YASKAWA VS-616P5, VS-616PC5 User Manual

VS-616PC5/P5 Series

User’s Manual

Variable Torque Inverter

(with software version 5110/5120 and newer)

! WARNING

PRECAUTIONS

1)Read this manual in its entirety before installing or operating the VS616PC5/P5 inverter. This manual applies to inverters with software versions 5110 and 5120 only and is not intended to be used in conjunction with any other software.

2)Do not connect or disconnect wiring, or perform signal checks while the power supply is turned ON.

3)The VS-616PC5/P5 internal capacitor may be charged even after the power supply is turned OFF. To prevent electrical shock, disconnect all power before servicing the inverter. Then wait at least five minutes after the power supply is disconnected and all LEDs are extinguished.

4)Do not perform a withstand voltage test or a megger test on any part of the VS-616PC5/P5. This electronic equipment uses semiconductors and is vulnerable to high voltage.

5)Do not remove the operator unless the power supply is turned OFF. Never touch the printed control board while the power supply is turned ON.

6)The VS-616PC5/P5 is suitable for use on a circuit capable of delivering not more than 65,000 RMS symmetrical amperes, 480 Volts maximum (460V class units), 240 Volts maximum (230V class units).

Failure to observe these and other precautions highlighted in this manual will expose the user to high voltages, resulting in equipment damage, serious injury or death.

NOTICE

Printed April, 1999. The information contained within this document is the proprietary property of Yaskawa Electric America, Inc., and may not be copied, reproduced or transmitted to other parties without the expressed written authorization of Yaskawa Electric America, Inc.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly improving its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

2 |

VS-616PC5/P5 User’s Manual |

|

|

Contents |

CONTENTS |

|

|

Section |

Description |

Page |

1 |

RECEIVING & INSTALLATION |

|

1.1 |

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 6 |

1.2 |

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 7 |

|

VS-616PC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 7 |

|

VS-616P5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 9 |

1.3 |

PRELIMINARY INSPECTION . . . . . . . . . . . . . . . . . . . . |

. . . . . 11 |

|

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 11 |

|

Checking the Nameplate . . . . . . . . . . . . . . . . . . . . |

. . . . . 11 |

|

Identifying the Parts. . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 12 |

1.4 |

MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 13 |

|

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 13 |

|

Choosing a Location . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 13 |

|

Removing and Replacing the Digital Operator . . |

. . . . . 14 |

|

Removing and Replacing the Front Cover. . . . . . |

. . . . . 14 |

|

Dimensions/Heat Loss. . . . . . . . . . . . . . . . . . . . . . |

. . . . . 15 |

|

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 17 |

1.5 |

WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 18 |

|

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 18 |

|

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 18 |

|

VS-616PC5 Connection Diagram . . . . . . . . . . . . |

. . . . . 19 |

|

VS-616P5 Connection Diagram . . . . . . . . . . . . . . |

. . . . . 20 |

|

Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 21 |

|

Terminal Functions . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 24 |

|

Wire and Terminal Screw Sizes . . . . . . . . . . . . . . |

. . . . . 25 |

|

Control Circuit Wiring. . . . . . . . . . . . . . . . . . . . . . |

. . . . . 28 |

2 |

OPERATION |

|

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1 |

TRIAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

Display at Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

Operation Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

2.2 |

DIGITAL OPERATOR DISPLAY. . . . . . . . . . . . . . . . . . . . . . . |

35 |

2.3 |

LED DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

2.4 |

OPERATION MODE SELECTION . . . . . . . . . . . . . . . . . . . . . . |

37 |

3 |

PROGRAMMING FEATURES |

|

3.1 |

VS-616PC5/P5 PARAMETERS (n001~n116) . . . . . . . . . . . |

41 |

3.2 |

PARAMETER SET-UP & INITIALIZATION. . . . . . . . . . . . . . . |

49 |

3.3 |

VS-616PC5/P5 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

Accel/decel time adjustment . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

Automatic fault retry . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

Automatic restart after momentary power loss . . . . . . . |

51 |

|

Carrier frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

VS-616PC5/P5 User’s Manual |

3 |

Contents

Current limit (Stall prevention). . . . . . . . . . . . . . . . . . . . 52 DC injection braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 Energy savings control . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Frequency agree set point . . . . . . . . . . . . . . . . . . . . . . . . 57 Frequency meter or ammeter . . . . . . . . . . . . . . . . . . . . . 58 Frequency meter or ammeter calibration . . . . . . . . . . . . 58 Frequency signal adjustment. . . . . . . . . . . . . . . . . . . . . . 58 Jog operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Jump frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 MODBUS communication . . . . . . . . . . . . . . . . . . . . . . . 61 Motor overload detection . . . . . . . . . . . . . . . . . . . . . . . . 62 Multi-step speed selection. . . . . . . . . . . . . . . . . . . . . . . . 64 Phase loss detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 Reverse run prohibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 Soft-start characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 68 Speed limit adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 69 Stopping method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 Torque adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 Torque detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 Tripless operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 V/f pattern adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 Slip compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.4 |

INPUTS & OUTPUTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

78 |

|

Multi-function input signals . . . . . . . . . . . . . . . . . . . . . . |

78 |

|

Analog input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

Multi-function output signals . . . . . . . . . . . . . . . . . . . . . |

83 |

4 |

DIAGNOSTICS |

|

|

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

4.1 |

MAINTENANCE & INSPECTION . . . . . . . . . . . . . . . . . . . . . . |

87 |

|

Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

|

Parts Replacement Schedule . . . . . . . . . . . . . . . . . . . . . . |

87 |

4.2 |

ALARM & FAULT DISPLAY. . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

Alarm Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

Fault Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

|

Motor Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

A |

APPENDIX |

|

A-1 |

BRAKING CONNECTION DIAGRAMS . . . . . . . . . . . . . . . . . . |

94 |

A-2 |

DIGITAL OPERATOR MONITOR DISPLAY . . . . . . . . . . . . . . |

95 |

A-3 |

CE CONFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

4 |

VS-616PC5/P5 User’s Manual |

Chapter 1 - Receiving & Installation

- CHAPTER 1 -

RECEIVING & INSTALLATION

Section |

Description |

Page |

1 |

RECEIVING & INSTALLATION |

|

1.1 |

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 6 |

1.2 |

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 7 |

|

VS-616PC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 7 |

|

VS-616P5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 9 |

1.3 |

PRELIMINARY INSPECTION . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

|

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

|

Checking the Nameplate . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

|

Identifying the Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 12 |

1.4 |

MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 13 |

|

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 13 |

|

Choosing a Location . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 13 |

|

Removing and Replacing the Digital Operator . . . . . |

. . 14 |

|

Removing and Replacing the Front Cover. . . . . . . . . |

. . 14 |

|

Dimensions/Heat Loss. . . . . . . . . . . . . . . . . . . . . . . . . |

. . 15 |

|

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 17 |

1.5 |

WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 18 |

|

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 18 |

|

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 18 |

|

VS-616PC5 Connection Diagram . . . . . . . . . . . . . . . . |

. 19 |

|

VS-616P5 Connection Diagram . . . . . . . . . . . . . . . . . . |

. 20 |

|

Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 21 |

|

Terminal Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 24 |

|

Wire and Terminal Screw Sizes . . . . . . . . . . . . . . . . . . |

. 25 |

|

Control Circuit Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . |

. 28 |

VS-616PC5/P5 User’s Manual |

5 |

Chapter 1 - Receiving & Installation

Introduction

1.1 INTRODUCTION

The VS-616PC5/P5 is a series of high quality, variable torque inverters. With a power range of 5 to 500 HP, it provides all the functionality of prior series, in a compact, low cost package. This functionality includes Yaskawa proprietary features like full-range automatic torque boost, electronic thermal motor overload, energy savings and PID operation, lownoise operation and various other features. It also features a new digital operator for simple programming. Utilizing the latest microprocessor technology, members of Yaskawa’s design team have collaborated to make the VS-616PC5/P5 the world’s first optimized inverter specifically designed for variable torque applications.

This manual details installation, start-up and operating procedures for the VS-616PC5/P5 series adjustable frequency drive controller. Descriptions of diagnostic and troubleshooting procedures are also included herein.

6 |

VS-616PC5/P5 User’s Manual |

Chapter 1 - Receiving & Installation

Specifications

1.2 SPECIFICATIONS

VS-616PC5

|

Inverter Model |

|

|

|

|

VS-616PC5 |

|

|

|

|

||

|

CIMR-P5U |

20P4 |

20P7 |

21P5 |

22P2 |

23P7 |

25P5 |

27P5 |

2011 |

2015 |

- |

|

|

Motor Output (HP) * |

0.5 |

1 |

2 |

3 |

5 |

7.5 |

10 |

20 |

25 |

- |

|

|

Capacity (kVA) |

1.2 |

2.3 |

3.0 |

4.2 |

6.7 |

9.5 |

13 |

19 |

24 |

- |

|

Characteristics |

Rated Output |

3.2 |

6 |

8 |

11 |

17.5 |

27 |

36 |

54 |

68 |

- |

|

Current (A)-VT** |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|||

Rated Output |

3.2 |

6 |

8 |

11 |

17.5 |

25 |

33 |

49 |

64 |

- |

||

Current (A)-CT** |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|||

Max. Voltage |

|

|

|

3-Phase, 200/208/220/230V |

|

|

|

|||||

Output |

|

|

|

|

|

|

||||||

|

|

|

(Proportional to input voltage) |

|

|

|

||||||

|

|

|

|

|

|

|

||||||

Rated Output Frequency |

|

|

|

|

0.1 to 400 Hz |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

||||||

|

Overload Capacity - VT |

|

|

120% Rated Output Current for 1 minute |

|

|

||||||

|

Overload Capacity - CT |

|

|

150% Rated Output Current for 1 minute |

|

|

||||||

Supply |

Input Current (A) |

3.9 |

7.2 |

9.6 |

13.2 |

21 |

33 |

44 |

65 |

82 |

- |

|

Rated Voltage & |

|

|

|

|

3-Phase |

|

|

|

|

|||

Frequency |

|

|

|

220 - 230V, 50/60Hz |

|

|

|

|||||

Power |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||

Voltage Fluctuation |

|

|

|

|

+10%, -15% |

|

|

|

|

|||

Frequency Fluctuation |

|

|

|

|

±5% |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||||

|

CIMR-P5U |

40P4 |

40P7 |

41P5 |

42P2 |

43P7 |

44P0 |

45P5 |

47P5 |

4011 |

4015 |

|

|

Motor Output (HP) * |

0.5 |

1 |

2 |

3 |

5 |

7.5 |

10 |

15 |

20 |

25 |

|

|

Capacity (kVA) |

1.4 |

2.6 |

3.7 |

4.7 |

6.1 |

8.6 |

11 |

14 |

21 |

26 |

|

Characteristics |

Rated Output |

1.9 |

3.6 |

5.1 |

6.6 |

8.5 |

11.7 |

14.8 |

21.0 |

28.6 |

34.0 |

|

Current (A)-VT** |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|||

Rated Output |

1.9 |

3.6 |

5.1 |

6.6 |

8.5 |

11.7 |

14.8 |

18 |

28.6 |

34.0 |

||

Current (A)-CT** |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|||

Max. Voltage # |

|

|

3-Phase, 380/400/415/440/460V |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||

Output |

|

|

|

(Proportional to input voltage) |

|

|

|

|||||

|

|

|

|

|

|

|

||||||

Rated Output Frequency |

|

|

|

|

0.1 to 400 Hz |

|

|

|

|

|||

|

Overload Capacity-VT** |

|

|

120% Rated Output Current for 1 minute |

|

|

||||||

|

|

|

(Model 47P5 is rated 150% / 1 minute) |

|

|

|||||||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

||||||

|

Overload Capacity-CT** |

|

|

150% Rated Output Current for 1 minute |

|

|

||||||

Supply |

Input Current (A) |

2.3 |

4.3 |

6.1 |

8.0 |

10.2 |

14.0 |

17.8 |

26.0 |

35.0 |

40.0 |

|

Rated Voltage & |

|

|

|

|

3-Phase |

|

|

|

|

|||

Frequency # |

|

|

|

380 -440 - 460V, 50/60Hz |

|

|

|

|||||

Power |

|

|

|

|

|

|

|

|

|

|

||

Voltage Fluctuation |

|

|

|

|

+10%, -15% |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

Frequency Fluctuation |

|

|

|

|

±5% |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||||

* HP ratings based on standard NEMA 4-pole motor data.

# For 380V operation, the motor rated current must be less than or equal to the inverter rated current.

** VT: Variable Torque rating (n116=1), CT: Constant Torque rating (n116=0) Note: Shaded areas indicate factory settings.

VS-616PC5/P5 User’s Manual |

7 |

Chapter 1 - Receiving & Installation

Specifications

|

Control Method |

Sine wave PWM with full-range, automatic torque boost |

|

|

Frequency Control |

0.1 to 400 Hz |

|

|

Range |

||

|

|

||

|

|

|

|

Characteristics |

Frequency Accuracy |

Digital command: 0.01%, Analog command: 0.1% |

|

Frequency Setting Reso- |

0.01 Hz |

||

|

Digital Operator Reference: 0.1Hz, |

||

|

lution |

Analog Reference: 0.06Hz (@60Hz) |

|

|

Output Frequency Reso- |

|

|

Control |

lution |

|

|

Frequency Setting |

0 to +10VDC (20kΩ), 4-20mA (250Ω) |

||

|

|||

|

|

|

|

|

Accel/Decel Time |

0.0 to 3600.0 sec. |

|

|

(Accel/Decel time setting independently: 0.1 sec ) |

||

|

|

||

|

Braking Torque |

Approx. 20% |

|

|

|

|

|

|

No. of V-f Patterns |

1 preset V/f pattern and 1 custom pattern |

|

|

Motor Overload Protec- |

Electronic thermal overload relay (I2T) |

|

|

tion |

||

|

|

||

|

Instantaneous Overcur- |

Motor coasts to stop at approx. 200% rated output current. |

|

|

rent |

||

|

|

||

|

|

|

|

|

Fuse Protection |

Motor coasts to stop at blown fuse. |

|

|

Overload |

Motor coasts to stop after 1 min. at rated overload capacity. |

|

|

|

|

|

Functions |

Overvoltage |

Motor coasts to a stop if converter output voltage exceeds 410VDC |

|

Motor coasts to stop if converter output voltage drops below user |

|||

|

|

(820VDC at 460V input) |

|

Protective |

Undervoltage |

tion during power loss less than 2 sec is equipped as standard.) |

|

Momentary Power Loss |

|||

|

|

adjustable value |

|

|

|

Immediate stop after 15 ms or longer power loss. (Continuous system opera- |

|

|

|

|

|

|

Heatsink Overheat |

Thermistor - OH1, OH2 |

|

|

|

|

|

|

Stall Prevention |

Stall prevention at acceleration/deceleration and constant speed |

|

|

operation |

||

|

|

||

|

Ground Fault |

Provided by electronic circuit |

|

|

|

|

|

|

Power Charge Indication |

Charge LED stays on until voltage drops below 50VDC |

|

|

Input Phase Loss |

Single-phase protection |

|

Conditions |

Location |

Indoor (protected from corrosive gases and dust) |

|

|

|||

|

Ambient |

+14 to 104°F (-10 to 40°C) for NEMA 1 type (not frozen) |

|

|

Temperature |

+14 to 113°F (-10 to 45°C) for open chassis type |

|

Environmental |

Storage |

9.8m/s2 (1G) less than 20Hz, up to 1.96m/s2 (0.2G) at 20 to 50Hz |

|

Vibration |

|||

|

Temperature |

-4 to 140°F (-20 to 60°C) |

|

|

Humidity |

95% RH (non-condensing) |

|

|

|

|

8 |

VS-616PC5/P5 User’s Manual |

Chapter 1 - Receiving & Installation

Specifications

VS-616P5

|

Inverter Model |

|

|

|

|

|

|

VS-616P5 |

|

|

|

|

|

|

|

|

|

CIMR-P5U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2018 |

2022 |

2030 |

2037 |

2045 |

2055 |

2075 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor Output (HP) * |

30 |

40 |

50 |

60 |

75 |

|

100 |

125 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capacity (kVA) |

30 |

37 |

50 |

61 |

70 |

|

85 |

110 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

— |

|

|

Characteristics |

Rated Output |

80 |

104 |

130 |

160 |

192 |

|

248 |

312 |

|

|

|

|

|

|

|

Current (A) - VT ** |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Rated Output |

64 |

83 |

104 |

128 |

154 |

|

198 |

250 |

|

|

|

|

|

|

|

|

Current (A) - CT ** |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-Phase, 200/208/220/230V |

|

|

|

|||||||||

Output |

Max. Voltage |

|

|

|

|

|

|

|||||||||

|

|

|

(Proportional to input voltage) |

|

|

|

||||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated Output Frequency |

|

|

|

|

|

0.1 to 400 Hz |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||||||||

|

Overload Capacity - VT ** |

|

|

120% Rated Output Current / 1 minute |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|||||||||

|

Overload Capacity - CT ** |

|

|

150% Rated Output Current / 1 minute |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Supply |

Input Current (A) |

88 |

119 |

143 |

176 |

212 |

|

270 |

344 |

|

|

|

|

— |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated Voltage & |

|

|

|

|

|

|

3-Phase |

|

|

|

|

|

|

|

||

Frequency |

|

|

|

|

220 - 230V, 50/60Hz |

|

|

|

|

|

||||||

Power |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Voltage Fluctuation |

|

|

|

|

|

+10%, -15% |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency Fluctuation |

|

|

|

|

|

±5% |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

CIMR-P5U |

4018 |

4022 |

4030 |

4037 |

4045 |

4055 |

4075 |

4110 |

4160 |

4185 |

4220 |

4300 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor Output (HP) * |

30 |

40 |

50 |

60 |

75 |

|

100 |

150 |

200 |

|

250 |

|

300 |

400 |

500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capacity (kVA) |

31 |

40 |

50 |

61 |

73 |

|

98 |

130 |

170 |

|

230 |

|

260 |

340 |

460 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Characteristics |

Rated Output |

41 |

52 |

65 |

80 |

96 |

|

128 |

180 |

240 |

|

302 |

|

380 |

506 |

675 |

Current (A) - VT ** |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Rated Output |

32 |

42 |

52 |

64 |

77 |

|

102 |

144 |

182 |

|

242 |

|

304 |

404 |

540 |

|

Current (A) - CT ** |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-Phase, 380/400/415/440/460V |

|

|

|

|||||||||

Output |

Max. Voltage # |

|

|

|

|

|

|

|||||||||

|

|

|

(Proportional to input voltage) |

|

|

|

||||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated Output Frequency |

|

|

|

|

|

0.1 to 400 Hz |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||||

|

Overload Capacity - VT ** |

|

|

|

120% Rated Current / 1 minute |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

||||||||

|

Overload Capacity - CT ** |

|

|

|

150% Rated Current / 1 minute |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Supply |

Input Current (A) |

46 |

58 |

72 |

88 |

106 |

|

141 |

198 |

264 |

|

330 |

|

456 |

608 |

810 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated Voltage & |

|

|

|

|

|

|

3-Phase |

|

|

|

|

|

|

|

||

Frequency # |

|

|

|

|

380 -440 - 460V, 50/60Hz |

|

|

|

|

|

||||||

Power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Voltage Fluctuation |

|

|

|

|

|

+10%, -15% |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency Fluctuation |

|

|

|

|

|

±5% |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* HP ratings based on standard NEMA 4-pole motor data.

# For 380V operation, the motor rated current must be less than or equal to the inverter rated current.

** VT: Variable Torque rating (n116=1), CT: Constant Torque rating (n116=0) Note: Shaded areas indicate factory settings.

VS-616PC5/P5 User’s Manual |

9 |

Chapter 1 - Receiving & Installation

Specifications

|

Control Method |

Sine wave PWM with full-range, automatic torque boost |

|

|

|

|

|

|

Frequency Control Range |

0.1 to 400 Hz |

|

|

|

|

|

|

Frequency Accuracy |

Digital command: 0.01%, Analog command: 0.1% |

|

Characteristics |

|

|

|

Frequency Setting |

Digital Operator Reference: 0.1Hz, |

||

|

|||

|

Resolution |

Analog Reference: 0.06Hz (@60Hz) |

|

|

|

|

|

|

Output Frequency |

0.01 Hz |

|

|

Resolution |

||

|

|

||

Control |

|

|

|

Frequency Setting |

0.0 to 3600.0 sec. |

||

|

0 to +10VDC (20kΩ), 4-20mA (250Ω) |

||

|

Accel/Decel Time |

(Accel/Decel time setting independently: 0.1 sec ) |

|

|

|

||

|

|

|

|

|

Braking Torque |

Approx. 20% |

|

|

|

|

|

|

No. of V-f Patterns |

1 preset V/f pattern and 1 custom pattern |

|

|

|

|

|

|

Motor Overload Protection |

Electronic thermal overload relay (I2T) |

|

|

Instantaneous Overcurrent |

Motor coasts to stop at approx. 180% rated output current. |

|

|

|

|

|

|

Fuse Protection |

Motor coasts to stop at blown fuse. |

|

|

|

|

|

|

Overload |

Motor coasts to stop after 1 min. at rated overload capacity. |

|

|

|

|

|

Functions |

Overvoltage |

Motor coasts to stop if converter output voltage exceeds 410VDC |

|

(820VDC at 460V input) |

|||

Undervoltage |

|||

|

|

||

|

|

|

|

|

|

Motor coasts to stop if converter output voltage drops below user |

|

Protective |

|

adjustable value |

|

|

|

||

Momentary Power Loss |

Immediately stop after 15 ms or longer power loss. (Continuous system |

||

|

|||

|

operation during power loss less than 2 sec is equipped as standard.) |

||

|

|

||

|

|

|

|

|

Heatsink Overheat |

Thermistor - OH1, OH2 |

|

|

|

|

|

|

Stall Prevention |

Stall prevention at acceleration/deceleration and constant speed operation |

|

|

|

|

|

|

Ground Fault |

Provided by electronic circuit |

|

|

|

|

|

|

Power Charge Indication |

Charge LED stays on until voltage drops below 50VDC |

|

|

|

|

|

|

Input Phase Loss |

Single-phase protection |

|

|

|

|

|

Conditions |

Location |

Indoor (protected from corrosive gases and dust) |

|

|

|

||

|

+14 to 113°F (-10 to 45°C) for open chassis type |

||

|

Ambient Temperature |

+14 to 104°F (-10 to 40°C) for NEMA 1 type (not frozen) |

|

|

|

||

Environmental |

|

|

|

Vibration |

9.8m/s2 (1G) less than 20Hz, up to 1.96m/s2 (0.2G) at 20 to 50Hz |

||

|

Storage Temperature |

-4 to 140°F (-20 to 60°C) |

|

|

Humidity |

95% RH (non-condensing) |

|

|

|

|

10 |

VS-616PC5/P5 User’s Manual |

Chapter 1 - Receiving & Installation

Preliminary Inspection

1.3 PRELIMINARY INSPECTION

Receiving

After unpacking the VS-616PC5/P5:

·Verify that the part numbers on the drive nameplate match the numbers on your purchase order or packing slip.

·Check the unit for physical damage which may have occurred during shipping. If any part of the drive is missing or damaged, notify the carrier and your Yaskawa representative immediately.

·Verify that all internal hardware (i.e. components, screws, etc.) is seated properly and fastened securely.

·Verify that the instruction manual is included (YEA-TOA-S616-12).

·If the drive will be stored after receiving, place it in its original packaging and store according to temperature specifications on page 8.

Checking the Nameplate

Inverter |

|

|

MODEL : CIMR-P5U43P7 SPEC : 43P71F_ |

|

|

|

Inverter |

|||

|

|

|

||||||||

Model |

|

|

|

|

|

|

Spec. |

|||

INPUT : AC 3PH 380-440V 50Hz |

10.2A |

|||||||||

Input Spec. |

|

|

|

|

|

|

||||

|

|

|

|

|

||||||

|

|

|

380-460V 60Hz |

|

|

|

|

|

|

|

Output Spec. |

|

|

OUTPUT : AC 3PH 0-460V 6.1kVA |

8.5A |

|

|

|

|

||

|

|

|

|

|

||||||

Lot No. |

|

|

LOT NO : |

MASS : 4.5 kg |

|

|

|

Mass |

||

|

|

|

||||||||

Serial No. |

|

|

SER NO : |

|

Mg |

|

|

|

|

|

|

|

|

|

|

|

|||||

UL File No. |

|

|

UL FILE NO : E131457 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

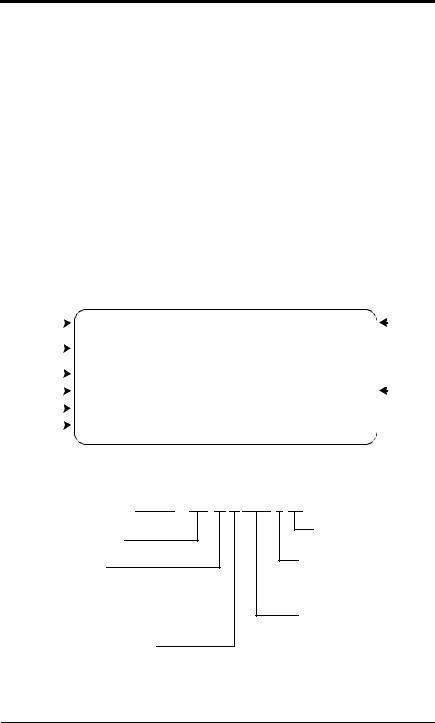

Figure 1 Nameplate Example of American Model CIMR-P5U43P7

CIMR - P5 U 4 3P7 1 F

Inverter

VS-616PC5/P5 Series

Specifications

A:Japanese specifications

E:European specifications

U:American specifications

Voltage Class

2:3-phase, 230V

4:3-phase, 460V

Figure 2 Nameplate Description

Revision symbol

Enclosure

0:Open chassis

1:NEMA 1 (IP20)

Model Designation 3P7 to 300

See Specifications, pp 7-10

VS-616PC5/P5 User’s Manual |

11 |

Chapter 1 - Receiving & Installation

Preliminary Inspection

Identifying the Parts

Protective Cover (top/bottom)

DRIVE FWD REV

Front Cover

0 P

4 Mounting Holes

4 Mounting Holes

Digital Operator

Digital Operator

JVOP-130P

Heatsink

Nameplate

Nameplate

Ventilation Slots

Figure 3 Parts Identification - Model CIMR-P5U43P7

12 |

VS-616PC5/P5 User’s Manual |

Chapter 1 - Receiving & Installation

Mounting

1.4 MOUNTING

! CAUTION

PRECAUTIONS

1)When preparing to mount the VS-616PC5/P5, lift it by its base. Never lift it by the front cover.

2)Mount the inverter onto nonflammable material.

3)The VS-616PC5/P5 generates heat. For the most effective cooling possible, mount it vertically. For more details, refer to “Dimensions/ Heat Loss” on pages 15 & 16 and “Clearances” on page 17.

4)When mounting units in an enclosure, install a fan or other cooling device to keep the intake air temperature below 113°F (45°C).

Failure to observe these precautions may result in equipment damage.

Choosing a Location

Be sure that the inverter is mounted in a location protected against the following conditions:

·Extreme cold and heat. Use only within the ambient temperature range: 14 to 104°F (-10 to 40°C).

·Direct sunlight (not for use outdoors)

·Rain, moisture

·High humidity

·Oil sprays, splashes

·Salt spray

·Dust or metallic particles in the air

·Corrosive gases (e.g. sulfurized gas) or liquids

·Radioactive substances

·Combustibles (e.g. thinner, solvents, etc.)

·Physical shock, vibration

·Magnetic noise (e.g. welding machines, power devices, etc.)

VS-616PC5/P5 User’s Manual |

13 |

Chapter 1 - Receiving & Installation

Mounting

Removing and Replacing the Digital Operator

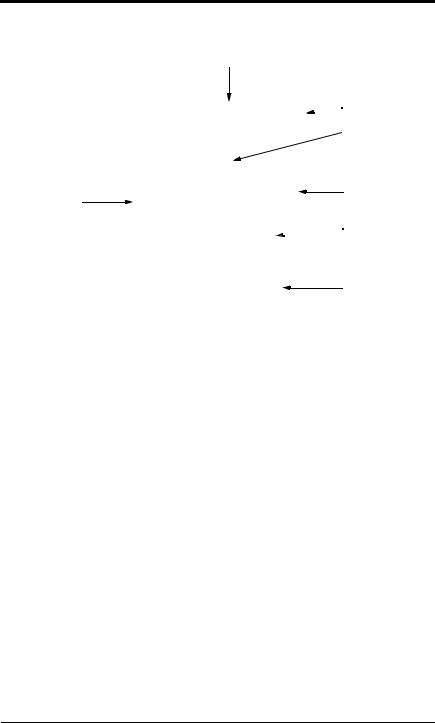

To remove the digital operator from the front cover, push the operator lever in the direction shown by arrow 1 and lift the digital operator in the direction shown by arrow 2 (see Figure 4).

To replace the digital operator, engage the operator onto retaining tabs A in the direction shown by arrow 1 and then onto retaining tabs B in the direction shown by arrow 2, locking the digital operator into place (see Figure 5).

Front Cover |

2 |

|

|

|

|

|

|

Digital Operator |

|

||||

|

1 |

|

|

|

|

|

|

Digital Operator |

|

|

2 |

||

|

|

|||||

|

|

|

|

|

|

|

|

1 |

Retaining |

||||

Figure 4 |

Front Cover |

|

|

Tabs A |

||

Removing the Digital Operator |

|

|||||

Retaining

Tabs B

Figure 5 Replacing the Digital Operator

Removing and Replacing the Front Cover

To remove the front cover, first remove the digital operator (see previous section). Then squeeze the cover on both sides in the direction shown by arrows 2 and lift the cover in the direction shown by arrow 3.

1

Front Cover

2

3

2

Figure 6 Removing and Replacing the Front Cover

14 |

VS-616PC5/P5 User’s Manual |

Chapter 1 - Receiving & Installation

Mounting

Dimensions/Heat Loss

Open Chassis Type (IP00)

|

Model |

|

Open Chassis Dimensions in inches (mm) |

|

|

Mass |

Heat Loss (W) |

||||||

Voltage |

CIMR |

|

|

|

|

|

|

|

Heat |

Inside |

Total |

||

W |

H |

D |

W1 |

H1 |

H2 |

lbs (kg) |

|||||||

|

-P5U |

sink |

unit |

||||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20P4 |

|

|

|

|

|

|

|

|

15 |

50 |

65 |

|

|

20P7 |

5.51 (140) |

11.02 (280) |

6.30 (160) |

4.96 (126) |

10.47 |

(266) |

0.28 (7) |

6.5 (3) |

25 |

65 |

90 |

|

|

21P5 |

|

|

|

|

|

|

|

|

40 |

80 |

120 |

|

|

22P2 |

5.51 (140) |

11.02 (280) |

7.09 (180) |

4.96 (126) |

10.47 |

(266) |

0.28 (7) |

10 (4.5) |

80 |

60 |

140 |

|

|

23P7 |

135 |

80 |

215 |

|||||||||

|

|

|

|

|

|

|

|

|

|||||

|

25P5 |

7.87 (200) |

11.81 (300) |

8.07 (205) |

7.32 (186) |

11.22 (285) |

0.31 (8) |

12 (5.5) |

210 |

90 |

300 |

||

|

27P5 |

13 (6) |

235 |

110 |

345 |

||||||||

|

|

|

|

|

|

|

|

||||||

230V |

2011 |

9.84 (250) |

14.96 (380) |

8.86 (225) |

9.29 (236) |

14.37 |

(365) |

0.30 (7.5) |

24 (11) |

425 |

160 |

585 |

|

2015 |

525 |

200 |

725 |

||||||||||

|

|

|

|

|

|

|

|

|

|||||

|

2018 |

12.80 (325) |

17.72 (450) |

11.22 (285) |

10.83 (275) |

17.13 |

(435) |

0.30 (7.5) |

62 (28) |

655 |

230 |

885 |

|

|

2022 |

830 |

280 |

1110 |

|||||||||

|

|

|

|

|

|

|

|

|

|||||

|

2030 |

16.73 (425) |

26.57 (675) |

13.78 (350) |

12.60 (320) |

25.59 |

(650) |

0.49 (12.5) |

134 (61) |

1050 |

500 |

1550 |

|

|

2037 |

137 (62) |

1250 |

700 |

1950 |

||||||||

|

2045 |

18.70 (475) |

31.50 (800) |

13.78 (350) |

14.57 (370) |

30.51 |

(775) |

0.49 (12.5) |

176 (80) |

1550 |

750 |

2300 |

|

|

2055 |

1950 |

1000 |

2950 |

|||||||||

|

|

|

|

|

|

|

|

|

|||||

|

2075 |

22.64 (575) |

36.42 (925) |

15.75 (400) |

17.52 (445) |

35.24 (895) |

0.59 (15) |

298 (135) |

2300 |

1300 |

3600 |

||

|

40P4 |

|

|

|

|

|

|

|

6.5 (3) |

10 |

50 |

60 |

|

|

40P7 |

5.51 (140) |

11.02 (280) |

6.30 (160) |

4.96 (126) |

10.47 |

(266) |

0.28 (7) |

20 |

65 |

85 |

||

|

|

||||||||||||

|

41P5 |

|

|

|

|

|

|

|

8.8 (4) |

30 |

80 |

110 |

|

|

42P2 |

|

|

|

|

|

|

|

|

65 |

60 |

125 |

|

|

43P7 |

5.51 (140) |

11.02 (280) |

7.09 (180) |

4.96 (126) |

10.47 |

(266) |

0.28 (7) |

10 (4.5) |

80 |

65 |

145 |

|

|

44P0 |

|

|

|

|

|

|

|

|

120 |

80 |

200 |

|

|

45P5 |

7.87 (200) |

11.81 (300) |

8.07 (205) |

7.32 (186) |

11.22 (285) |

0.31 (8) |

13 (6) |

135 |

85 |

220 |

||

|

47P5 |

240 |

120 |

360 |

|||||||||

|

|

|

|

|

|

|

|

|

|||||

|

4011 |

9.84 (250) |

14.96 (380) |

8.86 (225) |

9.29 (236) |

14.37 |

(365) |

0.30 (7.5) |

24 (11) |

305 |

150 |

455 |

|

|

4015 |

390 |

180 |

570 |

|||||||||

|

|

|

|

|

|

|

|

|

|||||

460V |

4018 |

12.80 (325) |

17.72 (450) |

11.22 (285) |

10.83 (275) |

17.13 |

(435) |

0.30 (7.5) |

60 (27) |

465 |

195 |

660 |

|

4022 |

620 |

260 |

880 |

||||||||||

|

|

|

|

|

|

|

|

|

|||||

|

4030 |

|

|

|

|

|

|

|

|

705 |

315 |

1020 |

|

|

4037 |

12.80 (325) |

24.61 (625) |

11.22 (285) |

10.83 (275) |

24.02 |

(610) |

0.30 (7.5) |

97 (44) |

875 |

370 |

1245 |

|

|

4045 |

|

|

|

|

|

|

|

|

970 |

415 |

1385 |

|

|

4055 |

17.91 (455) |

32.28 (820) |

13.78 (350) |

13.78 (350) |

31.30 |

(795) |

0.49 (12.5) |

174 (79) |

1110 |

710 |

1820 |

|

|

4075 |

176 (80) |

1430 |

890 |

2320 |

||||||||

|

4110 |

22.64 (575) |

36.42 (925) |

14.76 (375) |

17.52 (445) |

35.24 |

(895) |

0.59 (15) |

298 (135) |

1870 |

1160 |

3030 |

|

|

4160 |

15.75 (400) |

320 (145) |

2670 |

1520 |

4190 |

|||||||

|

|

|

|

|

|

|

|||||||

|

4185 |

37.40 (950) |

57.09 (1450) |

17.13 (435) |

29.53 (750) |

55.12 (1400) |

0.98 (25) |

794 (360) |

3400 |

1510 |

4910 |

||

|

4220 |

4740 |

2110 |

6850 |

|||||||||

|

|

|

|

|

|

|

|

|

|||||

|

4300 |

37.80 (960) |

62.99 (1600) |

17.91 (455) |

29.53 (750) |

61.02 (1550) |

0.98 (25) |

926 (420) |

6820 |

2910 |

9730 |

||

VS-616PC5/P5 User’s Manual |

15 |

Chapter 1 - Receiving & Installation

Mounting

Enclosed Type (NEMA 1, IP20)

|

Model |

|

NEMA 1 Dimensions in inches (mm) |

|

|

Mass |

||||

Voltage |

(CIMR- |

|

|

|

|

|

|

|

||

W |

H |

D |

W1 |

H1 |

H2 |

lbs (kg) |

||||

|

P5U) |

|||||||||

|

|

|

|

|

|

|

|

|

||

|

20P4 |

|

|

|

|

|

|

|

|

|

|

20P7 |

5.51 (140) |

11.02 (280) |

6.30 (160) |

4.96 (126) |

10.47 |

(266) |

0.28 (7) |

6.5 (3) |

|

|

21P5 |

|

|

|

|

|

|

|

|

|

|

22P2 |

5.51 (140) |

11.02 (280) |

7.09 (180) |

4.96 (126) |

10.47 |

(266) |

0.28 (7) |

10 (4.5) |

|

|

23P7 |

|||||||||

|

|

|

|

|

|

|

|

|

||

|

25P5 |

7.87 (200) |

11.81 (300) |

8.07 (205) |

7.32 (186) |

11.22 (285) |

0.31 (8) |

12 (5.5) |

||

|

27P5 |

13 (6) |

||||||||

|

|

|

|

|

|

|

|

|||

230V |

2011 |

9.84 (250) |

14.96 (380) |

8.86 (225) |

9.29 (236) |

14.37 |

(365) |

0.30 (7.5) |

24 (11) |

|

2015 |

15.75 (400) |

1.08 (27.5) |

||||||||

|

|

|

|

|

|

|

||||

|

2018 |

12.99 (330) |

24.02 (610) |

11.22 (285) |

10.83 (275) |

17.13 |

(435) |

3.44 (87.5) |

71 (32) |

|

|

2022 |

26.57 (675) |

6.00 (152.5) |

|||||||

|

|

|

|

|

|

|

||||

|

2030 |

16.93 (430) |

38.78 (985) |

13.78 (350) |

12.60 (320) |

25.59 |

(650) |

8.37 (212.5) |

148 (67) |

|

|

2037 |

150 (68) |

||||||||

|

|

|

|

|

|

|

|

|||

|

2045 |

18.90 (480) |

43.70 (1110) |

13.78 (350) |

14.57 (370) |

30.51 |

(775) |

8.37 (212.5) |

192 (87) |

|

|

2055 |

|||||||||

|

|

|

|

|

|

|

|

|

||

|

2075 |

22.83 (580) |

50.79 (1290) |

15.75 (400) |

17.52 (445) |

35.24 |

(895) |

10.63 (270) |

320 (145) |

|

|

40P4 |

|

|

|

|

|

|

|

6.5 (3) |

|

|

40P7 |

5.51 (140) |

11.02 (280) |

6.30 (160) |

4.96 (126) |

10.47 |

(266) |

0.28 (7) |

||

|

|

|||||||||

|

41P5 |

|

|

|

|

|

|

|

8.8 (4) |

|

|

42P2 |

|

|

|

|

|

|

|

|

|

|

43P7 |

5.51 (140) |

11.02 (280) |

7.09 (180) |

4.96 (126) |

10.47 |

(266) |

0.28 (7) |

10 (4.5) |

|

|

44P0 |

|

|

|

|

|

|

|

|

|

|

45P5 |

7.87 (200) |

11.81 (300) |

8.07 (205) |

7.32 (186) |

11.22 (285) |

0.31 (8) |

13 (6) |

||

|

47P5 |

|||||||||

|

|

|

|

|

|

|

|

|

||

|

4011 |

9.84 (250) |

14.96 (380) |

8.86 (225) |

9.29 (236) |

14.37 |

(365) |

0.30 (7.5) |

24 (11) |

|

460V |

4015 |

|||||||||

|

|

|

|

|

|

|

|

|||

|

4018 |

12.99 (330) |

24.02 (610) |

11.22 (285) |

10.83 (275) |

17.13 |

(435) |

3.44 (87.5) |

68 (31) |

|

|

4022 |

|||||||||

|

|

|

|

|

|

|

|

|

||

|

4030 |

|

30.91 (785) |

|

|

|

|

3.44 (87.5) |

|

|

|

4037 |

12.99 (330) |

11.22 (285) |

10.83 (275) |

24.02 |

(610) |

106 (48) |

|||

|

|

|

||||||||

|

4045 |

33.46 (850) |

6.00 (152.5) |

|||||||

|

|

|

|

|

|

|

||||

|

4055 |

18.11 (460) |

44.49 (1130) |

13.78 (350) |

13.78 (350) |

31.30 |

(795) |

8.37 (212.5) |

187 (85) |

|

|

4075 |

190 (86) |

||||||||

|

|

|

|

|

|

|

|

|||

|

4110 |

22.83 (580) |

50.79 (1290) |

14.76 (375) |

17.52 (445) |

35.24 |

(895) |

10.63 (270) |

320 (145) |

|

|

4160 |

15.75 (400) |

342 (155) |

|||||||

|

|

|

|

|

|

|

||||

16 |

VS-616PC5/P5 User’s Manual |

Chapter 1 - Receiving & Installation

Mounting

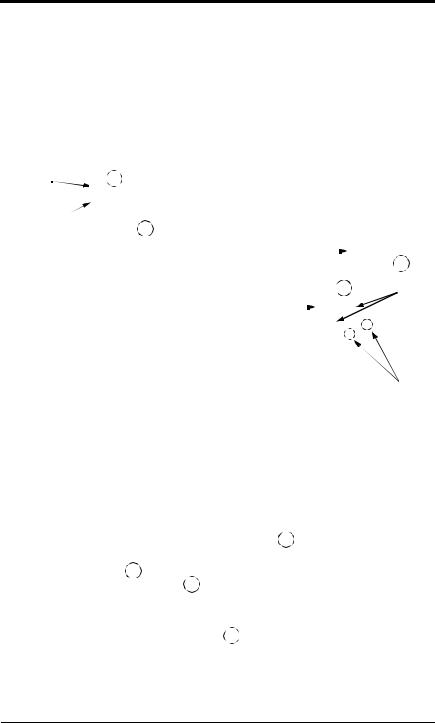

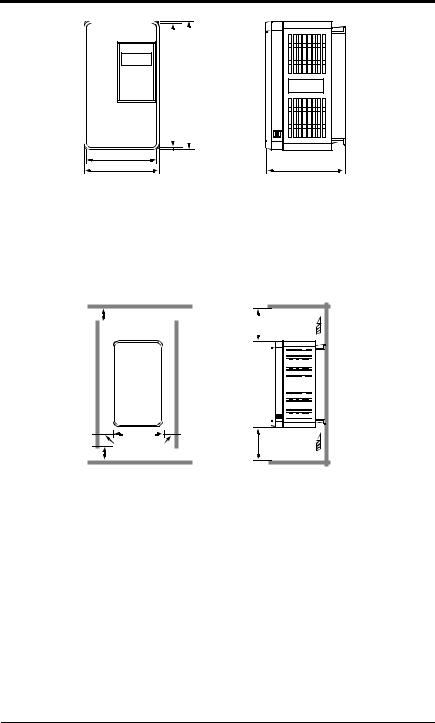

W1

W

H1 |

|

H |

|

||

|

|

|

|

|

|

H2

H2

D

Front View |

Side View |

Figure 7 VS-616PC5/P5 Dimension Diagram

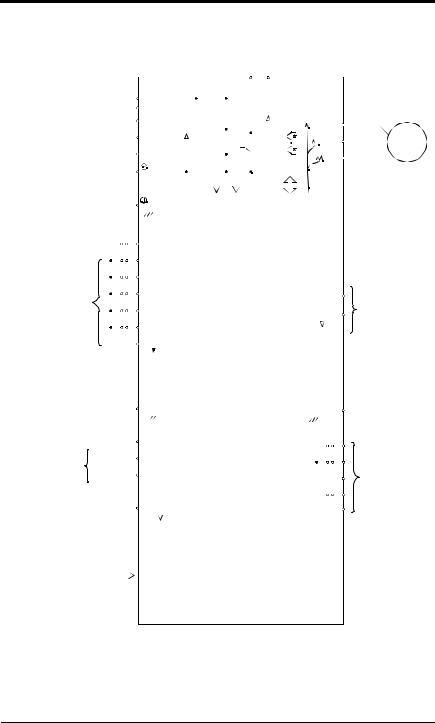

Clearances

When mounting the VS-616PC5/P5, allow sufficient clearances for effective cooling as shown below:

1.97in (50mm) |

|

|

|

|

|

|

|

|

Air |

||

|

|

|

|

|

|

|

|

||||

|

|

|

|

4.72in (120mm) |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.18in (30mm) |

4.72in (120mm) |

|

1.97in (50mm) |

||

Air |

Front View |

Side View |

Figure 8 VS-616PC5/P5 Clearances

Notes:

1)The required clearances at the top, bottom, and both sides of the inverter are the same for both open chassis and NEMA 1 enclosures.

2)For inverter models 25HP and less (230V & 460V), remove the top and bottom covers to convert NEMA 1 units to open chassis

3)Allowable intake air temperature:

Open chassis: |

14°F to 113°F (-10°C to +45°C) |

NEMA 1: |

14°F to 104°F (-10°C to 40°C) |

4)When mounting units in an enclosure, install a fan or other cooling device to limit the air temperature within the inverter to below 113°F (45°C).

VS-616PC5/P5 User’s Manual |

17 |

Chapter 1 - Receiving & Installation

Wiring

1.5 WIRING

! CAUTION

PRECAUTIONS

1)Do not connect or disconnect wiring, or perform signal checks while the power supply is turned ON.

2)Connect the power supply wiring to terminals L1, L2 and L3 on the main circuit input section. DO NOT connect the power supply wiring to output terminals T1, T2 and T3.

3)Connect the motor wiring to terminals T1, T2 and T3 on the main circuit output section.

4)Never touch the output circuit directly or place the output line in contact with the inverter enclosure.

5)Do not connect a phase-advancing capacitor or an LC/RC noise filter to the output circuit.

6)The motor wiring must be less than 328ft (100m) in length and in a separate conduit from the input power wiring.

7)Control wiring must be less than 164ft (50m) in length and in a separate conduit from both the motor wiring and the power wiring.

8)Tighten the screws on the main circuit and control circuit terminals.

9)Low voltage wires shall be wired with Class 1 wiring.

10)Please observe national electrical code (NEC) when wiring electrical devices.

Failure to observe these precautions may result in equipment damage.

Inspection

After wiring is complete, verify that:

All wiring is correctly installed.

Excess screws and wire clippings are removed from inside of the unit. Screws are securely tightened.

Exposed wire has no contact with other wiring or terminals.

18 |

VS-616PC5/P5 User’s Manual |

Chapter 1 - Receiving & Installation

Wiring

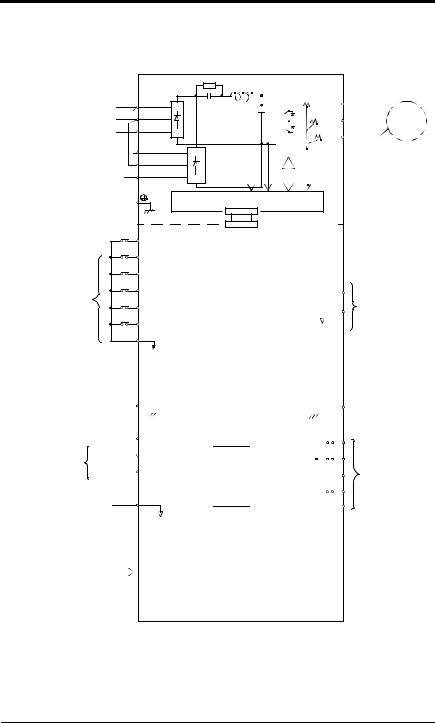

VS-616PC5 Standard Connection Diagram

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

230V: Models 20P4 through 27P5 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

460V: Models 40P4 through 4015 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC Link Reactor (option) |

Å1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B1 |

B2 |

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

Å2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

L1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T1 |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

L2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T2 |

|

|

IM |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

L3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T3 |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Ground |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gate Drive |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

230V units: 100W or less |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

460V units: 10W or less |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

S1 - Fixed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

S2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

S3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

S4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0~10V |

|

|

AM |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

Multi-Function |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PWM |

|

|

Multi-Function |

|||||||||||||||||||||||||||

|

|

S5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

Contact Inputs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Com) AC |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 bit |

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Analog Outputs |

||||||||||||||||||||||||||

|

|

|

|

S6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

SC (Com) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|