Pfaff hobbylock 4870 User Manual [nl]

I

PFAFF

hobbylock

4870

Instruction

manual

For

easier

understanding

of

this

instruction

manual

please

fold

this

or

the

last

page

out

when

reading.

Safety

rules

For

the

United

Kingdom

only

The

leads

must

under

no

circumstances

be

connected

to

the

safety-lead

terminal

I

nor

to

a

plug

with

three

pins.

The

wires

in

the

mains

lead

are

coloured

according

to

the

following

code:

Blue:

Neutral

Brown:

Live

As

the

colours

of

the

wires

in

the

mains

lead

of

this

appliance

may

not

correspond

to

the

colour

coding

of

the

terminals

in

your

plug.

proceed

as

follows:

The

wire

which

is

coloured

blue

must

be

con

nected

to

the

terminal

which

is

marked

with

the

lettter

N

or

coloured

black.

The

wire

which

is

coloured

brown

must

be

connected

to

the

terminal

which

is

marked

with

the

letter

L

or

coloured

red.

Under

no

circumstances

should

cut-off

mains

plugs

be

used.

They

should

be

disposed

of

immediately.

Defective

mains

leads

must

be

completetly

replaced.

Only

3

A

spare

fuses

must

be

used

as

appro

ved

by

ASTA

according

to

BS

1362

and

the

fuse

cover

must

be

marked

3

A

or

with

the

corresponding

colour

code.

The

plug

must

never

be

used

without

fuse

covers.

Spare

fuse

covers

are

available

from

electrical

suppliers

or

the

PFAFF

agencies.

Please

also

observe

the

general

safety

notes

on

page

2.

ZfindZntsonPae4an>

r

1

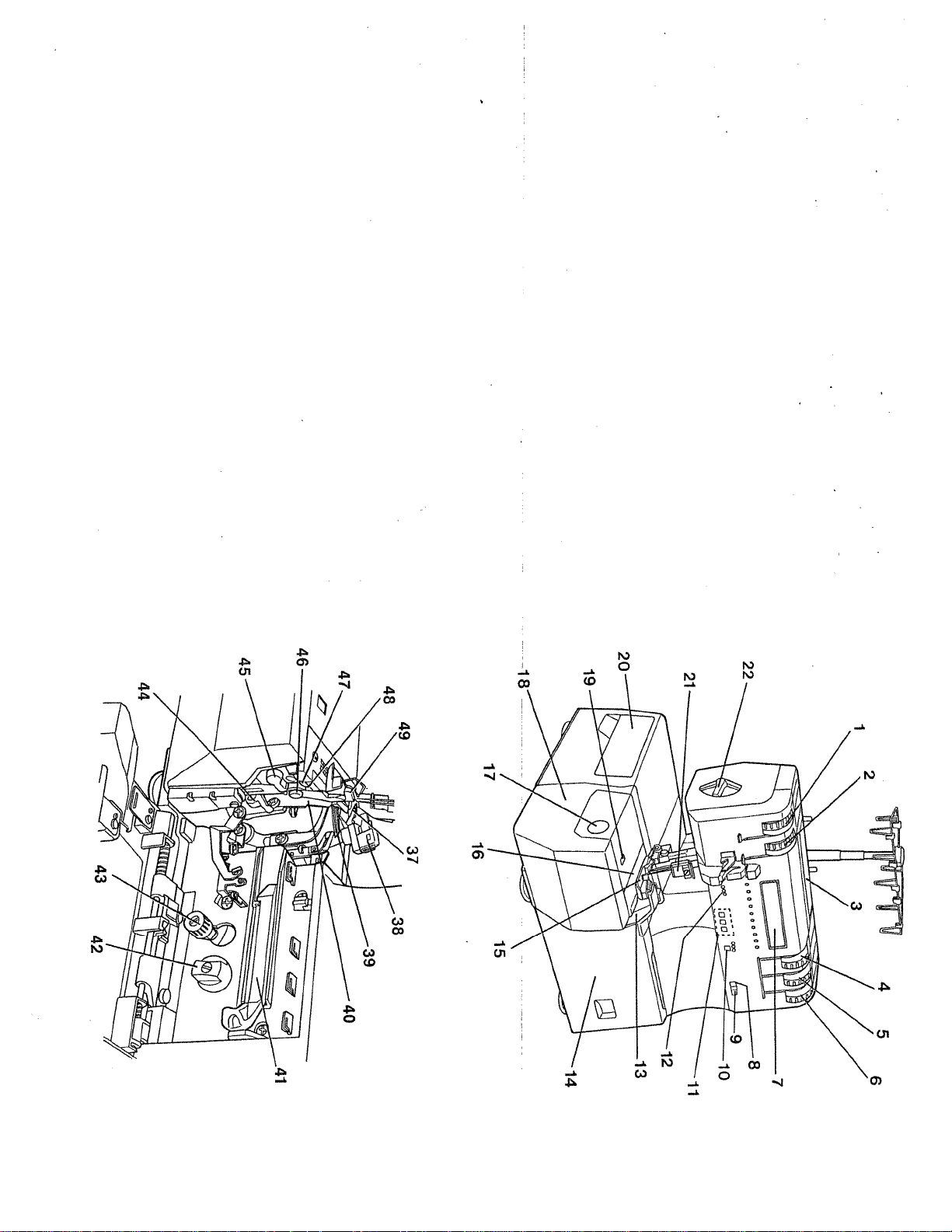

Parts

of

the

hobbylock

4870

(1)

Upper

thread

tension

—

left

(2)

Upper

thread

tension

—

right

(3)

Handle

to

carry

(4)

Looper

thread

tension

—

right

(5)

Looper

thread

tension

—

left

(6)

Looper

thread

tension

for

chainstitch

(7)

Display

(8)

Window

for

the

stitch

length

(9)

Window

for

the

differential

feed

(1

0)

Key

for

speed

selection

(11)

Program

key—left

Cursor

key

—

middle

Mod

key

(right)

(1

2)

LED

needle

display

A,B,C

(13)

Knife

guard

(14)

Looper

cover

(1

5)

Sewing

foot

(combination

foot)

(16)

Needle

plate

(17)

Adjusting

knob for

seam

width

(1

8)

Detachable

work

support

(1

9)

Window

for

the

seam

width

(20)

Accessories

box

(21)

Needle

holder

(22)

Lever

for

the

sewing

foot

pressure

(37)

Right

overedge

looper

(38)

Converter

(39)

Left

overedge

looper

(40)

Chainstitch

looper

(41)

Automatic

looper

threader

for

the

left

looper

(42)

Knob

to

disengage

upper

knife

(43)

Knob

to

disengage

the

right

overedge

looper

(44)

Positioning

lever

for

the

chainstitch

looper

(45)

Lever

to

disengage

needle

plate

(46)

Screw

to

secure

upper

knife

(47)

Screw

to

secure

lower

knife

(48)

Lower

knife

(49)

Upper

knife

A.

Important

safety

instructions

For

the

United

States

only

‘

This

sewing

machine

is

designed

and

manufactured

for

HOUSEHOLD

use

only.

When

you

use

an

electric

appliance,

the

following

basic

safety

precautions

should

always

be

adhered

to:

Read

all

instructions

before

using

this

sewing

machine.

DANGER

To

reduce

the

risk

of

electric

shock:

1.

The

sewing

machine

should

never

be

left

unattended

when

plugged

in.

Always

unplug

this

appliance

from

the

electric

outlet

immediately

after

using

and before

cleaning.

2.

Always

unplug

before relamping.

Replace

bulb

with

same

type

rated

1

5

Watts.

3.

Do

not

reach

for

a

sewing

machine

that

has

fallen

into

water.

Unplug

immediately.

4.

Do

not

place

or

store

a

sewing

machine

where

it

can

fall

or

be

pulled

into

a

tub

or

sink.

Do

not

place

in

or

drop

into

water

or

other

liquid.

WARNING

To

reduce

the

risk

of

burns,

fire,

electric

shock,

or

injury

to

persons:

1.

Do

not

allow

to

be

used

as

a

toy.

Great

care

is

necessary

when

this sewing machine

is

used

by

or

near

children.

2.

Only

use

this

sewing

machine

for

its

intended

purpose

as

described

in

this

manual.

Only

use

attachments

recommended

by

the

manufacturer

as

contained

in

this

manual.

3.

Never

operate

this

sewing

machine

if

it

has

a

damaged

cord

or

plug,

if

it

is

not

working

pro

perly,

if

it

has

been dropped

or

damaged,

or

dropped

into

water.

Return

the

appliance

to

the

nearest

authorized

dealer

or

service

center

for

examination,

repair,

electrical

or

mechanical

adjustment.

4. Never

operate the

sewing

machine

with

any

air

openings

blocked.

Keep

ventilation

openings

of

the

sewing machine

and

foot

control

free

from

the

accumulation

of

lint,

dust,

and

loose

cloth.

5.

Never

drop

or insert anything

into

any

opening.

6.

Do

not

use

out

of

doors.

7.

Do

not

operate

where

aerosol

(spray)

products

are being

used

or

where

oxygen

is

being

administered.

8.

To

disconnect,

turn

all

controls to

off

(,,O”)

position,

then

remove

plug

from

socket.

9.

Never

operate

on

a

soft

surface such as

a

bed

or

couch

where

the

air

openings

may be

blocked.

10.

Do

not

unplug

by

pulling

on

cord.

To

unplug,

hold

the

plug,

not

the

cord.

11.

Keep

fingers

away from

all

moving

parts.

Special

care

is

required

around

the

sewing

machine

needle.

12.

Always

use

the

proper

needle

plate.

The

wrong plate

can

cause

the

needle

to break.

1

3:fYonot

use

bent

or

blunt

rm&tles.

Only

use

needles

recommended

by

the

manufacturer.

14.

Do

not

pull

or

push

fabric

while

stitching.

It

may

deflect

the

needle,

causing

it

to

break.

1

5.

Switch

the

sewing machine

off

(NO”)

when

making

any

adjustments

in

the

needle

area,

such

as

threading

needle, changing needle,

threading

bobbin,

or

changing

presser

foot,

etc.

16.

Always

unplug

sewing

machine

from

the

electric

outlet

when

removing

covers,

lubricating,

or

when

making

any

other user

servicing

adjustments

mentioned

in

the

instruction manual.

1

7.

Hold

plug

when

rewinding

into

cord

reel.

Do

not

allow

plug

to whip

when

rewinding.

Please

also

observe

the

general

safety

notes

on

page

2.

KEEP

THESE

INSTRUCTiONS

IN

A

SAFE

PLACE

—

Notes

on

safety

Notes

on

safety

for

domestic

sewing

machines

according

to

DIN

57

700,

Section

28

or

IEC

335, Section

28.

1.

The

user

must

exercise

adequate

caution

with

regard

to

the

up

and

down

move

ment

of

the

needle

and

keep

the

sewing

area

under

constant

observation

while

working.

2.

When

leaving

the

machine,

during

maintenance

work

or

when

changing

mechanical

parts

or

accessories,

always

disconnect

the

machine

from

the

mains

by

pulling

out

the

mains

plug.

3.

Ihe

maxim

“n

permissible

wattage

for

the

sewing

lamp

is

5

Watts.

4.

TI,?

tension

of

the

drive

belt

should

only

be

idjusted

by

a

Pfaff

mechanic.

5.

Th

‘-3c[..ie

should

be

put

into

operation

as

i.

iicated

on

the

specification plate.

6.

Do

r..

place

any

objects

in

openings

on

the

machine.

7.

Do

not

use

the

sewing

machine

if:

—

there

is

visible

damage,

—

its

function

is

defective,

—

it is

wet,

e.g. with

condensation.

8.

Do

not

pull

the

mains

plug

out

of

the

socket

by

its

cord.

9.

If

this

appliance

is

used

for

another

pur

pose than

that

intended

or

if

it

is

wrongly

operated,

we

cannot

accept

any

liability

for

any

damage

caused.

10.

To

avoid

the

risk

of

electric

shock,

do

not

open

the

machine.

There

are

no

parts

inside

the

machine

which

the user

can

repair.

This

the

exclusive

responsibility

of

our

qualified

service

staff.

11.

Be

sure

to

use

only original

PFAFF

parts.

Environment

The

recommended

environment

is:

Ambient

temperature

1000

C

to

40°

C

Humidity

20%

to

80%

This

sewing

machine

is

a

high-quality

elec

tro-mechanical

appliance;

it

is

a

machine

for

supervised

use

in

the

home.

It

should

be

operated

in

such

a

way

that

it

is

not

exposed

to:

dust,

severe

dampness,

direct

sunlight,

static

elec

tricity,

heat-producing objects,

corro

sive

chemicals

or

liquids.

To

permit

adequate

ventilation

the

machine

must

be

kept

unblocked

and

used

on

a

firm

and

even

surface.

Treatment

Always

make

sure

not

to

damage

your

machine

by

knocking

or

dropping

it.

Cleaning

—

Housing

and

display:

To

clean

the

housing,

use

a

dry,

clean

and

soft

cloth

which

is

free

of fluff.

To

remove

any

stubborn

dirt,

use

a

soft

cloth

with

alcohol

or paraffin.

Please

Note!

Never

use

insecticides

or

che

mical

products

such

as

petrol

(gas)

or

thin

chemicals

to

clean

the

housing.

2

Simple,

up-to-date

sewing

Congratulations!

You

have

bought

a

high-quality

product

that

provides

unique

advantages.

Your

new

hobbylock

4870

can

take

any

material

in

its

stride

and

will

sew,

trim

and

neaten

up

for

you

in

one

operation.

Your

PFAFF

hobbylock

features

the

very

latest

in

design

and

technology,

and

it

is

just

as

easy

to

use

as

this

instruction

manual

is

to

follow.

If

you

now

take

a

bit

of

time

to

study

the

instruction

manual

nothing

can

go

amiss.

It

is

certainly

time

well

spent,

since

it

is

the

only

way

to

find

out

just

what

your

machine

can

do

and

put

it

to

full

use.

If

you

have

any

further

questions

just

ask

your

PFAFF

dealer.

He

is

happy

to

be

of

service

with

any

help

or

advice.

So

now

let’s

get

started!

We

wish

you

many

enjoy

able

hours

creating

your

very

own

fashion

ideas.

3

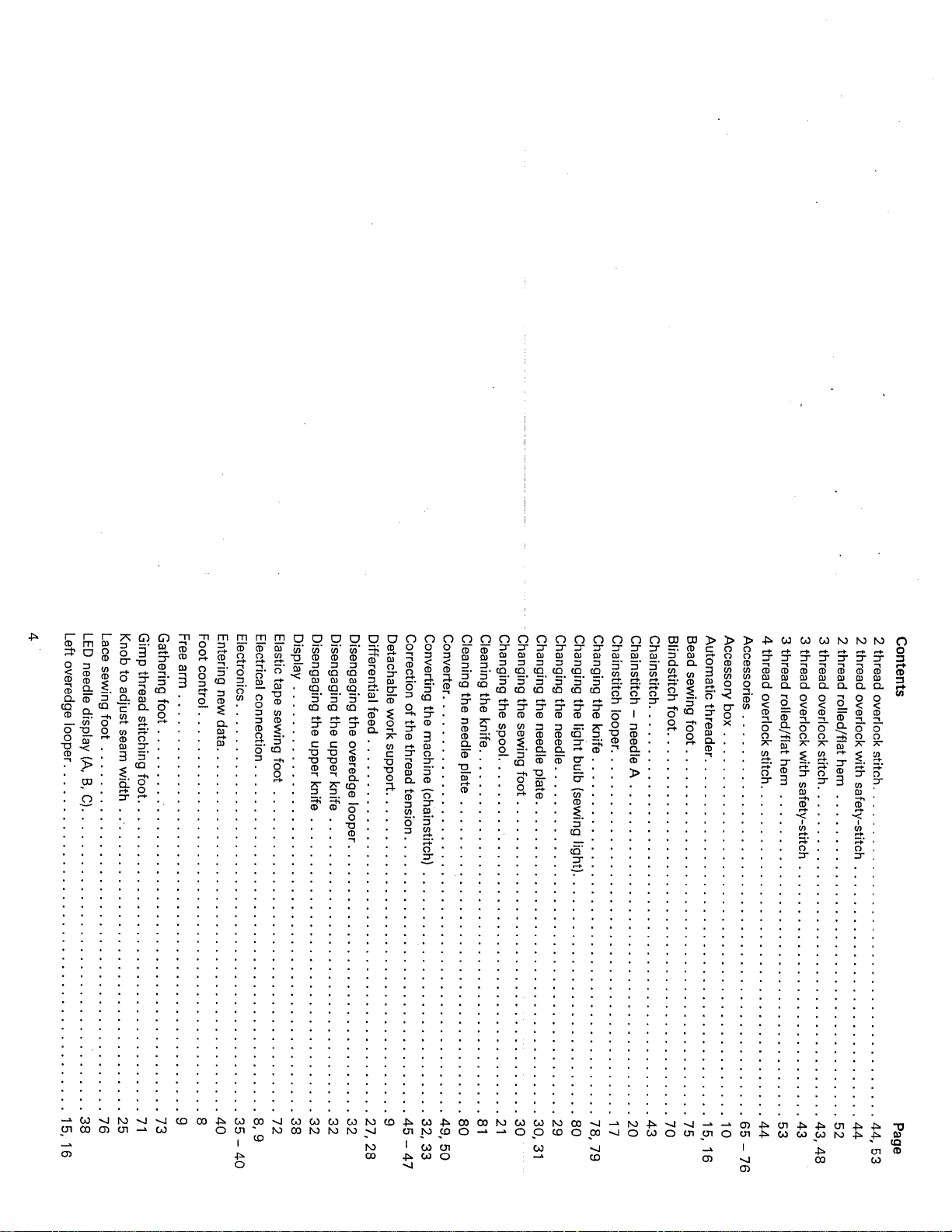

Contents

2

thread

overlook

stitch...........

2

thread

overlock

with

safety-stitch

.

-

2

thread

rolled/flat

hem

3

thread

overlook

stitch

3

thread

overlook

with

safety-stitch

3

thread

rolled/flat

hem

4

thread

overlock

stitch

Accessories

Accessory

box

Automatic

threader

Bead

sewing

foot

Blindstitch

foot

Chainstitch

Chainstitch

—

needle

A

Chainstitch

looper

Changing

the

knife

Changing

the

light

bulb

(sewing

light).

Changin9

the

needle

Changing

the

needle

plate

Changing

the

sewing

foot

Changing

the

spool

Cleaning

the

knife

Cleaning

the

needle

plate

Converter

Converting

the

machine

(chainstitch)

Correction

of

the

thread

tension

Detachable

work

support

Differential

feed

Disengaging

the

overedge

looper.

Disengaging

the

upper

knife

Disengaging

the

upper

knife

Display

Elastic

tape

sewing

foot

Electrical

connection

Electronics

Entering

new

data

Foot

control

Free

arm

Gathering

foot

Gimp

thread

stitching

foot

Knob

to

adjust

seam

width

Lace

sewing

foot

LED

needle

display

(A,

B,

C)

Left

overedge

looper

Page

44,53

44

52

43,48

43

53

44

65—76

10

15,16

75

70

43

20

17

78,79

80

29

30,31

30

21

81

80

49,50

32,33

45-47

9

27,28

32

32

32

38

72

8,9

35—40

40

8

9

73

71

25

76

38

15,16

4

Spool

net.

67

5

Looper

cover

1

2

Lower

knife

.

79

Main

switch

9

Maintenance

and malfunction

77

—

83

Material

guide

plate

33

Needle

plates

N

and

R

53

Needle

threader

1

9

Normal

accessories

66,

67

Oiling

81

Overedge

needles

20,

21

Practical

sewing

41

—

55

Problems

when

sewing

82

—

83

Program

chart

56

—

63

Programming

language

36

Right

overedge

looper

14

Rolled

hem

52,

53

Safety

instructions

1

Securing

the

seam

14

Setting the

programs

39

Sewing

foot

chart

68

Sewing

foot

lever

22

Sewing foot

pressure

34

Sewing

test

23

Special

accessories

68

—

76

Specifications

84

Speed

pre-selection

37

Spool

disc

67

Spool

stands

1

1

Standard

thread

tension

42

Stitch

length

adjusting

knob

26

Taping

foot

69

Technical

part

7

—

3

Thread

charts

54,

55

Thread

cutter

24

Thread

unreeling

disc

67

Threading

the

looper

14

—

18

Threading

the

needles

20,

21

Threading

the

thread

guides

1

3

Upper

knife

78

Upper

knife

lock

34

Waste

box

1

2

—

*

Technical

part

Electrical

connection

Detachable

work

support

Accessory

box

Spool

stands

Waste

box

/

looper

cover

Threading

the

thread

guides

and

the

looper

Threader

Threading

the

needles

Sewing

foot

lever

Sewing

test

/

thread

cutter

Seam

width

adjusting

knob

Stitch

length

adjusting

knob

Differential

feed

Changing

the

needle,

sewing

foot

and

needle

plate

Converting

the

machine

for

chainstitch

seam

Fixing

the

upper

knife

/sewing

foot

pressure

page

8,

9

page

9

page

10

page

11

page

12

page

13—18

page

19

page

20,

21

page

22

page

23,

24

page

25

page 26

page

26

—

28

page

29

—

31

page

32,

33

page

34

7

—...-n,-v--—

,,.,,

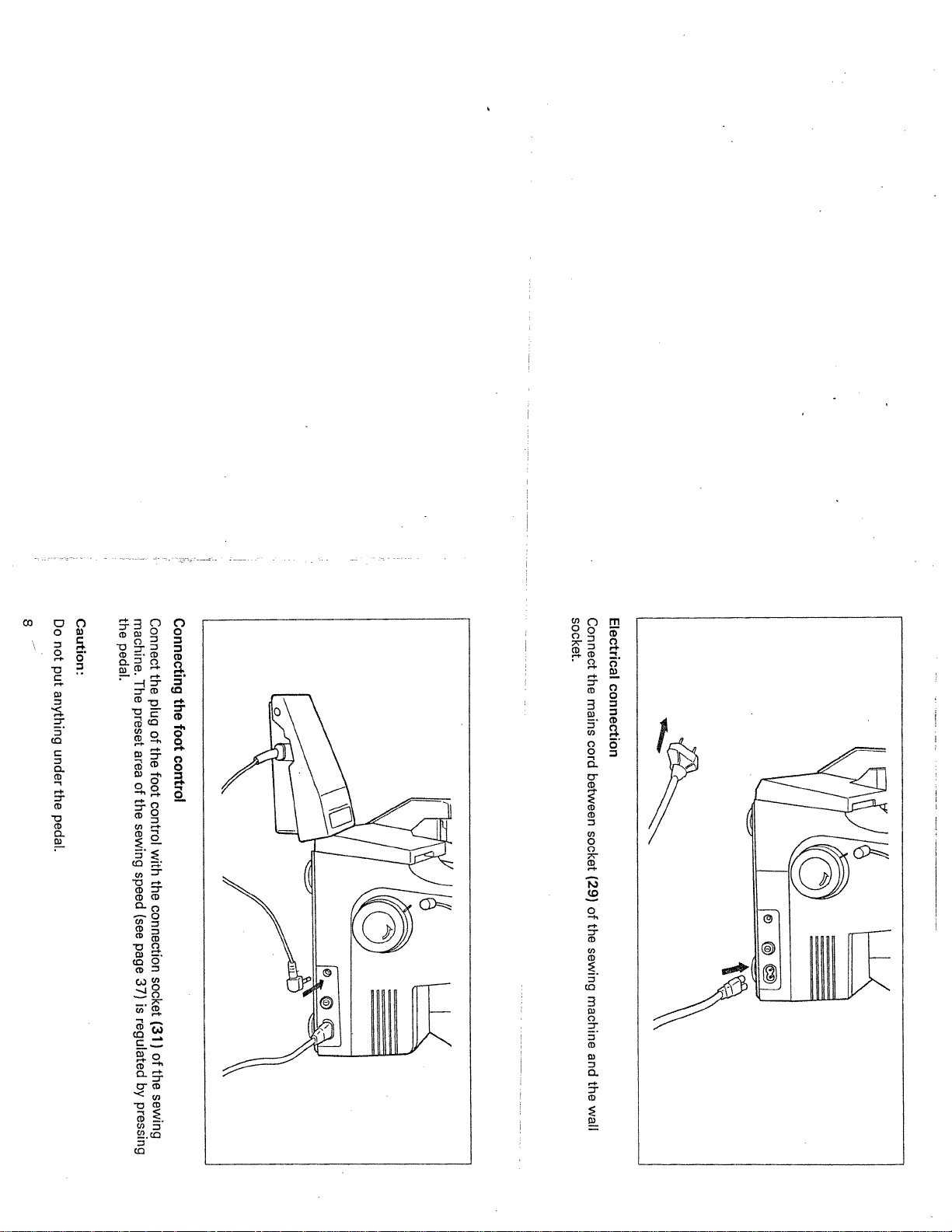

Electrical

connection

Connect

the

mains

cord

between

socket

(29)

of

the

sewing

machine

and

the

wall

socket.

Connecting

the

foot

control

Connect

the

plug

of

the

foot

control

with

the

connection

socket

(31)

of

the

sewing

machine.

The

preset

area

of

the

sewing

speed

(see

page

37)

is

regulated

by

pressing

the

pedal.

Caution:

Do

not

put

anything

under

the

pedal.

8

I

ri

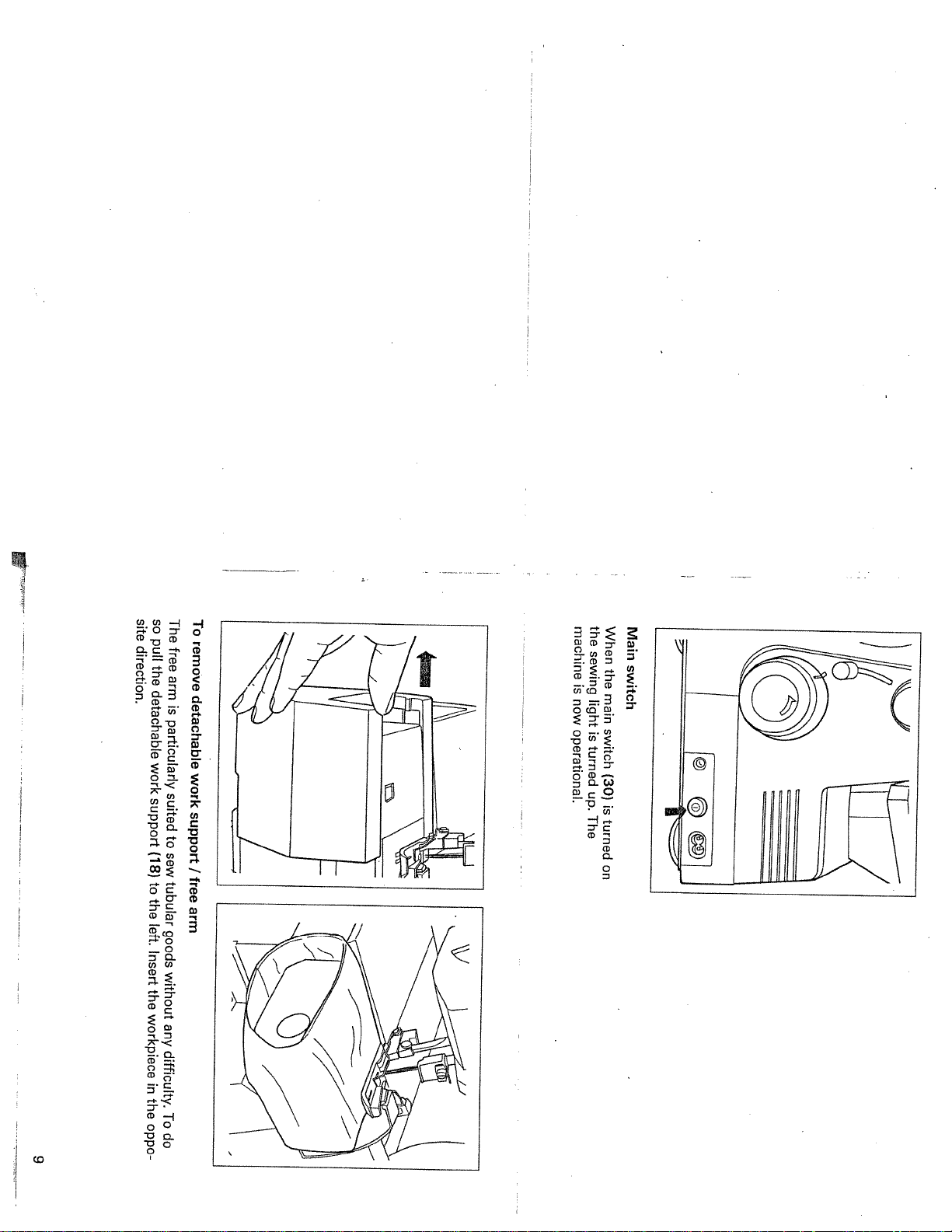

Main

switch

When

the

main

switch

(30)

is

turned

on

the

sewing

light

is

turned

up.

The

machine

is

now

operational.

To

remove

detachab’e

work

support

/

free

arm

The

free

arm

is

particularly

suited

to

sew

tubular

goods

without

any

difficulty.

To

do

so

pull

the

detachable

work

support

(18)

to

the

left.

Insert

the

workpiece

in

the

oppo

site

direction.

9

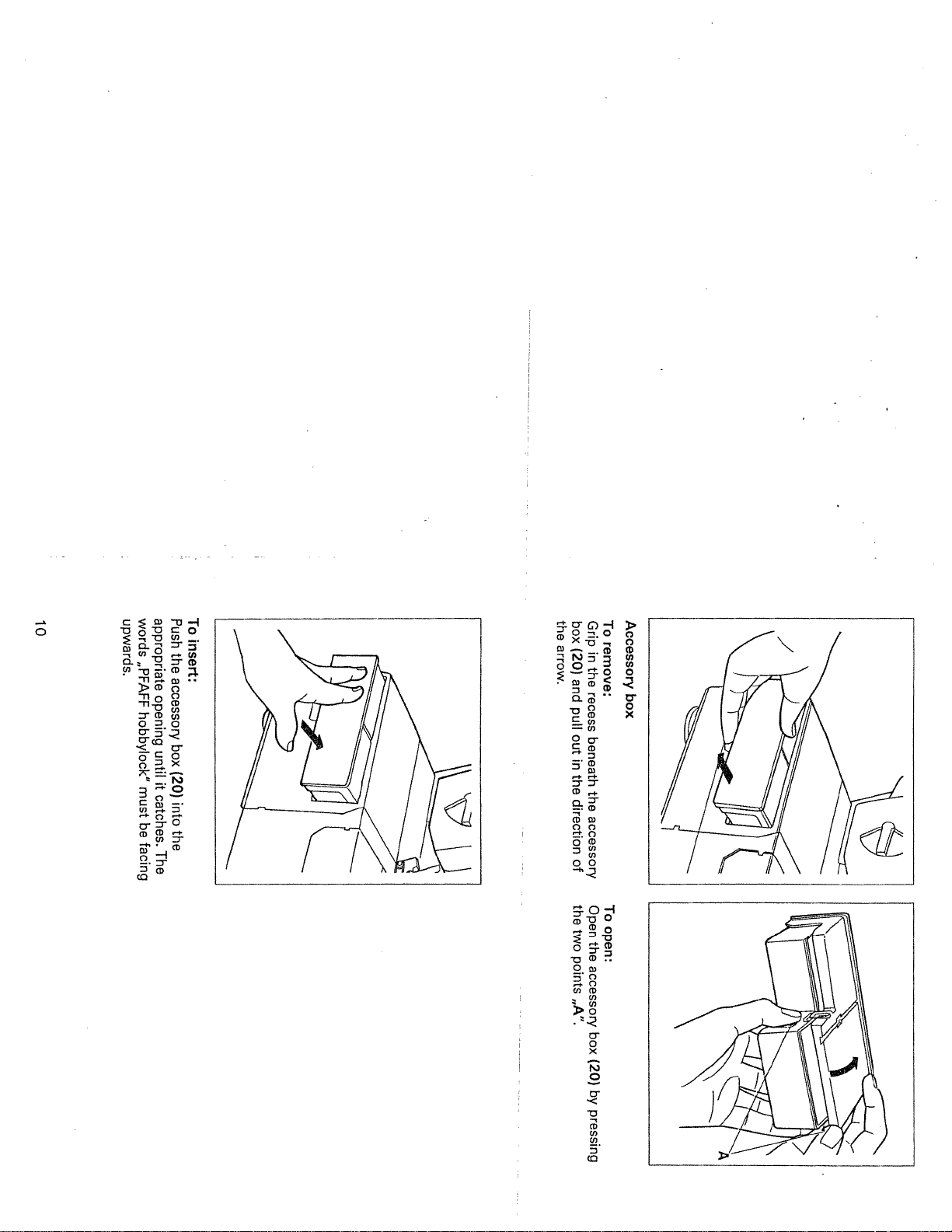

Accessory

box

To

remove:

To

open:

Grip

in

the

recess

beneath

the

accessory

Open

the

accessory

box

(20)

by

pressing

box

(20)

and

pull

out

in

the

direction

of

the

two

points

,,A”.

the

arrow.

To

insert:

Push

the

accessory

box

(20)

into

the

appropriate

opening

until

it

catches.

The

words

,PFAFF

hobbylock”

must

be

facing

upwards.

10

--

-,

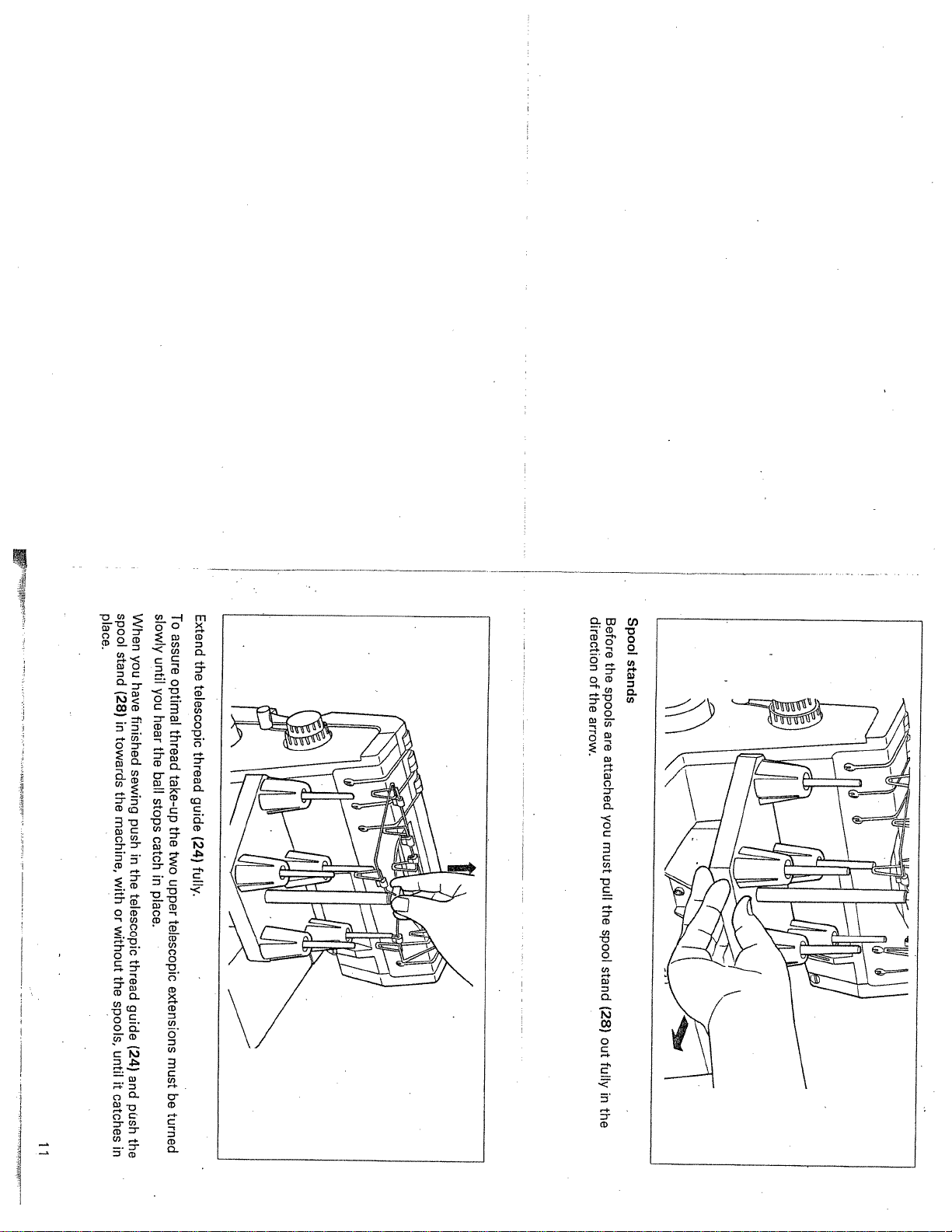

Spool

stands

Before

the

spools

are

attached

you

must

pull

the

spool

stand

(28)

out

fully

in

the

direction

of

the

arrow.

Extend

the

telescopic

thread

guide

(24)

fully.

To

assure

optimal

thread

take-up

the

two

upper

telescopic

extensions

must

be

turned

slowly

until

you

hear

the

ball

stops

catch

in

place.

When

you

have

finished

sewing

push

in

the

telescopic

thread

guide

(24)

and

push

the

spool

stand

(28)

in

towards

the

machine,

with

or

without

the

spools,

until

it

catches

in

place.

11

V

N

I

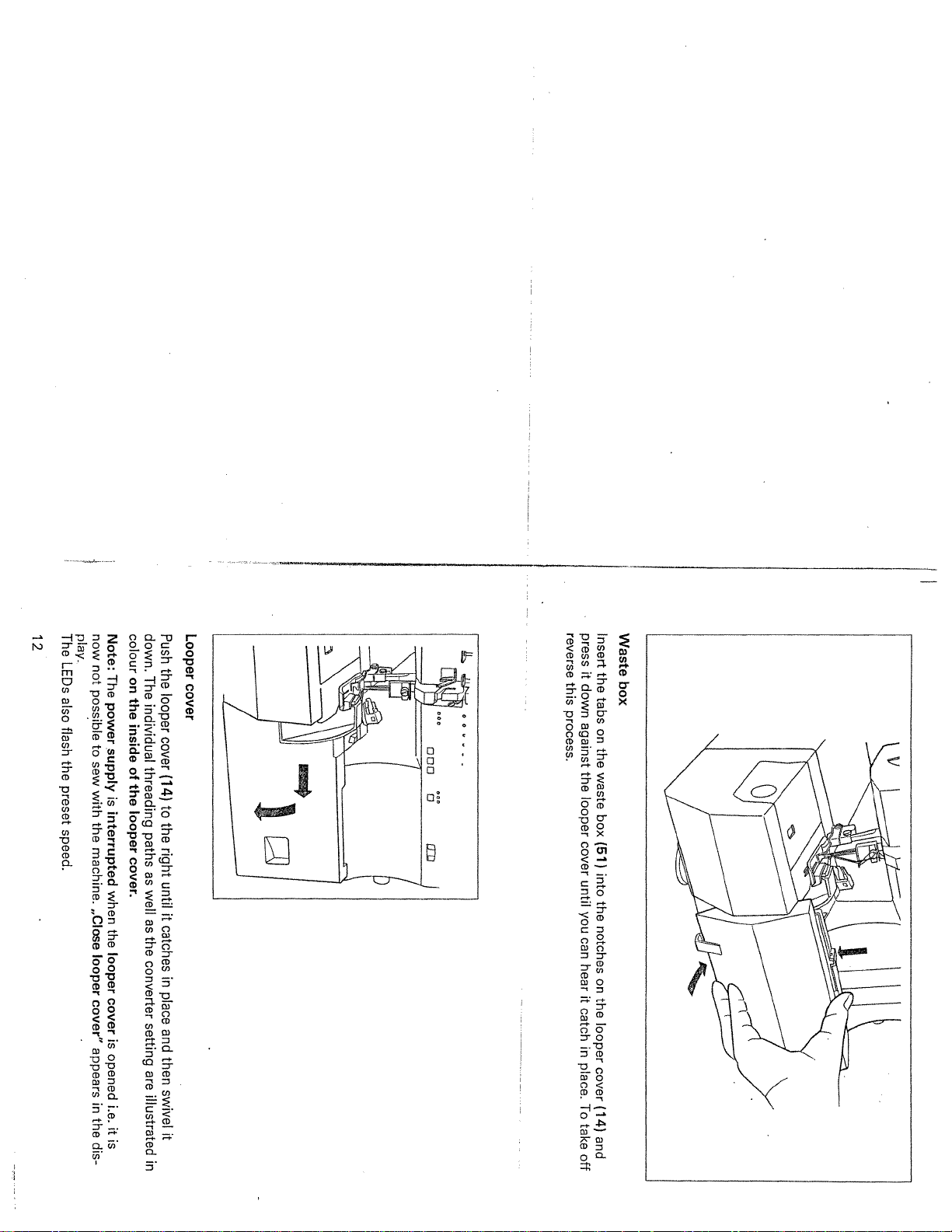

Waste

box

Insert

the

tabs

on

the

waste

box

(51)

into

the

notches

on

the looper

cover

(14)

and

press

it

down

against

the

looper

cover

until

you

can

hear

it

catch

in

place.

To

take

off

reverse

this

process.

ODD

C

0

Looper

cover

Push

the

looper

cover

(14)

to

the

right

until

it

catches

in

place

and

then

swivel

it

down.

The

individual

threading paths

as

well

as

the

converter

setting

are

illustrated

in

colour

on

the

inside

of

the

looper

cover.

Note:

The

power

supply

is

interrupted

when

the

looper

cover

is

opened

i.e.

it

is

now

not

possible

to

sew

with

the

machine.

,,Close

looper

cover” appears

in

the

dis

play.

The

LEDs

also

flash

the

preset

speed.

12

-

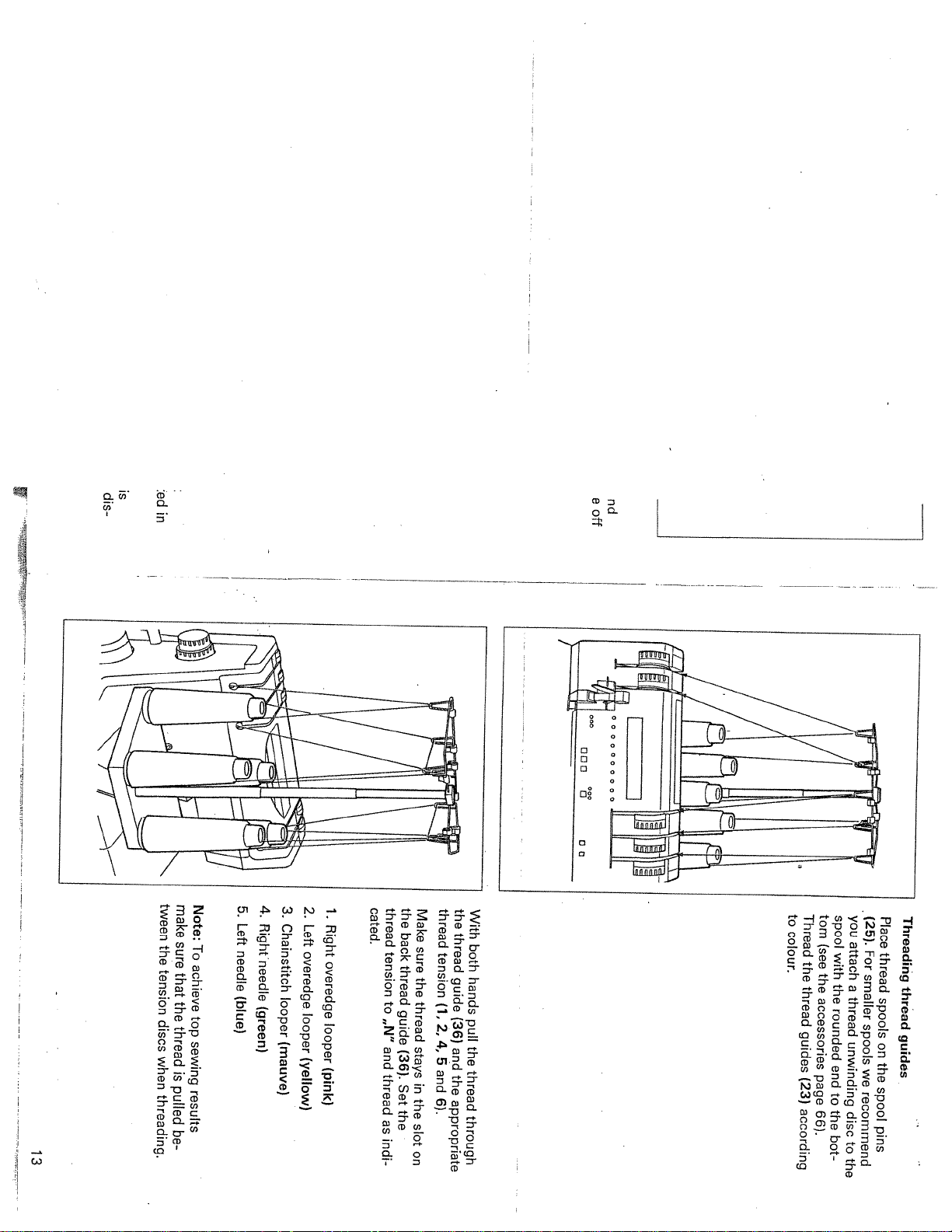

Threading

thread

guides

Place

thread

spools

on

the

spool

pins

(25).

For

smaller

spools

we

recommend

you

attach

a

thread

unwinding

disc

to

the

spool

with

the

rounded

end

to

the

bot

nd

accrding

e

off

ccc

ccc

000

0

00

With

both

hands

pull

the

thread

through

the

thread

guide

(36)

and

the

appropriate

thread

tension

(1,

2,

4,

5

and

6).

Make

sure

the

thread

stays

in

the

slot

on

the

back

thread

guide

(36).

Set

the

thread

tension

to

,,N”

and

thread

as

indi

cated.

1.

Right

overedge

looper

(pink)

2.

Left

overedge

looper

(yellow)

3.

Chainstitch

looper

(mauve)

4.

Right

needle

(green)

=

5.

Left

needle

(blue)

Note:

To

achieve

top

sewing

results

make

sure

that

the

thread

is

pulled

be

tween

the

tension

discs

when

threading.

:ed

n

is.

—

dis

13

-,---1

CD

.-CD

CD-I

CD

CD

CD

_.CD

CD(!)

a

CD

CDD

a

CDO

‘c

CD

÷

.

D

-‘

o

cc

a

_

Ot3

DCDCDOO<D

CDCD

o

-—ø

o

CD

CD

0

CD

CD

CD

—

O

0

CD

j

-

a

j

-.

CD

D

a

-1

CD

0

a

cc

CD

-I

CD

a

cc

0

CD

-I

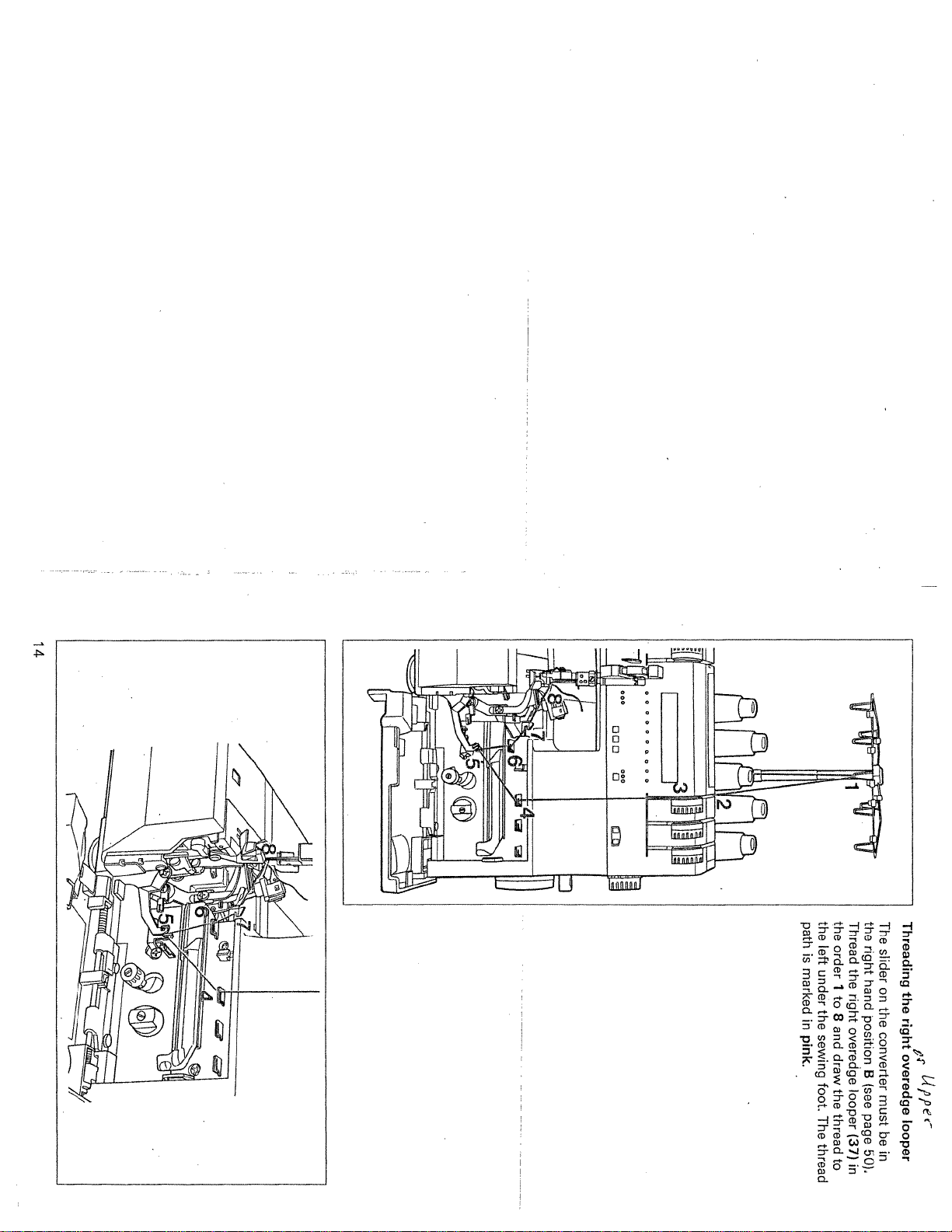

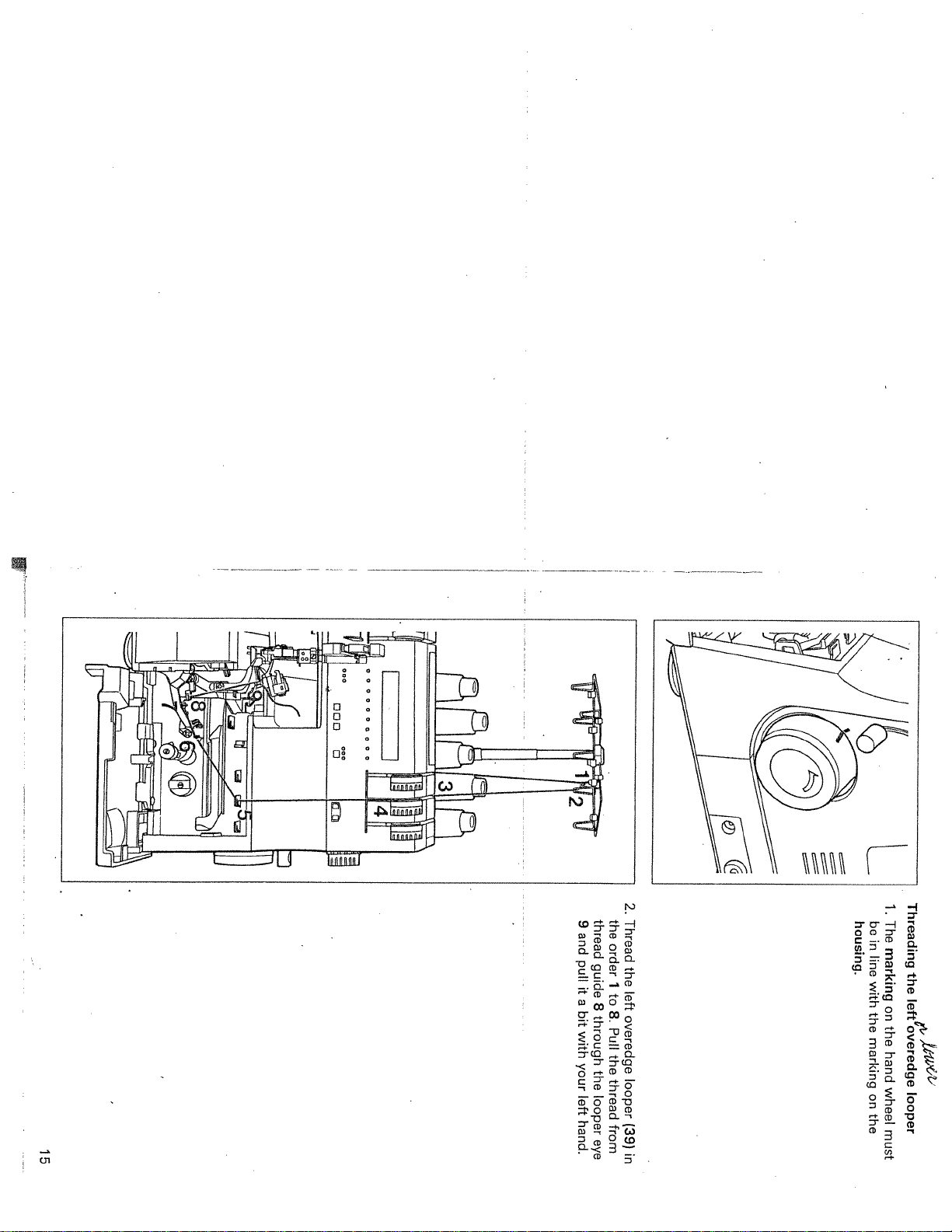

Threading

the

left

overedge

looper

1.

The

marking

on

the

hand

wheel

must

be

in

line

with

the

marking

on

the

hou&ng.

2.

Thread

the

left

overedge

looper

(39)

in

the

order

1

to

8.

Pull

the

thread

from

thread

guide

8

through

the

looper

eye

1

2

9

and

pull

it

a

bit

with

your

left

hand.

C

—

000

000

DOD

D

15

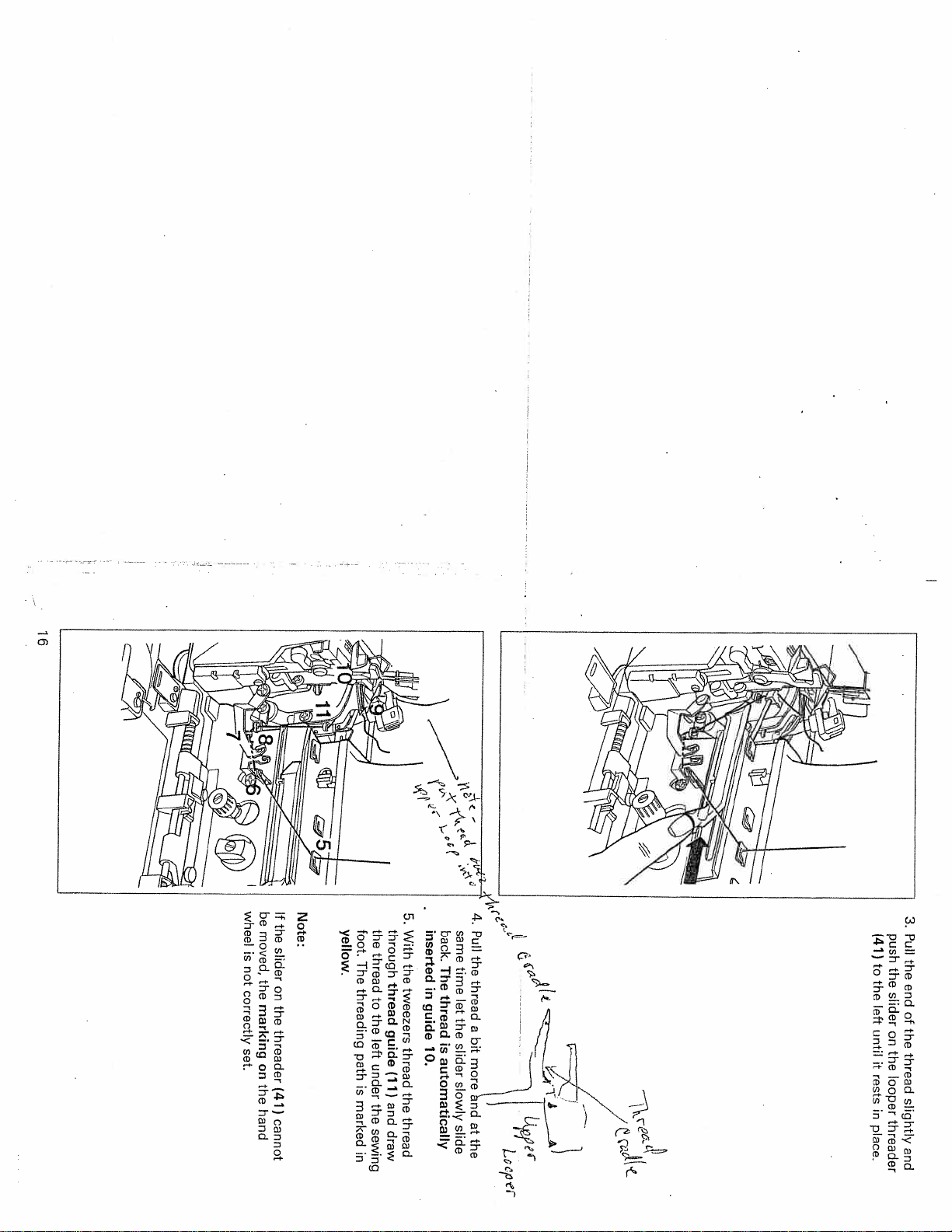

3.

Pull

the

end

of

the

thread

slightly

and

push

the

slider

on

the

looper

threader

(41)

to

the

left

until

it

rests

in

place.

çgtL

/

Q

4.

Pull

the

thread

a

bit

more

nd

at

the

same

time

let

the

slider

slowly

slide

back.

The

thread

is

automatically

inserted

in

guide

10.

5.

With

the

tweezers

thread

the

thread

through

thread

guide

(1

1)

and

draw

the

thread

to

the

left

under

the

sewing

foot.

The

threading

path

is

marked

in

yellow.

Note:

If

the

slider

on

the

threader

(41)

cannot

be

moved,

the

marking

on

the

hand

wheel

is

not

correctly

set.

N

,

11

7

0

16

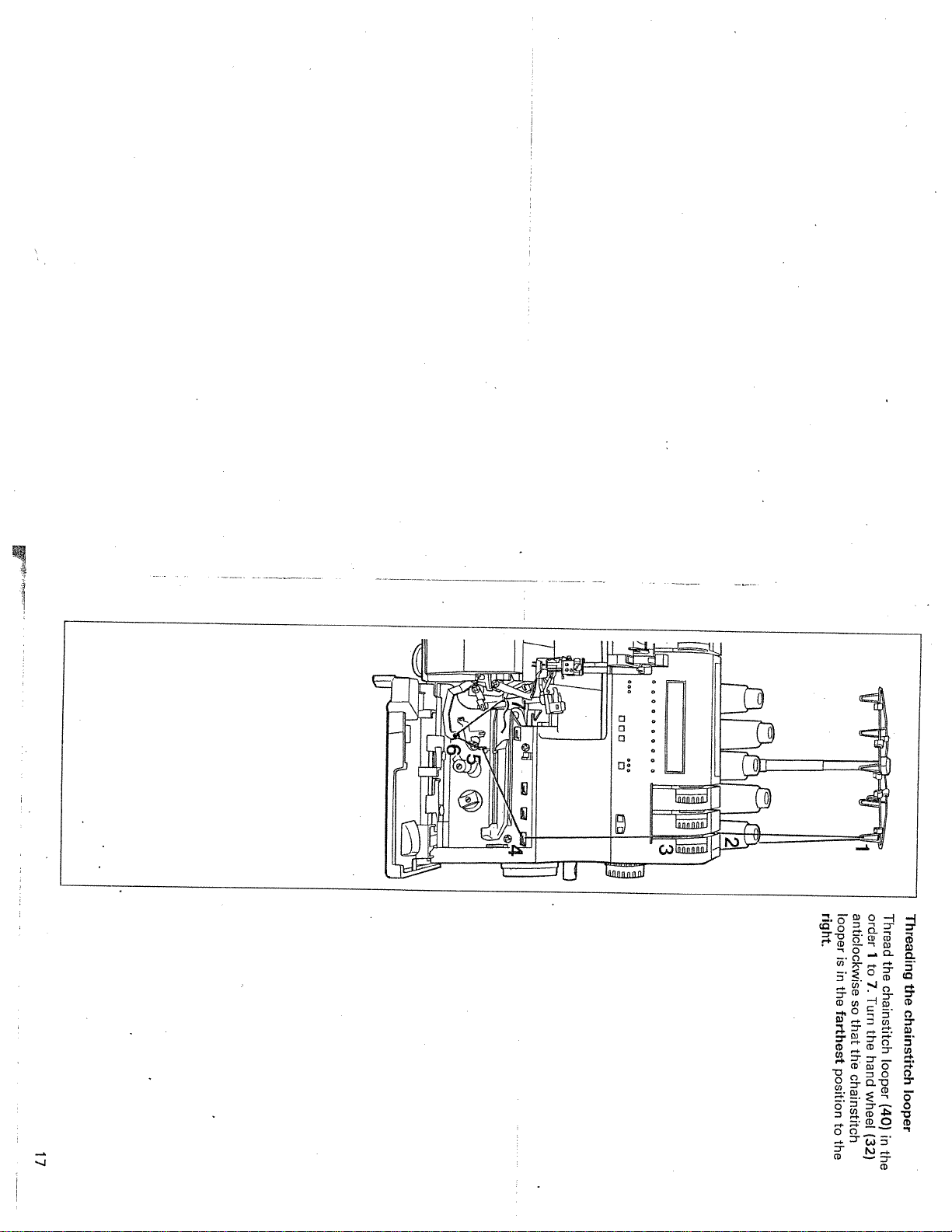

Threading

the

chainstitch

looper

ooper(4O)

in

the

looper

is

in

the

farthest

position

to

the

right.

Il

1

antiolockwjse

so

that

the

chainstitch

zz

ID

—

17

V

/

o

4

o

/

—

,

—

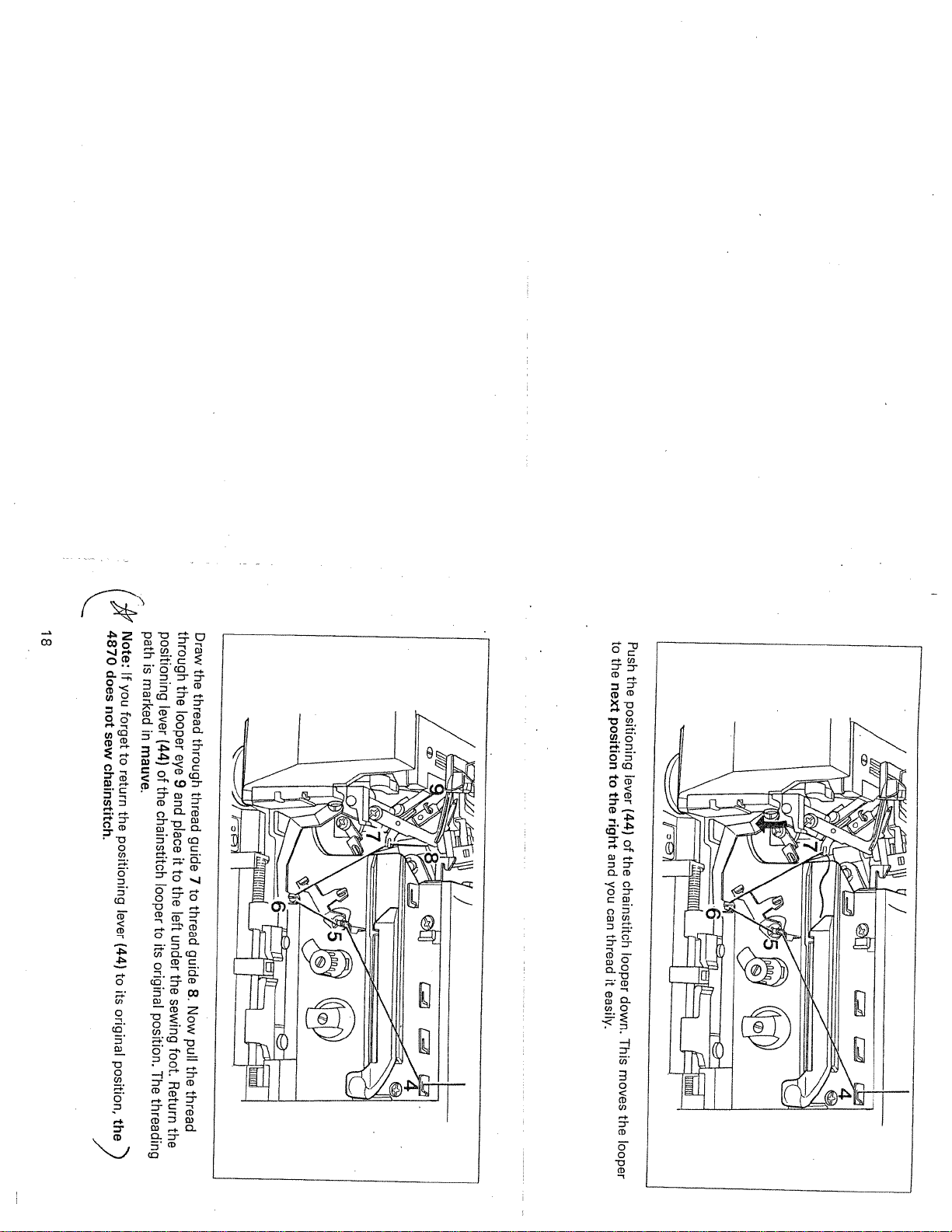

Push

the

positioning

lever

(44)

of

the

chainstitch

looper

down.

This

moves

the

looper

to

the

next

position

to

the

right

and

you

can

thread

it

easily.

I

8

0

V

6

—

Draw

the

thread

through

thread

guide

7

to

thread

guide

8.

Now

pull

the

thread

through

the

looper

eye

9

and

place

it

to

the

left

under

the

sewing

foot.

Return

the

positioning

lever

(44)

of

the

chainstitch

looper

to

its

original

position.

The

threading

,

path

is

marked

in

mauve.

/

Note:

If

you

forget

to

return

the

positioning

lever

(44)

to

its

original

position,

the

/1

4870

does

not

sew

chainstitch.

/

18

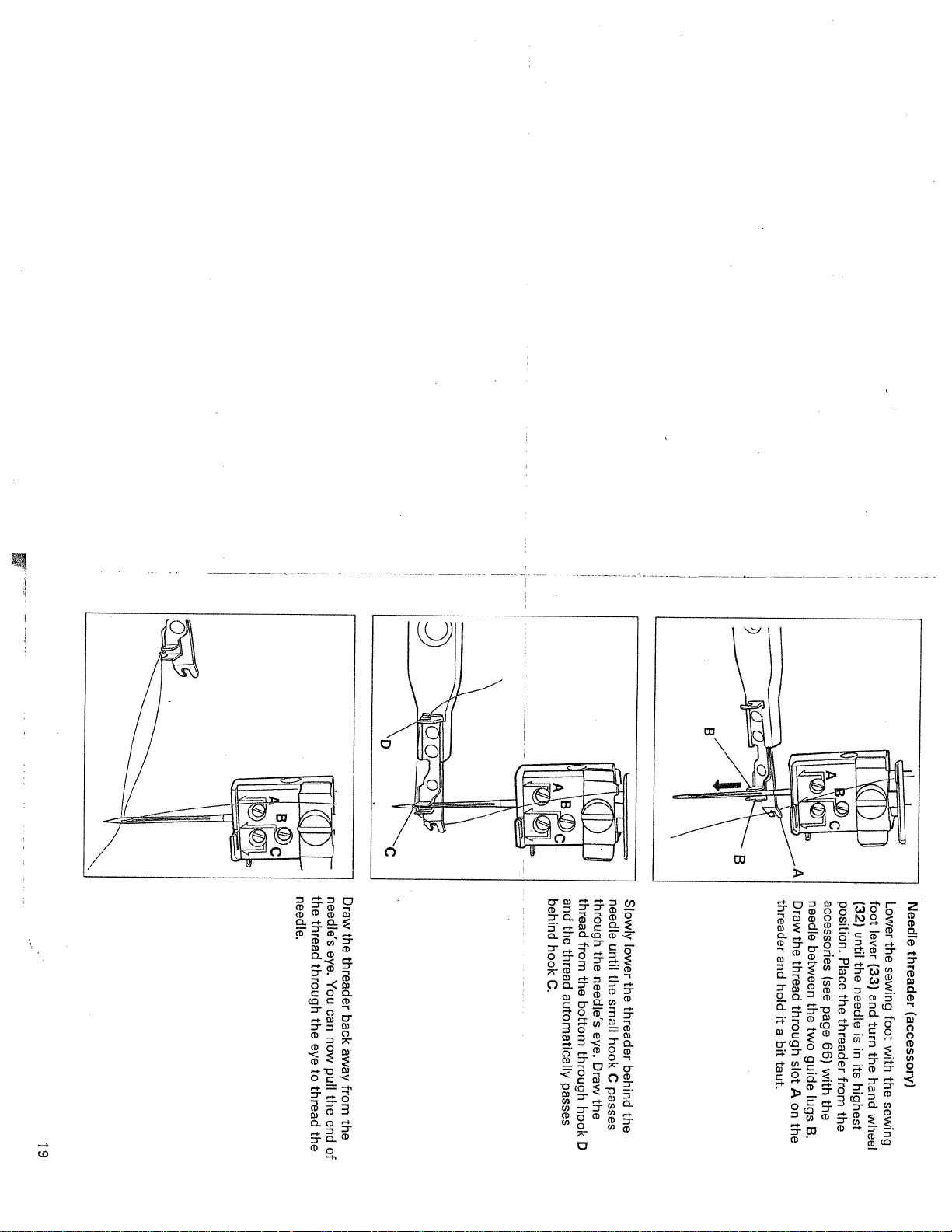

Needle

threader

(accessory)

Lower

the

sewing

foot

with

the

sewing

foot

lever

(33)

and

turn

the

hand

wheel

(32)

until

the

needle

is

in

its

highest

position.

Place

the

threader

from

the

A

C

accessories

(see

page

66)

with

the

‘42)

needle

between

the

two

guide

lugs

B.

A

Draw

the

thread

through

slot

A

on

the

threader

and

hold

it

a

bit

taut.

B

1

B

,

Slowly

lower

the

threader

behind

the

needle

until

the

small

hook

C

passes

through

the

needle’s

eye.

Draw

the

thread

from

the

bottom

through

hook

D

B

and

the

thread

automatically

passes

A

behind

hook

C.

D

Draw

the

threader

back

away

from

the

!

needle’s

eye.

You

can

now

pull

the

end

of

the

thread

through

the

eye

to

thread

the

needle.

B

19

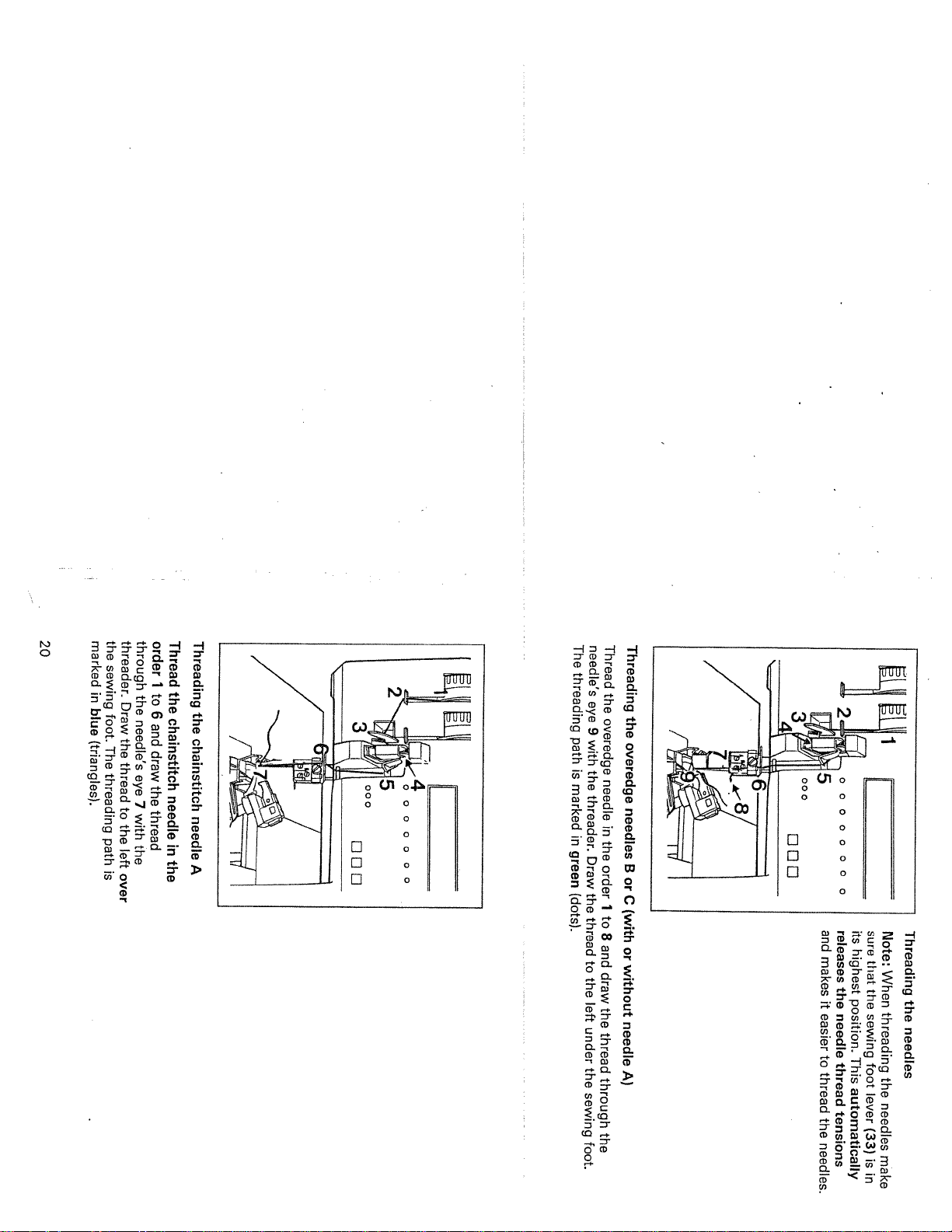

Threading

the

needles

1

Note:

When

threading

the

needles

make

sure

that

the

sewing foot

lever

(33)

is

in

II

its

highest

position.

This

automatically

2

0

0

0

0

0 0

0

0

releases

the

needle

thread

tensions

5

and

makes

it

easier

to

thread

the

needles.

000

6

7

Threading

the

overedge

needles

B

or

C

(with

or

without

needle

A)

Thread

the

overedge

needle

in

the order

1

to

8

and

draw

the

thread

through

the

needle’s

eye

9

with

the

threader.

Draw

the

thread

to

the

left

under

the

sewing

foot.

The

threading

path

is

marked

in

green

(dots).

I

1

IhL-4

I

0000000

j2

5

000

3

I

DOD

7

Threading

the

chainstitch

needle

A

Thread

the

chainstitch

needle

in

the

order

1

to

6

and

draw

the

thread

through

the

needle’s

eye

7

with

the

threader.

Draw

the

thread

to

the

left

over

the

sewing

foot.

The

threading

path

is

marked

in

blue

(triangles).

20

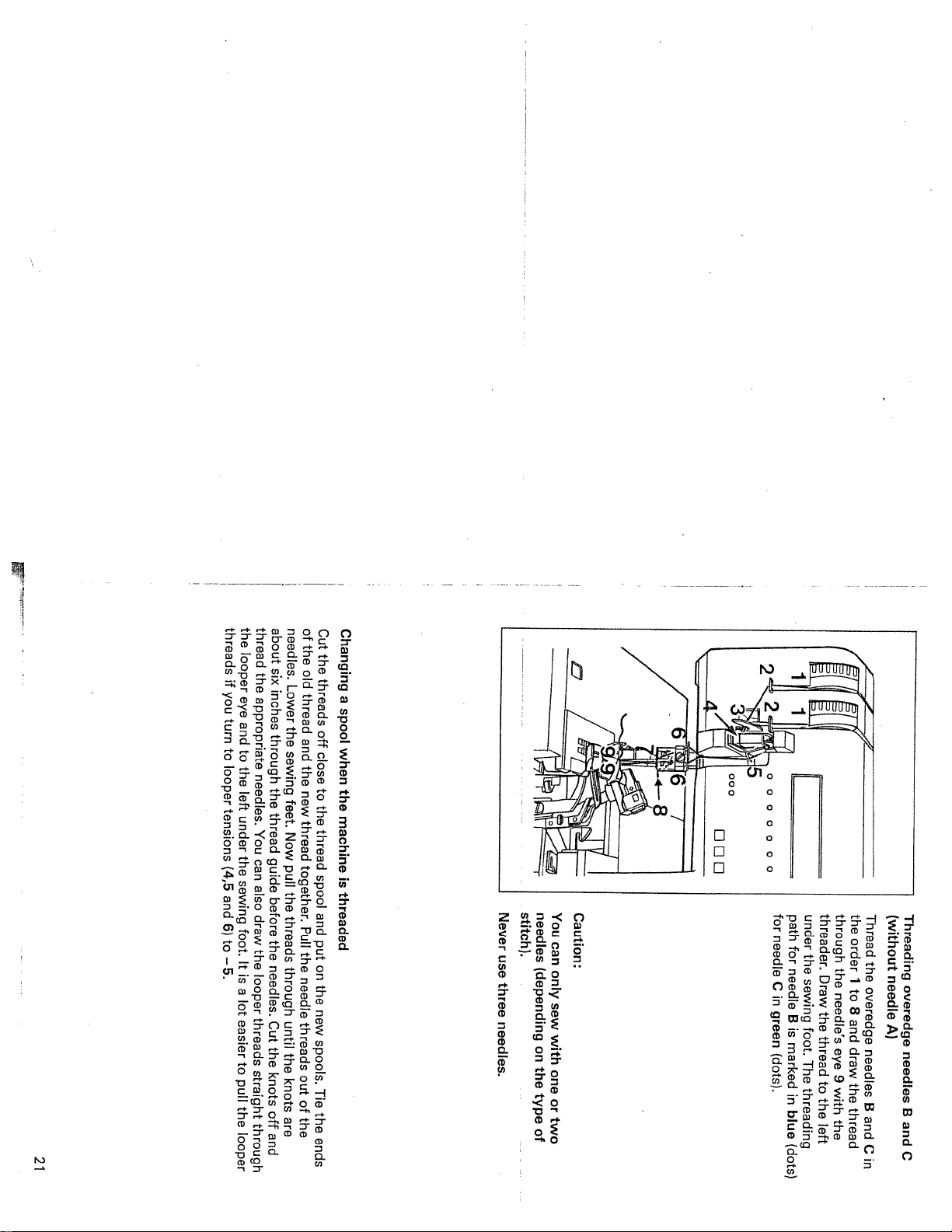

Threading

overedge

needles

B

and

C

(without

needle

A)

Thread

the

overedge

needles

B

and

C

in

7

the

order

1

to

8

and

draw

the

thread

through

the

needle’s

eye

9

with

the

_______________

threader.

Draw

the

thread

to

the

left

under

the

sewing

foot.

The

threading

1

1

path

for

needle

B

is

marked

in

blue

(dots)

for

needle

C

in

green

(dots).

2

2

0000000

‘5

3’

000

LJDD

67

8

o

Caution:

You

can

only

sew

with

one

or

two

—

needles

(depending

on

the

type

of

stitch).

_______________________________

Never

use

three

needles.

Changing

a

spooi

when

the

machine

is

threaded

Cut

the

threads

off

close

to

the

thread

spool

and

put

on

the

new

spools.

Tie

the

ends

of

the

old

thread

and

the

new

thread

together.

Pull

the

needle

threads

out

of

the

needles.

Lower

the

sewing

feet.

Now

pull

the

threads

through

until

the

knots

are

about

six

inches

through

the

thread

guide

before

the

needles.

Cut

the

knots

off

and

thread

the

appropriate

needles.

You

can

also

draw

the

looper

threads

straight

through

the

looper

eye

and

to

the

left

under

the

sewing

foot.

It

is

a

lot

easier

to

pull

the

looper

threads

if

you

turn

to

looper

tensions

(4,5

and

6)

to

—5.

21

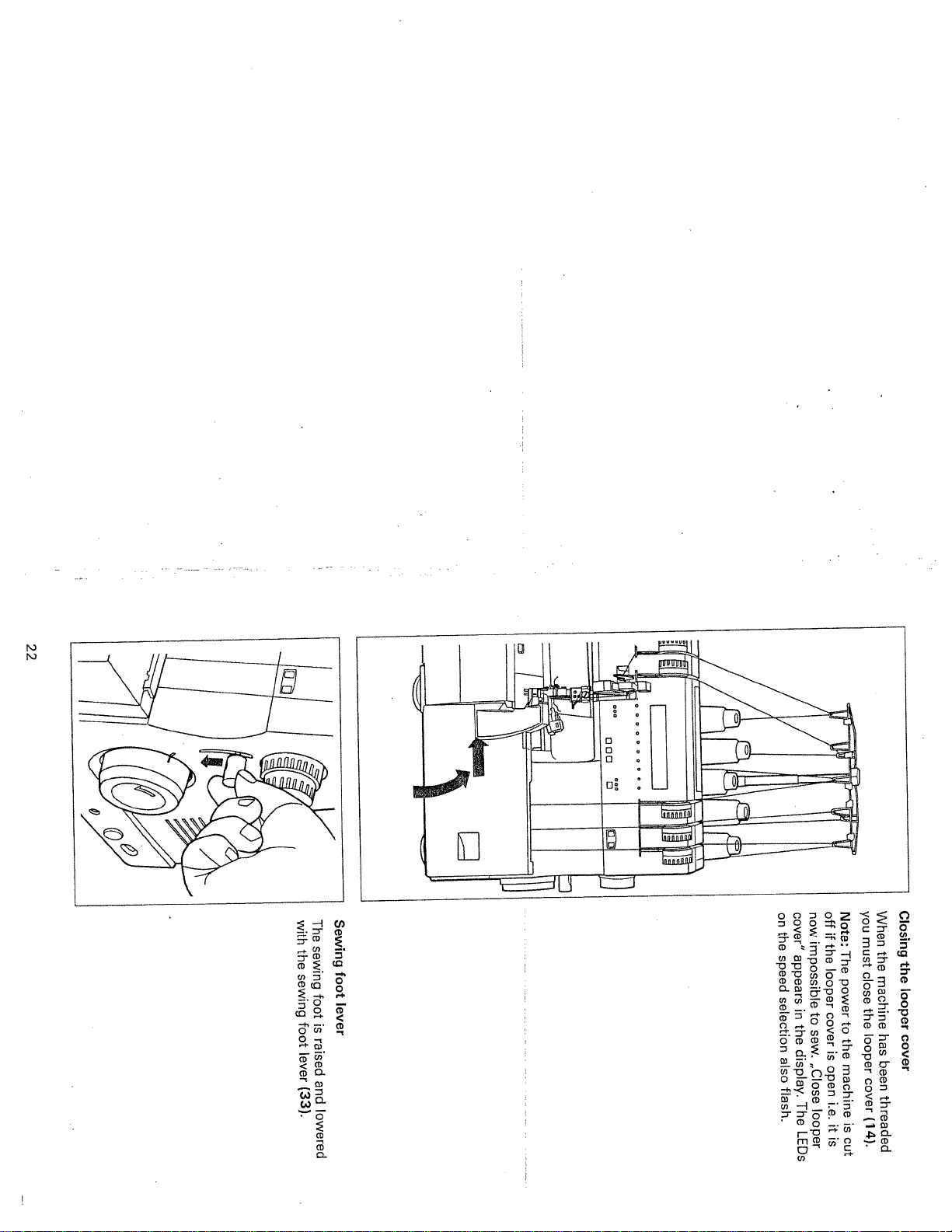

Closing

the

looper

cover

When

the

machine

has

been

threaded

you

must

close

the

looper

cover

(14).

Note

The

power

to

the

machine

is

cut

off

if

the

looper

cover

is

open

i.e.

it

is

now

impossible

to

sew.

,,Close

looper

cover”

appears

in

the

display.

The

LEDs

on

the

speed

selection

also

flash.

Sewing

foot

lever

The

sewing

foot

is

raised

and

lowered

with

the

sewing

foot

lever

(33).

I

.1

22

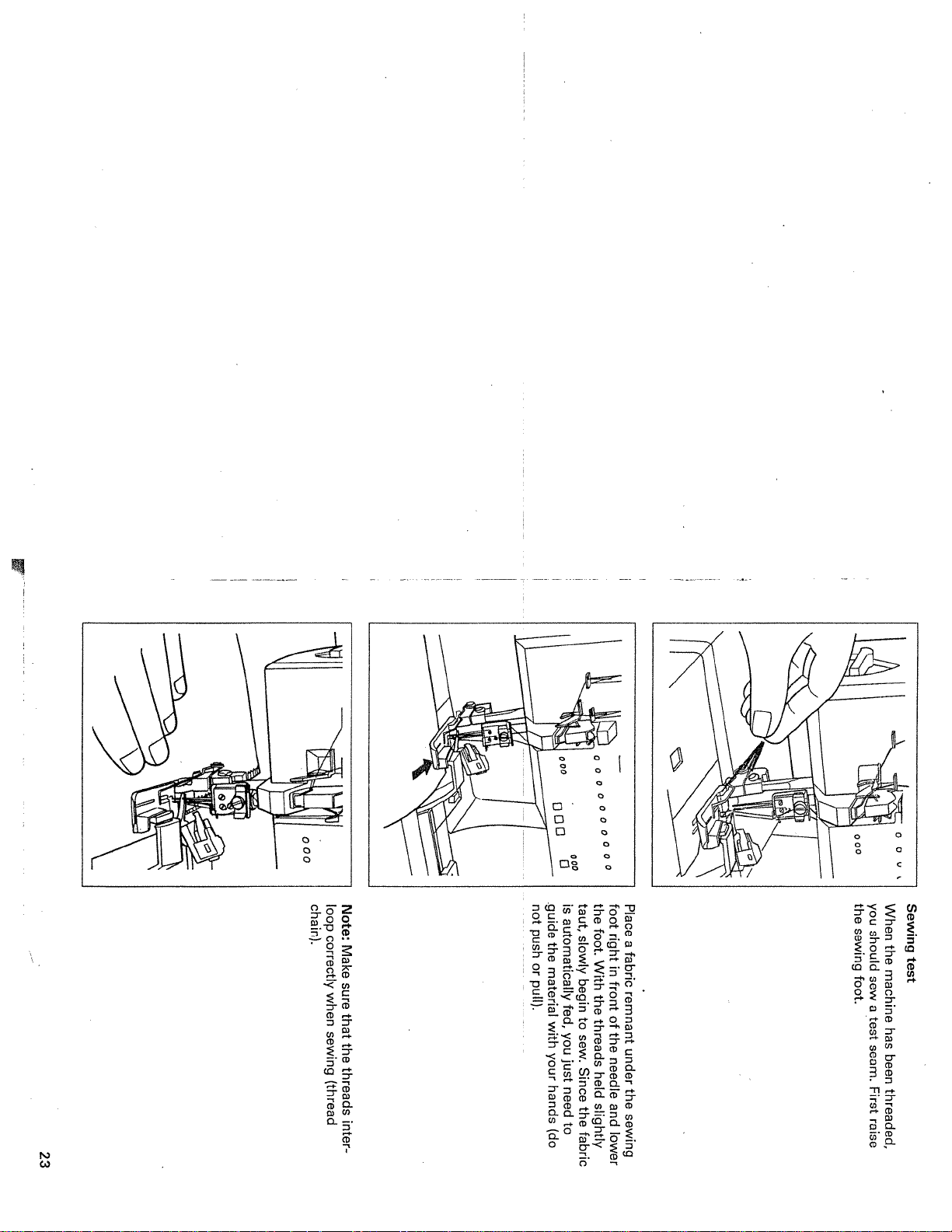

Sewing

test

When

the

machine

has been

threaded,

you

should

sew

a

test

seam.

First

raise

the

sewing foot.

Place

a

fabric

remnant

under

the

sewing

foot

right

in

front

of

the

needle

and

lower

the

foot. With

the

threads

held

slightly

taut,

slowly

begin

to

sew. Since

the

fabric

is

automatically

fed,

you

just

need

to

guide

the

material

with

your

hands

(do

not

push

or

pull).

Note:

Make

sure

that

the

threads

inter-

loop

correctly

when

sewing

(thread

chain).

-

0

0

‘

000

\

0

0

000

000

DO

0

000

23

Loading...

Loading...