Pfaff Mauser Spezial Series 40 Manual

MAUSER

SPEZIAL

Serie

40

Adjustment

instructions

Pfaff

Industriemaschinen

GmbH

675

Kaisersiautern

West-Germany

From the library of: Superior Sewing Machine & Supply LLC

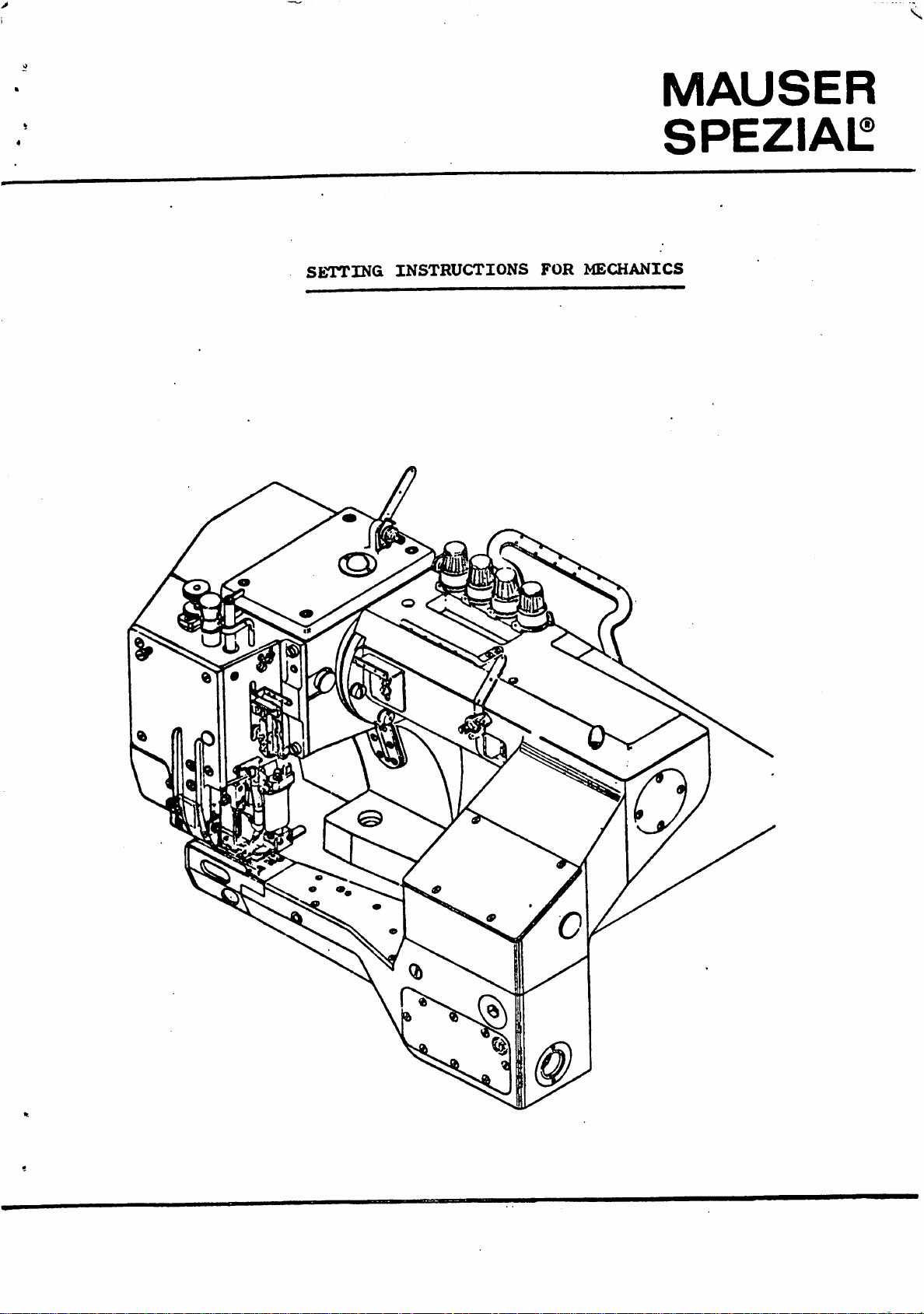

MAUSER

SPEZiAl^

SETTING

INSTRUCTIONS

FOR

MECHANICS

From the library of: Superior Sewing Machine & Supply LLC

Supplement

to

the

service

manual

for

Mauser

Cl,

^0,

for

machines

with

low

needle-bar

link

needle

stroke

29*5

mm,

looper

stroke

20.4

mm)

1«

Needle

bar

height:

Looper

clearance:

3«

Needle

rise:

4.

Looper

avoiding

motion:

5*

Elliptical

movement:

6.

Check:

Preliminary

adjustment:

Clearance

between

top

surface

of

needle

plate

and

point

of

the

fourth

needle:

9.3

mm

From

looper

tip

to

middle

of

first

needle:

mm

2.^

nun

to

middle

of

first

needle.

1.8

to

2

mm,

depending

on

fabric.

Forwards:

from

first

needle

to

fourth

needle:

0.15

mm

1.

The

looper

point

should

pick

up

at

a

position

1 mm

above

the

eyeaof

the

fourth

needle.

2.

When

the

looper

is

between

the

third

and

fourth

needle

the

tip

of

the

third

needle

shoulde

be

0.3

ram

below

the

underside

of

the

looper.

From the library of: Superior Sewing Machine & Supply LLC

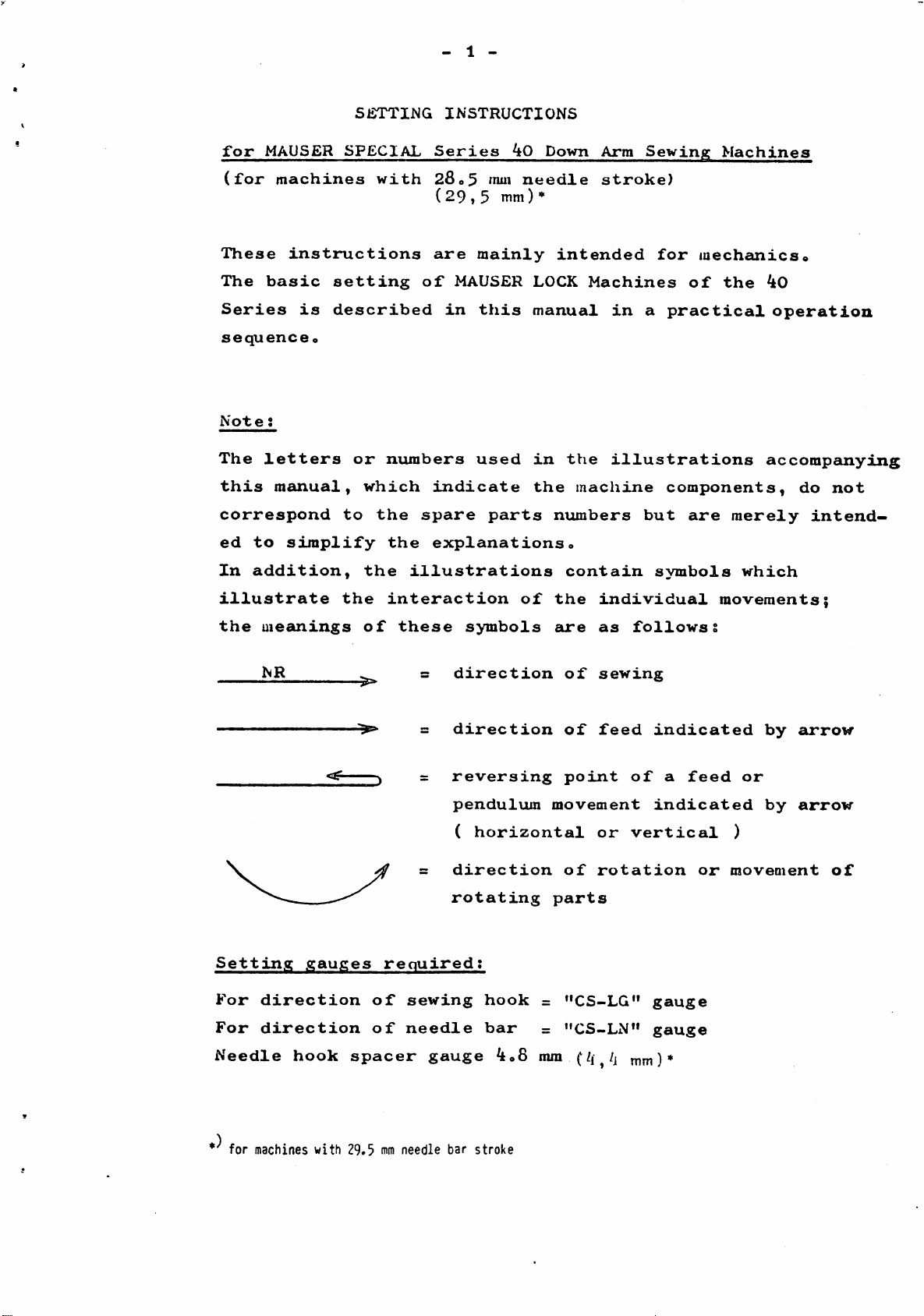

- 1 -

S12TTING

INSTRUCTIONS

for

MAUSER

SPECIAL

Series

kO

Down

Arm

Sewinja;

Machines

(for

machines

with

2Se5

mm

needle

stroke)

(29,5

mm)»

These

instructions

are

mainly

intended

for

mechanics«

The

basic

setting

of

MAUSER LOCK

Machines

of

the

kO

Series

is

described

in

this

manual

in

a

practical

operation

sequence

o

Note

s

The

letters

or

numbers

used

in

the

illustrations

accompanying

this

manual,

which

indicate

the

machine

components,

do

not

correspond

to

the

spare

parts

numbers

but

are

merely

intend

ed

to

simplify

the

explanationso

In

addition,

the

illustrations

contain

symbols

which

illustrate

the

interaction

of

the

individual

movements;

the

meanings

of

these

symbols

are

as

followss

NR

=

direction

of

sewing

=

direction

of

feed

indicated

by

arrow

reversing

point

of

a

feed

or

pendulum

movement

indicated

by

arrow

(

horizontal

or

vertical

)

direction

of

rotation

or

moveoient

of

rotating

parts

SettdLng

gauges

required;

For

direction

of

sewing

hook

=

"CS-LG"

gauge

For

direction

of

needle

bar

=

"CS-LN"

gauge

Needle

hook

spacer

gauge

^08

mm

mm)*

for

machines

with

29.5

mm

needle

bar

stroke

From the library of: Superior Sewing Machine & Supply LLC

- 2 -

CONTENTS

TABLE

1.

Tlie

necessary

needle

system

2*

The

needle

arrangement

3«

Needle

check

4.

Temporary

synchronization

of

needle

and

longitudinal

hook

movement

5*

Temporary

setting

of

feed

and

transverse

hook

movement.

6.

Temporary

setting

of

needle

bar

height

7»

Radial

adjustment

of

needle

bar

8»

Setting

the

stroke

ot

the

hook

deflection

movement

9*

Setting

the

hook

inclination

vritlx

the

"CS-LG" gauge

10*

Setting

the

hook

spacing

11.

Final

synchronization

of

needle

and

longitudinal

hook

movement

12.

Final

setting

of

needle

bar

height

13*

Final

setting

of

the

hook

deflection

movement

l4.

Alignment

of

main

and

differential

feeder

15*

Final

setting

of

"lifting

and

lowering"

feeder

movement

16.

Stitch

length

and

differential

regulation

17.

Setting

the

needle

stop

l8•

Setting

the

take—up

lever

movement

19*

Setting

the

looper

thread

puller

20.

Fitting

and

setting

of

the

trimmer

blades

From the library of: Superior Sewing Machine & Supply LLC

- 3 -

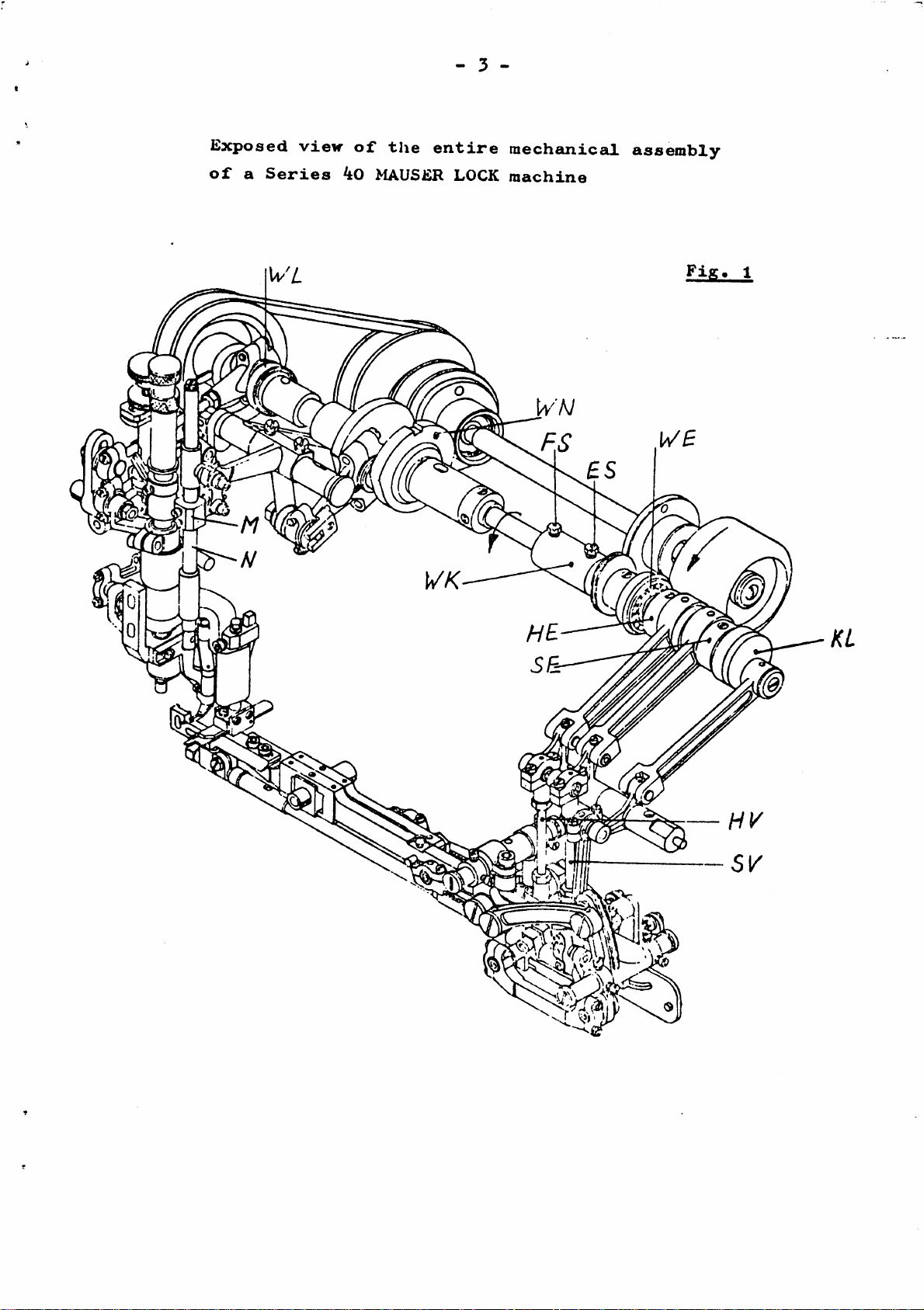

Lxposed

view

of

the

entire

mechanicaJL

assembly

of

a

Series

40

MAUSiiR LOCK

machine

Fig

From the library of: Superior Sewing Machine & Supply LLC

My

1014

B

My.1014

C

iZ^ZZZZ^

Y

Mv

1014

D

- 4 -

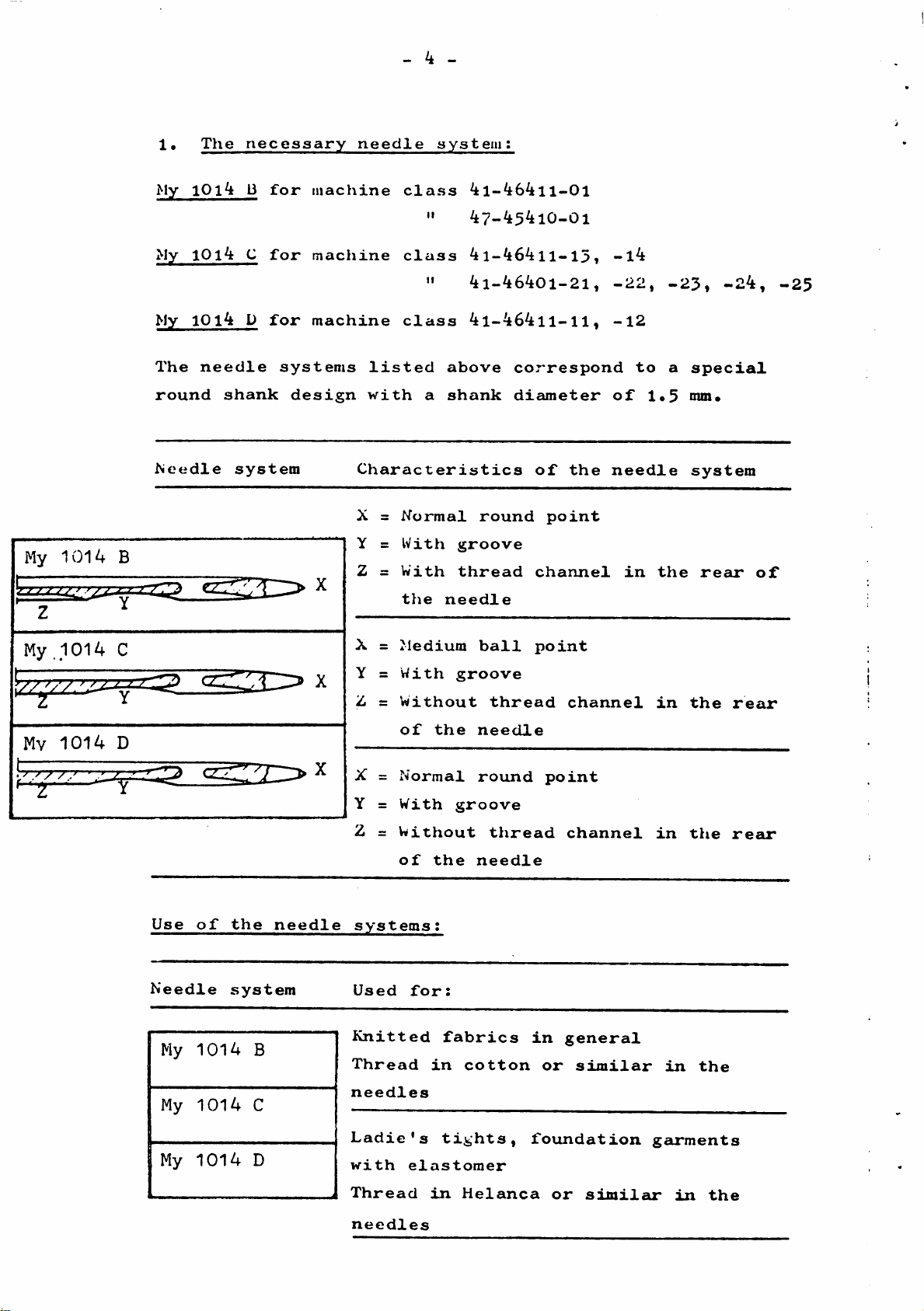

1•

The

necessary

needle

system:

My

10i3

for

machine

class

4l-464ll-01

"

47-45410-01

My

1014

C

for

machine

class

4l-464ll-l5,

-l4

"

4i-46401-21,

-22,

-23,

-24,

-25

My

10l4

D

for

machine

class

4l-464ll-ll,

-12

The

needle

systems

listed

above

correspond

to

a

special

round

shank

design

with

a

shank

diameter

of

1.5

nun.

Needle

system

Characteristics

of

the

needle

system

X =

Normal

round

point

Y =

With

groove

Z =

With

thread

channel

in

the

rear

of

the

needle

X =

Medium

ball

point

Y =

With

groove

Z =

Without

thread

channel

in

the

rear

of

the

needle

X =

Normal

round

point

Y =

With

groove

Z =

Without

thread

channel

in

the

rear

of

the

needle

Use

of

the

needle

systems;

Needle

system

My

1014

B

My

1014

C

My

1014

D

1

Used

for:

Knitted

fabrics

in

general

Thread

in

cotton

or

similar

in

the

needles

Ladie's

tights,

foundation

garments

with

elastomer

Thread

in

Helanca

or

simileu*

in

the

needles

From the library of: Superior Sewing Machine & Supply LLC

- 5 -

3•

Needle

check

Only

new

needles

must

be

used

for

setting

up

the

machine.

To

avoid

all

risks,

the

needles

must

be

checked

for

straight

running

before

use

by

rolling

them

on

a

flat

surface

(fig.

3).

k•

Temporary

synchronization

of

needle

and

longitudinal

hook

movement

The

mechanism

for

the

feeder

and

longitudinal

hook

move

ment

situated

in

the

suj)port

arm

of

the

machine

is

controlled

by

tlie

drive

shaft

"WE",

which

is

adjustably

connected

to

the

needle

drive

shaft

"WN"

by

means

of

the

shaft

coupling

"WK"

(fig.

l).

The

crank

"KL"

(for

the

drive

of

the

longitudinal

hook

movement)

is

firmly

connected

to

the

drive

shaft

"WE"

(fig.

l)

.

Tlie

synchronization

of

the

needle

and

longitudinal

hook

movement

CcUi

therefore

only

be

set

at

the

shaft

coupling

I

The

basic

adjustment

of

a,

for

exsimple,

completely

unadjusted

machine

starts

first

with

the

temporary

syn

chronization

of

the

needle

movement

\>rita

the

longitudinal

hook

movement«

Fig.

4

From the library of: Superior Sewing Machine & Supply LLC

- 6 -

Sett

ing:

Helease

pair

of

screws

"£S"«

Align

the

groove

"N"

with

the

fixing

screw

"FS"

by

a

corresponding

rotation

of

the

shaft

"WE"

(fig.

^)o

Note:

The

fixing

screw

"FS"

(1st

screw

in

the

direction

of

rotation)

is

located

on

a

surface

of

the

shaft

"WN"

(fig*

4).

Final

setting:

(see

Point

ll).

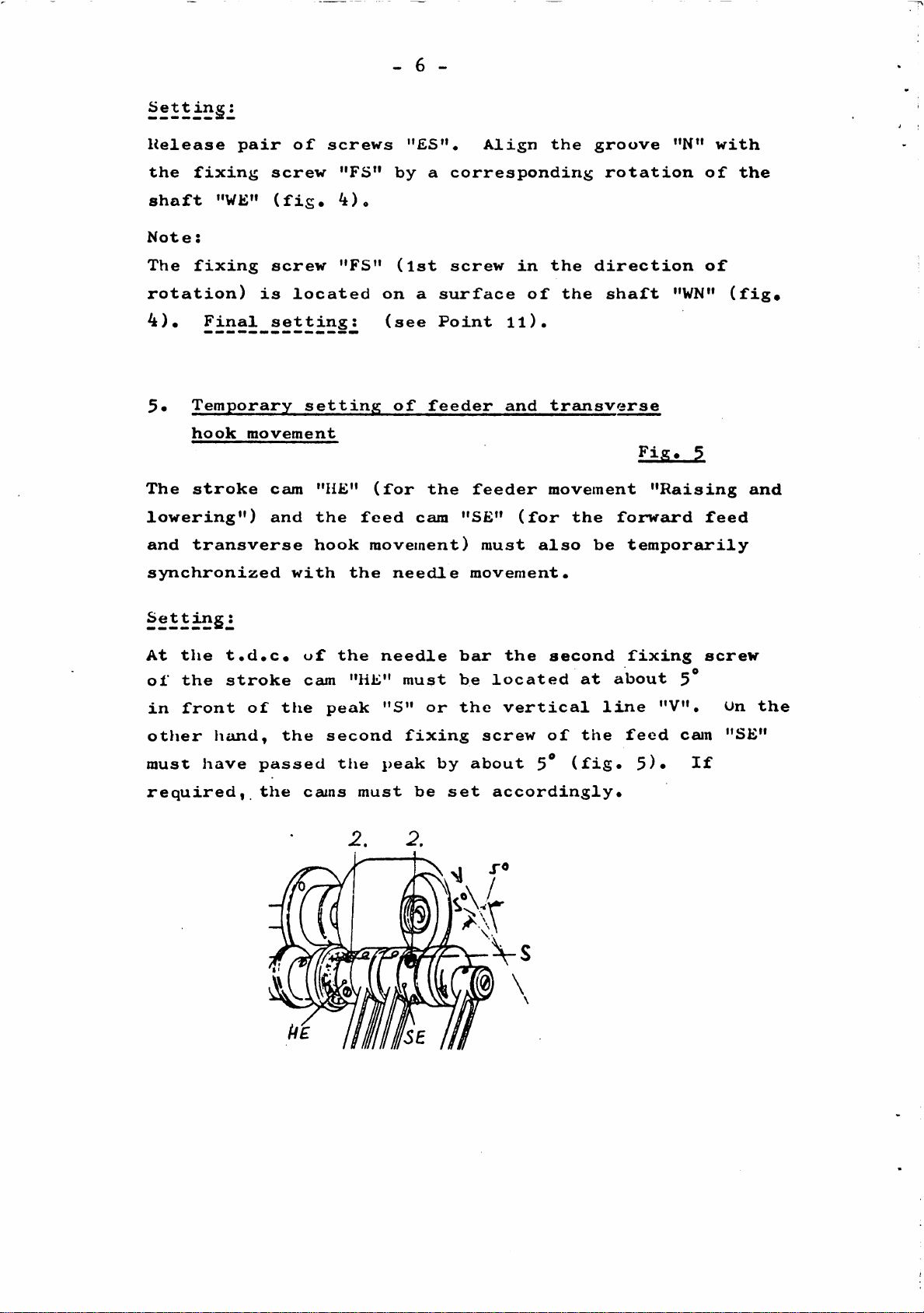

5*

Temporary

setting

of

feeder

and

transverse

hook

movement

£i£.

The

stroke

cam

"HE"

(for

the

feeder

movement

"Raising

and

lowering")

and

the

feed

cam

"SE"

(for

the

forward

feed

and

transverse

hook

movement)

must

also

be

temporarily

synchronized

with

the

needle

movement.

Setting:

At

the

t.d.c.

uf

the

needle

bar

the

second

fixing

screw

of

the

stroke

cam

"HE"

must

be

located

at

about

5*

in

front

of

the

peak

"S"

or

the

vertical

line

"V",

On

the

otJier

hcUid,

the

second

fixing

screw

of

the

feed

cam

"SE"

must

have

passed

tlie

peak

by

about

5^

(fig.

5)*

If

required,

the

cams

must

be

set

accordingly.

s

From the library of: Superior Sewing Machine & Supply LLC

- 7 -

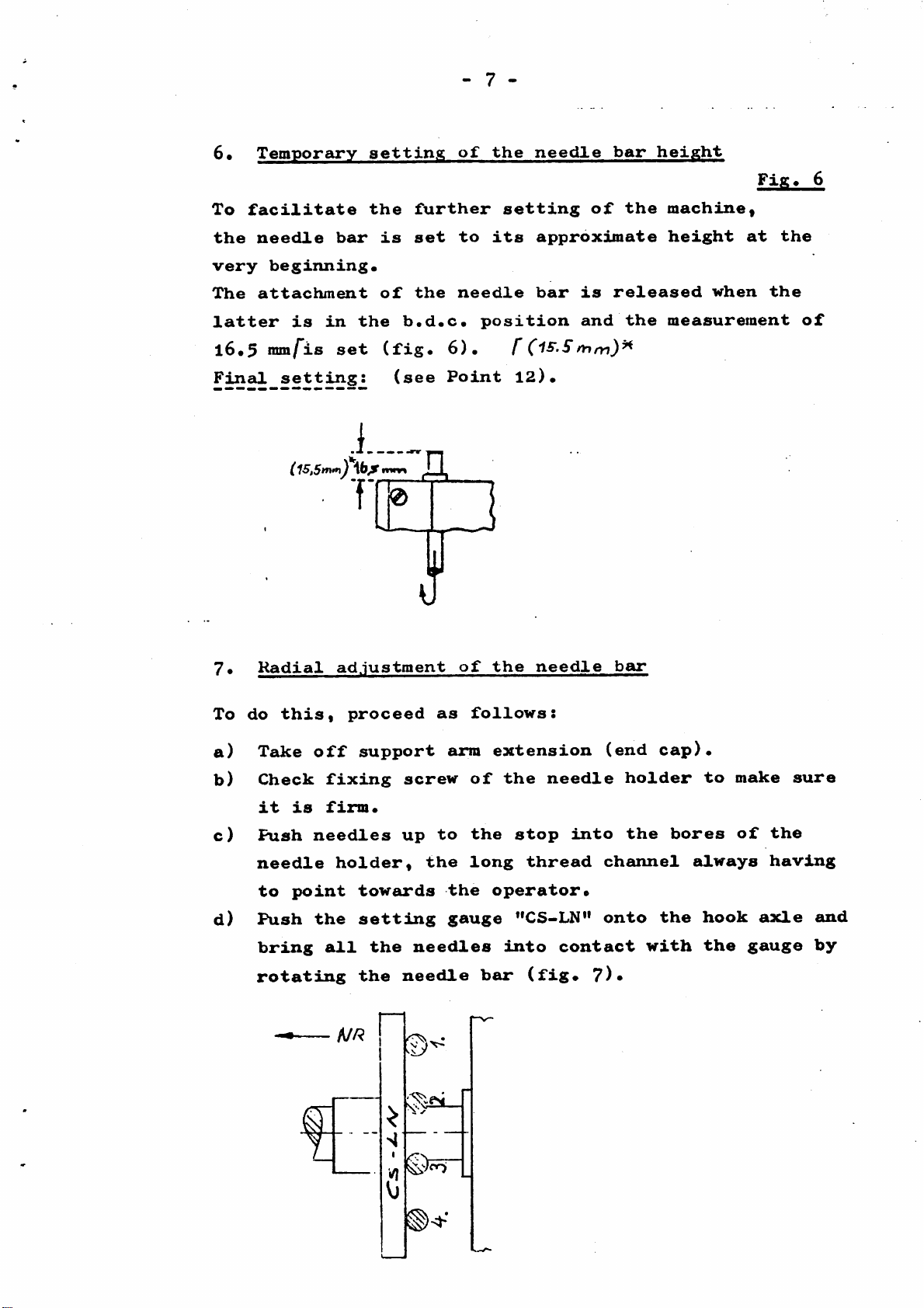

6*

Temporary

setting

of

the

needle

bar

height

Fig^

6

To

facilitate

the

further

setting

of

the

machine«

the

needle

bar

is

set

to

its

approximate

height

at

the

very

beginning*

The

attachment

of

the

needle

bar

is

released

when

the

latter

is

in

the

b.d.c*

position

and

the

measurement

of

l6*5

mm/"is

set

(fig*

6)* f

Final

setting:

(see

Point

12)*

C

15,5nvn^

T

]

7•

Radial

adjustment

of

the

needle

bar

To

do

this,

proceed

as

follows:

a)

Take

off

support

arm

extension

(end

cap)*

b)

Check

fixing

screw

of

the

needle

holder

to

make

sure

it

is

firm*

c)

Push

needles

up

to

the

stop

into

the

bores

of

the

needle

holder,

the

long

thread

channel

always

having

to

point

towards

the

operator*

d)

Push

the

settdLng

gauge

"CS-LN"

onto

the

hook

axle

and

bring

all

the

needles

dlnto

contact

with

the

gauge

by

rotating

the

needle

bcur

(fig*

?)•

A//?

n

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...