leads.

• NEVER connect AC main power to output terminals T1 ( U ), T2 ( V ), and T3 ( W ).

• NEVER allow wire leads to contact the GPD 503 enclosure. Short-circuit may result.

• NEVER connect power factor correction capacitors or noise filter to GPD 503 output.

• SIZE OF WIRE MUST BE SUITABLE FOR CLASS I CIRCUITS.

• Use UL listed closed loop connectors or CSA certified ring connectors sized for the

selected wire gauge. The connectors are to be installed using the correct crimp tool

recommended by the connector manufacturer.

WIRE SIZE

TERMINAL CLOSED-LOOP

CLAMPING TORQUE

AWG mm

2 SCREW CONNECTOR

STEEL COPPER

lb-in N-m lb-in N-m

20 0.5 M3.5 1.25 - 3.5 7.8 0.9 7.0 0.8

18 0.75 M4 1.25 - 4 13.0 1.5 10.4 1.2

16 1.25 M4 1.25 - 4 13.0 1.5 10.4 1.2

M4 2 - 4 13.0 1.5 10.4 1.2

14 2

M5 2 - 5 26.1 20.9 3.1 2.4

M4 3.5 - 4 13.0 1.5 10.4 1.2

12 3.5

M5 3.5 - 5 26.1 20.9 3.1 2.4

M4 5.5 - 4 13.0 1.5 10.4 1.2

10 5.5

M5 5.5 - 5 26.1 20.9 3.1 2.4

M5 8 - 5 26.1 20.9 3.1 2.4

88

M6 8 - 6 40.9 34.8 4.8 4.1

6 14 M6 14 - 6 40.9 34.8 4.8 4.1

4 22 M8 22 - 8 100.0 82.6 11.7 10.7

M8 38 - 8 100.0 82.6 11.7 10.7

238

M10 38 - 10 182.6 156.5 21.4 18.4

1/0 60 M10 60 - 10 182.6 156.5 21.4 18.4

3/0 80 M10 80 - 10 182.6 156.5 21.4 18.4

M10 100 - 10 182.6 156.5 21.4 18.4

4/0 100

M12 100 - 12 313.0 191.3 36.7 23.1

MCM300 150 M12 150 - 12 313.0 191.3 36.7 23.1

MCM400 200 M12 200 - 12 313.0 191.3 36.7 23.1

MCM650 325 M12 325 - 12 313.0 191.3 36.7 23.1

1-2

HP TERMINAL WIRE SIZE

RATING TERMINAL SYMBOL SCREW AWG MM2

DS305 L1 (R),L2 (S),L3 (T),–, B1/+, B2, T1 (U), T2 (V),T3 (W),G (E) M4 14 - 10 2 - 5.5

DS302, L1 (R), L2 (S), L3 (T),–,B1/+, B2, T1 (U), T2 (V), T3 (W) M4 14 - 10 2 - 5.5

DS306 G (E) M4 12 - 10 3.5 - 5.5

DS307 L1 (R),L2 (S),L3 (T),–, B1/+, B2, T1 (U), T2 (V),T3 (W),G (E) M4 10 5.5

DS308, L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M5 8 8

DS309 G (E) M5 10 5.5

DS310 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M6 4 22

G (E)

8 - 2 8 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS311 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 3 - 1/0 30 - 60

G (E)

8 - 2 8 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS322 L1 (R), L2 (S), L3 (T), B0/–, B1/–, B1/+, T1 (U), T2 (V), T3 (W) M8 2 - 1/0 38 - 60

G (E)

6 - 2 14 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS323 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 1/0 60

G (E)

6 - 2 14 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS2040 L1 (R), L2 (S), L3 (T), –, +1, +3, T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E)

4 - 2 22 - 38

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

GPD503-2L40

L1 (R), L2 (S), L3 (T), – (N), +3 (P3), T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E)

4 - 2 22 - 38

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

DS2050 L1 (R), L2 (S), L3 (T), –, +1, +3, T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E)

4 - 2 22 - 38

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

GPD503-2L50

L1 (R), L2 (S), L3 (T), – (N), +3 (P3), T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E)

4 - 2 22 - 38

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

DS2060 L1 (R), L2 (S), L3 (T), –, +1, +3, T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E)

4 - 2 22 - 38

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

GPD503-2L60

L1 (R), L2 (S), L3 (T), – (N), +3 (P3), T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E) 4 - 2 22 - 38

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

DS2075 L1 (R), L2 (S), L3 (T),–,+1, +3, T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E)

3 - 2 30 - 38

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

GPD503-2L75

L1 (R), L2 (S), L3 (T), – (N), +3 (P3), T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E)

4 - 2 22 - 38

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

DS2100 L1 (R), L2 (S), L3 (T),–,+1, +3, T1 (U), T2 (V), T3 (W) M12 4/0 -

MCM400

100 - 200

G (E)

1 - 2/0 50 - 67

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

GPD503-2L100

L1 (R), L2 (S), L3 (T), – (N), +3 (P3), T1 (U), T2 (V), T3 (W) M12 4/0 -

MCM400

100 - 200

G (E)

1 - 2/0 50 - 67

l

1 (r),

l

2 (

s

) M4 20 - 14 0.5 - 2

SECTION A. 230V

DRIVE TERMINAL

WIRE SIZE

MODEL NO.

TERMINAL SYMBOL

SCREW AWG mm

2

1-2.1

Table 1-1. Wire Sizing For Main Circuit

indicates terminal uses a pressure lug.

( "L" ) (06/22/95)

DRIVE TERMINAL WIRE SIZE

MODEL NO. TERMINAL SYMBOL SCREW AWG mm

2

DS313, DS304,

L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W), G (E) M4 14 - 10 2 - 5.5

DS314

DS315 L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M4 14 - 10 2 - 5.5

G (E) M5 12 - 10 3.5 - 5.5

DS316 L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M4 12 - 10 3.5 - 5.5

G (E) M5 12 - 10 3.5 - 5.5

DS317 L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M4 10 5.5

G (E) M5 10 5.5

DS318, L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M5 8 8

DS326 G (E) 10 - 2 5.5 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS325 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M6 6 - 4 14 - 22

G (E) 8 - 2 8 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS330 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M6 4 22

G (E) 8 - 2 8 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS340 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 3 - 1/0 30 - 60

G (E) 8 - 2 8 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS350 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 2 - 1/0 38 - 60

G (E) 6 - 2 14 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS360 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 1/0 60

G (E) 6 - 2 14 - 38

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS075, L1 (R), L2 (S), L3 (T), –, B1/+, B2, +3, T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

DS100 G (E) 4 - 2 22 - 38

l

1 (r),

l

2 200 (

s

200),

l

2 400 (

s

400), x, y M4 20 - 14 0.5 - 2

GPD503-4L75,

L1 (R), L2 (S), L3 (T), – (N), +3 (P3), T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

GPD503-4L100

G (E) 4 - 2 22 - 38

l

1 (r),

l

2 200 (

s

200),

l

2 400 (

s

400), x, y M4 20 - 14 0.5 - 2

DS150 L1 (R), L2 (S), L3 (T), –, B1/+, B2, +3, T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E) 3 - 2 30 - 38

l

1 (r),

l

2 200 (

s

200),

l

2 400 (

s

400), x, y M4 20 - 14 0.5 - 2

GPD503-4L150

L1 (R), L2 (S), L3 (T), –, B1/+, B2, +3, T1 (U), T2 (V), T3 (W) M10 2 - 4/0 38 - 100

G (E) 3 - 2 30 - 38

l

1 (r),

l

2 200 (

s

200),

l

2 400 (

s

400), x, y M4 20 - 14 0.5 - 2

DS200 L1 (R), L2 (S), L3 (T), –, B1/+, B2, +3, T1 (U), T2 (V), T3 (W) M12 4/0-

MCM

400 100 - 200

G (E) 1 - 2/0 50 - 67

l

1 (r),

l

2 200 (

s

200),

l

2 400 (

s

400), x, y M4 20 - 14 0.5 - 2

GPD503-4L200

L1 (R), L2 (S), L3 (T), – (N), +3 (P3), T1 (U), T2 (V), T3 (W) M12 4/0 -

MCM

400 100 - 200

G (E) 1 - 2/0 50 - 67

l

1 (r),

l

2 200 (

s

200),

l

2 400 (

s

400), x, y M4 20 - 14 0.5 - 2

DS250, L1 (R), L2 (S), L3 (T), –, +1, +3, T1 (U), T2 (V), T3 (W) M12

MCM

650x2

P

325 x 2

P

DS303 G (E) 1/0 - 2/0 54 - 67

l

1 (r),

l

2 (

s

), x, y M4 20 - 14 0.5 - 2

DS400 L1 (R), L2 (S), L3 (T), –, +1, +3, T1 (U), T2 (V), T3 (W) M12

MCM

650x2

P

325 x

2P

G (E) 2/0 67

l

1 (r),

l

2 (

s

), x, y M4 20 - 14 0.5 - 2

Section B. 460V

DRIVE TERMINAL

WIRE SIZE

MODEL NO.

TERMINAL SYMBOL

SCREW AWG mm

2

indicates terminal uses a pressure lug.

1-2.2

Table 1-1. Wire Sizing For Main Circuit - Continued

( "L" ) (04/27/95)

1-2.3

DRIVE TERMINAL WIRE SIZE

MODEL NO. TERMINAL SYMBOL SCREW AWG mm

2

DS5003, L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M4 14 - 10 2 - 5.5

DS5004 G (E) M4 14 - 10 2 - 5.5

DS5006 L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M4 14 - 10 2 - 5.5

G (E) M5 14 - 10 2 - 5.5

DS5009, L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M4 12 - 10 3.5 - 5.5

DS5012 G (E) M5 12 - 10 3.5 - 5.5

DS5017 L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M5 10 - 8 5.5 - 8

G (E) 12 - 2 3.5 - 30

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS5022 L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M6 8 - 6 8 - 14

G (E) 12 - 2 3.5 - 30

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS5027 L1 (R), L2 (S), L3 (T), –, B1/+, B2, T1 (U), T2 (V), T3 (W) M6 8 - 6 8 - 14

G (E) 10 - 2 5.5 - 30

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS5032 L1 (R), L2 (S), L3 (T), B0/–, B1/+, B2, T1 (U), T2 (V), T3 (W) M6 8 - 6 8 - 14

G (E) 10 - 2 5.5 - 30

l

1 (r),

l

2 (

s

) M4 14 - 10 2 - 5.5

DS5043 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 6 - 1 14 - 38

G (E) 10 - 2 5.5 - 30

l

1 (r),

l

2 (

s

), x, y M4 14 - 10 2 - 5.5

DS5054 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 4 - 1 22 - 38

G (E) 8 - 2 8 - 30

l

1 (r),

l

2 (

s

), x, y M4 14 - 10 2 - 5.5

DS5064 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 3 - 1/0 27 - 50

G (E) 8 - 2 8 - 30

l

1 (r),

l

2 (

s

), x, y M4 14 - 10 2 - 5.5

DS5081 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 1 - 2/0 38 - 60

G (E) 8 - 2 8 - 30

l

1 (r),

l

2 (

s

), x, y M4 14 - 10 2 - 5.5

DS5112 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M8 2/0 - 3/0 60 - 80

G (E) 6 - 2/0 14 - 60

l

1 (r),

l

2 (

s

), x, y M4 14 - 10 2 - 5.5

DS5130 L1 (R), L2 (S), L3 (T), B0/–, B1/+, T1 (U), T2 (V), T3 (W) M10 3/0 - 300 80 - 150

G (E) 6 - 2/0 14 - 60

l

1 (r),

l

2 (

s

), x, y M4 14 - 10 2 - 5.5

DS5172 L1 (R), L2 (S), L3 (T), –, B1/+, B2, +3, T1 (U), T2 (V), T3 (W) M12 3000 - 400 150 - 200

G (E) 4 - 2/0 22 - 60

l

1 (r),

l

2 (

s

), x, y M4 14 - 10 2 - 5.5

DS5202 L1 (R), L2 (S), L3 (T), –, B1/+, B2, +3, T1 (U), T2 (V), T3 (W) M12 300 - 400 177 - 200

G (E) 4 - 2/0 22 - 60

l

1 (r),

l

2 (

s

), x, y M4 14 - 10 2 - 5.5

Section C. 575V

DRIVE TERMINAL

WIRE SIZE

MODEL NO.

TERMINAL SYMBOL

SCREW AWG mm

2

indicates terminal uses a pressure lug.

Table 1-1. Wire Sizing For Main Circuit - Continued

1-2.4

SECTION A. 230V

TERMINAL FUNCTION

1 HP 3 TO 40 HP

L1 (R)

Three phase Main circuit input power supply

L2 (S)

200 / 208 / 220V at 50 Hz; 200 / 208 / 220 / 230V at 60 Hz

L3 (T)

T1 (U)

Three phase AC output to motor

T2 (V)

0V to max. input voltage level

T3 (W)

l

1 (r) Power for heat sink fan

l

2 (

s

)

– – – – – –

200-230 Vac, single phase – two lines from input power

B0/–

– – – – – –

DB Unit terminals *

B1/+ DB Unit terminals (B1/+ & B2) * DC bus terminals – – – – – –

B2

– [ – (N) ]** DC bus terminals (B1/+ & –)

– – – – – –

+3 (P3) DB Unit terminals (+1 & –)

+1 (P1) [ (+3 & –) ]**

– – – – – –

DC bus terminals (+1 & –)

[ (+3 & – ) ]**

x Power supply output for

y

– – – – – –

options (220 Vac, 30 VA)

G (E) Ground terminal (100 ohms or less)

SECTION B. 460V

TERMINAL FUNCTION 1 TO 60 HP

L1 (R)

Three phase Main circuit input power supply

L2 (S)

380 / 400 / 415 / 460V at 50/60 Hz

L3 (T)

T1 (U)

Three phase AC output to motor

T2 (V)

0V to max. input voltage level

T3 (W)

l

2 (

s

) Power for heat sink fan

– – – – –

l

1 (r)

– – – – –

230 Vac single phase Power for heat sink fan:

l

2 200 (

s

200)

l

1 to

l

2 200: 230 Vac

l

2 400 (

s

400)

– – – – –

l

1 to

l

2 400: 460 Vac

B0/–

– – – – –

DB Unit Terminals *

B1/+ DB Unit terminals DB Unit terminals DC bus terminals – – – – –

B2 (B1/+ & B2) * (B1/+ & B2)

– [ – (N) ]**

DC bus terminals DC bus terminals

– – – – –

DB Unit Terminals

(B1/+ & –) (B1/+ & B0/–) (+1 & –) * [ (+3 & –) ]**

+3 (P3) DC bus terminals

+1 (P1)

– – – – –

(+1 & –) [ (+3 & –) ]**

x Power supply output for

y

– – – – –

options (220 Vac, 30 VA)

G (E) Ground terminal (100 ohms or less)

SECTION A. 230V

FUNCTION

TERMINAL

1 - 10HP (CT) 15 - 30HP (CT) 40 - 100HP (CT)

SECTION B. 460V

FUNCTION

TERMINAL

1 - 10HP (CT) 15 - 20HP (CT) 25 - 60HP (CT) 75 - 400HP (CT)

Table 1-2. Terminal Functions and Voltages of Main Circuit

– – – – – indicates that terminals are not present.

* For installation of DB (Dynamic Braking) Units, see Appendix 7.

** indicates terminal marking or connection difference for units with "L" in Model No.

( "L" ) (04/27/95)

1-3

SECTION C. 575V

TERMINAL FUNCTION 1 HP 3 TO 40 HP

L1 (R) Three phase Main circuit

L2 (S) input power supply

L3 (T) 500 / 575 / 600V at 50/60 Hz

T1 (U)

Three phase AC output to motor

T2 (V)

0V to max. input voltage level

T3 (W)

l

1 (r) Power for heat sink fan

l

2 (

s

)

– – – – –

230 Vac, single phase

B0/–

– – – – –

DB Unit terminals *

B1/+ DB Unit (B1/+ & –) DB Unit terminals (B1/+ & B2) DC bus terminals

B2 DB Resistor (B1/+ & B2) DC bus terminals (B1/+ * –)

–

– – – – –

+3 (P3)

+1 (P1)

x Power supply output for options

y

– – – – –

(220 Vac, 30 VA)

G (E) Ground terminal (100 ohms or less)

SECTION C. 575V

FUNCTION

TERMINAL

2-10HP (CT) 15 - 30HP (CT) 40 - 200HP

(CT)

Table 1-2. Terminal Functions and Voltages of Main Circuit - Continued

– – – – – indicates that terminals are not present.

* For installation of DB (Dynamic Braking) Units, see Appendix 7.

1.4 ELECTRICAL INSTALLATION Continued

1.4.2 Control Circuit

All basic control circuit (signal) interconnections are shown in the appropriate diagram:

• Interconnections for external two-wire control in combination with the Digital

Operator are shown in Figure 1-3 (for 230V or 460V rated drives) and Figure

1-5 (for 575V rated drives).

• Interconnections for external three-wire control in combination with the Digital

Operator are shown in Figure 1-4 (for 230V or 460V rated drives) and Figure

1-6 (for 575V rated drives).

Make wiring connections according to Figures 1-1 thru 1-4 and Table 1-3, observing the

following :

• Signal Leads : Terminals 1-8, 11-17, and 21-27.

• Control Leads : Terminals 9 & 10 and 18-20.

• Power Leads : Input Terminals L1 (R), L2 (S), and L3 (T), and Output Terminals

T1 (U), T2 (V), and T3 (W).

• Use twisted shielded or twisted-pair shielded wire (20-14 AWG (0.5-2mm

2

)for

1-60HP (CT); 18-14 AWG (0.75-2mm

2

)for 75-400HP (CT) ) for control and signal

circuit leads. When using shielded wire, the shield sheath MUST be connected

at the GPD 503 ONLY (terminal 12). The other end should be dressed neatly and

left unconnected (floating). See Figure 1-1.

• Lead length should NOT EXCEED 164 feet (50 meters). Wire sizes should be

determined considering the voltage drop.

TO GPD 503

SIGNAL

TERMINALS

TO SHIELD

SHEATH

TERMINAL

(TERM. 12)

WRAP BOTH ENDS

OF SHEATH WITH

INSULATING TAPE

CRIMP

CONNECTION

SHIELD SHEATH

OUTER JACKET

DO NOT

CONNECT

TO

EXTERNAL

CIRCUIT

Figure 1-1. Shielded Sheath Termination

1-4

TERMINAL FUNCTIONS LEVELS

1 2-WIRE CONTROL: Forward Run / Stop signal Run at closed, stop at open (See NOTE 2)

(See NOTE 1)

3-WIRE CONTROL: Run signal Run at closed (See NOTE 2)

2 2-WIRE CONTROL: Reverse Run / Stop signal Run at closed, stop at open (See NOTE 2)

(See NOTE 1)

3-WIRE CONTROL: Stop signal Stop at open (See NOTE 2)

3 External fault input Fault at closed (see NOTE 2). When the External

Fault input is applied, the GPD 503’s Fault relay

trips (shutdown) and the motor coasts to a stop.

The Digital Operator displays “

EF3

” failure.

4 Fault Reset input (external) Fault Reset at closed (see NOTE 2). The Fault

Reset input will reset the Fault relay, if the

GPD 503 is in “stopped” condition. Both Forward

Run/Stop signal and Reverse Run/Stop signal

must be OPEN.

5 - 8 External signal inputs (see NOTE 2); functions as defined by settings of system constants Sn-15 thru Sn-18.

See MULTI-FUNCTION INPUT TERMINALS in the PROGRAMMABLE FEATURES section of this manual.

9, 10 Multi-function contact output. Contact capacity:

One of 18 functions are available, by setting 250 Vac at 1A or below

of system constant Sn-20. (N.O.) 30 Vdc at 1A or below

11 Sequence control input common Sequence control input 0 V

for terminals (1 - 8).

12 Connection for shield sheath of signal leads – – – –

13 0 to +10V (20K ohms)

Auto frequency reference input

14 4-20 mA (250 ohms)

15 Manual frequency reference power supply +15V (Control power supply for frequency setting:

max 20 mA)

16 Multi-function analog input; function of input signal 0 to +10V/100% (20K ohms)

is selected by setting of system constant Sn-19

17 Multi-function analog input common 0 V

18 Closed at fault

Contact capacity:

Fault contact output

19 (N.O./N.C.) Open at fault 250 Vac at 1A or below

20 Common

30 Vdc at 1A or below

TERMINAL FUNCTIONS LEVELS

Table 1-3. Terminal Functions and Signals of Control Circuit

1-5

•• •

•

•• •

•• •

CORRECT CORRECT NOT

ACCEPTABLE

TERMINAL FUNCTIONS LEVELS

21 Multi-function analog monitor (+) Output current or Type of analog signal (operating parameter) to be

output frequency output is selected by setting of constant bn-13.

22 Multi-function analog monitor (-) is selectable Monitor output: 0 to +11V; 2 mA maximum

25 Multi-function open One of 18 functions Photocoupler insulation output: +48V, 50mA

collector output 1 are available, by or less

setting of system

26 Multi-function open constants Sn-21

collector output 2 and Sn-22.

27 Multi-function open collector output common 0V

TERMINAL FUNCTIONS LEVELS

NOTES:

1. When Forward Run and Reverse Run inputs are both closed for more than 500 ms, the Digital

Operator flashes “

EF

” and the motor (if rotating) is decelerated by the GPD 503 to a stop. This stop

condition is not stored by the GPD 503 (on Digital Operator, red lamp at STOP key does not light);

IF ONE OF THE INPUTS IS OPENED, THE MOTOR WILL IMMEDIATELY START UP

AGAIN.

2. Terminals 1-8 source +24 Vdc and operate in a Low = True (ON) configuration when connected to

terminal 11.

When using relays for input to terminals 1-8, use relays with highly reliable contacts (for very small

current) with a capacity of 30 Vdc or more and rated current of 100mA or higher. When using

transistor (open collector) input, use transistors with rated voltage of 35 Vdc or more and rated

current of 100mA or more.

Table 1-3. Terminal Functions and Signals of Control Circuit - Continued

1-6

1.4.3 Grounding

• The GPD 503 must be solidly grounded using main circuit ground terminal G (E).

Ground resistance should be 100 ohms or less. Select lead size suitable for size

of terminal screw. Make the length as short as possible.

• NEVER ground the GPD 503 in common with welding machines, motors, or

other large-current electrical equipment.

• Where several GPD 503s are used, ground each directly or daisy-chain to the

ground pole(s). DO NOT FORM A LOOP WITH THE GROUND LEADS.

1.4 ELECTRICAL INSTALLATION Continued

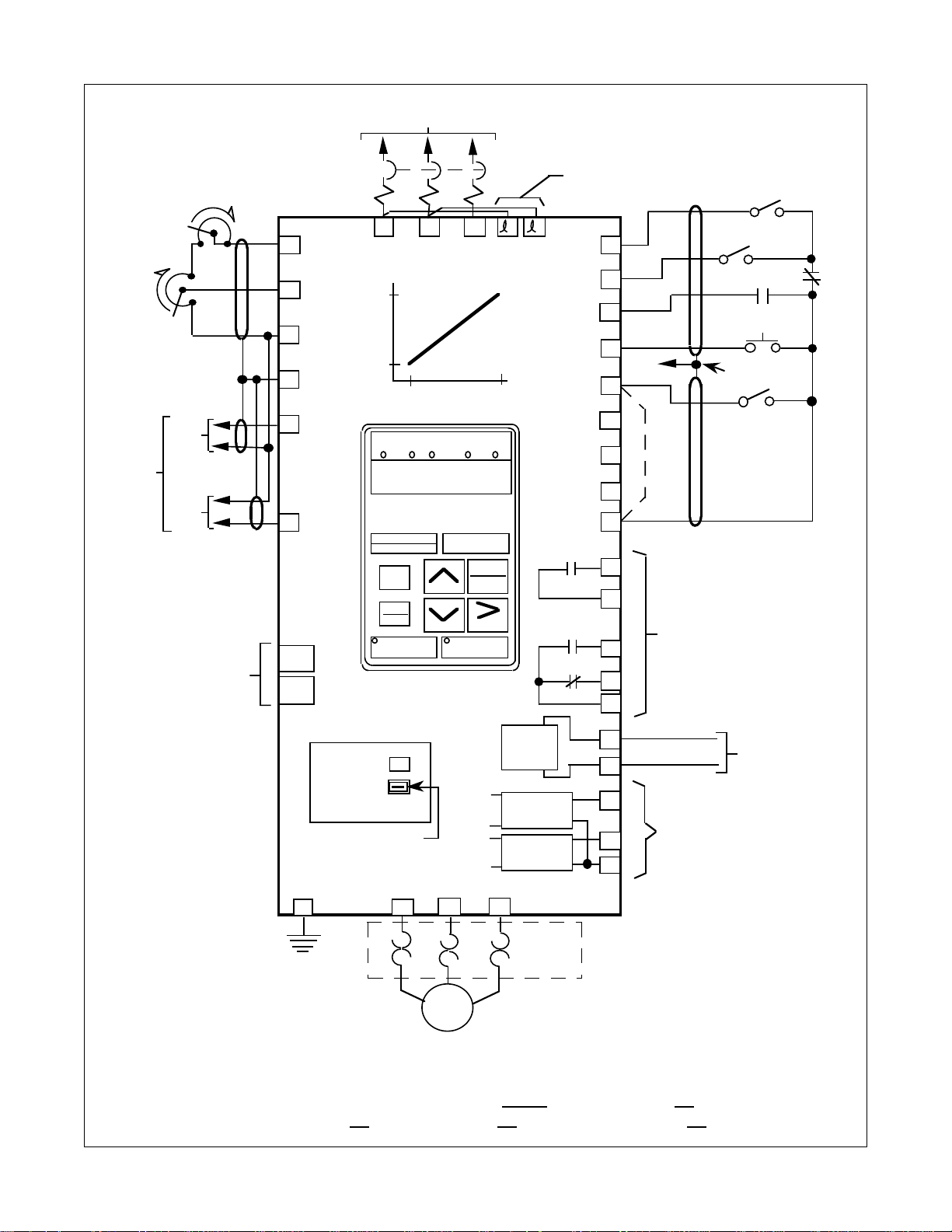

1.4.4 Auxiliary Input and Output Power Option Devices

Figure 1-2 is a factory guideline for proper wiring practices and relative locations within

the electrical path from the line to the load. It does not imply what devices are needed for

a particular application, nor does it show what devices were shipped with a particular

order. Therefore, disregard those items in the diagram which are not being used in your

installation.

Mount all power option devices as close to the drive, and keep electrical connections as

short as possible.

DO NOT run input and output wiring in the same conduit.

ISOLATION

TRANSFORMER

INPUT

REACTOR

INPUT

RFI FILTER

L3

L2

L1

H3

H2

H1

X3

X2

X1

C1

B1

A1

C2

B2

A2

C1(L3)

B1(L2)

A1(L1)

(L3)C2

(L2)B2

(L1)A2

L

I

N

E

L

O

A

D

CUSTOMER'S

3Ø A.C. LINE

POWER

SUPPLY

EARTH GROUND

SEE NOTE 2

(G)

RF NOISE

FILTER

SEE NOTE 5

SEE NOTE 3

L3

L2

L1

T3

T2

T1

INPUT

OUTPUT

MagneTek Drive

GND

EARTH GROUND

SEE NOTE 1

SEE NOTES 3, 4

OUTPUT

REACTOR

OUTPUT

RFI FILTER

TO CASE

EARTH

GROUND

SEE NOTE 2

SEE NOTES 3, 4

SEE NOTES 3, 4

A.C. MOTOR

1

2

3

4

5

6

IN

OUT

T3

T2

T1

C1

B1

A1

C2

B2

A2

EARTH GROUND

SEE NOTE 2

SEE NOTE 6

Figure 1-2. Customer Connection Diagram For Isolation Transformers,

Input Reactors, Input RFI Filters, Output Reactors and Output RFI FIlters

1-7

NOTES

1. Connect drive ground terminal or panel to

earth ground. Always use low impedance

paths and connections.

2. Mount input and output RFI filters

physically

as

close to the drive as possible (on the same

panel, if possible). Filters should have a solid

connection from filter case or ground terminal

to drive panel or ground terminal (conduit with

good bare metal to bare metal connections

may serve as the path). If multiple input or

output RFI filters are used, they must be wired

in parallel.

3. Shield conductors with metallic conduit.

4. Connect output conduit in a manner that

allows it to act as an unbroken shield from the

drive panel to the motor casing.

5. RF noise filter (different from RFI filter) part

no. 05P00325-0023 is a delta wye capacitor

network which is wired in parallel with the

drive input terminals. On the smaller drives

with die cast chassis, it must be mounted

externally. On the larger drives with sheet

metal chassis, it may be mounted inside the

area where the input power wiring enters the

drive. On units equipped with bypass, it may

be wired to the primary side of the circuit

breaker and mounted to the bypass panel or

sidewall.

6. Connection points:

Drive w/o Bypass Drive w/ Bypass

Input

L1, L2, L3

Ckt Brkr

L

1,

L

2,

L

3

Output

T1, T2, T3

Unwired side of

Overload relay

NOTES FOR FIGURE 1-3

✱ – Indicates components not supplied.

■ – Indicates customer connection terminal. Wire only to terminals shown.

( ) – Indicates alternate terminal marking, i.e., (R) and L1.

▲ – Function labels shown for these terminals are determined by factory settings of System Constants

Sn–15 through Sn-18.

● – Function labels shown for these terminals are determined by factory settings of System Constants

Sn–20 through Sn-22.

■ – Function labels shown for these terminals are determined by factory setting of System Constant

Sn-05 ( X X X X ).

– Function label shown for this terminal is determined by factory setting of System Constant Sn-19.

1. If only a remote Manual Speed pot (1RH) is used, 3SS is not needed; in that case, a jumper must be

added between terminals 5 and 11. This jumper will override both the Auto and Digital Operator

frequency references, regardless of the programming of Sn-04 X X X X. If you are using a remote speed

command or the Digital Operator, DO NOT install this jumper.

2. The GPD 503 Electronic Thermal Overload function (Sn-17, Cn-09) meets standards set by UL and CSA

for motor thermal overload protection. If local code requires separate mechanical overload protection,

an overload relay should be installed, interlocked with the GPD 503 as shown. It should be the manual

reset type to prevent automatic restart following a motor fault and subsequent contact reclosure after

cool down.

3. Insulated twisted shielded wire is required.

2-conductor #18 GA. (Beldon #8760 or equivalent).

3-conductor #18 GA. (Beldon #8770 of equivalent).

Connect shield ONLY AT GPD 503 END. Stub and isolate other end.

4. Digital Operator is standard on every GPD 503. Remote operators, as shown, may not be required.

5. Customer to connect terminal G (E) to earth ground.

6. Wire only one Auto Reference input.

7. If the Dynamic Braking (DB) option is used, wire per Appendix 7 instructions.

1-8

1-9

3ø POWER SUPPLY (SEE NAMEPLATE DATA)

1CB ✱

GPD 503

L1 L2 L3

15

16

17

12

14

13

V/HZ PROFILE

+15Vdc

(20mA MAX)

MAN REF. IN

(0 TO 10Vdc)

FWD

▲

▲

▲

▲

▲

▲

●

●

●

FWD

RUN/STOP

OUTPUT

VOLTAGE

(%)

COM

SHIELD

4-20mA

(250

OUTPUT FREQUENCY

(HZ)

DIGITAL

OPERATOR

PRGM

DRIVE

DATA

ENTER

0 TO 10Vdc

(20K

SEE

NOTE 4

REMOTE

DRIVE FWD REV SEQ REF

DSPL

4-20mA

0-10V

ISOLATED

AUTO

REFERENCE ✱

SEE NOTE 6

1OL ✱

SEE

NOTE 2

EXT. FAULT ✱

EXT. FAULT RESET

1PB ✱

SEE

NOTE 3

TO

TERM. 12

JOG

1R ✱

2K

MAN SPEED

1RH ✱

2K / 2.5K

SEE NOTE 1

AUTO

MAN

3SS ✱

1SS ✱

SEE

NOTE 1

1

2

3

4

5

6

7

8

11

9

REV

EXT. FAULT

FAULT RESET

AUTO/MAN

MULTI-STEP FREQ

SELECT

JOG

SPEED

COAST STOP

(BASE BLOCK)

0 VOLTS

RUN CONTACT

RY1

10

FAULT

CONTACTS

RY2

RY2

18

19

20

ANALOG

OUTPUT

(0-10 Vdc)

OPEN

COLLECTOR

CIRCUIT

OPEN

COLLECTOR

CIRCUIT

21

22

25

26

27

RESET

FWD

REV

RUN

STOP

RY CONTACTS

CAPACITY:

1A AT 250Vac

1A AT 30Vdc

MULTI-FUNCTION

MONITOR OUTPUT

0 - +10V

2mA MAX.

MULTI-

FUNCTION

OPEN

COLLECTOR

OUTPUTS

CAPACITY:

50mA AT 48Vdc MAX.

AC MOTOR ✱

(T2)

(T1) (T3)

G

T1 T2 T3

200V 380V 440V

220/ 400/ 460V

230V 415V

VOLTAGE SELECTOR

(460V, 15HP (CT) AND ABOVE)

FACTORY SET FOR 460V

EARTH

GROUND

SEE NOTE 5

1OL ✱

SEE NOTE 2

L1 L2 L3

GPD 503 BASIC INTERCONNECT DIAGRAM FOR 2-WIRE CONTROL

(R) (S) (T)

(E)

(U) (V) (W)

2SS ✱

REV

RUN/STOP

■

TERMINALS 1-8:

IF INPUT FROM RELAY CONTACTS:

RATED 30Vdc OR MORE,

100mA OR MORE

IF OPEN COLLECTOR INPUT:

RATED 35Vdc OR MORE,

100mA OR MORE

B1 or

B0/–

B2 or

B1/+

FOR WIRING

DYNAMIC

BRAKING

OPTION

SEE NOTE 7

1

2

COOLING

FAN

POWER

(15HP (CT) AND ABOVE)

Figure 1-3. 230V or 460V Interconnections - 2-Wire Control

(with constant Sn-04 set to 0000, Sn-15 set to 03,

Sn-16 set to 04, Sn-17 set to 06, and Sn-18 set to 08 )

FOR UNITS

WITH "L" IN

MODEL NO.

( "L" ) (04/27/95)

– (N)

+3

(P3)

NOTES FOR FIGURE 1-4

✱ – Indicates components not supplied.

■ – Indicates customer connection terminal. Wire only to terminals shown.

( ) – Indicates alternate terminal marking, i.e., (R) and L1.

▲ – Function labels shown for these terminals are determined by 3-Wire Control settings of System

Constants Sn-16 through Sn-18: Sn-16 =

03

, Sn-17 =

04

, Sn-18 =

06

.

● – Function labels shown for these terminals are determined by factory settings of System Constants

Sn–20 through Sn-22.

■ – Function labels shown for these terminals are determined by factory setting of System Constant

Sn-05 ( X X X X ).

– Function label shown for this terminal is determined by factory setting of System Constant Sn-19.

1. If only a remote Manual Speed pot (1RH) is used, 2SS is not needed; in that case, a jumper must be

added between terminals 6 and 11. This jumper will override both the Auto and Digital Operator

frequency references, regardless of the programming of Sn-04 X X X X. If you are using a remote speed

command or the Digital Operator, DO NOT install this jumper.

2. The GPD 503 Electronic Thermal Overload function (Sn-17, Cn-09) meets standards set by UL and CSA

for motor thermal overload protection. If local code requires separate mechanical overload protection,

an overload relay should be installed, interlocked with the GPD 503 as shown. It should be the manual

reset type to prevent automatic restart following a motor fault and subsequent contact reclosure after

cool down.

3. Insulated twisted shielded wire is required.

2-conductor #18 GA. (Beldon #8760 or equivalent).

3-conductor #18 GA. (Beldon #8770 or equivalent).

Connect shield ONLY AT GPD 503 END. Stub and isolate other end.

4. Digital Operator is standard on every GPD 503. Remote operators, as shown, may not be required.

5. Customer to connect terminal G (E) to earth ground.

6. Wire only one Auto Reference input.

7. If the Dynamic Braking (DB) option is used, wire per Appendix 7 instructions.

CAUTION

Before running, Sn-03 must be set to "0000".

Resetting drive constant Sn-03 to "1110" may cause

the motor to run in the reverse direction WITHOUT A

RUN COMMAND, and possibly result in damage to the

equipment or personal injury.

1-10

1-11

3ø POWER SUPPLY (SEE NAMEPLATE DATA)

1CB ✱

GPD 503

L1 L2 L3

15

16

17

12

14

13

V/HZ PROFILE

+15Vdc

(20mA MAX)

MAN REF. IN

(0 TO 10Vdc)

RUN

▲

▲

▲

▲

▲

●

●

●

RUN

1PB ✱

OUTPUT

VOLTAGE

(%)

COM

SHIELD

4-20mA

(250

OUTPUT FREQUENCY

(HZ)

DIGITAL

OPERATOR

PRGM

DRIVE

DATA

ENTER

0 TO 10Vdc

(20K

SEE

NOTE 4

REMOTE

DRIVE FWD REV SEQ REF

DSPL

4-20mA

0-10V

ISOLATED

AUTO

REFERENCE ✱

SEE NOTE 6

STOP

2PB ✱

1OL ✱

SEE

NOTE 2

EXT. FAULT ✱

EXT. FAULT RESET

3PB ✱

SEE

NOTE 3

TO

TERM. 12

JOG

1R ✱

2K

MAN SPEED

1RH ✱

2K / 2.5K

SEE NOTE 1

AUTO

MAN

2SS ✱

1SS ✱

FWD

REV

SEE

NOTE 1

1

2

3

4

5

6

7

8

11

9

STOP

EXT. FAULT

FAULT RESET

AUTO/MAN

MULTI-STEP

FREQ

SELECT

JOG

SPEED

FWD/REV

0 VOLTS

RUN CONTACT

RY1

10

FAULT

CONTACTS

RY2

RY2

18

19

20

ANALOG

OUTPUT

(0-10 Vdc)

OPEN

COLLECTOR

CIRCUIT

OPEN

COLLECTOR

CIRCUIT

21

22

25

26

27

RESET

FWD

REV

RUN

STOP

RY CONTACTS

CAPACITY:

1A AT 250Vac

1A AT 30Vdc

MULTI-FUNCTION

MONITOR OUTPUT

0 - +10V

2mA MAX.

MULTI-

FUNCTION

OPEN

COLLECTOR

OUTPUTS

CAPACITY:

50mA AT 48Vdc MAX.

AC MOTOR ✱

(T2)

(T1) (T3)

G

T1 T2 T3

200V 380V 440V

220/ 400/ 460V

230V 415V

VOLTAGE SELECTOR

(460V, 15HP (CT) AND ABOVE)

FACTORY SET FOR 460V

EARTH

GROUND

SEE NOTE 5

1OL ✱

SEE NOTE 2

L1 L2 L3

GPD 503 BASIC INTERCONNECT DIAGRAM FOR 3-WIRE CONTROL

(R) (S) (T)

(E)

(U) (V) (W)

■

TERMINALS 1-8:

IF INPUT FROM RELAY CONTACTS:

RATED 30Vdc OR MORE,

100mA OR MORE;

IF OPEN COLLECTOR INPUT:

RATED 35Vdc OR MORE,

100mA OR MORE

FOR WIRING

DYNAMIC

BRAKING

OPTION

SEE NOTE 7

B1 or

B0/–

B2 or

B1/+

1

2

COOLING

FAN

POWER

(15HP (CT) AND ABOVE)

Figure 1-4. 230V or 460V Interconnections - 3-Wire Control

(with constant Sn-04 set to 0000, Sn-15 set to 00,

Sn-16 set to 03, Sn-17 set to 04, and Sn-18 set to 06 )

( "L" ) (04/27/95)

FOR UNITS

WITH "L" IN

MODEL NO.

– (N)

+3

(P3)

1-12

NOTES FOR FIGURE 1-5

✱ – Indicates components not supplied.

■ – Indicates customer connection terminal. Wire only to terminals shown.

( ) – Indicates alternate terminal marking, i.e., (R) and L1.

▲ – Function labels shown for these terminals are determined by factory settings of System Constants

Sn–15 through Sn-18.

● – Function labels shown for these terminals are determined by factory settings of System Constants

Sn–20 through Sn-22.

■ – Function labels shown for these terminals are determined by factory setting of System Constant

Sn-05 ( X X X X ).

– Function label shown for this terminal is determined by factory setting of System Constant Sn-19.

1. If only a remote Manual Speed pot (1RH) is used, 3SS is not needed; in that case, a jumper must be

added between terminals 5 and 11. This jumper will override both the Auto and Digital Operator

frequency references, regardless of the programming of Sn-04 X X X X. If you are using a remote speed

command or the Digital Operator, DO NOT install this jumper.

2. The GPD 503 Electronic Thermal Overload function (Sn-17, Cn-09) meets standards set by UL and CSA

for motor thermal overload protection. If local code requires separate mechanical overload protection,

an overload relay should be installed, interlocked with the GPD 503 as shown. It should be the manual

reset type to prevent automatic restart following a motor fault and subsequent contact reclosure after

cool down.

3. Insulated twisted shielded wire is required.

2-conductor #18 GA. (Beldon #8760 or equivalent).

3-conductor #18 GA. (Beldon #8770 of equivalent).

Connect shield ONLY AT GPD 503 END. Stub and isolate other end.

4. Digital Operator is standard on every GPD 503. Remote operators, as shown, may not be required.

5. Customer to connect terminal G (E) to earth ground.

6. Wire only one Auto Reference input.

7. If the Dynamic Braking (DB) option is used, wire per Appendix 7 instructions.

1-13

3ø POWER SUPPLY (SEE NAMEPLATE DATA)

1CB ✱

GPD 503

L1 L2 L3

15

16

17

12

14

13

V/HZ PROFILE

+15Vdc

(20mA MAX)

MAN REF. IN

(0 TO 10Vdc)

FWD

▲

▲

▲

▲

▲

▲

●

●

●

FWD

RUN/STOP

OUTPUT

VOLTAGE

(%)

COM

SHIELD

4-20mA

(250

OUTPUT FREQUENCY

(HZ)

DIGITAL

OPERATOR

PRGM

DRIVE

DATA

ENTER

0 TO 10Vdc

(20K

SEE

NOTE 4

REMOTE

DRIVE FWD REV SEQ REF

DSPL

4-20mA

0-10V

ISOLATED

AUTO

REFERENCE ✱

SEE NOTE 6

1OL ✱

SEE

NOTE 2

EXT. FAULT ✱

EXT. FAULT RESET

1PB ✱

SEE

NOTE 3

TO

TERM. 12

JOG

1R ✱

2K

MAN SPEED

1RH ✱

2K / 2.5K

SEE NOTE 1

AUTO

MAN

3SS ✱

1SS ✱

SEE

NOTE 1

1

2

3

4

5

6

7

8

11

9

REV

EXT. FAULT

FAULT RESET

AUTO/MAN

MULTI-STEP FREQ

SELECT

JOG

SPEED

COAST STOP

(BASE BLOCK)

0 VOLTS

RUN CONTACT

RY1

10

FAULT

CONTACTS

RY2

RY2

18

19

20

ANALOG

OUTPUT

(0-10 Vdc)

OPEN

COLLECTOR

CIRCUIT

OPEN

COLLECTOR

CIRCUIT

21

22

25

26

27

RESET

FWD

REV

RUN

STOP

RY CONTACTS

CAPACITY:

1A AT 250Vac

1A AT 30Vdc

MULTI-FUNCTION

MONITOR OUTPUT

0 - +10V

2mA MAX.

MULTI-

FUNCTION

OPEN

COLLECTOR

OUTPUTS

CAPACITY:

50mA AT 48Vdc MAX.

AC MOTOR ✱

(T2)

(T1) (T3)

G

T1 T2 T3

5000V

575/600V

VOLTAGE SELECTOR

(15HP AND ABOVE)

FACTORY SET FOR 575/600V

EARTH

GROUND

SEE NOTE 5

1OL ✱

SEE NOTE 2

L1 L2 L3

GPD 503 BASIC INTERCONNECT DIAGRAM FOR 2-WIRE CONTROL

(R) (S) (T)

(E)

(U) (V) (W)

2SS ✱

REV

RUN/STOP

■

TERMINALS 1-8:

IF INPUT FROM RELAY CONTACTS:

RATED 30Vdc OR MORE,

100mA OR MORE

IF OPEN COLLECTOR INPUT:

RATED 35Vdc OR MORE,

100mA OR MORE

B1 or

B0/–

B2 or

B1/+

FOR WIRING

DYNAMIC

BRAKING

OPTION

SEE NOTE 7

12

COOLING

FAN

POWER

(15HP AND ABOVE)

Figure 1-5. 575V Interconnections - 2-Wire Control

(with constant Sn-04 set to 0000, Sn-15 set to 03,

Sn-16 set to 04, Sn-17 set to 06, and Sn-18 set to 08 )

1-14

NOTES FOR FIGURE 1-6

✱ – Indicates components not supplied.

■ – Indicates customer connection terminal. Wire only to terminals shown.

( ) – Indicates alternate terminal marking, i.e., (R) and L1.

▲ – Function labels shown for these terminals are determined by 3-Wire Control settings of System

Constants Sn-16 through Sn-18: Sn-16 =

03

, Sn-17 =

04

, Sn-18 =

06

.

● – Function labels shown for these terminals are determined by factory settings of System Constants

Sn–20 through Sn-22.

■ – Function labels shown for these terminals are determined by factory setting of System Constant

Sn-05 ( X X X X ).

– Function label shown for this terminal is determined by factory setting of System Constant Sn-19.

1. If only a remote Manual Speed pot (1RH) is used, 2SS is not needed; in that case, a jumper must be

added between terminals 6 and 11. This jumper will override both the Auto and Digital Operator

frequency references, regardless of the programming of Sn-04 X X X X. If you are using a remote speed

command or the Digital Operator, DO NOT install this jumper.

2. The GPD 503 Electronic Thermal Overload function (Sn-17, Cn-09) meets standards set by UL and CSA

for motor thermal overload protection. If local code requires separate mechanical overload protection,

an overload relay should be installed, interlocked with the GPD 503 as shown. It should be the manual

reset type to prevent automatic restart following a motor fault and subsequent contact reclosure after

cool down.

3. Insulated twisted shielded wire is required.

2-conductor #18 GA. (Beldon #8760 or equivalent).

3-conductor #18 GA. (Beldon #8770 or equivalent).

Connect shield ONLY AT GPD 503 END. Stub and isolate other end.

4. Digital Operator is standard on every GPD 503. Remote operators, as shown, may not be required.

5. Customer to connect terminal G (E) to earth ground.

6. Wire only one Auto Reference input.

7. If the Dynamic Braking (DB) option is used, wire per Appendix 7 instructions.

CAUTION

Before running, Sn-03 must be set to "0000".

Resetting drive constant Sn-03 to "1110" may cause

the motor to run in the reverse direction WITHOUT A

RUN COMMAND, and possibly result in damage to the

equipment or personal injury.

Loading...

Loading...