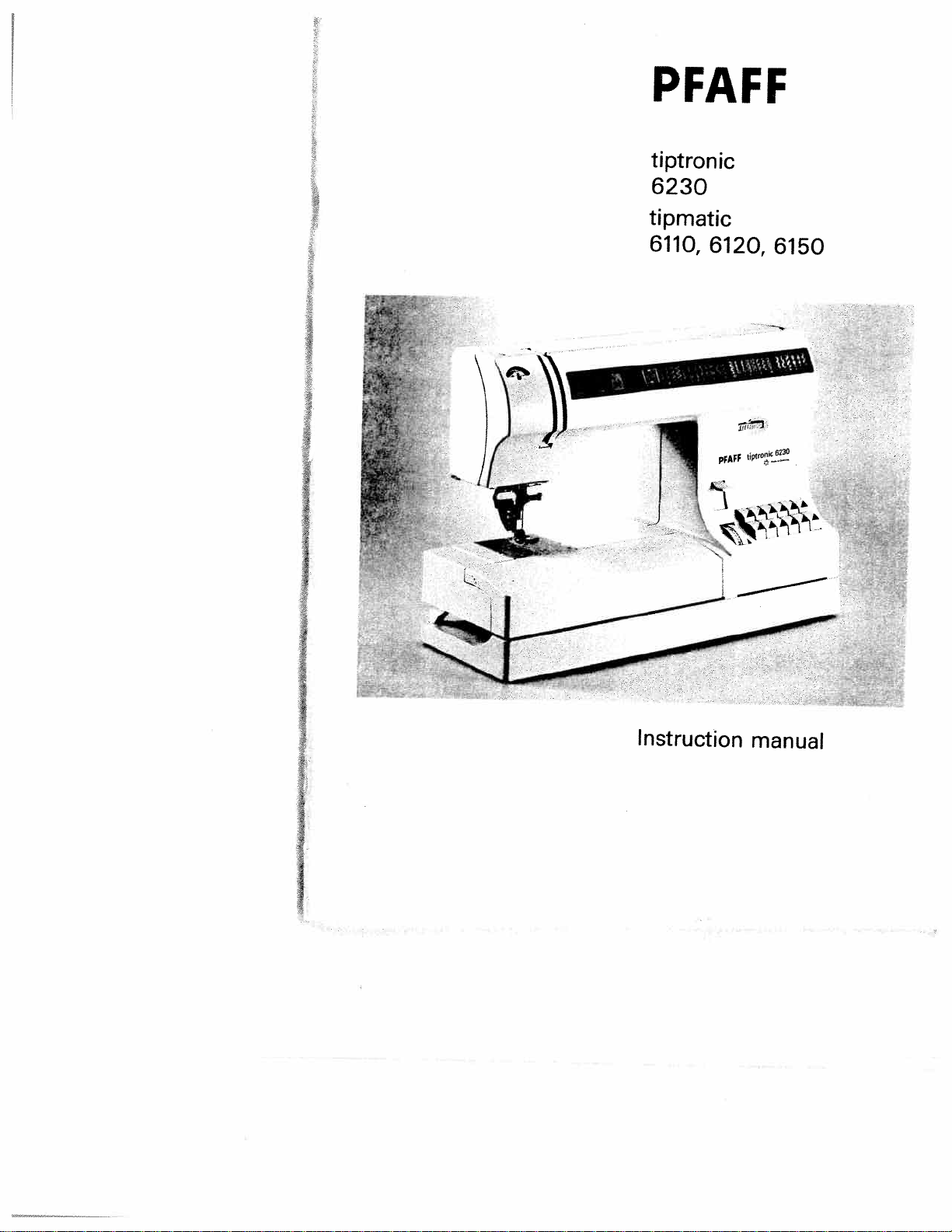

Pfaff tipmatic 6110, tipmatic 6120, tipmatic 6150 User Manual

D

C’,

1

C

C)

C

D

3

0)

D

C

0)

og

C-)

03

0)

.sfl

NJ

0

C.)

-a

01

0

•0

an

‘1

IT’

For

easier

understanding

of

this

instruction

book

please

fold

this

or

the

last

page

open

when

reading

it.

Safety

rules

For

the

United

Kingdom

only

The

leads

must

definitely

not

be

connected

to

the

safety

lead

terminal

I

nor

to

a

plug

with

three

pins.

The

wires

in

the

mains

lead

are

coloured

according

to

the

following

code:

Neutral

Live

As

the

colours

of

the

wires

in

the

mains

lead

of

this

appliance

may

not

correspond

with

the

colour

coding

of

the

terminals

in

your

plug.

proceed

as

follows:

The

wire

which

is

coloured

blue

must

be

con

nected

to

the

terminal

which

is

marked

with

the

lettter

N

or

coloured

black.

The

wire

which

is

coloured

brown

must

be

connected

to

the

terminal

which

is

marked

with

the

letter

L

or

coloured

red.

Cut-off

mains

plugs

are

definitely

not

to

be

used,

but

disposed

of

immediately.

Defective

mains

leads

must

be

replaced

completely.

Only

3

A

spare

fuses

must

be

used

as

approved

by

ASTA

according

to

BS

1362

and

the

fuse

cover

must

be

marked

3

A

or

with

the

corresponding

colour

code.

The

plug

must

never

be

used

without

fuse

cover.

Spare

fuse

covers

are

available

from

electrical

suppliers

or

the

PFAFF

agencies.

Please

also

observe

the

general

safety

notes

on

page

2.

nfinIisfctentnPaZn>

I

I

I

I

Blue:

Brown:

MrsJ

—

-

OCD

‘.a

owl

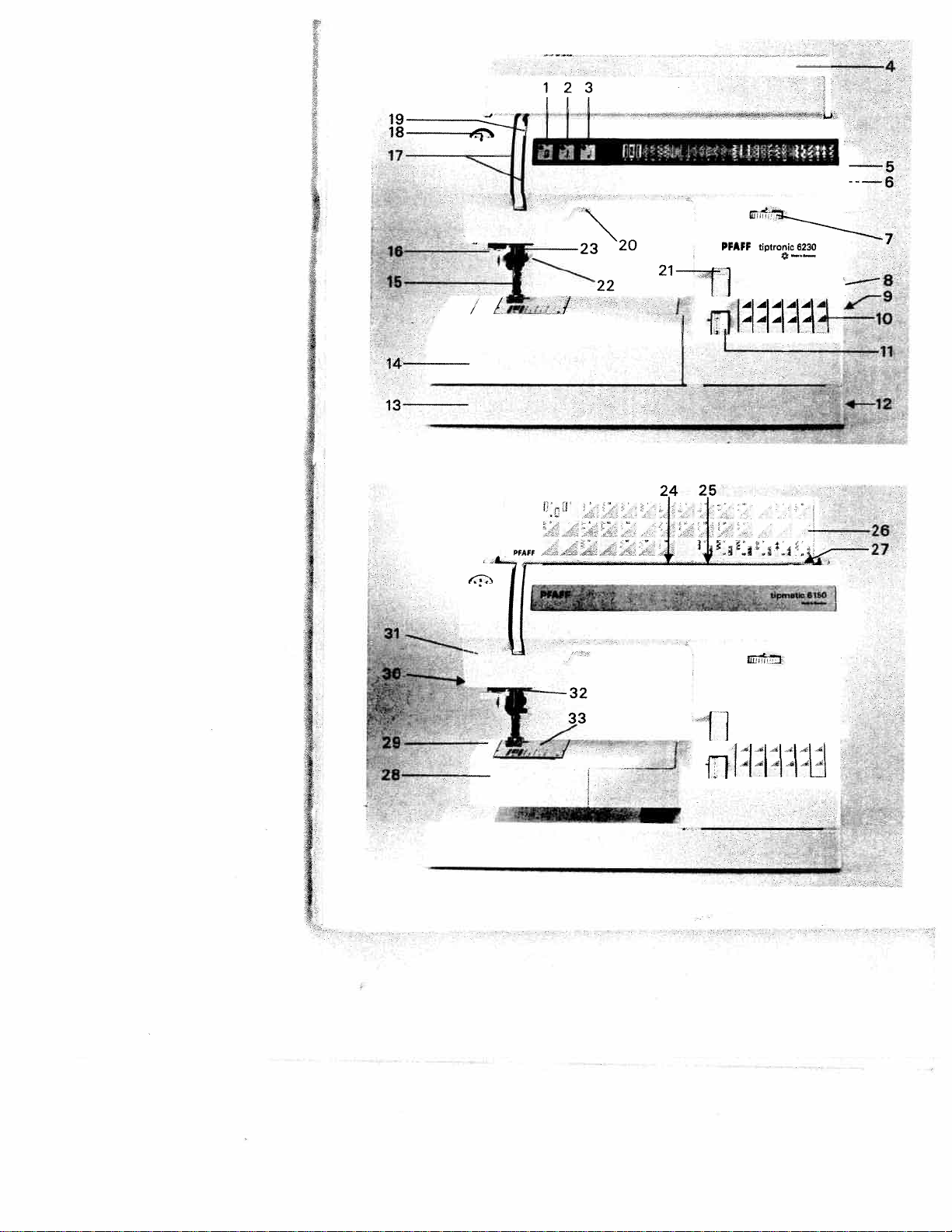

Parts

of

the

sewing machine

(Models

6230

and

6150)

(1)

Key

for

,,slow

sewing”

(Model

6230)

(2)

Key

for

,,needle

down position”

(Model

6230)

(3)

Key

for

,,tacking”

(Model

6230)

(4)

Carrying

handle

(5)

Hand-wheel

(6)

Hand-wheel

release

disk

(7)

Fancy

stitch

knob

(8)

Main

switch

(9)

Connection

socket

,,mains

cord”

(Model

6230)

Connection

socket

,,foot

control with

mains

cord”

(Model

6150)

(10)

Touch

controls

(11)

Stitch

length

knob

(1

2)

Connection

socket

,,foot

control”

(Model

6230)

(13)

Base

plate

(14)

Detachable

work

support

(1

5)

Sewing foot

holder

with

sewing foot

(16)

Needle

threader

(17)

Threading

slit

(1

8)

Needle

thread

tension

(19)

Take-up

lever

(20)

Presser

bar

lifter

(21)

Key

for ,,reverse

sewing”

(22)

Needle

holder

with

fixing

screw

(23)

Dual

feed

(top

feed)

(24)

Reel

holder

with

unwinding

disk

(25)

Second spare

reel

holder

(26)

Lid

with

program

table

(27)

Bobbin

winder

(28)

Hook

cover

(29)

Free

arm

(30)

Thread

trimmer

(31)

Sewing

lamp

(max.

15

watt)

(32)

Thread

guide

(33)

Needle

plate

Important

safety

instructions

For

the

United

States

only

This

sewing

machine

is

designed

and

manufactured

for

HOUSEHOLD

use

only.

When

you

use

an

electric

appliance,

basic

safety

precautions

should

always

be

adhered

to

as

fol

lows:

Read

all

instructions

before

using

this

sewing

machine.

DANGER

To

reduce

the

risk

of

electric

shock:

1

The

sewing

machine

should

never

be

left

unattended

when

plugged

in.

Always

unplug

this

appliance

from

the

electric

outlet

immediately

after

using

and

before

cleaning

it.

2.

Always

unplug

before

relamping.

Replace

bulb

with

same

type

rated

15

Watts

3.

Do

not

reach

for

a

sewing

machine

that

has

fallen

into

water.

Unplug

immediately.

4

Do

not

place

or

store

a

sewing

machine

where

it

can

fall

or

be

pulled

into

a

tub

or

sink.

Do

not

place

in

or

drop

into

water

or

other

liquid.

WARNING

ro

reduce

the

risk

of

burns,

fire,

electric

shock,

or

Injury

to

persons:

I

Do

not

allow

to

be

used

as

a

toy.

Close

attention

is

necessary

when

this

sewing

machine

is

used

by

or

near

children

2.

Use

this

sewing

machine

only

for

ifs

intended

use

as

described

in

this

manual.

Use

only

attachments

recommended

by

the

manufacturer

as

contained

in

this

manual.

3

Never

operate

this

sewing

machine

if

it

has

a

damaged

cord

or

plug,

if

it

is

not

working

pro

perly,

if

it

has

been

dropped

or

damaged,

or

dropped

into

water.

Return

the

appliance

to

the

nearest

authorized

dealer

or

service

center

for

examination,

repair,

electrical

or

mechanical

adlustment

4

Never

operate

the

sewing

machine

with

any

air

openings

blocked.

Keep

ventilation

openings

of

the

sewing

machine

and

foot

control

free

from

the

accumulation

of

lint,

dust,

and

loose

cloth.

5

Never

drop

or

insert

any

object

into

any

opening.

6

Do

not

use

outdoors.

7.

Do

not

operate

where

aerosol

Isprayl

products

are

being

used

or

where

oxygen

is

being

administered.

8.

To

disconnect,

turn

all

controls

to

off

(.01

position,

then

remove

plug

from

outlet.

9.

Never

operate

on

a

soft

surface

such

as

a

bed

or

couch

where

the

air

openings

may

be

blocked.

10

Do

not

unplug

by

pulling

on

cord.

To

unplug,

grasp

the

plug,

not

the

cord

11

Keep

fingers

away

from

all

moving

parts

Special

care

is

required

around

the

sewing

machine

needle.

1

2.

Always

use

the

proper

needle

plate

The

wrong

plate

can

cause

the

needle

to

break.

1

3.

Do

not

use

bent

or

blunt

needles.

Use

needles

recommended

by

the

manufacturer

only.

14

Do

not

pull

or

push

fabric

while

stitching.

It

may

deflect

the

needle,

causing

it

to

break

1

5

Switch

the

sewing

machine

off

l,.0”(

when

making

any

adjustments

in

the

needle

ai’ea,

such

as

threading

needle,

changing

needle,

threading

bobbin,

or

changing

presser

foot,

etc.

1

6.

Always

unplug

sewing

machine

from

the

electric

outlet

when

removing

covers,

lubricating,

or

when

making

any

other

user

servicing

adjustments

mentioned

in

the

instruction

manual

17.

Hold

plug

when

rewinding

into

cord

reel

Do

not

allow

plug

to

whip

when

rewinding.

Please

also

observe

the

general

safety

notes

on

page

2

SAVE

THESE

INSTRUCTIONS

Notes

on

safety

Notes

on

safety

for

domestic

sewing

machines

according

to

DIN

57

700,

Section

28

or

IEC

335,

Section

28.

1.

The

user

must

exercise

adequate

caution

with

regard

to

the

up

and

down

moving

of

the

needle

and

constantly

observe

the

sewing

area

during

work.

2.

When

leaving

the

machine,

during

maintenance

work

or

when

changing

mechanical

parts

or

accessories,

always

disconnect

the

machine

from

the

mains

by

pulling

out

the

mains

plug.

3.

The

maximum

permissible

wattage

for

the

sewing

lamp

is

15

Watts.

4.

The

tension

of

the

drive

belt

must

only

be

adjusted

by

a

Pfaff

mechanic.

5.

The

machine

must

be

put

into

operation

according

to

the

indications

on

the

specification

plate.

6.

Do

not

place

any

objects

in

openings

on

the

machine.

7.

Do

not

use

the

sewing

machine

if:

—

there

is

visible

damage.

its

function

is

disturbed,

—

it

is

wet,

e.g.

with

condensation.

8.

Do

not

pull

the

mains

plug

out

of

the

socket

by

its

cord.

9.

If

this

appliance

is

used

for

another

pur

pose

than

intended

or

if

it

is

wrongly

ope

rated,

we

will

not

accept

any

liability

for

any

damage

caused.

10.

To

avoid

the

risk

of

electric

shock,

do

not

open

the

machine.

There

are

no

paris

inside

the

machine

which

the

user

can

repair.

This

is

solely

the

responsibility

of

our

qualified

service

staff.

11.

Be

sure

to

use

only

original

PFAFF

parts.

Environment

The

recommended

environment

is:

Ambient

temperature

10°

C

to

40°

C,

Humidity

20%

to

80%.

This

sewing

machine

is

a

high-quality

electro

nic-mechanical

appliance;

it

is

a

machine

for

supervised

use

in

the

home.

It

should

be

ope

rated

in

such

a

way

that

it

is

not

subjected

to:

dust,

severe

dampness,

direct

sunlight,

sta

tic

electricity,

heat-producing

objects,

cor

rosive

chemicals

or

liquids.

For

ventilation

purposes

the

machine

must

be

used

on

a

free

surface,

which

is

both

firm

and

even.

Treatment

Always

protect

the

machine

against

damage

by

hitting

or

dropping.

Cleaning

Housing:

To

clean

the

housing,

use

a

dry,

clean

and

soft

cloth

which

is

free

of

fluff.

To

remove

any

stubborn

dirt,

use

a

soft

cloth

with

alcohol

or

paraffin.

Please

Note!

Do

not

use

any

insecticides

or

chemical

pro

ducts

such

as

petrol

lgasl

or

thin

chemicals

for

cleaning

the

housing.

2

Modern,

uncomplicated

—

Sewing

by

puchbutton

control

—

Congratulations!

You

have

bought

a

high-quality

product

that

offers

unique

advantages.

Your

new

sewing

machine

can

take

any

material

in

its

stride

and

will

sew

through

thick

and

thin

for

you.

It

features

the

very

latest

in

design

and

technology

and

this

instruction

book

is

Just

as

uncomplicated

as

your

PFAFF

sewing

machine

If

you

now

take

time

enough

to

study

the

instruction

book

nothing

can

go

wrong

After

all

this

is

the

only

way

to

learn

all

the

things

the

machine

can

do and

to

make

full

use

of

them

If

you

have

any

further

questions,

that

is

no

prob

lem!

Your

PFAFF

dealer

will

be

at your

service

with

any

help

or

advice

you

need.

So

now

you

can

get started!

We

wish

you

many

enjoyable

hours

of

creating

your

fashion

ideas.

3

Contents

Accessories

and

needles

.

72

—

81

Accessory

compartment

14

Applique

66

Appliqué

foot

78

Bias

tape

binder

.

.

.

.

77

Blind

stitch

38

Bobbin

case.

.

18,

19

Bobbin

thread

tension

.

.

.

19

Bobbin

winding

.

.

.

15

—

1

7

Borders

.

.

. .

.

.

62.

63,

64

Buttonholes

.

.

. .

.

.

.

46, 47

Changing

the

needle

26

Changing

the

needle

plate

.

.

.

84

Changing

the

sewing

foot

23

Cleaning

and

oiling

.

.

.

.

84

Closed

overlock

stitch

. .

.

.

42

Detachable

work

support

14

Cording

foot

. .

.

76

Cording

foot

.

.

78

Covering

stitches

.

.

.

.

44.

45

Darning

.

.

.

.

51

—

53

Darning

tears

.

.

.

53

Darning

with

elastic

stitch

52.

53

Darning

with

straight

stitch

.

.

.

51

Decorative

stitches

.

.

61

—

64

Dual

fabric

feed

24,

25

Elastic

stitch

.

41

Elastic

stitches

40

43

Electrical

connection

.

12,

13

Eyelet

embroidery

.

68

Fancy

elastic

knob.

.

30

Fancy

elastic

stitch

.

.

.

.

45

Fancy

stitch

table

.

.

10

Faults.

. .

.

86

Foot

control

.

.

.

.

1

3

Foot

control

.

.

.

.

13

Free

arm.

.

.

.

14

Fringe

foot

79

Function

keys

.

.

31

Gathering

foot

.

.

75

Gathering

with

elastic

thread

.

50

Gathering

with

straight

stitch

.

49

General

sewing

aids

.

.

.

. .

.

35

Hand

wheel

release

disk

.

.

1

5

Hem

with

the

twin

needle

.

48

Hemstitching

.

.

.

.

.

-

69

Honeycomb

stitch

.

.

.

.

41

Inserting

bobbin

.

.

.

16

Inserting

patches

.

.

.

52

Inserting

zippers

54,

55

Lace

work

.

57

Lamp

.

.

.

.

.

.

85

Lap

feller

75

Left

needle

position

.

36

Linen

buttonhole

47

Linen

buttonhole

with

gimp

thread

.

.

47

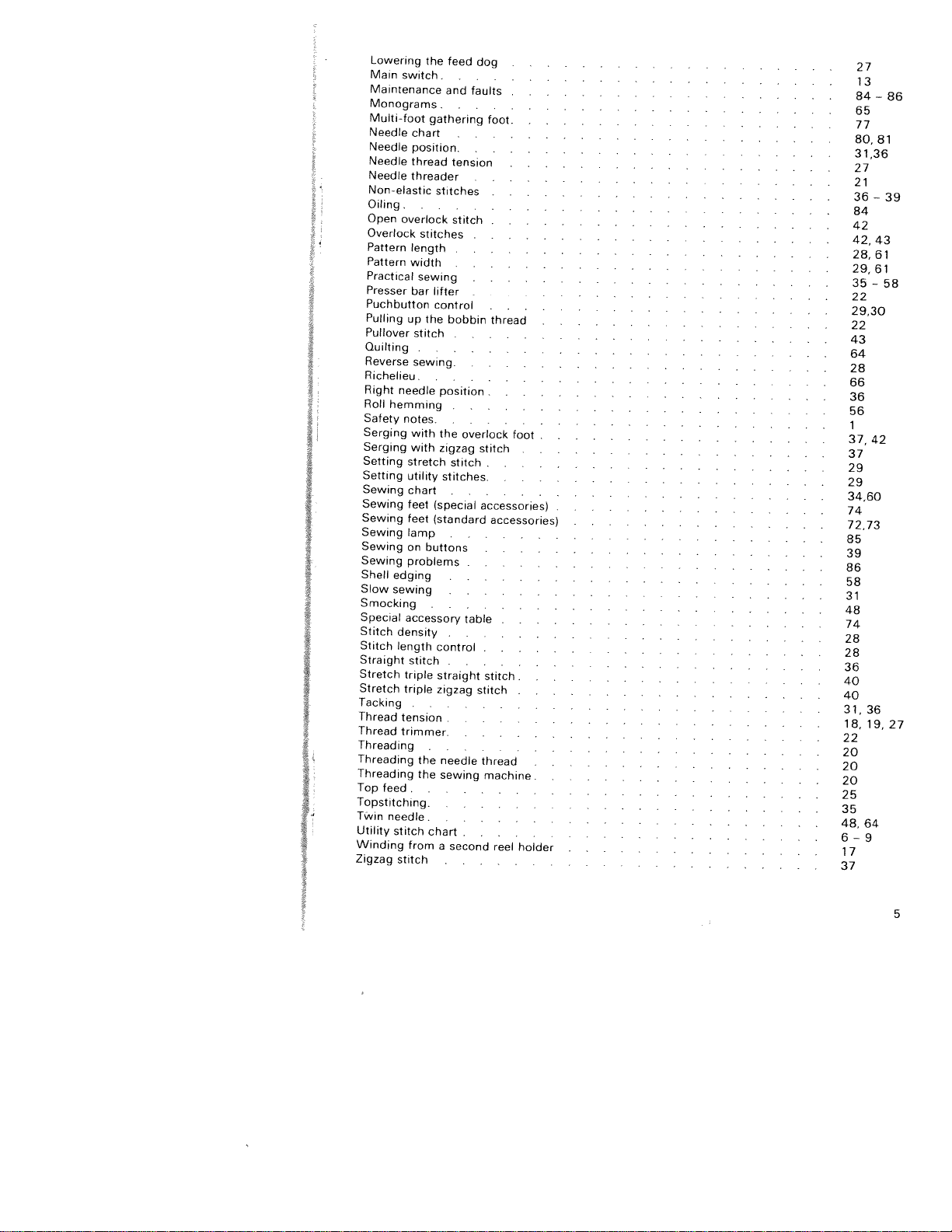

4

Lowering

the

feed

dog

Main

switch

Maintenance

and

faults

Monograms

Multi4oot

gathering

foot.

Needle

chart

Needle

position.

Needle

thread

tension

Needle

threader

Nonelastic

stitches

-

Oiling

.

Open

overlock

stitch

Overlock

stitches

Pattern

length

.

Pattern

width

Practical

sewing

Presser

bar

litter

Puchbutton

control

Pulling

up

the

bobbin

thread

Pullover

stitch

.

.

.

-

Quilting

.....

Reverse

sewing.

Richelieu.........

Right

needle

position

Roll

hemming

Safety

notes

Serging

with

the

overlock

foot

Serging

with

zigzag

stitch

Setting

stretch

stitch

.

Setting

utility

stitches.

Sewing

chart

Sewing

feet

lspecial

accessories(

Sewing

feet

(standard

accessories(

Sewing

lamp

Sewing

on

buttons

Sewing

problems

.

.

Shell

edging

Slow

sewing

Smocking

.

.

.

Special

accessory

table

Stitch

density

.

Stitch

length

control

Straight

stitch

j

Stretch

triple

straight

stitch.

Stretch

triple

zigzag

stitch

Tacking

.

J

Thread

tension

Thread

trimmer

Threading

.

.

Threading

the

needle

thread

Threading

the

sewing

machine.

Top

feed.

.

.

.

Topstitching.

Twin

needle.

Utility

stitch

chart

.

.

Winding

from

a

second

reel

holder

Zigzag

stitch

13

84—86

65

77

84

28,61

29,61

35—58

22

22

28

66

36

56

37

34,60

74

85

39

86

58

74

28

28

36

40

20

20

6—9

17

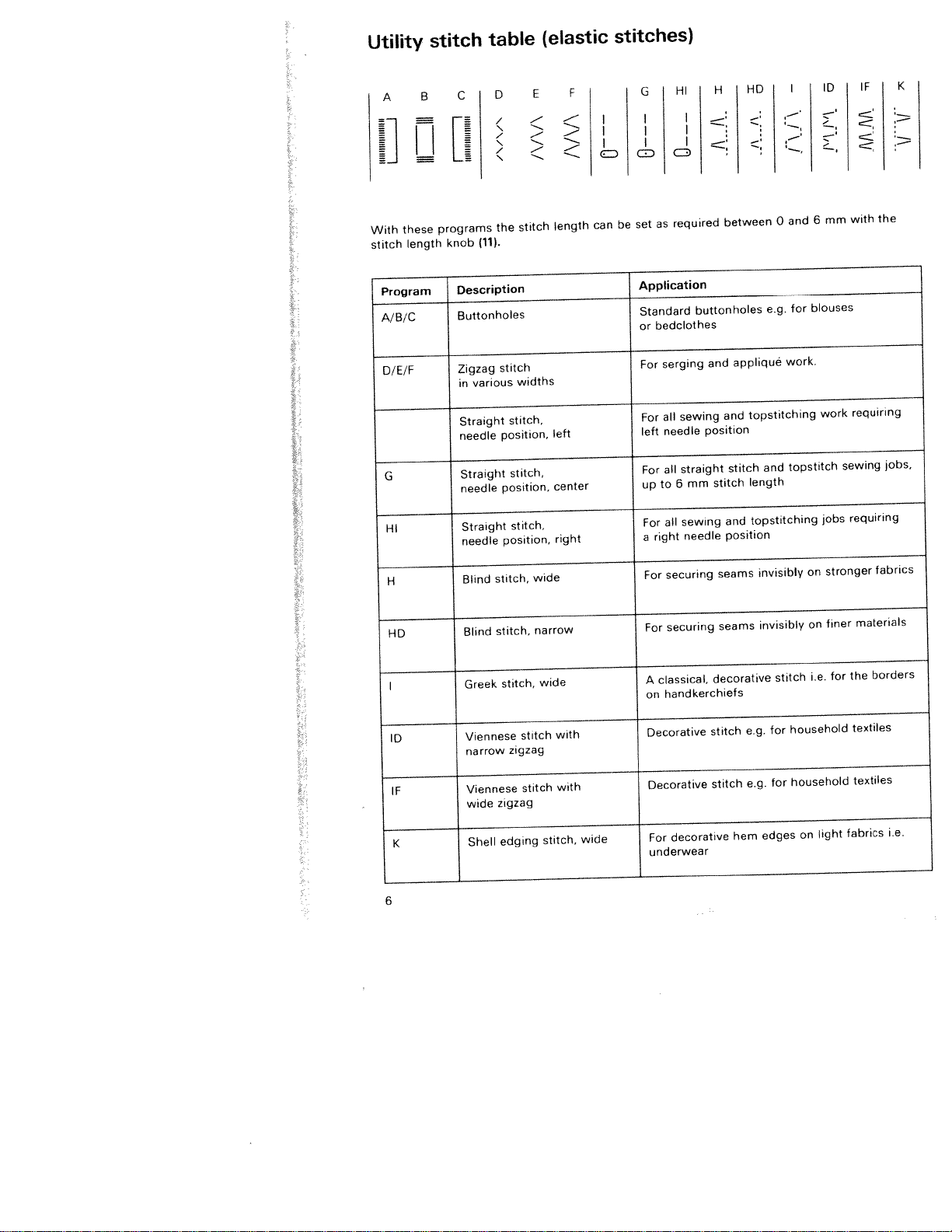

Utility

stitch

table

(elastic

stitches)

D

E

F

G

HI

H

HD

ID

IF

K

<

<

_:

_:

,—‘

c—’

‘

/

I

“

“

-‘

‘-

I

I

-

‘

I

(

<

ED

ED

c

:

“:

,

With

these

programs

the

stitch

length

can

be

set

as

required

between

0

and

6

mm

with

the

stitch

length

knob

(11).

Program

Description

Application

A/B/C

Buttonholes

Standard buttonholes

e.g.

for

blouses

or

bedclothes

D/E/F

Zigzag

stitch

For

serging

and

appliqué

work.

in

various

widths

Straight

stitch,

For

all

sewing

and

topstitching

work

requiring

needle

position,

left

left

needle

position

G

Straight

stitch,

For

all

straight

stitch

and

topstitch

sewing

jobs,

needle

position,

center

up

to

6

mm

stitch

length

HI

Straight

stitch,

For

all

sewing

and

topstitching

jobs

requiring

needle

position,

right

a

right

needle

position

H

Blind

stitch,

wide

For

securing

seams

invisibly

on

stronger

fabrics

HD

Blind

stitch,

narrow

For

securing

seams

invisibly

on

finer

materials

I

Greek

stitch,

wide

A

classical,

decorative

stitch

i.e.

for

the

borders

on

handkerchiefs

ID

Viennese

stitch

with

Decorative

stitch

e.g.

for

household

textiles

narrow

zigzag

IF

Viennese

stitch

with

Decorative

stitch

e.g.

for

household

textiles

wide

zigzag

1<

Shell

edging

stitch,

wide

For

decorative

hem

edges

on

light

fabrics

i.e.

underwear

6

I

I

I

S

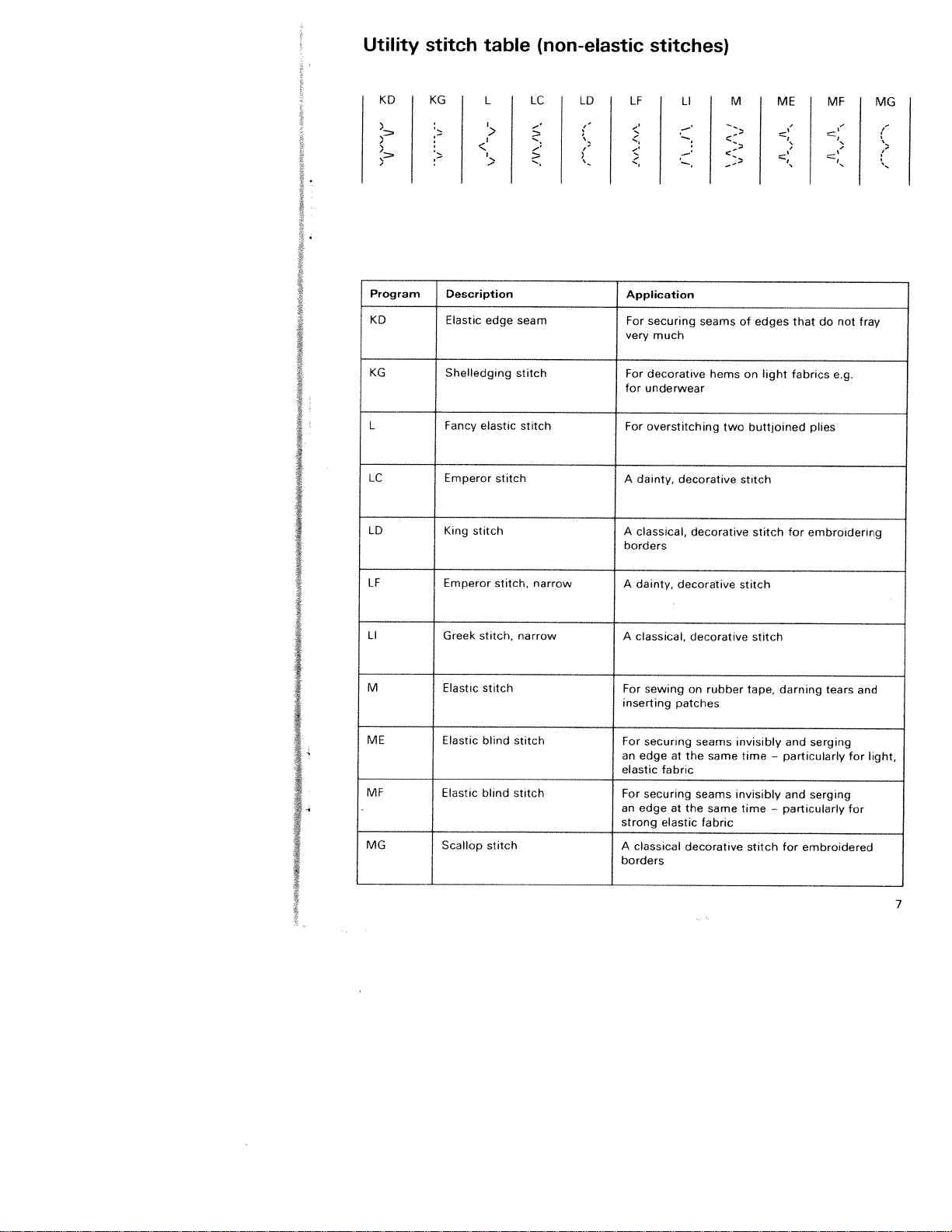

Utility

stitch

table

(non-elastic

stitches)

KU

KG

L

LC

LU

LF

LI

M

ME

MF

MG

Program Description

Application

KD

Elastic

edge

seam

For

securing

seams

of

edges

that

do

not fray

very

much

KG

Shelledging

stitch

For

decorative

hems

on

light

fabrics

e.g.

for

underwear

L

Fancy

elastic

stitch

For

overstitching

two

buttjoined

plies

LC

Emperor

stitch

A

dainty,

decorative

stitch

LU

King

stitch

A

classical,

decorative

stitch

for

embroidering

borders

LF

Emperor

stitch,

narrow

A

dainty,

decorative

stitch

LI

Greek

stitch,

narrow

A

classical,

decorative

stitch

M

Elastic

stitch

For

sewing

on

rubber

tape,

darning

tears

and

inserting

patches

ME

Elastic

blind

stitch

For

securing

seams

invisibly

and

serging

an

edge

at

the

same

time

—

particularly

for light,

elastic

fabric

MF

Elastic

blind

stitch

For

securing

seams

invisibly

and

serging

an

edge

at

the

same

time

—

particularly

for

strong

elastic

fabric

MG

Scallop

stitch

A

classical

decorative

stitch

for

embroidered

borders

7

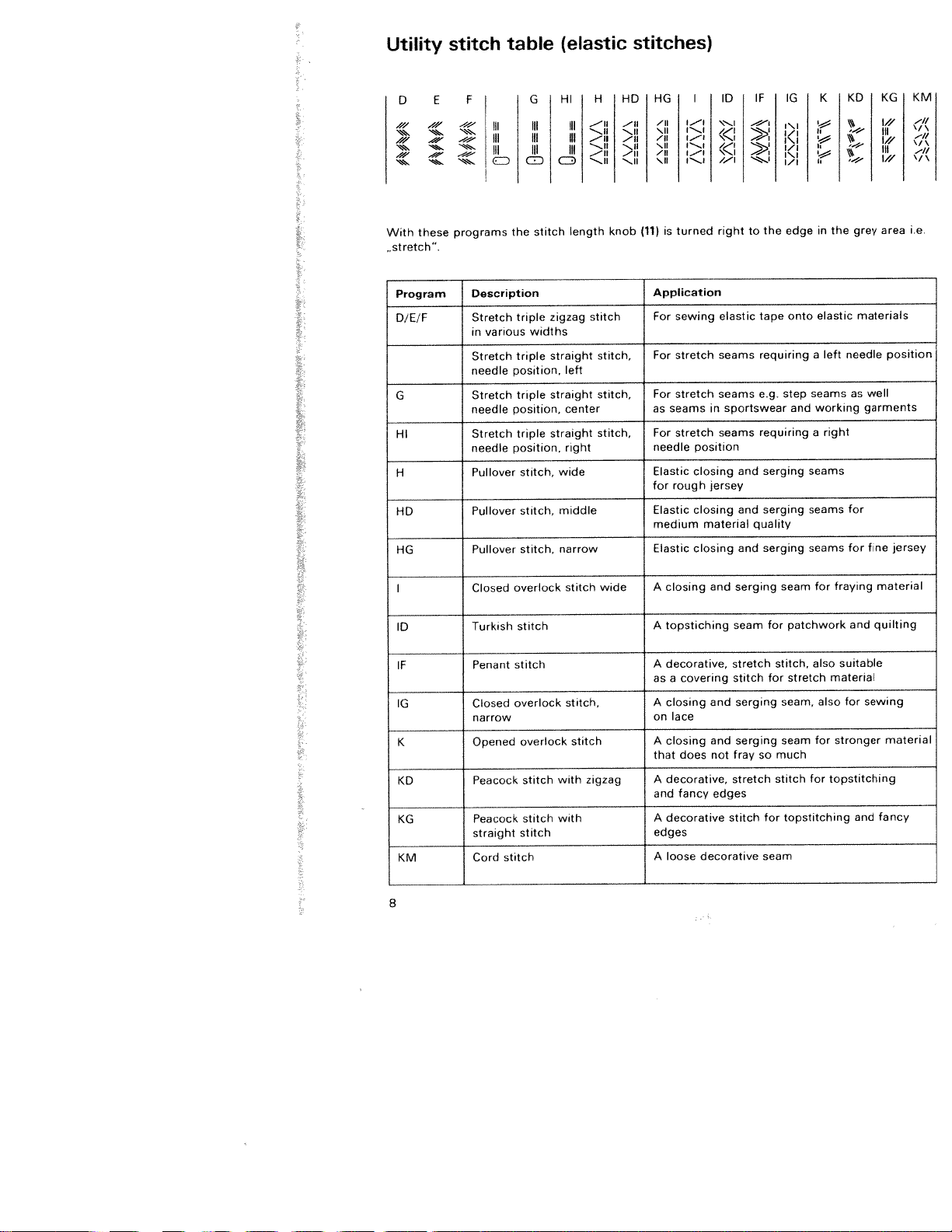

Utility

stitch

table

(elastic

stitches)

D

E

F

G

Hi

I

H

HO

I

HG

I

ID

IF

I

IG

I

K

I

KO

I

KGI

KMI

Ill

lii

‘i

I

\I

I

11/

I

l’

‘,

I

III

I

I

ii

\ii

I

i”i

I

/

—‘I,

‘..

‘.‘.

‘.‘,

I

Ill

Iii

0

“,ii

I

“,,ii

‘sit

I

i”..i

,,,

,

,,—

II

Ih

ill

I

—“i

..—‘ii

—II

‘

,.—

—

III

Hi

I

iii

__.—ii

—ii

‘—‘—

I

i

‘,

‘.

‘..

JcD

1

E

1

c

i”.,.i

1

/_”I

1

”.j

1

1/,’

With

these

programs

the

stitch

length

knob

(11)

is

turned

right

to

the

edge

in

the

grey

area

i.e.

,,stretch”.

Program

Description

Application

D/E/F

Stretch

triple

zigzag

stitch

For

sewing

elastic

tape

onto

elastic

materials

in

various

widths

Stretch

triple

straight

stitch,

For

stretch

seams

requiring

a

left

needle

position

needle

position,

left

G

Stretch

triple

straight

stitch,

For

stretch

seams

e.g.

step

seams

as

well

needle

position,

center

as

seams

in

sportswear

and

working

garments

Hi

Stretch

triple

straight

stitch,

For

stretch

seams

requiring

a

right

needle

position,

right

needle

position

H

Pullover

stitch,

wide

Elastic

closing

and

serging

seams

for

rough

jersey

HD

Pullover

stitch,

middle

Elastic

closing

and

serging

seams

for

medium

material

quality

HG

Pullover

stitch,

narrow

Elastic

closing

and

serging

seams

for

fine

jersey

I

Closed

overlock

stitch

wide

A

closing

and

serging

seam

for

fraying

material

ID

Turkish

stitch

A

topstiching

seam

for

patchwork

and

quilting

IF

Penant

stitch

A

decorative,

stretch

stitch,

also

suitable

as

a

covering

stitch

for

stretch

material

lG

Closed

overlock

stitch,

A

closing

and

serging

seam,

also

for

sewing

narrow

on

lace

K

Opened

overlock

stitch

A

closing

and

serging

seam

for

stronger

material

that

does

not

fray

so

much

KO

Peacock

stitch

with

zigzag

A

decorative,

stretch

stitch

for

topstitching

and

fancy

edges

KG

Peacock

stitch

with

A

decorative

stitch

for

topstitching

and

fancy

straight

stitch

edges

KM

Cord

stitch

A

loose

decorative

seam

8

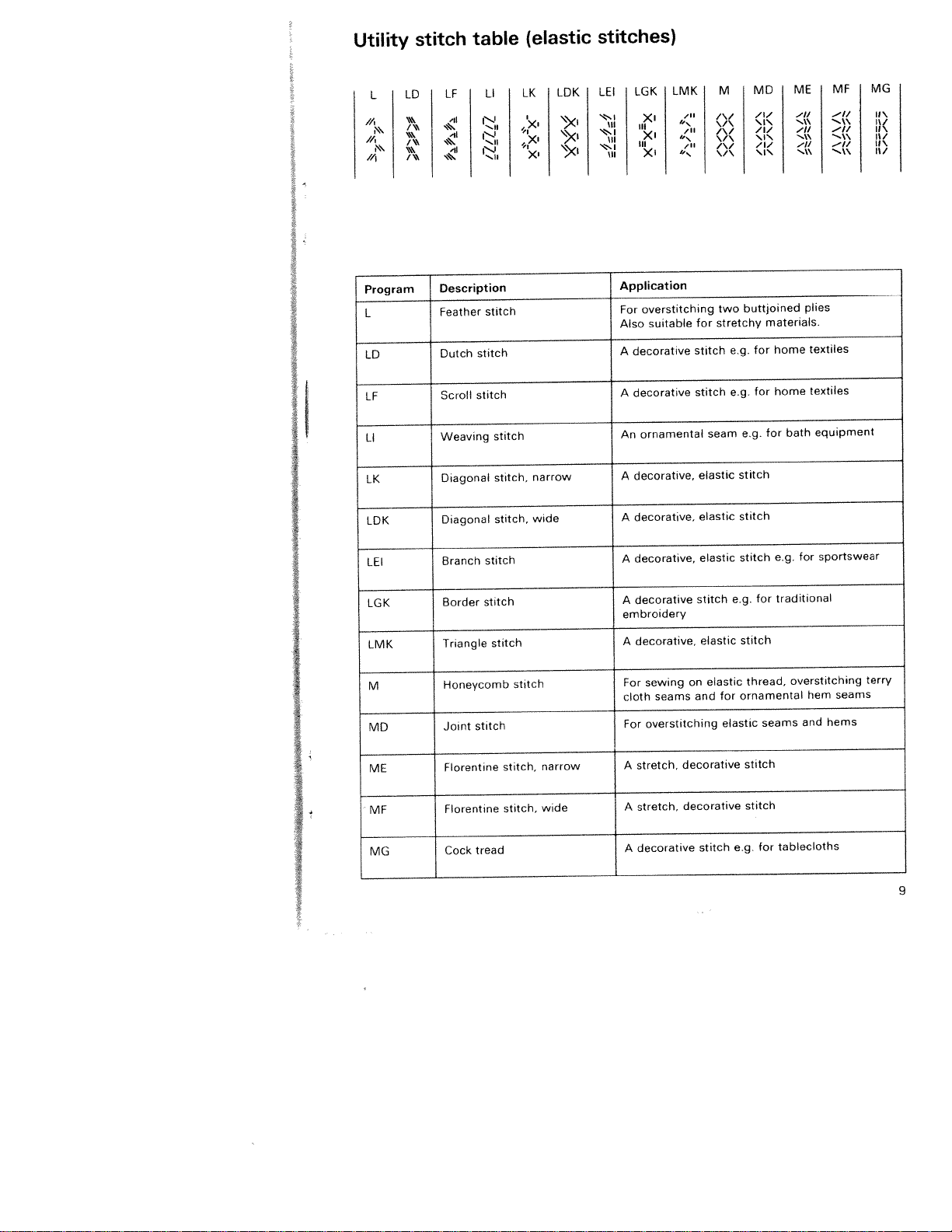

Utility

stitch

table

(elastic

stitches)

‘5’

-ii

NJ

\XI

\..i

XI

/1,’

I

I

I

J’t%

I

I

‘.ii

,X’

iii

•

III

I

I

I

\i\

“.i.\

‘.i\

I

11/

L

LD

LF

LI

I

LK

LDK

LEI

LGK

LMK

f

M

I

MD

ME

MF

I

MG

,“

I

—I’

I

I

ll\

i

I

•.ii

Xi

5

41

I

X’

I

\/\

I

\I

I

11/

I

I

-ii

I

I

\)<i

‘“i

7”

I

/1/

II\

.1i

Xi

in

XI

\/‘s

11/

Program

Description

Application

L

Feather

stitch

For

overstitching

two

butt;oined

plies

Also

suitable

for

stretchy

materials.

LD

Dutch

stitch

A

decorative

stitch

e.g.

for

home

textiles

LF

Scroll

stitch

A

decorative

stitch

e.g.

for

home

textiles

LI

Weaving

stitch

An

ornamental

seam

e.g.

for

bath

equipment

LK

Diagonal

stitch,

narrow

A

decorative,

elastic

stitch

LDK

Diagonal

stitch,

wide

A

decorative,

elastic

stitch

LEI

Branch

stitch

A

decorative,

elastic

stitch

e.g.

for

sportswear

LGK

Border

stitch

A

decorative

stitch

e.g.

for

traditional

embroidery

LMK

Triangle

stitch

A

decorative,

elastic

stitch

M

Honeycomb

stitch

For

sewing

on

elastic

thread,

overstitching

terry

cloth

seams

and

for

ornamental

hem

seams

MD

Joint

stitch

For

overstitching

elastic

seams

and

hems

ME

Florentine

stitch,

narrow

A

stretch,

decorative

stitch

MF

Florentine

stitch,

wide

A

stretch,

decorative

stitch

MG

Cock

tread

A

decorative

stitch

e.g.

for

tablecloths

9

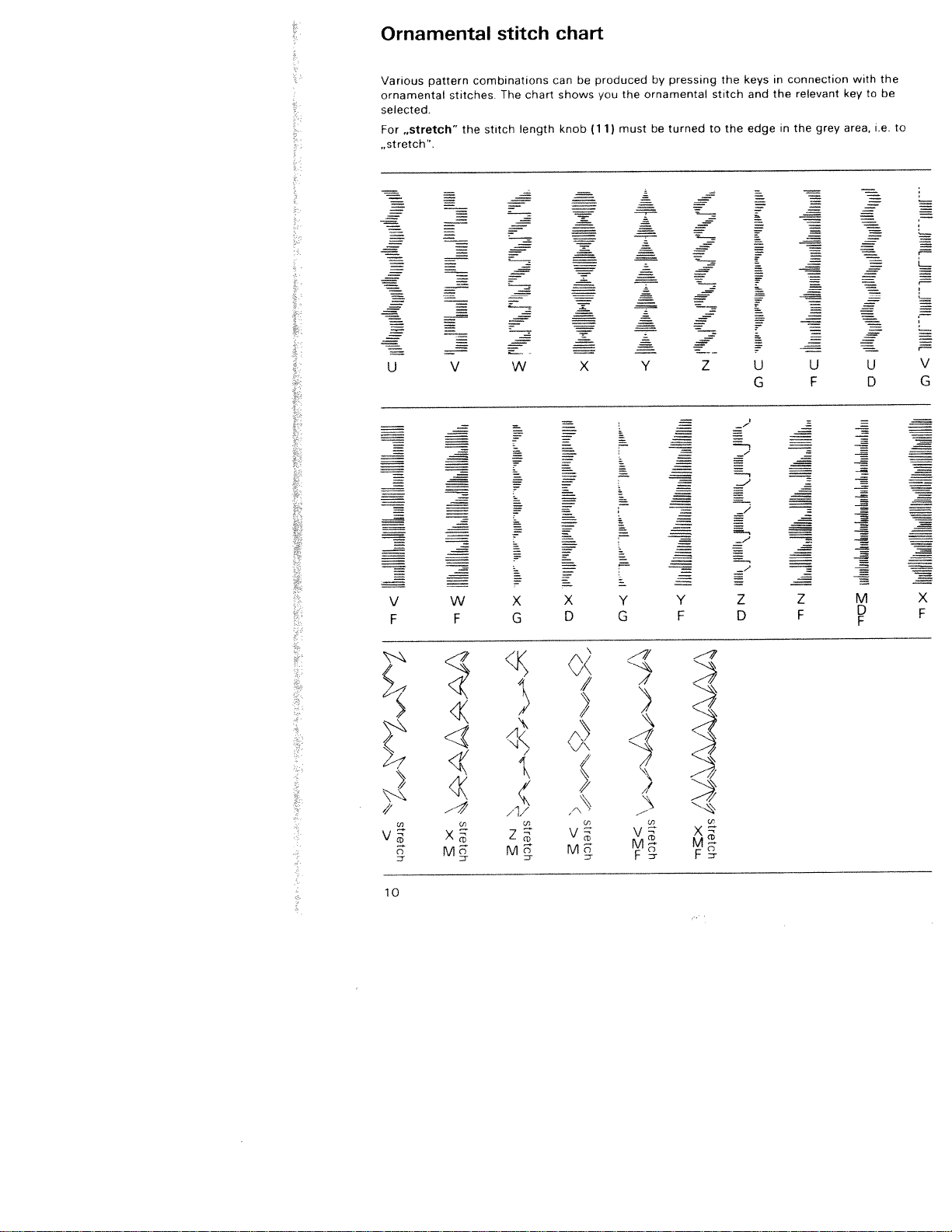

1IllIII

VIIIILilII{ll.

ifIIIIIJlIWIL

‘

11111

PIljjjljjjIIlj

11111111

{fjjjjIIIIjlIl

liii

II

I1IIIUI

1

D

II

ill

II

a)

95a)

Q)

>

C)

1

III,IqIIp

C

lilt

ii

jliiJlijifi

ijlilIIil

lj

1

i

D

_L

‘iii

o

111111

liii!

‘liii

iii!!

iiIh

0

2

a)

D

C)

iIlIIlidlTlIIiIllIiIIiIIIillTlhIlilUIi

iilii.

D

(_

a)

—

—\

1f”ilifJiTI”TN}ill[’’iTjiTHh[’lliilTl[

ijj

r’

ci

o

a)

a)

0

C

-

C)

0

‘I

‘I

stretch

—

i’

ii—

i’’

il

il’,

Oil

liii

a)

V

00

iillIllilillijillIiltIiijIllIlIliliillITllI!IfllIlIlllIliljI

::‘•—

2

‘lIhi

liii

‘IllIj

>-

a)

I

stretch

ilillflililIiTliIII

Tili

11111111

II

iij

111111

a)a)

—

2

01

tiiLiitl1

..,iiLiilL..iiilL.i

o

c

—

—

t

°‘

I’

a)

.0

llIlllhIIIllIIllhIIllIllIIli.ilIlllhlIliIIIliUlIlIlIll

:>(

stretch

.r

o

0

C

C

C

o

-

x

o

0

t

-C

C

C)

.2

-

a) a)

—

I

Ih

I

ii

I

ih

I

ih

I

I

Ii’

IIlilill,dlliitlh,.iili,

it,,

..

stretch

C

f

C

iihi

‘iii,i

1iIi

‘liii

iil

iiii

il

U)

-

0

oC

a)

0

C

N

stretch

I

C

2

—

Oil)!

liii))

liii!

I)))))!

111111

1111111

Iiiiul

ililh

lniil

1111111

ii>

111111

11111

0Ii

liii!

91111

111111

liii

x

E

0

0

-C

_

_:

.

lIlIlllliiiIliliiIlIilIlllllililIliiiiiiiiiIiIiiilliliiIIIiil

D

iIl1IIt!IlII1111lIlIIl11hJIIIIIII1IIIIII111I

j

1

stretch

>

C

C

a)

>

0

0

LL

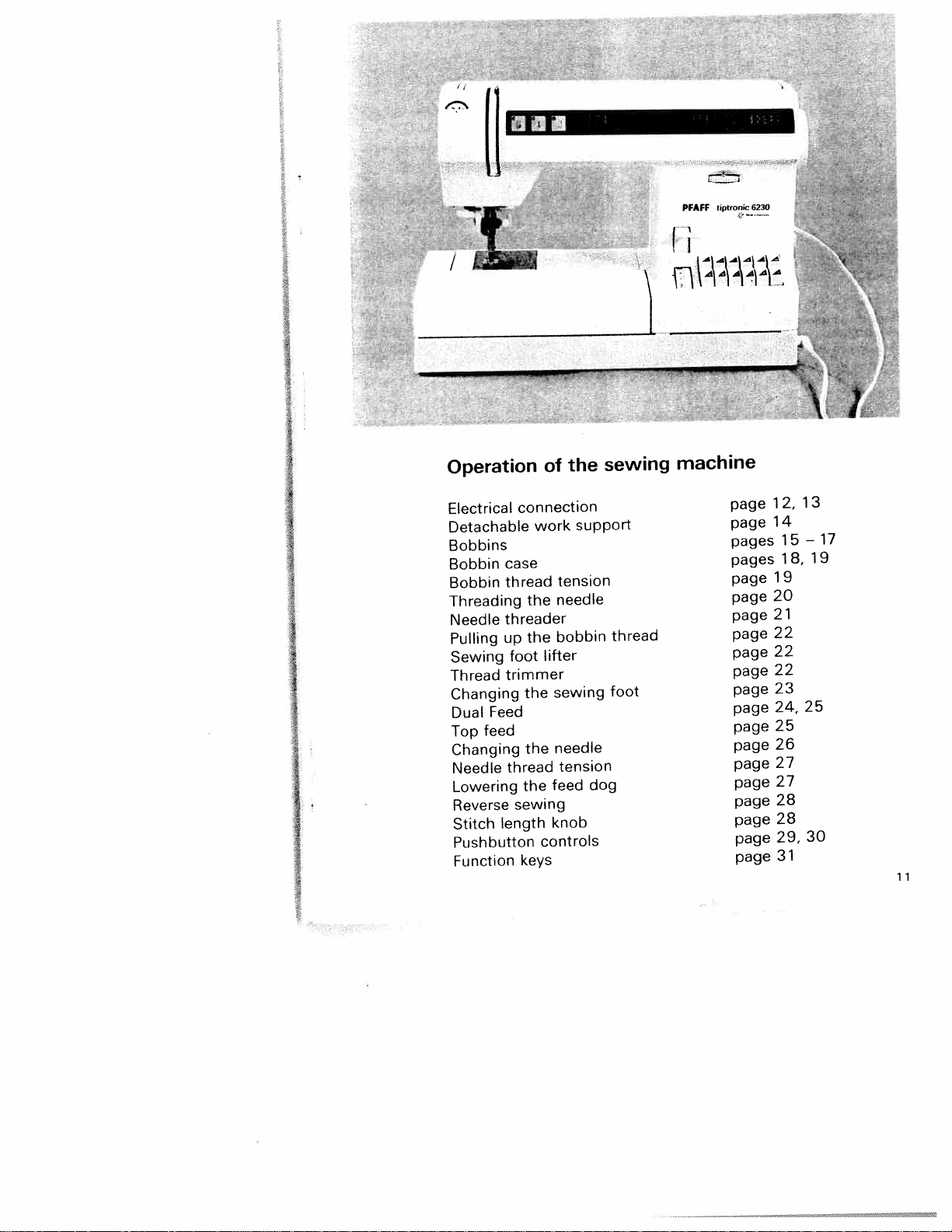

PFAFF

I

pt

onlc

6230

/

i!II

———

Operation

of

the

sewing

machine

I

Electrical

connection

page

1

2,

1

3

I

Detachable

work

support

page

1

4

Bobbins

pages

15

—

17

Bobbin

case

pages

1

8,

1

9

Bobbin

thread

tension

page

1

9

J

Threading

the

needle

page

20

Needle

threader

page

21

I

Pulling

up

the

bobbin

thread

page

22

Sewing

foot

lifter

page

22

Thread

trimmer

page

22

I

Changing

the

sewing

foot

page

23

Dual

Feed

page

24,

25

Top

feed

page

25

Changing

the

needle

page

26

Needle

thread

tension

page

27

Lowering

the

feed

dog

page

27

Reverse

sewing

page

28

-i

Stitch

length

knob

page

28

I

Pushbutton

controls

page

29,

30

I

Function

keys

page

31

11

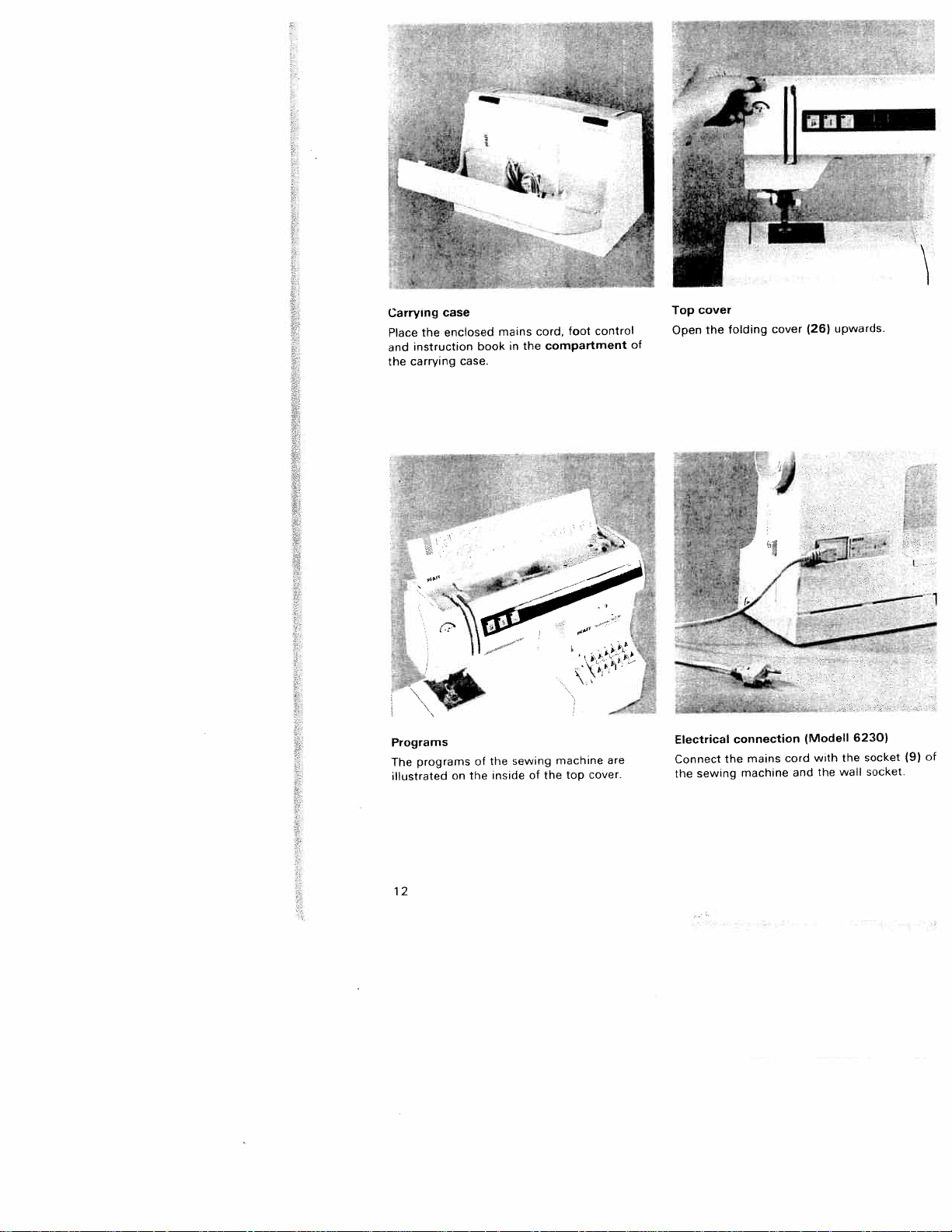

Carrying

case

Place

the

enclosed

mains

cord,

foot

control

and

instruction

book

in

the

compartment

of

the

carrying

case.

0’

Programs

The

programs

of

the

sewing

machine

are

illustrated

on

the

inside

of

the

top

cover

Top

cover

Open

the

folding

cover

(26)

upwards.

Electrical

connection

(Modell

6230)

Connect

the

mains

cord

with

the

socket

(9)

of

the

sewing

machine

and

the

wall

socket

F.

Ii

N

N’

]

12

Connecting

the

foot

control

(Model

6230)

Connect

the

plug

of

the

foot

control

with

the

connection

socket

(12)

of

the

sewing

machine.

The

sewing

speed

is

regulated

by

pressing

the

pedal.

Main

switch

Connect

the

plug of

the

foot

control

with

the

connection

socket

(9)

of

the

sewing

machine.

The

sewing

speed

is

regulated

by

pressing

the

pedal.

The

sewing

speed

can

also

be

regulated

with

the

slide

control

on

the

head

of

the

foot control.

Position

=

half

speed

Position

44

=

full

speed

When

the

main

switch

(8)

is

switched

on.

the

sewing

lamp

lights

up.

The

sewing

machine

is

now

ready

to

use.

-

-

Connecting

the

foot

control

(Models

6110.

6120.

6150)

13

A

I

J

41

41

41

.41

.4

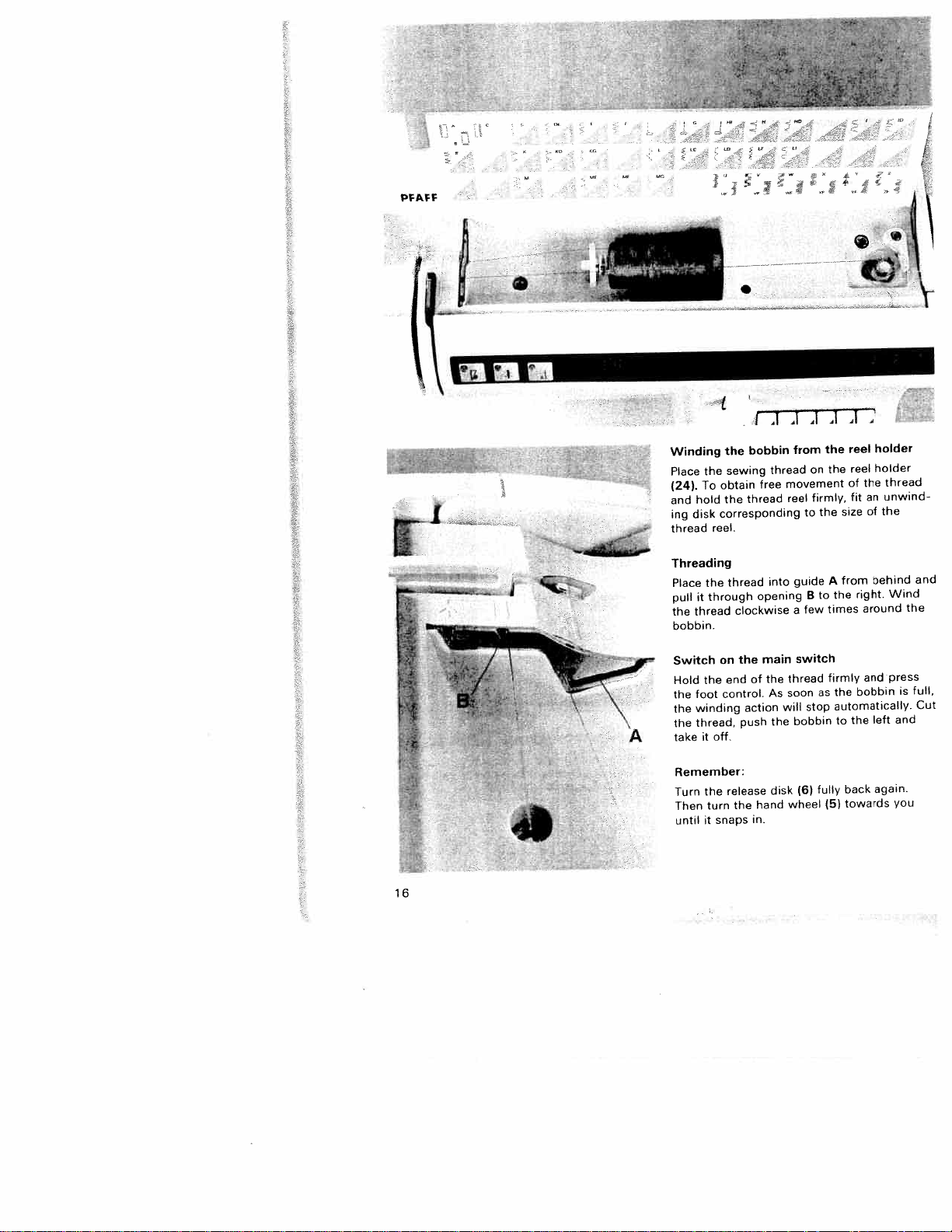

Winding

the

bobbin

from

the

reel

holder

Place

the

sewing

thread

on

the

reel

holder

(24).

To

obtain

free

movement

of

the

thread

and

hold

the

thread

reel

firmly,

fit

an

unwind

ing

disk

corresponding

to

the

size

of

the

thread

reel.

Threading

Place

the

thread

into

guide

A

from

behind

and

pull

it

through

opening

B

to

the

right.

Wind

the

thread

clockwise

a

few

times

around

the

bobbin.

Switch

on

the

main

switch

Hold

the

end

of

the

thread

firmly

and

press

the

foot

control.

As

soon

as

the

bobbin

is

full,

the

winding

action

will

stop

automatically.

Cut

the

thread,

push

the

bobbin

to

the

left

and

A

take

it

off.

Remember:

Turn

the

release

disk

(6)

fully

back

again.

Then

turn

the

hand

wheel

(5)

towards

you

until

it

snaps

in.

I

S

16

I

3

V

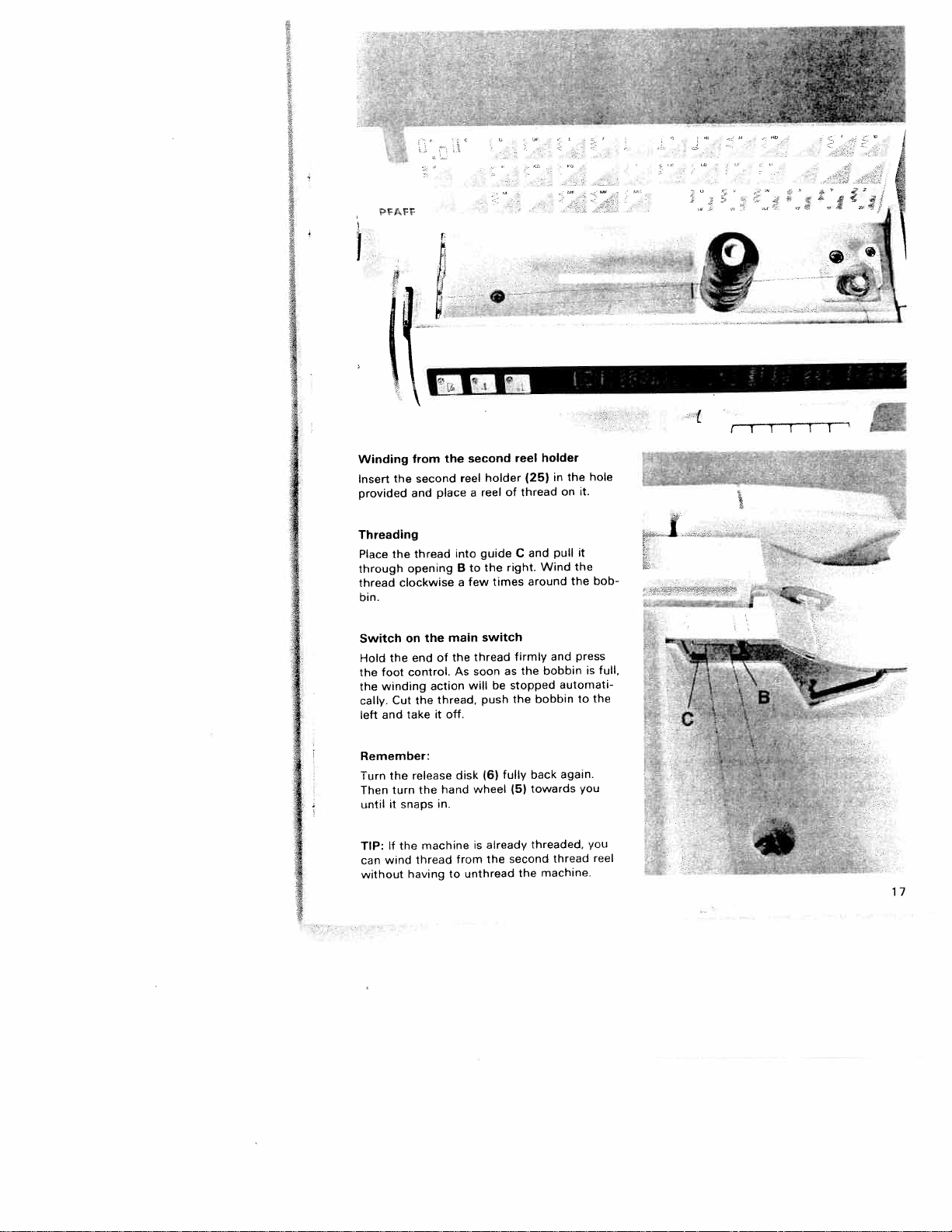

Winding

from

the

second

reel

holder

Insert

the

second

reel

holder

(25)

in

the

hole

provided

and

place

a

reel

of

thread

on

it.

Threading

Place

the

thread

into

guide

C

and

pull

it

through

opening

B

to

the

right.

Wind

the

thread

clockwise

a

few

times

around

the

bob

bin.

Switch

on

the

main

switch

Hold

the

end

of

the

thread

firmly

and

press

the

foot

control.

As

soon

as

the

bobbin

is

full,

the

winding

action

will

be

stopped

automati

cally.

Cut

the

thread,

push

the

bobbin

to

the

left

and

take

it

off.

Remember:

Turn

the

release

disk

(6)

fully

back

again.

Then

turn

the

hand

wheel

(5)

towards

you

until

it

snaps

in

TIP:

If

the

machine

is

already

threaded,

you

can

wind

thread

from

the

second

thread

reel

without

having

to

unthread

the

machine.

I

-4

I

I

I

I

I

I

17

A

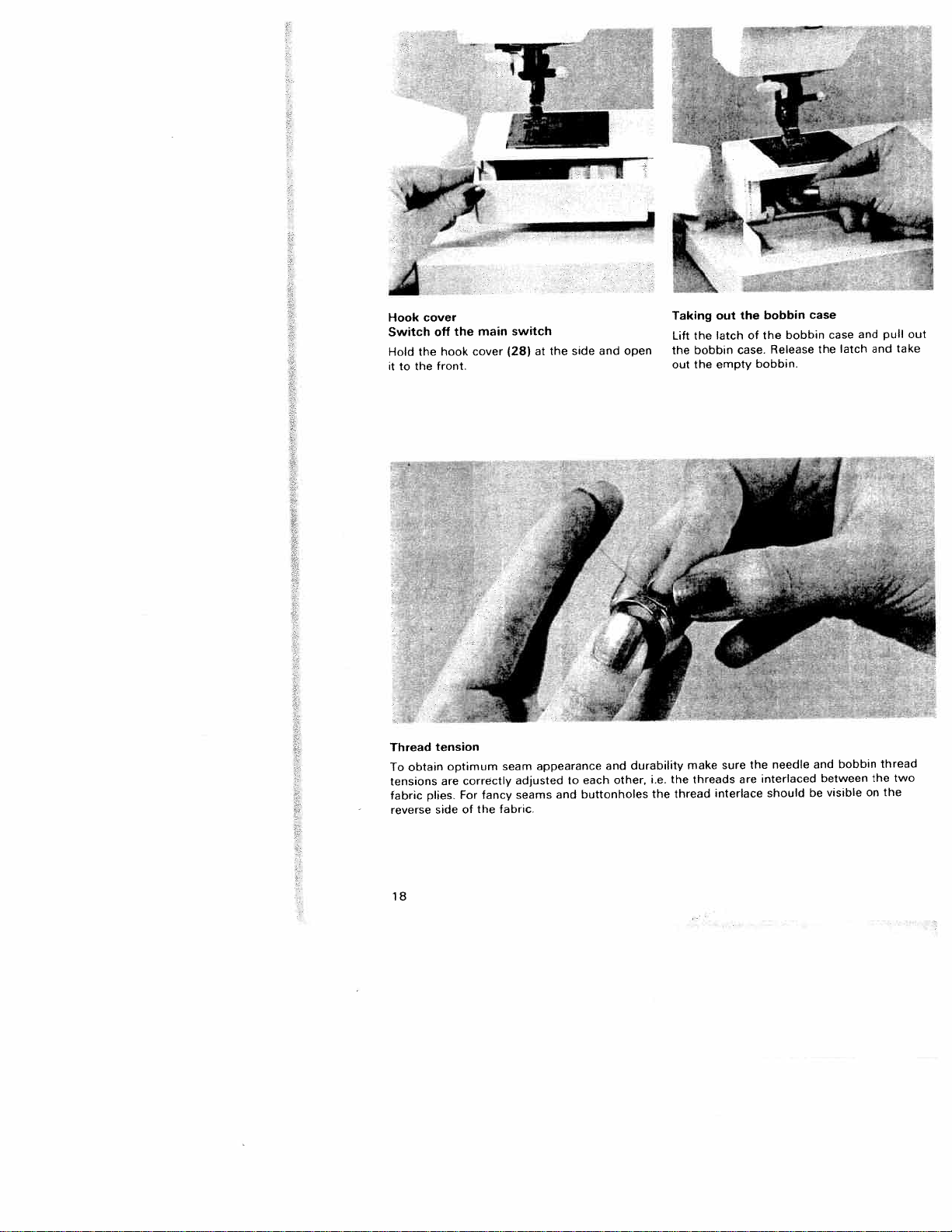

Hook

cover

Switch

off

the

main

switch

Hold

the

hook

cover

(28)

at

the

side

and

open

it

to

the

front.

Thread

tension

Lift

the

latch

of

the

bobbin

case

and

pull

out

the

bobbin

case.

Release

the

latch

and

take

out

the

empty

bobbin.

To

obtain

optimum

seam

appearance

and

durability

make

sure

the

needle

and

bobbin

thread

lensions

are

correctly

adjusted

to

each

other,

i.e.

Ihe

threads

are

interlaced

between

the

two

fabric

plies.

For

fancy

seams

and

buttonholes

the

thread

interlace

should

be

visible

on

the

reverse

side

of

the

fabric.

Taking

out

the

bobbin

case

18

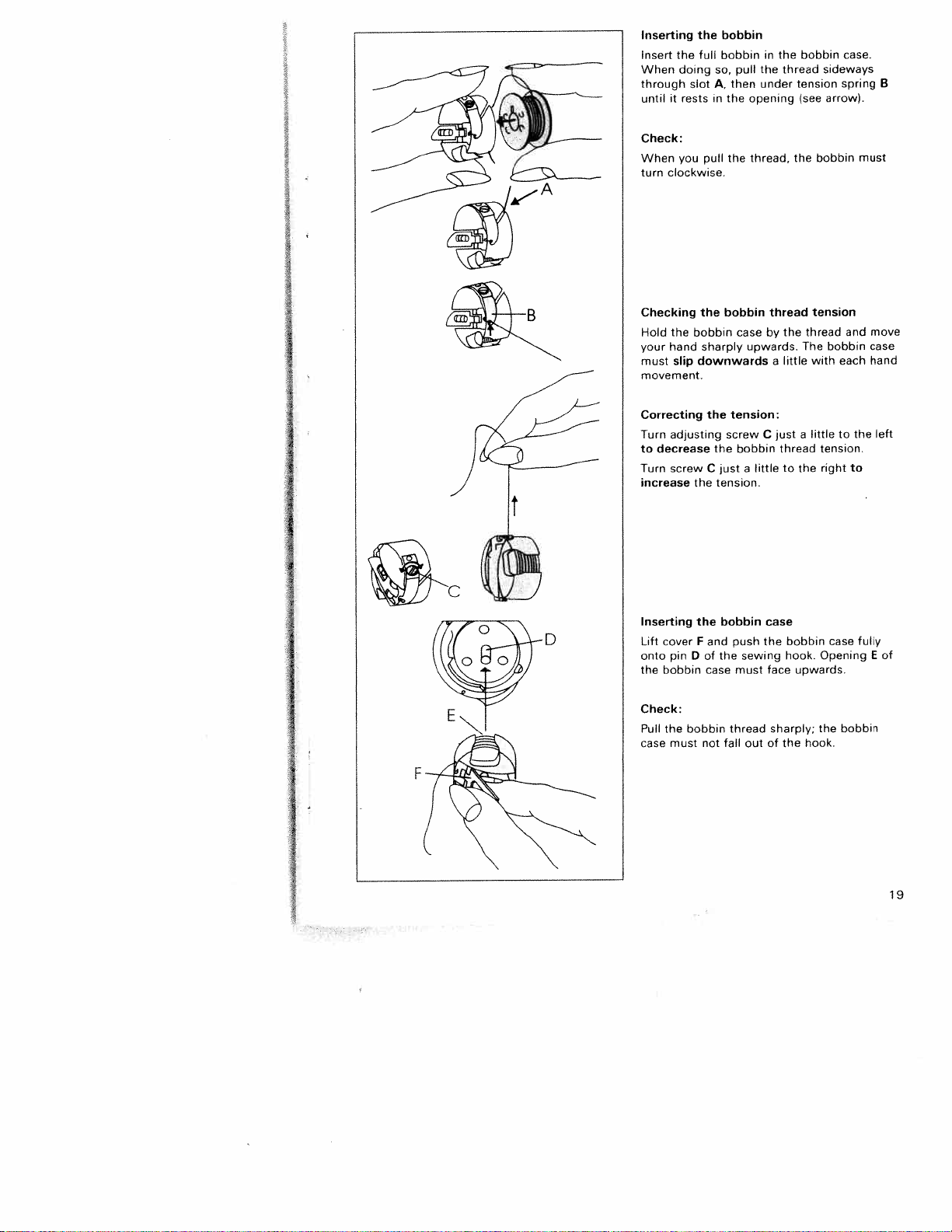

Inserting

the

bobbin

F

Insert

the

full

bobbin

in

the

bobbin

case.

When

doing

so,

pull

the thread

sideways

through

slot

A,

then

under

tension

spring

B

until

it

rests

in

the

opening

(see

arrow).

Check:

When

you

pull

the

thread,

the

bobbin

must

turn clockwise.

Checking

the

bobbin

thread

tension

Hold

the

bobbin

case

by

the

thread

and

move

your

hand

sharply

upwards.

The

bobbin

case

must

slip

downwards

a

little

with

each

hand

movement.

Correcting

the

tension:

Turn

adjusting

screw

C

just

a

little

to

the

left

to

decrease

the

bobbin

thread

tension.

Turn

screw

C

lust

a

little

to

the

right

to

increase

the

tension.

Inserting

the

bobbin

case

Lift

cover

F

and

push

the

bobbin

case

fully

onto

pin

0

of

the

sewing

hook.

Opening

E

of

the

bobbin

case

must

face

upwards.

Check:

Pull

the

bobbin

thread

sharply;

the

bobbin

case

must

not

fall

out

of

the

hook.

19

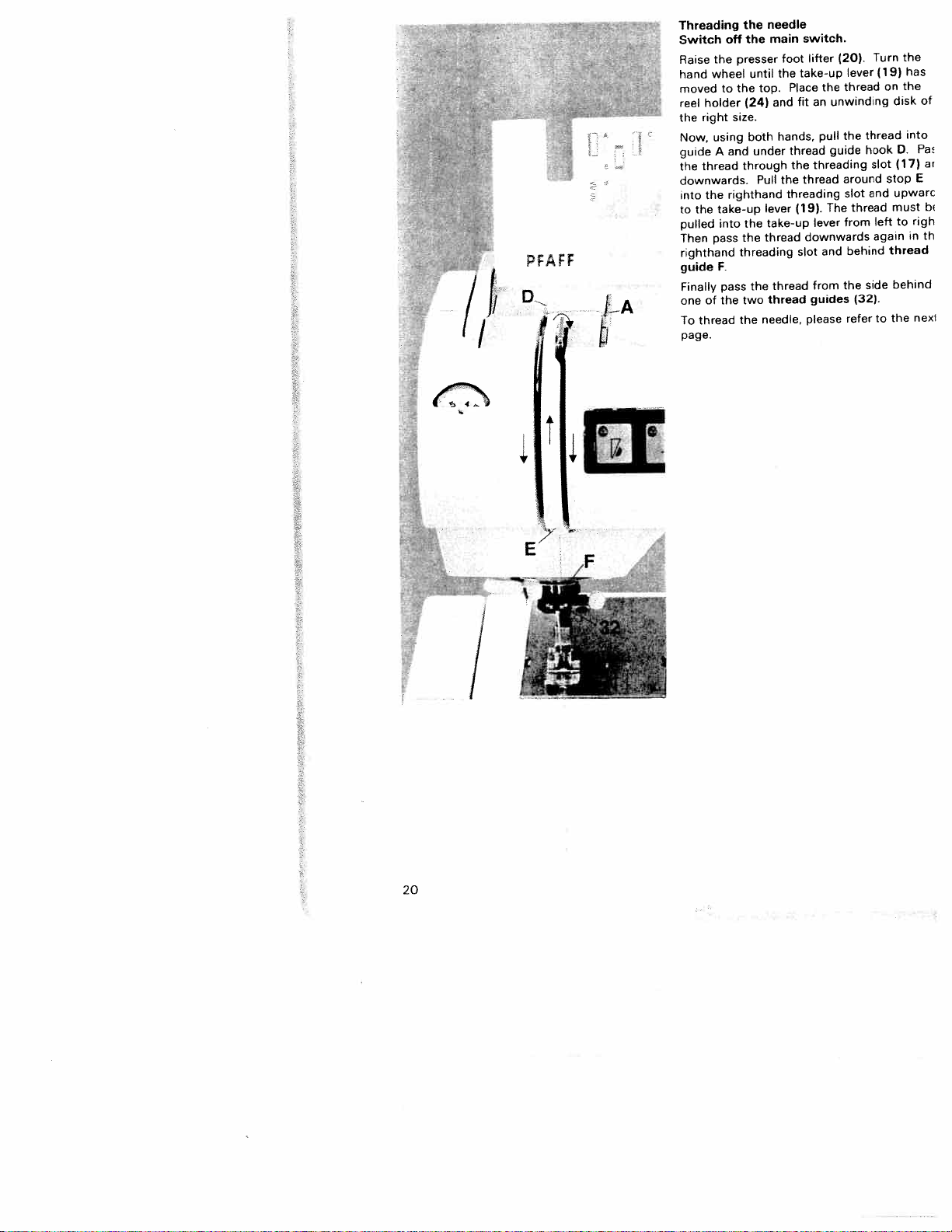

Threading

the

needle

Switch

off

the

main

switch.

Raise

the

presser

foot

lifter

(20).

Turn

the

hand

wheel

until

the

take-up

lever

(19)

has

moved

to

the

top.

Place

the

thread

on

the

reel

holder

(24)

and

fit

an

unwinding

disk

of

the

right

size.

Now,

using

both

hands,

pull

the

thread

into

guide

A

and

under

thread

guide

hook

D.

Pa

the

thread

through

the

threading

slot

(17)

ar

downwards.

Pull

the

thread

around

stop

E

nto

the

righthand

threading

slot

and

upwarc

to

the

take-up

lever

(19).

The

thread

must

b

pulled

into

the

take-up

lever

from

left

to

righ

Then

pass

the

thread

downwards

again

in

th

righthand

threading

slot

and

behind

thread

guide

F.

Finally

pass

the

thread

from

the

side

behind

one

of

the

two

thread

guides

(32).

To

thread

the

needle,

please

refer

to

the

nexi

page.

PFAFF

/

D

jA

(/

F;

b

a

V

/

20

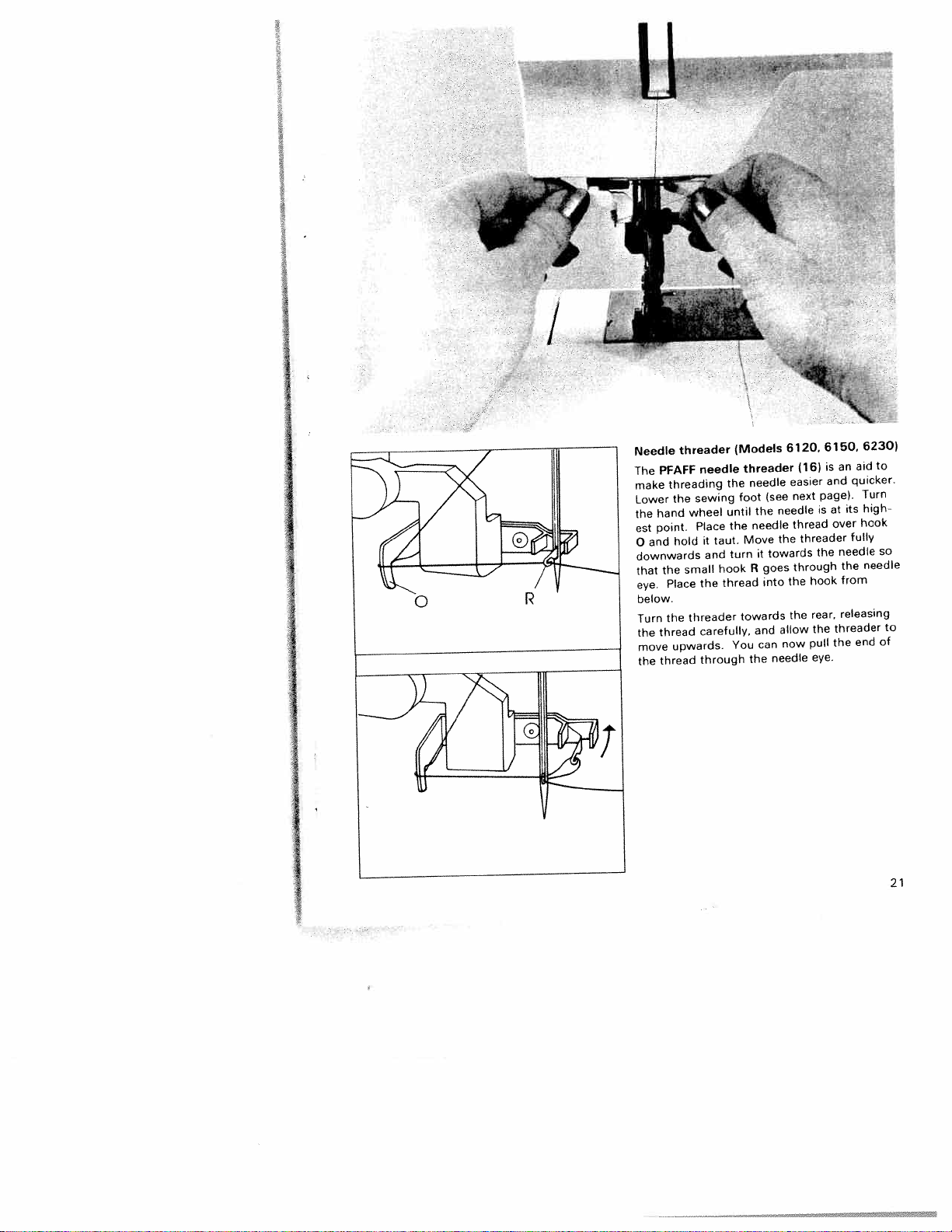

Needle

threader

(Models

6120.

6150.

6230)

The

PFAFF

needle

threader

(16)

is

an

aid

to

make

threading

the

needle

easier

and

quicker.

Lower

the

sewing

foot

(see

next

page).

Turn

the

hand

wheel

until

the

needle

is

at

its

high

est

point.

Piace

the

needle

thread

over

hook

o

and

hold

it

taut.

Move

the

threader

fully

downwards

and

turn

it

towards

the

needle

so

that

the

small

hook

R

goes

through

the

needle

eye.

Place

the

thread

into

the

hook

from

below.

Turn

the

threader

towards

the

rear,

releasing

the

thread

carefully,

and

allow

the

threader

to

move

upwards.

You

can

now

pull

the

end

of

the

thread

through

the

needle

eye.

/

21

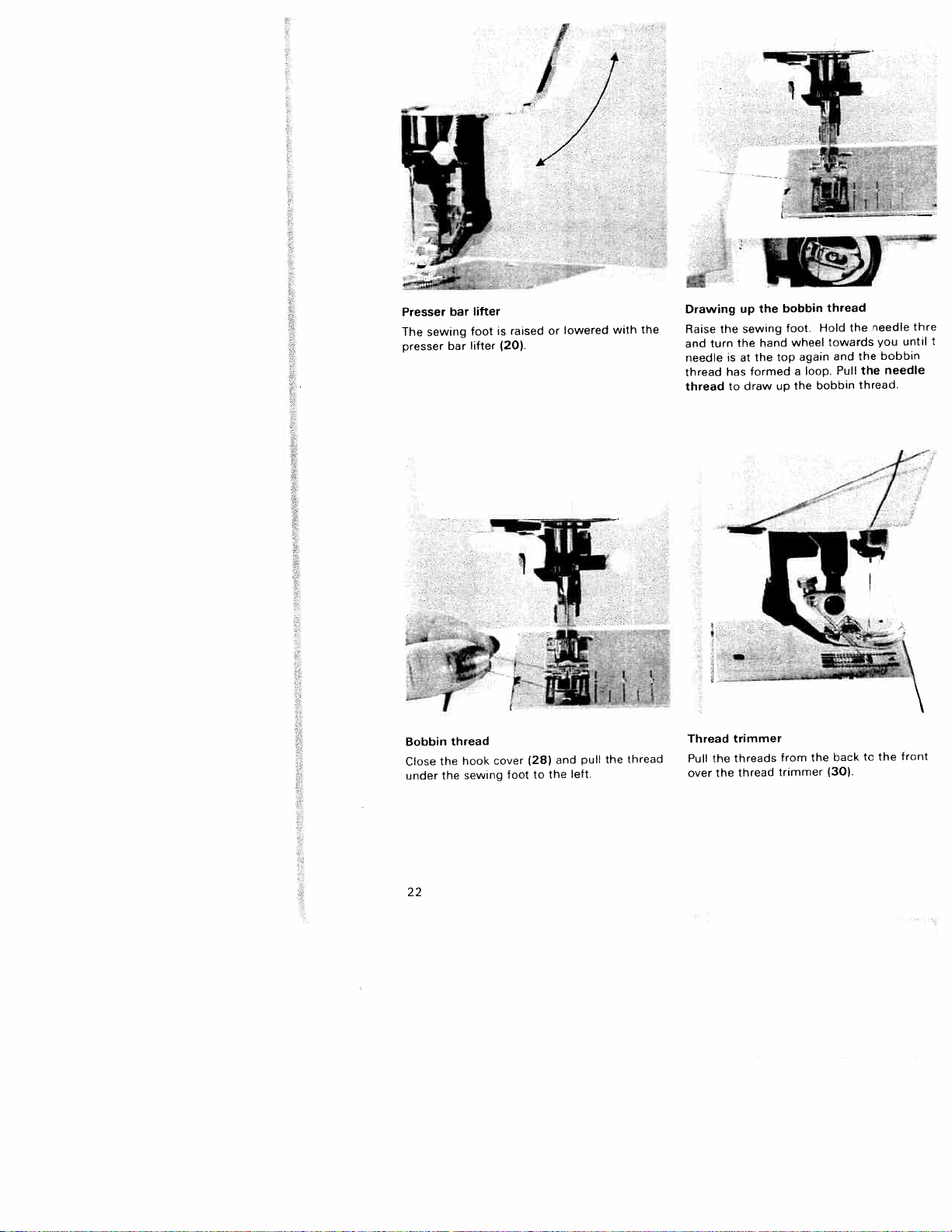

The

sewing

foot

is

raised

or

lowered

with

the

presser

bar

lifter

(20).

Drawing

up

the

bobbin

thread

Raise

the

sewing

foot.

Hold

the

needle

thre

and

turn

the

hand

wheel

towards

you

until

needle

is

at

the

top

again

and

the

bobbin

thread

has

formed

a

loop.

Pull

the

needle

thread

to

draw

up

the

bobbin

thread.

—r

Bobbin

thread

Close

the

hook

cover

(28)

and

pull

the

thread

under

the

sewing

foot

to

the

left.

Pull

the

threads

from

the

back

to

the

front

over

the

thread

trimmer

(30).

I,

Presser

bar

lifter

Thread

trimmer

22

U

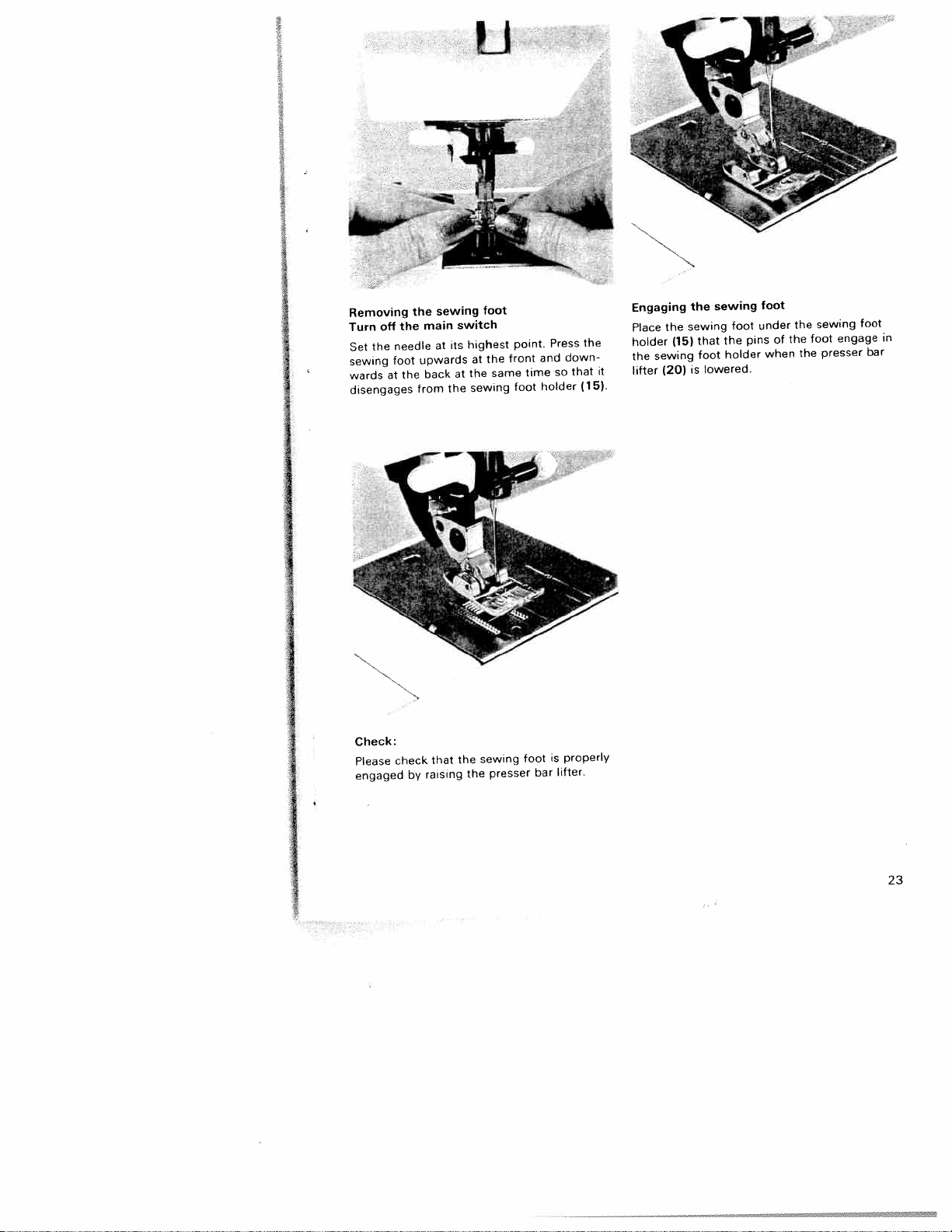

Removing

the

sewing

foot

Turn

off

the

main

switch

Set

the

needle

at

its

highest

point.

Press

the

sewing

foot

upwards

at

the

front

and

down

wards

at

the

back

at

the

same

time

so

that

it

disengages

from

the

sewing

toot

holder

(15).

Check:

Place

the

sewing

foot

under

the

sewing

foot

holder

(15)

that

the

pins

of

the

foot

engage

in

the

sewing

foot

holder

when

the

presser

bar

lifter

(20)

is

lowered.

Please

check

that

the

sewing

foot

is

properly

engaged

by

raising

the

presser

bar

lifter.

Engaging

the

sewing

foot

23

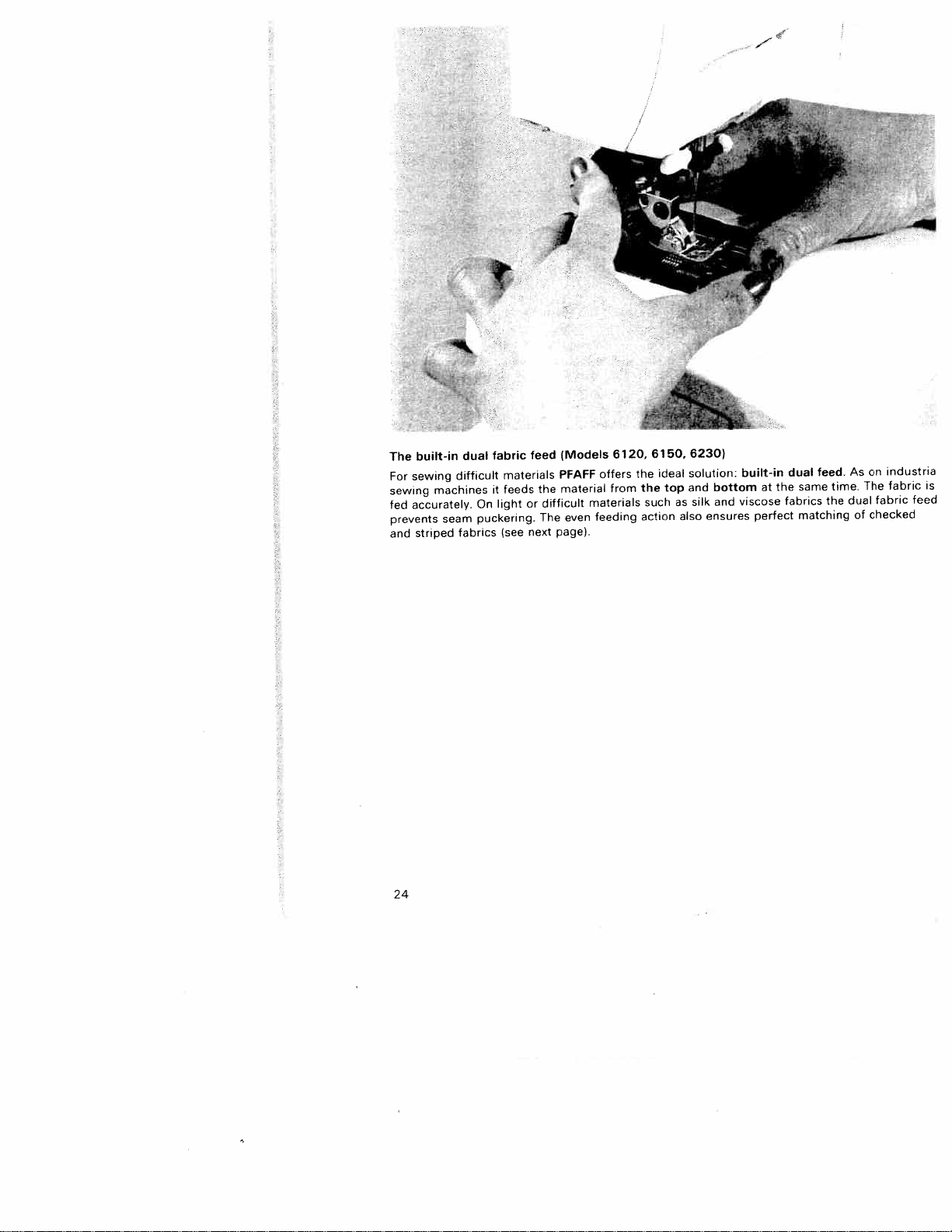

The

built-in

dual

fabric

feed

(Models

6120,

6150,

6230)

For

sewing

difficult

materials

PFAFF

offers

the

ideal

solution:

built-in

dual

feed.

As

on

industria

sewing

machines

it

feeds

the

material

from

the

top

and

bottom

at

the

same

time.

The

fabric

is

fed

accurately.

On

light

or

difficult

materials

such

as

silk

and

viscose

fabrics

the

dual

fabric

feed

prevents

seam

puckering.

The

even

feeding

action

also

ensures

perfect

matching

of

checked

and

striped

fabrics

(see

next

page).

24

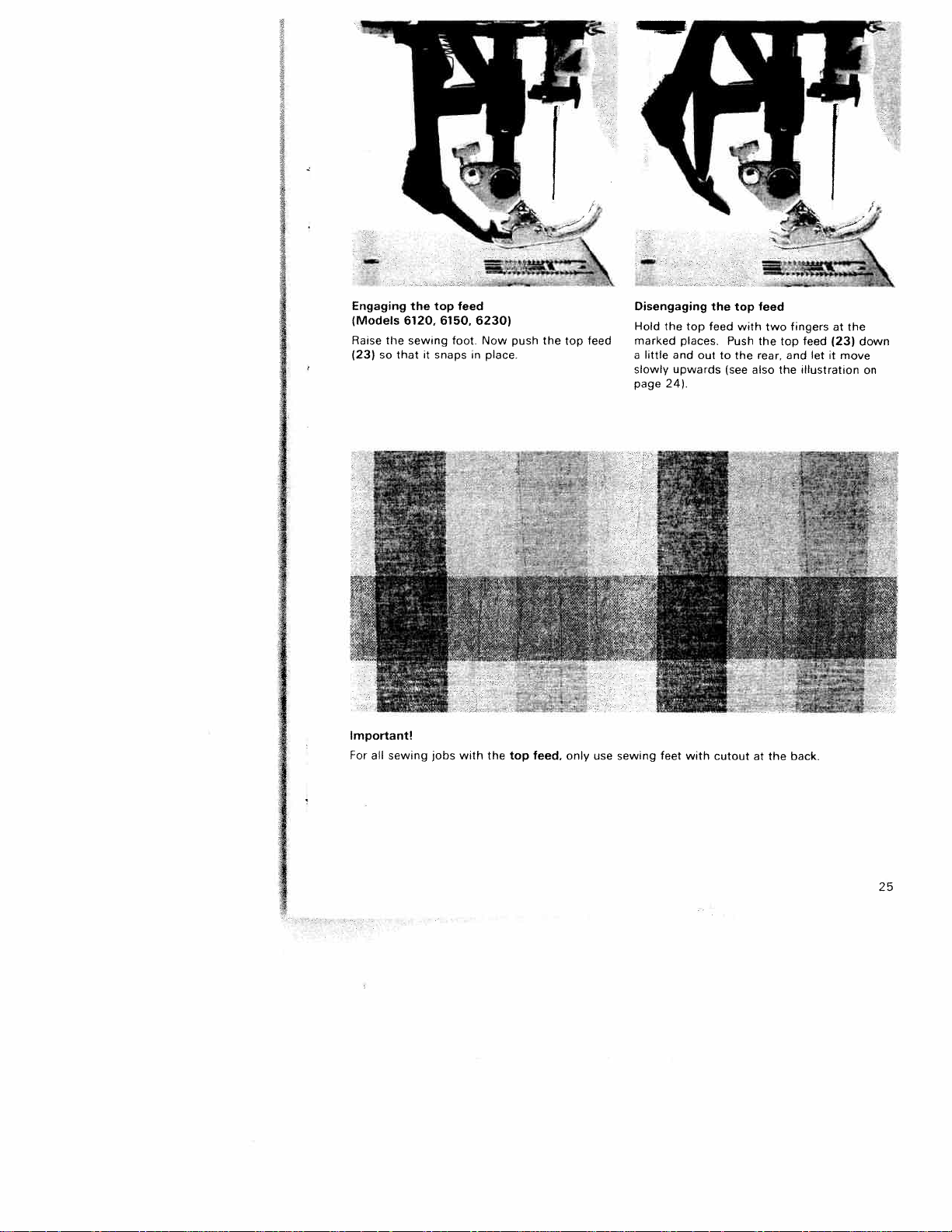

Disengaging

the

top

feed

Hold

the

top

feed

with

two

fingers

at

the

marked

places.

Push

the

top

feed

(23)

down

a

little

and

out

to

the

rear,

and

let

it

move

slowly

upwards

(see

also

the

illustration

on

page

24(.

Engaging

the

top

feed

(Models

6120.

6150.

6230)

Raise

the

sewing

foot.

Now

push

the

top

feed

(23) so

that

it

snaps

in

place

Important!

For

all

sewing jobs

with

the

top

feed,

only

use

sewing

feet

with

cutout

at

the

back.

25

Loading...

Loading...