Panasonic EX-11SEB-PN, EX-11SEA-PN, EX-11SA-PN, EX-13SA-PN, EX-13SB-PN User guide

...

INSTRUCTION MANUAL

Photoelectric Sensor |

Ultra-slim type |

|

|

EX-10 Series

MEUEN-EX10 V2.0 Thank you for purchasing products from Panasonic Electric Works SUNX Co., Ltd. Please read this Instruction Manual carefully and thoroughly for the correct and optimum use of this product. Kindly keep this manual in a convenient place for quick reference.

WARNING

WARNING

• Never use this product as a sensing device for personnel protection.

• In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

1 CAUTIONS

This product has been developed / produced for industrial use only.

For the convergent reflective type EX-14, maintain adequate distance from reflective objects in the background, e.g. conveyors, since they may adversely effect sensing.

A thin 0.1mm2 cable is used for this product. Do not use excessive force when pulling on the cable: it may cause cable to break.

Make sure that the power supply is off while wiring.

Incorrect wiring will damage the sensor.

Verify that the supply voltage including the ripple is within the rating. Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity of this product, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

Do not run the wires together with high-voltage lines or power lines or put them in the same raceway. This can cause malfunction due to induction.

You can extend the cable up to 50m max. with 0.3mm2 or more cable for both emitter and receiver. However, in order to reduce noise, make the wiring as short as possible.

Do not use during the initial transient time (0.5s) after the power supply is switched on.

Ensure that the sensor is not directly exposed to the following light sources as they may adversely effect sensing performance: fluorescent light from a rapid-starter lamp, a high frequency lighting device, sunlight etc.

This sensor is suitable for indoor use only.

Avoid dust, dirt and steam. Do not use this sensor in places having excessive vapor, dust, etc., or where it may come in direct contact with corrosive gas.

Take care that the sensor does not come in contact with oil, grease, organic solvents such as thinner, etc., strong acid, or alkalines.

Do not apply stress directly to the sensor cable joint by forcibly bending or pulling.

Since the cable end is not waterproof, do not use the sensor in an application where water could seep in from the cable end.

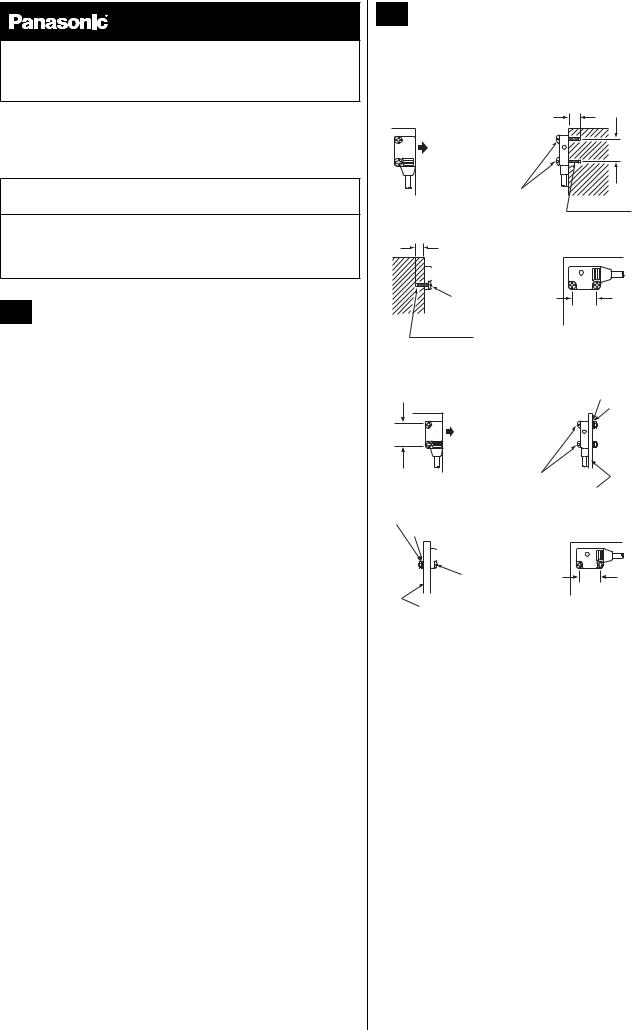

2MOUNTING

The tightening torque should be 0.2N·m or less.

Mounting using tapped holes

Side sensing

|

6mm |

Sensing direction |

11mm |

10mm M2 |

M2 x 0.4mm ø |

|

Front sensing

7mm

Sensing direction

Sensing direction

8mm M2

11mm

M2 x 0.4mm ø

When using the attached screws and nuts

Side sensing

|

Flat washers |

|

Spring washers |

11mm |

Sensing direction |

|

10mm M2 |

Thickness of mounting plate: 2mm or less

Front sensing

Spring washers Flat washers

Sensing direction

Sensing direction

8mm M2

11mm

Thickness of mounting plate: 2.5mm or less

1

Loading...

Loading...