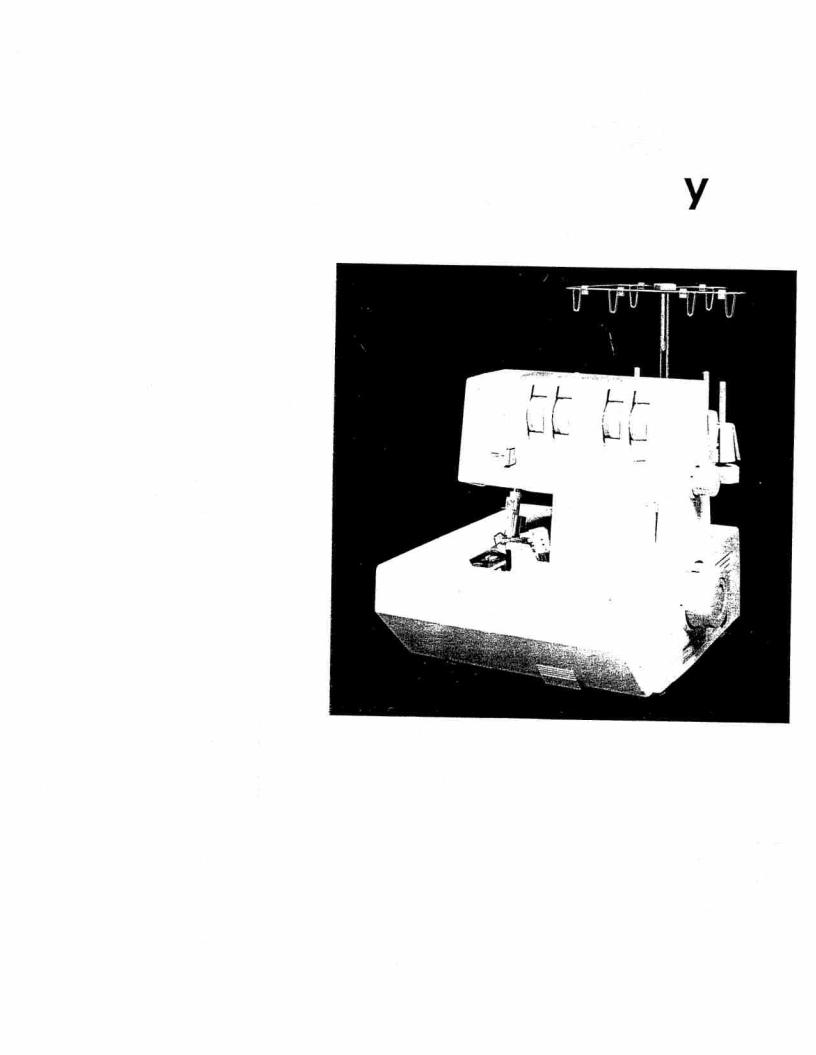

Pfaff hobbylock 788 User Manual

p

fr:

\

hobbylock

787

•

788

Instruction

manual

IMPORTANT

SAFETY

INSTRUCTIONS

-This sewing |

rrachine is |

designed |

and manufactured for HOUSEHOLD use |

When using |

an electric |

appliance, |

basic safety precautions should always |

including the |

following: |

|

|

only. be followed,

Read

all

instructions

before

using

this sewing

machine.

D

AI\IG

ER

To

reduce

the

risk

of

electric

schock:

1.

2. 3. 4.

The |

sewing machine should never be |

left unattended when plugged |

in. |

Always |

||||||

unplug |

this appliance |

from the electric outlet immediately after using |

and |

before |

||||||

cleaning. |

|

|

|

|

|

|

|

|||

Always |

unplug before |

relamping. Replace bulb with same type rated |

15 |

Watts. |

||||||

Do |

not reach |

for a sewing machine that |

has fallen into water. Unplug |

immediately. |

||||||

Do |

not |

place |

or store |

sewing machine |

where it |

can fall or be pulled |

into a |

tub or |

||

sink. |

Do |

not place in or drop into water |

or other |

liquid. |

|

|

|

|||

|

|

|

|

|

||||||

VV

To |

reduce |

the |

to |

persons: |

|

risk

of

burns,

fire,

electric

schock,

or

injury

1. 2. 3.

4.

5. 6. 7.

8. 9.

Do not allow to be |

used as |

a toy. Close attention |

is |

necessary when |

this |

sewing |

||||||||

machine |

is used |

by or near children. |

|

|

|

|

|

|

|

|||||

Use this |

sewing |

machine only for its intended use |

as |

described in this |

manual. Use |

|||||||||

only attachments recommended by the manufacturer |

as contained |

in this manual. |

||||||||||||

Never |

operate this |

sewing |

machine if it has a |

damaged |

cord or |

plug, if it is not |

||||||||

working |

properly, |

if |

it |

has |

been dropped or |

damaged, |

or dropped |

into |

water. |

|||||

Return |

the appliance |

to |

the |

nearest authorized |

dealer or |

service center for |

exami |

|||||||

nation, repair, electrical |

or mechanical adjustment. |

|

|

|

|

|

|

|||||||

Never operate the sewing machine with any air openings |

||||

openings |

of the sewing machine and |

foot controller free |

||

lint, dust, |

and loose cloth. |

|

||

Never |

drop or insert any object into any opening. |

|||

Do |

not |

use outdoors. |

|

|

Do |

not |

operate where aerosol (spray) |

products are being |

|

bein-g administered. |

|

|||

blocked. |

Keep ventilation. |

||

from |

the |

accumulation |

of |

used |

or |

where oxygen |

is |

|

|

- |

|

To |

disconnect, |

turn |

|

all controls to |

off (“0”) |

position, |

then remove |

plug from outlet. |

|

Never |

operate |

on |

a |

soft surface |

such as |

a bed or |

couáh where |

the air openings |

|

may be blocked. |

|

|

|

|

|

|

|||

10. 11.

12. 13.

Do not |

unplug |

by pulling |

on |

cord. To |

unplug, |

grasp the plug, |

not the cord. |

|

Keep fingers |

away from |

all |

moving |

parts. |

Special care is |

required around the |

||

sewing |

machine needle. |

|

|

|

|

|

|

|

Always |

use the proper needle plate. The wrong |

plate can cause the needle to break. |

||||||

Do not |

use bent or blunt |

needles. Use needles |

recommended by the manufacturer |

|||||

only. |

|

|

|

|

|

|

|

|

14. 15.

Do not |

pull or push fabric while stitching. It may deflect the |

needle causing |

it to break. |

|||||

Switch |

the sewing machine off |

(“Os) when |

making |

any |

adjustments |

in |

the needle |

|

area, |

such as threading needle, |

changing |

needle, |

threading bobbin, |

or changing |

|||

presser foot, etc. |

|

|

|

|

|

|

||

16.

Always unplug |

sewing |

machine from the electrical outlet when removing covers, |

|||

lubricating, or |

when making |

any |

other user servicing adjustments mentioned |

in |

|

the instruction |

manual. |

|

|

|

|

17.

Hold plug winding.

when

rewinding into cord reel. Do not allow plug to whip when re

SAVE THESE INSTRUCTIONS

Contents

Controls of the |

sewing |

machine |

|

|

|

||||||

|

|

|

|

|

|

||||||

Accessory |

box |

|

|

|

|

|

|

|

|

|

|

Electrical connection |

|

light |

|

|

|

||||||

Master switch |

and |

sewing |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||

Foot control |

|

|

|

|

|

|

|

|

|

||

Notes on safety |

|

thread |

spool |

stand |

|||||||

How to |

handle |

the |

|||||||||

Opening the looper cover |

and |

the |

swivel-type |

||||||||

Threading |

guide |

wires |

18 |

and |

22 |

|

|

||||

Threading |

the |

right looper |

|

|

|

slide |

|||||

Threading |

the |

left |

looper / threading |

||||||||

Threading the |

left |

and |

right needle |

|

|||||||

Needle |

threader |

|

|

threaded |

machine |

||||||

Thread |

reel change on |

||||||||||

Inserting the lint |

box |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

work

support.

Seam allowance |

|

|

|||

Sewing test |

|

|

|

||

Points |

to observe during sewing |

|

|||

Thread |

cutter |

|

|

||

Securing the seam |

thread tensions |

|

|||

Setting the |

standard |

corrections |

|||

Possibilities |

requiring |

thread tension |

|||

|

|||||

3-thread overecige |

seam |

|

the |

||||

Engaging and |

disengaging |

||||||

Thread |

tension adjustment |

for |

|||||

Thread |

chart |

stitch |

length |

|

|||

Adjusting the |

|

||||||

Adjusting the |

differential |

feed |

|||||

Disengaging the upper knife |

|||||||

Adjusting the seam |

|

width |

|

|

|||

Changing the |

sewing |

foot |

|

||||

Changing the |

light |

|

bulb |

|

|

||

|

|

|

|

|

|

||

converter (Hobbylock |

788) . |

||

sewing with |

1 needle |

and 2 threads |

|

(Hobbylock |

788) |

- . |

|

Cleaning |

the |

thread |

tensions |

|

Rolled |

hem |

with |

3 |

threads |

|

|

|

|

|

|

||||

Rolled |

hem |

with |

2 |

threads |

|

|

|

|

|

|

||||

Changing the |

needles |

|

|

|

|

|

|

|

||||||

Changing |

the |

knives |

knife |

|

|

|

|

|

|

|

||||

Changing |

the |

upper |

|

|

|

|

|

|

|

|||||

knife |

|

|

|

|

|

|

|

|||||||

Changing |

the |

lower |

|

|

|

|

|

|

|

|||||

Upper |

knife |

arresting |

|

|

|

|

|

|

|

|||||

Cleaning the |

knives |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||||

Oiling |

the machine |

|

|

|

|

|

|

|

|

|||||

Stitch |

selection |

table |

|

removal |

|

|

|

|

||||||

Sewing problems |

and their |

|

|

|

|

|||||||||

Accessories |

|

net/thread |

unreeling |

disc |

|

|

|

|

||||||

Thread spool |

|

|

|

|

||||||||||

Mounting |

of |

the Converter |

|

|

|

|

|

|

||||||

Special accessories |

|

of the cardboard |

box |

|

|

|

||||||||

Specifications / |

contents |

• |

• |

. |

||||||||||

• |

2.3 |

|

|

|

|

.6 |

|

|

|

.8 |

|

• |

. |

10 |

• |

. . |

11 |

|

|

• |

|

11 |

• |

. . |

12 |

|

|

• |

. |

12 |

|

• |

• |

13 |

• |

. |

|

14 |

• |

|

. . |

14 |

• |

|

- |

14 |

• |

|

. . |

15 |

• |

|

. . |

16 |

• |

|

|

17 |

• . . |

18 |

||

|

|

|

19 |

|

|

21,22 |

|

26,27

32

42 43

1

(0

Controls

of

the

sewing

machine

1 2 3 4 5 6 7

Thread |

spool |

stand |

|

|

|

|||||

Carrying |

handle |

|

|

dial |

||||||

|

thread tension |

|||||||||

Left needle |

||||||||||

|

dial |

|||||||||

|

thread |

tension |

||||||||

Right |

needle |

|||||||||

dial |

||||||||||

thread |

tension |

|||||||||

Right |

looper |

|||||||||

|

||||||||||

Left looper |

thread tension |

dial |

||||||||

|

|

|||||||||

Thread |

tension |

cover |

|

|

||||||

|

|

|

|

|||||||

|

8 |

|

9 |

1 |

0 |

11 |

|

1 |

2 |

1 |

3 |

14 |

|

Lint box |

|

|

|

||

Handwheel |

|

with |

recess |

||

Looper |

cover |

||||

Upper |

knife |

work |

support |

||

|

|||||

Swivel-type |

|||||

|

|

|

|||

Needle |

plate |

|

|

||

Sewing foot |

|

|

|

||

1 |

5 |

1 |

6 |

1 |

7 |

18 |

|

1 |

9 |

20 21 22 23

Needle |

holder |

lever |

|

|||||

Sewing |

foot |

|

lifting |

|

||||

|

|

|

|

holder |

|

|||

Thread spool |

|

|||||||

Color-coded |

|

thread guides |

||||||

Telescopic |

thread |

guide |

bar |

|||||

|

||||||||

Machine |

socket |

|

|

|||||

|

|

|

|

|

|

|||

Master |

switch |

(4x) |

|

|||||

Rear thread |

guide |

|

||||||

|

|

|||||||

feed adjustment |

||||||||

Differential |

|

|||||||

|

788) |

|

|

|||||

(Hobbylock |

|

|

|

|||||

|

|

|

|

|

||||

knob

24 25 26 27

Accessory |

box |

|

|

knob |

|||

Stitch |

length |

adjustment |

|||||

knob |

|||||||

Seam |

width |

adjustment |

|||||

|

|||||||

Rotary lever |

for |

upper |

knife |

||||

|

|

||||||

|

|

|

|

||||

disengagement

28 29 30 31

Foot control |

|

Foot control |

|

Mains |

plug |

Right |

looper |

plug

for

machine

socket

32 33 34 35 36 37

Left looper |

|

|

|

|

|

|

|||

Lower |

knife |

|

|

of lower |

knife |

||||

Retaining |

screw |

||||||||

screw |

of upper |

knife |

|||||||

Retaining |

|||||||||

|

|

piece |

|||||||

Thread spool |

centering |

||||||||

|

|

||||||||

Upper |

knife |

arresting |

screw |

||||||

|

|

|

|||||||

|

|

|

|

|

|

||||

38 39 40

Lamp cover |

|

Thread |

cutter |

Looper |

threader |

|

|

41 42 43

Converter |

|

Needle |

threader |

|

|

Tweezers |

|

29

Accessory |

box |

|

Swing open |

work |

support |

out accessory box |

24. |

|

1 |

2 |

and

pull

The

accessory

box

can

only

be

inserted

in

its

compartment

when

held

as

shown

in

the

illustration

at

left.

The

guide of the

groove is box faces

up and the projection the machine.

Electrical

connection

Use this machine only on a flat or on a special machine table.

surface

Connecting

foot

control

28: Insert plug

29 of the control in |

machine |

Then connect mains |

plug 30 |

socket to a

20.

power

source.

Caution: When the |

machine is |

not |

use, always switch |

it off at master |

|

switch 21 and disconnect the |

plug |

|

in

from the power source. any objects on the foot

do not |

place |

control. |

|

4

e3-O ———— |

I |

How to handle the thread spool |

|

|

stand |

|

|

Pull thread spool stand 1 as far as it |

|

|

will go in the direction indicated by the |

|

|

arrow. |

\ |

Fully extend telescopic thread guide |

bar 19. Slowly turn the two upper tele |

|

— |

scopic sections until you hear their |

|

detent balls snap in place. |

After use fold up telescopic thread guide bar 19.

read spool stand (with or

machine.

6

___

1

f1\ |

|

|

|

|

—‘ ____ |

|

|

|

|

— / |

- |

|

||

|

-D |

|

|

|

/— |

i’) |

|

||

‘-== |

I |

|||

A |

|

|||

|

|

|||

|

|

|

||

— /_____________ |

— |

|||

|

|

|||

Opening |

and |

|

closing |

|

looper |

|

|

|

|

|

|

|

|||||||||||

cover and |

work |

support |

|

|

|

|

|

|

|

|

|||||||||||||

Push |

looper |

cover |

10 |

|

fully |

to |

the |

right, |

|

||||||||||||||

hold |

it, |

and |

swing |

it |

down. |

|

|

|

|

|

|

|

|

||||||||||

To |

close |

the |

looper |

cover, |

push |

it |

|

up |

|

||||||||||||||

until |

it |

locks. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

To |

open work |

support |

12. |

push |

it |

in |

|

||||||||||||||||

|

|

|

|||||||||||||||||||||

|

by the |

|

arrow. To |

||||||||||||||||||||

the |

direction |

|

indicated |

|

|||||||||||||||||||

close the |

work support, |

push |

it |

lightly |

|

||||||||||||||||||

until |

it |

locks. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Behind |

the |

looper |

cover converter |

|

41 |

|

|||||||||||||||||

(Hobbylock |

788) |

is |

illustrated |

|

with |

its |

|

||||||||||||||||

slide |

settings |

|

for |

the |

respective |

stitch |

|

||||||||||||||||

type. |

On |

the |

|

inside |

of |

|

the |

looper |

cover |

|

|||||||||||||

the |

individual |

threading paths |

are |

|

|

|

|||||||||||||||||

|

|

|

|

|

|

||||||||||||||||||

illustrated |

in |

colors. |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

lmportantl |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

While the |

ooøer |

cover |

or |

work |

support |

||||||||||||||||||

|

|

|

|

|

|

|

|

to the machine |

is |

||||||||||||||

s open, power supply |

|||||||||||||||||||||||

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

inrorrupted. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Threading of |

guide |

wires 18 |

and |

19 |

|||||||||||||

|

|

||||||||||||||||

Place thread |

spools on |

thread |

|

spoo1 |

|

||||||||||||

stands. The |

machine |

must be |

threaded |

||||||||||||||

correctly. |

First |

pull |

the |

threads |

through |

||||||||||||

|

|

|

|

|

to |

colors. |

Then |

lift |

|||||||||

guides |

18 according |

||||||||||||||||

|

|||||||||||||||||

carrying handle 2 |

and |

place the |

thread |

||||||||||||||

in |

rear |

guides |

|

22. |

Set |

the thread |

tensi |

||||||||||

ons at |

N |

and |

thread |

the machine |

in |

the |

|||||||||||

following |

sequence: |

|

|

|

|

|

|

|

|

|

|||||||

1. |

right looper |

(yellowl |

|

|

|

|

|

|

|

||||||||

2. |

left |

looper |

(redl |

|

|

|

|

|

|

|

|

|

|

||||

3. |

right needle |

(green) |

|

|

|

|

|

|

|

||||||||

4. |

left |

needle |

(blue) |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Push carrying |

|

handle |

2 |

down |

again. |

|

|||||||||||

7

- |

CD |

|

—. |

|

— Z CD |

|

||

l |

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

-1 |

CDZT |

ci |

|

O •-“ C) |

O |

< |

||

CO CD .CflCD |

|

|

||||||

0 |

|

__ lCD |

||||||

|

|

|

o |

|

|

|

|

|

|

|

ci |

|

CD |

|

|

0 |

|

|

|

CD |

|

D |

1 |

U) |

3CD |

CD |

|

|

D |

C |

|

|

|

||

|

|

|

|

|

T |

|

|

|

|

|

|

o |

|

|

|

|

|

|

ao |

CD |

- |

|

|

|

O(DCDCDD a |

|

|

CD D |

7U) |

|

U) |

|

|||

—

CD ciCD U)3CD

0

co

“U)CD

0

co

•c

•0

• CD<CD

CDm

••‘

CD

o •

CT |

CD |

U) (IC |

|

CDOD |

C) |

CD a |

|

-, CD DC |

|

CD—. 3 . - CD

CD - CD

cT CD a -

U)

CD

j

Threadng |

the left |

looper |

|

|

|||||

|

|

|

|

|

|

||||

Thread |

left |

looper |

32 (yellow |

thread |

|||||

path) |

in |

sequence |

1 |

to |

6. From |

thread |

|||

looper |

|||||||||

guide |

6 |

pull the thread |

through |

||||||

|

|||||||||

eye 7. |

|

|

|

|

|

|

|

|

|

/ z/__w__J

Align the |

mark on |

handwheel |

9 with |

||

the mark |

|

. |

Tauten the |

||

on the housing |

in thread |

||||

thread |

a |

little and |

place it |

||

guide |

B by means |

of tweezers |

43. |

||

|

|||||

1

Thread guide |

9 |

is |

threaded |

of looper threader |

40. |

||

|

|||

by

means

1

2.

The mark on |

handwheel |

9 |

must be |

|||

aligned |

with |

the mark on |

the |

hou |

||

|

|

|

|

|

|

|

sing. |

|

|

|

|

|

|

Tauten |

the thread a little. |

|

|

|

||

3.

Push |

the slide of the |

looper |

threader |

|||||

fully |

to the |

left, |

then |

pull |

lightly |

on |

||

the thread |

and |

allow the |

slide to |

|||||

return |

|

. By this |

means |

the |

|

|||

slowly |

|

|

9. |

|

|

|||

thread |

is placed in guide |

|

|

|||||

|

|

|

||||||

Note: |

slide |

can |

not |

|

If the |

||||

on the hand |

wheel |

|||

|

|

|||

be moved the |

marks |

|

and the housing |

are |

|

|

||

not

correctly

aligned.

C

Threading the right needle

Threading of guide wires 18 and 22 is shown on page 7.

In the left-hand illustration the threa

ding path is |

shown from green tension |

1 up to right |

needle eye 6. Thread the |

needle from the front. |

|

The use of needle threader 42 is desc ribed on the next page.

Threading the left needle

Threading of guide wires 18 and 22 is shown on page 7.

In the left-hand illustration the threa ding path is shown from blue tension 1 up to left needle eye 6. Thread the needle from the front.

The use of needle threader 42 is desc ribed on the next page.

10

|

Needle threader |

|

|

is |

Lower the |

sewing foot by means of lif |

|

|

|||

|

ting lever |

16. |

|

|

Turn the hand wheel until right looper |

||

|

31 is positioned |

right of the needle |

|

|

(see top of page |

18). Place the thread |

|

|

in slot A of needle threader 42 and |

||

|

tauten it a little, holding the needle |

||

|

threader a little turned to the front. |

||

|

With the needle located between the |

||

|

two guide lugs B move the needle |

||

|

threader slowly downwards at the rear |

||

|

side of the needle until small hook C |

||

|

engages in the needle eye. |

||

|

Hold the thread taut and place it in |

||

|

hook D; it will then automatically be |

||

|

placed in hook C, |

too. |

|

Pull the needle threader to the rear, out of the needle eye, and the thread will be pulled through the eye.

Pull the thread completey through the needle eye.

Thread spool change on threaded machine

Cut the threads close to the thread spool. Place new thread spools on spool holders 1 7. Tie the threads still in the machine and the new threads to-gether. Pull the needle threads out of the needles. Now pull at the thread ends until the knots are about 1 5 cm past the last thread guide before the needles. Cut the knots off and pull the threads through the respective needle eyes. The looper threads can be pulled until past the looper eyes without interruption. Pull about 10 cm of thread through the looper eye.

11

After threading the machine, push handle 2 down, and close work support 12 and looper cover 1 0.

Inserting the lint box:

Insert the two tabs of lint box 8 down wards in the recess of looper cover 10. Then push the bottom of the box against the machine.

For removal of the lint box, use the revese order.

Seam allowance

If the cutting is guided along below mark N on looper cover 10, a seam allowance of 16 mm must be taken into consideration when cutting the fabric.

12

Sewing test |

|

|

|

After threading, |

a |

sewing test |

should |

be made. |

|

|

|

Raise sewing foot |

lever 16, as |

shown |

|

the illustration. |

|

|

|

in

Hold

hand

the thread ends with your left while turning the hand wheel

with

your

right

hand

in

the

direction

indica

ted |

by |

the |

arrow |

on |

the |

wheel. |

|

Hold |

the |

threads |

taut |

and |

lay |

|

|

|

|

|

them

back sure

under sewing foot |

14. |

Make |

|

the threads interlock |

correctly |

||

|

|

||

during

sewing

(thread

chain).

Insert the test fabric |

up |

to |

11 and lower sewing |

foot |

|

upper |

knife |

lever 1 |

6. |

13

Loading...

Loading...