BCPM Series Panelboard Monitoring Systems

BCPMSCE

User Guide

Panelboard Monitoring System with Ethernet Communication,

Split-Core Branch Current Sensors

Z206857-0C

04/2020

www.se.com

Branch Circuit Power Meter with Ethernet Communication

Safety Information

Important information

Read these instructions carefully and look at the equipment to become familiar with

the device before trying to install, operate, service or maintain it. The following special

messages may appear throughout this bulletin or on the equipment to warn of potential

hazards or to call attention to information that claries or simplies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates that an electrical

hazard exists which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER indicates an hazardous situation which, if not avoided,

will result in death or serious injury.

Z206857-0C

04/2020

DANGER

WARNING

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

Notice is used to address practices not related to physical injury.

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

A qualified person is one who has skills and knowledge related to

the construction and operation of this electrical equipment and

installations, and has received safety training to recognize and

avoid the hazards involved.

If this product is used in a manner not specified by the

manufacturer, the protection provided by the product may be

impaired. No responsibility is assumed by Schneider Electric for

any consequences arising out of the use of this material.

DANGER

04/2020

Safety Precautions

Branch Circuit Power Meter with Ethernet Communication

Safety Precautions

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC

FLASH

• Follow safe electrical work practices. See NFPA 70E in the

USA, CSA Z462 in Canada, or applicable local codes.

• Read and understand the instructions before installing the

product. Follow the instructions during installation.

• Installation, wiring, testing or service must be performed

only by qualified persons in accordance with all applicable

codes and regulations.

• Install the product in an appropriate electrical and fire

enclosure per local regulations.

• Do not use the product for life or safety applications.

• Do not install the product in hazardous or classified locations.

• Do not exceed the product’s ratings or maximum limits.

• The product may use multiple voltage/power sources.

• Turn off ALL power supplying equipment before working on

or inside the equipment.

• Use a properly rated voltage sensing device to confirm that

all power is off.

• Do NOT depend on the product for voltage indication.

• Products rated only for basic insulation must be installed on

insulated conductors.

• Current transformer secondaries (current mode) must be

shorted or connected to a burden at all times.

• Remove all wire scraps and tools, replace all doors, covers

and protective devices before powering the equipment.

Failure to follow these instructions will result in death or

serious injury.

© 2020 Schneider Electric All Rights Reserved.

NEC Article 100

i

Branch Circuit Power Meter with Ethernet Communication

Control system design must consider the potential failure modes of

1

Solid-State Controls or its equivalent in your specific country, language,

and/or location.

Provide a disconnect device to disconnect the meter from the supply

source. Place this device in close proximity to the equipment and within

easy reach of the operator, and mark it as the disconnecting device.

The disconnecting device shall meet the relevant requirements of IEC

60947-1 and IEC 60947-3 and shall be suitable for the application. In

the US and Canada, disconnecting fuse holders can be used. Provide

overcurrent protection and disconecting device for supply conductors

with approved current limiting devices suitable for protecting the wiring.

For use in a Pollution Degree 2 or better environment only. A Pollution

Degree 2 environment must control conductive pollution and the

possibility of condensation or high humidity. Consider the enclosure,

the correct use of ventilation, thermal properties of the equipment, and

the relationship with the environment.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found

This Class A digital apparatus complies with Canadian ICES-003.

FCC Notice

control paths and, for certain critical control functions, provide a means

to acheive a safe state during and after a path failure. Examples of

critical control functions are emergency stop and over-travel stop.

WARNING

LOSS OF CONTROL

• Assure that the system will reach a safe state during and

after a control path failure.

• Separate or redundant control paths must be provided for

critical control functions.

• Test the effect of transmission delays or failures of

communication links.

• Each implementation of equipment using communication

links must be individually and thoroughly tested for proper

operation before placing it in service.

Failure to follow these instructions may cause injury,

death or equipment damage.

For additional information about anticipated transmission delays or

failures of the link, refer to NEMA ICS 1.1 (latest edition). Safety

Guidelines for the Application, Installation, and Maintenance of

1

Z206857-0C

04/2020

FCC Notice

ii

to comply with the limits for a class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at

his own expense. Modifications to this product without the express

authorization of the manufacturer nullify this statement.

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

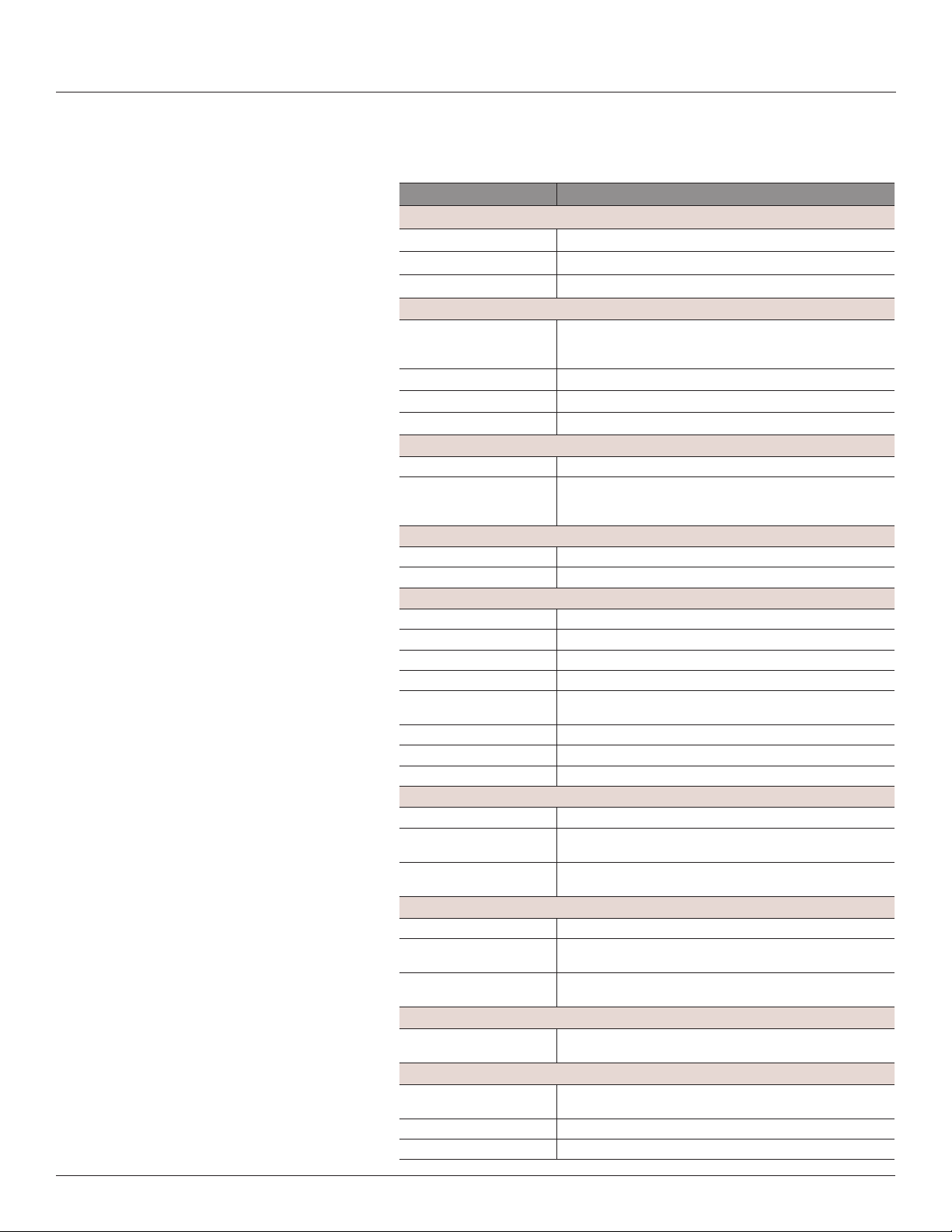

Specifications

Branch Circuit Power Meter with Ethernet Communication

Specifications

Table 1: Specifications

Typ e Description

Voltag e Inputs

Measurement Voltage 90 to 300 Vac line-to-neutral, 50/60 Hz

Control Power 100 to 277 Vac line-to-neutral, 50/60 Hz, 15 VA max.

Frequency 50/60 Hz

Accuracy

Power/Energy IEC 62053-21 Class 1, ANSI C12.1-2008

Voltage ±0.5% of reading 90 to 277 V line-to-neutral

Current ±0.5% of reading

Minimum ON Current 50 mA

Operation

Sampling Frequency 2560 Hz

Update Rate Modbus: 1.8 seconds (both panels)

Ethernet Communication

Physical Interface RJ45 connector with 10/100 Mbit Ethernet

Protocols Supported Modbus TCP, BACnet IP, SNMP V2c

Serial Communication

Physical Interface 2-wire RS-485

Serial Protocols Supported Modbus RTU or BACnet MS/TP

Address Range 1 to 247 for Modbus RTU; 0 to 127 for BACnet MS/TP

Baud Rate 9600, 19200, 38400

Parity Modbus RTU: NONE, ODD, EVEN

Communication Format 8 data bits, 1 start bit, 1 stop bit

Termination 2x3 position connector

Wire Size Up to 16 AWG

Wire Size Range

Aux CT Terminals 24 to 14 AWG

Voltage Input and Control

Power Connectors

Terminals on CT Adapter

Boards

Terminal Block Torque

Aux CT Terminals 3.5 to 4.4 in-lb (0.4 to 0.5 N-m)

Voltage Input and Control

Power Connectors

Terminals on Branch CT

Adapter Boards

Mechanical

Ribbon Cable Support 4 ft. (1.2 m) at ribbon cable ships standard; up to 20 ft. (6 m) at

Environmental

Operating Temperature

Range

Storage Temperature Range -40 to 70 °C (-40 to 158 °F)

Altitude of Operation 3000 m

(1% system accuracy includes both the BCPMSCE main unit and

50 A or 100 A branch current sensors)

BACnet: 14 seconds

SNMP: 20 seconds

BACnet MS/TP: NONE (xed)

22 to 12 AWG

26 to 16 AWG

4.4 to 5.3 in-lb (0.5 to 0.6 N-m)

1.9 to 2.2 in-lb (0.22 to 0.26 N-m)

or round ribbon cables are available

0 to 60 °C (32 to 122 °F)

(<95% RH, non-condensing)

© 2020 Schneider Electric All Rights Reserved.

1

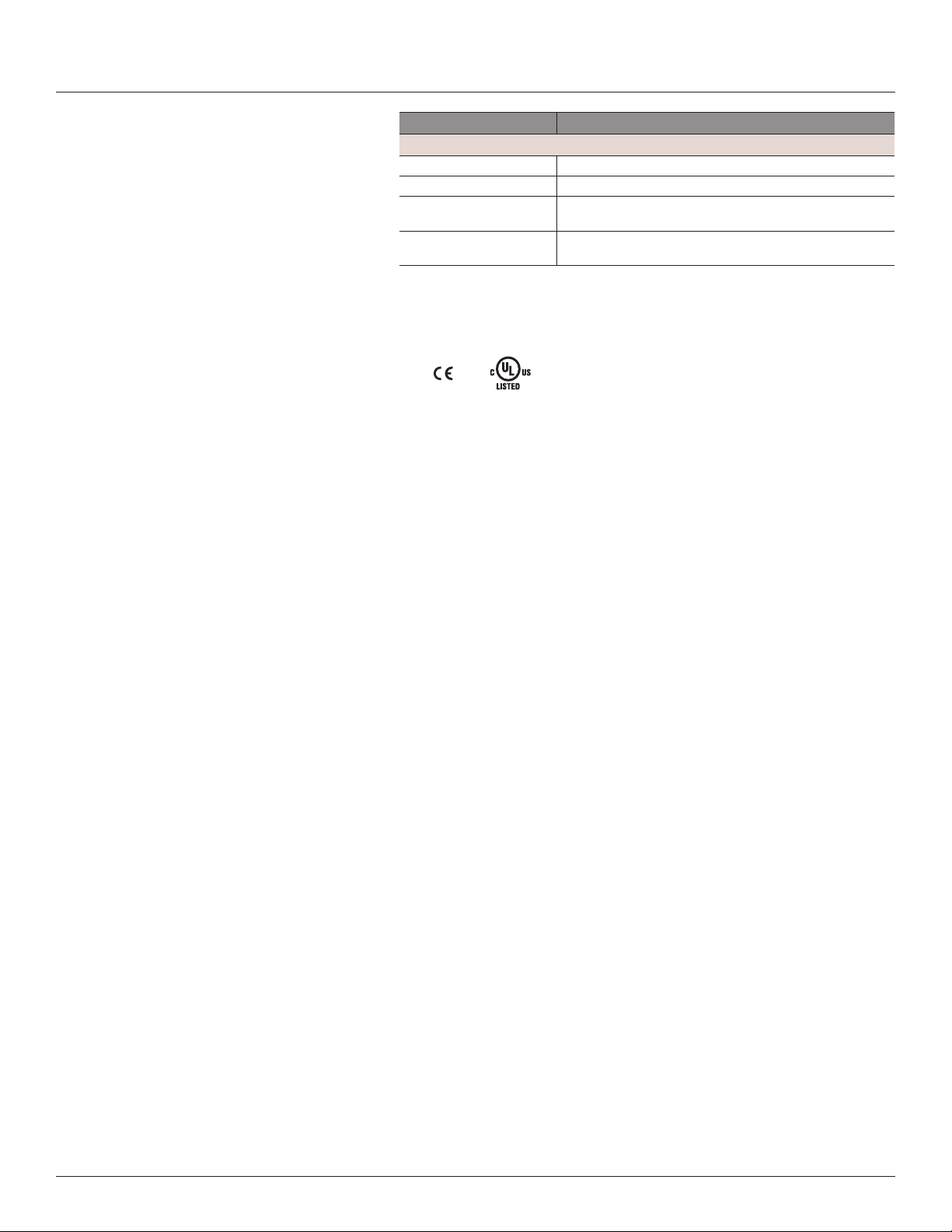

Branch Circuit Power Meter with Ethernet Communication

Introduction

Z206857-0C

04/2020

Typ e Description

Compliance Information

Agency Approvals UL508 open type device**, IEC/EN61010-1

Installation Category* Cat. III, Pollution Degree 2

Conducted and Radiated

Emissions

Conducted and Radiated

Immunity

*For indoor use only.

**BCPM internal circuitry (cables and CTs) are not circuits as dened by UL508A, as they do not

extend beyond the BCPM itself without further safety/re isolation.

FCC part 15 Class A, EN55011/EN61000-6-4 Class A (heavy

industrial)

EN 61000-6-2 and EN 61326-1

Introduction

Note: The CE mark indicates RoHS2 compliance. Please refer to the CE Declaration of Conformity for

additional details.

The PowerLogic™ BCPMSCE Series panelboard monitoring system is

designed to measure the current, voltage, and energy consumption of up to 92

circuits (84 branch circuits, two 3-phase mains, two neutrals), enabling users to

monitor two panelboards or an entire data center PDU with a single product. It

also includes Ethernet capability, allowing communication in multiple protocols.

The BCPMSCE consists of a data acquisition module, up to 4 current sensor

adapter boards and up to 84 split-core current sensors (50 A, 100 A, or 200

A), with eight auxiliary inputs. Each conductor passes through the appropriate

current sensor before terminating at the breaker. Each sensor transmits the

current data to the data acquisition board. The BCPMSCE measures both

current and power for the mains and branch circuits. The BCPMSCE can easily

accommodate different panel congurations, including any combination of

multi-phase breaker positions, voltage phase mapping, and breaker sizes. To

congure the BCPMSCE for operation, use the Schneider Electric ION Setup

conguration software tool. Get the latest version at

https://schneider-electric.box.com/ionsetuplatest.

Data is transmitted via Ethernet with Modbus TCP, BACnet IP or SNMP

protocol, or via RS-485 with Modbus RTU or BACnet MS/TP protocols. Some

protocols can be used simultaneously, and the Ethernet protocols all support

access by multiple masters. Each data acquisition board requires two Modbus

addresses, one for each set of 42 current sensors, and four auxiliary inputs.

When a circuit exceeds the user-dened thresholds, the BCPMSCE activates

the event indicators. The communication interfaces and protocols require some

conguration at the time of installation.

2

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Figure 1 Branch Circuit Power Meter with Ethernet Communication

Branch Circuit Power Meter with Ethernet Communication

Introduction

Parts of the BCPMSCE

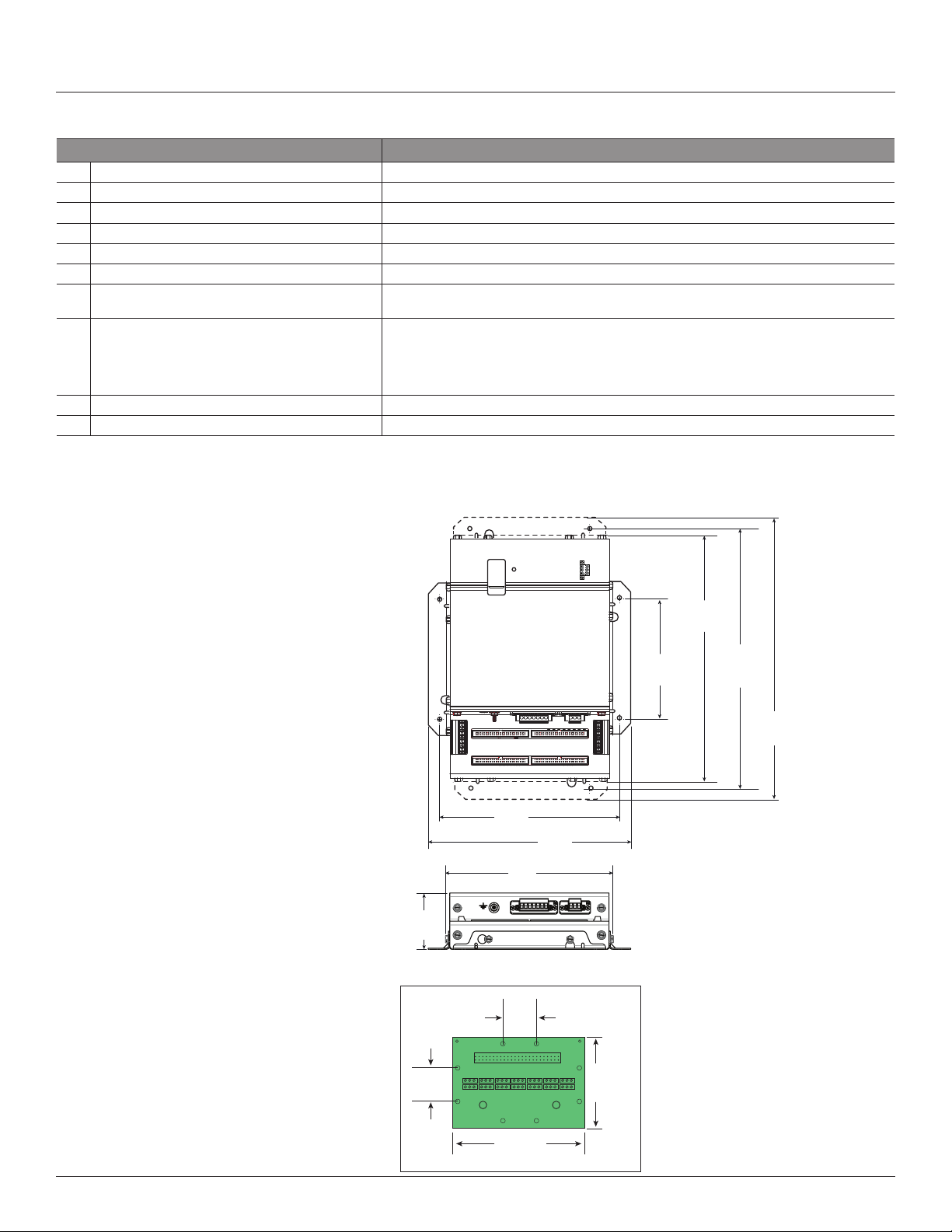

Figure 2 shows the parts of the BCPMSCE, while Table 2 describes these parts.

Figure 2 BCPMSCE Panel Board Monitoring System

1

2

4

3

9

65

10

7 7

© 2020 Schneider Electric All Rights Reserved.

8

3

Branch Circuit Power Meter with Ethernet Communication

Introduction

Table 2: Parts Description of the BCPMSCE

Part Description

1 Ethernet port Provides Ethernet connection for the gateway component.

2 Power LED Indicates power is applied to the meter.

3 2x3 RS-485 serial connection Used for Modbus, BACnet, and SNMP serial communications.

4 Protective ground connection Provides a grounding point for the device.

5 Voltage taps 1, 2, or 3 phase plus neutral connections. For voltage sensing and power calculations.

6 Control power connection Provides power to operate the meter.

7 Auxiliary CT inputs These 0.333 Vac inputs are used for monitoring the main breaker or other high amperage source.

Inputs on the left are for panelboard 2; inputs on the right are for panelboard 1.

8 50-pin ribbon cable connectors 48-inch (1220 mm) ribbon cables are provided for easy connection of the adapter boards to this

point of the data acquisition board. Other ribbon cable lengths are available (sold separately). The two

connectors on the left are for panelboard 2; the two on the right are for panelboard 1. Connect adapter

boards A and B to the correct ribbon cable connectors for each panel. The top connectors are for Board

B, and the bottom connectors are for Board A.

9 Current sensors Up to 84 sensors can be used with the BCPMSCE.

10 Adapter board Includes connectors for a ribbon cable and up to 42 current sensors.

Dimensions

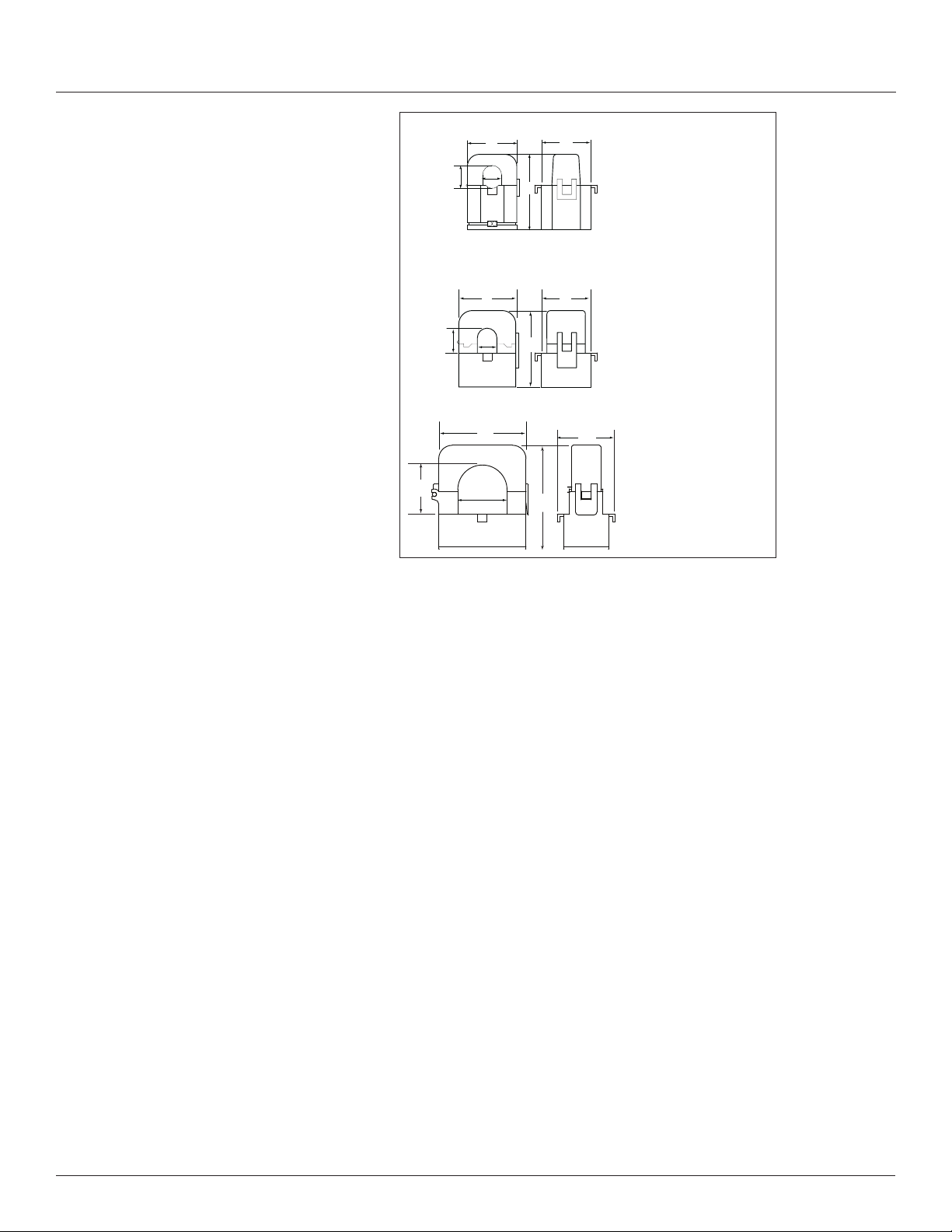

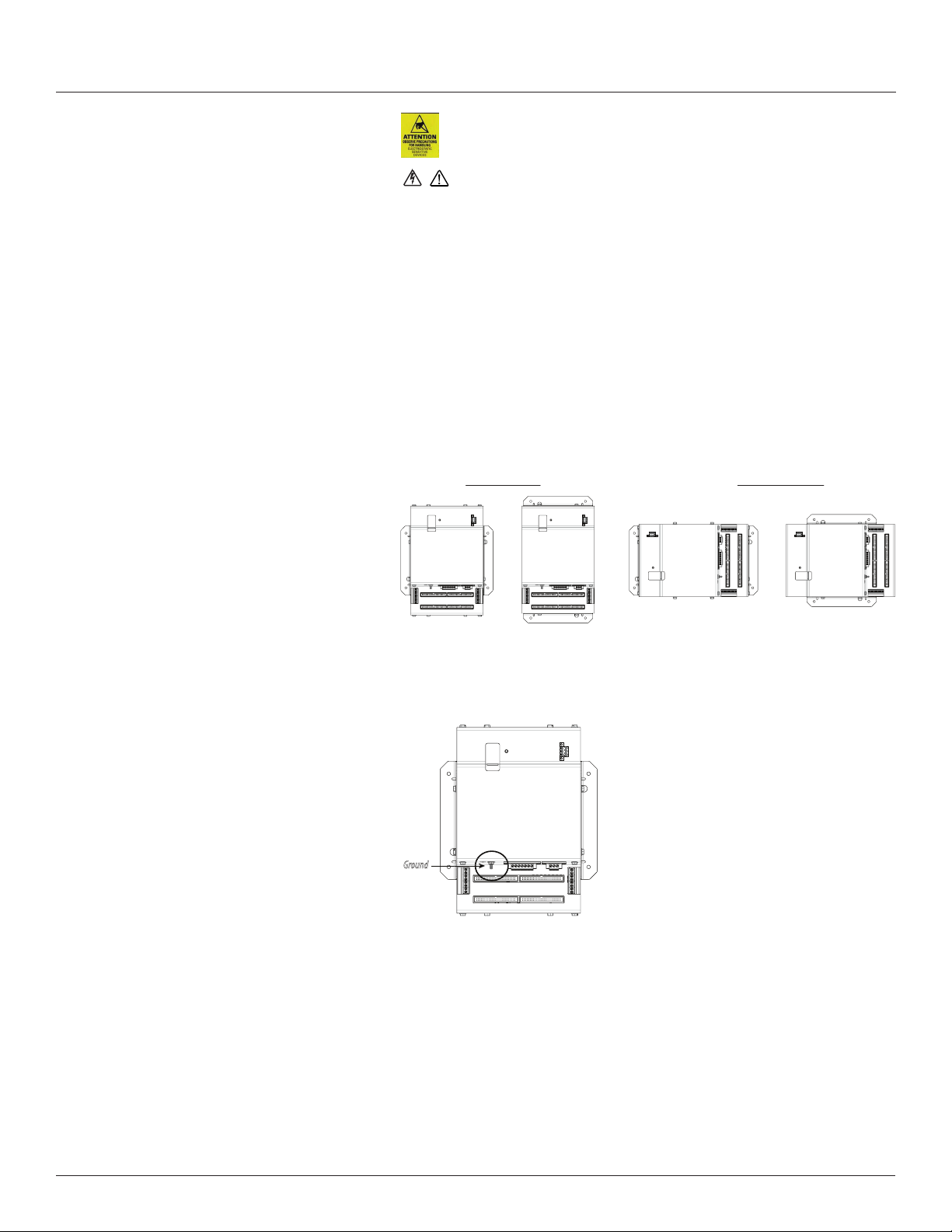

Figure 3 Housing and Mounting Brackets

Z206857-0C

04/2020

2x: 5.9”

(150 mm)

8.9”

2.8”

(71 mm)

(225 mm)

8.2”

(210 mm)

10.0”

(253 mm)

Figure 4 Adapter Board and Current Sensors

1.00”

(26 mm)

12.1”

(307 mm)

12.8”

(325 mm)

13.9”

(353 mm)

Note: The dotted lines

indicate dimensions if the

two brackets are placed in

the alternate orientation. At

the factory, the brackets are

placed as shown with solid

lines. See the Installation

section for more information.

1.00”

(26 mm)

4.6”

(117 mm)

4

2.75”

(70 mm)

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

E = 2.8” (71 mm)

04/2020

Branch Circuit Power Meter with Ethernet Communication

Introduction

D

A

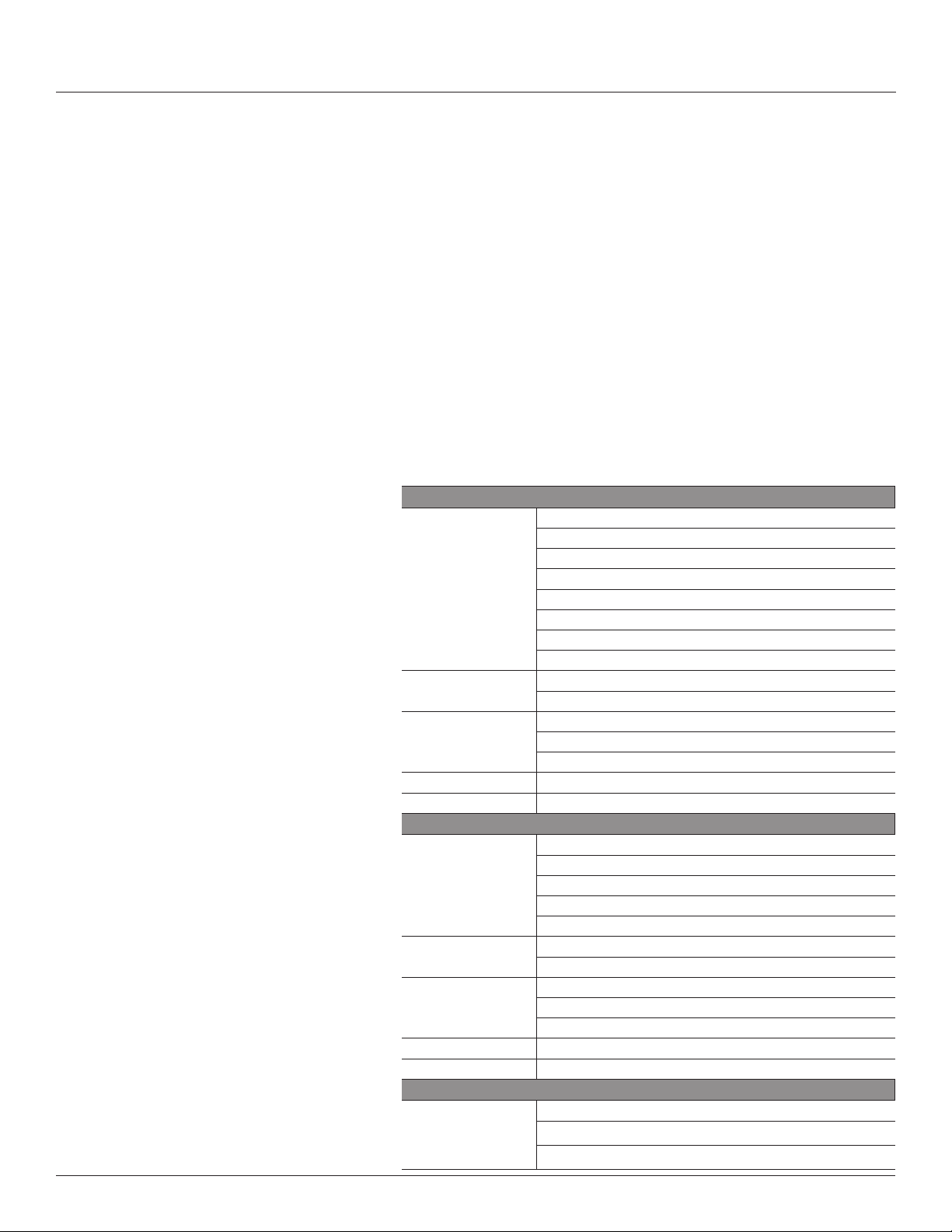

BCPMSCCT0 50 A

A = 1.0” (26 mm)

C

B

E

B = 0.5” (11 mm)

C = 0.4” (10 mm)

D = 0.9” (23 mm)

E = 1.6” (40 mm)

BCPMSCCT1 100 A

D

A

A = 1.5” (37 mm)

B = 0.6” (16 mm)

C

B

E

C = 0.6” (16 mm)

D = 1.85” (47 mm)

E = 2.1” (53 mm)

D

A

BCPMSCCT3 200 A

A = 1.5” (39 mm)

B

C

E

B = 1.25” (32 mm)

C = 1.25” (32 mm)

D = 2.5” (64 mm)

Data Output

The BCPMSCE provides several types of measurements that give a

comprehensive view of power consumption for every monitored load on the

panel:

• Real-time measurements: A live and up-to-date view of present power

levels and the factors that affect them.

• Demand measurements: Averages of values measured over a

specied time interval. The time interval (typically 15 minutes) can

be set from 10 seconds to more than a day. The demand calculation

can be congured to use single intervals or the sliding average of

up to 6 sub-intervals. Demand measurements are useful for tracking

or graphing load levels over time to correlate with total energy

consumption.

• Historic maximum measurements: These measurements store the

largest value recorded for a specic measurement since the last time

they were cleared. They are useful for identifying peak levels critical to

equipment sizing or demand limits in utility agreements.

• Accumulated energy measurements: Ongoing totals of cumulative

energy used since the last time the value was cleared. Energy values

provide the informational basis for billing, cost allocation, carbon

offset, BTU equivalent calculations, and other applications of overall

energy use.

• Energy snapshots: Energy totals that only change when the demand

intervals are updated. They are samples of the free-running energy

accumulators at the end of each demand interval, as congured by the

user. These provide energy readings that are easily correlated to the

demand values to simplify the tasks of sub-billing and cost allocation.

• Over-threshold Events (previously referred to as Alarms): Provide a

warning of excessively high or low current on each branch and aux

channel. The user can set two high-level and two low-level thresholds,

and a delay time for latching events. Events are reported as both

non-latched events and latched events. Non-latching events are active

while the current exceeds the threshold, but go inactive if the current

© 2020 Schneider Electric All Rights Reserved.

5

Branch Circuit Power Meter with Ethernet Communication

Introduction

Z206857-0C

04/2020

returns to a level within the specic thresholds. Latching events

become active when the current exceeds the threshold for a time

period greater than the specied delay and remain active until they

are cleared remotely. Event status can be polled via any protocol. Via

BACnet, Subscribe_COV can be used to generate event notications.

Via SNMP, they drive SNMP event notications.

Advanced Features - The BCPMSCE supports a number of advanced features.

Some are always active, and others are congured manually via Modbus

register 62017, BACnet object AV164, or SNMP MIB variable “spanels/

panel1/p1Conguration/p1Setup/p1UserDenedSettings” (OID .1.3.6.1

.4.1.3833.1.30.1.1.6.3.4.0). For models with 42 channels or more, these

features are congured independently for each panel.

• Logical meter support: The BCPMSCE can be congured to map any

set of 1, 2 or 3 channels that are adjacent in the panel to a logical

meter, referred to in the point map as a logical circuit, that provides

accurate multi-phase measurement totals. Map these logical circuits

by writing the desired logical circuit number into a set of registers/data

objects provided for each branch and aux channel (per panel).

• The channels assigned to each logical circuit must be adjacent in

the panel (usually used for multi-phase breakers), but there are no

limitations on where those adjacent channels are aligned in the panel

(any position where a multi-phase breaker can be installed). This

functionality is always active, but a user selection affects the how the

data can be accessed via Modbus. Measurement data via Modbus

for logical circuits is presented in two ways, arranged either by logical

circuit number (looks more like a collection of individual meters) or by

measurement type (arranged similar to the single-phase data section

of the point map).

• Legacy point map or alternate logical circuit point map: The

BCPMSCE can be congured to select a preferred version of the

Modbus registers in the address range 4000 to 9999. If enabled

(default), the logical circuits by measurement type is active. Otherwise,

the legacy point maps for 2-phase and 3-phase breakers used in

BCPMSCE models with a rmware version earlier than 1.023 is active.

The logical circuits functionality can also be accessed via the “Logical

Circuits by Circuit” section of the point map (address range 10000 to

45000), regardless of the state of this selection.

• Phase angle measurements: The BCPMSCE measures the phase

angle of every voltage and current input and presents these

measurements (in degrees) in additional data registers/objects. These

values are used to verify that current inputs are assigned to the proper

voltage phases and to help determine how power factor variations are

inuenced by current phase changes vs. harmonic distortion. Phase

angle measurements are instantaneous and always active.

• User CT phase assignment: In the default mode, the BCPMSCE

assigns each channel to the corresponding phase that most 3-phase

panels implement, so that the user does not have worry about it. The

user can opt to replace this self-assignment paradigm with a mode

that allows explicit specication of the phase assignment for each

channel. The explicit assignments set by the user are stored by the

BCPMSCE in non-volatile memory.

• Phase angle reference: The BCPMSCE measures the phase angle

of every current and voltage input. The user can select whether the

phase angles are stated relative to an absolute reference (the phase

angle of voltage input V1) or relative to the voltage phase assigned to

that specic current input channel.

• Signed power: Users can congure the BCPMSCE to report power

as a signed value indicating whether the power is currently being

delivered (imported from the grid) or received (exported to the grid)

for channels with generation sources or bi-directional (regenerative)

6

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Branch Circuit Power Meter with Ethernet Communication

loads. When signed power is disabled, the energy accumulators

include all energy measured, regardless of direction. When signed

power is enabled, the energy accumulators only include all energy

delivered (imported from the grid).

• Signed power factor: By default the BCPMSCE reports power factor

as an unsigned value. The user can set it to report as a signed value,

where the sign indicates whether the current phase angle leads or

lags the corresponding voltage phase.

• Demand/snapshot time interval source: The BCPMSCE offers two

mechanisms for driving the demand/snapshot time interval, an interval

timer or an RTC (real-time clock). The legacy mode (default) uses an

interval timer that does not need to be set to an absolute time. When

using the interval timer the demand/snapshot interval can be set from

10 to 32767 seconds (over 9 hours). An alternate mode utilizes an

RTC set to a specic date and time to synchronize the results with a

larger system. The RTC must rst be set in order to run and capture

demand values and energy snapshots. When power is interrupted, the

RTC resets to a default date and time and must be set again in order

to run. When using the RTC, the demand/snapshot interval can be set

from 10 to 3600 seconds (1 hour).

Table 3: Data Outputs Table

Monitoring of Mains

Current: multi-phase average and per phase

Current phase angle

Real power (kW): multi-phase total and per phase

Real Time

Measurements

Demand Measurements

Historic Maximums

Accumulated Energy Energy (kWh): multi-phase total and per phase

Energy Snapshots Energy (kWh): multi-phase total and per phase

Real Time

Measurements

Demand Measurements

Historic Maximums

Accumulated Energy Energy (kWh): multi-phase total and per phase

Energy Snapshots Energy (kWh): multi-phase total and per phase

Events

Apparent power (kVA): multi-phase total and per phase

Power factor: multi-phase average and per phase

Voltage - L-L: multi-phase average and per phase

Voltage - L-N: multi-phase average and per phase

Frequency (phase A)

Current present demand: multi-phase average and per phase

Real Power (kW) present demand: multi-phase average and per phase

Maximum instantaneous current: multi-phase average and per phase

Maximum current demand: multi-phase average and per phase

Maximum real power demand: multi-phase total and per phase

Monitoring of Branch Circuits

Current: multi-phase average and per phase

Current phase angle per branch

Real power (kW): multi-phase total and per phase

Apparent power (kVA): multi-phase total and per phase

Power factor: multi-phase average and per phase

Current present demand: multi-phase average and per phase

Real power (kW) present demand: multi-phase average and per phase

Maximum instantaneous current: multi-phase average and per phase

Maximum current demand: multi-phase average and per phase

Maximum real power demand: multi-phase total and per phase

Modbus Events

Voltage over/under

Branch current over/under

Mains current over/under

Introduction

© 2020 Schneider Electric All Rights Reserved.

7

Branch Circuit Power Meter with Ethernet Communication

A qualified person is one who has skills and knowledge related to

the construction and operation of this electrical equipment and

installations, and has received safety training to recognize and

avoid the hazards involved.

If this product is used in a manner not specified by the

manufacturer, the protection provided by the product may be

impaired. No responsibility is assumed by Schneider Electric for

any consequences arising out of the use of this material.

DANGER

Installation

Split Core Current Sensors

Installation

Table 4: Current Sensor Specs

50 A 100 A 200 A

Voltage Rating 300 Vac 300 Vac (CE),

Measurement

Range

Temperature 0 to 60 °C

Agency UL61010 Recognized,

*Momentary.

60 A* 120 A* 240 A*

(32 to 122 °F)

EN61010-1

600 Vac (UL)

0 to 60 °C

(32 to 122 °F)

UL61010 Recognized,

EN61010-1

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC

FLASH

• Follow safe electrical work practices. See NFPA 70E in the

USA, CSA Z462 in Canada, or applicable local codes.

• Read and understand the instructions before installing the

product. Follow the instructions during installation.

• Installation, wiring, testing or service must be performed

only by qualified persons in accordance with all applicable

codes and regulations.

• Install the product in an appropriate electrical and fire

enclosure per local regulations.

• Do not use the product for life or safety applications.

• Do not install the product in hazardous or classified locations.

• Do not exceed the product’s ratings or maximum limits.

• The product may use multiple voltage/power sources.

• Turn off ALL power supplying equipment before working on

or inside the equipment.

• Use a properly rated voltage sensing device to confirm that

all power is off.

• Do NOT depend on the product for voltage indication.

• Products rated only for basic insulation must be installed on

insulated conductors.

• Current transformer secondaries (current mode) must be

shorted or connected to a burden at all times.

• Remove all wire scraps and tools, replace all doors, covers

and protective devices before powering the equipment.

Failure to follow these instructions will result in death or

serious injury.

Z206857-0C

04/2020

300 Vac (CE),

600 Vac (UL)

0 to 60 °C

(32 to 122 °F)

UL61010 Recognized,

EN61010-1

8

NEC Article 100

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Branch Circuit Power Meter with Ethernet Communication

Observe precautions for handling static sensitive

devices to avoid damage to the circuitry that

is not covered under the factory warranty.

Installation

The protective ground connection on the housing should be used

if the device will not be mounted to a suitably grounded surface. Assure

conductivity to the protective ground.

1. Determine where you will mount the BCMPSCE measurement unit.

The preferred location is inside the enclosure of the panelboard being

monitored. If sufcient space is not available there, then mount the unit

in an appropriate enclosure nearby. Decide whether to mount it vertically

or horizontally. The meter is shipped with the brackets placed for vertical

mounting. If desired, you can move the brackets from the sides to the ends

of the housing. Loosen the screws on the sides of the BCPMSCE that hold

the brackets in place (do not fully remove the screws from the housing).

Loosen the screws on the two ends of the housing (do not fully remove the

screws from the housing), and set the brackets into their new positions.

Tighten all screws to 25 in-lb (2.8 N-m).

Figure 5 Brackets positioned for vertical and horizontal mounting

Vertical Mounting Horizontal Mounting

2. Install the BCPMSCE in the panel. A grounding connection is located on

the housing (see below).

Figure 6 BCPMSCE ground stud

Ground

3. Choose a location to mount the adapter boards. If space permits, mount

them in the panelbord being monitored. There are two channel numbering

congurations available, for different applications (see the examples below).

Odd/even numbering is used with panelboards that have odd numbers on

one side (usually the left side) and even numbers on the other. Sequential

numbering is generally used in other applications, where the panelboard

has breakers numbered sequentially or where the branch circuits are used

to monitor discrete loads rather than an entire panelboard. Select the

conguration that best ts your application and install the adapter boards

as close as you can to the location where the branch CTs will be installed.

Mount the adapter boards using either DIN rail or SNAPTRACK. You can

set the conguration during commissioning by writing to Modbus Register 6

© 2020 Schneider Electric All Rights Reserved.

9

Branch Circuit Power Meter with Ethernet Communication

Installation

Z206857-0C

04/2020

(or the corresponding BACnet object or SNMP variable) or use ION Setup

conguration software.

A. Use the supplied screws to secure the plastic DIN clips to the adapter

board. Afx the clip to the DIN rail.

Figure 7 DIN mount configuration options

DIN Option 1:

Vertical Mount

DIN Option 2:

Horizontal Mount

B. Secure the SNAPTRACK to the mounting surface. Click the adapter

board into place.

Figure 8 SNAPTRACK mounting

4. Install the current sensors onto the conductors to be monitored.

NOTE: If the signed power factor feature is NOT enabled, then

the current sensor orientation does not affect meter behavior. If this

feature IS enabled, orient the current sensors so that the arrow points

toward the load for proper operation.

NOTE: Clean split-core contact surfaces before closing. The hinge

can detach, allowing the base and the top to separate for easier

cleaning and installation.

10

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Branch Circuit Power Meter with Ethernet Communication

Installation

Figure 9 Install current sensors on the conductors

Close CTs until the clasp

clicks into place to ensure

that contact surfaces are

rmly seated.

✓

The 50 A CT accepts a maximum #2 AWG (0.384” O.D.) /

33.6 mm2 (9.753 mm O.D.) wire with THHN insulation.

The 100 A CT accepts a maximum 3/0 AWG (0.584” O.D.)

/ 85.0 mm2 (14.833 mm O.D.) wire with THHN insulation.

The 200 A CT accepts a maximum of 350 MCM / 177.3

mm2 wire with THHN insulation.

5. Connect the adapter boards to the main board using ribbon cable. Ribbon

6. Connect the current sensors to the terminals on the adapter boards.

Figure 10 Connect adapter boards to main board

If the signed power factor feature

is NOT enabled, then the current

sensor orientation does not affect

meter behavior.

If this feature IS enabled, orient the

current sensors so that the arrow

points toward the load for proper

operation.

cables are keyed to ensure proper installation.

Panel 2,

Strip B

Panel 2,

Strip A

Panel 1,

Strip B

Panel 1,

Strip A

Align ribbon

cable key with

connector

keyhole.

© 2020 Schneider Electric All Rights Reserved.

NOTE: Some adapter boards have serial numbers. These serial

numbers are independent of the serial numbers on the main board.

They do not need to match each other.

11

Branch Circuit Power Meter with Ethernet Communication

Installation

Z206857-0C

04/2020

7. Plastic cable ties are included with the product for strain relief. Insert the

strain relief device into one of the available holes on the adapter board (A).

Gather all current sensor wires connected to that adapter board and secure

the cable tie around them (B).

(A)

(B)

8. The adapter boards are silk screened with two rows of numbers. For

applications that require odd/even branch circuit numbering, use the row

designated ODD or EVEN. Odd/even numbering is used with panelboards

that have odd numbers on one side (usually the left side) and even

numbers on the other. For applications that require sequential numbering,

use the number row marked SEQ. Sequential numbering is generally

used in other applications, where the panelboard has breakers numbered

sequentially or where the branch circuits are used to monitor discrete loads

rather than an entire panelboard.

BLACK

WHITE

41

39

37

35

33

31

29

27

25

23

21

19

17

15

13

11

9

7

SEQ

531

456

789

10

11

12

13

14

15

16

17

18

19

20

21

123

ODD

Adapter Board A numbering:

ODD 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41

SEQ 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

12

BLACK

WHITE

42

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

SEQ

642

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

24

24

23

22

EVEN

Adapter Board B numbering:

EVEN 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

SEQ 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

DANGER

04/2020

Aux CT Installation

Branch Circuit Power Meter with Ethernet Communication

Wiring

1. Connect the (optional) 0.333 Vac current transformers (CTs) to the mains

(see Figure 11), observing local codes regarding bending radius. Refer to

the appropriate CT installation instructions for further information.

Figure 11 CT connection

Panel 2 Panel 1

E30 CURRENT SENSOR STRIP

E30 CURRENT SENSOR STRIP

E30 CURRENT SENSOR STRIP

E30 CURRENT SENSOR STRIP

NOTE: The BCPMSCE measures and reports the phase angle of

each voltage input and each CT (when there is active current through

the primary of that CT).

Wiring

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR

ARC FLASH

• While removing or installing panels and covers, assure that

they do not contact an energized bus.

• NEVER bypass external fusing.

• NEVER short the secondary of a potential transformer.

• Before closing covers and doors, carefully inspect the work

area and remove any tools, wire scraps or other objects that

may have been left inside the equipment.

Failure to follow these instructions will result in death or

serious injury.

Figure 12 Aux CT wiring

CT Input

(0 to 0.333 Vac)

X1 X1 X1 X1

N 3 2 1

X2 X2 X2 X2

CT Input

(0 to 0.333 Vac)

© 2020 Schneider Electric All Rights Reserved.

Set up Modbus registers 115 to 118

(or the corresponding BACnet object or

SNMP variable) for CT scaling. Use base

+ 1 address for Panel 2 setup.

X2 X2 X2 X2

1 2 3 N

X1 X1 X1 X1

13

Branch Circuit Power Meter with Ethernet Communication

3-wire (ungrounded)

Corner-grounded

4-wire

3-wire

2-wire

Single-phase

120/240V High-Leg

L2

Wiring

Z206857-0C

04/2020

1. Connect 2-wire 100 to 277 Vac power to the control power terminals.

Observe polarity. Connect voltage lines to the voltage inputs. Provide

overcurrent protection and disconnecting means to protect the wiring. Use

EMFP1, EMFP2, EMFP3 fuse packs, or equivalent. Suggested: 0.5 A, time

delay fuses.

Figure 13 Connect to voltage inputs

Voltage taps are shared by both panels.

Delta

L3

N

N

L1 L2 L1

120 V/240 V Delta High Leg (where the center tap of one of the three

phase-to-phase transformers is grounded): the BCPMSCE supports these

applications, as long as the line-to neutral voltage [especially of the High Leg]

does not exceed 300 Vac (as in North American 120/240 V High Leg Delta

congurations).

Voltage Inputs

90 to 300 V 50/60 Hz

N V3 V2 V1

L-N V1 V2/NL-L

Figure 14 Wiring configurations

Delta

L3 L3

X

Delta

L2 L1

Control Power

100 to 277 V 50/60 Hz 15 VA

V1 V2/N

Wye

L3

N

L2 L1

Split-phase

L2

L1

N

N

L1

14

In 3-wire (ungrounded) Delta applications, the BCPMSCE supports these

applications with the following caveats:

Control Power for the meter cannot exceed 277 Vac. In applications

where the L-L voltage is 277 Vac or less (e.g. 208 V line-to-line) it can be

connected to two of the phases being monitored without exceeding the

limit. For higher voltages (e.g. 480 V line-to-line), this must be supplied

from a source that is 277 Vac or less. It could be a separate source or

a transformer can be used to step it down from two of the phases being

measured.

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Branch Circuit Power Meter with Ethernet Communication

Wiring

All of the CT inputs (both branches and Aux inputs) are neutralreferenced. One side of each CT is essentially connected directly

to the neutral voltage input. If this is left oating, the solid-core CT

strips, split-core CT adapter boards and all CTs will oat at the same

potential (while the panel is energized). This does not present a risk

to the equipment as long as it is within 300 V of ground, but should be

considered from a safety perspective in the overall application. The

BCPMSCE will provide measurements in this application with the

accuracy specied, with the exception of line-to-neutral voltages, which

will be calculated and reported, based on a derived virtual neutral

voltage, even though they are not relevant.

Corner-grounded delta: the BCPMSCE does not support these applications at

any voltage level.

The BCPMSCE supports measurement of all 4-wire Wye, 3-wire split-phase

and 2-wire single phase and congurations that operate between 90 and 300

Vac line-to neutral.

2. Connect the 2-wire Modbus RS-485 network.

Figure 15 RS-485 connection

RS-485

S

–

+

S

–

+

3. Mechanically secure the RS-485 cable(s) where they enter the electrical

panel.

4. If using Modbus RTU or BACnet MS/TP protocol, connect a serial cable(s)

from the RS-485 loop to the serial connector on the BCPMSCE. Connect all

RS-485 devices in a daisy-chain, and properly terminate the chain.

Figure 16 Daisy chain connection

120 Ω terminator

where specied

RS-485

S

–

+

S

–

+

RS-485 cable

by the applicable

standard

© 2020 Schneider Electric All Rights Reserved.

15

Branch Circuit Power Meter with Ethernet Communication

Wiring

Z206857-0C

04/2020

Two sets of connections are provided to simplify daisy-chain connections

and enable retention of each wire.

Follow all applicable wiring and termination connection guidelines for

the standard in use. Note that while both the Modbus RTU and BACnet

MS/TP standards identify requirements for RS-485 line polarization/

bias and termination, the value and placement of these resistors varies

for each standard. The BCPMSCE does not implement any RS-485 line

polarization/bias or termination internally. Shield the RS-485 cable using

twisted-pair wire. Use cable that is voltage-rated for the installation. The

shield is not internally connected to Earth Ground. Connect the shield to

Earth Ground somewhere on the RS-485 bus (single point connection

only).

5. Connect an Ethernet cable to a local PC if not already connected. Secure a

ferrite lter (included) around the Ethernet cable to ensure the device meets

emission requirements. Use the PC to congure the gateway (next section

of this document).

Note: 100 to 277 Vac must be applied to control power inputs to supply

power to the gateway during conguration.

Figure 17 Ethernet port location

6. Once congured, disconnect the local PC. If desired (and the device is

congured for operation on the network), connect the BCPMSCE directly

to the network for ongoing access to the GUI even if primarily using a serial

protocol to access and control the BCPMSCE.

16

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

A qualified person is one who has skills and knowledge related to

the construction and operation of this electrical equipment and

installations, and has received safety training to recognize and

avoid the hazards involved.

If this product is used in a manner not specified by the

manufacturer, the protection provided by the product may be

impaired. No responsibility is assumed by Schneider Electric for

any consequences arising out of the use of this material.

DANGER

04/2020

Gateway Configuration

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC

FLASH

• Follow safe electrical work practices. See NFPA 70E in the

USA, CSA Z462 in Canada, or applicable local codes.

• Read and understand the instructions before installing the

product. Follow the instructions during installation.

• Installation, wiring, testing or service must be performed

only by qualified persons in accordance with all applicable

codes and regulations.

• Install the product in an appropriate electrical and fire

enclosure per local regulations.

• Do not use the product for life or safety applications.

• Do not install the product in hazardous or classified locations.

• Do not exceed the product’s ratings or maximum limits.

• The product may use multiple voltage/power sources.

• Turn off ALL power supplying equipment before working on

or inside the equipment.

• Use a properly rated voltage sensing device to confirm that

all power is off.

• Do NOT depend on the product for voltage indication.

• Products rated only for basic insulation must be installed on

insulated conductors.

• Current transformer secondaries (current mode) must be

shorted or connected to a burden at all times.

• Remove all wire scraps and tools, replace all doors, covers

and protective devices before powering the equipment.

Failure to follow these instructions will result in death or

serious injury.

Accessing the Graphical User Interface (GUI)

© 2020 Schneider Electric All Rights Reserved.

NEC Article 100

Note: The screen captures in this section were taken using Windows 7; other

operating systems will look different.

If the BCPMSCE IP address parameters are already congured to work on the

network and is being accessed from a PC on that same network, then open

a web browser and enter the IP address of the BCPMSCE into the address/

URL eld on the browser. Press enter. On the rst time login to the device GUI,

follow the instructions in the section "Accessing the GUI for the rst time

with rmware version 1.027 or higher" to congure the web server's security

settings and log in. If already congured, the GUI login page appears. Enter the

username and password and click Login. The GUI launches and appears, as

shown, in the browser window below.

Note: Devices with rmware version 1.026 and earlier will not have a login page

and will not require a password.

17

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

Z206857-0C

04/2020

If the IP address parameters are not congured for the network, connect a PC

directly and access the GUI from it as follows:

1. Connect a standard Ethernet cable between a PC and the BCPMSCE. If

not already connected, secure a ferrite lter (included) around the Ethernet

cable to ensure the device meets emission requirements.

2. Temporarily change the IP address of the PC to a static value on the same

subnet as the BCPMSCE. For example: If the BCPMSCE is set to its

factory default IP address of 192.168.1.24, set the PC to an unused static

IP address on the 192.168.1.xxx subnet (where xxx is any value between 1

and 255, except 24). Set the subnet mask to 255.255.255.0.

a. Open the Control Panel:

b. In the Control Panel, select Network and Sharing Center. In the Sharing

Center, select Change Adapter Settings in the list at the upper left corner.

c. Select the connection for the network that the BCPMSCE is connected

to.

18

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

When the Local Area Connection Status dialog box appears, click on

Properties.

d. Highlight Internet Protocol Version 4 (TCP/IPv4), and click OK.

e. Select <Use the following IP Address>. Make note of the IP address that

appears, then enter the static IP address (e.g. if the BCPMSCE is still set

to its default address of 192.168.1.24, then change it to 192.168.1.100).

Enter 255.255.255.0 for the subnet mask. Click OK.

© 2020 Schneider Electric All Rights Reserved.

19

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

Z206857-0C

04/2020

Enter static

IP address

Enter subnet

mask

f. Click OK.

3. Open a PC web browser and enter the IP address of the BCPMSCE

(default address is 192.168.1.24) to access the GUI. On the rst time login

to the device GUI, follow the instructions in the section "Accessing the GUI

for the rst time with rmware version 1.027 or higher" to congure the

web server's security settings and log in. The GUI launches and appears in

the browser window.

Using the GUI to set up the IP address

4. When nished using the GUI, unplug the Ethernet cable from the PC and

restore the IP settings as needed.

1. Access the GUI according to the instructions in the “Accessing the

Graphical User Interface (GUI)” section. To set IP address parameters, click

the button labeled “Network Settings.”

The Network Settings screen appears.

20

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

Have the desired IP settings ready in advance (contact the system

administrator). IP parameters for use with BACnet IP are static, not

dynamic.

2. Set the IP address for use on the BACnet/IP network:

a. Enter the desired IP address in the N1_IP_Address eld (in the format

xxx.xxx.xxx.xxx)

b. If necessary, change the Subnet Mask by entering the appropriate new

value in the N1_Netmask eld

c. If the BCPMSCE is connected to an Ethernet gateway, enter its IP

address in the Default Gateway eld. This is especially critical if the

BCPMSCE will be used as a BACnet BBMD device.

d. Click the Update IP settings button. The BCPMSCE changes its settings.

e. Click the System Restart button and wait for the BCPMSCE to fully

initialize. The GUI will connect when the BCPMSCE is installed on a

network that matches the settings and the new IP address is entered into a

web browser on a PC properly congured for the network. .

Using the GUI to Configure the Communication Protocols

Access the GUI according the instructions in the “Accessing the Graphical User

Interface (GUI)” section.

© 2020 Schneider Electric All Rights Reserved.

21

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

Z206857-0C

04/2020

The home screen on the GUI provides elds for conguration of the BCPMSCE.

The BCPMSCE has four primary modes of operation, each of which support

a different combination of protocols. Each option eld has a Submit button to

the right. When changing the value in any eld, click Submit to store the new

value. The GUI prompts the user to restart the system. If multiple values are

changed, it is easiest to submit all changes and restart only once when nished

with the whole screen. To restart, click the System Restart button in the row

at the bottom of the screen. The restart takes several seconds, during which

the server may lose its connection. Messages appear at the top of the screen

indicating current status, but do not perform any actions. Simply allow the tool

to complete the restart cycle.

The rst selection in the GUI is Operating_Mode, which has two choices:

a. Locked: used for all normal product operation. It is provided as a tool

for high-level technical support. The gateway retains its current prole

conguration when powered.

b. Discovery mode (default): deletes proles and rediscovers them when

the device is powered again. The results are the same, unless the prole

conguration is intentionally altered. Prole selection and discovery are

especially important when using BACnet or SNMP protocols. For normal

operation, always use discovery mode.

The second selection in the GUI is Protocol_Mode, used to select the

combination of protocols the product communicates with. The BCPMSCE

supports ve protocols, some of which can operate simultaneously. The table

below shows what protocols are supported in each mode.

Protocol Mode Primary Protocol Ethernet Protocol RS-485 Protocol

1 BACnet MS/TP Modbus TCP BACnet MS/TP

2 BACnet IP BACnet IP/Modbus TCP Modbus RTU

3 SNMP SNMP/Modbus TCP Modbus RTU

4 Modbus Modbus TCP Modbus RTU

22

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

1. BACnet MS/TP mode

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

To select a primary protocol mode, enter the corresponding number into the text

eld adjacent to the Primary Protocol option and click the Submit button to the

right of the text eld. A prompt appears at the top of the screen instructing the

user to restart the system. When nished, the screen refreshes itself with the

appropriate elds for the selected mode.

The next GUI selection, in any protocol mode, is the Upstream_Baud rate

selection. If you have selected BACnet MS/TP (mode 1) as the primary protocol

mode, this value sets the MS/TP baud rate. If you have selected modes 2 or 3

as the primary protocol mode, you may not be using the RS-485 interface at all.

If so, this setting can be ignored.

If you have selected BACnet IP, SNMP or Modbus mode, the next selection is

Modbus_Parity, which sets the parity of the upstream serial connection. If using

Modbus RTU protocol, set this to match your Modbus master. If not, ignore this

eld.

The following sections show the eld selections (with factory default values)

specic to each of the four Protocol_Modes.

© 2020 Schneider Electric All Rights Reserved.

The rst three options are discussed previously.

The DeviceID_Offset parameter is used to assign Device_IDs on power-up

or on restart until they have been overwritten via BACnet. Enter your desired

value here and click submit. The new value is rst used at the next power-up or

system restart. Valid Device_ID numbers range from 1 to 4194303. Since the

numbers assigned during discovery are the sum of the Offset and the Modbus

address (which can be any value from 1-247), the Offset values entered in the

GUI must be no larger than 4194057.

23

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

Z206857-0C

04/2020

The BCPMSCE gateway creates a BACnet virtual router and separate BACnet

devices for each 42-channel meter panel behind this virtual router, allowing

the devices to be discoverable and independently accessed via BACnet, even

if the virtual router is connected by MS/TP, using a single MAC address. To

use this product with MS/TP, the BACnet system must support the discovery

and use of a BACnet router on the MS/TP trunk and any devices beyond it.

This virtual router creates an exclusive BACnet network on which the meter’s

BACnet devices reside. This network must have a BACnet network number

that is different from any other networks in the entire BACnet enterprise. When

multiple BCPMSCE products are added anywhere in the enterprise, each one

must have a unique network number. Failure to set an exclusive value in this

eld causes communication conicts in the BACnet system.

Enter a non-conicting value here and click submit. Valid network numbers

range from 1 to 65534; if other values are entered, the network number defaults

to 5. The new value is rst used at the next power-up or system restart. If using

an external BACnet router to connect the BCPMSCE as an MS/TP device,

it is recommended that the router also be restarted after the BCPMSCE has

completed discovery, when the network number is changed.

The next eld for the BACnet MS/TP protocol mode is the MSTP_Max_Master,

which allows this value to be set prior to using BACnet software to access the

BCPMSCE. The default value of 127 works regardless of the addresses the

MS/TP network uses, but selecting a lower value may optimize the network.

Do not set this value lower than the highest address on the network. To set this

value via BACnet, write to the Max_Master property of the device object for the

BCPMSCE’s virtual router.

The nal eld is the MSTP_MAC_Addr, which sets the MAC address for the

virtual router. The BCPMSCE panel(s) are devices on the internal BACnet

network and are not directly addressable as MAC addresses on the MS/TP

network.

24

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

2. BACnet IP mode

Branch Circuit Power Meter with Ethernet Communication

Gateway Configuration

BACnet IP mode uses the same DeviceID_Offset and Virt_Router_Net

parameters described above for BACnet MS/TP mode. One additional

parameter, BACnet_IP_Port, is used to set the UDP port. Most BACnet systems

use the default port (47808 decimal, 0xBAC0 hex) that is recommended in the

BACnet standard as the only UDP port. Some large systems need to segment

the enterprise and use more than port. If so, enter the number of the port you

need to use to access this device. BACnet IP mode does not use MSTP_Max_

Master or MSTP_MAC_Ad

© 2020 Schneider Electric All Rights Reserved.

25

Branch Circuit Power Meter with Ethernet Communication

Commissioning

3. SNMP mode

Z206857-0C

04/2020

Operating the BCPMSCE

Commissioning

BACnet Network Management

SNMP mode uses four unique parameters. SNMP Community strings are used

to control access to the device. Whatever values are entered here must be

used in the MIB browser or SNMP access software to communicate with this

device. The Read_Community string is used to enable reading data. The Write_

Community string is used to enable writing data. The Trap_Community string is

used to enable the receipt of event notications.

The last parameter, SNMP_Notif_IP will be used to set the IP address of the

client that used to receive SNMP event notications for over-threshold events.

Restart the BCPMSCE by using the button at the bottom of the GUI or by

cycling the power. It takes about 30 seconds to initialize completely and be

ready for external communication.

Commission the BCPMSCE for operation using ION Setup software. See the

ION Setup Conguration Guide for instructions.

BACnet conguration uses two default settings that might need to be changed,

depending on the application.

26

a. Virtual router network ID number. Every logical network segment (IP

subnet, MS/TP trunk, etc.) in an entire system must have a (16-bit) network

ID number that is unique from all other BACnet networks in the enterprise.

The BACnet network administrator assigns this network ID so that no two

ID numbers conict (whether using BACnet/IP or MS/TP). Within each

segment, every device is physically identied by the combination of its 8-bit

MAC address and the 16-bit network ID number.

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Branch Circuit Power Meter with Ethernet Communication

BACnet PICS (Protocol Implementation Conformance Statement)

To support multiple meter panels (panel 1 and panel 2 are separate) with

a single gateway, the BCPMSCE creates a virtual BACnet router that

presents multiple BACnet devices using a single (its own) MS/TP MAC

address. Each BCPMSCE must have its own (internal) network ID, and

it creates a device object for itself and one for each Modbus address

discovered.

The factory default network address is 50 (decimal). If that number is

already in use in the system, assign a unique address using the graphical

user interface (GUI) on the built-in web server (this requires an Ethernet

connection to a web browser; see BACnet/IP Setup section for instructions

on changing conguration settings using the GUI). Valid network numbers

range from 1 to 65534; if other values are entered, the network number

defaults to 5.

b. Device_ID Offset. Every BACnet device must have a BACnet

Device_ID number that is unique throughout the entire enterprise. Since

the BCPMSCE presents every Modbus meter as a BACnet device, each

connected meter that has a Modbus address must have a BACnet Device_

ID.

By default, each device discovered receives a Device_ID number that

is the sum of an offset value (default is 50000) and the Modbus address

of the device. If these Device_ID numbers cause a conict with existing

devices in the system, or if the system includes multiple BCPMSCEs,

change the Device_ID numbers before connecting the BCPMSCE to the

system. This can be managed one of two ways:

i. Connect to the BCPMSCE directly (ofine from the system) with

the devices (meters). After the BCPMSCE discovers the devices and

assigns their default ID numbers, the user can choose new Device_ID

values and write these to each device using BACnet software.

Subsequent discoveries will not overwrite these values with defaults

even if the BCPMSCE is then set to Discovery mode.

ii. Use the GUI on the built-in web server to modify the offset value

used to calculate default Device_IDs in the discovery process (this

requires an Ethernet connection to a web browser; see BACnet/IP

Setup section for instructions on changing conguration settings using

the GUI). The BCPMSCE retains this offset value and uses it to assign

Device_ID numbers every time power is cycled if the BCPMSCE is in

Discovery mode. Valid Device_ID numbers range from 1 to 4194303.

Since the numbers assigned during discovery are the sum of the Offset

and the Modbus address (which can be any value from 1-247), any

Offset values entered in the GUI must be less than 4194057.

BACnet PICS (Protocol Implementation Conformance Statement)

Vendor Name: Schneider Electric

BACnet Vendor ID 335

Product Name: BCPMSCE Series Branch Circuit Monitor

Product Model Number: <Model Number>

© 2020 Schneider Electric All Rights Reserved.

Product Description: Branch Circuit Monitor

BACnet Protocol Version: Version 1 Revision 12

BACnet Standardized Device Prole (Annex L) – [Note: BCPMSCE

incorporates a gateway device]

• BACnet Application Specic Controller (B-ASC)

27

Branch Circuit Power Meter with Ethernet Communication

General BACnet Programming Information

Standard Object Types Supported

Z206857-0C

04/2020

BACnet Interoperability Building Blocks Supported (Annex K):

• K.1.2 BIBB - Data Sharing - ReadProperty-B (DS-RP-B)

• K.1.4 BIBB - Data Sharing - ReadPropertyMultiple-B (DS-RPM-B)

• K.1.8 BIBB - Data Sharing - WriteProperty-B (DS-WP-B)

• K.1.10 BIBB - Data Sharing - WritePropertyMultiple-B (DS-WPM-B)

• K.1.12 BIBB - Data Sharing - COV-B (DS-COV-B)

• K.2.2 BIBB - Alarm and Event-Notication Internal-B (AE-N-I-B)

• K.2.5 BIBB - Alarm and Event-ACK-B (AE-ACK-B)

• K.2.11 BIBB - Alarm and Event-Information-B (AE-INFO-B)

• K.5.2 BIBB - Device Management - Dynamic Device Binding-B

(DM-DDB-B)

• K.5.4 BIBB - Device Management - Dynamic Object Binding-B

(DM-DOB-B)

• K.5.6 BIBB - Device Management - DeviceCommunicationControl-B

(DM- DCC-B)

• K.5.12 BIBB - Device Management - TimeSyncronization-B (DM-TS-B)

• K.5.22 BIBB - Device Management – List Manipulation-B (DM-LM-B)

• K.5.20 BIBB – Device Management-Restart-B (DM-R-B)

• Device Object

• Analog Input

• Analog Output

• Analog Value

Unsupported Properties and Restrictions

Data Link Layer Options

Networking Options

Character Sets Supported

General BACnet Programming Information

The BCPMSCE consists of a BACnet virtual router and one or two 42-channel

branch circuit meters. The BACnet virtual router has its own device object

and an internal BACnet network. The branch circuit monitors have their own

device objects that are logical devices on the network internal to (beneath) the

virtual router. It is critical that the network number of the virtual router’s internal

network be different than any other network number in your entire BACnet

system. The network number is set to 50 at the factory, but can be changed in

the GUI or by writing to the Present_Value of the AV2 data object associated

with that device. Changes to the network number do not take effect until the

BCPMSCE is re-started, either from the GUI or by cycling the power.

• Does not support BACnet CreateObject

• Does not support BACnet DeleteObject

• Does not support any proprietary properties

• No proprietary properties exist

• No range restrictions exist

• Max_Master is writable

• BACnet IP, (Annex J)

• MS/TP master (Clause 9), baud rate up to 76.8 kbps

• BACnet/IP Broadcast Management Device (BBMD)

• Registrations by Foreign Devices

• ISO 10646 (UTF-8) / ANSI X3.4

28

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Branch Circuit Power Meter with Ethernet Communication

General BACnet Programming Information

The default Device ID of the virtual router is the Device_Offset parameter which

is set to 5000 at the factory, but can be changed in the GUI or by writing to

Present_Value of the AV1 data object associated with that device. Changes to

the network number do not take affect until the BCPMSCE is re-started, either

from the GUI or by cycling the power. The default Device IDs are numbered to

consecutively follow the Device ID of the virtual router (e.g. if the Device_Offset

parameter is 50000, the virtual router has a Device_ID of 50000, the branch

circuit monitor called Panel 1 has a Device_ID of 50001 and the branch circuit

monitor called Panel 2 (if present) has a Device_ID of 50002.

All Device_IDs are writable. Once a device’s Object_Identier is overwritten,

changes to the ID Offset no longer affect that Object_Identier, even in

Discovery mode. Make further changes to the value by writing the Object_

Identier property.

The default Object_Name property value of each device object is an

abbreviated name of the meter series discovered with an underscore and the

Modbus address of the meter appended to it. The Object_Name is a writable

property. Once a device’s Object_Name is overwritten, the Object_Name does

not revert to the initial default, even in Discovery mode. Make further changes

to the value by writing the Object_name property.

The BCPMSCE supports Subscribe_COV, with default COV increment values

assigned as shown in the data object tables. If these values are not appropriate

for a specic application, write them as needed when they are subscribed. On

subsequent power cycles, no subscriptions are active and the COV increments

return to their default values.

BBMD Support

Data values written to AV objects are accepted (without error) by the data

object and passed through to the corresponding Modbus register. There is no

direct indication via the BACnet protocol if invalid values are rejected. After

an invalid value is written to the Present_Value of an AV, subsequent reads of

that property return the new (invalid) value until the next time the BCPMSCE

refreshes its data (this may take several seconds).

When the BCPMSCE is in BACnet IP mode, it can be congured as a BACnet

Broadcast Management Device (BBMD) by adding devices to a comma

separated value text le named bdt.ini, and loading it onto the device. The

example below shows the syntax required. All lines beginning with two forward

slashes are interpreted as comments. Use exactly one line per device,

separated by commas (no spaces). Once edited, upload the btd.ini le to the

gateway through the GUI. Click the <Diagnostics and Debugging> button in

the lower right corner of the GUI and follow the folder tree under Navigation

to the following folder: "Schneider Electric BCPM Series Gateway/Setup/

File Transfer." Select the "General" tab (this is important - using the wrong tab

can overwrite critical les). Click the <Browse> button and select your bdt.

ini le. Then click <Submit>. The GUI should quickly indicate "The le was

updated successfully." Click the <System Restart> button, click <OK> on the

conrmation dialog and wait for the gateway to reinitialize (takes about 30

seconds). BBMD changes are made by uploading a new btd.ini le.

// Bdt.ini

// The format of this table must be (without the forward slashes - they are

comment indicators):

© 2020 Schneider Electric All Rights Reserved.

//

//BBMD IP_Address , BBMD port , BBMD subnet Mask

//

147.26.116.217,47808,255.255.255.255

172.16.17.198,47808,255.255.255.255

29

Branch Circuit Power Meter with Ethernet Communication

General SNMP Programming Information

General SNMP Programming Information

The BCPMSCE can be congured to support the SNMP V2c protocol over

Ethernet. The SNMP community string and the IP address for the client

receiving SNMP V2c event notications can be set via the GUI. MIB les are

available for download from the BCPM Downloads and Documents page at

www.se.com to enable accessing the BCPMSCE from an MIB browser.

The BCPMSCE OID structure organizes the data under two “panels”

representing the two breaker panels that can be monitored by a fully populated

BCPMSCE. Panel 1 corresponds to the CT strips connected to the “Panel 1A”

and “Panel 1B” connectors and to the data set under Modbus address 1 or

BACnet device identied as Node_1 in the GUI. Panel 2 corresponds to the CT

strips connected to the “Panel 2A” and “Panel 2B” connectors and to the data

set under Modbus address 2 or BACnet device identied as Node_2 in the GUI.

For each panel, data is arranged under six tree branches.

Z206857-0C

04/2020

• The Conguration branch contains all writable conguration

parameters.

• The Alarms branch contains all the event notication traps, the global

event status registers and counters and tables of the event status

indicators.

• The Voltage Inputs branch contains all data measurements pertaining

to the voltage inputs.

• The Auxiliary Inputs branch contains all data measurements

pertaining to the aux inputs other than voltage-related.

• The Branch Inputs branch contains all data measurements to the

branch inputs in table format.

• The Flex Circuits branch contains all data measurements to the logical

meter summaries in table format.

30

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Cybersecurity

Overview

Branch Circuit Power Meter with Ethernet Communication

Cybersecurity

This chapter contains up-to-date information about your product’s cybersecurity.

network administrators, system integrators and personnel that commission,

maintain or dispose of a device should:

• Apply and maintain the device’s security capabilities. See “Device

security capabilities" for more details.

• Review assumptions about protected environments. See "Protected

environment assumptions" for more details.

• Address potential risks and mitigation strategies. See “Potential Risks

and compensating controls” for more details.

• Follow recommendations to optimize cybersecurity.

Your device has security capabilities that:

• Allow it to be part of a NERC CIP compliant facility. Go to the North

American Electric Reliability Corporation website for information on

NERC Reliability Standards.

• Align with cybersecurity standards in the IEC 62443 international

standard for business IT systems and Industrial Automation

and Control Systems (IACS) products. Go to the International

Electrotechnical Commission website for information about the

IEC 62443 international standard.

Product defense-in-depth

To communicate a security topic affecting a Schneider Electric product or

solution, go to www.se.com/en/work/support/cybersecurity/vulnerabilitypolicy.jsp.

WARNING

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY,

INTEGRITY, AND CONFIDENTIALITY

• Change default passwords to help prevent unauthorized

access to device settings and information.

• Disable unused ports/services and default accounts, where

possible, to minimize pathways for malicious attacks.

• Place networked devices behind multiple layers of cyber

defenses (such as firewalls, network segmentation, and

network intrusion detection and protection).

• Use cybersecurity best practices (for example: least

privilege, separation of duties) to help prevent unauthorized

exposure, loss, modification of data and logs, interruption of

services, or unintended operation.

Failure to follow these instructions can result in death,

serious injury, or equipment damage.

Use a layered network approach with multiple security and defense controls

in your IT and control system to minimize data protection gaps, reduce singlepoints-of-failure and create a strong cybersecurity posture. The more layers of

security in your network, the harder it is to breach defenses, take digital assets

or cause disruption.

© 2020 Schneider Electric All Rights Reserved.

31

Branch Circuit Power Meter with Ethernet Communication

Cybersecurity

Device security capabilities

Protected environment assumptions

Z206857-0C

04/2020

This section describes the security capabilities available with your device.

User accounts

These security capabilities help enforce authorizations assigned to users,

segregation of duties and least privilege:

• User authentication is used to identify and authenticate software

processes and devices managing accounts.

• Device conguration and security communications conguration.

Hardening

These security capabilities help prohibit and restrict the use of unnecessary

functions, ports, protocols and/or services:

• Least functionality can be applied to prohibit and restrict the use of

unnecessary functions, ports, protocols and/or services.

• Port numbers can be changed from default values to lower the

predictability of port use.

• Cybersecurity governance – available and up-to-date guidance on

governing the use of information and technology assets in your company.

• Perimeter security – installed devices, and devices that are not in service,

are in an access-controlled or monitored location.

• Emergency power – the control system provides the capability to switch to

and from an emergency power supply without affecting the existing security

state or a documented degraded mode.

• Firmware upgrades – device upgrades are implemented consistently to the

current version of rmware.

• Controls against malware – detection, prevention and recovery controls

to help protect against malware are implemented and combined with

appropriate user awareness.

• Physical network segmentation – the control system provides the capability

to:

• Physically segment control system networks from non-control system

networks.

• Physically segment critical control system networks from non-critical

control system networks.

• Logical isolation of critical networks – the control system provides the

capability to logically and physically isolate critical control system networks

from non-critical control system networks. For example, using VLANs.

• Independence from non-control system networks – the control system

provides network services to control system networks, critical or non-critical,

without a connection to non-control system networks.

• Encrypt protocol transmissions over all external connections using an

encrypted tunnel, TLS wrapper or a similar solution.

• Zone boundary protection – the control system provides the capability to:

• Manage connections through managed interfaces consisting of

appropriate boundary protection devices, such as: proxies, gateways,

routers, rewalls and encrypted tunnels.

32

© 2020 Schneider Electric All Rights Reserved.

Z206857-0C

04/2020

Potential risks and compensating controls

Area Issue Risk Compensating controls

User accounts Default account settings

are often the source of

unauthorized access by

malicious users.

Secure protocols Modbus TCP, BACnet/IP and

SNMP protocols are unsecure.

The device does not have

the capability to transmit

encrypted data using these

protocols.

Branch Circuit Power Meter with Ethernet Communication

• Use an effective architecture, for example, rewalls protecting application

gateways residing in a DMZ.

• Control system boundary protections at any designated alternate

processing sites should provide the same levels of protection as that of

the primary site, for example, data centers.