Panasonic EX33, EX31B, EX31A, EX31BPN, EX31APN User guide

...

INSTRUCTION

MANUAL

AmplifierBuilt-inTypeThreadedMiniaturePhotoelectricSensor

EX-30 Series

MJEC-EX30 No.0054-69V

Thank you very much for purchasing Panasonic products. Read this Instruction Manual carefully and thoroughly for the correct and optimum use of this product. Kindly keep this manual in a convenient place for quick reference.

●●Please refer to “users manual on our web site (http:// panasonic.net/id/pidsx/global)” for more details (specification, and operation etc.)

●●Access method is “Download” → “Model no.”

●●If you could not visit our web site, contact our sales office near your sight.

WARNING

WARNING

●●Never use this product as a sensing device for personnel protection.

●●In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

1INTENDED PRODUCTS FOR CE MARKING

●●Refer “our web site (http://panasonic.net/id/pidsx/global)” for the intended products.The models listed under “SPECIFICATIONS” come with CE Marking.As for all other mod-

els, please contact our office.

●●Contact for CE

Panasonic Marketing Europe GmbH Panasonic Testing Center Winsbergring 15, 22525 Hamburg,Germany

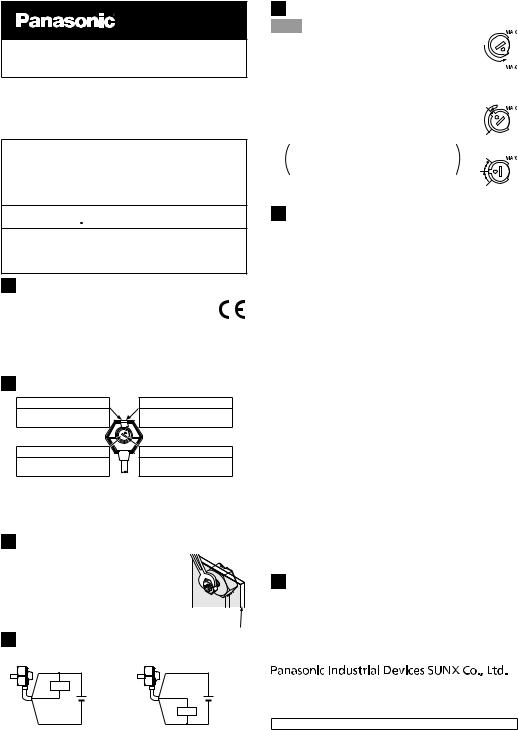

2 PART DESCRIPTION

Operation indicator (Orange) (Note 1)

Lights up when the sensing output is ON

Operation mode switch (Note 2)

L: Light-ON

D: Dark-ON

Stability indicator (Green) (Note 1)

Lights up under the stable light condition or the stable dark condition

Sensitivity adjuster (Note 3)

Sensing range be-comes longer when turned clockwise

Notes: 1) Not incorporated on the thru-beam type sensor emitter.

2)Incorporated on EX-33□. Not incorporated on the receiver for EX-31□, and EX-32□.

3)Incorporated on the emitter for EX-33□, and EX-32□. Not incorporated on EX-31□.

3MOUNTING

●●Mount the sensor on a mounting plate 3mm or less thick and Use the enclosed nut and toothed lock washer for mounting.

●●When the nut is tightened, hold the the sensor with hand or a spanner etc. and the tightening torque should be 0.6N•m or less. (EX-32□: 1N•m or less) Do not tighten the sensor itself.

Mounting plate (3mm or less thick)

4 WIRING DIAGRAMS

●● NPN output type |

|

●● PNP output type |

|

|||

(Brown) +V |

|

(Brown) +V |

|

|

||

Load |

<![if ! IE]> <![endif]>DC |

|

(Black) |

|

<![if ! IE]> <![endif]>DC |

|

|

|

<![if ! IE]> <![endif]>12to 24V |

|

|||

|

<![if ! IE]> <![endif]>±10% |

Output(Note) |

<![if ! IE]> <![endif]>±10% |

|||

(Black) |

<![if ! IE]> <![endif]>12to24V |

|

|

|||

|

|

Load |

|

|

|

|

Output(Note) |

|

|

|

|

|

|

(Blue) 0V |

|

|

(Blue) 0V |

|

|

|

Note: The thru-beam type sensor emitter does not incorporate the output.

5 SENSITIVITY ADJUSTMENT

Step

1.Turn the sensitivity adjuster fully counterclockwise to the minimum sensitivity position, MIN.

2.In the light received condition, turn the sensitivity adjuster slowly clockwise and confirm the point A where the sensor enters the “Light” state operation.

3.In the dark condition, turn the sensitivity adjuster further clockwise until the sensor enters the “Light” state operation and then bring it back to confirm point B where the sensor just returns to the “Dark” state operation.

If the sensor does not enter the “Light” state operation even when the sensitivity adjuster is turned fully clockwise, the position is point B.

4.The position at the middle of points A and B is the optimum sensing position.

<![endif]>Optimum position

A

B

A

B

A

6CAUTIONS

●●This product has been developed / produced for industrial use only.

●●The thin cable 0.1mm2 is used for this product. Thus, take care that if the cable is pulled with excessive force, it may cause cable break.

●●Extension up to total 50m (emitter and receiver each for thrubeam type), or less, is possible with 0.3mm2, or more, cable.

●●Make sure that stress by forcible bend or pulling is not applied directly to the sensor cable joint.

●●Make sure to carry out wiring in the power supply OFF condition.

●●Take care that wrong wiring will damage the sensor.

●●Verify that the supply voltage variation is within the rating.

●●If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

●●In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity of this product, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

●●Do not run the wires together with high-voltage lines or power lines or put them in the same raceway. This can cause malfunction due to induction.

●●Do not use during the initial transient time (50ms) after the power supply is switched ON.

●●Take care that the sensor is not directly exposed to fluorescent lamp from a rapid-starter lamp, a high frequency lighting device or sunlight etc., as it may affect the sensing performance.

●●This sensor is suitable for indoor use only.

●●Do not use this sensor in places having excessive vapor, dust, etc., or where it may come in contact with corrosive gas, etc.

●●Take care that the sensor does not come in contact with oil, grease, organic solvents such as thinner, etc., strong acid, or alkaline.

●●This sensor cannot be used in an environment containing inflammable or explosive gases.

●●Never disassemble or modify the sensor.

●●In case of using the sensor at a place where static electricity is generated, use a metal mounting plate.Also, ensure to ground the mounting plate.

7RoHS DIRECTIVE

●●This equipment complies with RoHS (EC and Chinese directive).

●●ChineseRoHSindicatesinclusiondespiteregulationvalue.(ReferChinesepart.)

http://panasonic.net/id/pidsx/global

Overseas Sales Division (Head Office)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan Phone: +81-568-33-7861 FAX: +81-568-33-8591

For sales network, please visit our website.

© Panasonic Industrial Devices SUNX Co., Ltd. 2016 PRINTED IN JAPAN

Loading...

Loading...