Omega Products DP116 Installation Manual

User’sGuide

Shop on line at

™

™

®

www.omega.com e-mail: info@omega.com

DP116

Thermocouple Miniature

Panel Thermometer

|

|

|

|

® |

|

|

® |

|

|

|

|

|

|

|

|

OMEGAnet® On-Line Service |

|

Internet e-mail |

|

|

|

www.omega.com |

|

info@omega.com |

|

|

|

|

|

|

|

Servicing North America: |

||

USA: |

One Omega Drive, P.O. Box 4047 |

|||

ISO 9001 Certified |

Stamford CT 06907-0047 |

|

||

|

|

TEL: (203) 359-1660 |

FAX: (203) 359-7700 |

|

|

|

e-mail: info@omega.com |

|

|

Canada: |

976 Bergar |

|

||

|

|

Laval (Quebec) H7L 5A1 |

|

|

|

|

TEL: (514) 856-6928 |

FAX: (514) 856-6886 |

|

|

|

e-mail: info@omega.ca |

|

|

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA® Customer Service: 1-800-622-2378 / 1-800-622-BEST® Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN®

Mexico and |

TEL: (001)800-TC-OMEGA® |

FAX: (001) 203-359-7807 |

Latin America: |

En Español: (001) 203-359-7803 |

|

|

e-mail: espanol@omega.com |

|

Servicing Europe:

Benelux: |

Postbus 8034, 1180 LA Amstelveen, The Netherlands |

||

|

|

TEL: +31 20 3472121 |

FAX: +31 20 6434643 |

|

|

Toll Free in Benelux: 0800 0993344 |

|

|

|

e-mail: sales@omegaeng.nl |

|

Czech Republic: |

Frystatska 184, 733 01 Karviná |

|

|

|

|

TEL: +420 59 6311899 |

FAX: +420 59 6311114 |

|

|

e-mail: info@omegashop.cz |

|

France: |

11, rue Jacques Cartier, 78280 Guyancourt |

||

|

|

TEL: +33 1 61 37 29 00 |

FAX: +33 1 30 57 54 27 |

|

|

Toll Free in France: 0800 466 342 |

|

|

|

e-mail: sales@omega.fr |

|

Germany/Austria: |

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany |

||

|

|

TEL: +49 7056 9398-0 |

FAX: +49 7056 9398-29 |

|

|

Toll Free in Germany: 0800 639 7678 |

|

|

|

e-mail: info@omega.de |

|

United Kingdom: |

One Omega Drive |

|

|

ISO 9002 Certified |

River Bend Technology Centre |

|

|

|

|

Northbank, Irlam Manchester M44 5BD United Kingdom |

|

|

|

||

|

|

TEL: +44 161 777 6611 |

FAX: +44 161 777 6622 |

|

|

Toll Free in England: 0800 488 488 |

|

|

|

e-mail: sales@omega.co.uk |

|

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or commissioning this device as the guide contains important information relating to safety and EMC.

This device is marked with the international caution |

symbol. It is important to read the Setup Guide before installing or commissioning this device as the guide contains |

! important information relating to safety and EMC. |

|

TABLE OF CONTENTS

SECTION |

|

PAGE |

|

|

|

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .ii |

|

|

Models Available . . . . . . . . . . . . . . . . . . . . . . . |

. . .iii |

Section |

1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .1 |

|

1.1 |

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .1 |

|

1.2 |

Safety Considerations . . . . . . . . . . . . . . . . . . . |

. . .2 |

Section |

2 |

About the Meter . . . . . . . . . . . . . . . . . . . . . . . . |

. . .3 |

|

2.1 |

Front of the Meter . . . . . . . . . . . . . . . . . . . . . . |

. . .3 |

|

2.2 |

Back of the Meter . . . . . . . . . . . . . . . . . . . . . . |

. . .4 |

|

2.3 |

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .4 |

Section |

3 |

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . |

. . .5 |

|

3.1 |

Main Board Power Jumpers . . . . . . . . . . . . . . . |

. . .5 |

|

3.2 |

Converting °F to °C (vice versa) . . . . . . . . . . . . |

. . .7 |

|

3.3 |

Installation and Panel Mounting . . . . . . . . . . . . |

. . .8 |

|

3.4 |

Sensor Input Connections . . . . . . . . . . . . . . . . |

. .10 |

|

3.5 |

Analog Output Connections . . . . . . . . . . . . . . . |

. .12 |

|

3.6 |

Display Hold Connections . . . . . . . . . . . . . . . . |

. .13 |

|

3.7 |

Main Power Connections . . . . . . . . . . . . . . . . . |

. .14 |

|

3.8 |

Disassembly/Assembly . . . . . . . . . . . . . . . . . . |

. .16 |

Section |

4 |

Operation and Calibration . . . . . . . . . . . . . . . . |

. .18 |

|

4.1 |

Equipment Required . . . . . . . . . . . . . . . . . . . . |

. .18 |

|

4.2 |

Calibration Procedure . . . . . . . . . . . . . . . . . . . |

. .19 |

Section |

5 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . |

. .28 |

Section |

6 |

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. .32 |

i

PREFACE

Manual Objectives: This manual shows you how to set up and use the Panel Thermometer.

This meter is an economical Miniature Temperature Panel Thermometer featuring a large display with a linearized analog output that is supplied as a standard feature.

Each of the models* can be converted by the user to display in degrees Fahrenheit or Celsius. However, due to the internal design of the meter, the input type and resolution CANNOT be changed on any J, K, T, or E unit.

The meter is available in many different styles. All of the Thermocouple models listed in Table 1-1 come standard with red LEDs, and can be ordered with a green LED display as an option. The part numbers would then end with “-GR”.

Example: DP116-JF1-GR

Also, these thermocouple meters can be ordered with different power configurations. Refer to Table 1-3 for available choices.

*Refer to Table 1-1 for the complete listing of models available.

ii

TABLE 1-1

TC MODELS AVAILABLE

The following 3-1/2 digit mini thermocouple panel thermometers are discussed in this operator’s manual.

|

MODEL |

TYPE |

°C or °F |

RESOLUTION |

|

|

|

|

|

|

|

|

DP116-JF1 |

J |

F |

1.0°F |

|

|

DP116-JF2 |

J |

F |

0.1°F |

|

|

DP116-JC1 |

J |

C |

1.0°C |

|

|

DP116-JC2 |

J |

C |

0.1°C |

|

|

|

|

|

|

|

|

DP116-KF1 |

K |

F |

1.0°F |

|

|

DP116-KF2 |

K |

F |

0.1°F |

|

|

DP116-KC1 |

K |

C |

1.0°C |

|

|

DP116-KC2 |

K |

C |

0.1°C |

|

|

|

|

|

|

|

|

DP116-TF1 |

T |

F |

1.0°F |

|

|

DP116-TF2 |

T |

F |

0.1°F |

|

|

DP116-TC1 |

T |

C |

1.0°C |

|

|

DP116-TC2 |

T |

C |

0.1°C |

|

|

|

|

|

|

|

|

DP116-EF1 |

E |

F |

1.0°F |

|

|

DP116-EF2 |

E |

F |

0.1°F |

|

|

DP116-EC1 |

E |

C |

1.0°C |

|

|

DP116-EC2 |

E |

C |

0.1°C |

|

|

|

|

|

|

|

The accuracies and ranges are listed in Section 5.

The accuracies and ranges are listed in Section 5.

iii

Table 1-2

Other Models Available

The following 3-1/2 digit mini RTD panel meters are available and discussed in a separate RTD Operator’s Manual.

|

MODEL |

TYPE |

°C or °F |

RESOLUTION |

|

|

|

|

|

|

|

|

DP116-MF1 |

RTD |

F |

1.0°F |

|

|

DP116-MF2 |

RTD |

F |

0.1°F |

|

|

DP116-MC1 |

RTD |

C |

1.0°C |

|

|

DP116-MC2 |

RTD |

C |

0.1°C |

|

|

|

|

|

|

|

Table 1-3

Power Options Available

|

MODEL |

POWER |

|

|

|

|

|

|

DP116-TC type |

115 Vac ±15%, 50/60 Hz |

|

|

|

|

|

|

DP116-TC type-230 |

230 Vac ±15%, 50/60 Hz |

|

|

|

|

|

|

DP116-TC type-9/26 |

9-26 Vdc @ 110mA max, |

|

|

|

non-isolated. |

|

|

|

Use ungrounded Thermocouples |

|

|

|

to avoid ground loops. |

|

|

|

|

|

|

DP116-TC type-100 |

100 Vac ±15%, 50/60 Hz |

|

|

|

|

|

|

DP116-TC type-24 |

24 Vac ±15%, 50/60 Hz |

|

|

|

|

|

iv

NOTES, WARNINGS and CAUTIONS

Information that is especially important to note is identified by these labels:

NOTE: provides you with information that is important to successfully setup and use the Programmable Digital Meter.

CAUTION or WARNING: tells you about the risk of electric shock.

CAUTION, WARNING or IMPORTANT: tells you of circumstances or practices that can effect the meter's functionality and must refer to accompanying documents.

v

SECTION 1 INTRODUCTION

1.1 UNPACKING

Remove the Packing List and verify that all equipment has been received. If there are any questions about the shipment, use the phone numbers listed on the back cover to contact the Customer Service Department nearest you.

Upon receipt of shipment, inspect the container and equipment for any signs of damage. Take particular note of any evidence of rough handling in transit. Immediately report any damage to the shipping agent.

The carrier will not honor any claims unless all shipping material is saved for their examination. After examining and removing contents, save packing material and carton in the event reshipment is necessary.

Verify that you received the following items in the shipping box:

QTY DESCRIPTION

1Panel Thermometer with 3 small connectors plugged into the rear of the meter.

1Operator’s Manual

1

1.2 SAFETY CONSIDERATIONS

This device is marked with the international Caution symbol. It is important to read this manual before installing or commissioning this device as it contains important information relating to Safety and EMC (Electromagnetic Compatibility).

Unpacking & Inspection

Unpack the instrument and inspect for obvious shipping damage. Do not attempt to  operate the unit if damage is found.

operate the unit if damage is found.

This instrument is a panel mount device protected in accordance with Class I of EN 61010 (115/230 AC power connections). Installation of this instrument should be done by Qualified personnel. In order to ensure safe operation, the following instructions should be followed.

This instrument has no power-on switch. An external switch or circuit-breaker shall be included in the building installation as a disconnecting device. It shall be marked to indicate this function, and it shall be in close proximity to the equipment within easy reach of the operator. The switch or circuit-breaker shall not interrupt the Protective Conductor (Earth wire), and it shall meet the relevant requirements of IEC 947–1 and IEC 947-3 (International Electrotechnical Commission). The switch shall not be incorporated in the mains supply cord.

Furthermore, to provide protection against excessive energy being drawn from the mains supply in case of a fault in the equipment, an overcurrent protection device shall be installed.

•The Protective Conductor must be connected for safety reasons. Check that the power cable has the proper Earth wire, and it is properly connected. It is not safe to operate this unit without the Protective Conductor Terminal connected.

•Do not exceed voltage rating on the label located on the top of the instrument

housing.

•Always disconnect power before changing signal and power connections.

•Do not use this instrument on a work bench without its case for safety reasons.

•Do not operate this instrument in flammable or explosive atmospheres.

•Do not expose this instrument to rain or moisture.

•Unit mounting should allow for adequate ventilation to ensure instrument does not exceed operating temperature rating.

•Use electrical wires with adequate size to handle mechanical strain and power requirements. Install without exposing bare wire outside the connector to minimize electrical shock hazards.

EMC Considerations

•Whenever EMC is an issue, always use shielded cables.

•Never run signal and power wires in the same conduit.

•Use signal wire connections with twisted-pair cables.

•Install Ferrite Bead(s) on signal wires close to the instrument if EMC problems persist.

2

SECTION 2 ABOUT THE METER

2.1Front of the Meter

Figure 2-1 shows the panel thermometer.

Figure 2-1. Panel Thermometer

Features:

Display: 3 1/2 Digit, 7-Segment Red or Green LED Full-size 14.2 mm (0.56") LED Display

Analog Output Standard

3/64 DIN Standard Panel Cutout Removable Screw-Clamp Cable Connector Display Hold Capability

3

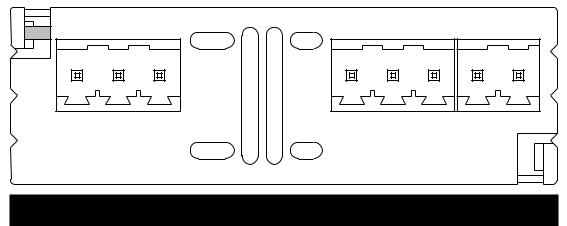

2.2Back of the Meter

Figure 2-2 illustrates the rear of the meter.

1 2 3

P1

1 |

2 |

3 |

1 |

2 |

|

P2 |

|

P3 |

|

Figure 2-2. Rear View Showing P1, P2, P3 Connectors

2.3 Connector Description

|

Connector Description |

Connector |

PIN # |

|

|

(AC) Earth Ground |

P1 |

1 |

|

|

(AC) Neutral |

P1 |

2 |

|

|

(AC) Line |

P1 |

3 |

|

|

|

|

|

|

|

(DC) -DC Return |

P1 |

1 |

|

|

(DC) +DC |

P1 |

2 |

|

|

(DC) No Connection (Not used) P1 |

3 |

|

|

|

|

|

|

|

|

Display Hold (Active Low) |

P2 |

1 |

|

|

Return |

P2 |

2 |

|

|

Analog Output |

P2 |

3 |

|

|

|

|

|

|

|

-TC (Neg. Lead) † |

P3 |

1 |

|

|

+TC (Pos. Lead) † |

P3 |

2 |

|

|

|

|

|

|

† For wire colors, refer to Table 3-1

4

SECTION 3 GETTING STARTED

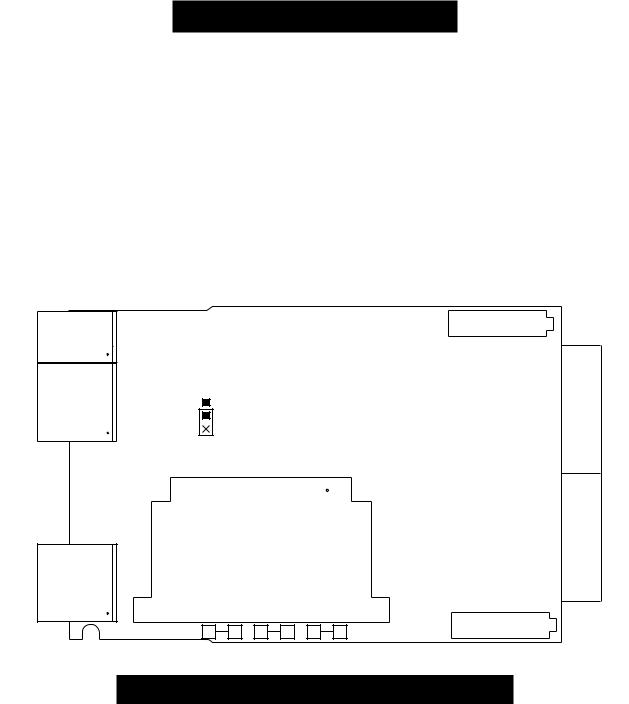

3.1 Main Board Power Jumpers

Caution: The meter has no power-on switch, so it will be in operation as soon you apply power.

The meter can be configured to operate on 115 Vac or 230 Vac by the proper combination of the soldered wire jumpers that are located on the printed circuit board. The meter is set at the factory to be powered by the voltage specified at the time of ordering. The same transformer is used for either configuration, so all you need to do is to select the jumpers as described in this section.

Important: These changes must be performed by a qualified technician.

To change the Factory preset jumpers, do the following steps:

Disconnect the power from the unit before proceeding.

Disconnect the power from the unit before proceeding.

1.Remove the main board from the case. Refer to Disassembly/Assembly Section 3.8.

2.Locate the solder jumpers W1, W2, and W3 (located near the edge of the main board alongside the transformer).

3.If your power requirement is 115 Vac, solder jumpers W1 and W3 should be wired, but jumper W2 should not. If your power requirement is 230 Vac, solder jumper W2 should be wired, but jumpers W1 and W3 should not.

5

Voltage Jumper Pin Settings

|

AC VOLTAGE |

INSTALL |

REMOVE |

|

|

115 Vac |

W1, W3 |

W2 |

|

|

230 Vac |

W2 |

W1, W3 |

|

|

|

|

|

|

Figure 3-1 shows the location of solder jumpers W1 through W3.

|

|

(COMPONENT SIDE) |

P3 |

2 |

ZERO |

1 |

|

|

|

|

|

|

3 |

|

P2 |

2 |

S3 |

|

1 |

|

|

|

DISPLAY

|

3 |

TRANSFORMER |

P1 |

2 |

|

|

1 |

|

SPAN

W1 W2 W3

Figure 3-1. PC Board Jumper Locations

6

Loading...

Loading...