Panasonic FA-F350, FA-F355 Service manual

FA-F350/F355 |

Back to Model List |

FA-F350/F355

Contents /Index

WARNING

I. Introduction

1.1 |

Specifications .......................................................................................... |

1-1 |

1.2 |

Features .................................................................................................. |

1-3 |

1.3 |

Exterior Parts .......................................................................................... |

1-4 |

1.4 |

Structual Drawing ................................................................................... |

1-4 |

1.5 |

Component Location............................................................................... |

1-5 |

II. Operation

2.1 |

Outline .................................................................................................... |

2-1 |

2.2 |

Mechanism ............................................................................................. |

2-6 |

III. Maintenance

3.1 |

Maintenance chart .................................................................................. |

3-1 |

3.2 |

Disassembly and Assembly .................................................................... |

3-2 |

IV. Electrical

4.1 |

Electrical parts Operation ....................................................................... |

4-1 |

4.2 |

Signal information ................................................................................... |

4-6 |

4.3 |

Adjustment .............................................................................................. |

4-11 |

V. Trouble Shooting

5.1 |

Self-diagnosis/Detection of malfunction ................................................. |

5-1 |

5.2 |

Service mode .......................................................................................... |

5-6 |

5.3 |

Self-checking .......................................................................................... |

5-7 |

5.4 |

Error Code .............................................................................................. |

5-10 |

VI. Unpacking/Installation

6.1 |

Installation requirements......................................................................... |

6-1 |

6.2 |

Installation procedure ............................................................................. |

6-2 |

|

Introduction |

|

|

|

|

|

Operation |

|

|

|

|

|

Maintenance |

|

|

|

|

|

Electrical |

|

|

|

|

Trouble |

Shooting |

|

|

|

|

Unpacking/ |

Installation |

|

|

WARNING

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or products dealt with in this service information by anyone else could result serious injury or death.

(For USA)

This manual was developed and is supplied to authorized servicing dealers by Panasonic Communications & Systems Co. for the sole purpose of providing information necessary for the equipment's proper support. It is intended that this information be confidential and may not be reproduced without prior written consent from Panasonic Communications & Systems Co. Panasonic Communications & Systems Co. reserves the right to change any information enclosed herein without prior notification.

This manual was developed and is supplied to authorized servicing dealers by Panasonic Co. for the sole purpose of providing information necessary for the equipment's proper support. It is intended that this information be confidential and may not be reproduced without prior written consent from Panasonic Co. Panasonic Co. reserves the right to change any information enclosed herein without prior notification.

© February, 1999

Section I Introduction

1.1 Specifications

Item |

|

|

|

|

|

||

Loading Style |

Three-layer tray, descending style |

||

|

|

||

Loading Method |

Face-up/Face-down loading |

||

|

|

||

Copy Paper Size |

A,B series A3,A4,A4R,A5R,B4,B5,B5R,post Inch-series |

||

|

LDR,LGL,LTR,LTRR,INV |

||

|

|

|

|

Copy Paper Weight |

12-32Ibs/50-128g/m2 |

|

|

Number of Bins |

Tray for interruption copies/1-3 bins |

||

|

|

||

Modes |

Staple mode, Non-staple mode, Sort-mode:Single copy |

||

|

shift mode |

|

|

|

|

|

|

Loading Capacity |

Interruption |

50(S)30(L) |

|

|

|

|

|

|

Non-staple sort |

1bin: |

300(S)150(L) |

|

|

2bins: |

1,000(S)500(L) |

|

|

3bins: |

200(S)100(L) |

|

|

|

|

|

Staple Sort |

1bin: |

300(S)150(L) |

|

|

Max: |

30(S)30(L) |

|

|

2bins: |

750(S)500(L) |

|

|

Max: |

30(S)30(L) |

|

|

3bins: |

200(S)100(L) |

|

|

Max: |

20(S)20(L) |

|

|

||

|

(L) Ledger, Legal, Letter-R, A3, B4, A4R |

||

|

|

||

|

(S) Letter, Invoice, A4, A5, B5 |

||

|

|

||

Staple plus Non-Staple |

Possible under certain conditions |

||

|

|

||

Stacking |

Offset stacking (Top sheet of paper for each set is shifted by 30mm) |

||

|

|

|

|

Paper Detecting |

1-3 bins |

|

|

|

|

|

|

Operation Part |

None |

|

|

|

|

|

|

Display |

None |

|

|

|

|

||

Size (W) (D) (H) |

26.3”x22.9”x41.2” / 669x582x1,039mm (FA-F350) |

||

|

26.3”x23.7”x41.2” / 669x603x1,039mm (FA-F355) |

||

|

|

||

Weight |

76lbs./34.5kg(FA-F350), 79lbs/36kg(FA-F355) |

||

|

|

||

Power Source |

24VDC supplied from copier |

||

|

|

|

|

Power |

Approx. 70W |

|

|

Consumption |

|

|

|

Introduction

1-1

Item |

|

|

|

|

|

Stapled copy size |

Diagonal stapling Front A3, B4, A4, A4R, B5, LDR, |

|

|

LGL, LTR, LTRR, |

Rear A3, B4, |

|

A4, B5, LDR, LGL, LTR One-point |

|

|

stapling Rear A4R, LTRR Two- |

|

|

point stapling A3, B4, A4, B5, LDR, |

|

|

LGL, LTR, LTRR |

|

|

|

|

Stapling Position |

Refer to illustration below (Tolerance : ±2mm) |

|

Stapled Number of copies |

Stapled Number of Copies Small size 50 |

Large size 30 |

|

|

|

Staple Mounting |

Staple cartridge (5,000 staples) |

|

|

|

|

Staples |

Exclusive staples (FQ-SS75) |

|

|

|

|

Staple Detecting Sensor |

No |

|

Mounted Manual Stapling |

|

|

Stapling position |

|

Rear one-point stapling |

Front diagonal stapling |

5±2mm |

6±2mm |

30˚ |

4.4±2mm |

4.5±2mm

Rear diagonal stapling

30˚ |

4±2mm |

6±2mm

Two point stapling

A3, A4 |

B4, B5 |

LDR, LTR |

5±2mm |

82.7±4mm |

202.7±4mm |

5±2mm

62.7±4mm |

182.7±4mm |

5±2mm

73.7±4mm |

193.7±4mm |

Fig. 1-01

1-2

1.2 Features

(1)Large Capacity

A maximum of 1,500 copies can be stacked in normal 3 bins (20Ibs/80g/m2 small size paper, not stapled).

(2)Improved Paper Transport Performance

Copy paper 12-32Ibs/50-128g/m2 can be used.

(3)Job Offset

The first or the last copy of each job can be discharged to the foreground position, so that copies in a tray can be sorted.

(4)Four Auto Staple Modes

Stapling position can be selected from 4 modes (one point on rear side, diagonal stapling on front side, diagonal stapling on rear side, two-point stapling).

(5)Buffer Roller

Buffer roller allows continuous operation of the copier during stapler or offset operation. (Small size only)

(6)Interruption

The tray for interruption copies can receive up to 50 copies (20Ibs/80g/m2).

Introduction

1-3

1.3 Exterior Parts

Front lower cover

Tray

P.C.B. cover

1.4 Structural Drawing

(1) Finisher

Range sensor

Transport roller

Swing guide

Paper exit roller

Tray1/2/3

Shutter

Knurling belt

Tray movement motor

Interrupt tray

Rear cover

Rear lower cover

Fig. 1-02

Interruption tray

Rolling flapper

Buffer roller

Interruption flapper

Buffer inlet flapper

Transport roller 1

Transport roller 1  Longitudinal path

Longitudinal path

Stapler

Fig. 1-03

1-4

1.5 Component Location

1. Sensor

Height sensor (PS1)

Buffer path paper sensor (PI14)

Tray 1 paper sensor (PI11)

Tamper guide home position sensor (PI6)

Door open sensor (PI16)

Tray 2 paper sensor (PI12)

Paper exit sensor (PI3)

Stapler home position sensor (PI7)

Tray 3 paper sensor (PI13)

Shutter open sensor (PI5)

Buffer path entrance paper sensor (PI17)

Swing guide open sensor (PI18)

Entrance sensor (PI1)

Entrance sensor (PI1)

Staple tray sensor

Staple tray sensor

(PI4)

Joint sensor (PI15)

Joint sensor (PI15)

Tray shift motor clock sensor 2 (PI19)

Tray shift motor clock sensor 1 (PI9)

Tray home position sensor (PI8)

Paper exit motor clock sensor (PI10)

Fig. 1-04

2. Switch

Door switch (MS1)

Shutter close detecting switch (MS4)

Staple detecting switch (MS8)

Tray upper limit detecting switch (MS5)

Swing guide close detecting switch 1 (MS2)

Safety area switch (MS3)

Swing guide close |

detecting switch 2 (MS6) |

Tray shift motor thermo-switch (TS1)

Staple home position switch (PI21)

Cartridge switch (MS7)

Fig. 1-05

Introduction

1-5

3. Motor

Paper exit motor (M2)

Tamper motor (M3)

4. Solenoid

Paddle solenoid (SL5)

Buffer exit

solenoid (SL3)

solenoid (SL3)

Shunting  solenoid (SL6)

solenoid (SL6)

Transport motor 2 (FA-F355 only) (M8)

Transport motor 1 (M1)

Transport motor 1 (M1)

Tray shift motor (M5)

Tray shift motor (M5)

Stapler shift motor (M4)

Staple motor (M6)

Fig. 1-06

Interruption solenoid (SL4)

Buffer entrance solenoid (SL2)

Buffer entrance solenoid (SL2)

Fig. 1-07

1-6

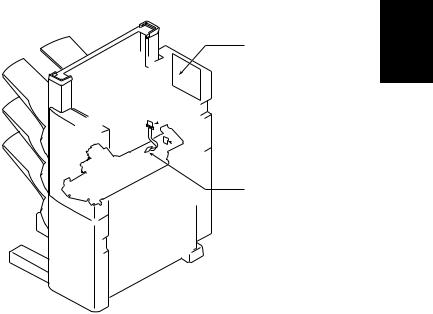

5. PCB

Finisher controller

PCB

Introduction

Relay PCB 4

Relay PCB 4

Sensor PCB

Sensor PCB

Relay PCB 3

Fig. 1-08

1-7

Section II Operation

2.1 Outline

This finisher receives commands from the copier and discharges into the tray the

papers sent from the copier in normal mode, shift mode or staple mode.

If the command to discharge into interruption copy bin is sent from the copier, it will

operate accordingly.

There are four paper exit modes.

Paper exit mode |

|

Normal exit |

|

Interruption copy exit

Simple loading Job offset

Stapling Front diagonal stapling Rear one-point stapling Rear diagonal stapling Two-point stapling

Simple loading

2.1.1 Normal Exit

(1)Nomal mode

The paper is sent into the exit tray face up.

Paper exit tray

Paper

Transport roller 1

Transport roller 2

Paper exit roller

Operation

2-1

(2)Job Offset Mode

The first or the last paper of each sort, is discharged into the staple tray faceup, shifted by 30mm.

Whether the first paper should be shifted or the last one should be shifted depends on the command from the copier.

The second paper or the first paper of the next sort, is not discharged into the staple tray but to the tray.

The first paper or the last paper of each sort

Swing guide

Staple

tray Stopper

Paper exit roller |

Transport roller 1 |

Fig. 2-04 |

The second paper or the papers following the first paper of the next sort

tray

Second paper or first paper of the next sort

First paper or last paper of each sort

Swing guide |

|

|

Staple |

Stopper |

|

tray |

|

|

|

|

|

|

Transport roller 1 |

|

Paper exit roller |

|

Fig. 2-05 |

2-2

(3)Staple mode

The paper is loading in the staple tray. Next the first item into the tray.

tray

Paper

Staple

Swing guide

Staple

tray Stopper

Fig. 2-06

Paper exit roller Transport roller 1

Width of paper

Front diagonal stapling |

2-point stapling |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rear diagonal stapling |

Rear 1-point stapling |

Fig. 2-07 |

2.1.2Interruption copy exit

When the paper enters the finisher, they are guided by the reversing plate and discharged into the bin.

Interruption tray

Interruption tray

Fig. 2-08

Operation

2-3

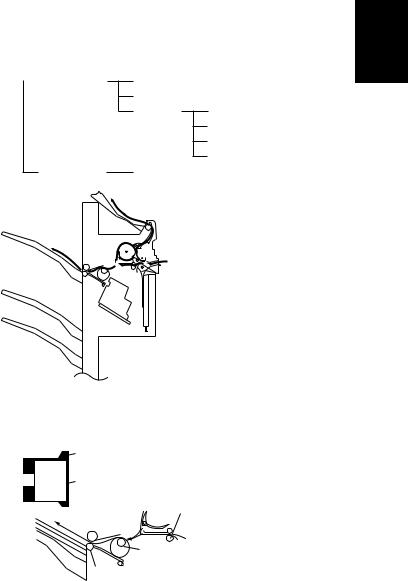

2.1.3Exit route

There are three normal exit routes. The route that is used depends on the paper size and discharge mode.

(1)Route for small size

When small size paper is loaded normally, the paper passes under the buffer roller.

Buffer roller

Paper exit roller

Fig. 2-09

(2)Route for large size

When large size paper is loaded or the paper is loaded in R direction, the paper passes above the buffer roller.

This has an effect of expanding the distance between papers.

Buffer roller

Transport roller 2

Paper exit roller

Fig. 2-10

2-4

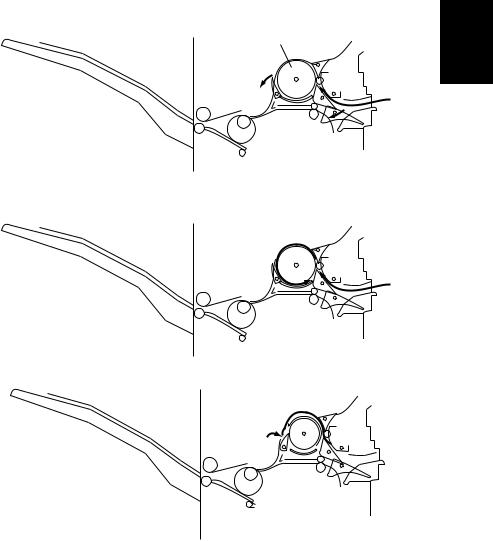

(3)Buffer route

Paper takes this route when small size paper is used in the job offset or staple mode.

Offset paper or the first and the second sheet of paper which follows the final paper to be stapled takes this route.

a) The first sheet of paper is transported toward the buffer roller.

buffer roller

Operation

Fig. 2-11

b)When the first sheet of paper is rolled around the buffer roller, the second sheet of paper is transported from the copier.

Fig. 2-12

c) The second sheet of paper lies on the first sheet of paper.

Fig. 2-13

d)The first and the second sheets of paper are discharged into the tray or pulled inside the staple tray at the same time.

2-5

2.2 Mechanism

2.2.1Job offset

The job offset operation, the first or last copy of each job is shifted forward, and the other copies of that job are exited in the normal position.

Papers are moved by the tamper.

Tamper home position detecting sensor (PI6) checks whether or not the tamper is on the home position.

When the switch is turned on, the finisher controller P.C.B. drives the tamper motor to return the tamper to the home position.

Finisher controller P.C.B. stops paper exit motor (M3) at the moment the rear end of the paper comes out of the transport roller 2.

Then the finisher controller P.C.B. reverses the rotation of paper exit motor, and the paper exit motor gear is shifted to drive position.

In response, the drive of paper exit motor is transmitted to swing guide, pushing up the guide.

When the swing guide open detecting sensor (PI18) detects the swing guide, paper exit motor stops, and swing guide stays elevated.

When swing guide is shifted up, papers are transported to the staple tray by rollet belt attached to the transport roller.

Papers transported to the staple tray are detected by staple tray paper detecting sensor (PI4).

The finisher controller P.C.B. drives tamper motor (M3) and adjusts the position of tamper to the point approximately 7mm from the rear end of the paper. When the paper is received by the staple tray, guide plate shunting solenoid (SL6) shunts the guide plate and places under the staple tray.

Then the tamper motor shifts papers forward by 30mm.

After shifting the paper, finisher controller P.C.B. reverses the rotation of tamper motor, and shifts the tamper to the position 7mm from the rear end of papers. Then the finisher controller P.C.B. reverses the rotation of paper exit motor again, and lowers swing guide.

When the swing guide is lowered and swing guide open/close detecting switch 2 (MS6) is turned on, paper exit motor rotates normally, causing normal rotation of the paper exit roller, and consequent discharge of papers into the tray.

After the paper is discharged, the guide plate returns to the elevated position.

2-6

Guide plate

Paper

Shunting solenoid (SL6)

Operation

Fig. 2-14

Tamper

Tamper guide

Position sensor (PI6)

Tamper motor (M3)

Fig. 2-15

Job offset sequence

Paper exit motor (M2) |

Transport motor 1,2 (M1/M8) |

Tamper motor (M3) |

Tamper home position |

sensor (PI6) |

Swing guide open detecting sensor (PI18)

Staple tray paper sensor (PI4)

Swing guide open/close detecting switch (MS2)

Guide plate shunting solenoid

Fig. 2-16

(SL6)

|

: |

Normal |

|

: |

Reversed |

|

rotation |

|

rotation |

||

|

|

*Transport motor 2 : FA-F355 only

2-7

2.2.2 Stapling

(1)Outline

Copies can be stapled by the stapler unit when staple mode is selected. The stapling position is decided by the selected staple mode and paper size. The stapler shifting/home-position sensor (PI7) detects whether or not the stapler unit is in the home position.

When the switch is turned on, the finisher driver P.C.B. drives the stapler shifting motor (M4) to return the stapler unit to the home position.

If the stapler unit is in the home position, it will stay there.

Width of paper /2

Front diagonal stapling |

2-point stapling |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 2-17 |

Rear diagonal stapling |

Rear 1-point stapling |

|

|

|

Stapler shift motor (M4) |

Paper

Stapler

Stapler shift home

Fig. 2-18

position sensor (PI7)

2-8

(2) The first paper

When the rear end of the first paper rolls out of transport roller 2, the finisher |

|

||

controller P.C.B. stops the paper exit motor (M2). |

|

|

|

Then the rotation of the paper exit motor is reversed, and the gear is shifted to |

|

||

the swing guide drive. |

|

|

|

The paper exit motor shifts the swing guide up until it is detected by the swing |

Operation |

||

guide detecting sensor (PI18). |

|

|

|

|

|

|

|

When the swing guide opens, the paper is transported by the rollet belt, (attached |

|

||

to transport roller 2) to staple tray. |

|

|

|

The paper is detected by the staple tray paper detecting sensor (PI4). |

|

||

|

|||

After the staple tray paper detecting sensor detects paper, the finisher controller |

|

||

P.C.B. drives the tamper shifting motor (M3) to tap the paper. |

|

||

The tamper is positioned 10mm from the end of paper. |

|

||

The swing guide stays elevated until the last paper is loaded on the staple tray. |

|

||

Swing guide |

|

|

|

First paper |

|

|

|

|

|

Transport roller 2 |

|

|

|

Rollet belt |

|

Tray 1/2 |

Paper |

|

|

exit |

|

|

|

|

|

|

|

|

roller |

|

|

|

Staple tray |

Stapler |

|

|

|

|

|

|

|

Fig. 2-19 |

|

Swing guide

Swing guide open

sensor (PI18)

Paper exit motor

Swing guide close detecting switch (MS2/MS6)

Fig. 2-20

Paper exit motor clock sensor (PI10)

Paper exit motor clock sensor (PI10)

Paper exit motor (M2)

2-9

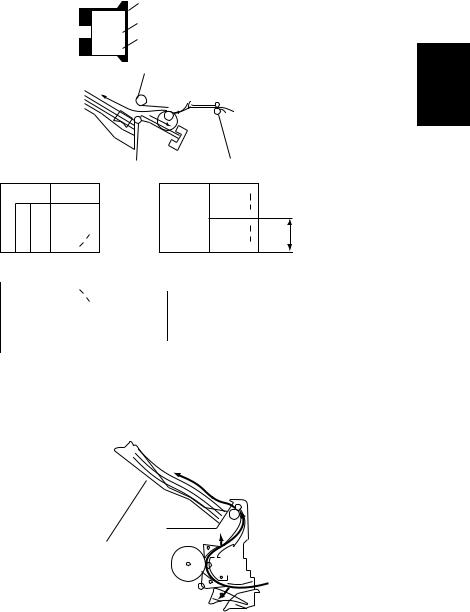

(3)The second and the proceeding papers

When the tail edge of the second and the proceeding paper roll out of transport roller 2, the finisher controller P.C.B. turns the paddle solenoid (SL5) on. Then the transport motor's (M1) drive rotates the paddle.

Papers pushed by the paddle are transported to staple tray.

Paddle operates twice for each B4, A3, LDR and LGL, and once for the other sizes.

When paper is loaded into the staple tray, the finisher controller drives the tamper shifting motor (M3) and taps the paper.

Swing guide

Paddle

2nd and following papers

Transport roller 2

Rollet belt

Rollet belt

Tray 1/2 |

Paper |

|

exit |

||

|

||

|

roller |

|

|

Staple tray |

Stapler

Fig. 2-21

Paddle

Paddle solenoid (SL5) |

Paddle |

|

2nd and following papers

1st paper

M1

or Stapler M8

Transport motor 1 or 2 Stopper Fig. 2-22 * Transport motor 2 : FA-F355only

2-10

(4) The last paper

After the last sheet of paper is finished being tapped, the finisher controller |

|

|

P.C.B. shifts the tamper to the tapping position (holding paper with tamper), |

|

|

then stops the tamper motor (M3). |

|

|

Then the finisher controller P.C.B. reverses the rotation of the paper exit motor |

|

|

(M2) again, and lowers the swing guide. |

Operation |

|

The finisher controller P.C.B. shifts the stapler and carries out stapling according |

||

|

||

to the staple mode (P2-19, Illustration 2-2-12) set on the copier. |

|

|

After stapling is finished, the finisher controller P.C.B. drives the tamper motor |

|

|

and shifts the tamper to the point 10mm from the rear end of paper. |

|

|

|

||

Then normal rotation of the paper exit motor (M2) occurs to discharge stapled |

|

|

paper into the tray. |

|

|

Swing guide |

|

|

paper |

|

|

Transport roller 2 |

|

|

Rollet belt |

|

Paper

Tray 1/2 exit  roller

roller

Staple tray

Stapler

Fig. 2-23

(5)Stapler unit shift control

The stapler unit is moved by the stapler shift motor (M4).

Home position is detected by the stapler shift/home position sensor (PI7). When the signal is sent from the copier, the stapler moves to the center of its shift range.

This movement occurs in every mode, because the selected mode is not yet been detected.

When the first sheet of paper reaches the registration sensor of the copier, the staple mode is signalled from the copier and the unit moves to the appropriate position depending on stapling point and paper size.

2-11

Stapler modes and home position:

a)Front diagonal stapling

Home position is the stapling point in this mode.

Stopper

Staple tray direction

Stopper

Guide

Stapler |

Fig. 2-24 |

|

b)Rear one-point stapling

The stapler moves back and forth between the center position and the stapling

point.

Stopper

Stapling point

Home position

Staple tray direction

Stopper

Stapler

Guide |

Fig. 2-25 |

2-12

c) Rear diagonal stapling

When LTR or B5 is used, home position is in the back of the stapling point Stapler moves back and forth between home position and stapling point.

Stapler

Home position

Stapling point

Stopper

Staple tray direction

Stopper

Guide |

Fig. 2-26 |

d)Two-point stapling

The home position is the center of paper. The stapling starts from the rear side.

|

Stopper |

|

Stapling point |

|

Home position |

Staple tray direction |

Stapler |

Stapling point

Stopper

Guide |

Fig. 2-27 |

|

Operation

2-13

Rear one-point stapling of 2 papers

Starting signal

Paper exit motor (M2)

Mode detection

Loaded paper

Staple Paper exit 1st paper 2nd paper

Transport motor 1 (M1) |

|

Transport motor 2 (M8) |

|

Tamper motor (M3) |

|

Tamper home position |

|

sensor (PI6) |

|

Swing guide open |

|

detecting sensor (PI18) |

|

Staple tray paper |

|

sensor (PI4) |

|

Swing guide open/close |

|

detecting switch (MS2) |

|

Stapler home position |

|

sensor (PI7) |

|

Paddle solenoid (SL5) |

|

Stapler shift motor (M4) |

|

Stapler motor (M4) |

Fig. 2-28 |

|

: |

Normal |

|

: |

Reversed |

|

rotation |

|

rotation |

||

|

|

* Transport motor 2 : FA-F355 only

2-14

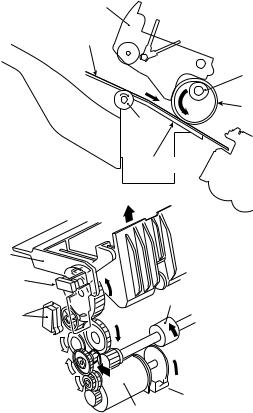

(6) Stapler unit

Stapling is carried out by the staple motor (M6). One staple is made every time |

|

|

the cam is rotated by the motor. |

|

|

The cam home position is detected when the staple movement home position |

|

|

detecting sensor (PI2) is turned ON. |

|

|

Normal rotation and reversed rotation of the staple motor is controlled by micro |

Operation |

|

computer (Q1) on finisher controller P.C.B.. |

||

|

||

When the staple movement home position detecting sensor is OFF, the finisher |

|

|

controller P.C.B. revolves staple motor in reversed direction until the sensor is |

|

|

turned ON, returning staple cam to the initial condition. |

|

|

|

||

The staples inside staple cartridge are detected by staple switch (MS9). |

|

|

Finisher controller P.C.B. drives staple motor (M6) only when swing guide close |

|

|

detecting switch 2 (MS6) is ON (swing guide is closed). |

|

|

This is to ensure safety in case fingers are put inside the stapler. |

|

.B.C.P controller Finisher

Staple motor |

|

|

drive signal |

M6 |

|

Staple home |

||

|

position detecting signal

Satapler detecting signal

Fig. 2-29

Fig. 2-30

2-15

2.2.3 Tray Operation

(1)Outline

There are three paper exit trays used for normal feed.

Vertical movement of trays is carried out by the drive of the vertical shift motor (M5). Clock pulses from the tray vertical movement motor clock sensors 1 and 2 (PI19/PI9) detect the tray position after the home position detecting sensor (PI8) is activated.

Tray shift motor thermo switch (TP1) is attached to the tray vertical shift motor

(M5).

When the sensor temperature reaches approximately 73.5°C after continued movement of the motor, the sensor is turned ON and the finisher controller

P.C.B. shuts off the load to the motor.

When the sensor temperature cools down to approximately 40°C, the sensor is turned OFF and the finisher controller P.C.B. resumes, the loading on the motor.

When the power supply switch is turned on, the tray is returned to home position by the tray vertical shift motor (M5) which is driven by the finisher controller P.C.B.

When the tray is in home position, it will stay there.

The finisher controller P.C.B. moves the trays up and down to place the selected tray in the paper exit position.

The upper limit of the tray is detected by the tray upper limit detecting switch (MS5).

When the tray upper limit detecting switch is ON, the finisher controller P.C.B. stops the drive of the tray shift motor (M5).

The height of papers discharged into the tray is detected by height sensor (PS1). The sensor measures the distance between the upper half of the paper stack and the paper exit. If the distance becomes less the prescribed value, the tray is lowered.

When the safety area detecting switch (MS3) is turned ON while the shutter or swing guide is open, the finisher controller P.C.B. stops movement of finisher by shutting off the +24V power supplied to tray shift motor (M5).

2-16

Tray 1

Tray 2

Tray 3

Tray shift motor thermoswitch (TP1)

Tray shift motor (M5)

Tray guide

Tray upper limit detecting switch (MS5)

Tray upper limit detecting switch (MS5)

Encoder

Tray shift motor clock detecting sensor 1 (PI9)

Tray shift motor clock detecting sensor 2 (PI19)

Safety area switch (MS3)

Tray home position sensor (PI8)

Fig. 2-31

Operation

Shift from Tray 1 to Tray 2

Shutter |

Tray |

Shutter |

Tray |

close |

shift |

open |

shift |

Transport motor (M1)

Tray shift motor (M5)

Shutter close sensor (PI6)

Shutter open detecting |

|

switch (MS4) |

|

|

Detecting of |

Height sensor (PS1) |

appropriate height |

|

|

: Normal rotation |

: Reversed rotation |

|

Fig. 2-32 |

2-17

(2)Shutter Operation

Before changing, by tray shift motor (M5) operation, the trays for receiving papers, the finisher controller P.C.B. closes the shutter on paper exit.

This prevents jamming of papers loaded on tray at paper exit.

The shutter moves upward (closes) when the transport motor 1 or 2 rotates in reverse, and stays in that position when the motor stops.

Next time the motor rotates in reverse, the shutter moves downward (opens, paper exit possible).

When the shutter stays in the elevated position, claws extended from the swing guide engage with the back face of shutter.

This prevents the swing guide from opening due to friction between loaded paper and swing guide at the time of tray shifting.

The claws are withdrawn and disengaged when the shutter is lowered. Upward movement of the shutter is detected by the shutter open sensor (PI5). Downward movement of the shutter is detected by the close detecting sensor (MS4).

The process is shown below:

a)Transport motor 1 or 2 rotates in reverse and the shutter moves upward.

M1

or

M8 Transport motor 1 or 2

Fig. 2-33

* Transport motor 2 : FA-F355 only

2-18

b)Tray shift motor rotates and shifts the new tray to the lowest loading point. Tray shifting distance is detected by the tray shift motor clock sensor 1,2 (PI19,9).

M5

Tray shift motor

Operation

Fig. 2-34

c) Transport motor 1 or 2 rotates in reverse and shutter moves downward.

M1 |

Fig. 2-35 |

or |

Transport motor 1 or 2 |

M8 |

|

* Transport motor 2 : FA-F355 only |

|

2-19

d)Tray shift motor rotates and adjusts the tray to the height of loaded papers. Appropriate height is detected by height sensor (PS1).

Height sensor (PS1)

M5

Tray shift motor |

Fig. 2-36 |

M1 Transport motor

Claw

Shutter

Claw

Shutter open switch (MS4)

Shutter close  sensor (PI5)

sensor (PI5)

|

|

Fig. 2-37 |

|

|

One-way cam |

Shutter drive sequence |

|

|

Shift from Tray 1 to Tray 2 |

|

|

Shutter |

Tray |

Shutter Tray |

Transport motor 1or 2 close |

shift |

open shift |

(M1/M8) |

|

|

Tray shift motor (M5) |

|

|

Shutter close sensor (PI6) |

|

|

Shutter open |

|

|

detecting switch (MS4) |

|

|

Height sensor (PS1) |

Detecting of appropriate height |

|

|

|

|

: Normal rotation |

: Reversed rotation |

Fig. 2-38 |

* Transport motor 2 : FA-F355 only |

|

|

2-20

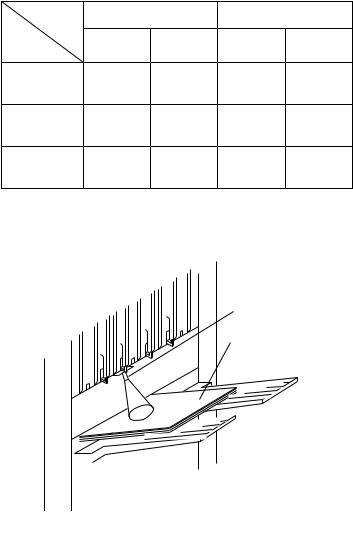

(3) Detection of tray-loaded paper amount

The amount of copies made in the sort mode (stapling or offset number) and |

|

||||||

discharged into tray, are memorized by the finisher controller P.C.B.. |

|

||||||

The height of the paper stack is detected by the height sensor (PS1). |

|

||||||

The maximum loading amount in each tray is shown in table 2-01. |

|

|

|||||

When the tray is loading amount shown in table 2-01, the finisher controller |

Operation |

||||||

P.C.B. stops operation and sends the signal to the copier that the tray is fully |

|||||||

|

|||||||

loaded. |

|

|

|

|

|

|

|

Loading |

Non-staple sort |

Staple sort |

|

|

|||

mode |

|

|

|||||

|

|

|

|

|

|

||

Tray |

Small size |

Large size |

Small size |

Large size |

|

|

|

|

|

|

|

|

|

||

|

|

|

300 sheets or |

150 sheets or |

|

|

|

Tray 1 |

300 |

150 |

30 sorts |

30 sorts |

|

|

|

|

|

|

(whichever less) (whichever less) |

|

|

||

|

|

|

750 sheets or |

500 sheets or |

|

|

|

Tray 2 |

1000 |

500 |

30 sorts |

30 sorts |

|

|

|

|

|

|

(whichever less) (whichever less) |

|

|

||

|

|

|

200 sheets or |

100 sheets or |

|

|

|

Tray 3 |

200 |

100 |

20 sorts |

20 sorts |

|

|

|

|

|

|

(whichever less) (whichever less) |

Table. 2-01 |

|

||

|

|

|

|

|

|

||

Note:

1.Small size : A4, Letter, B5

2.Large size : A3, A4R, B4, Legal, Ledger, Letter R

Height sensor (PS1)

Paper

Fig. 2-39

2-21

Loading...

Loading...