Omega Products FTB-1300 Installation Manual

User’sGuide

User’sGuide

Shop online at

omega.com e-mail: info@omega.com For latest product manuals: omegamanual.info

FTB-1300 Series

Turbine Flow Meters

|

OMEGAnet® Online Service |

|

Internet e-mail |

|

|

|

omega.com |

|

info@omega.com |

|

|

|

|

|

|

|

Servicing North America: |

||

U.S.A.: |

One Omega Drive, Box 4047 |

|

||

ISO 9001 Certified |

Stamford, CT 06907-0047 |

|

||

|

|

Tel: (203) 359-1660 |

|

|

|

|

FAX: (203) 359-7700 |

|

|

|

|

e-mail: info@omega.com |

|

|

Canada: |

976 Bergar |

|

||

|

|

Laval (Quebec) H7L 5A1, Canada |

|

|

Tel: (514) 856-6928 FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA®

Customer Service: 1-800-622-2378/1-800-622-BEST®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN®

Mexico: |

En Espan˜ol: (001) 203-359-7803 |

|

e-mail: espanol@omega.com |

|

FAX: (001) 203-359-7807 |

|

info@omega.com.mx |

|

Servicing Europe: |

Czech Republic:

Frystatska 184, 733 01 Karvina´, Czech Republic Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678 e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488 e-mail: sales@omega.co.uk

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

FTB-1300 Series - Turbine Flow Meters

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operational Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Repair Kit Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation and Technical Data Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

FTB-1301 through FTB-1308

Installation and Technical Data Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10

FTB-1311 through FTB-1318

FTB-1300 Series Turbine Flow Meter

General Description:

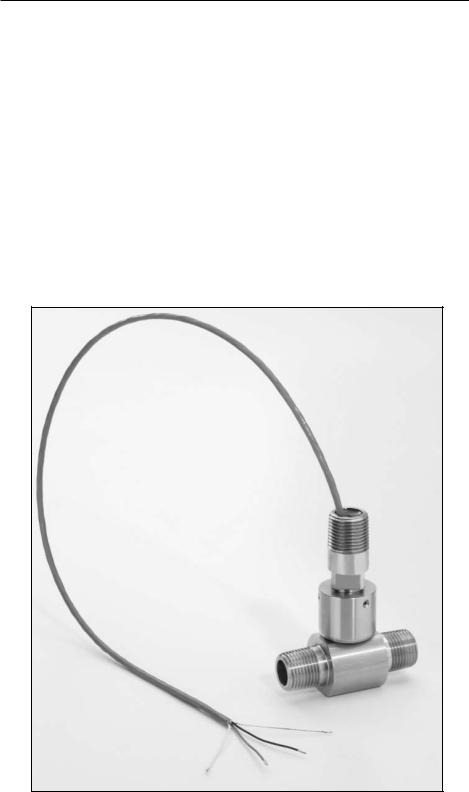

The FTB-1300 series of turbine flow meters is designed with a wear resistant rotor assembly to provide trouble free operation and a long service life. Fluid moving through the flow meter causes the rotor to turn at a speed proportional to the flow rate, and as the rotor blades cut through the magnetic field of the pickup, an electronic pulse is generated.

The pulse train is used to represent the actual flow or total amount of fluid passing through the flow meter. The number of electronic pulses generated per unit volume is known as a K-factor. The value is constant over each flow meter's operating range, and is unique to each meter.

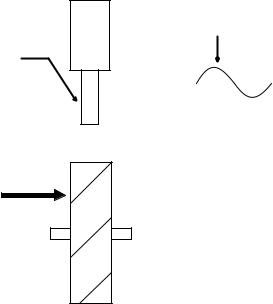

MAGNETIC PICKUP

FLUID FLOW

OUTPUT SIGNAL

ROTOR

ROTOR

Operating Limitations of the FTB-1300 Series Turbine Flow Meters:

1)Pressure - 5,000 PSI max

WARNING: Pressure in excess of allowable rating may cause the housing to burst and cause serious personal injury.

2)Corrosion - The internal parts of the meter are constructed of stainless steel (316L & 1.4122) and carbide with nickel binder. Be sure that the operating fluid is compatible with these materials. Incompatible fluids will deteriorate internal parts, and cause the meter to read inaccurately.

3)Pulsation - Severe pulsation will affect accuracy, and shorten the life of your meter.

4)Vibration & Shock - Severe mechanical vibration may decrease service life of the meter.

5)Filtration - A strainer should be installed upstream of the meter if small particles are present (see Table 1 for filtration requirements)

-1-

Loading...

Loading...