Pfaff hobbylock 799 User Manual [nl]

0 C) |

p |

(0 (0 |

|

D C’) |

- C 0 |

0 D |

|

‘ |

|

0 C)

3 C) D C C)

•

I

I,

‘I

p

P

IMPORTANT

SAFETY

INSTRUCTIONS

This sewing When using

machine is designed and |

manufactured for HOUSEHOLD |

use |

|||

|

|||||

an |

electric appliance, basic safety |

precautions should |

always |

||

|

|

||||

only. be followed,

including the following Read all instructions before

using

this sewing

machine

DANGER |

To reduce the |

risk of electric schock: |

|

|

|

||||

|

|

|

|

|

|

||||

1 |

The sewing |

machine should |

never |

be |

left unattended when |

plugged |

|||

|

|

outlet immediately |

after |

using |

|||||

|

unplug this |

appliance |

from the electric |

||||||

|

|

||||||||

in |

Always |

and |

before |

2. 3 4

cleaning. |

|

|

Replace bulb with same type |

rated |

15 Watts. |

|

|||||

Always |

unplug before relamping. |

|

|||||||||

Do not |

reach |

for a |

sewing machine that has fallen into water |

Unplug |

|

immediately |

|||||

|

into a tub |

or |

|||||||||

Do not |

place |

or store sewing machine where it |

can fall or |

be |

pulled |

||||||

|

|

||||||||||

sink. Do not place |

in or drop into |

water or other |

liquid. |

|

|

|

|

|

|||

W

ARNING

To |

reduce |

to |

persons |

the

risk

of

burns,

fire,

electric

schock,

or injury

1 2. 3.

4

5

Do not allow to |

be |

used as |

a toy Close attention |

is necessary when |

this |

sewing |

||||||||||||

machine is used |

by or near children. |

|

|

as described |

in |

this |

manual. Use |

|||||||||||

Use this sewing |

machine only for its intended use |

|||||||||||||||||

|

|

in this manual |

||||||||||||||||

only attachments recommended by the |

manufacturer as contained |

|||||||||||||||||

Never |

operate |

this |

sewing |

machine if |

it has a |

damaged |

cord |

or |

plug, |

if it is not |

||||||||

working properly, |

if |

it |

has |

been dropped or |

damaged, |

or dropped |

into |

water. |

||||||||||

exami |

||||||||||||||||||

Return |

the appliance |

to |

the |

nearest authorized |

dealer or |

service |

center |

for |

||||||||||

|

|

|||||||||||||||||

nation |

repair |

electrical |

or mechanical adjustment |

|

blocked |

|

Keep |

ventilation |

||||||||||

Never operate the sewing machine with |

any air openings |

|

||||||||||||||||

openings of the |

sewing |

machine and foot controller free from |

the |

accumulation of |

||||||||||||||

|

|

|

|

|||||||||||||||

lint, dust, and |

loose |

cloth. |

|

opening |

|

|

|

|

|

|

|

|

||||||

|

any object into any |

|

|

|

|

|

|

|

|

|||||||||

Never drop or |

insert |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

6 7.

8 9

Do |

not use outdoors |

|

products are |

being |

used or where |

oxygen |

is |

||||

Do |

not operate where aerosol (spray) |

|

|||||||||

|

|

|

|||||||||

being administered. |

all controls to off |

( |

0 |

) |

position |

then remove plug from outlet |

|

||||

To disconnect |

turn |

|

|||||||||

Never operate |

on a |

soft surface such |

as |

|

a bed or |

couch |

where the air |

openings |

|||

10. 11

12. 13.

may be blocked. |

on |

cord. To |

unplug, grasp the plug, |

not the |

cord. |

|

||||||

Do not unplug |

by pulling |

the |

||||||||||

Keep fingers |

away from |

all |

moving |

parts Special care is |

|

required |

around |

|||||

|

|

|

||||||||||

sewing machine needle |

|

|

|

plate can cause |

the |

needle to break. |

||||||

Always use the proper needle plate. The wrong |

||||||||||||

|

manufacturer |

|||||||||||

Do not use bent or blunt |

needles. Use needles |

recommended by the |

||||||||||

|

|

|

||||||||||

14 15.

only. |

|

Do not |

pull |

Switch |

the |

area, such |

|

or |

push |

fabric while stitching It may deflect the |

needle causing |

it to break |

||||

sewing |

machine off |

(0) when |

making |

any |

adjustments |

in |

the needle |

|

as |

threading needle, |

changing |

needle, |

threading bobbin, |

or changing |

|||

16

17.

presser foot, etc. |

|

from |

the electrical outlet |

when |

removing |

covers |

|||||

Always unplug sewing machine |

|||||||||||

|

in |

||||||||||

lubricating, or |

when making any |

other user servicing adjustments mentioned |

|||||||||

|

|||||||||||

the instruction |

manual. |

into |

|

cord |

reel. Do |

not allow |

plug |

to whip when |

re |

||

Hold plug when rewinding |

|

||||||||||

winding |

SAVETHESE |

INSTRUCTIONS |

|||||||||

|

|||||||||||

|

|

|

|

|

|

||||||

Contents

Controls of the sewing machine . Accessory box

Electrical connection

Main switch and sewing light Foot control

Notes on safety

Handling the thread spool stand

Thread guides behind the carrying handle

Opening the looper cover and the swingout work support Threading diagram on waste box

Threading thread guides 2 and 34 Needle combinations

Threading the right looper Threading the left looper Threading the chainstitch looper Threading the needles

Needle threader

Thread reel change with machine threaded Fitting the waste box

Thread regulator Sewing test

Points to observe during sewing/thread trimmer

Securing the seam/sewing foot pressure/upper knife lock . . Setting the standard thread tensions

2-thread chainstitch, 4-thread safety stitch. 3-thread overedge stitch 2- or 4-thread overedge stitch / 4-thread safety stitch

4-thread safety stitch, 2-thread chainstitch with overedge stitch Correcting the thread tensions

3-thread overedge stitch

Engaging and disengaging the converter

Correcting the thread tensions of the twothread seam Thread chart for 5-thread overedge stitch

Thread chart for 4-thread overedge stitch Pushlock for stitchlength settings

Setting the stitch length Setting the differential feed Disengaging the upper knife

Disengaging the everedge looper

Converting the machine to 2-thread chainstitch (stitch type 1) . Inserting the workpiece guide plate

Adjusting the seam width Thread regulator Changing the sewing foot Changing the needles Changing the lower knife Changing the upper knife Changing the light bulb

Cleaning the thread tensions Stitch selection table

Sewing problems and their remedies Oiling the machine

Accessories

Thread spool net and thread unreeling disc Special accessories

Specifications

2,3

4

4,5

5

5

5

6

6

7

7

8

8

9

2

22-24

.29,30 31,32

.33.34

44-51

52-53

56-62

LL

z

__________________________

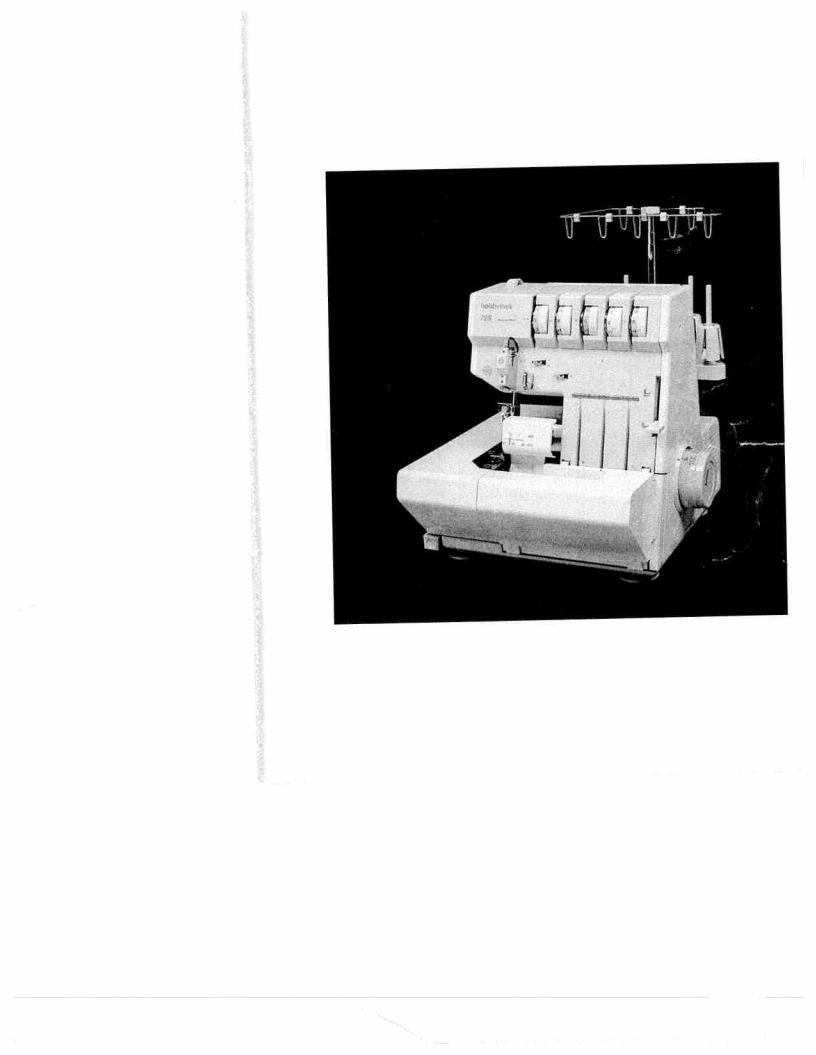

Controls

of

the

sewing machine

1

2 3 4

Thumbwheel for sewing foot |

|

pressure |

|

Thread guides with |

colour markings |

Carrying handle |

|

Thumbwheel for left needle thread |

|

tension |

|

5 6 7 8

Thumbwheel |

for right needle thread |

||

tension |

|

|

|

Thumbwheel |

for right looper thread |

||

tension |

|

|

|

Thumbwheel for |

left looper |

thread |

|

tension |

|

|

|

Thumbwheel |

for |

chainstitch |

looper |

tension |

|

|

|

|

9 |

10 |

|

11 |

|

1 |

2 |

13 |

|

14 |

|

1 |

5 |

16 |

|

17 |

|

18 |

|

Thread tension |

cover |

|

|

Knife guard |

|

|

|

Handwheel and |

stitch |

length |

|

adjustment |

|

|

|

Looper cover |

|

|

|

Loopercover opening |

recess |

||

Upper knife |

|

|

|

Swingout work support |

|||

Adjusting |

knob for differential |

||

Needle plate |

|

|

|

Sewing foot |

|

|

|

feed

19 |

Needle |

holder |

|

20 |

Sewing foot |

lifting lever |

|||||

21 |

Thread |

spool |

stand |

|

|

||

22 |

Thread |

spool |

pins |

|

|

||

|

|

|

|

|

|

|

|

23 |

Machine socket |

|

|

||||

24 |

Main |

switch |

|

|

|

|

|

25 |

|

|

|

|

|||

Lint box |

|

|

|

|

|||

26 |

Foot |

control |

|

|

|

|

|

27 |

Foot |

control |

plug |

|

|

||

28 |

Mains plug |

|

|

|

|

||

29 |

Lower knife |

|

|

|

|

||

30 |

Lower knife |

set screw |

|

|

|||

31 |

Right |

looper |

|

|

|

||

32 |

|

|

|

||||

Left looper |

|

|

|

|

|||

33 |

Twothread chainstitch |

looper |

|||||

34 |

Thread |

guide |

behind carrying |

||||

35 |

(see p.6) |

|

|

|

|

||

Seam width |

adjusting |

knob |

|||||

36 |

Upper knife |

retainer |

|

|

|||

37 Thread |

spool |

centering |

piece |

||||

38 |

Telescopic thread guide |

bar |

|||||

39 |

Pushlock (for |

stitch length) |

|||||

40 |

Converter |

|

|

|

|

||

41 |

Thread |

regulator |

|

|

|||

42 |

Thread |

cutter |

|

|

|

||

43 |

Sewing |

light |

cover |

|

|

||

|

|

|

|

|

|

|

|

44 |

Upper knife set screw |

|

|

||||

handle

3

Accessory box

Fully open work support 15 and take out the accessory box.

The accessory box can only be inserted in its compartment as shown in the illustration. The guide groove of the box must face downwards.

Electrical connection

This machine must only be used on a flat and even surface or on a special sewing table.

Connecting foot control 26:

Insert plug 27 of the control in

machine socket 23, then connect mains plug 28 to the mains socket.

Caution:

Always remember!

When the machine is not in use, always switch it off at main switch 24 and dis connect the plug from the power source. Do not place any objects on the foot control.

4

Handling |

the |

thread spool |

stand |

|

Pull |

thread spool stand 21 |

as far as |

||

will |

go in |

the |

direction shown by the |

|

arrow. |

|

|

|

|

it

Fully extend bar 38.

telescopic thread

guide

Slowly

turn

the

two

upper

telescopic

sections |

until |

snap in |

place. |

you

hear

their

arresters

After guide

use, bar

fold 38.

up

telescopic

thread

Push |

thread |

spool |

stand |

(with or |

||

without spools) |

fully |

against the |

||||

machine. |

|

|

|

|||

|

|

|

|

|

||

Thread

handle

guides

behind

the

carrying

Swing shown

carrying handle by the arrow.

3

upwards

as

Thread

guides

34 then

become

visible.

6

Opening and closing looper cover and work support

Push looper cover 12 fully to the right, hold it, and swing it down.

To close the looper cover, push it up until it locks.

To open work support 15, push it in the direction shown by the arrow. To close the work support, push it lightly until it locks.

Selecting stitch types

Stitch types 1 to 8 are illustrated on the machine behind the looper cover. The needle combinations (A, B and C) and the thread tensions used are colourcoded. A needle chart with the corresponding set screws is printed underneath.

Important!

While the looper cover or work sup port is open, power supply to the machine is interrupted.

|

Important! |

|

|

While the looper cover or work sup |

|

|

port is open, the power supply to the |

|

A |

machine is cut off. |

|

Threading paths for different stitch |

||

|

||

|

types on the rear side of the waste |

|

|

box. |

|

|

On the righthand side the stitch types |

|

|

(1 to 8) with the corresponding threa |

|

|

ding points A are indicated. |

|

|

Each threading path has its own colour. |

|

|

Move the slide so that threading point |

|

|

A for the required stitch type (1 to 8) is |

|

|

coloured orange. |

|

|

Now thread all colourcoded threading |

|

|

paths, see pages 8 to 1 2. |

|

|

Indication B shows you whether the |

|

|

overedge looper must be engaged or |

|

|

disengaged (see pages 33, 34). |

|

|

Please note Only the eight stitch |

|

|

types on the rear side of the waste box |

|

|

can be set using the slide. |

|

|

Other sttch types are shown in the |

|

|

stitch selection table (pages 44 to 51). |

7

Threading thread guides 2 and 34 Place thread spools on the spool pins.

Threading must be done carefully. First thread up guides 2 according to colours.

Then lift carrying handle 3 and place the thread in rear guides 34.

Set the thread tensions at N and thread the machine in the following sequence:

1.right looper (red)

2.left looper (yellow)

3.right needle (green)

4.left needle (blue)

Fold carrying handle 3 down again.

Needle combinations

In the table behind looper cover 12 the needle combinations for stitch types 1 to 8 are indicated.

Remove any needles not in use by loo

sening their set screws A, B or C (for needle change see page- 40).

8

Threading the right looper

Thread the right looper in sequence 1 to B and pull about four inches of thread through the looper eye. The thread path is marked in green in the threading diagram on the rear side of the waste box.

Important:

In order to achieve perfect sewing results, the thread must be pulled between the tension discs during threading.

Note:

Changing a spool with the machine threaded

Cut the threads off close to the thread spool. Place new thread spools on spool holders 22. Tie the ends of the old thread and new thread together. Pull the needle threads out of the needles. Now pull the threads through until the knots are about six inches past the last thread guide before the needles. Cut the knots off and thread up the respective needles. The looper threads can be pulled through beyond the looper eyes. Pull about four inches of thread through the looper eye.

I

9

Threading |

the |

left |

looper |

|

|

|

|

|

|||

Thread |

the |

left |

looper |

in sequence |

1 |

to |

|||||

10 |

and |

pull |

about four |

inches |

of thread |

||||||

through the looper |

eye. |

|

|

|

|

|

|||||

The |

threading path |

is indicated |

in |

yel |

|

||||||

low |

in the threading diagram |

on |

the |

|

|||||||

rear side of |

the |

waste box. |

|

|

|

|

|

||||

Important: |

|

|

|

|

|

|

|

|

|

||

In order to achieve |

perfect |

sewing |

|

|

|||||||

results |

the |

thread must be |

pulled |

bet |

|

||||||

ween the tension discs |

during |

threa |

|

||||||||

ding. |

|

|

|

|

|

|

|

|

|

|

|

L

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Changing a |

spool |

with the |

machine |

||||||||||||

threaded |

|

|

|

|

|

|

|

|

|

|

|

||||

Cut |

|

the |

threads off |

close |

to |

the |

thread |

||||||||

spool. |

Place |

new thread |

spools |

on |

|||||||||||

spool holders |

22 |

Tie |

the ends |

of the |

|||||||||||

old |

thread and |

new thread |

together. |

||||||||||||

Pull |

|

the |

needle threads out of |

the |

|||||||||||

needlesS |

Now pull |

the threads |

|

through |

|||||||||||

until |

the |

knots |

are about |

six |

inches |

||||||||||

past |

the |

last |

thread |

guide |

before the |

||||||||||

needles. |

Cut |

the |

knots off |

and |

thread |

||||||||||

up the respective |

needles. |

The |

|

looper |

|||||||||||

threads |

can |

be |

pulled |

through |

beyond |

||||||||||

the |

looper |

eyes. |

Pull |

about |

four inches |

||||||||||

of thread |

through the |

looper eye. |

|||||||||||||

t

-..

10

Threading

the

chainstitch

looper

Thread

the chainstitch

looper

in

sequence |

1 to 9 |

and pull |

inches of |

thread |

through |

eye. The threading path |

||

about four the looper is marked

mauve in rear side

the |

threading diagram |

|

of the waste |

box. |

|

on

the

Important:

In order results,

to the

achieve thread

perfect sewing must be pulled

bet

ween ding.

the

tension

discs

during

threa

Note:

Changing threaded

a

spool

with

the

machine

Cut the |

threads off |

close |

to the |

||

spool. |

|

Place |

new thread |

spools |

|

spool |

holders |

22. |

Tie the ends |

||

thread on of the

old

thread

and

new

thread

together.

Pull

the

needle

threads

out

of

the

needles. |

|

until |

the |

past |

the |

needles. |

|

Now pull |

the threads through |

||

knots are |

about six inches |

||

last |

thread guide |

before the |

|

Cut |

the knots off |

and thread |

|

up

the

respective needles,

The

looper

threads |

can be |

|

the |

looper eyes. |

|

|

||

pulled |

through |

beyond |

||

Pull |

about |

four inches |

||

of

thread

through the

looper

eye.

11

Threading

the

needles

Threading |

|

the chainstitch |

|

Carry out threading |

for the |

needle in sequence |

1 to 7. |

needle (A> chainstitch

The |

|

threading path |

|

angular |

symbol). |

is

marked

blue

(tri

Threading needle without needle A).

B

or

C

(with

or

Carry out needle in

threading sequence

for the 1 to 6.

overedge

The threading symbol).

path

is

marked

pink

(dot

Threading overedge (without needle A).

needles

B

and

C

Carry out needle in

threading sequence

for the 1 to 6.

overedge

The |

threading path for needle |

|

|

||

(dot |

symbol) |

and for needle C |

symbol). |

|

|

B is pink

blue (dot

Threading sequence

must be carried blue/pink.

out

in

the

Important: Only with one or two on stitch type).

use the machine needles (depending

12

Needle threader |

(accessory) |

|||

|

|

|||

Lower the |

sewing foot |

using |

lifting |

|

20. |

|

|

||

|

|

|

|

|

lever

Turn |

the hand wheel |

until right looper |

|||||||

31 |

is |

positioned |

right |

of the |

|

needle. |

|||

Place |

|

||||||||

the thread |

in |

slot |

A of |

the needle |

|||||

threader and tauten |

it |

a |

little, |

holding |

|||||

the |

needle threader turned a |

|

little to the |

||||||

front. |

With the needle |

between the two |

|||||||

guide |

|||||||||

lugs B, move the |

needle threader |

||||||||

slowly |

|

|

|

|

|

|

|||

|

|

downwards at the rear side of |

|||||||

the needle |

|

ges in |

the |

tion>. |

|

until |

the |

small hook C enga |

||

needle eye |

(middle |

illustra |

||

Hold hook place

the |

thread taut |

and place |

it in |

||||

|

|

||||||

0 and |

the thread |

will |

automatically |

||||

itself |

in hook C, |

too. |

|||||

|

|

||||||

Pull |

the needle threader to |

the |

rear, out |

||||

of the |

needle eye, |

and the |

thread will be |

||||

pulled |

through the |

eye. |

Pull the |

thread |

|||

fully |

|

|

|

|

|

|

|

|

through the |

needle |

eye. |

|

|||

|

|

|

|

||||

Note:

Changing

a

spool

with

the

machine

threaded

Cut |

the threads |

off close |

to |

the |

thread |

spool. Place new thread |

spools |

on |

spool |

hol |

||||||||||||

ders |

||||||||||||||||||||||

22. |

Tie the |

ends of |

the |

old |

thread |

|||||||||||||||||

and |

new thread together. Pull |

the |

needle |

|||||||||||||||||||

threads out of the |

needles. |

Now pull the |

|

|

||||||||||||||||||

threads through until the |

knots are |

about |

six |

|||||||||||||||||||

inches |

past the last thread |

guide |

before |

|

|

|||||||||||||||||

the |

needles. |

Cut the |

knots |

off and thread up |

the |

|||||||||||||||||

respective |

needles. |

The looper |

threads |

|||||||||||||||||||

can |

|

be |

pulled |

through |

|

|||||||||||||||||

Pull |

about |

|

beyond the looper eyes. |

|||||||||||||||||||

four inches of thread |

through the |

|

||||||||||||||||||||

looper eye. |

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

13

After threading, close work support 1, fold down carrying handle 2 and close looper cover 3.

Fitting the waste box

Insert the tonues of the box in the cutouts on the front cover.

Seam depth graduations:

Application example:

If the seam allowance of a cut part is 20 mm, the edge of the butting must be guided along the 20 mm graduation on knife guard 10.

Press the waste box downwards against the front cover until it snaps in place.

Rmoval of the waste box is carried out in the reverse order.

14

Thread

regulator

Depending 41 must be

on the set in

stitch |

type, regulator |

|

position |

R or N. |

|

Position

R

is

for

all

rolledhem

seams.

Position

N

is

for

all

other seams.

How

to

use

thread

regulator

41:

Pull

regulator

41

outwards

and

push

it

downwards n (see ill.).

to

position

R

until

it

snaps

Pull regulator upwards until

41 |

outwards and |

||

it |

snaps |

in |

(see ill.). |

|

|||

15

Sewing

test

After threading, be carried out.

a

sewing

test

should

Raise 20 as

the sewing foot with lifting shown in the illustration.

lever

Hold

the

thread

ends

with

your

left

hand your

and right

turn the hand in

hand wheel with the direction indica

ted

by

the

arrow

on

the

wheel.

Hold

the

threads

taut

and

place

them

back

under sewing

foot

18.

Place |

in |

knife |

14 |

the and

test fabric against upper lower lifting lever 20.

Make rectly

sure the threads interloop |

cor |

||

during |

sewing (thread |

chain). |

|

Points to remember during sewing!

Sew the first stitches sIowy. If the machine has been rethreaded, place the fabric under sewing foot 8 and push it up to the needle before starting to sew.

Since the fabric is fed automatically, do not pull or push the fabric. Use your hands for guiding only

Thread cutter

In order to use thread cutter 42 it is necessary to sew beyond the end of the seam.

Draw the resulting thread chain through the thread cutter from the rear (see bottom illustration).

Securing the seam

Knot the thread chain. For knit fabrics, a crochet needle can be used to pull the thread chain into the seam.

Or:

Sew about two inches beyond the end of the seam. Turn the workpiece around and sew a few stitches over the seam just sewn without cutting the thread chain.

17

Adjusting

the

sewing

foot

pressure:

Setting ,,N” of thumbwheel 1 is standard sewing foot pressure.

the

If very thick fabrics |

||

the |

thumbwheel |

at |

|

||

are ,,4’.

to

be

sewn,

set

For heel

very thin at ,,1”.

fabrics

set

the

thumbw

Upper knife |

lock |

Sewing very |

thick |

ply |

|

thicknesses: |

|

fabrics

in

different

This

machine

can

sew

all

kinds

of

fabric |

from very light to very |

|

For extremely heavy fabrics, |

||

pieces |

of different |

thickness, |

|

||

heavy. or work- the screw

of the ned as screw

upper |

tighte |

|

knife must be fully |

||

shown in the illustration. |

|

When |

36 is tightened, the upper |

knife |

|

is

locked

axially.

Please note:

To sew light or mediumheavy loosen screw 36 for the upper

fabrics, knife

lock by |

|

about two turns, |

|

upper knife can |

move in |

direction. |

|

so the

that the axial

18

Loading...

Loading...