Omega Products DPG4000 Installation Manual

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User ’s Guide

M-4290/0107

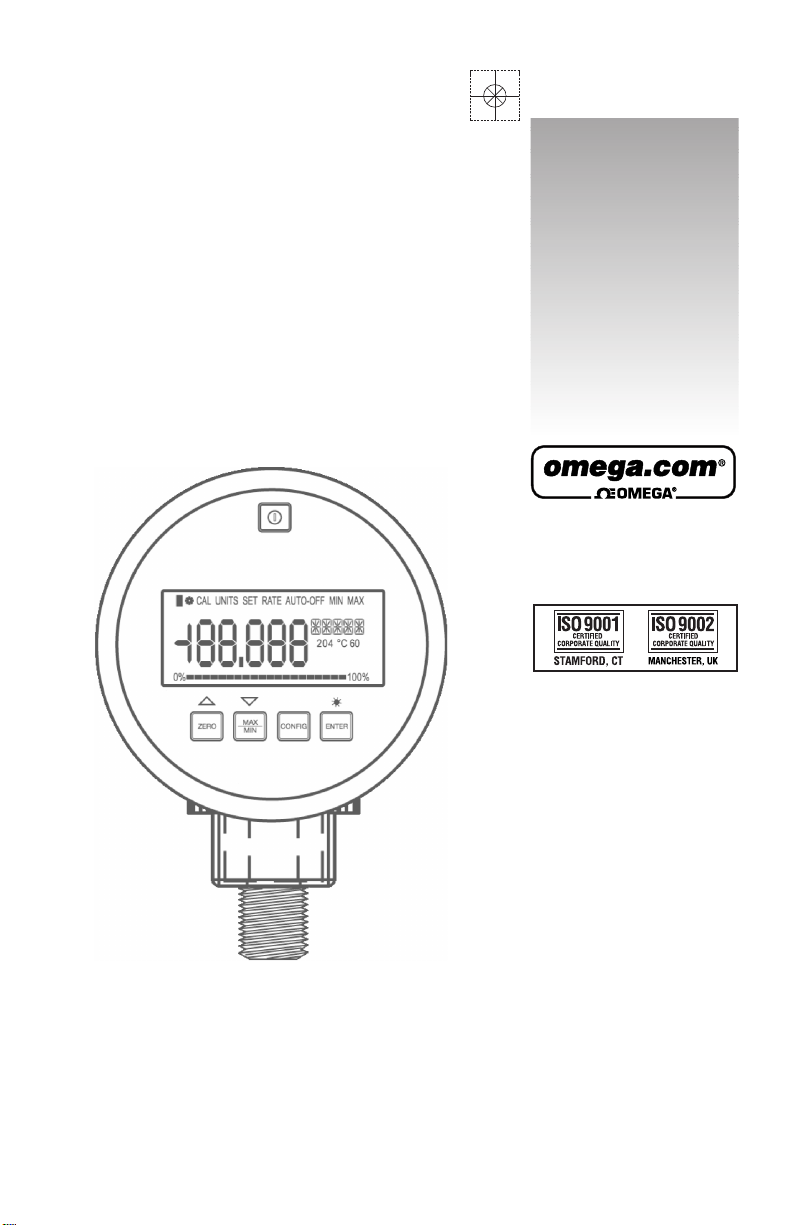

DPG4000 Digital Test Gauge

Shop online at

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0) 5 9 6 3 1111 4

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet

®

Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

1

Introduction

The DPG4000 combines the high accuracy of digital electronics with

the convenience and ease of use of an analog test gauge. Accurate to

± 0.05% FS, the DPG4000 can be used as a calibration reference, or

in any application where high accuracy pressure measurement is

required.

Many user configurable functions have been designed into the

DPG4000 including sampling rate, TARE, damping, auto shut off, and

min-max. Once the gauge is configured, settings can be locked and

password protected to prevent unauthorized changes to configuration.

1.1 Customer Service

Omega Engineering

One Omega Drive

Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

Fax: (203) 359-7811

www.omega.com

email: cservice@omega.com

1.2 Standard Equipment

Check to see that your DPG4000 has arrived intact. Batteries are

factory installed unless you have purchased the optional 24V powered

version, in which case batteries are not supplied or installed. Save the

packing materials at least until you have verified that there is no

concealed damage.

1.3 Safety information

A Warning identifies conditions and actions that pose hazard(s) to the

user; a Caution identifies conditions and actions that may damage the

Calibrator or the equipment under test.

2

Symbols Used

The following table lists the International Electrical Symbols. Some or all

of these symbols may be used on the instrument or in this manual.

Symbol Description

Power OFF

Power ON

Earth ground

Risk of Danger. Important information. Refer to manual.

Battery

Hazardous Voltage

Conforms to ATEX requirements

Conforms to relevant European Union directives.

Wheeled bin, conforms to EC directive 2002/96/EC

Hazard Location Information

Ex Hazardous Areas

An Ex-hazardous area as used in this manual refers to an area made

hazardous by the potential presence of flammable or explosive vapors.

These areas are also referred to as hazardous locations, see NFPA 70

Article 500.

Misuse

Should the DPG4000 be exposed to overpressure or sudden physical

shock (i.e. being dropped) it should be examined for any damage that

may cause a safety concern. If in doubt please return the unit for

evaluation to Omega Engineering, Inc. Please refer to the Customer

Service Section for contact information.

Caution

To avoid possible damage to calibrator or to equipment under test:

• If the message changes to "OL" the range limit is exceeded and the

pressure source must immediately be removed from the DPG4000 to

prevent damage to the pressure transducer inside.

• Maximum torque allowed is 13,5 Nm = 10 ftlbs. NEVER exceed the

torque allowed.

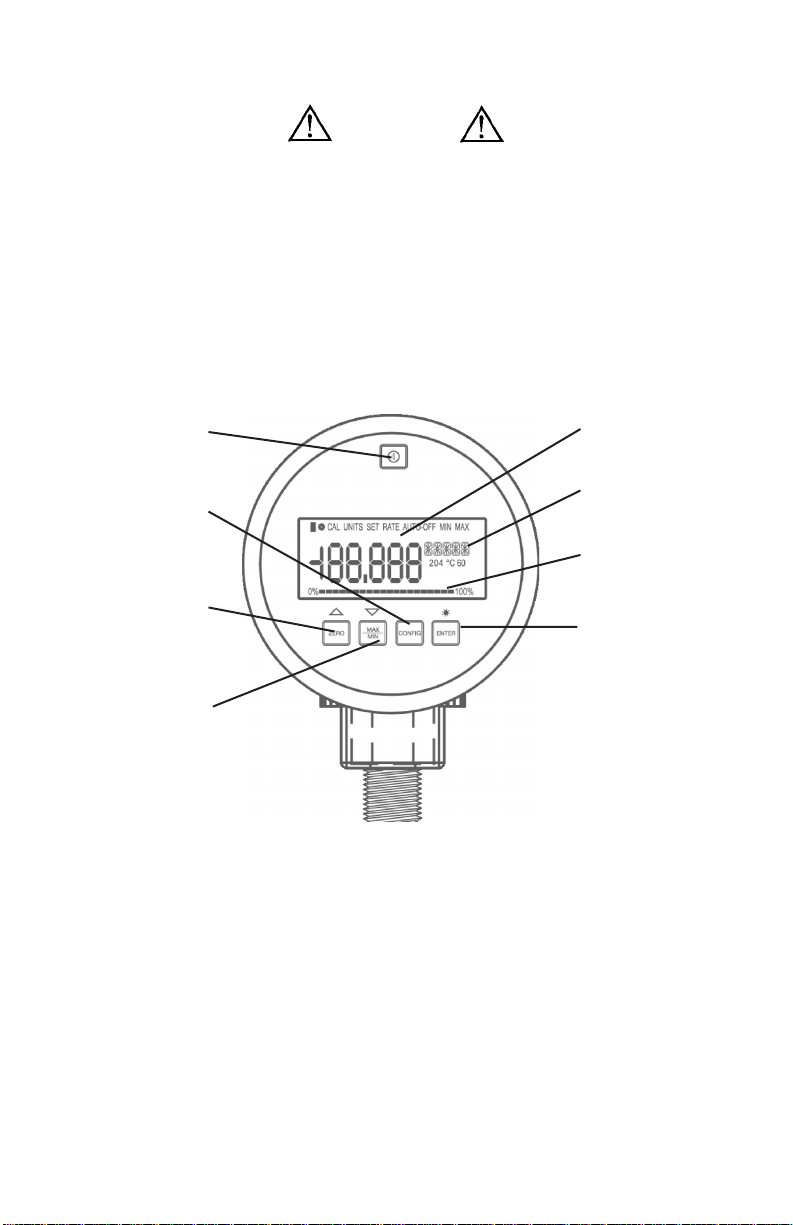

DPG4000 Display and Controls

Operation

Power: The standard DPG4000 is supplied with 3 AA batteries

installed. If you purchased the optional 24Volt powered version,

batteries are not installed. Connect a 24V power supply to the terminal

block on the rear of the gauge, noting proper polarity.

Do not install batteries when external power will be used.

Push the power button momentarily to turn the unit on. Push it again

to turn it off.

Set-up and configuration:

Push the CONFIG button to access the user-settable functions on the

gauge. Each time the CONFIG button is pressed; the display advances

3

Pressure display

Engineering Units

0 - 100% bar graph

Selects an action in

configuration.

Also turns the

back-light on/off

Turns Power on/off

Enters set-up and

configuration menus

Zeros the display,

Scrolls forward through

menu displays

Recalls min and max

readings.

Scrolls backwards

through menu displays

4

to the next function. Once a function has been set, press ENTER to

exit the configuration menu, or CONFIG to continue with further

configuration. In order, the configuration menu and operation is as

follows:

1. Engineering Units set. The unit is shipped configured to display

PSI. By pressing the ▲ and ▼ (ZERO and MAX/MIN) keys you

can scroll forward and backwards through the 18 standard

engineering units plus a one custom unit/scale. When the desired

unit is displayed, press ENTER or CONFIG. Pressure will now be

displayed in the chosen engineering units.

See the Specifications section of this manual for a list of available

engineering units. See the Supervisory Mode section for details on

setting up custom units.

2. Set Auto Off. The auto-shut off can be set in 1 minute increments

from 1 to 30 minutes or “off” (continuous operation). The unit is

shipped set for 30 minutes. Use the ▲ and ▼ keys to set the

desired interval. The “off” setting is at the low end of the choices,

below 1 minute.

3. Display battery voltage. Actual voltage and a percent of life

bargraph indicate battery condition

4. Display actual temperature. The DPG4000 is temperature

compensated, this displays the temperature measured by the

internal sensor. The value can be set to degrees F or degrees C

using the arrow keys.

5. Set damping. Choices are “on” and “off” set with the ▲ and ▼

keys. Turning damping on will smooth readings from pulsating

pressure sources.

6. Set sample rate: This determines how often pressure is sampled

and the display is updated. Choices are 0.5, 1, 3, and 10

samples/second. Note that 10/sec provides the fastest response

time.

7. Set TARE. This allows you to set a constant offset value, which is

then subtracted from the measured pressure. For example if a

TARE is set at 30 PSI, and the measured pressure is 37 PSI, the

displayed value will be 7 PSI.

A pressure of 27 PSI would be displayed as –3 PSI.

The tare value is set manually with the ▲ and ▼ keys, and is

based on the engineering units and resolution selected for display.

TARE value can be set to the maximum range of the gauge.

The bar graph will always display the actual pressure based on the

full range of the gauge regardless of the tare setting. This is done

Loading...

Loading...