Saeco Espresso Machine Aroma User Manual

Professional espresso coffee machine

Models:

AROMA SM / SE

INSTRUCTION AND MAINTENANCE MANUAL

English

2

Carefully read the following instruction booklet before starting up the machine.

Carefully read the following instruction booklet before starting up the machine.

Important ! Hot surfaces.

Important! Particularly important and/or delicate operations

Important ! Operations essential to guarantee efficient function

Operations which may be carried out by the user

Operations to be undertaken solely by an installer or authorized technician.

We thank you for your custom in the purchase of this product.

By carefully following the instructions contained in this manual you will be sure to appreciate the quality of our machine.

Please therefore carefully read the instructions of use contained in this manual, which comply with essential safety regulations.

3

English

INDICE

INDICE. .............................................................................................................. 3

1- INSTRUCTIONS BOOKLET CONSERVATION

AND USE

. ............................................................................................ 4

2- ENVISAGED MACHINE USE

. ............................................ 4

3 - SAFETY ADVICE

. ........................................................................... 5

4 - TECHNICAL FEATURES

. .......................................................... 6

5 - INSTALLATION

. ............................................................................. 7

5.1 Water connection

. ....................................................... 7

5.2 Electrical connection

. .................................................. 7

6 - START UP

. ........................................................................................... 8

6.1 Long coffee gigleuri

. ................................................... 8

6.2 Pressure switch adjustment

. ..................................... 9

6.3 Pump pressure calibration

. ...................................... 9

6.4 Filters for coffee machine

. ........................................ 9

6.5 Replacement of the thermostat to reduce the

coffee dispensing group temperature. ........ 10

6.6 With spouts

. ..................................................................... 10

7 - FUNCTION / USE AND PROGRAMMING

. ........ 10

7.1 Coffee measure programming

. ............................. 11

7.2 Tea measure programming (hot water)

. .......... 13

7.3 Coffee delivery

. ............................................................. 14

7.4 Continuous coffee measures

. ................................. 14

7.5 Special functions

. .......................................................... 15

7.6 Tea delivery

. .................................................................... 16

7.7 Cappuccino and milk function

. ............................ 17

7.8 Cappuccino delivery and programming

. ....... 18

7.9 Milk programming and delivery

. ......................... 18

7.10 Further functions on machines equipped

with display

. ..................................................................... 19

7.11 Alarm condition

. ............................................................ 22

8 - PURIFIER REGENERATION

. ............................................... 23

9 - MAINTENANCE AND USEFUL ADVICE

. .................. 24

10 -TROUBLE SHOOTING

. ........................................................... 25

11 -MACHINE DISMANTLING

. ................................................. 25

English

4

2. ENVISAGED MACHINE USE

The machine must be operated by a single operator only.

The authorized operator must have firstly read and fully

understood all the instructions contained in the present booklet

to ensure correct machine function.

This machine is specifically intended for the professional

preparation of espresso coffee using blended coffee, as

well as the drawing and delivery of water and/or steam.

Its components are made of resilient non toxic materials,

and they are easily accessible for cleaning or maintenance

operations.

1 - INSTRUCTIONS BOOKLET

CONSERVATION

The present instructions booklet has been prepared for the

machine user, the owner and the installation technician and

must be always available for reference purposes.

The manual is destined for the user, the maintenance

technician and machine installation technician.

The purpose of the instructions booklet is to indicate the

envisaged uses of the machine for which it has been

designed, its technical features and in order to provide advice

on correct use, cleaning and regulation. It also provides

important maintenance information, and details on any

residual risks, and all those operations which require

particular care.

The present manual is to be considered as an integral part

of the machine and must be CONSERVED FOR FUTURE

REFERENCE until the final dismantling of the machine.

This instructions booklet must always be available for

consultation and must be kept in a protected and dry place.

In the event of loss or damage to the same, the user may ask

the manufacturer or local dealer for a new manual, indicating

the machine model and serial number of the same as

indicated on the identification plate.

The present manual reflects the state of the art, at the time of

its preparation, the manufacturer however reserves the right

to revise production and subsequent manuals without being

obliged to update previous versions.

The manufacturer declines all responsibility in the event of :

- the improper or incorrect use of the coffee machine

- use that fails to comply with that specifically stated in the

present booklet

- serious lack of maintenance as envisaged or

recommended

- machine modifications or any non-authorized intervention

- use of either non-original or non-specific spares

- total or partial failure to observe the instructions

This machine is intended for internal use only.

Ambient temperature for the correct operation of the machine

5°C ÷ 40°C.

English

5

3 - SAFETY ADVICE

The machine is to be used solely by adults who have carefully

read and fully understood this manual and all the safety advice

contained in the same.

The user is responsible in relation to third parties in the working

area.

The installer, user and maintenance technician are obliged

to notify the constructor of any defects or faults which may

effect the original safety of the system.

Installation must be effected solely by authorized and

qualified personnel.

The machine is to be used solely in the presence of suitable

lighting.

For safety reasons, all worn or damaged parts must be

promptly replaced.

Regularly check that the power supply cable is in good

conditions. Damaged cables must never be repaired using

insulating tape or clamps.

Do not expose the machine to the elements (sun, rain , etc).

Prolonged machine standstill at temperatures of under 0°C

(zero degrees centigrade), may cause serious damage or

breakage to the boiler piping: it is therefore necessary to

completely empty the water circuit before every prolonged

standstill.

The removal of guard and/or safety elements fitted on the

machine is forbidden.

The packaging components must be consigned to special

disposal centres and must in any event never be left

unguarded or within reach of children, animals or non-

authorized persons.

The constructor declines responsibility for any damage to

things, persons or animals caused by eventual interventions

on the machine by personnel not specifically authorized to

undertake such operations.

In the event of any non-authorized interventions or repairs

on the machine, or in the event of the use of non-original

spares all guarantee terms become void, and the company

reserves the right to reject validity.

The user must comply with the current safety laws in force in

the country of installation, as well as common sense and

ensure that all maintenance operations are regularly carried

out.

Never clean the inside of the machine with power supply

on and plug connected and in any event avoid the use of

water sprays or detergents.

The user must not touch the machine if his hands or feet are

wet or damp, neither must be use the machine in bare feet.

Although the machine is earthed it is advisable to use wooden

platforms or a cut-out box complying with local laws in order

to prevent the risk of electrocution.

English

6

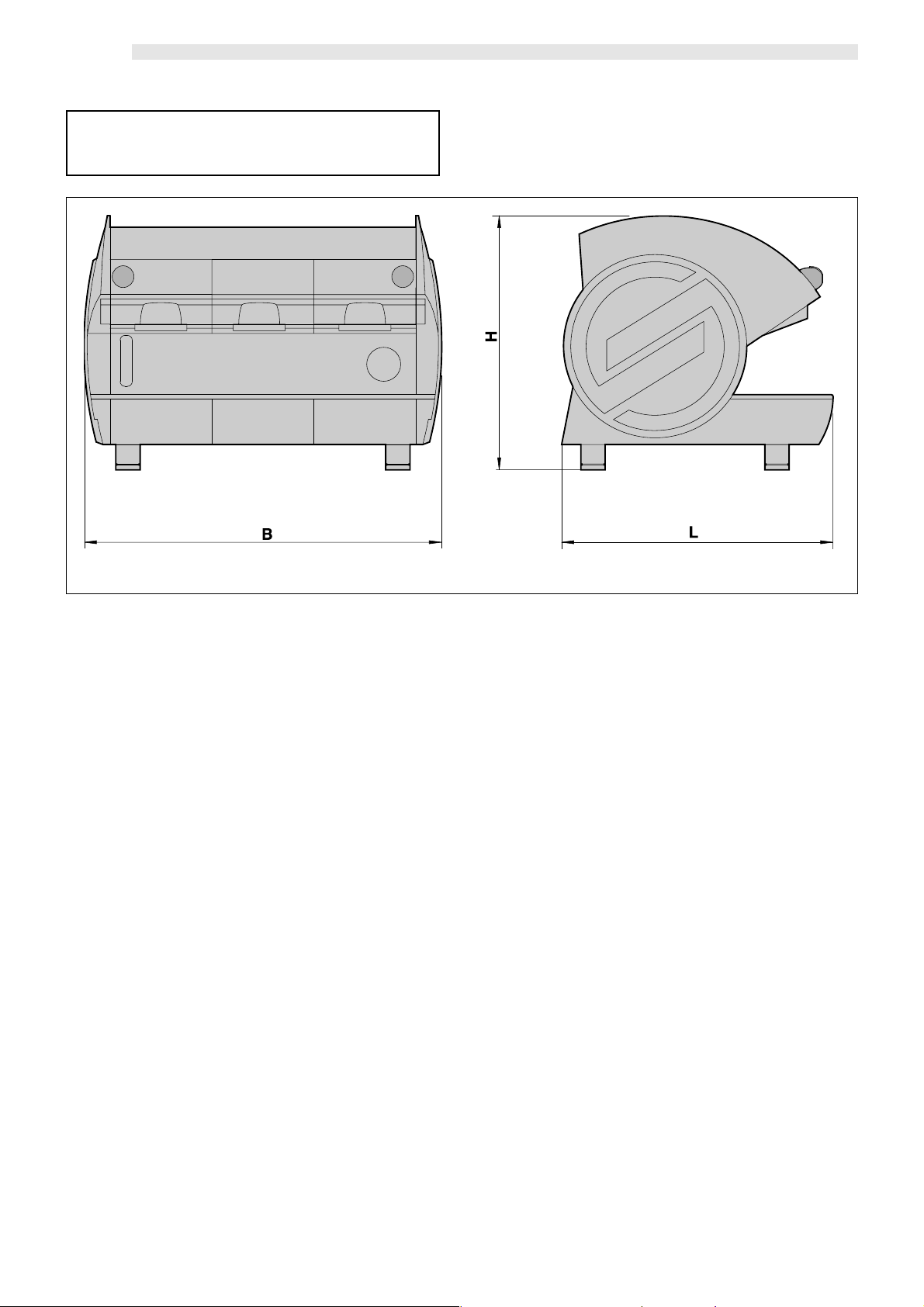

4 - TECHNICAL FEATURES

fig. 1

spuorg2spuorg3spuorg4

snoisnemiDBB

B

BB0670790811

HH

H

HH035035035

LL

L

LL045045045

thgieWgkgk

gk

gkgk0709011

yticapacrelioBLL

L

LL311282

rewopdebrosbaecnatsiserrelioB

~N3V514/042WW

W

WW067405950417

~N3V004/032WW

W

WW073456455556

rewopdebrosbaecnatsiserreliobxaMOCE

~N3V514/042WW

W

WW071305930574

~N3V004/032WW

W

WW009204630634

rotompmuPWW

W

WW561561561

rewopdebrosballarevO

~N3V514-004/042-032WW

W

WW002500260027

gnitaehsaGh/lacKh/lacK

h/lacK

h/lacKh/lacK007100520043

English

7

5 - INSTALLATION

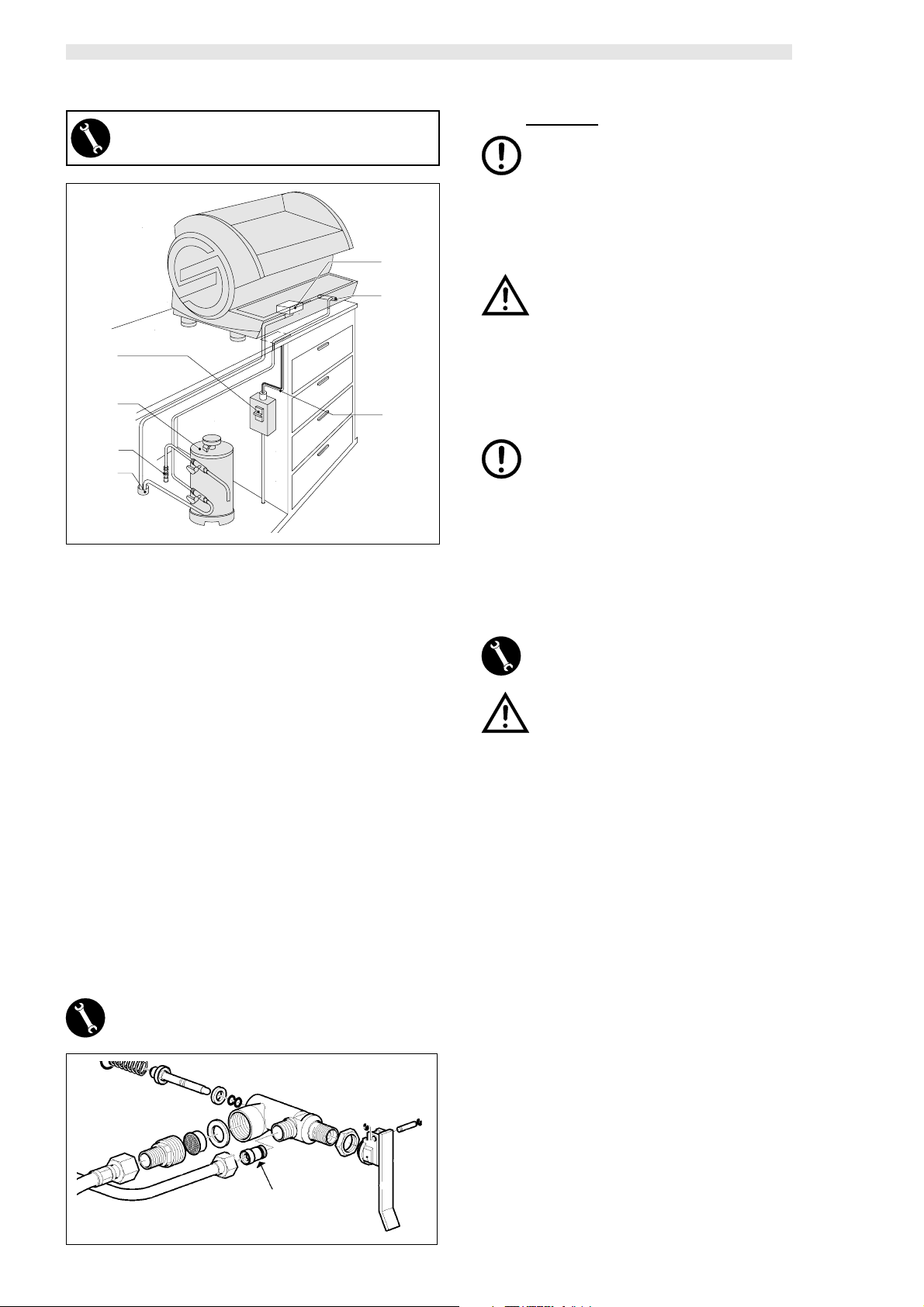

G

F

D

E

A

B

C

fig. 2

A. MAINS SUPPLY

B. DISCHARGE DUCTS

C. POWER CABLE

D. PROTECTION SWITCH

E. PURIFIER

F. BOILER SUPPLY TAP

G. DRIP BOWL

Before proceeding with installation check that:

- there are no bumps, signs of knocks or deformities.

1 there are no damp patches or marks which could lead

one to assume that the packaging has been exposed to

the elements

2 there are no signs of tampering

Once one is satisfied that transportation has been correctly

effected proceed with installation.

Proceed with installation following the instructions according

to the sequence as described below.

N.B. The least height of the support's top must be 110cm.

5.1 Water connection

Important: The machine must be supplied with water

of over 8

°

F hardness.

The installation of a water softener is recommended for the

machine water supply.

Check that the water mains to which connection is to be

made supplies drinking water.

- Connect purifier (E) to the water mains (A).

NB: before connecting the purifier to the machine,

wash out thoroughly until the water becomes clear,

then proceed to connect the purifier to the machine.

- Connect the drain cup (G) to the drainage pipe (B)

- Should the mains pressure be higher than 5 bar a pressure

reducer balanced for high pressure should be installed

(device in which any mains pressure increase does not

effect the output pressure).

5.2 Electrical connection

Important ! Before proceeding with electrical

connection it is necessary to check to ensure that the

voltage rating corresponds with that indicated on

the CE plate and on the connection plate on the

power supply cable.

Check to ensure that the electrical supply line is able to support

the machine load (see chap. 4 – technical features table).

Connect to an earthing socket which complies with current

legislation.

Check that the power supply cable is efficient and that it

complies with national and European safety standards.

The user must undertake to power the machine protecting the

power line using a suitable safety switch (cut-out) that complies

with the legislation in force in the actual country itself.

Connect the power cable (1) to the electric line using a plug,

or in the case of fixed installation, using a multi-polar switch

(D) for mains separation, with a contact distance of at least 3

mm.

For voltage change refer to the diagram shown on the general

mains switch box.

The yellow-green coloured cable MUST be connected to the

room’s earthing system.

IMPORTANT

Before connecting to the water mains, assemble the one-

way valve (valvola di non ritorno), indicated in the dia-

gram, as follows:

Unscrew the nut, remove boiler filling valve pipe and insert

the one-way valve with the gasket towards the boiler valve

body. Reattach pipe, tighten the nut and connect to the

water mains.

English

8

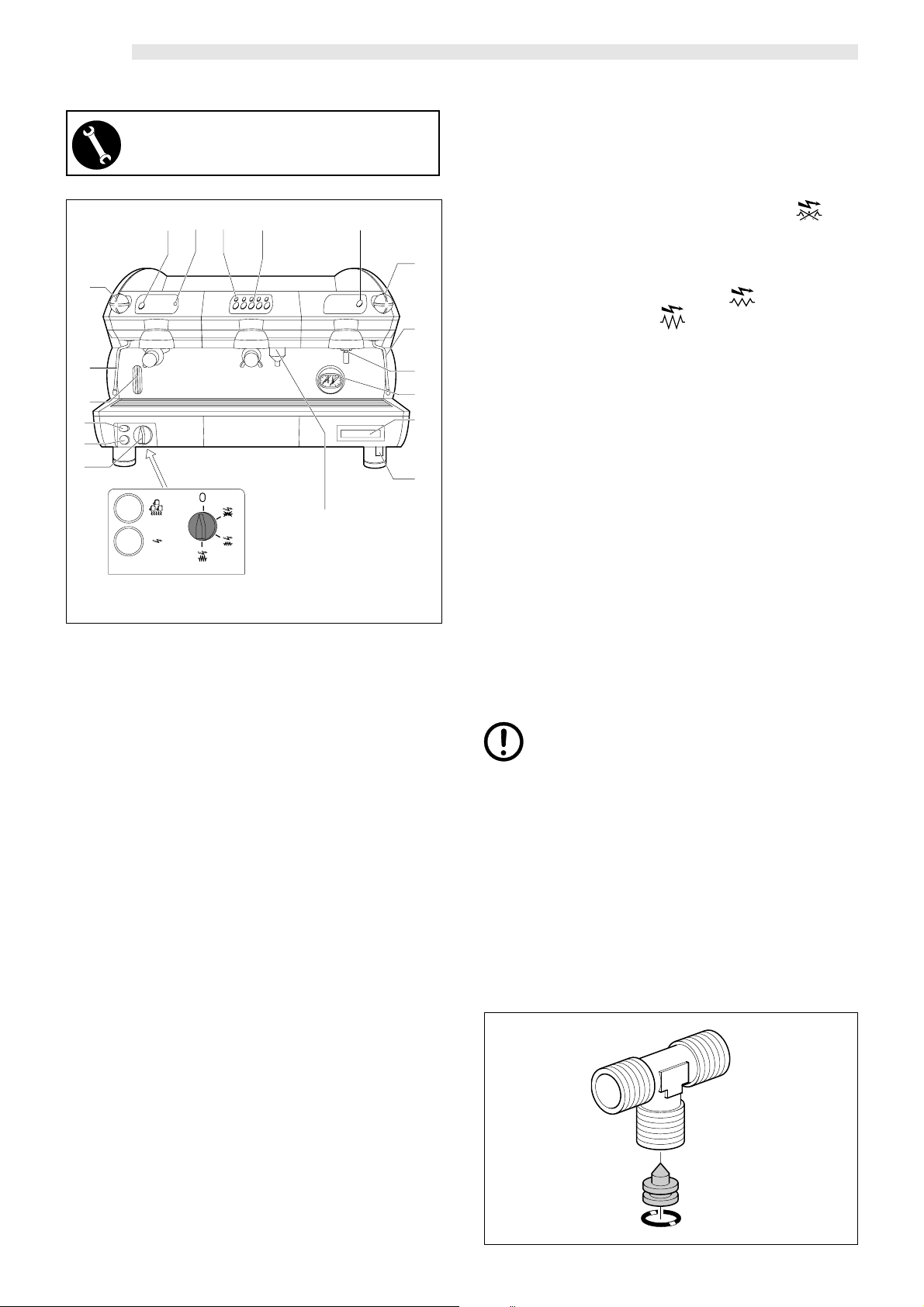

fig. 4

6.1 Long coffee gigleur

The machine is fitted with a gigleur ( 1 per unit) with a

clearance of 0.6 mm (Cod. WGA26G0074/01).

For greater coffee delivery speed, in the case of long coffees,

no.2 gigleurs are also included with the machine (complete

with seals) with a clearance of 0.8 mm (Cod.

WGA26G0073/01). The gigleur is located in the

exchanger supply fitting (1 per group).

6 - START UP

Once the water, gas and electrical connections have been

made, proceed to start up the machine.

Open the mains water supply tap (A) (fig 2).

Close the protection switch (D) (fig 2).

Position the machine main switch (8) to position the

machine on indicator will come on (3).

The auto-levelling device will come into operation so that

the water reaches a normal level in the boiler (12).

Position the main switch (6) to position for operation at

normal power or to position for operation at full power,

thereby powering the resistances.

Wait for the pressure to reach its operational pressure

1.11.3 atm checking the boiler pressure on the gauge

(10).

Should the machine fail to stabilize on the indicated values

it is necessary to calibrate the pressure switch as described

in paragraph 6.2.

In the event of a machine featuring a gas heating system, it

is necessary to switch on the gas by operating the gas valve

(4) after operating the main switch (6), keeping the

piezoelectric switch pressed (5) until the gas remains on.

Then check the pressure on the pump gauge (10) putting a

unit into operation with filter holder engaged filled with

ground, dosed and pressed coffee in order to achieve an

effective working pressure of 8/9 atm.

Should re-calibration of the pump pressure be necessary

this operation should be undertaken as indicated in

paragraph 6.3.

The machine is now ready for use.

1. Loading boiler tap

2. hot water outlet button

3. hot water outlet switch

4. E delivery indicator

5. D delivery led

6. main switch

7. right vaporiser tap

8. left vaporiser tap

9. cup-warmer switch

10. boiler/pump pressure gauge

11. cappuccino maker

12. boiler level indicator

13. left vaporiser tap

14. right vaporiser tap

15. hot water outlet pipe

16. Unit D control keyboard

17. unit E control keyboard

18. optional dose-counter display

IMPORTANT:

Do not press the hot water delivery switch or button

(2) before the correct working temperature of 1.1

atm is reached, as indicated on the boiler gauge

(10).

fig. 3

12

9

3

6

13

8

17

16

2

7

14

1

18

10

15

11

15

3

4

5

English

9

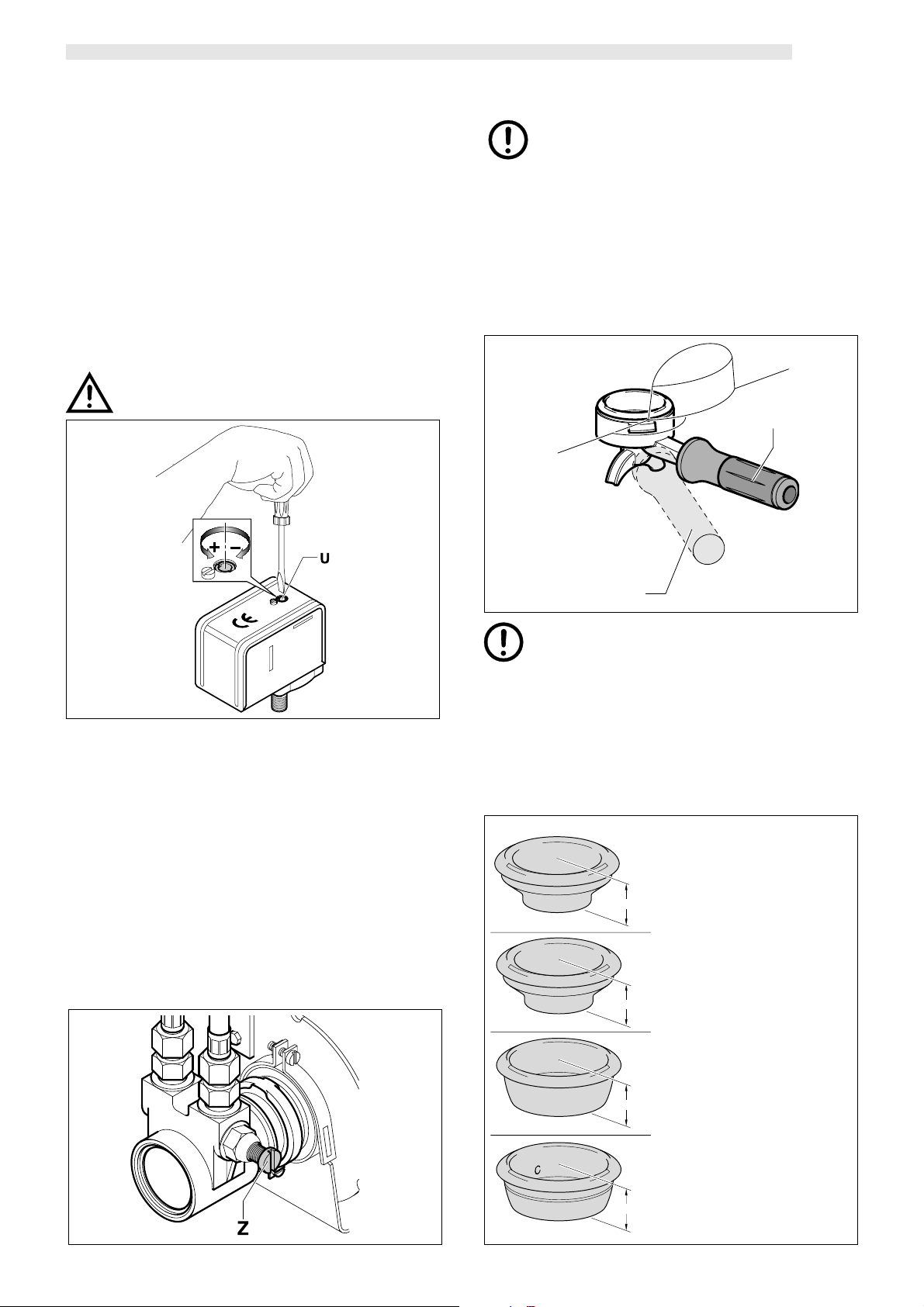

6.2 Pressure switch adjustment

The pressure switch shown in the figure acts to keep the

boiler pressure constant by engaging or de-activating the

electrical heating resistance.

This pressure switch is already calibrated to 1.1-1.3 bar

during the initial machine testing stage, but should a different

working pressure be required, it is possible to vary the

operational field of the pressure switch using the regulation

screw (U); pressure reduction results in a reduction in tempe-

rature, whilst increasing the pressure will also increase the

water temperature. The regulation direction is shown in the

figure and on the pressure switch itself. The pressure varies

by 0.1 atm for every complete screw turn.

Warning: Disconnect the electricity supply before

undertaking this operation.

fig. 5

fig. 6

fig. 7

6.3 Pump pressure calibration

Insert the filter holder into the unit filled with regularly ground,

dosed and pressed coffee.

Switch on the unit switch (AROMA SM) or the unit control

keyboard (AROMA SE) (16) and read the pressure on the

pump pressure gauge (10).

NB: The correct pressure is of 8-9 atm.

Should the pressure indicated on the pressure gauge be

incorrect, turn it clockwise to increase the pump pressure

and anti-clockwise to reduce the pressure.

Once adjustment is complete check pump calibration by

delivering one or more coffees.

Z= Pump pressure adjustment screw.

Warning !!

When the machine is new the filter-holder sump may

not be aligned (perpendicular to the machine itself)

as shown in the figure at the side, however this does

not effect the efficient function of the same.

After a short period of use the sump will gradually

settle into a correct position.

A = Position of closed filter-holder with new machine.

B = Position of closed filter holder with machine after a

short period of use.

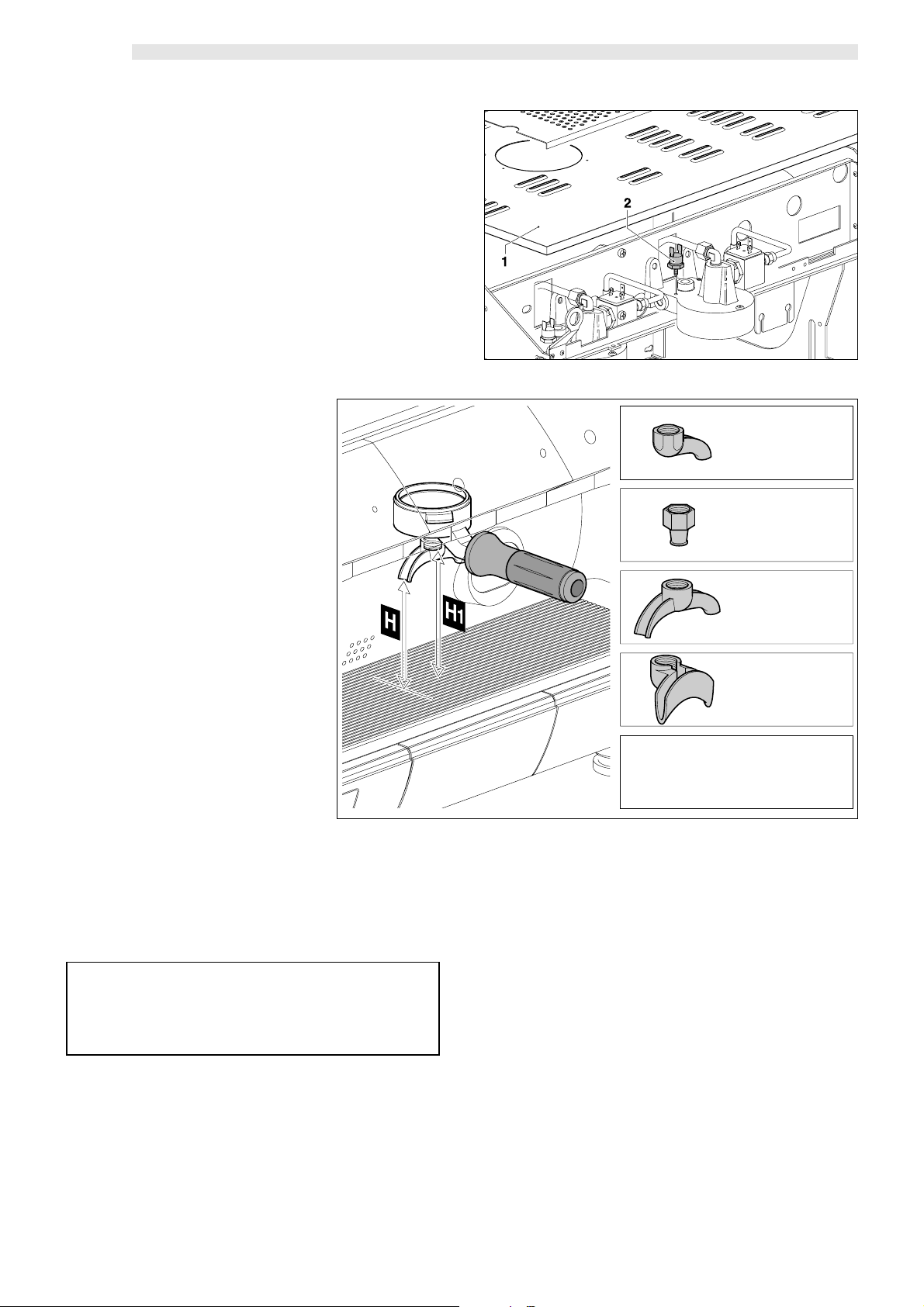

6.4 Filters for coffee machine

Depending on the quantity of coffee ground, the appropriate

filter must be used as shown below to avoid that, once the

coffee has dripped out, the leftover powder remains attached

to the nozzle.

IMPORTANT: N°2 under-tile packings with are thinner

(8.1mm ) than that fitted as standard are included. These

packings may be used in the event of difficulty with inser-

tion of the filter holder.

20 mm

24,5 mm

24,5 mm

21 mm

WGANF08/002/B

1 Coffee cup of 5,5 gr. ÷ 6,6 gr.

Pod for 1 coffee

Barley pod for 1 dose

WGANF08/004/B

1 Coffee cup of 6 gr. ÷ 7 gr.

WGANF08/005/B

2 Coffee cup of 12 gr. ÷ 14 gr.

WGANF08/009/B

Double pod for 2 coffees

The filter may be recognised by the

letter “C” printed inside.

.

A

B

English

10

7. FUNCTION / USE AND

PROGRAMMING

INTRODUCTION

The programming software permits the checking of the

following operations:

- handling of 2-3-4 coffee units

- simultaneous function of both coffee and tea units

- cappuccino/milk function

- volumetric check on coffee measures

- timed tea measure check

- simulated measure programming

- filling level check and control

6.5 Replacement of the thermostat to

reduce the coffee dispensing

group temperature.

Remove cup heating bowl (1). Disconnect group thermostat

(2) (Code WGADM1561 – T 103°C) and replace it with

the lower temperature thermostat (Code WGADM1736 –

T 98°C), included in the machine equipment.

- system supervision through alarms

- continuos, delivery time-out and further functions

- serial connection with accounting devices

- 16 X 2 LCD display (not rear-lit) for functional state display.

Important: the last selection made always appears on the

display

6.6 Spouts included in

the supply.

No. 4 spouts are supplied with the

machine to dispense one or two coffees.

The figure (beside) shows the different

distances from the cup-holding tray (H),

depending on the different types of spouts

fitted on the filter holder.

Cod. WGAAS0146/CL

H = 85 mm

Cod. WGA26G0112

H = 95 mm

Cod. WGA6301004010

H = 100 mm

Cod. WGA6001023000

H = 92 mm

H1 = 120 mm

WITHOUT SPOUTS

English

11

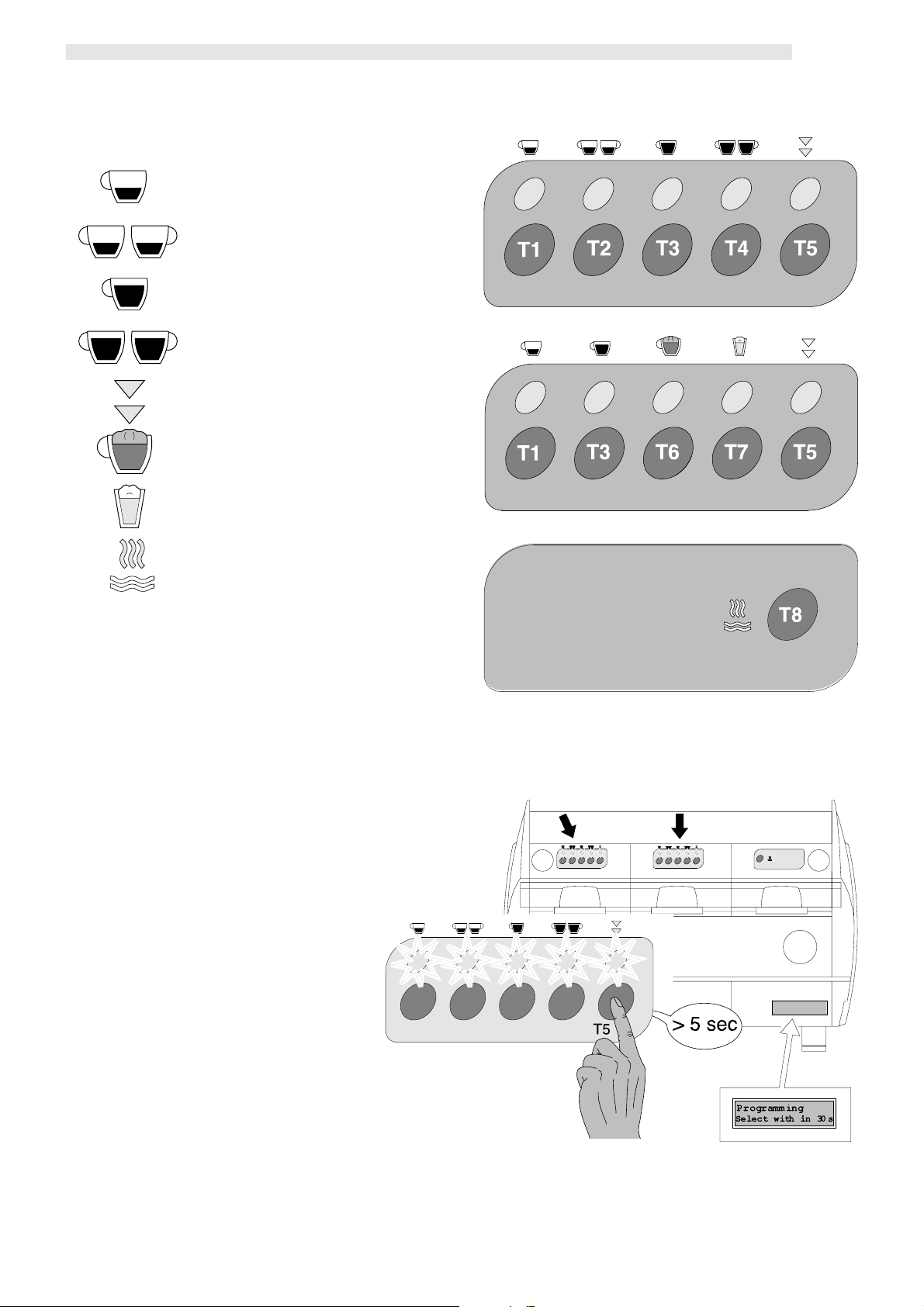

7.1 Coffee measure

programming

T1 – single espresso coffee

T2 – double espresso coffee

T3 – single long coffee

T4 – double long coffee

T5 – Programming/continuos

T6 – Cappuccino

T7 – Milk

T8 – Tea (hot water)

The measured amounts of coffee may be

modified (by means of volumetric checking) and

memorized as follows:

- press key T5 (of keyboard relative to group

1) and keep pressed for over 5 seconds and

check that all the keyboard leds come on. In

which case, (by operating on the keyboard

relative to group 1) all the units will be

programmed, while by pressing key T5 of

another unit, only the programming of the

unit on which one is operating is possible.

IMPORTANT !! The settings made on unit 1

(operating on the first keyboard) will be

automatically copied on to all the other units.

Loading...

Loading...