Pfaff hobbylock 794, hobbylock 796 User Manual [nl]

Notes on safety

A)Due to the up and down movement of the needle, the user must take sufficient care to avoid injury and observe the sewing area continuously while sewing.

B)When leaving the machine,

changing parts or accessories, the machine must be disconnected from the power source.

C)The maximum approved wattage of the light bulb is 15 watts.

D)The drive belt must never be adjusted by anyone but an authorized Pfaff agent.

Contents |

|

|

|

|

|

|

|

|

|

||

The controls |

of the sewing |

machine |

|

||||||||

Accessory |

box |

|

|

|

|

|

|

|

|||

Electrical |

connection |

|

|

|

|

||||||

Foot control |

|

|

|

|

|

|

|

|

|||

Preparing |

for |

threading |

|

|

|

seam |

|||||

Threading, 4-thread |

double-overedge |

||||||||||

Threading |

right looper |

|

|

|

|

||||||

Threading |

left |

looper |

|

|

|

|

|||||

Threading the |

needles |

|

|

|

|

||||||

Inserting |

the |

lint |

box |

|

|

|

|

||||

Sewing |

test |

|

|

|

|

|

|

|

|

||

Points |

to |

observe during |

sewing |

|

|||||||

Securing |

the |

seam |

|

thread tension |

|||||||

Checking |

and |

adjusting |

|||||||||

3-thread |

overedge seam |

|

|

|

|

||||||

Thread chart |

|

|

|

|

|

on 794 |

|

||||

Adjusting |

the |

stitch |

length |

|

|||||||

Adjusting |

the |

stitch |

length |

on |

796 |

|

|||||

Adjusting |

the |

differential |

feed |

on 796 |

|

||||||

Regulating the |

sewing foot |

pressure |

|

||||||||

Adjusting |

the |

seam |

width |

|

|

|

|||||

Changing |

the sewing feet |

|

|

|

|||||||

Sewing rolled |

hems |

|

|

|

|

|

|||||

Changing |

needles |

|

|

|

|

|

|||||

Changing |

lower |

knife |

|

|

|

|

|||||

Changing |

upper |

knife |

|

|

|

|

|||||

Changing |

light |

bulb |

|

|

|

|

|

||||

Cleaning |

|

the |

thread |

tensions |

|

|

|||||

Oiling the |

machine |

|

|

|

|

|

|||||

Sewing problems and solutions |

|

||||||||||

Accessories |

|

|

|

|

|

|

|

|

|||

Specifications |

|

|

|

|

|

|

|

||||

2, |

3 |

|

4 |

4, |

5 |

|

5 |

6, |

7 |

7—11 |

|

|

8 |

|

9 |

|

10 |

|

11 |

|

12 |

|

13 |

|

14 |

15, |

16 |

|

17 |

|

18 |

|

18 |

|

19 |

20,21 |

|

|

18 |

|

22 |

|

23 |

24, |

25 |

|

26 |

26, |

27 |

|

28 |

|

29 |

|

29 |

|

30 |

|

31 |

|

32 |

|

32 |

C,’

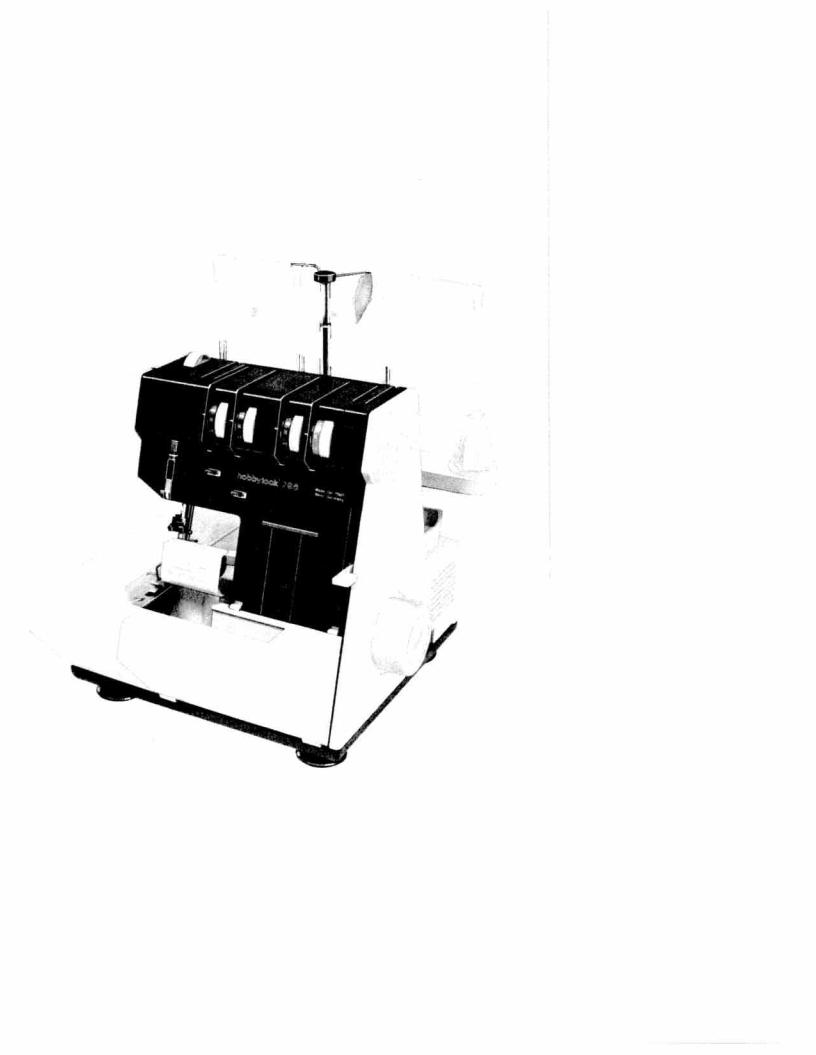

Controls of the sewing machine

1 Foot pressure regulating dial

2Thread guide

3Carrying handle

4Left needle thread tension dial

5Right needle thread tension dial

6Right looper thread tension dial

7Left looper thread tension dial

cover

11Presser foot lifter lever

12Hand wheel and feed regulator

13Looper cover

14Looper cover lever

15Work support

16Stitch length setting key on 794 Differential feed setting on 796

17Needle plate

18Presser foot

19Needle bar

20Thread reel stand

21Thread reel pins

22Adjusting knob

23Machine plug socket

24Master switch

25Lint box

26Foot control

27Foot control plug

28Mains plug

29Lower knife

30Knife clamp screw

31Right looper

32Left looper

33 Thread guide bar

_______________________________________

28

/// 2

-- /

26 ‘N

27

9 |

31 |

32

30

if 29

I

Accessory |

box |

|

|

Swing the work |

support to |

the |

|

pull out the |

accessory box. |

|

|

left

and

To |

replace |

the accessory |

box, slide |

it |

|

into |

the grooves and push |

|

it until it |

|

|

locks. The |

accessories are |

illustrated |

|||

page 32. |

|

|

|

|

|

on

Electrical connection |

|

|

Use this |

machine only |

on a flat |

or on a |

special sewing |

table. |

surface

Attaching

the

toot

control:

Insert the

machine

plug plug

of the socket.

control into the Then connect the

mains

plug

to

a

power

source.

Caution:

When

the

machine

is

not

in

use, disconnect |

plug |

source. Do not |

place |

from |

power |

any |

objects |

on

the

foot

control.

Switching

the

machine

ON

and

OFF

Power and sewing |

light are |

||

and off |

simultaneously |

with |

|

Switch |

|

||

|

|

|

|

switched |

on |

|

|

||

the |

master |

|

SWitching |

on: |

|

|

|

|

|

|

||

|

|

. |

|

|

and |

sewing |

|||

Press switch |

|

Machine |

|||||||

are |

|

|

|

. |

|

|

|

|

|

switched |

|

on |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

Switching |

off: |

. |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

and |

|

Press switch |

|

again |

Machine |

||||||

sewing light |

are switched |

|

. |

|

|||||

off |

|

||||||||

light

Foot |

Control |

The speed of the HObbyIo

regula as follows:

is

When press,g |

the |

foot Control |

gently |

|||||||

the |

|

|

will |

run at |

low |

|

. |

when |

||

machine |

Speed |

|||||||||

|

|

|

it |

will |

run |

|

. |

|

||

Pressing |

harder |

|

|

|

||||||

|

faster |

|

||||||||

Electronic |

foot |

control |

|

|

|||

Maximum |

speed is adjusted |

||

5grad by the switch |

on the |

||

Pos,ho,, |

= |

Half |

Speed |

Posillon 4 = |

Full |

speed |

|

|

|||

in two

foot control

JL_L_LjjJ

j

L

Preparing |

for |

threading |

|

|

|

|

|

||||

Adjustment |

of |

thread |

reel |

stand: |

|

|

|

||||

Loosen |

the |

adjusting |

knob on the |

|

and |

||||||

thread |

reel |

|

stand, |

slide it |

to the left |

||||||

tighten |

it. |

|

|

|

|

|

|

|

|

|

|

Adjustment |

of |

the |

thread |

guides: |

align |

it |

|||||

Pull up |

the |

|

thread |

guide |

bar |

and |

|||||

so that |

the |

|

thread guides are |

directly |

|

||||||

above the |

reel |

stand. |

|

|

|

|

|

|

|||

N \

zr’

Carrying handle and |

thread |

guide bar |

|||

|

|

|

|||

behind it: |

|

|

|

|

|

Insert fingers into the groove of |

the |

||||

carrying handle and |

pull |

it |

up. |

This |

|

movement automatically |

raises |

|

the |

||

thread guide bar |

|

|

|

|

|

Opening and closing looper cover and work support

Push looper cover lever to the right, swing cover in the direction of the arrow and lower it.

To close the looper cover, push the cover until it locks.

To open the work support, push it to the left. To close the work support, push it to the right until it locks.

A threading diagram is affixed to the machine (A).

Threading procedure

Threading must be done correctly to obtain a well-formed seam. Thread the machine in the following sequence:

1.Right looper (red)

2.Left looper (orange)

3.Right needle (green)

4.Left needle (blue)

Diagram B shows threading of the thread guides behind the carrying handle.

Diagram C shows threading of the thread tension.

Now pull the respective thread into the corresponding guides and tension discs.

7

-pea

aqnop

e6paJaAo

was

Jo bU1MeS |

pu 6uiqsui |

OMI |

||

|

||||

Duqe |

|

:iedooi |

||

6uipeaiqj |

eq q6ii |

|||

|

|

|||

SeAej

LO

pEeJqJ

eq

q6i

iedooi

ut

eouenbes

o ()

o |

pu jjnd AIeew!xoJddE .oi wo |

|

pEeJig 6noJ1B g.ei iadooj eAs |

||

to |

eip,)

peiqi

qed

si

pajiew

(pai

Threading the left looper:

Insert the left looper thread in sequence 1 to 10 and pull approximately 10 cm

(4) of thread through the looper eye (the thread path is marked orange).

0

Loading...

Loading...